Challenges for Implementing Environmental Management Plans in Construction Projects: The Case of Malaysia

Abstract

:1. Introduction

2. Literature Review

2.1. Challenges in EMP Implementation

2.2. Positioning This Study

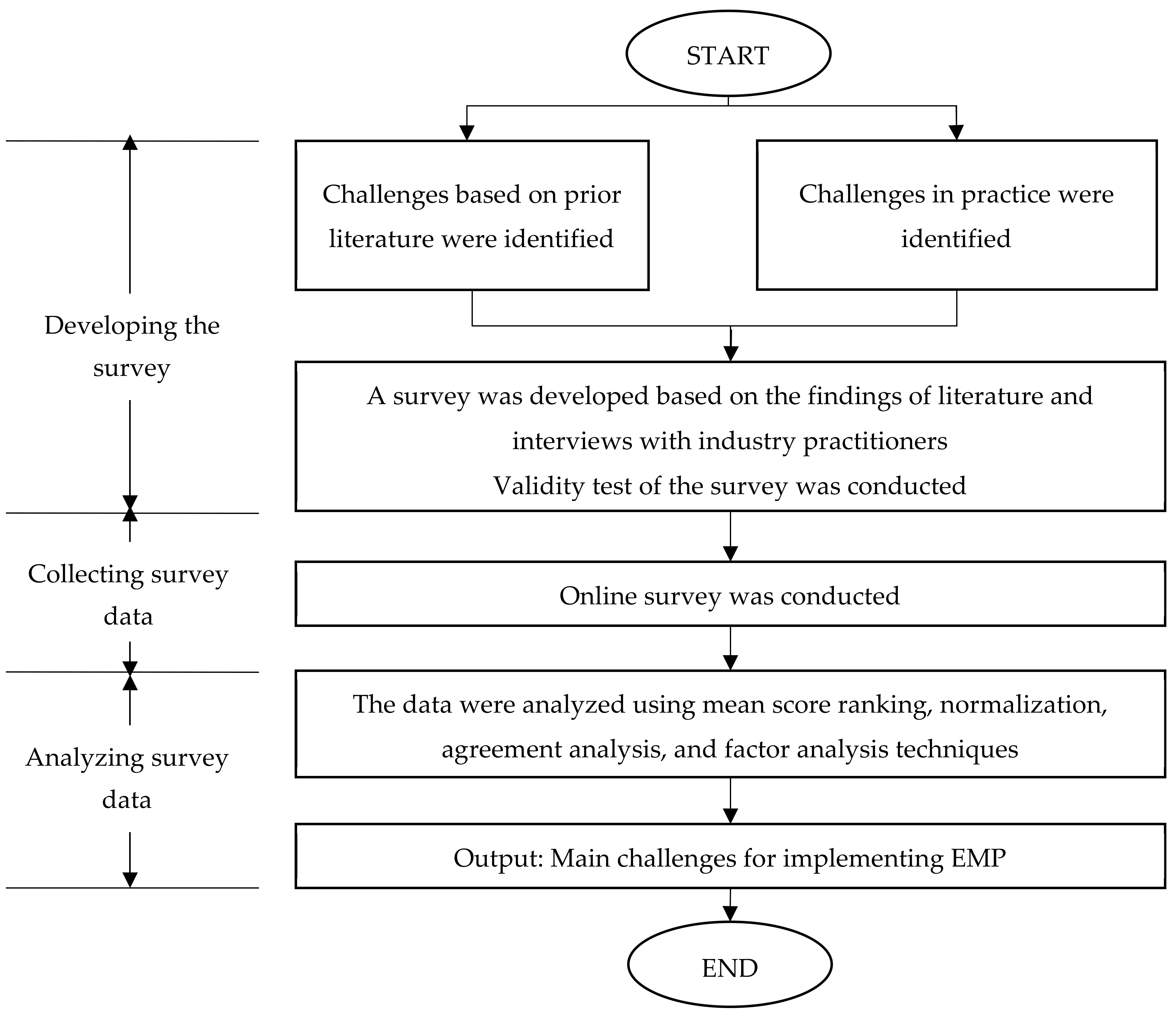

3. Method

3.1. Survey Development

3.1.1. Semi-Structured Interviews

3.1.2. Systematic Literature Review

3.1.3. Survey Design

3.1.4. Pilot Study

3.2. Data Collection

3.3. Data Analysis

3.3.1. Reliability Testing

3.3.2. Ranking Analysis

3.3.3. Exploratory Factor Analysis

3.3.4. Agreement Analysis

4. Results

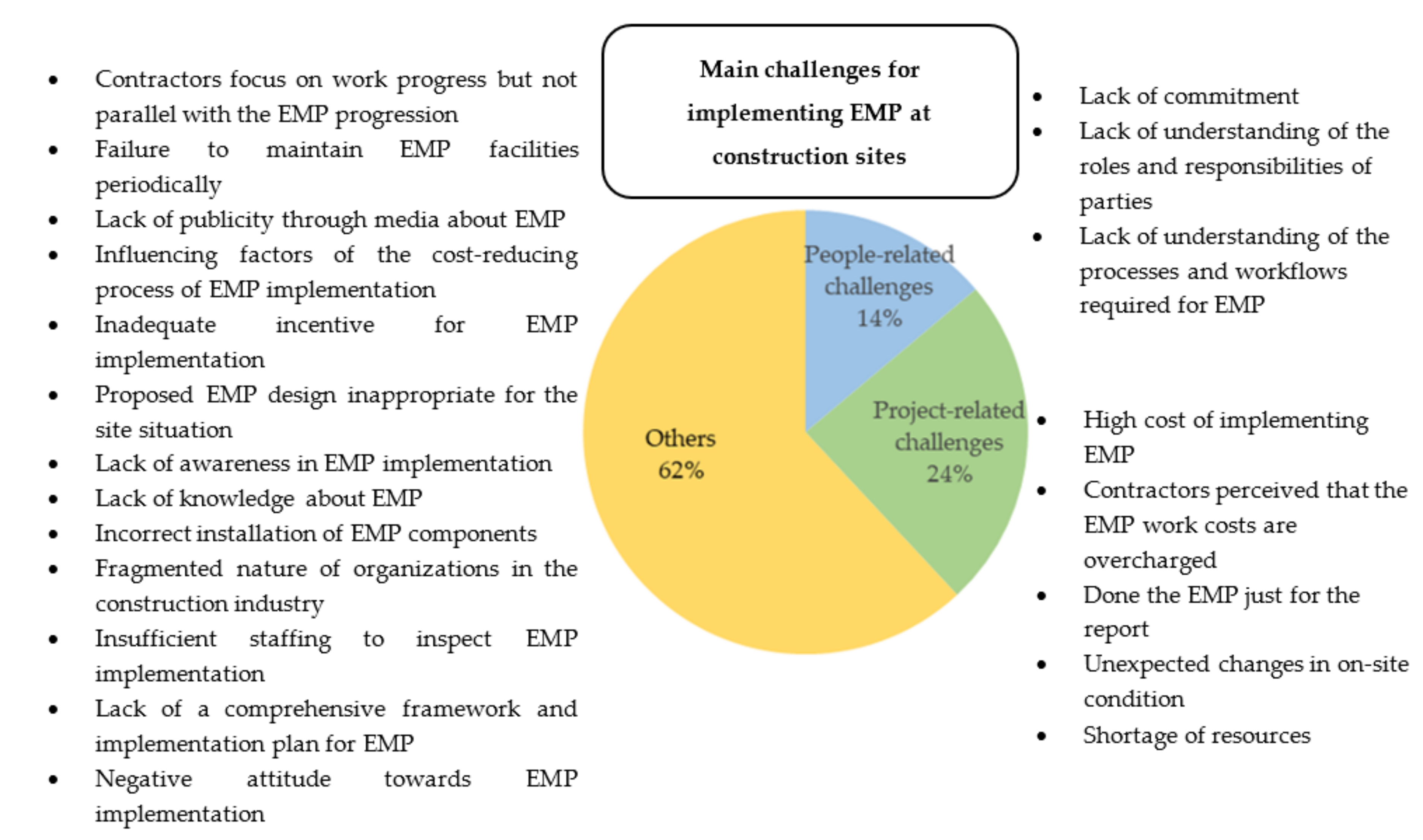

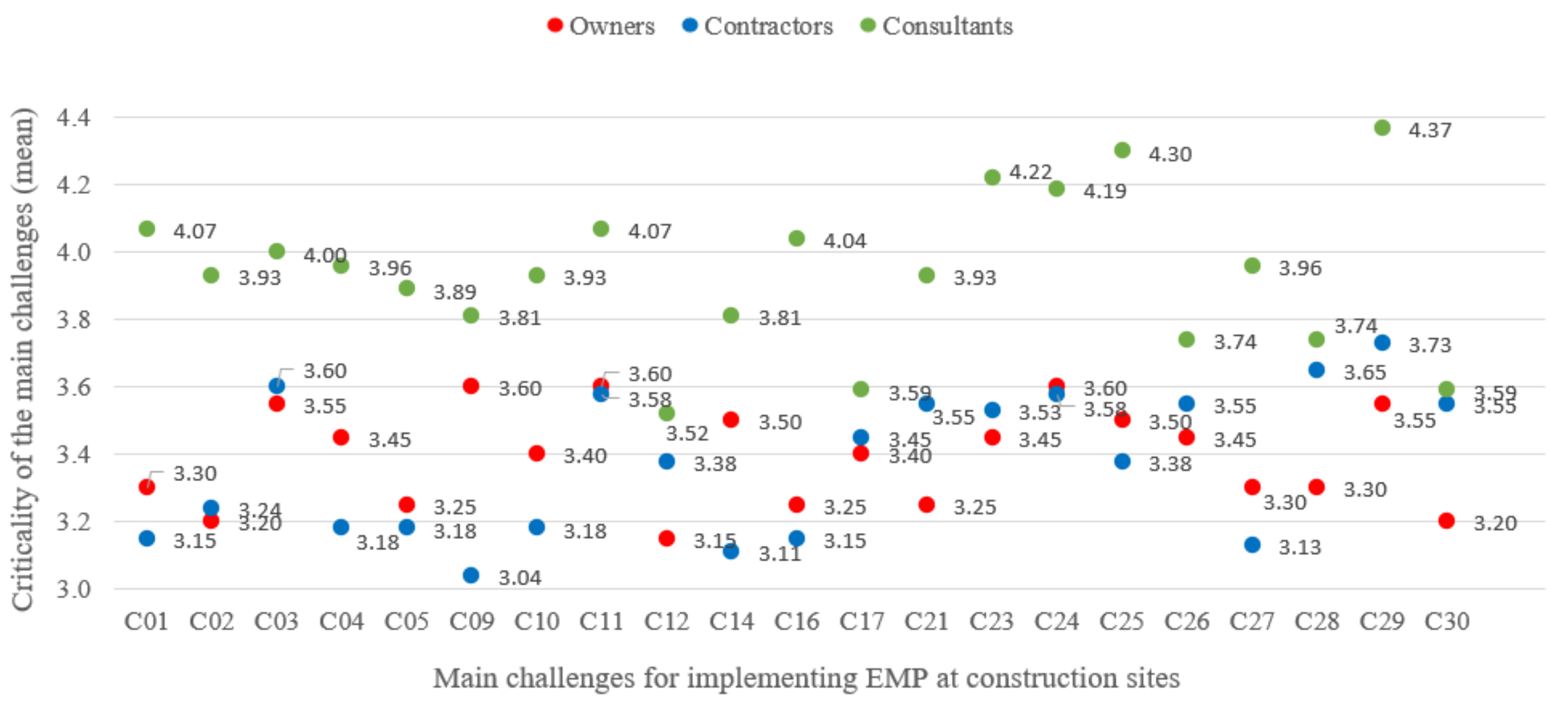

4.1. Results for the Mean Ranking Analysis

4.2. Results for the Exploratory Factor Analysis

4.3. Results of the Agreement Analysis

5. Discussion

5.1. Component 1: People-Related Challenges

5.2. Component 2: Project-Related Challenges

6. Implication

7. Conclusions

- Lack of commitment

- Lack of understanding of the roles and responsibilities of parties

- Lack of understanding of the processes and workflows required for EMP implementation

- High cost of implementing EMP

- Contractors perceived that the EMP work costs are overcharged

- Did the EMP just for the report

- Unexpected changes in on-site condition

- Shortage of resources for EMP implementation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Challenges Identified from the Interviews and Systematic Literature Review

| Code | Challenge | Source | Interview |

| CH01 | Lack of commitment (e.g., owner’s commitment, contractor’s commitment) | [1,12,14,16,17,50] | ✓ |

| CH02 | Lack of understanding of the roles and responsibilities of parties | [1,12,14,16,17,50] | ✓ |

| CH03 | Influencing factors of the cost-reducing process of EMP implementation | [8,12] | ✓ |

| CH04 | Lack of understanding of the processes and workflows required for EMP implementation | [8,12] | ✓ |

| CH05 | Fragmented nature of organizations in the construction industry | [15,51] | ✓ |

| CH06 | Absence of industry standards for EMP | [15] | ✓ |

| CH07 | Individual practitioners neglected to consider their belief systems and impact of policy decisions in implementing EMP | [5,11,12,17,49] | ✓ |

| CH08 | Decision makers not seeking professional advisors | [5,15] | ✓ |

| CH09 | Negative attitude towards EMP implementation | [4,5,6,13,24,50,52] | ✓ |

| CH10 | Lack of awareness of EMP implementation | [1,4,5,17,24,27,51] | ✓ |

| CH11 | Lack of publicity through media about EMP | [4,5,24,52] | ✓ |

| CH12 | Lack of a comprehensive framework and implementation plan for EMP | [3] | ✓ |

| CH13 | Lack of comprehensive rules and regulations | [3] | ✓ |

| CH14 | Insufficient staffing to inspect EMP implementation | [3] | ✓ |

| CH15 | Inefficiency in EMP inspection procedures | [6,19] | - |

| CH16 | Lack of knowledge about EMP | [17,19] | ✓ |

| CH17 | High cost of implementing EMP | [6,11,12,19,52] | ✓ |

| CH18 | Corruption in the process of EMP implementation | [14] | ✓ |

| CH19 | Lack of competitive advantage from EMP implementation | [14] | ✓ |

| CH20 | Shortage of qualified personnel | [14] | ✓ |

| CH21 | Inadequate incentive for EMP implementation | [12,14,16,17,52] | ✓ |

| CH22 | Miscommunication between team members | [14] | ✓ |

| CH23 | Contractors perceived that the EMP work costs are overcharged | [4,5,6,12,28] | ✓ |

| CH24 | Failure to maintain EMP facilities | [24] | ✓ |

| CH25 | Did the EMP just for the report | [16] | ✓ |

| CH26 | Proposed EMP design inappropriate for the site situation | [16] | - |

| CH27 | Incorrect installation of EMP components | [17,49] | - |

| CH28 | Unexpected changes in on-site conditions | [6] | ✓ |

| CH29 | The contractor focused on work progress but not parallel with the EMP progression | [6] | - |

| CH30 | Shortage of resources (e.g., workforce, material, machinery) for EMP implementation | - | ✓ |

Appendix B. The Survey

- Owners (e.g., government, developers)

- Consultants

- Contractors

- Others: _____________

- High School Certification

- Diploma

- Bachelor’s Degree

- Master’s Degree

- Doctoral Degree

- Less than 2 years

- 2–5 years

- 6–9 years

- More than 10 years

- Less than 2 years

- 2–5 years

- 6–9 years

- More than 10 years

- Less than 2 projects

- 2–5 projects

- 6–9 projects

- More than 10 projects

- Northern Region (Perlis, Kedah, Penang, Perak)

- East Coast Region (Kelantan, Terengganu, Pahang)

- Central Region (Selangor, Kuala Lumpur, Putrajaya)

- Southern Region (Negeri Sembilan, Melaka, Johor)

- East Malaysia (Sabah, Sarawak, Labuan)

| Challenge (In Random Order Using Online Survey Platform) | Criticality | ||||

| Lack of commitment (e.g., owner’s commitment, contractor’s commitment) | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| … | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| … | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| … | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| … | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| … | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| … | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| … | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| … | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Shortage of resources (e.g., workforce, material, machinery) for EMP implementation | Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical |

| Additional Challenge | Criticality | ||||

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical | |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical | |

| Not Critical | Slightly Critical | Moderately Critical | Critical | Very Critical | |

References

- Wang, N.; Ma, M.; Wu, G.; Liu, Y.; Gong, Z.; Chen, X. Conflicts concerning construction projects under the challenge of cleaner production—Case study on government funded projects. J. Clean. Prod. 2019, 225, 664–674. [Google Scholar] [CrossRef]

- Wang, L.; Xue, X.; Zhao, Z.; Wang, Z. The impacts of transportation infrastructure on sustainable development: Emerging trends and challenges. Int. J. Environ. Res. Pub. Health 2018, 15, 1172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yin, B.C.L.; Laing, R.; Leon, M.; Mabon, L. An evaluation of sustainable construction perceptions and practices in Singapore. Sustain. Cities. Soc. 2018, 39, 613–620. [Google Scholar] [CrossRef]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Attitudinal and behavioral approaches to improving waste management on construction projects in Australia. Int. J. Constr. Manag. 2015, 15, 137–147. [Google Scholar]

- Maund, K.; Gajendran, T.; Brewer, G. Key issues for implementation of environmental planning policy: Construction management practice. Sustainability 2018, 10, 2156. [Google Scholar] [CrossRef] [Green Version]

- Ofori, G. The environment: The fourth construction project objective? Constr. Manag. Econ. 1992, 10, 360–395. [Google Scholar] [CrossRef]

- United Nations Environment Programme. 2021 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; UN: New York, NY, USA, 2021. [Google Scholar]

- Qin, J.Y.; Ma, H.H. Ecological environmental pollution caused by construction engineering in China and relevant energy-saving and cost-reducing measures. Nat. Environ. Poll. Technol. 2019, 18, 485–490. [Google Scholar]

- Li, J.; Zhou, Y.; Li, Q.; Yi, S.; Peng, L. Exploring the Effects of Land Use Changes on the Landscape Pattern and Soil Erosion of Western Hubei Province from 2000 to 2020. Int. J. Environ. Res. Pub. Health 2022, 19, 1571. [Google Scholar] [CrossRef]

- Jiu, J.; Wu, H.; Li, S. The Implication of land-use/land-cover change for the declining soil erosion risk in the Three Gorges Reservoir region, China. Int. J. Environ. Res. Pub. Health 2019, 16, 1856. [Google Scholar] [CrossRef] [Green Version]

- Yuan, H. Barriers and countermeasures for managing construction and demolition waste: A case of Shenzhenin China. J. Clean. Prod. 2017, 157, 84–93. [Google Scholar] [CrossRef]

- Tam, W.Y.; Tam, C.M.; Yiu, K.T.W.; Cheung, S.O. Critical factors for environmental performance assessment (EPA) in the Hong Kong construction industry. Constr. Manag. Econ. 2006, 24, 1113–1123. [Google Scholar] [CrossRef] [Green Version]

- Nasirzadeh, F.; Khanzadi, M.; Mir, M. A hybrid simulation framework for modelling construction projects using agent-based modelling and system dynamics: An application to model construction workers’ safety behavior. Int. J. Constr. Manag. 2018, 18, 132–143. [Google Scholar] [CrossRef]

- Nielsen, K.J. A comparison of inspection practices within the construction industry between the Danish and Swedish Work Environment Authorities. Constr. Manag. Econ. 2017, 35, 154–169. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Li, H.; Xia, B.; Skitmore, M. Impact of environment regulation on the efficiency of regional construction industry: A 3-Stage Data Envelopment Analysis (DEA). J. Clean. Prod. 2018, 200, 770–780. [Google Scholar] [CrossRef]

- Göçmen, Z.A. Exploring land developer perspectives on conservation subdivision design and environmentally sustainable land development. Environ. Manag. 2014, 54, 1208–1222. [Google Scholar] [CrossRef]

- Testa, F.; Iraldo, F.; Frey, M. The effect of environmental regulation on firms’ competitive performance: The case of the building & construction sector in some EU regions. J. Environ. Manag. 2011, 92, 21–36. [Google Scholar] [CrossRef]

- Ajibike, W.A.; Adeleke, A.Q.; Mohamad, F.; Bamgbade, J.A.; Mashood, T.D. The impact of social responsibility on the environmental sustainability performance of the Malaysian construction industry. Int. J. Constr. Manag. 2021. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C. Strategies to promote green building technologies adoption in developing countries: The case of Ghana. Build. Environ. 2018, 130, 74–84. [Google Scholar] [CrossRef]

- Ferronato, N.; Torretta, V. Waste mismanagement in developing countries: A review of global issues. Int. J. Environ. Res. Pub. Health 2019, 16, 1060. [Google Scholar] [CrossRef] [Green Version]

- Badraddin, A.K.; Rahman, R.A.; Almutairi, S.; Esa, M. Main Challenges to Concrete Recycling in Practice. Sustainability 2021, 13, 11077. [Google Scholar] [CrossRef]

- Salim, H.K.; Padfield, R.; Hansen, S.B.; Mohamad, S.E.; Yuzir, A.; Syayuti, K.; Papargyropoulou, E. Global trends in environmental management system and ISO14001 research. J. Clean. Prod. 2018, 170, 645–653. [Google Scholar] [CrossRef] [Green Version]

- Falqi, I.; Alsulamy, S.; Mansour, M. Environmental performance evaluation and analysis using ISO 14031 guidelines in construction sector industries. Sustainability 2020, 12, 1774. [Google Scholar] [CrossRef] [Green Version]

- Park, W.J.; Kim, R.; Roh, S.; Ban, H. Identifying the major construction wastes in the building construction phase based on life cycle assessments. Sustainability 2020, 12, 8096. [Google Scholar] [CrossRef]

- Brown, J.S.; Loosemore, M. Behavioural factors influencing corrupt action in the Australian construction industry. Eng. Constr. Arch. Manag. 2015, 22, 372–389. [Google Scholar] [CrossRef]

- Shiers, D.; Rapson, D.; Roberts, C.; Keeping, M. Sustainable construction: The development and evaluation of an environmental profiling system for construction products. Constr. Manag. Econ. 2006, 24, 1177–1184. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Strategies for minimizing construction and demolition wastes in Malaysia. Resour. Conserv. Recycl. 2017, 120, 219–229. [Google Scholar] [CrossRef]

- Begum, R.A.; Siwar, C.; Pereira, J.J.; Jaafar, A.H. Factors and values of willingness to pay for improved construction waste management—A perspective of Malaysian contractors. Waste. Manag. 2007, 27, 1902–1909. [Google Scholar] [CrossRef]

- Radzi, A.R.; Rahman, R.A.; Doh, S.I.; Esa, M. Construction Readiness for Highway Projects: Key Decision Criteria. J. Constr Engin Manag. 2022, 148, 04021196. [Google Scholar] [CrossRef]

- Rowley, J. Designing and using research questionnaires. Manag. Res. Rev. 2014, 37, 308–330. [Google Scholar] [CrossRef]

- Braun, V.; Clarke, V. Using thematic analysis in psychology. Qual. Res. Psychol. 2006, 3, 77–101. [Google Scholar] [CrossRef] [Green Version]

- Pallant, J. SPSS Survival Manual: A Step to Step Guide to Data Analysis Using SPSS for Windows; Open University Press: Berkshire, UK, 2010. [Google Scholar]

- Tober, M. PubMed, ScienceDirect, scopus or Google scholar: Which is the best search engine for an effective literature research in laser medicine? Med. Laser. App. 2011, 26, 139–144. [Google Scholar] [CrossRef]

- Radzi, A.R.; Rahman, R.A.; Doh, S.I. Decision making in highway construction: A systematic review and future directions. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- King, S.S.; Rahman, R.A.; Fauzi, M.A.; Haron, A.T. Critical analysis of pandemic impact on AEC organizations: The COVID-19 case. J. Eng. Des. Technol. 2021, 20, 358–383. [Google Scholar] [CrossRef]

- Farouk, A.M.; Rahman, R.A.; Romali, N.S. Economic analysis of rehabilitation approaches for water distribution networks: Comparative study between Egypt and Malaysia. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- Wilkins, J.R. Construction workers’ perceptions of health and safety training programmes. Constr. Manag. Econ. 2011, 29, 1017–1026. [Google Scholar] [CrossRef]

- Ott, R.; Longnecker, M. An Introduction to Statistical Methods and Data Analysis; Cengage Learning: Belmont, CA, USA, 2008. [Google Scholar]

- Al-Mohammad, M.S.; Haron, A.T.; Esa, M.; Aloko, M.N.; Alhammadi, Y.; Anandh, K.S.; Rahman, R.A. Factors affecting BIM implementation: Evidence from countries with different income levels. Constr. Innov. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Santos, J.R.A. Cronbach’s alpha: A tool for assessing the reliability of scales. J. Ext. 1999, 37, 1–5. [Google Scholar]

- Nunnally, J. Psychometric Theory, 2nd ed.; McGrow-Hill: New York, NY, USA, 1978. [Google Scholar]

- Al-Mohammad, M.S.; Haron, A.T.; Aloko, M.N.; Rahman, R.A. Factors affecting BIM implementation in post-conflict low-income economies: The case of Afghanistan. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics Using IBM SPSS Statistics, 4th ed.; Sage: London, UK, 2013. [Google Scholar]

- Hinton, P.R.; Brownlow, C.; McMurray, I.; Cozens, B. SPSS Explained; Routledge: London, UK, 2004. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis: A Global Perspective; Pearson: Upper Saddle River, NJ, USA; London, UK, 2010. [Google Scholar]

- Malhotra, N.K. Marketing Research: An Applied Orientation, 5th ed.; Pearson/Prentice Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Tam, V.W.; Shen, L.Y.; Fung, I.W.; Wang, J.Y. Controlling construction waste by implementing governmental ordinances in Hong Kong. Constr. Innov. 2007, 7. [Google Scholar] [CrossRef] [Green Version]

- Ofori, G.; Briffett, C.; Gang, G.; Ranasinghe, M. Impact of ISO 14000 on construction enterprises in Singapore. Constr. Manag. Econ. 2000, 18, 935–947. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H. Exploring critical success factors for waste management in construction projects of China. Resour. Conserv. Recy. 2010, 55, 201–208. [Google Scholar] [CrossRef] [Green Version]

- Koehn, E.E.; Datta, N.K. Quality, environmental, and health and safety management systems for construction engineering. J. Constr. Eng. Manag. 2003, 129, 562–569. [Google Scholar] [CrossRef]

- Din, S.; Abd-Hamid, Z.; Bryde, D.J. ISO 9000 certification and construction project performance: The Malaysian experience. Int. J. Proj. Manag. 2011, 29, 1044–1056. [Google Scholar] [CrossRef]

- Kein, A.T.T.; Ofori, G.; Briffett, C. ISO 14000: Its relevance to the construction industry of Singapore and its potential as the next industry milestone. Constr. Manag. Econ. 1999, 17, 449–461. [Google Scholar]

| Estimated Impact of Construction Projects on the Environment Globally | Reference | ||

|---|---|---|---|

| Consumption | Energy | 36% to 42% | [4,5,6,7] |

| Resources | 34% | [4] | |

| Freshwater | 12% to 25% | [4,5,6] | |

| Raw materials | 30% | [6] | |

| Land | 12% | [6] | |

| Releases | Solid waste | 25% to 40% | [4,5,6,7] |

| Greenhouse gases | 30% | [4,5] | |

| Water effluents | 20% | [6] | |

| Other types of pollution | 13% | [6] | |

| ID | Sector | Stakeholder | Position | Organization |

|---|---|---|---|---|

| 1 | Public | Law enforcer 1 | City Council Engineer | City Council |

| 2 | Public | Law enforcer 2 | Environmental Officer | Public Works Department |

| 3 | Public | Law enforcer 3 | Environmental Officer | Public Works Department |

| 4 | Public | Law enforcer 4 | DID Officer | Department of Irrigation and Drainage |

| 5 | Public | Law enforcer 5 | DID Officer | Department of Irrigation and Drainage |

| 6 | Public | Law enforcer 6 | DID Officer | Department of Irrigation and Drainage |

| 7 | Public | Law enforcer 7 | Engineer | Department of Irrigation and Drainage |

| 8 | Private | Contractor 1 | Environmental Officer | Contractor |

| 9 | Private | Contractor 2 | Environmental Officer | Contractor |

| 10 | Private | Contractor 3 | Environmental Officer | Contractor |

| 11 | Private | Contractor 4 | Environmental Officer | Developer |

| 12 | Private | Contractor 5 | Environmental Officer | Contractor |

| 13 | Private | Consultant 1 | Hydrology Engineer | Hydrology Consultant |

| 14 | Public | Consultant 2 | Environmental Officer | Consultant |

| 15 | Private | Consultant 3 | Environmental Officer | Consultant |

| 16 | Private | Consultant 4 | Environmental Officer | Consultant |

| 17 | Public | Engineer 1 | PWD Engineer | Public Works Department |

| 18 | Private | Engineer 2 | Hydrology Engineer | Hydrology Consultant |

| 19 | Private | Engineer 3 | Site Engineer | Developer |

| 20 | Private | Engineer 4 | Engineer | Contractor |

| Type of Distribution | Description | Frequency | (%) | Cumulative (%) |

|---|---|---|---|---|

| Type of organization | Contractors | 21 | 20.59 | 20.59 |

| Owners | 55 | 53.92 | 74.51 | |

| Consultants | 26 | 25.49 | 100.00 | |

| Title/position | Government Officer | 14 | 13.73 | 13.73 |

| Engineer | 27 | 26.47 | 40.20 | |

| Environment Officer | 59 | 57.84 | 98.04 | |

| Project Manager | 2 | 1.96 | 100.00 | |

| Academic qualification | Diploma | 9 | 8.82 | 8.82 |

| Bachelor’s Degree | 67 | 65.69 | 74.51 | |

| Master’s Degree | 24 | 23.53 | 98.04 | |

| Doctoral Degree | 2 | 1.96 | 100.00 | |

| Years of experience | <2 years | 23 | 22.55 | 22.55 |

| 2–5 years | 36 | 35.29 | 57.84 | |

| 6–9 years | 16 | 15.69 | 73.53 | |

| >10 years | 27 | 26.47 | 100.00 | |

| Number of projects | <2 projects | 24 | 23.53 | 23.53 |

| 2–5 projects | 41 | 40.20 | 63.73 | |

| 6–9 projects | 12 | 11.76 | 75.49 | |

| >10 projects | 25 | 24.51 | 100.00 |

| Code | Challenge | Mean | SD | NV | Rank |

|---|---|---|---|---|---|

| CH29 | Contractors focus on work progress but not parallel with the EMP progression | 3.86 | 1.161 | 1.000 | 1 |

| CH24 | Failure to maintain EMP facilities periodically | 3.75 | 1.114 | 0.889 | 2 |

| CH11 | Lack of publicity through media about EMP | 3.72 | 1.23 | 0.861 | 3 |

| CH03 | Influencing factors of the cost-reducing process of EMP implementation | 3.70 | 0.91 | 0.843 | 4 |

| CH23 | Contractors perceived that the EMP work costs are overcharged | 3.70 | 1.159 | 0.843 | 5 |

| CH25 | Did the EMP just for the report | 3.65 | 1.302 | 0.796 | 6 |

| CH28 | Unexpected changes in on-site conditions | 3.61 | 1.109 | 0.759 | 7 |

| CH21 | Inadequate incentive for EMP implementation | 3.59 | 1.075 | 0.741 | 8 |

| CH26 | Proposed EMP design inappropriate for the site situation | 3.58 | 1.173 | 0.731 | 9 |

| CH30 | Shortage of resources for EMP implementation | 3.49 | 1.15 | 0.648 | 10 |

| CH17 | High cost of implementing EMP | 3.48 | 1.088 | 0.639 | 11 |

| CH04 | Lack of understanding of the processes and workflows required for EMP implementation | 3.44 | 1.02 | 0.602 | 12 |

| CH10 | Lack of awareness of EMP implementation | 3.42 | 1.13 | 0.583 | 13 |

| CH01 | Lack of commitment | 3.42 | 1.076 | 0.583 | 14 |

| CH02 | Lack of understanding of the roles and responsibilities of parties | 3.41 | 1.056 | 0.574 | 15 |

| CH16 | Lack of knowledge about EMP | 3.40 | 1.128 | 0.565 | 16 |

| CH27 | Incorrect installation of EMP components | 3.38 | 1.169 | 0.546 | 17 |

| CH05 | Fragmented nature of organizations in the construction industry | 3.38 | 0.912 | 0.546 | 18 |

| CH14 | Insufficient staffing to inspect EMP implementation | 3.37 | 1.098 | 0.537 | 19 |

| CH12 | Lack of a comprehensive framework and implementation plan for EMP | 3.37 | 1.089 | 0.537 | 20 |

| CH09 | Negative attitude towards EMP implementation | 3.35 | 1.295 | 0.519 | 21 |

| Construct | Code | Challenges for Implementing an EMP in Construction Projects | Factor Loading | Eigenvalues | Variance Explained (%) | Cronbach’s Alpha |

|---|---|---|---|---|---|---|

| People-related challenges | CH01 | Lack of commitment | 0.893 | 7.275 | 57.089 | 0.876 |

| CH02 | Lack of understanding of the roles and responsibilities of parties | 0.831 | ||||

| CH04 | Lack of understanding of the processes and workflows required for EMP implementation | 0.654 | ||||

| Project-related challenges | CH17 | High cost of implementing EMP | 0.680 | 1.426 | 12.678 | 0.864 |

| CH23 | Contractors perceived that the EMP work costs are overcharged | 0.735 | ||||

| CH25 | Did the EMP just for the report | 0.682 | ||||

| CH28 | Unexpected changes in on-site conditions | 0.695 | ||||

| CH30 | Shortage of resources | 0.551 |

| Code | Challenge | Owners | Contractors | Consultants | α | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M | SD | NV | R | M | SD | NV | R | M | SD | NV | R | |||

| CH09 | Negative attitude towards EMP implementation | 3.60 | 1.23 | 1 | 1 | 3.04 | 1.32 | 0.27 | 27 | 3.81 | 1.15 | 0.52 | 17 | 0.02 a |

| CH24 | Failure to maintain EMP facilities | 3.60 | 1.31 | 1 | 2 | 3.58 | 1.10 | 0.85 | 4 | 4.19 | 0.88 | 0.84 | 4 | 0.06 |

| CH11 | Lack of publicity through media about EMP | 3.60 | 1.23 | 1 | 3 | 3.58 | 1.27 | 0.85 | 5 | 4.07 | 1.11 | 0.74 | 6 | 0.21 |

| CH29 | Contractors focus on work progress but not parallel with the EMP progression | 3.55 | 1.32 | 0.96 | 4 | 3.73 | 1.22 | 1.00 | 1 | 4.37 | 0.69 | 1.00 | 1 | 0.02 a |

| CH03 | Influencing factors of the cost-reducing process of EMP implementation | 3.55 | 0.89 | 0.96 | 5 | 3.60 | 0.92 | 0.87 | 3 | 4.00 | 0.88 | 0.68 | 8 | 0.13 |

| CH14 | Insufficient staffing to inspect EMP implementation | 3.50 | 1.19 | 0.92 | 6 | 3.11 | 1.01 | 0.35 | 23 | 3.81 | 1.08 | 0.52 | 16 | 0.02 a |

| CH25 | Did the EMP just for the report | 3.50 | 1.32 | 0.92 | 7 | 3.38 | 1.38 | 0.64 | 12 | 4.30 | 0.87 | 0.94 | 2 | 0.01 a |

| CH26 | Proposed EMP design inappropriate for the site situation | 3.45 | 1.19 | 0.89 | 8 | 3.55 | 1.20 | 0.81 | 8 | 3.74 | 1.13 | 0.45 | 18 | 0.67 |

| CH23 | Contractors perceived that the EMP work costs are overcharged | 3.45 | 1.05 | 0.89 | 9 | 3.53 | 1.23 | 0.79 | 9 | 4.22 | 0.93 | 0.87 | 3 | 0.02 a |

| CH04 | Lack of understanding of the processes and workflows required for EMP implementation | 3.45 | 0.89 | 0.89 | 10 | 3.18 | 1.06 | 0.42 | 16 | 3.96 | 0.85 | 0.65 | 9 | 0.00 a |

| CH17 | High cost of implementing EMP | 3.40 | 1.05 | 0.85 | 11 | 3.45 | 1.12 | 0.71 | 10 | 3.59 | 1.08 | 0.32 | 21 | 0.81 |

| CH10 | Lack of awareness of EMP implementation | 3.40 | 1.10 | 0.85 | 12 | 3.18 | 1.11 | 0.42 | 17 | 3.93 | 1.07 | 0.61 | 12 | 0.02 a |

| CH28 | Unexpected changes in on-site condition | 3.30 | 1.13 | 0.77 | 14 | 3.65 | 1.16 | 0.92 | 2 | 3.74 | 0.98 | 0.45 | 19 | 0.37 |

| CH27 | Incorrect installation of EMP components | 3.30 | 1.08 | 0.77 | 15 | 3.13 | 1.17 | 0.37 | 22 | 3.96 | 1.06 | 0.65 | 10 | 0.01 a |

| CH01 | Lack of commitment | 3.30 | 0.92 | 0.77 | 17 | 3.15 | 1.08 | 0.39 | 21 | 4.07 | 0.92 | 0.74 | 5 | 0.00 a |

| CH21 | Inadequate incentive for EMP implementation | 3.25 | 1.12 | 0.73 | 18 | 3.55 | 1.10 | 0.81 | 7 | 3.93 | 0.92 | 0.61 | 11 | 0.09 |

| CH16 | Lack of knowledge about EMP | 3.25 | 1.21 | 0.73 | 19 | 3.15 | 1.11 | 0.39 | 20 | 4.04 | 0.85 | 0.71 | 7 | 0.00 a |

| CH05 | Fragmented nature of organizations in the construction industry | 3.25 | 0.85 | 0.73 | 20 | 3.18 | 0.88 | 0.42 | 15 | 3.89 | 0.85 | 0.58 | 14 | 0.00 a |

| CH30 | Shortage of resources for EMP implementation | 3.20 | 1.15 | 0.69 | 21 | 3.55 | 1.18 | 0.81 | 6 | 3.59 | 1.08 | 0.32 | 22 | 0.45 |

| CH02 | Lack of understanding of the roles and responsibilities of parties | 3.20 | 1.06 | 0.69 | 24 | 3.24 | 1.05 | 0.48 | 13 | 3.93 | 0.92 | 0.61 | 13 | 0.01 a |

| CH12 | Lack of a comprehensive framework and implementation plan for EMP | 3.15 | 1.09 | 0.65 | 26 | 3.38 | 1.06 | 0.64 | 11 | 3.52 | 1.16 | 0.26 | 25 | 0.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asnor, A.S.; Al-Mohammad, M.S.; Wan Ahmad, S.; Almutairi, S.; Rahman, R.A. Challenges for Implementing Environmental Management Plans in Construction Projects: The Case of Malaysia. Sustainability 2022, 14, 6231. https://doi.org/10.3390/su14106231

Asnor AS, Al-Mohammad MS, Wan Ahmad S, Almutairi S, Rahman RA. Challenges for Implementing Environmental Management Plans in Construction Projects: The Case of Malaysia. Sustainability. 2022; 14(10):6231. https://doi.org/10.3390/su14106231

Chicago/Turabian StyleAsnor, Asri Syahmi, Mohammad S. Al-Mohammad, Saffuan Wan Ahmad, Saud Almutairi, and Rahimi A. Rahman. 2022. "Challenges for Implementing Environmental Management Plans in Construction Projects: The Case of Malaysia" Sustainability 14, no. 10: 6231. https://doi.org/10.3390/su14106231

APA StyleAsnor, A. S., Al-Mohammad, M. S., Wan Ahmad, S., Almutairi, S., & Rahman, R. A. (2022). Challenges for Implementing Environmental Management Plans in Construction Projects: The Case of Malaysia. Sustainability, 14(10), 6231. https://doi.org/10.3390/su14106231