Abstract

Brazil is one of the world’s major ornamental stone producers. As a consequence, ornamental stone wastes are generated on a large scale and are usually open air disposed. Thus, it is important to develop novel material reusing these accumulated wastes, aiming to minimize environmental impact. The development of artificial stones made with ornamental stone wastes agglomerated by a synthetic polymer represents an excellent alternative and, therefore, is currently the subject of several works. This work seeks to develop an innovative artificial stone containing 85%wt of granite waste and 15%wt of vegetable polyurethane from castor oil, a biodegradable resin, from a renewable source. The purpose is creating a sustainable material, technically viable to be applied as a civil construction coating. To manufacture the artificial stone plates, granite and polyurethane were mixed and transferred to a metallic mold subjected to vibration, vacuum and, later, hot compression. The artificial stone presented low water absorption (0.13%) and apparent porosity (0.31%) as well as a favorable 17.31 MPa bend strength. These results were confirmed through the excellent particles/matrix adhesion displayed in the micrographs, in addition to great chemical resistance.

1. Introduction

The building materials demand is rapidly increasing, especially in developing countries, on account of the rapid urbanization and the improving life standart. Consequently, decorative stone mining has grown to be an remarkably prosperous activity [1]. Brazil is one of the world’s largest ornamental stone producers, having produced nine million tons of stone for coating and decoration in 2020, despite the pandemic that devastated the world, only 2.2% lower than the previous year [2]. The large amount of waste generated by the ornamental stone industry produces several environmental impacts such as water, landscape and flora pollution, since most of this waste is improperly disposed of [3,4]. Furthermore, according to Cordon et al. about 75% of natural resources are consumed for the development of this activity [5].

In the current scenario, environmental preservation is crucial, bringing prominence to the development of sustainable building materials that contribute to its preservation while simultaneously fulfilling their functions. Several researches around the world have been carried out in order to reuse granite wastes, thus reducing their environmental impacts [1,3]. It is worth mentioning that, under regular working conditions, granite waste is not environmentally deleterious, being classified as a non-inert and non-hazardous waste, i.e., it does not react and does not dissolve in water [6].

Some specific granite waste characteristics favor its industrial use as raw material for novel products, such as: fine granulometry, predefined chemical composition and the absence of mixed grains between the basic components [1]. For instance, in mortar manufacturing, it is possible to use granite wastes to replace natural aggregates, saving natural resources and providing a good mechanical performance without harming the mortar’s appearance, once granite contains in its composition [1]. For concrete, it is possible to reuse granite waste to partially replace the fine aggregates, which even increases its compressive and flexural strength [7]. For ceramic products manufacturing, fine granite waste can be mixed in the clay mass, producing ceramic bodies with promising properties, depending on the firing temperature, and without altering its color, due to oxides content in granite’s chemical composition [8]. Thereby, granite wastes are able to partially replace the fine aggregates in concrete, increasing its bending and compression strength [1,7,8].

Another alternative for recycling granite waste is its reuse as a raw material in the development of other construction materials, such as artificial stone. Indeed, artificial stones are made of a high content of particulate aggregates bonded by polymeric resins. The aesthetics and properties of artificial stones are distinct since their manufacturing occurs under different conditions, from a wide range of compositions, different types of aggregates and resins binders as well as different types of processing [9,10].

Artificial stones are, in general, technically superior compared to natural ornamental stones. As the particles are bonded together by a polymeric resin, which results in a lighter material. In fact, the artificial stones’ density is lower. To improve even more, the resin fulfills most of the voids and pores, shaping a material to be further resistant to liquid infiltration, granting its use in humid environments for a long term without its performance being impaired. Likewise, the mechanical strength is superior, once voids can work as stress concentrators and facilitate crack expansion [11].

Several researches have been carried out in order to develop the most differentiated artificial stones, varying the types of aggregates and polymeric resins [12,13,14,15]. Shishegaran et al. [12] evaluated the mechanical properties of three artificial stones containing: traveline powder and sludge, traveline powder and sand and traveline powder, sand and sludge, using two distinct epoxy resins. Sarami and Mahdavian [13] evaluated the properties of artificial stones using travertine, marmarit stone with cement, water and unsaturated polyester resin. Borsellino et al. [14] produced artificial marbles using polyester or epoxy resin varying the power concentration of marble particles. Carvalho et al. [15] developed an artificial stone with an epoxy matrix incorporated with sintering steel industry waste. Notwithstanding, the researches carried out until then have used synthetic resins, derived from petroleum, in their polymer matrices, mainly epoxy and polyester resins.

Petroleum-derived polymers consumption has been growing over time, also giving rise to a large amount of waste that is often discarded inappropriately and, in aggravation, takes years to degrade. To minimize this problem, it is possible to use biodegradable polymers as their technical and economic feasibility has great potential for expansion [16]. Polyurethane (PU) castor oil is a widely found low-cost renewable oil that is attracting attention from researchers due to its utilization in coatings, adhesives, paints, sealants and encapsulating compounds. Castor oil-based PUs ordinarily have low mechanical strength and limited ductility due to their flexible, highly crosslinked and permanent network structure. In a sustainability concepts, it is interesting to replace polymers by this type of PU from a renewable source [17,18].

This work’s main goal is to develop and characterize a novel sustainable artificial stone that, together with the granite waste recycling, also proposes application of a biodegradable PU from castor oil, a renewable and non-toxic source, as matrix. The scope of this work is also the evaluation of whether it can be used as a coating in civil construction. The artificial stone waste/polyurethane resin (ASPU) developed composite allows the creation of sustainable material with suitable properties to be used as coating and reducing the harmful environmental impacts that would occur with the disposal of granite waste and the synthetic polymers utilization.

2. Materials and Methods

2.1. Materials

White granite waste from the slab finishing step that would be discarded was supplied by the Brumagran company located in Cachoeiro de Itapemirim, Brazil. The waste was hammered and subjected to a jaw crusher in order to be sieved according to the technical standard ABNT NBR 7181 [19] and thus classified into three granulometric ranges: coarse (2 to 0.42 mm), medium (between 0.42 to 0.075 mm), and fine (grains with particle sizes less than 0.075 mm).

Based on the three granulometric ranges, ten mixtures with different percentages of coarse, medium and fine particles were considered. A ternary diagram according to the Simplex Centroid Model was used in order to determine the mixture with the highest dry bulk density and consequently the one with the greatest packing. Therefore, the mixture selected for the development of ASPU was the one containing 4/6 of a coarse particle, 1/6 of a medium particle and 1/6 of a fine particle.

The resin used was vegetable polyurethane (PU) from castor oil. This resin is formulated by a prepolymer (component A) and a polyol (component B) cold mixing and a polyol (component B). The resin was supplied by company IMPERVEG, Brazil.

2.2. Methods

2.2.1. Development of Artificial Stone Plates

Initially, the waste was dried in an oven at 100 °C for 24 h to remove moisture. According to the resin manufacturer’s guidelines, 1wt.% of component A for each 1.2 wt.% of component B, for 15 wt.% production. The ASPU plates were manufactured in dimensions 1000 × 1000 × 12 mm3.

The mixture was made in an automatic cylindrical mixer and then the mass was placed into a mold that was previously connected to a vacuum system and over a vibrating table, Produtest, Brazil, to better spread the mass in the cavity and facilitate the removal of air bubbles.

After 2 min of vibration time in the mold, still under vacuum, the mass was compressed in a hydraulic press at a 10 tons compaction pressure, at 80 °C for 20 min. After pressing, the mold was disconnected from the vacuum system and cooled to room temperature [11] to remove the artificial stone plate.

The artificial stone plates were then subjected to post curing as shown in Table 1 to promote better cross-linking of polymer chains.

Table 1.

ASPU post cure steps.

The 60 °C was adopted as the minimum temperature based on the resin glass transition temperature (Tg). The maximum temperature was 80 °C because allophanate and biuret cross-links occur secondarily at high temperatures and are important in the polyurethane post-cure, increasing hardness, tensile strength and elastic modulus. The biuret cross-links are even more important because they occur at 80 °C range with the remaining isocyanate groups [20,21].

2.2.2. Thermogravimetric Analysis (TGA)

TGA was performed for natural granite, vegetable polyurethane and ASPU in a TGA-Q5000 TA Instruments, New Castle, DE, USA. The analysis was done with approximately 10 mg of each over a 30 to 935 °C temperature range with a heating rate of 10 °C/min, using an air flow of 60 mL/min during the test.

2.2.3. Physical Properties

Granite and ASPU density, apparent porosity and water absorption were determined by the method described in annex B of the NBR 15845 [22] standard. For the test, 12 specimens of each material with dimensions 30 × 30 × 10 mm3 were cut and sanded.

2.2.4. Mechanical Properties

Granite, polyurethane and ASPU 3-point bend rupture stress were determined. The test was performed in a Instron model 5582 universal machine, following the EN 14617-2 [22] and annex F of the NBR 15845 [23] standards guidelines. For each material, six specimens were used in the dimensions 10 × 25 × 100 mm3. The test was performed under 0.25 mm/min loading rate, 100 kN load cell and 80 mm distance between the two points.

The bend stress was calculated using Equation (1):

where: σF = bend rupture stress (MPa); F = load (N); L = distance between support bars (mm); b = width of specimen after test (mm); e = minimum thickness of specimen (mm).

2.2.5. Microstructural Analysis

The granite and ASPU fractured surface regions of specimens previously subjected to bending tests were observed through SHIMADZU’s Super Scan SSX-550 scanning electron microscope (SEM) for microstructural analysis, at 20 kV of secondary electrons. The microstructural analysis is important to determine the quality of the adhesion between the particles and the resin and the presence of voids.

2.2.6. Abrasive Wear

Abrasive wear was determined for granite and for ASPU, according to the NBR 12042 [24] standard, using MAQTEST Amsler equipment. Two specimens with 70 × 70 × 40 mm had their thicknesses measured before and after undergoing 500 and 1000 m track.

2.2.7. Chemical Attack Resistance

The granite and ASPU resistance to chemical attacks determination was performed according to a Brazilian standard NBR 13818 Annex H adaptation [25]. Sixteen specimens of each stone were used, four specimens for each reagent, namely: ammonium chloride, hydrochloric acid, citric acid and potassium hydroxide. Table 2 shows the reagents concentration and exposure time used according to the standard [25]. The specimens were weighed before and after the chemical attack in order to measure the weight loss.

Table 2.

Concentration and time of exposure of chemical attack agents.

3. Results and Analisys

3.1. Final Dimensions and Overall Aspects of ASPU

The 100 × 100 × 12 mm3 artificial stone plates were produced within the standards. Later, they were cut to the dimensions specified for carrying out the tests. Figure 1 shows an ASPU plate.

Figure 1.

ASPU plate.

3.2. Thermogravimetric Analysis

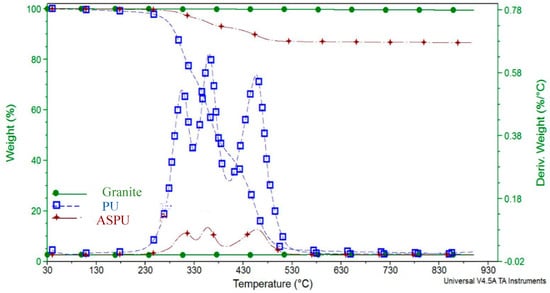

Figure 2 shows the TG and DTG curves for granite, polyurethane and ASPU.

Figure 2.

Thermogravimetric Analysis for granite, PU and ASPU.

In Figure 2, it was possible to verify that the PU has a three the decomposition stages, which is justified by releasing several gaseous products.

The first stage was around 230 °C, with a 23% mass loss. As urethane bonds break and degrade around 200 °C, this stage is likely associated with this event. The second stage takes place around 330 °C, with a 20% weight loss, probably due to CO degradation. The third and last stage, around 380 °C with a 57% mass loss, was attributed to the compounds produced after the second stage degradation [26,27].

The granite remained stable, with negligible mass loss, approximately 0.78%. Furthermore, it was possible to confirm the composition of ASPU, considering that after the analysis, 86.58% of waste remained, as the resin was the only material that suffered a degradation process.

3.3. Physical Properties

Table 3 presents the density, water absorption and apparent porosity values of granite and ASPU.

Table 3.

Physical Properties of granite and ASPU.

The granite and ASPU density were 2.62 ± 0.01 g/cm3 and 2.24 ± 0.01 g/cm3, respectively. ASPU presented a density 15% lower than granite, probably due to the polymer in its composition, which is, in general, a low density material among the others, including minerals.

The lower density results in a material with lower weight per square meter, i.e., lighter. The importance of density relies on the fact that the higher its value, the better the adhesion between the particles and the polymeric matrix, which reduces the occurrence of voids [28]. In their work, Lee et al. [29] used glass and PET (polyethylene terephthalate) crystals for the development of artificial stone varying the levels of compression, vacuum and vibration and the density values varied between 2.03 and 2.45 g/cm3. Granite and ASPU density, when compared to Lee et al., are within the expected range.

Regarding granite and ASPU water absorption, the values found were respectively 0.38 ± 0.02% and 0.13 ± 0.02%. The artificial stone developed had a result approximately three times lower than the ornamental stone. Lower water absorption levels and an impermeable surface are crucial for artificial stone once this material will be constantly in contact with water. Coating with low water absorption, following the guidelines of Chiodi Filho and Rodriguez [30], must be between 0.1–0.4% of water absorption. Ribeiro et al. [11] in its artificial marble developed with polyester resin obtained 0.19%, while Borsellino et al. [14] developed a 0.25% water absorption artificial marble, but with epoxy resin. With these comparisons, it is verified the good performance of ASPU, confirming the possibility of its use in humid environments.

The apparent porosity value was 0.99 ± 0.06% for granite and 0.31 ± 0.02% for ASPU. The ASPU water absorption was three times lower than that of granite. Chiodi Filho and Rodriguez [30] classify that high quality coating materials must have porosity below 0.5%, denoting the ASPU good performance. ASPU’s low porosity can be attributed to the homogeneity of the material, with granite particles well adhered to the polyurethane matrix, ensuring the filling of the voids.

3.4. Three-Points Bend Stress

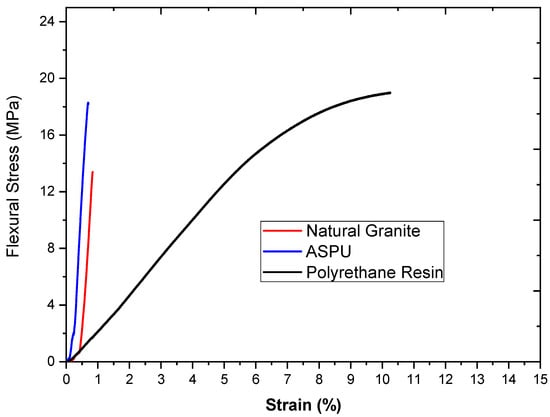

Figure 3 shows the bending stress vs. strain curves for ASPU, white granite and vegetable polyurethane.

Figure 3.

Stress vs. Strain curves for ASPU, granite and polyurethane (PU).

The tensile stress of granite, ASPU and vegetable polyurethane were respectively 13.50 ± 1.10, 17.31 ± 0.82 and 23.01 ± 5.30 MPa.

According to the ABNT NBR 15844 standard [31], which determines the necessary requirements for the use of granite as a coating, the 3-point bend strength must not be less than 10 MPa. Even though granite presented an elevated strength (13.5 MPa), its resistance was inferior to ASPU due to its high porosity shown by physical tests results.

Comparing the polyurethane behavior with its derived artificial stone, it is possible to observe that the granite inclusion as a resin filler contributed to increase the material stiffness stiffness. This is an expected behavior, considering that the rigid particles incorporation in a polymer matrix commonly enhances the material’s elasticity modulus [32].

According to Chiodi Filho and Rodriguez [30], artificial stones applied as coating are classified as high-strength materials when their ultimate bending strength is between 16–20 MPa, and are considered very high strength materials when this value exceeds 20 MPa. Therefore, ASPU was considered to be a high-strength material for coating, since its bending strength was 17.31 MPa, associated with its little porosity and proving the artificial stones quality performance as a coating.

3.5. Microstructural Analysis

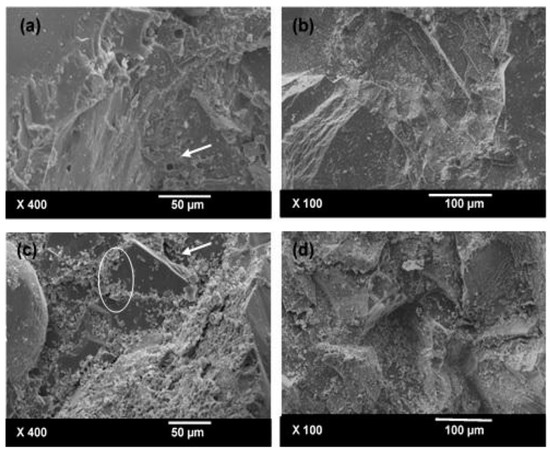

Figure 4 presents SEM micrographs of ASPU (a,b) and granite (c,d) fracture surfaces after thr three-point bending test.

Figure 4.

(a–d): Microscopic images of the fracture region obtained through scanning electron microscope (a) of the artificial stone ASPU with zoom 400× (b) ASPU with zoom 100×; (c) of the granite with zoom 400× and (d) granite with zoom 100×.

Figure 4a,b shows the ASPU’s optimal load/matrix interaction. According to Debnath et al. [33], the quality of interfacial interaction is directly related to the improvement of a composite’s mechanical strength. This is due to the fact that good interfacial wettability means higher adhesive strength.

Figure 4c,d shows the natural granite micrographs. Comparing granite to ASPU, one can notice that granite stone presented a higher incidence of voids and a greater particle detachment after the bending stress. The SEM micrographs confirmed the results found in porosity tests, with the ASPU presenting three times less porosity than the granite.

3.6. Abrasive Wear

Table 4 presents the results for ASPU and granite abrasive wear tests.

Table 4.

Abrasive wear test results.

According to a study carried out by Chiodi Filho and Rodriguez [30] that classified materials to be applied as floors according to the volume of traffic and the wear thickness reduction: high traffic floors must be less than 1.5 mm, medium traffic floors must be less than 3mm and low traffic floors must be less than 6mm.

Therefore, according to this study, granite can be used for high-traffic flooring since it presented a 0.53 mm thickness reduction after a 500 m run and 1.13 mm after 1000 m. However, ASPU can be used for medium traffic flooring considering a 0.97 mm and 1.75 mm wear after a 500 and 1000 m run, respectively.

Abrasive wear tests evaluate the material pullout when it undergoes wear friction. The inferior performance of ASPU can be explained by the greater ease of removal of granite particles from the polyurethane matrix [34].

However, according to the NBR 15844 standard [31], which classifies granites by to their wear properties, to guarante the granite’s quality, the thickness reduction must not exceed 1.0 mm after 1000 m run. Thereby, considering this specific standart, the both granite and ASPU presented wear higher than recommended, limiting its application as a pavement.

3.7. Chemical Attack Resistance

Table 5 displays the percentage weight loss suffered by the granite and ASPU under chemical attack.

Table 5.

Weight loss after chemical attack of granite and ASPU samples.

The norm NBR 13818 [25] proposed reagents are ammonia chloride and potassium hydroxide, used to make cleaning products, hydrochloric acid, which is found in floor, stone and tiles heavy cleaner products and citric acid, contained in several fruits, must be in constant contact with the specimens.

Through the obtained results it is possible to verify that the exposure to all the reagents provoked a weight loss in the stones. Although these losses could be considered insignificant, in the long term the constant use of these substances can compromise their performance and aesthetics.

Hydrochloric acid (HCl) was the most aggressive reagent for both granite and ASPU, with a 0.043 g weight loss, followed by potassium hydroxide (KOH), citric acid (C6H8O7) and ammonium chloride (NH4Cl). Hydrochloric acid is a strong and high degree of ionization acid manifesting the greatest weight loss. Therefore, cleaning materials containing this substance and potassium hydroxide should be especially avoided and it is recommended to clean with care using only a damp cloth with diluted neutral soap.

4. Conclusions

Through this study, it was possible to develop a sustainable polyurethane resin artificial stone (ASPU), using as matrix, for the first time, a polymer resin from renewable and biodegradable source, and as raw material, granite waste. The ASPU represents an innovative novel material, considering that so far, the artificial stones developed used only petroleum-derived resins as matrix.

Furthermore, the manufacturing process was an important factor to produce a technically viable material, with properties enabling its use as a coating in civil construction.

The values of density (2.24 g/cm3), water absorption (0.13%) and apparent porosity (0.31%) presented the possibility of using ASPU in humid environments and denoted the material homogeneity and good load/matrix adhesion.

The bending strength value of 17.31 MPa ranked ASPU as a higher-strength coating material. The SEM micrographs displayed an adequate interaction between granite particles and PU and the little presence of voids, confirming the physical indices and mechanical strength results.

Through the test results, it can be concluded that, owing to ASPU’s mechanical and physical properties, the novel artificial stone can be used as a wall covering, on bathroom’s and kitchen’s countertops and its use in floors must be avoided, specially for high traffic places such as airports and supermarkets.

For ASPU’s maintenance, the most aggressive reagents were HCl and KOH, causing the greatest weight loss, therefore, it should be avoided cleaning the stone with cleaning materials that contain these reagents in the components.

From this study, further research can be carried out aiming to evaluate the behavior of ASPU in cold weather countries through a bending test after freezing and thawing cycles. Besides, the changeability of the material can be studied by performing other tests like dilatometry, salt spray and UV rays exposure.

In addition, the PU from castor oil feasibility to be used as matrix resin in artificial stone allows further studies aimed at the development of other types of artificial stones varying the aggregates, wastes, matriz/load proportions and processing parameters.

Author Contributions

Conceptualization, C.M.F.V.; methodology, M.L.P.M.G. and E.A.S.C.; formal analysis, M.L.P.M.G.; investigation, R.J.S.R.; resources, C.M.F.V. and M.L.P.M.G.; data curation, G.N.S.B.; writing—original draft preparation, M.L.P.M.G.; writing—review and editing, G.N.S.B.; visualization, E.A.S.C.; supervision, R.J.S.R. and S.N.M.; project administration, E.A.S.C.; funding acquisition, M.L.P.M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Rio de Janeiro State Research Foundation—FAPERJ (E-26/200.139/2022).

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank the support of the Brazilian agencies: FAPERJ (E-26/200.847/2021), CNPQ (301634/2018-1) and UENF.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nayak, S.K.; Satapathy, A.; Mantry, S. Use of waste marble and granite dust in structural applications: A review. J. Build. Eng. 2022, 46, 103742. [Google Scholar] [CrossRef]

- ABIROCHAS—Brazilian Association of the Ornamental Stone Industry. Available online: https://abirochas.com.br/wp-content/uploads/2021/02/Informe-01_2021-Balanco-2020.pdf (accessed on 8 May 2022).

- Gautan, L.; Jain, J.K.; Kalla, P.; Danish, M. Sustainable utilization of granite waste in the production of green construction products: A review. Mater. Today Proc. 2020, 44, 4196–4203. [Google Scholar] [CrossRef]

- Demartini, T.J.C.; Rodriguez, R.J.S.; Silva, F.S. Phisycal and mechanical evalution of artificial marble produced with dolomitic marble residue processed by Diamond-plated bladed gang-saws. J. Mater. Res. Technol. 2018, 7, 308–313. [Google Scholar] [CrossRef]

- Cordon, H.C.F.; Cagnoni, F.C.; Ferreira, F.F. Comparison of physical and mechanical properties of civil construction plaster and recycled waste gypsum from São Paulo, Brazil. J. Build. Eng. 2019, 22, 504–512. [Google Scholar] [CrossRef]

- Braga, F.S.; Buzzi, D.C.; Couto, M.C.L. Environmental characterization of ornamental stone processing sludge. Sanit. Environ. Eng. 2010, 15, 237–244. (In Portuguese) [Google Scholar]

- Ahmadi, S.F.; Reisi, M.; Amiri, M.C. Reusing granite waste in eco-friendly foamed concrete as aggregate. J. Build. Eng. 2022, 46, 103566. [Google Scholar] [CrossRef]

- Singh, S.; Nagar, R.; Agrawal, V.; Rana, A.; Tiwari, A. Sustainable Utilization of Granite Cutting Waste in High Strength Concrete. J. Clean. Prod. 2016, 126, 223–235. [Google Scholar] [CrossRef]

- Hamoush, S.; Abu-Lebdeh, T.; Picornell, M.; Amer, S. Development of sustainable engineered stone cladding for toughness, durability, and energy conservation. Constr. Build. Mat. 2011, 25, 4006–4016. [Google Scholar] [CrossRef]

- Silva, S.F.; Ribeiro, C.E.G.; Rodriguez, R.J.S. Physical and Mechanical Characterization of Artificial Stone with Marble Calcite Waste and Epoxy Resin. Mater. Reser. 2018, 21, 6. [Google Scholar] [CrossRef]

- Ribeiro, C.E.G.; Rodriguez, R.J.S.; Vieira, C.M.F.; de Carvalho, E.A.; Candido, V.S.; Monteiro, S.N. Production of synthetic ornamental marble as a marble waste added polyestercomposite. In Materials Science Forum; Hotza, D., Novaes de Oliveira, A.P., Eds.; Trans Tech Publications: Zürich, Switzerland, 2014; pp. 341–345. [Google Scholar]

- Shishegaran, A.; Saeedi, M.; Mirvalad, S.; Korayem, A.H. The mechanical strength of the artificial stones, containing the travertine wastes and sand. J. Mater. Res. Technol. 2021, 11, 1688–1709. [Google Scholar] [CrossRef]

- Sarami, N.; Mahdavian, L. Effect of inorganic compound on artificial stones’ properties. Int. J. Ind. Chem. 2015, 6, 213–219. [Google Scholar] [CrossRef]

- Borselino, C.; Calbrese, L.; di Bella, G. Effects of powder concentration and type of resin on the performance of marble composite structures. Constr. Build. Mater. 2009, 23, 1915–1921. [Google Scholar] [CrossRef]

- Carvalho, E.A.S.; Marques, V.R.; Rodriguez, R.J.S.; Ribeiro, C.E.G.; Monteiro, S.N.; Vieira, C.M.F. Development of epoxy matrix artificial stone incorporated with sintering residue from steelmaking industry. Mater. Res. 2015, 18, 235–239. [Google Scholar] [CrossRef]

- Hablot, E.; Zheng, D.; Bouquey, M.; Avérous, L. Polyurethanes based on castor oil: Kinetics, Chemical, mechanical and termal properties. Macromol. Mater. Eng. 2008, 293, 922–929. [Google Scholar] [CrossRef]

- Clarinval, A.-M.; Halleux, J. Classification of biodegradable polymers. In Biodegradable Polymers for Industrial Applications; Woodhead Publishing: Sawston, UK, 2005; pp. 3–31. [Google Scholar] [CrossRef]

- Rajalakshmi, P.; Marie, J.M.; Maria Xavier, A.J. Castor oil-derived monomer ricinoleic acid based biodegradable unsaturated polyesters. Polym. Degrad. Stab. 2019, 170, 109016. [Google Scholar] [CrossRef]

- Brazilian Association of Technical Norms—ABNT. ABNT NBR 7181: Soil—Grain Size Analysis; ABNT: Rio de Janeiro, Brazil, 2016. (In Portuguese) [Google Scholar]

- Hepburn, C. Polyurethane Elastomers, 2nd ed.; Elsevier: New York, NY, USA, 1992. [Google Scholar]

- Reis, J.M.; Motta, E.P. Mechanical properties of castor oil polymer mortars. Mat. Res. 2014, 17, 1162–1166. [Google Scholar] [CrossRef][Green Version]

- Brazilian Association of Technical Norms—ABNT. ABNT NBR 15845-2: Rocks for Cladding. Part 2: Determination of Bulk Density, Apparent Porosity and Water Absorption; ABNT: Rio de Janeiro, Brazil, 2015. (In Portuguese) [Google Scholar]

- Spanish Association of Standards and Certification. UNE-EN 14617-2-08: Test Methods. Part 2: Determination of the Flexural Strength; UNE-EN: Madrid, Spain, 2008. (In Spanish) [Google Scholar]

- Brazilian Association of Technical Norms—ABNT. ABNT NBR 12042: Inorganic Materials—Determination of the Resistance to Abrasion; ABNT: Rio de Janeiro, Brazil, 2012. (In Portuguese) [Google Scholar]

- Brazilian Association of Technical Norms—ABNT. ABNT NBR 13818: Ceramic Tiles—Specification and Methods of Test; ABNT: Rio de Janeiro, Brazil, 1997. (In Portuguese) [Google Scholar]

- Ristic, I.S.; Bjelovic, Z.D.; Holló, B.; Szécsényi, K.M.; Budinski-Simendić, J.; Lazic, N.; Kicanovic, M. Thermal stability of polyurethanane materials based on castor oil as polyol componente. J. Therm. Anal. Calorin. 2013, 111, 1083–1091. [Google Scholar] [CrossRef]

- Moura Neto, F.N.; Fialho, A.C.V.; Moura, W.L.; Rosa, A.G.F.; Matos, J.M.E.; Reis, F.S.; Mendes, M.T.A.; Sales, E.S.D. Castor polyurethane used as osteosynthesis plates: Microstructural and thermal analysis. Polímeros 2019, 29. [Google Scholar] [CrossRef]

- Gomes, M.L.P.M.; Carvalho, E.A.S.; Sobrinho, L.N.; Monteiro, R.J.S.R.; Vieira, C.M.F. Production and characterization of a novel artificial stone using brick residue and quarry dust in epoxy matrix. J. Mater. Res. Technol. 2018, 7, 492–498. [Google Scholar] [CrossRef]

- Lee, D.J.; Shin, I.J. Effects of vacuum, mold temperature and cooling rate on mechanical properties of press consolidated glass fiber/PET composites. Compos. Part A 2002, 33, 1107–1114. [Google Scholar] [CrossRef]

- Chiodi Filho, C.; Rodriguez, H. Guide Application of Stone Coverings, 3rd ed.; ABIROCHAS: São Paulo, Brazil, 2009; p. 108. [Google Scholar]

- Brasilian Association of Technical Norms—ABNT. NBR 15844: Rocks for Cladding—Requiriments for Granites; ABNT: Rio de Janeiro, Brazil, 2015. [Google Scholar]

- Sujin Jose, A.; Athijayamani, A.; Jani, S.P. A review on the mechanical properties of bio waste particulate reinforced polymer composites. Mater. Today Proc. 2020, 37, 1757–1760. [Google Scholar] [CrossRef]

- Debnath, S.; Ranade, R.; Wunder, S.L.; Mccool, J.; Boberick, K.; Baran, G. Interface effects on mechanical properties of particle-reinforced composites. Dent. Mater. 2004, 20, 677–686. [Google Scholar] [CrossRef] [PubMed]

- Karaca, Z.; Yılmaz, N.G.; Goktan, R.M. Abrasion wear characterization of some selected stone flooring materials with respect to contact load. Constr. Build. Mater. 2012, 36, 520–526. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).