Sustainable Renovation and Assessment of Existing Aging Rammed Earth Dwellings in Hunan, China

Abstract

:1. Introduction

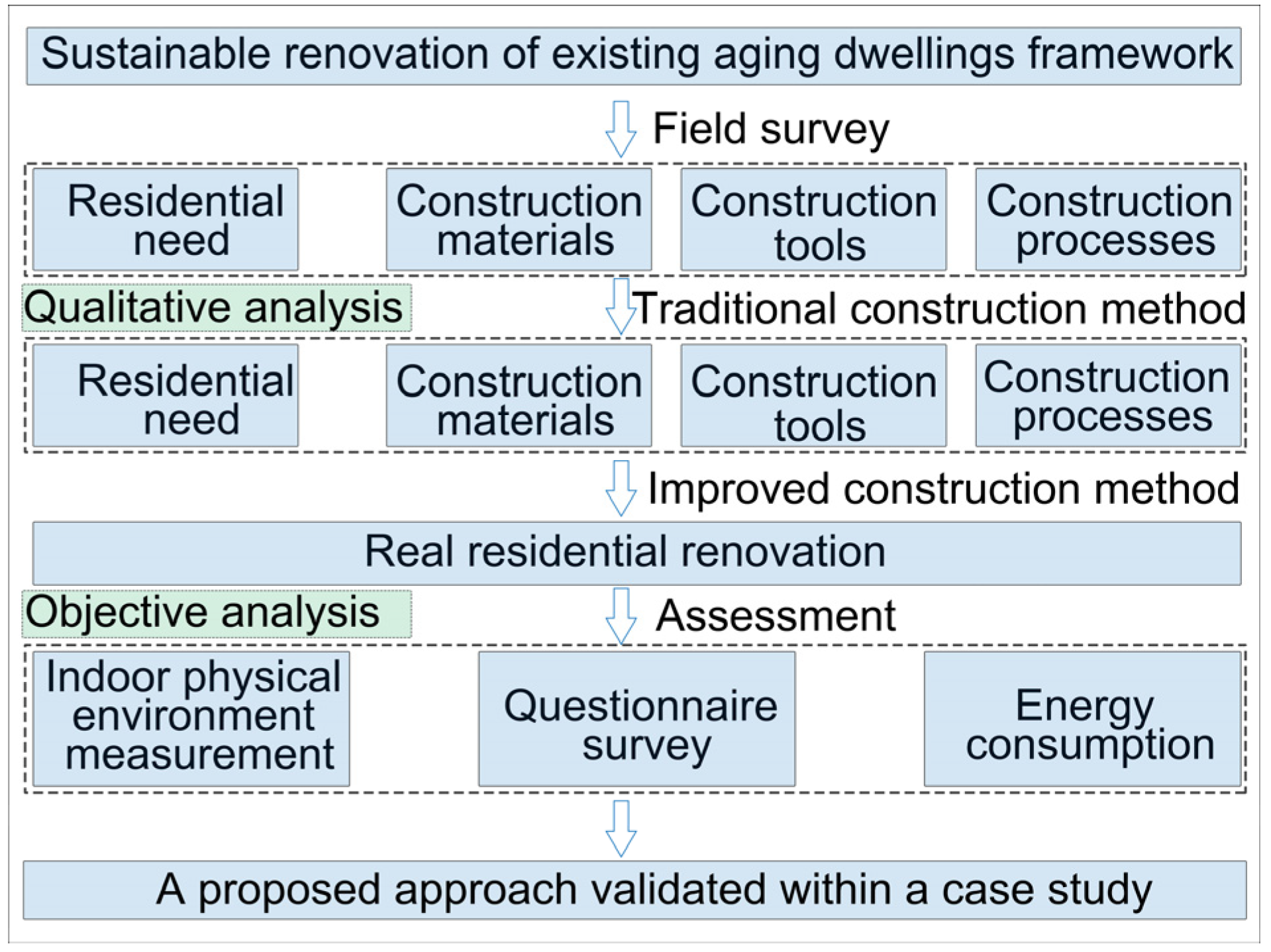

2. Methods

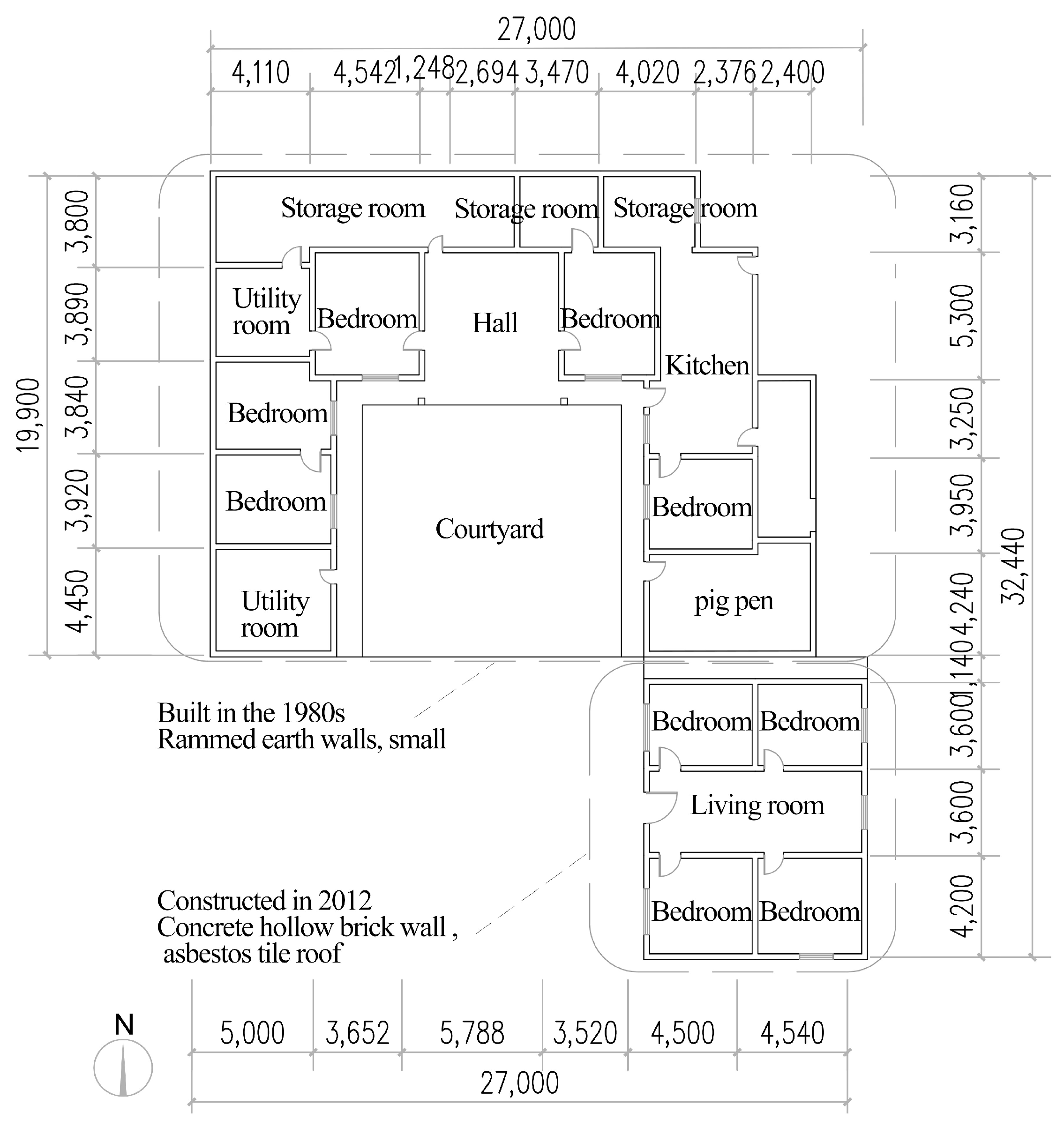

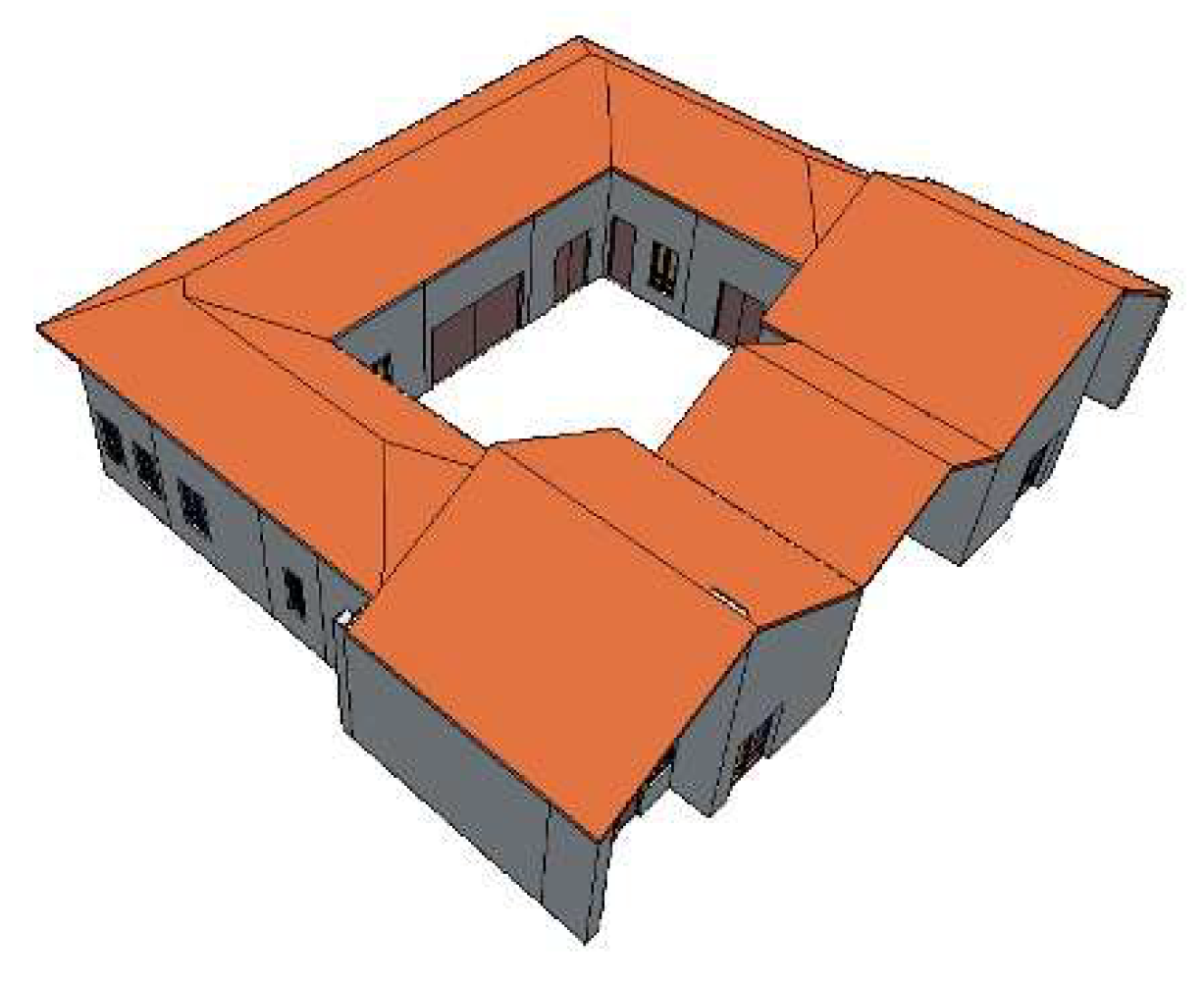

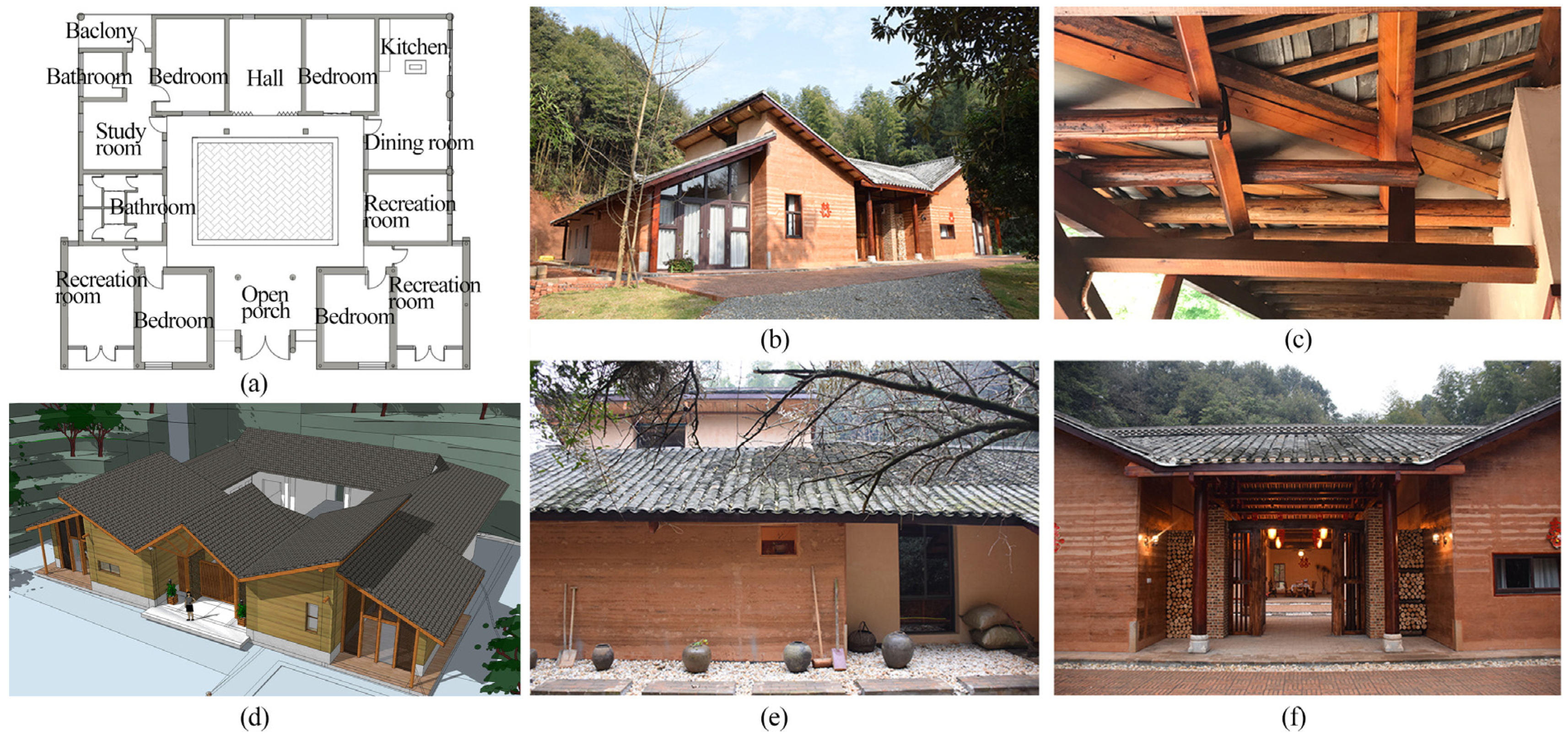

2.1. Research Case

2.2. Qualitative Analysis

2.2.1. Residential Function

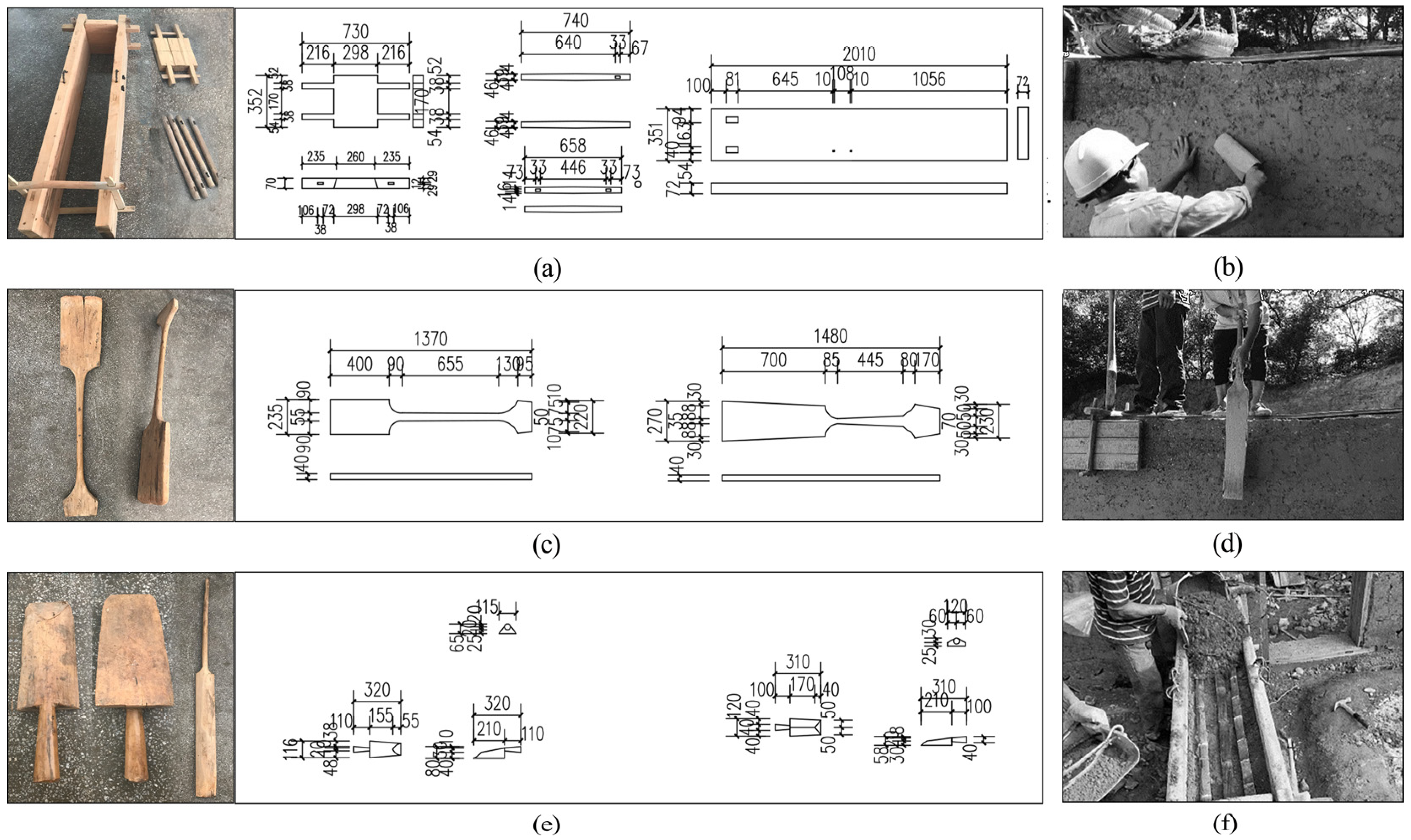

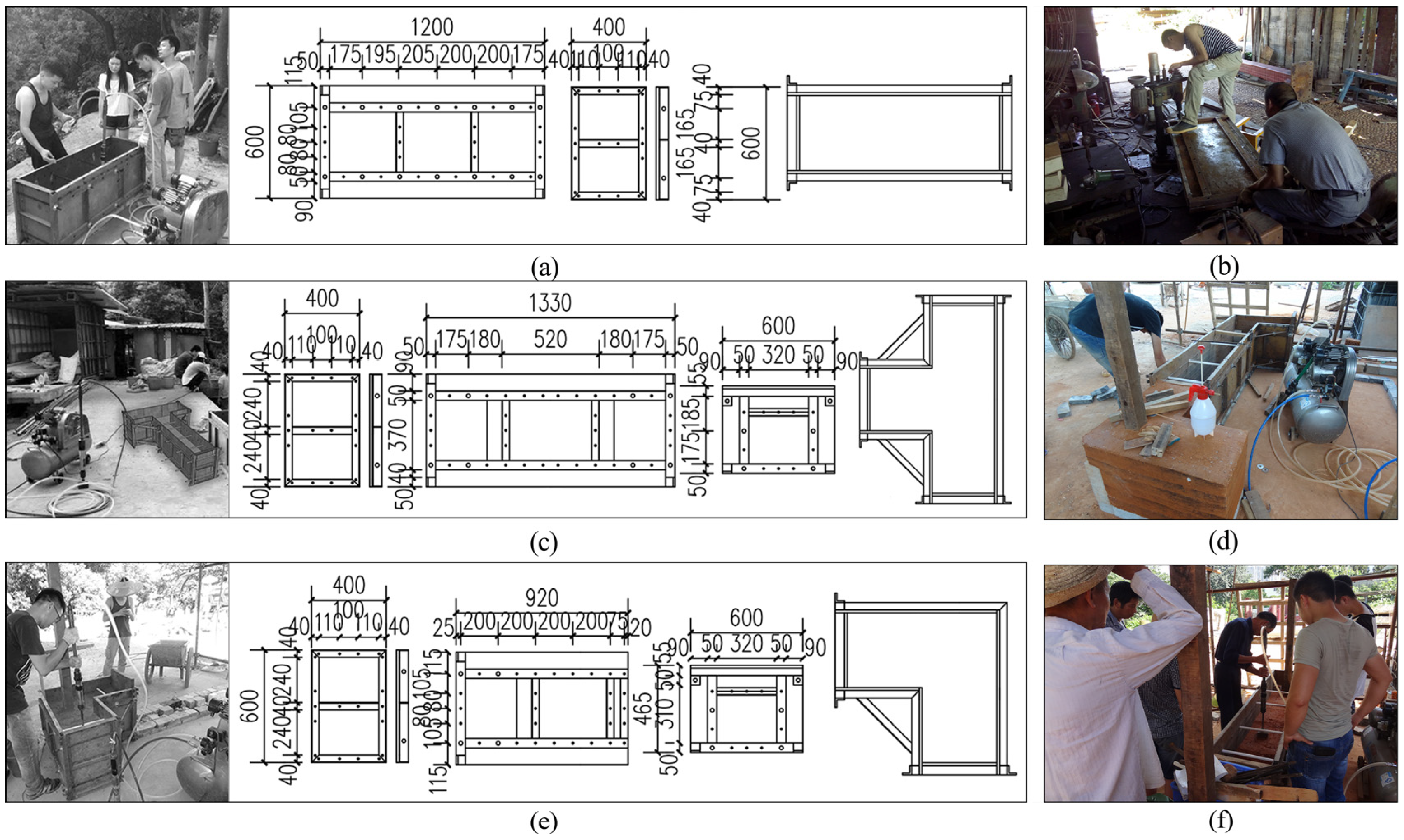

2.2.2. Construction Tools

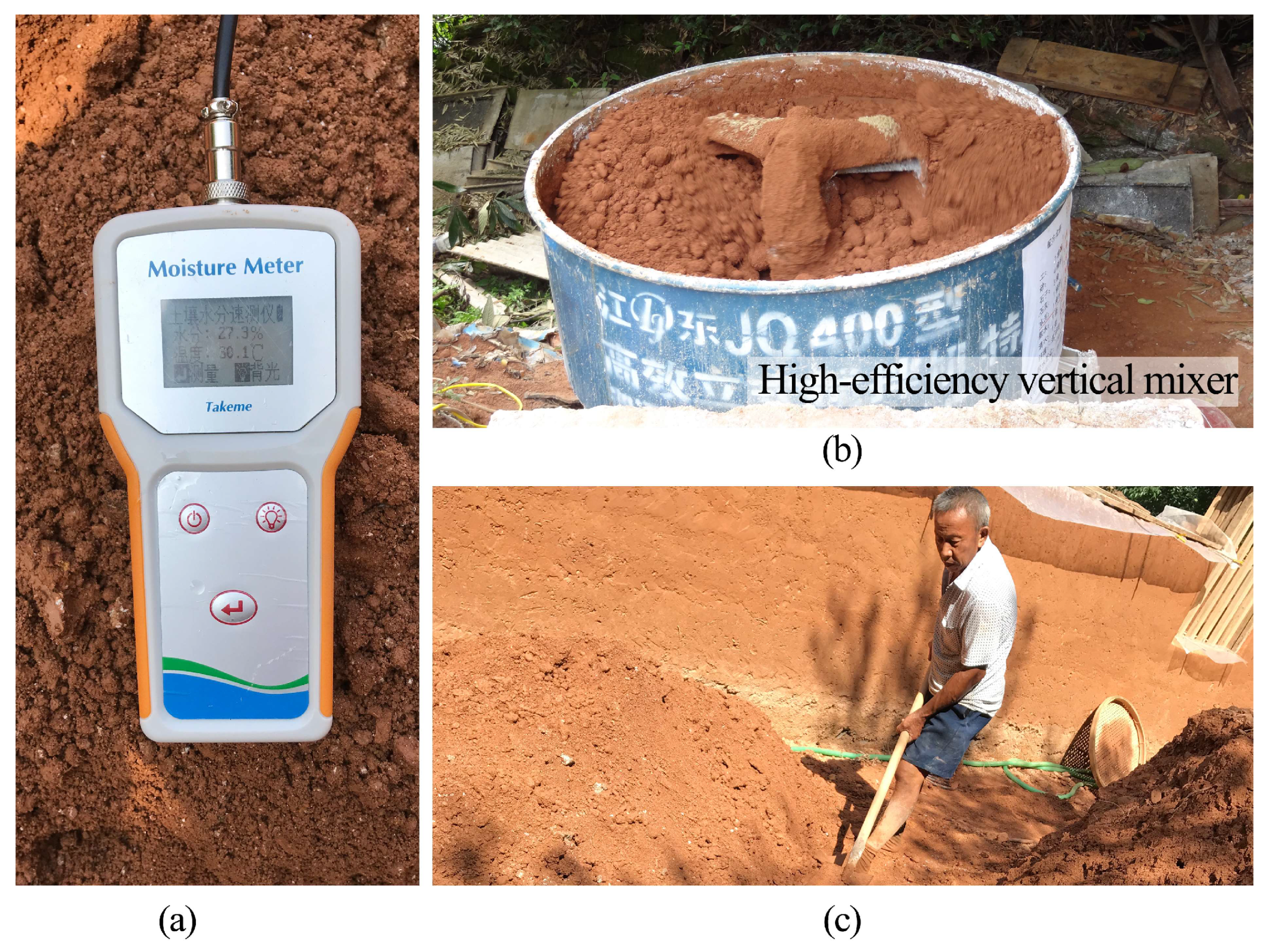

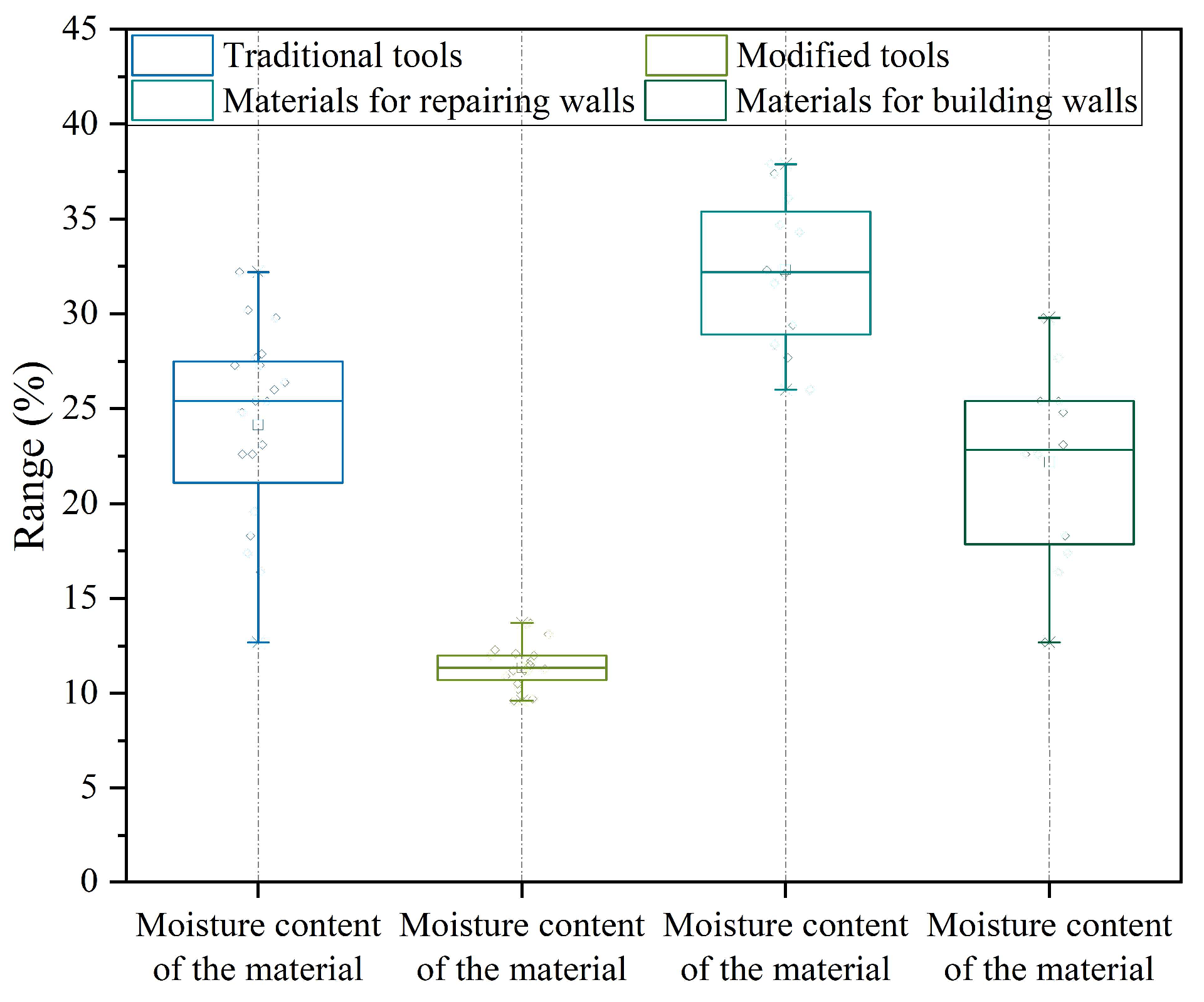

2.2.3. Construction Materials

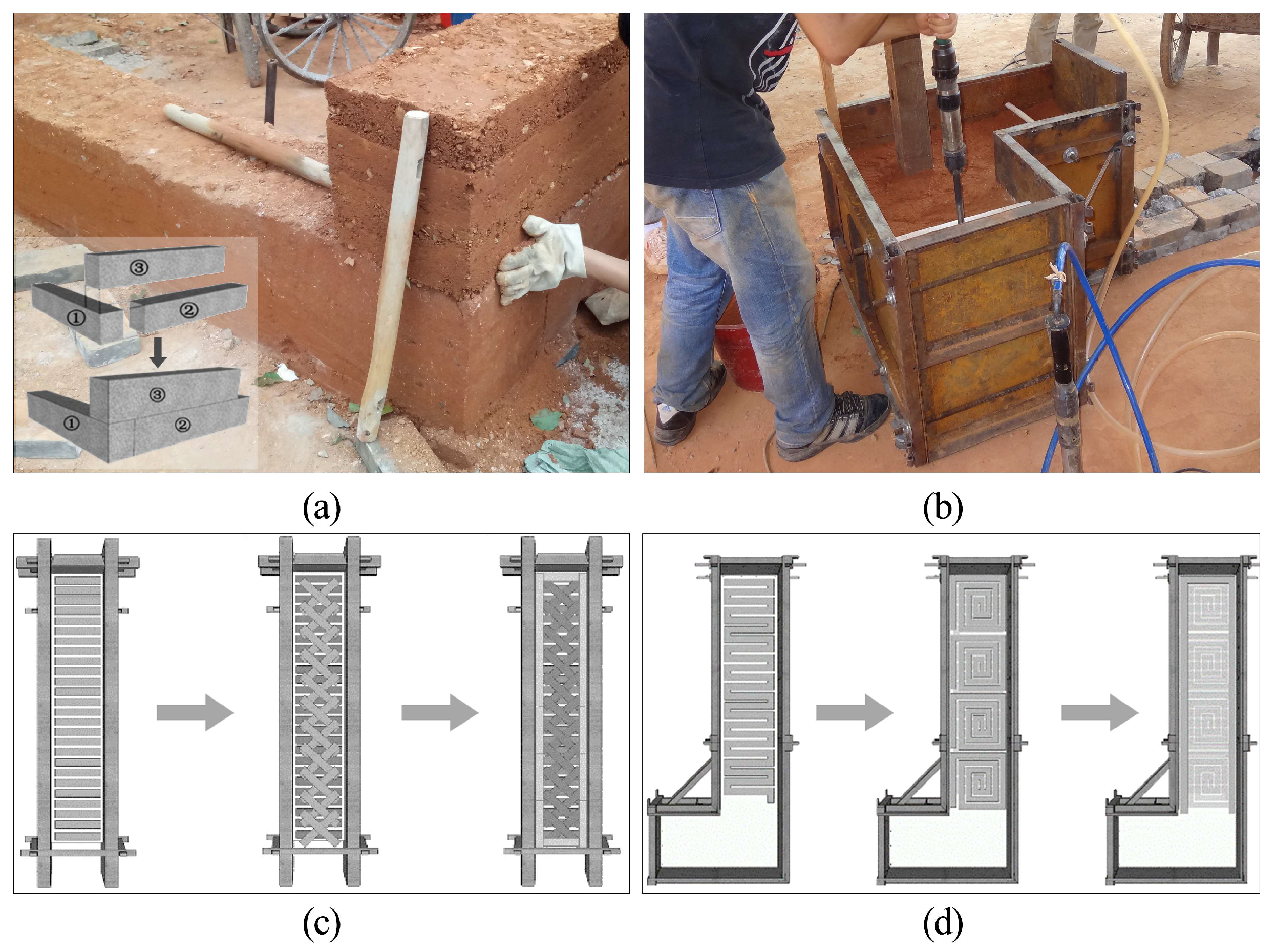

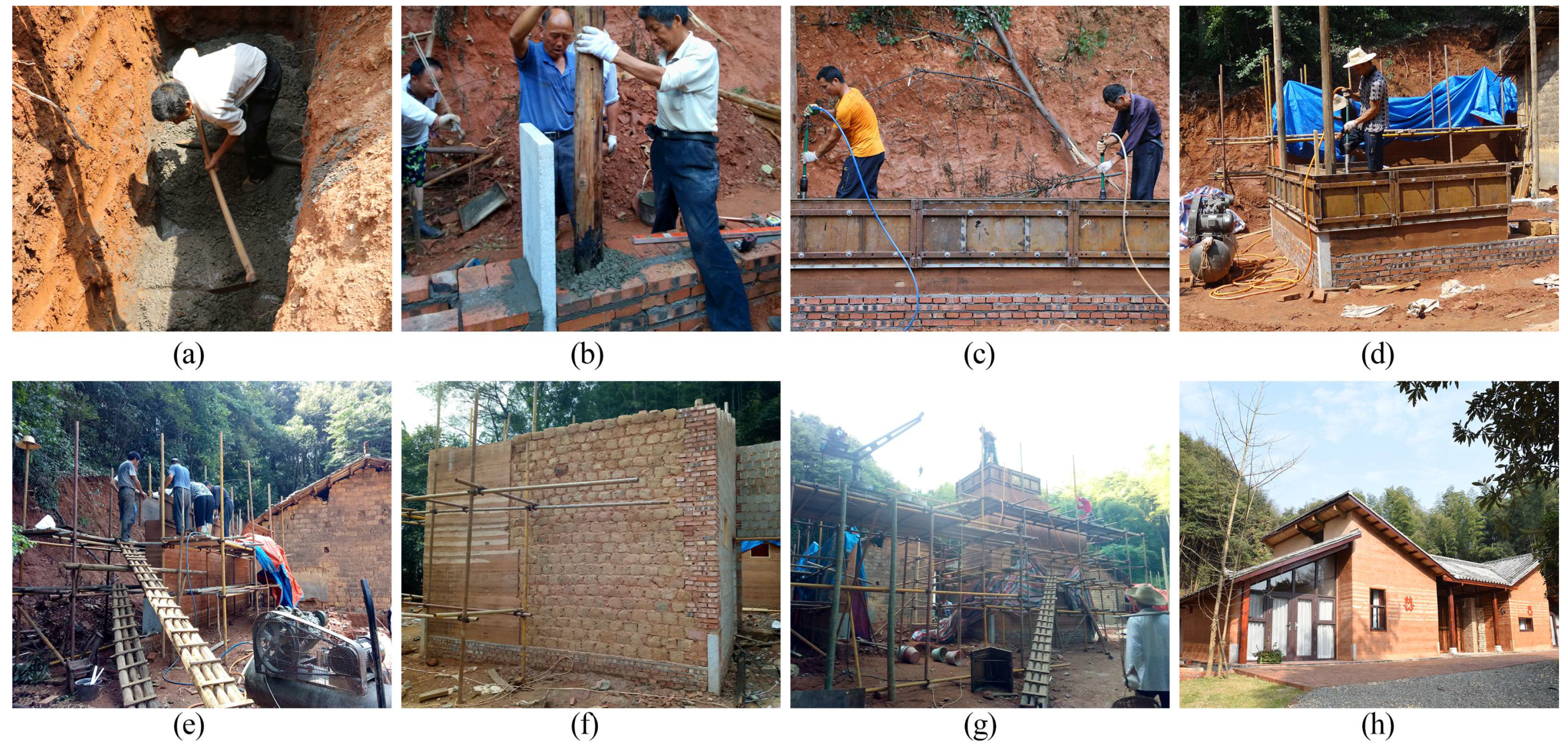

2.2.4. Construction Process

2.2.5. Questionnaire Survey

2.3. Quantitative Analysis

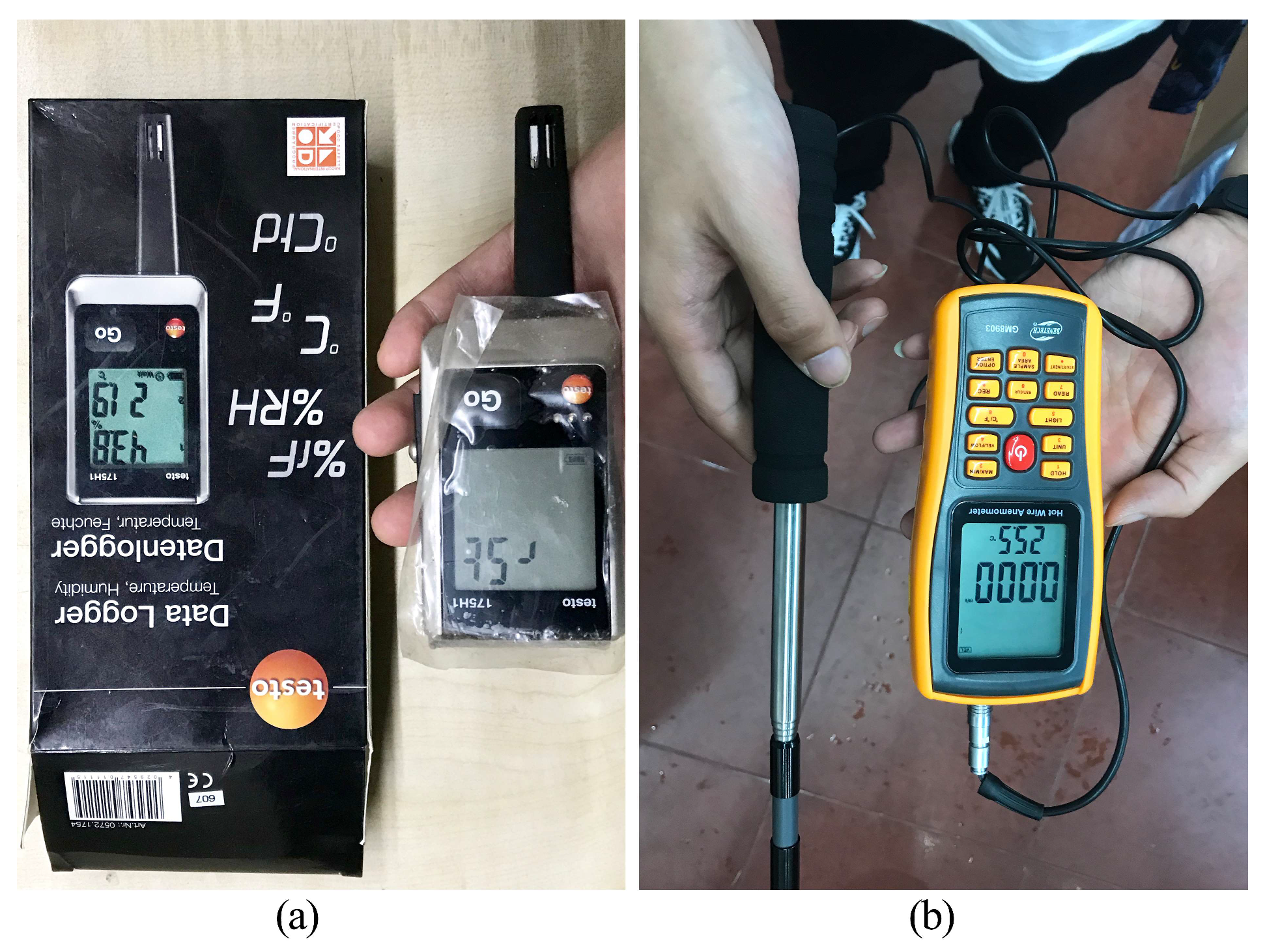

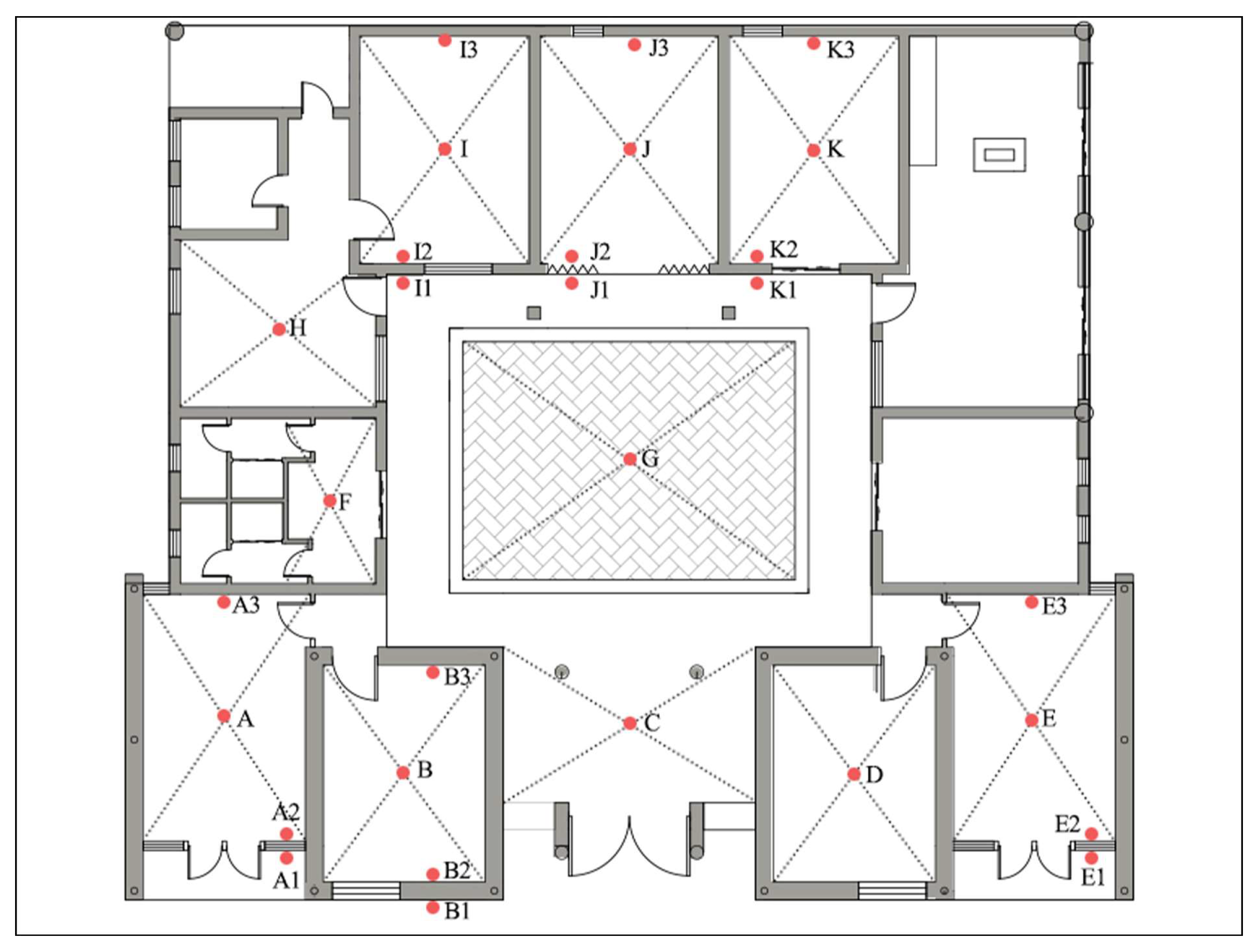

2.3.1. Objective Measurement

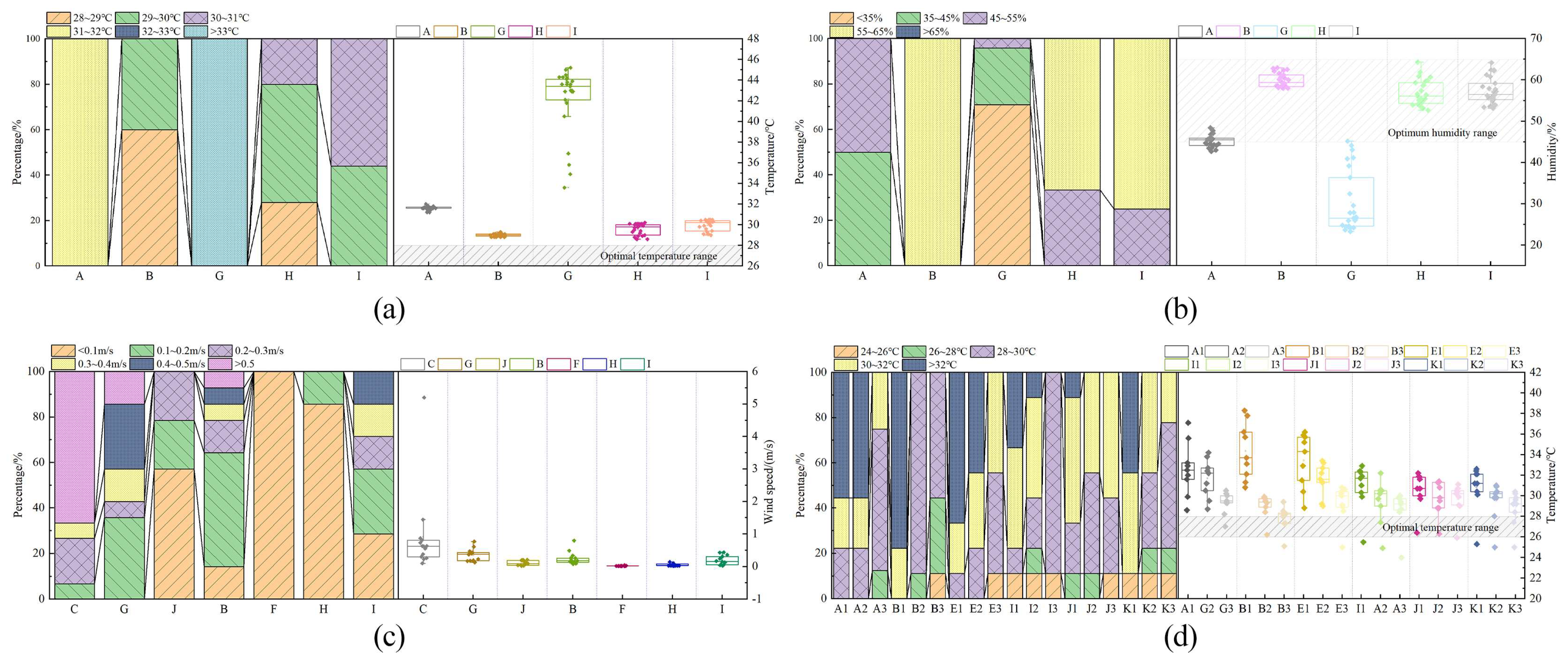

2.3.2. Objective Simulation

3. Renovation of the Rammed Earth Dwelling

3.1. Function Improvement Results

3.2. Construction Tool Improvement Results

3.3. Construction Material Improvement Results

3.4. Construction Process Improvement Results

3.5. Assessment Results of the Renovation of Residential Dwellings

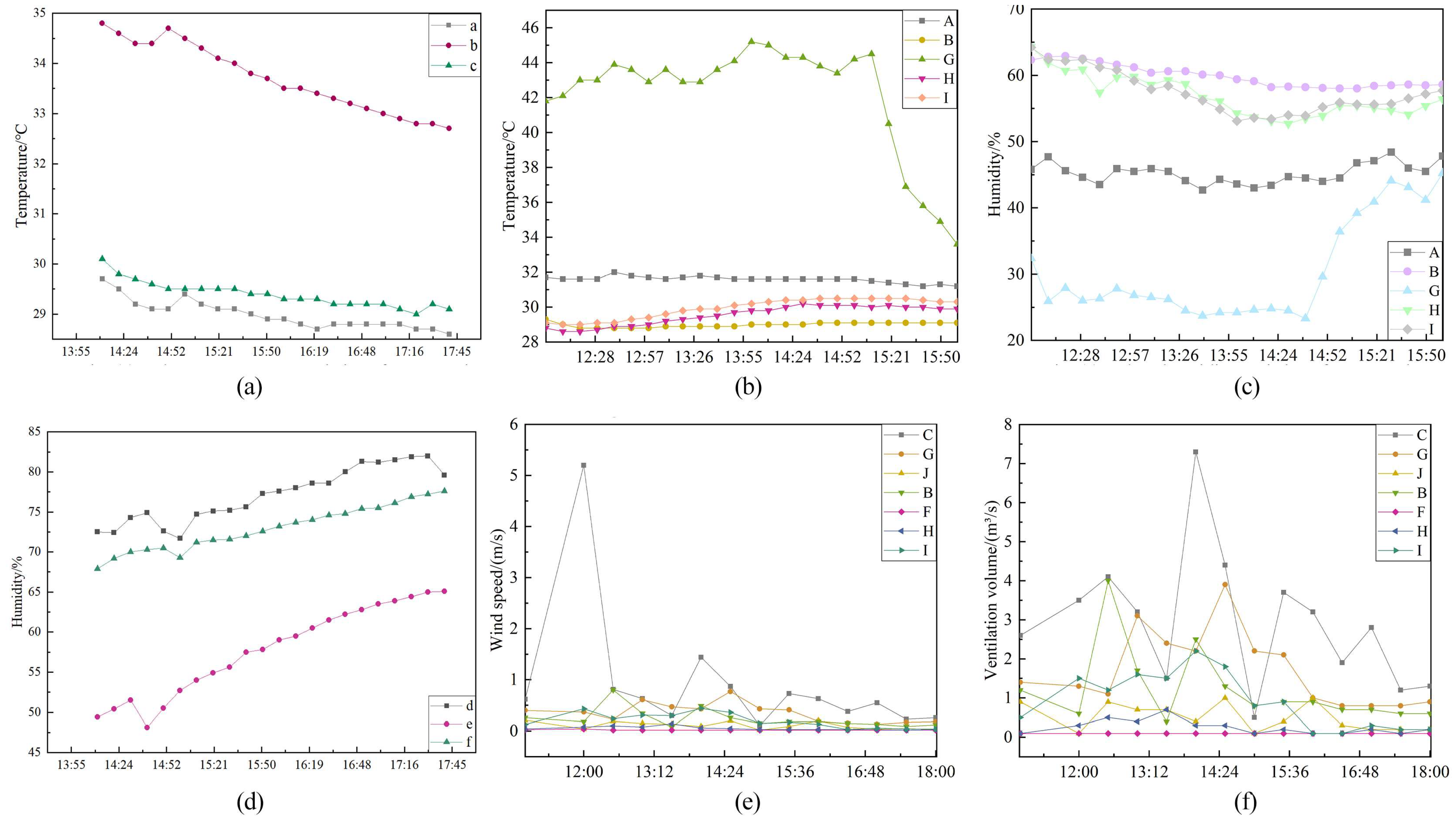

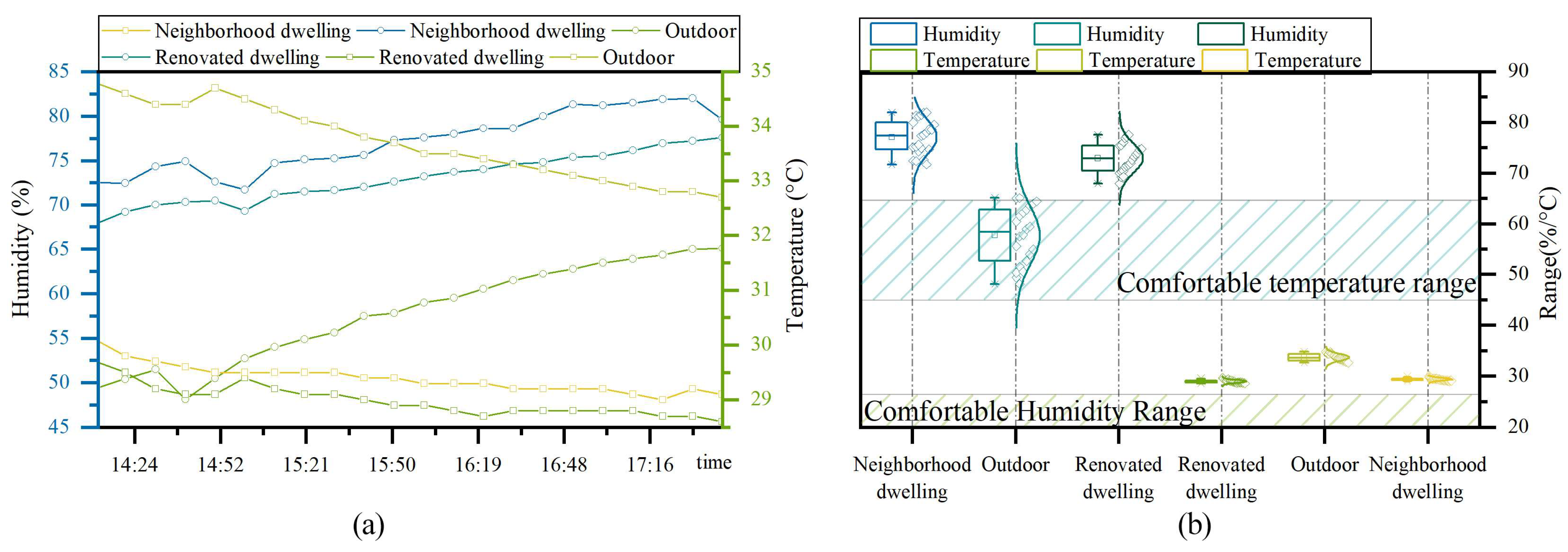

3.5.1. Indoor Physical Environment Measurement Results

3.5.2. Questionnaire Results

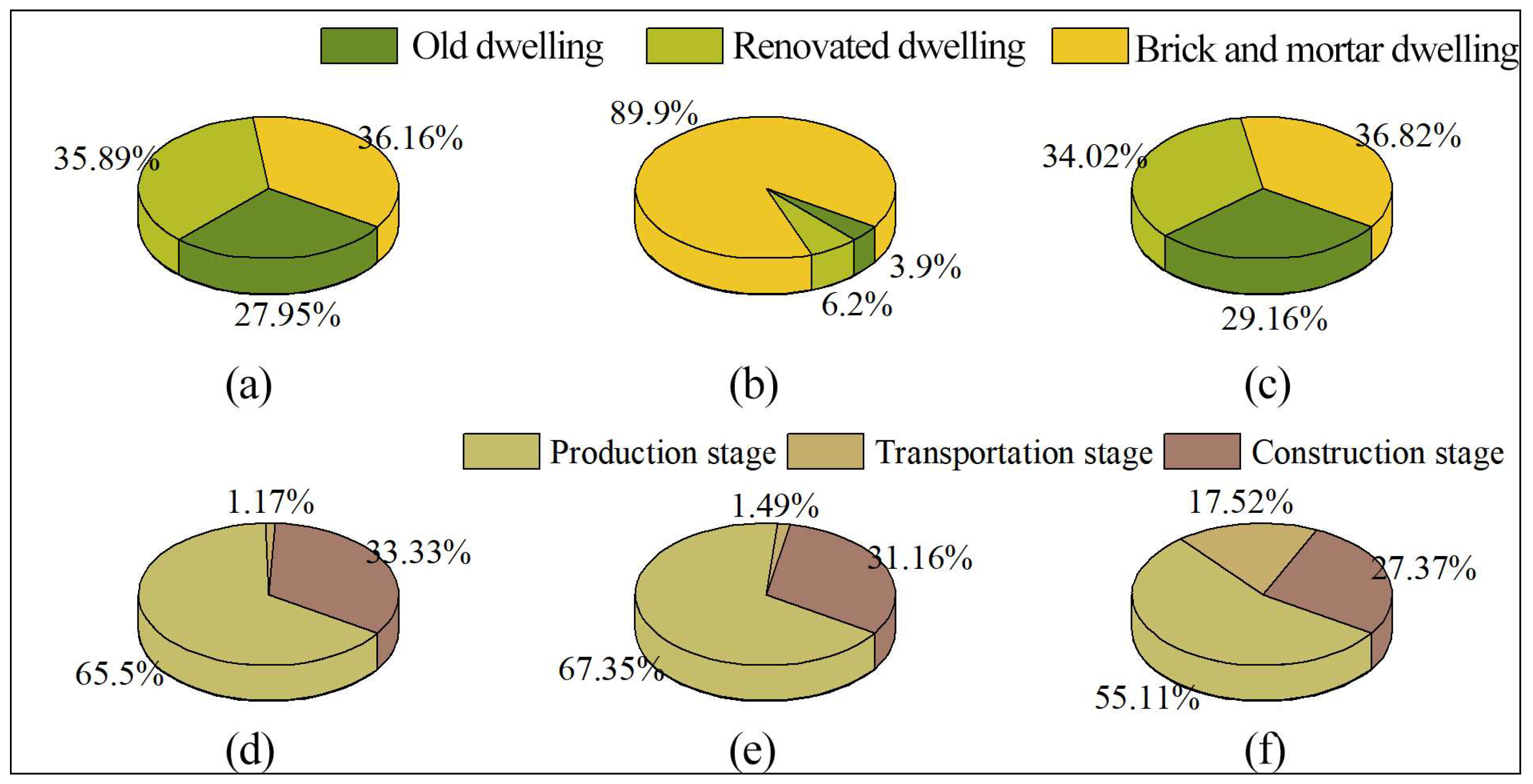

3.5.3. Carbon Emission

4. Discussion

5. Conclusions

- (1)

- The sustainable renovation method was successfully used to renovate aging rammed earth dwellings in Hunan Province. The floor plan function of the renovated dwelling maintains the owner’s living habits and local cultural customs, and meets their living needs. The improved tools can accommodate the construction of walls with different sizes and forms. These tools are significantly better than the traditional ones in terms of power duration and effectiveness. The construction materials make full use of waste materials from old homes, including green tiles, raw earth, and wood. The renovation materials were selected from local materials, effectively reducing costs and carbon emissions incurred during the transportation of building materials. In addition, the improved rammed earth wall materials have a more uniform and lower moisture content, which increases the construction efficiency. The improved construction process also contributes to the integrity of the wall and the construction results.

- (2)

- The assessment results of the renovated houses show that the average indoor temperature of the renovated houses is lower than that of the neighbouring and outdoor dwellings. The indoor humidity fluctuations are also lower than those of the neighbouring and outdoor dwellings. The results of the owner and participant questionnaires indicate that the renovation method is generally accepted by the residents. The carbon emissions caused by the production, transportation, and construction phases of the renovated homes are lower than those caused by the brick homes.

- (3)

- The actual project and evaluation results show that the proposed sustainable renovation method can effectively address the aging problem of rammed earth dwellings in Hunan. However, this study has some shortcomings. In the proposed renovation method, diverse measures to reduce carbon emissions, such as heating, ventilation, air conditioning system optimisation, increasing the area of green vegetation, and using renewable energy, were not completely considered. There was also no analysis of the carbon emissions in the operation and recycling phases of the renovated residential houses. These will be studied in detail in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Test Points | Room/Room Location |

|---|---|

| A | Chess room 1 |

| A1 | Exterior wall surface of chess room 1 |

| A2 | Inside surface of the exterior wall of chess room 1 |

| A3 | Inside surface of the inner wall of chess room 1 |

| B | Bedroom 1 |

| B1 | Exterior wall surface of bedroom 1 |

| B2 | Inside surface of the exterior wall of bedroom 1 |

| B3 | Inside surface of the inner wall of bedroom 1 |

| C | Porch |

| D | Bedroom 2 |

| E | Chess room 2 |

| E1 | Exterior wall surface of chess room 2 |

| E2 | Inside surface of the exterior wall of chess room 2 |

| E3 | Inside surface of the inner wall of chess room 2 |

| F | Bathroom |

| G | Courtyard |

| H | Study room |

| I | Bedroom 3 |

| I1 | Exterior wall surface of bedroom 3 |

| I2 | Inside surface of the exterior wall of bedroom 3 |

| I3 | Inside surface of the inner wall of bedroom 3 |

| J | Central room |

| J1 | Exterior wall surface of central room |

| J2 | Inside surface of the exterior wall of central room |

| J3 | Inside surface of the inner wall of central room |

| K | Bedroom 4 |

| K1 | Exterior wall surface of bedroom 4 |

| K2 | Inside surface of the exterior wall of bedroom 4 |

| K3 | Inside surface of the inner wall of bedroom 4 |

| a | Raw earth dwelling bedroom temperature |

| b | Outdoor temperature |

| c | Brick and concrete dwelling bedroom temperature |

| d | Raw earth dwelling bedroom humidity |

| e | Outdoor Humidity |

| f | Brick and concrete dwelling bedroom humidity |

References

- Lippiatt, N.; Ling, T.-C.; Pan, S.-Y. Towards carbon-neutral construction materials: Carbonation of cement-based materials and the future perspective. J. Build. Eng. 2020, 28, 101062. [Google Scholar] [CrossRef]

- Shi, Q.; Chen, J.; Shen, L. Driving factors of the changes in the carbon emissions in the Chinese construction industry. J. Clean. Prod. 2017, 166, 615–627. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Rønholt, J.; Birkved, M.; Birgisdottir, H. Circular Economy potential within the building stock-mapping the embodied greenhouse gas emissions of four Danish examples. J. Build. Eng. 2021, 33, 101845. [Google Scholar] [CrossRef]

- Hou, H.; Wang, J.; Yuan, M.; Liang, S.; Liu, T.; Wang, H.; Bai, H.; Xu, H. Estimating the mitigation potential of the Chinese service sector using embodied carbon emissions accounting. Environ. Impact Assess Rev. 2021, 86, 106510. [Google Scholar] [CrossRef]

- Zhang, S.-C.; Yang, X.-Y.; Xu, W.; Fu, Y.-J. Contribution of nearly-zero energy buildings standards enforcement to achieve carbon neutral in urban area by 2060. Adv. Clim. Change Res. 2021, 12, 734–743. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Y.; Teng, Y.; Yu, B.; Wang, J.; Zhang, H.; Duan, H. Can buildings sector achieve the carbon mitigation ambitious goal: Case study for a low-carbon demonstration city in China? Environ. Impact Assess Rev. 2021, 90, 106633. [Google Scholar] [CrossRef]

- Wu, Y.; Shen, L.; Shuai, C.; Jiao, L.; Liao, S.; Guo, Z. Key driving forces on the development of low carbon city (LCC) in China. Ecol. Indic. 2021, 124, 107379. [Google Scholar] [CrossRef]

- Gallipoli, D.; Bruno, A.W.; Perlot, C.; Mendes, J. A geotechnical perspective of raw earth building. Acta Geotech. 2017, 12, 463–478. [Google Scholar] [CrossRef] [Green Version]

- Almusaed, A.; Almssad, A.; Homod, R.Z.; Yitmen, I. Environmental profile on building material passports for hot climates. Sustainability 2020, 12, 3720. [Google Scholar] [CrossRef]

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. Application of agro and non-agro waste materials for unfired earth blocks construction: A review. Constr. Build. Mater. 2020, 254, 119346. [Google Scholar] [CrossRef]

- Mellaikhafi, A.; Tilioua, A.; Souli, H.; Garoum, M.; Hamdi, M.A.A. Characterization of different earthen construction materials in oasis of south-eastern Morocco (Errachidia Province). Case Stud. Constr. Mater. 2021, 14, e00496. [Google Scholar] [CrossRef]

- Schweiker, M.; Endres, E.; Gosslar, J.; Hack, N.; Hildebrand, L.; Creutz, M.; Klinge, A.; Kloft, H.; Knaack, U.; Mehnert, J. Ten questions concerning the potential of digital production and new technologies for contemporary earthen constructions. Build. Environ. 2021, 206, 108240. [Google Scholar] [CrossRef]

- Parracha, J.L.; Lima, J.; Freire, M.T.; Ferreira, M.; Faria, P. Vernacular earthen buildings from Leiria, Portugal–Architectural survey towards their conservation and retrofitting. J. Build. Eng. 2021, 35, 102115. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Earth construction: Lessons from the past for future eco-efficient construction. Constr. Build. Mater. 2012, 29, 512–519. [Google Scholar] [CrossRef] [Green Version]

- Niroumand, H.; Zain, M.; Jamil, M. Various types of earth buildings. Procedia Soc. Behav. Sci. 2013, 89, 226–230. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.; Cooper, P.; Daly, D.; Ledo, L. Existing building retrofits: Methodology and state-of-the-art. Energy Build. 2012, 55, 889–902. [Google Scholar] [CrossRef]

- Göswein, V.; Silvestre, J.D.; Monteiro, C.S.; Habert, G.; Freire, F.; Pittau, F. Influence of material choice, renovation rate, and electricity grid to achieve a Paris Agreement-compatible building stock: A Portuguese case study. Build. Environ. 2021, 195, 107773. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.; Wang, X.-J. Research on green renovations of existing public buildings based on a cloud model–TOPSIS method. J. Build. Eng. 2021, 34, 101930. [Google Scholar] [CrossRef]

- Tan, Y.; Luo, T.; Xue, X.; Shen, G.Q.; Zhang, G.; Hou, L. An empirical study of green retrofit technologies and policies for aged residential buildings in Hong Kong. J. Build. Eng. 2021, 39, 102271. [Google Scholar] [CrossRef]

- Jiang, Y.; Mohabir, N.; Ma, R.; Wu, L.; Chen, M. Whose village? Stakeholder interests in the urban renewal of Hubei old village in Shenzhen. Land Use Policy 2020, 91, 104411. [Google Scholar] [CrossRef]

- Pan, W.; Pan, M. A ‘demand-supply-regulation-institution’ stakeholder partnership model of delivering zero carbon buildings. Sust. Cities Soc. 2020, 62, 102359. [Google Scholar] [CrossRef]

- Jagarajan, R.; Asmoni, M.N.A.M.; Mohammed, A.H.; Jaafar, M.N.; Mei, J.L.Y.; Baba, M. Green retrofitting–A review of current status, implementations and challenges. Renew. Sust. Energy Rev. 2017, 67, 1360–1368. [Google Scholar] [CrossRef]

- Hashempour, N.; Taherkhani, R.; Mahdikhani, M. Energy performance optimization of existing buildings: A literature review. Sust. Cities Soc. 2020, 54, 101967. [Google Scholar] [CrossRef]

- Jensen, P.A.; Maslesa, E.; Berg, J.B.; Thuesen, C. 10 questions concerning sustainable building renovation. Build. Environ. 2018, 143, 130–137. [Google Scholar] [CrossRef]

- López-Ochoa, L.M.; Las-Heras-Casas, J.; López-González, L.M.; García-Lozano, C. Energy Renovation of Residential Buildings in Cold Mediterranean Zones Using Optimized Thermal Envelope Insulation Thicknesses: The Case of Spain. Sustainability 2020, 12, 2287. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Qian, Q.K.; Visscher, H.; Song, K. Homeowners’ Participation in Energy Efficient Renovation Projects in China’s Northern Heating Region. Sustainability 2021, 13, 9037. [Google Scholar] [CrossRef]

- Khadra, A.; Hugosson, M.; Akander, J.; Myhren, J.A. Development of a weight factor method for sustainability decisions in building renovation. Case study using renobuild. Sustainability 2020, 12, 7194. [Google Scholar] [CrossRef]

- Amoruso, F.M.; Dietrich, U.; Schuetze, T. Integrated BIM-parametric workflow-based analysis of daylight improvement for sustainable renovation of an exemplary apartment in Seoul, Korea. Sustainability 2019, 11, 2699. [Google Scholar] [CrossRef] [Green Version]

- D’Urso, S.; Cicero, B. From the efficiency of nature to parametric design. A holistic approach for sustainable building renovation in seismic regions. Sustainability 2019, 11, 1227. [Google Scholar] [CrossRef] [Green Version]

- Hema, C.M.; Van Moeseke, G.; Evrad, A.; Courard, L.; Messan, A. Vernacular housing practices in Burkina Faso: Representative models of construction in Ouagadougou and walls hygrothermal efficiency. Energy Procedia 2017, 122, 535–540. [Google Scholar] [CrossRef]

- Hu, X.; Xiang, Y.; Zhang, H.; Lin, Q.; Wang, W.; Wang, H. Active–passive combined energy-efficient retrofit of rural residence with non-benchmarked construction: A case study in Shandong province, China. Energy Rep. 2021, 7, 1360–1373. [Google Scholar] [CrossRef]

- Serrano-Jiménez, A.; Femenías, P.; Thuvander, L.; Barrios-Padura, Á. A multi-criteria decision support method towards selecting feasible and sustainable housing renovation strategies. J. Clean. Prod. 2021, 278, 123588. [Google Scholar] [CrossRef]

- He, C.; Hou, Y.; Ding, L.; Li, P. Visualized literature review on sustainable building renovation. J. Build. Eng. 2021, 44, 102622. [Google Scholar] [CrossRef]

- Jiménez-Pulido, C.; Jiménez-Rivero, A.; García-Navarro, J. Improved sustainability certification systems to respond to building renovation challenges based on a literature review. J. Build. Eng. 2022, 45, 103575. [Google Scholar] [CrossRef]

- Zhang, H.; Lei, S.L. An assessment framework for the renovation of existing residential buildings regarding environmental efficiency. Procedia Soc. Behav. Sci. 2012, 68, 549–563. [Google Scholar] [CrossRef] [Green Version]

- Amoruso, F.M.; Schuetze, T. Hybrid timber-based systems for low-carbon, deep renovation of aged buildings: Three exemplary buildings in the Republic of Korea. Build. Environ. 2022, 214, 108889. [Google Scholar] [CrossRef]

- Zhang, F.; Shi, L.; Liu, S.; Zhao, M.; Ma, Q. Red loam soils blocks modified using cement-lime: Assessment of its optimum ratio, performance, and practice. Proc. J. Phys. Conf. Ser. 2021, 1965, 012070. [Google Scholar] [CrossRef]

- Zhang, F.; Shi, L.; Liu, S.; Shi, J.; Ma, Q.; Zhang, J. Climate Adaptability Based on Indoor Physical Environment of Traditional Dwelling in North Dong Areas, China. Sustainability 2022, 14, 850. [Google Scholar] [CrossRef]

- Zhang, B.; Li, X.; Lin, B.; Zhu, Y. A CBR-based decision-making model for supporting the intelligent energy-efficient design of the exterior envelope of public and commercial buildings. Energy Build. 2021, 231, 110625. [Google Scholar] [CrossRef]

| Local Cultural Factors | Proportion | Remarks | |

|---|---|---|---|

| Cultural environment | Do you support the improvement of traditional craftsmanship to better suit modern needs? |  | −1: Not supportive; −1: Not very supportive 0: Neutral: 1: More supportive; 2: Supportive |

| Are you satisfied with the improved traditional rammed earth techniques? |  | −2: Dissatisfied; −1: Not very satisfied; 0: Moderate; 1: More satisfied; 2: Very satisfied | |

| Do you think the renovated rammed earth building can achieve harmony between traditional habits and modern life? |  | −2: Cannot; −1: Should not; 0: Not sure; 1: Should be able; 2: Definitely able | |

| Indoor environment | Are you satisfied with the indoor temperature conditions in summer/winter? |  | −2: not satisfied; −1: not very satisfied; 0: moderate; 1: more satisfied; 2: very satisfied |

| Are you satisfied with the indoor ventilation in summer/winter? | |||

| Are you satisfied with the indoor lighting conditions in summer/winter? | |||

| Do you think the renovated rammed earth building is convenient for your daily life? |  | −2: inconvenient; −1: not very convenient: 0: moderate; 1: more convenient; 2: very convenient | |

| Outdoor environment | Are you satisfied with the shape of the renovated rammed earth building? |  | −2: not satisfied; −1: not too satisfied; 0: moderate; 1: more satisfied; 2: very satisfied |

| Do you think the improved rammed earth buildings fit in with the existing village environment? |  | −2: not a good fit; −1: not too good a fit; 0: moderate; 1: better fit; 2: very good fit | |

| Do you think the improved rammed earth buildings fit in with the cultural characteristics of the region? | |||

| Overall evaluation | Are you satisfied with the overall condition of the renovated rammed earth buildings? |  | −2: not satisfied; −1: not too satisfied; 0: moderate; 1: more satisfied; 2: very satisfied |

| Do you think the renovated rammed earth buildings can promote cultural heritage? |  | −2: Cannot; −1: Should not; 0: Not sure; 1: Should be able; 2: Able | |

| Do you support the promotion of the renovated rammed earth buildings? |  | −1: Do not support; −1: Do not support 0: Neutral: 1: More support; 2: Support |

| Test Parameters | Test Instrument | Measuring Accuracy | Measuring Range |

|---|---|---|---|

| Air temperature and humidity | Testo 175H1 thermohygrometer | ±0.4 °C ± digit ±2% RH (2–98% RH) | −20 ± 55 °C 0–100% RH |

| Wind speed | Testo 0435 thermal anemometer | ±0.03 m/s +5% of reading | 0–20 m/s |

| Wall temperature | Infrared thermometer | ±1.5 °C/±1.5% | −50–950 °C |

| Production Stage | Transport Stage | ||||

|---|---|---|---|---|---|

| Num | Building Materials | Production Factor (tCO2e/t) | Transportation Method | Transport Factor tCO2e/(t km) | Transportation Distance |

| 1 | Cement mortar | 0.002510 | Light duty gasoline truck | 0.000334 | 10.00 |

| 2 | Red loam soil | 0.139000 | Light duty gasoline truck | 0.000334 | 1000.00 |

| 3 | Pine, wood, spruce (vertical wood grain in the direction of heat flow) | 20.887440 | Light duty gasoline truck | 0.000334 | 50.00 |

| 4 | Rock wool board | 0.002510 | Light duty gasoline truck | 0.000334 | 10.00 |

| 5 | Insulation metal profile multicavity seal Kf = 5.0 W/(m2 K) frame area 20% | 1.130000 | Light duty gasoline truck | 0.000334 | 30.00 |

| 6 | 6 transparent + 12 air + 6 transparent | 0.254000 | Light duty gasoline truck | 0.000334 | 30.00 |

| 7 | Wood (plastic) frame single solid door | 3.600000 | Light duty gasoline truck | 0.000334 | 30.00 |

| 8 | Block tile | 0.002510 | Light duty gasoline truck | 0.000334 | 10.00 |

| 9 | Plus grass clay (ρ = 1400) | 0.139000 | Light duty gasoline truck | 0.000334 | 50.00 |

| 10 | Wood chipboard | 0.139000 | Light duty gasoline truck | 0.000334 | 100.00 |

| 11 | Pine, wood, spruce (heat flow direction with wood grain) | 0.126000 | Light duty gasoline truck | 0.000334 | 40.00 |

| 12 | Fine stone concrete | 0.002510 | Light duty gasoline truck | 0.000334 | 10.00 |

| 13 | Compacted clay (ρ = 1800) | 0.132620 | Light duty gasoline truck | 0.000334 | 100.00 |

| 14 | Aerated concrete block B07 | 0.250000 | Light duty gasoline truck | 0.000334 | 100.00 |

| 15 | Reinforced concrete | 0.126000 | Light duty gasoline truck | 0.000334 | 100.00 |

| 16 | Extruded polystyrene foam board | 20.887440 | Light duty gasoline truck | 0.000334 | 100.00 |

| 17 | Light aggregate concrete clear pounding | 0.126000 | Light duty gasoline truck | 0.000334 | 100.00 |

| Type | Ramming Force | Ramming Speed | Wall Effect | Ramming Effort | Corner Effect | Shrinkage | Construction Process | Ramming Times |

|---|---|---|---|---|---|---|---|---|

| Traditional | 1.5 MPa | 25 h/m2 | Dense | Simple | Rough wall | 0.06% | Need tapping | three times |

| Improved | 4.5 MPa | 10 h/m2 | Dense | Difficult | Dense wall | 0.03% | Need tapping | three times |

| Structure | Materials | Size | Quantity | Price/RMB |

|---|---|---|---|---|

| Tile roof | Green tile | 300 × 240 mm | 18,043.00 | 4.15 |

| Small Green Tile | 180 × 200 mm | 78,187.00 | 0.55 | |

| Roof beams and bracing | Fir | 150 × 150× 4500 mm | 10.00 | 141.75 |

| Fir | 150 × 150 × 5500 mm | 10.00 | 173.25 | |

| Fir | 200 × 300 × 8500 mm | 2.00 | 700 | |

| Fir | 100 × 100 × 3000 mm | 8.00 | 42 | |

| Fir | 100 × 100 × 3500 mm | 13.00 | 49 | |

| Fir | 100 × 100 × 6000 mm | 4.00 | 84 | |

| Roof boarding | Fir | 100 × 15 × 5500 | 170.00 | 50 |

| Fir | 100 × 15 × 4500 | 170.00 | 42 | |

| Fir | 100 × 15 × 3500 | 120.00 | 33 | |

| Fir | 100 × 15 × 2000 | 70.00 | 19 | |

| Column in wall | Fir | Φ 200 mm, 3500 mm | 10.00 | 80 |

| Goalposts | Fir | Φ 200 mm, 5500 mm | 4.00 | 100 |

| Fir | Φ 200 mm, 3000 mm | 4.00 | 70 | |

| Beam in wall | Φ 150 mm, 6000 mm | 4.00 | 100 | |

| Φ 150 mm, 4500 mm | 4.00 | 70 | ||

| Wall | Red clay | — | 50 m3 | 0 |

| White Cement | — | 3.56 m3 | 750/t | |

| Lime | — | 3.56 m3 | 500/t | |

| Bathroom wall | Tile | — | 85 m2 | 20 |

| Bedroom floor | Anticorrosion wood | 5500 × 200 × 15 mm | 61.00 | 41 |

| Anticorrosion wood | 4500 × 200 × 15 mm | 45.00 | 34 | |

| Anticorrosion wood | 5000 × 200 × 15 mm | 72.00 | 38 | |

| Corridor | Anticorrosion wood | 5000 × 200 × 15 mm | 27.00 | 38 |

| Anticorrosion wood | 4500 × 200 × 15 mm | 20.00 | 34 | |

| Floor tile | Green brick | 240 × 120 × 60 mm | 4325 | 2 |

| Type | Regional Culture | Index | Satisfaction |

|---|---|---|---|

| Cultural Environment | Support for improved ramming process | 1.04 | |

| Satisfaction with improved rammed earth process | 0.94 | ||

| Harmony between traditional habits and modern life | 1.03 | ||

| Indoor Environment | Satisfaction with indoor temperature | Summer | 1.01 |

| Winter | 0.84 | ||

| Satisfaction with indoor ventilation | Summer | 1.38 | |

| Winter | 1.08 | ||

| Satisfaction with indoor lighting | Summer | 1.28 | |

| Winter | 1.01 | ||

| The convenience of daily life | 0.70 | ||

| Outdoor Environment | Satisfaction with architectural style | 1.02 | |

| Degree of compatibility with the existing | 1.10 | ||

| village environment | 1.41 | ||

| Overall Evaluation | Satisfaction with the overall situation | 1.29 | |

| Promotion of cultural heritage | 1.14 | ||

| Degree of support for the promotion | 1.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Shi, L.; Liu, S.; Shi, J.; Yu, Y. Sustainable Renovation and Assessment of Existing Aging Rammed Earth Dwellings in Hunan, China. Sustainability 2022, 14, 6748. https://doi.org/10.3390/su14116748

Zhang F, Shi L, Liu S, Shi J, Yu Y. Sustainable Renovation and Assessment of Existing Aging Rammed Earth Dwellings in Hunan, China. Sustainability. 2022; 14(11):6748. https://doi.org/10.3390/su14116748

Chicago/Turabian StyleZhang, Fupeng, Lei Shi, Simian Liu, Jiaqi Shi, and Yong Yu. 2022. "Sustainable Renovation and Assessment of Existing Aging Rammed Earth Dwellings in Hunan, China" Sustainability 14, no. 11: 6748. https://doi.org/10.3390/su14116748

APA StyleZhang, F., Shi, L., Liu, S., Shi, J., & Yu, Y. (2022). Sustainable Renovation and Assessment of Existing Aging Rammed Earth Dwellings in Hunan, China. Sustainability, 14(11), 6748. https://doi.org/10.3390/su14116748