Abstract

This study examined the viability and sustainable practices of farm management in smallholder chicken layer farms in Nakhon Phanom Province, Thailand, and their role in the local food system. The data for analysis were obtained through qualitative research methods, including focus group discussions and in-depth interviews with target groups. This research found that the chicken layer farms of Ban Klang have survived for over four decades. The viability and sustainable practices of the farms included traditional rice farming; production practices, including barn modification and construction using local materials; feed management; manure management; the distribution of farm products; and the support of local consumers. This study suggested that the smallholders of chicken layer farms in Ban Klang should develop their production according to their organic farming focus while co-investing with local governments and businesses. We also recommended the promotion of healthy, local food by linking production to local institutional consumption, such as school lunches, local hospitals, etc.

1. Introduction

Food is vital to human life. Many advancements in food production, especially the application of modern technologies in food production, have been generated through the green revolution [1], and global trade has evolved into a global food system [2] that has restructured the relationships among those involved in food production, distribution, and consumption. Theoretical speculation has suggested that the global industrial food system and its inherent capital-intensive production will extinguish small-scale food production. Meanwhile, there have been growing concerns regarding the negative consequences as a result of the global food system, including the erosion of ecosystems, the degradation of critical environmental resources, employment rates, consumer safety due to chemical applications, the effect on local economies, etc. [2,3,4,5,6,7].

In recent years, local food systems have been developed in response to the negative side of the global industrial food system. At present, although still a novel concept, certain aspects have reached a consensus [8]. Getz [9], who introduced the “foodshed” concept, suggested that the specific location, including both environmental as well as the social and cultural concerns in a community, would define the structure of food suppliers [10]. Feenstra [11] argued that there was a potential for the local food system to enhance the viability of farmers and local economies by developing food production rooted in particular places as well as promoting ecologically sound practices and engagements between producers and consumers. In short, increasing interaction between consumers and food producers within a defined local scope and shortening the supply chains of food [4,12,13] could overcome the negative consequences of the global industrial food system. In developing countries, the local food system includes family farms, which are classified as smallholders [14]. It is estimated that local family farms produce 80 percent of the food consumed in developing countries [15,16].

Given the influence and power of the global food system and its threat to small-scale food production, our research sought to explore how small chicken layer farms, as smallholder productions, could sustain their farms and whether they could be sustainable long-term. Although there have been theoretical constructs for a sustainable livelihood framework (SLF) [14,15,16,17,18,19,20], the focus has been on capital assets, those controlled by the smallholder, rather than the services they provide. Our study extended the SLF to demonstrate the potential long-term viability of smallholders, and the viability was extended beyond both the SLF and efficiency based on an economy of scale. In particular, our study showed that the interactions between local food systems and industrial systems are complex, and some elements between the two systems could be complementary.

Thailand is a good example to illustrate the viability and sustainability of the extensive roles of large agribusinesses in the food system. On the one hand, smallholders and family farms are common in Thailand. The prevalence of smallholders has been confirmed by the high rate of employment in agriculture, currently more than 30 percent of the total labor force, of which 6.4 million are smallholder/family farms. In the northeast of Thailand, laborers employed in the agricultural sector accounted for approximately 58 percent [21] of the total labor force. On the other hand, the global industrial food system has a strong presence. Some agribusinesses are top multinational corporations, for instance, Charoen Pokphand Group (C.P. Group) and Mitr Phol Group. The coexistence of smallholder food producers and large agribusinesses, as well as a strong agricultural base [22], have promoted consecutive decades of economic growth [23,24,25]. In 2019, the total value of exported agricultural food products from Thailand was THB 1.1 trillion (approximately USD 34.46 billion), accounting for 14.45 percent of the country’s total exports [26].

A chicken layer farm was selected as eggs are a common food product across modern (global) and traditional (local) food production. The wide consumption of eggs has created a significant and consistent demand for egg production. However, the high demand also motivated large agribusinesses to invest in egg production. The local food system may not be sustainable when competing against industrial food systems. The objective of this study was to examine these issues within their local contexts to determine what challenges small shareholders must overcome to have substantial, long-term viability.

The next section presents a literature review, followed by a description of methods employed to obtain the required data. The subsequent section presents the findings. The final section summarizes the research findings.

2. Literature

Avian eggs have been recognized as versatile and affordable sources of nutrients. One egg contains roughly 70 calories, 6 g of protein, several other vitamins and minerals, and no sugar. Eggs are not only a typical part of daily meals worldwide but are also used in processed food production as binders, emulsifiers, leavening agents, thickeners, and other secondary ingredients. In North America, the consumption per capita reached its height in 1945 at 402 eggs per person annually. In recent years, growing concerns regarding cholesterol intake have resulted in a drop in per capita consumption, which reached its lowest point in 1995 at 232 per person [27]. In the past decade, however, the world’s egg production has grown steadily from 61.7 million tons in 2008 to 76.7 million tons in 2018 [28]. Egg consumption can vary by region, ranging, for example, from 368 eggs per person annually in Mexico to 146 per person annually in Portugal. Dividing the gross global production of eggs by the global population yields an average of 161 eggs per person annually.

Animal husbandry contributes a significant share of emissions that have a negative impact on the global climate [29], but poultry industries release considerably fewer polluting emissions as compared to other producers. Gunnarsson et al. [30] systematically mapped the research published on farm-level sustainability in egg and chicken meat production and found that few studies had analyzed all three sustainability dimensions of poultry production. Most studies examined only one or two dimensions. Even fewer actually described the interrelated factors or discussed the possible trade-offs or synergies between different aspects of sustainability. Wegerif [31] studied food provision systems, specifically concerning egg production, in the growing urban city of Dar es Salaam in Tanzania. The study suggested that the diverse patterns in prices and accessibility of egg supplies dramatically outperformed that of large corporations that supplied retail outlets (e.g., grocery stores, supermarkets). Although this study did not detail the egg supply chain (e.g., who supplied the supplier), it did highlight that the diverse pattern of supply (e.g., small grocers, street vendors, etc.) minimized the transportation costs to consumers. Wegerif [31] also noted that the concept of a supply chain did not adequately present the diversities involved in food provisioning as the framework requires linear, rigid linking between participating actors.

There has been growing public concern over factory-farmed eggs, such as those produced by concentrated animal feeding operations (CAFOs) where layers are raised in cages, having a negative impact on animal welfare. The cages contain from six to ten hens each and are stacked on top of each other in rows along the length of a barn with no additional space for the hens to stretch their wings. This public concern has driven food businesses, such as McDonald’s, to commit to purchasing only cage-free eggs. This has led to egg producers adopting the cageless barn concept. However, some studies have indicated that there was no difference between cage-free barns and battery cages in terms of their respective environmental impacts [32]. The emissions caused by egg production have been associated with feed and manure management practices. A study by Pelletier et al. [33] found that feed production contributed the largest share of emissions, followed by the nitrogen losses from poultry manure management. Cage-free egg production, while enhancing animal welfare, adds land-use costs that could burden consumers.

There is a paucity of research examining chicken layer farms as a local food system. Researchers have examined chicken layer farm management practices and their impacts on the climate, and they have suggested measures to limit their effects, such as measures to incentivize reducing CO2 emissions [34], as these emissions are associated with economic growth [35]. However, these studies have typically focused on large-scale commercial enterprises and overlooked small-scale family farms, likely due to their smaller contributions to economic growth. Small-scale farming in developing countries plays a key role in local food systems, often similar to that of agroecological food systems, which are more environmentally friendly than other types of production. The characteristics of agroecological food include the following: (1) minimizing the use of external resources; (2) recycling internal resources; (3) developing resilience to stress; (4) multipurposed; (5) integrated and incorporated into a more complex system; (6) contextualized; (7) more equitable; (8) nourishing [36]. However, Stein and Santini [37] suggested that the local food system could not be equated with sustainable food systems. Furthermore, since studies specifically focused on small chicken layer farms and their involvement in sustainable local food systems are rare, none were discovered as a result of our literature review parameters.

Chicken layer farms in Thailand can be classified into three groups: (1) large-scale farms (2.8 percent), (2) contract farms (55.33 percent), and (3) independent small farms (41.87 percent) (less than 50,000 hens/farm) [38]. Records of farms from government statistics in 2020 indicated that there were 135,588 chicken layer farms in Thailand, with more than 57 million hens [34]. However, these statistics included all sizes of farms, ranging from one hen to millions. Thailand’s Department of Husbandry reported a total of 2524 chicken layer farms in operation that had at least 1000 layers as of 2021, and among these, 51 farms were located in Nakhon Phanom Province. In 2019, Thailand produced 14.996 million eggs while domestic consumption was 14.728 million eggs (an average of 221 eggs/person/year) or 98.21 percent; the rest were exported [39].

Between 2014 and 2017, nearly 50 percent of domestic egg production was generated by eight agribusiness farms [40]. After the 2004 outbreak of avian influenza and several subsequent husbandry endemics, a closed-system chicken layer farm was proposed and adopted by many enterprises. Currently, the government promotes the closed-system design to prevent avian disease. Standards of practice for chicken layer farms were issued by the government to prevent diseases that can be transmitted to humans. The practice guidelines (for farms with 1000 or more hens) include the management of the following [41]: (1) farm components (e.g., farm location, farm design, etc.), (2) feed, (3) water, (4) labor, (5) animal health, (6) avian welfare, (7) product, (8) environmental, and (9) database maintenance and records.

Egg prices fluctuate considerably over time, as egg production is subject to a number of factors, including changes in temperature, poultry disease, raw materials in feed, and relevant world markets. Chicken layer farming requires substantial technological and capital investments, from animal breeding and feeds to animal medical care and maintenance. In 2018, the plummeting egg prices resulted in independent producers filing a complaint with Thailand’s Department of Livestock Development, demanding that the State intervenes regarding market prices [42]. As Thailand is a member of the WTO (World Trade Organization), the state subsidiaries have been restricted; therefore, their egg production will continue to compete with international producers who can minimize their production costs. However, ongoing health concerns have resulted in import restrictions by a number of governments.

Research into sustainable agricultural production has increased in recent decades [43,44]. Thailand’s National Research Council database on chicken egg research contains 62 published studies; however, none of them included “environment” or “sustainable” as the topics [45] and keywords. Most were concerned with improving efficiency in egg production to enhance competitiveness. Only a few studies focused on alternative feeds, particularly natural ingredients. Therefore, our study and analysis of egg production and its sustainable contributions in Thailand can provide new insights.

3. Methods

To examine long-term viability and farm management when confronting stressors (both from socioeconomic conditions and climate), our study adopted a qualitative approach to explore the inside-out view of the target group. Rather than adapting existing structured questionnaires, we used semi-structured interviewing guides (Supplementary Materials) that allowed interviewers to probe beyond the initial questions. The data generated were qualitative based on the specific context.

Our data collection commenced with a community study to become acquainted with local people. This was followed by a focus group meeting, to which eight individuals were invited. The participants were selected based on their relevant knowledge and their willingness to participate in the meeting. At the focus group meeting, our inquiries focused on the history of the local community, the local socioeconomic conditions, and issues specific to chicken layer farms. The first focus group discussion allowed us to refine our scope and guided our construction of a semi-structured interviewing guide (Supplementary Materials); we were also able to identify six chicken layer farms in the local community for in-depth interviews.

During the fieldwork, we conducted data analysis to confirm our working assumptions (e.g., farm sizes, the scope of production activities, etc.) using content analysis. The data obtained and provisionally analyzed were verified, further analyzed, and expanded in the second focus group meeting, comprising the same eight participants. In addition, we re-interviewed the 6 chicken layer farms 1–2 times to deepen or clarify some points of data. Data related to production cycles and farm practices were further triangulated among 9 chicken layer farms. In addition, interviews with local authorities were also conducted, including interviewing the staff at the district husbandry office and the mayor of the Ban Klang sub-district municipality.

The data were analyzed using content analysis [46]. This research was reviewed and approved by the Khon Kaen University Ethics Committee in Human Research based on the Declaration of Helsinki and the ICH Good Clinical Practice Guidelines (reference no. HE623130, institutional review board number: IRB00008614).

4. Results

4.1. Rice-Based Chicken Layer Farmers as Local Food Producers

One distinctive feature of the chicken layer farms we studied was that they continued to grow rice crops, even though the income was relatively low compared to chicken layer farming. For example, those who owned rice farmlands either allowed their relatives to farm the land, rented the land to their neighbors, or managed the rice farm themselves while hiring laborers for production tasks. The rice yield was either consumed by their families or sold for cash income. However, their egg production was entirely for cash income.

Two chicken layer farm owners revealed to us in interviews that:

“Egg and rice are main activities for my household. We used to plant chilies and other vegetables for incomes, but the prices were varied, generally not good. We turned to chicken layer farming several years ago. Although the price is not always good, we earn money from it. Whether the price of egg is good or bad, the debts are always with us. But I feel comfortable when I have the paddy in the rice barn that can feed my children and grandchildren” (from the field notes of the interview with KI).

“After returning home from abroad, I started to grow rice and vegetables such as spring onions, chilies, and corn for one year. Vegetables were grown for income while rice growing was both for household consumption and income. After that, I was interested in chicken layer farming because egg is a daily food for every local household, and chicken layer farmers were few in number. I decided to cease vegetable growing and turned to chicken layer farming, but also continued rice farming” (from the field notes of the interview with KI).

The maintenance of rice farming by chicken layer farmers was associated with a sense of security and subjective wellbeing, as opposed to the economic results. As shown in Table 1, cash income from rice represented only a small proportion of the total annual income. In addition, income from other sources, such as from other types of agriculture, excluding rice and eggs, off-farming activities, etc., was higher compared to the income from rice crops. As compared to other smallholders (e.g., non-chicken-layer farmers), the similarities included the average size of the family, the number of laborers employed, and the percentage of total annual income from rice paddies. However, the total annual farm income was much higher for chicken layer farms.

Table 1.

Descriptive statistics of the egg and non-chicken layer farms.

Four out of six chicken layer farmers that we interviewed had experienced migration prior to engaging in chicken layer farming. For example, the 72-year-old farm owner who had started his chicken layer farm 23 years prior had moved away from his village before returning and starting his chicken layer farm. For the last six decades, it has been common practice for rice farmers to migrate elsewhere in order to support their families. Savings from migration-related earnings were then reinvested into other pursuits for income-earning purposes. For instance, a participant reported that he went overseas for a few years to work, and upon his return, he spent his savings from working overseas on the construction of a barn and started his chicken layer farm.

Our focus group discussion revealed that income earnings from non-farming activities, particularly from migration, were higher than from other agriculture on non-chicken-layer farms. The exception was for agriculture that is highly commercialized, such as growing vegetables. In Ban Klang, we found that a number of households cultivated spring onion and various vegetables to sell at local markets. However, nearly all shareholders cultivated rice. The continuity of rice growing was in part due to the relationship to the rice farmland, and the rice yield provided a sense of security and viability. As mentioned previously, the farmers felt that their rice stores ensured that their families would be fed. In addition, the tradition of transferring land, including rice paddies, to siblings or descendants remains a common practice in Thailand, and many rural food producers, particularly those in Ban Klang, are rice-based producers.

4.2. Production

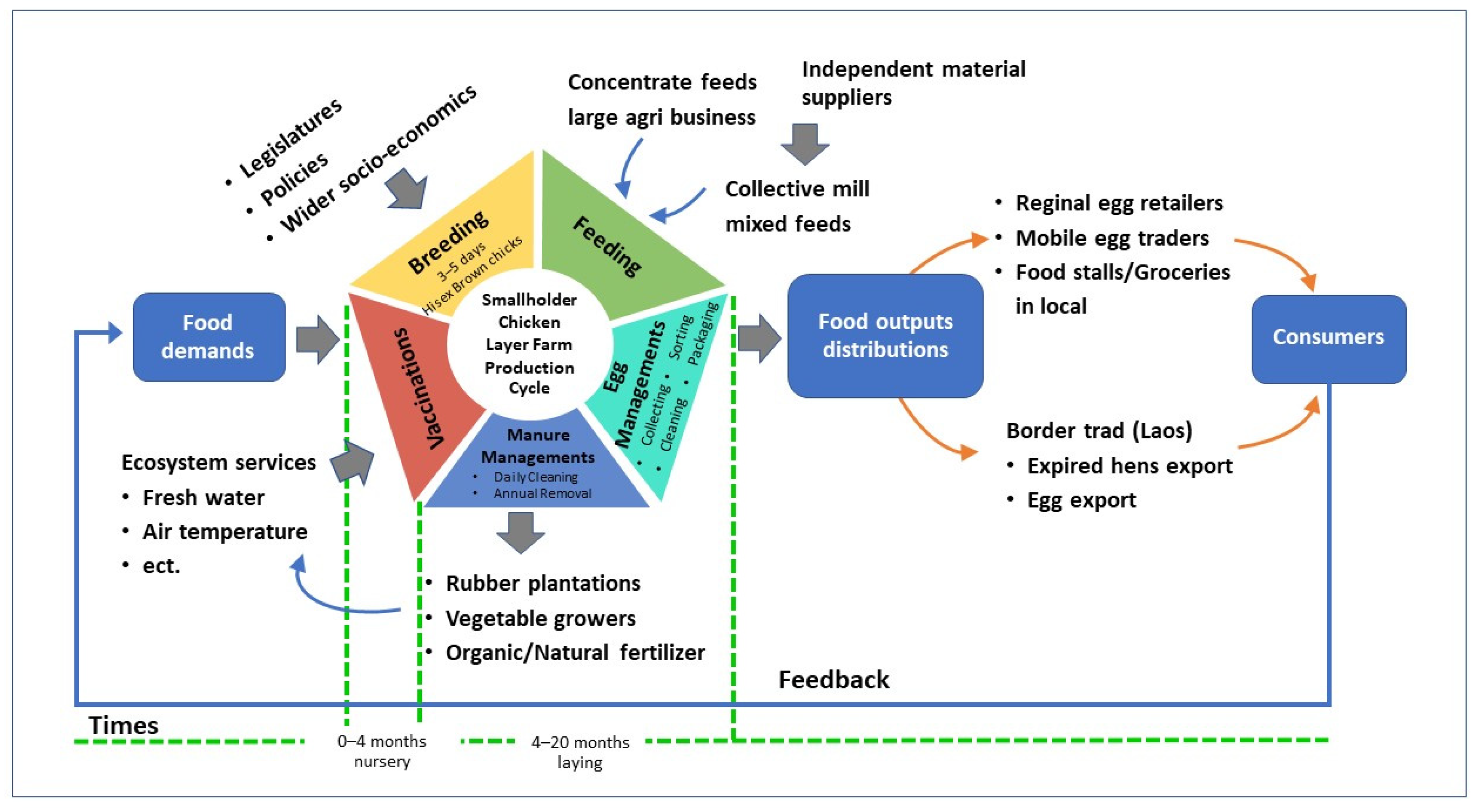

The diagram below shows an egg-based local food system and the production cycle of Ban Klang chicken layer farms. Egg production in Ban Klang was influenced by three subsystems: first, the government and relevant policies as well as the wider socioeconomic conditions around them; second, the product demand, whether local, regional, or international (Ban Klang is located on the border of Laos, where border trade has been promoted); third, the available ecosystem services. While local water and air temperatures have a significant impact on chicken layer farms, other external factors can affect them indirectly as well, such as forest erosion as a result of growing maize, which is used for chicken feed. These three external considerations provided additional context when examining the local food systems surrounding chicken layer farms. The cycle of production is shown in Figure 1.

Figure 1.

Production cycle of chicken layer farm.

4.2.1. Chicken Barn Construction and Preparation

The type of barn used in Ban Klang chicken layer farms has evolved over time. Early on, at the beginning of the 1970s, farmers constructed their barns using local textiles, especially wood and bamboo, and the thatched roofs were constructed of Cogon grass. Each barn could house a few hundred hens. Chicken layer farmers in Ban Klang adopted caged hens, and the cages were constructed of bamboo wood. However, managing the cleanliness of the barn and the cages was laborious. As previously mentioned, cage-free environments were later adopted among chicken layer farms of Ban Klang.

At the time of our study, the materials used for chicken barn construction relied on local materials, especially Cogon grass and bamboo. The barns were cage-free and approximately 6 m wide and 21 m long. The floor of the barn was elevated approximately 1.50 m above the ground. The floor was constructed of bamboo wood, and the width of each wood plank was approximately three centimeters, with an approximate two-centimeter gap between each plank to allow the manure to drop to the ground. Thatched Congo grass roofs were used to maintain cooler temperatures, particularly during the dry season. The barn walls were composed of square wire for maximum airflow. Nests were located on either side of the barn with a 10-degree slope, so the eggs were deposited into the egg collector outside the barn. The farmers said that this type of barn conserved labor. For example, the cage-free hens are fed one or two times per day, depending on the age of the hens, as opposed to caged hens that had to be fed three times a day. Most importantly, cage-free barns were easier to maintain and manage manure.

A chicken barn lasted for approximately 3–4 years or two cohorts of chicken layers. The construction costs ranged between USD 203.11 and USD 290.16, or even. Each barn could house 1000–1200 hens. In Ban Klang, the smallest farm had two barns, while the largest farm had eight.

4.2.2. Nursery

Chicken breeding requires substantial, precise technologies that are not accessible to the typical chicken layer farmer in Ban Klang. Therefore, they order 3–5-day-old chicks from breeding farms in the central plain of Thailand. Hisex Brown is the typical breed. At approximately 4–5 months old, the hens can lay eggs. Currently, there are 16 breeding companies in Thailand. The chicks were then vaccinated and nurtured at chicken layer farms until reaching maturity, and the participating farm owners were required to have the necessary experience and knowledge to care for them. The district agricultural office, breeders, and related businesses may also provide assistance.

4.2.3. Feeds

Two types of feeds were used by the chicken layer farms in our study. The first was a concentrated feed supplied by an animal feed business. Concentrated feeds were mixed with feed blends supplied by a cooperative mill, and the ratios between feeds varied between individual farms.

The second was a mixed feed. The raw materials used to produce chicken feed included maize, soybean meal, crushed acacia, fish meal, crushed shellfish, and di-calcium. In 1999, chicken layer farmers in Ban Klang formed a cooperative to manage and provide raw feed materials. The cooperative mill produces semi-completed feeds to sell to its members. At the time of our study, all the materials were supplied by the cooperative.

Considering the size of the farms, the labor demand was relatively small, with many of the farms employing family laborers. Some farms hired additional laborers for daily feeding for 1–2 h per day. Machines were also part of the feeding process, including a feed-mixer. Feeding, cleaning, and egg collection were performed by household laborers.

A daily schedule for chicken layer farms in Ban Klang is as follows:

- Feed is prepared between 0500 and 0600 h. Chicken barns are cleaned while the chicken feed is mixed. Between 0600 and 0700 h, laborers feed the hens using feed trays. Between 0800 and 0900 h, eggs are collected.

- Between 0900 and 1600 h, eggs are cleaned, sorted by size, and packaged. Family laborers repair the barn, vaccinate the animals, and perform other daily activities.

- Between 1600 and 1700 h, the chickens are fed, and eggs are once again collected.

According to a chicken layer farmer that we interviewed:

“Chicken layer farming requires full-time working all day. I cannot stop working because chickens need to be fed every day. Even when I need medication, I have to go to the private clinic because going to the public hospital is time-consuming. Raising chickens is full-time, strenuous works”, according to field notes of the interview with KI.

The strenuous labor of cultivating rice or vegetables is primarily during the growing and harvesting periods. In contrast, chicken layer farming requires daily labor all year, typically performed by household laborers.

4.2.4. Preventive Measures for Disease Transmission

After the avian influenza outbreak in 2004, the Thailand government adopted measures to prevent the spread of disease among animals as well as the transmission of disease from birds to humans. During this period, chicken layer farmers were negatively impacted as hens had to be incinerated and buried, though the government later compensated the farmers for their losses. Currently, Thailand’s Department of Husbandry has issued a decree specifying that if the avian influenza was discovered on a farm, all hens would be destroyed, and chemical disinfectant would be required in order to reduce the risk of contagion.

Though vaccination programs do not prevent avian influenza, healthy hens are less likely to be infected. The current vaccination schedule includes the following: (1) infectious bronchitis, Newcastle disease, and Gumboro disease at the age of 5–7 days; (2) fowl pox at 21 days; (3) booster for infectious bronchitis, Newcastle disease, and Gumboro disease at 1 month; (4) water-diluted booster for infectious bronchitis; (5) universal vaccination for all diseases every 1.5–2 months until the termination of the hen.

As described in the Introduction Section, the Department of Husbandry established standard guidelines for chicken layer farms with 1000 or more hens in 2021. In addition, a district husbandry officer provided the guidelines for farm owners to prevent the spread of disease, including: (1) chemical disinfection to control the germination of disease; (2) chemical disinfection of all vehicles entering the farm; (3) installation of a sterilizing tank; (4) all feed, packaging, and containers should remain on the farm property; (5) separation and treatment of sick chickens away from the healthy population; (6) incineration and/or burial of chickens that died of illness; (7) establishment of sanitation protocols for laborers working at more than one farm per day (e.g., must shower and change clothing between farms); (8) random inspections by a local husbandry officer to ensure the farm is free from disease.

4.2.5. Manure Management

The chicken barns were elevated approximately 1–1.50 m above the ground. This allowed the manure to collect underneath while promoting airflow to disperse the resultant ammonia and methane gases. The manure was collected once annually and sold as a natural fertilizer. Laborers loaded the manure into sacks, each of which weighed approximately 25 kg, and each barn produced approximately 40–60 sacks of dried manure (1000–1500 kg).

At the time of our study, one sack of manure cost THB 30, indicating that chicken layer farmers earned little income from selling manure. However, the practice conserved labor, managed manure levels, and provided a sustainable, environmentally friendly alternative to chemical fertilizers.

4.2.6. Outputs

The eggs that are collected daily from farms are sorted by size, the premium (the largest), the medium, and the smallest, and mixed. From our in-depth interviews of six farms, there are altogether 28,000 standing layers, with the total egg products of 5,365,500 eggs per year. This means that one standing layer produces 191.63 eggs per year. All six farms employed 25 laborers; half of these were part-time (piece-based) employed. Our calculation suggests that a farm with the size of three barns—the average size of farms in Ban Klang, would require three full-time employed laborers. On this basis, one full-time employed laborer produces 298,083.33 eggs per year. The annual investment costs from our records of six farms are THB 6,132,000 or, on average, THB 1,022,000 per farm. Our estimation shows that the net income of chicken layer farms is THB 354,666.67 (approx. USD 10,000) per year, or THB 85,120 per head per year (the average size of a household is 4.17 persons). The annual income per head of the chicken layer farm is slightly over the GPP (Gross Provincial Product Per Capita) of Nakhon Phanom Province, which stood at THB 74,000 in 2020.

4.3. Distribution of Farm Products

While the egg production in Ban Klang was dependent on larger agribusiness production, it was independent in terms of distributing its farm products. We found fresh egg products at local markets, both in Nakhon Phanom Province and the surrounding area.

Locally, in old provincial and district towns, one or two fresh food markets (sometimes referred to as “wet markets”) could serve the entire area. In sprawling suburban and growing urban communities, however, fresh food markets have gained increasing popularity. These markets vary in size and offerings, from less than a hundred stalls in small markets to several hundred in large markets near urban centers. In addition to the fresh food markets, grocers are found along the roadside or on street corners, selling fresh food to consumers. While supermarkets and convenient stores have been established in provincial, district, and sub-district towns, local eggs produced by Ban Klang chicken layer farms were only supplied to fresh food markets and small grocers.

The distribution of Ban Klang chicken layer farm eggs was classified into three types:

- On-farm sales. All chicken layer farms sold their products at their farms to neighbors and local grocers who would visit from up to 15 km away. In addition, small farms could opt to sell their products to larger farms, who would then be responsible for transportation, often via “pick-up” trucks. A few small mobile egg traders used tricycles to transport eggs from the farms to the surrounding villages and local markets.

- Wholesale outlets. The eggs were supplied to food stalls in fresh food markets, grocers, restaurants, etc. This market channel required a means of transporting the eggs and relied primarily on each farm’s network. The benefit of this arrangement was that the process (e.g., orders, payments, etc.) could be customized, and the local wholesale businesses could expect regular supplies of fresh eggs.

- Fresh food markets. In our research, we discovered that Ban Klang farmers sold their eggs at two nearby markets. Most buyers were grocers or wholesale business owners from Laos, who bought substantial amounts of eggs for transport. There were also periodic “border markets”, where traders from either side of the countries’ border transported products to a pre-determined location. However, the COVID-19 pandemic halted this practice when country borders were closed. However, periodic markets are commonly found in and around rural areas.

4.4. Localness

Given the competition of large agribusiness chicken layer farms, the recognition of eggs from Ban Klang could be critical. Normally, general consumers cannot distinguish the origin of eggs according to their physical appearances. However, a food stall owner in a Ban Klang fresh food market revealed to us in an interview that she had received supplies of eggs from both agribusinesses and Ban Klang chicken layer farms. She was able to determine the sources of the eggs: the eggshell colors of the agribusiness eggs were darker and their yolks paler. She reported that some customers had recognized the differences as well. The retail price of eggs from Ban Klang was also higher. Some consumers were seeking eggs from Ban Klang.

“Eggs from Ban Klang are still in demand for certain groups of customers, especially in middle-class people such as civil servants, health lovers, and the owners of Thai dessert and bakery shops. These customers prefer eggs from Ban Klang, so I serve them. Eggs of Ban Klang have a better color and are better for desserts and bakeries”, according to the field notes from the interview with a food stall owner.

The decision for most egg consumers was based on the price, however. Some retailers mixed eggs from both sources in order to equalize egg prices.

Farm-to-table distribution could be a promising option for some chicken layer farmers. One farm owner expressed:

“For my farm, I decided to sell the eggs to the consumers myself. Selling eggs by myself allows me to build regular customers. These customers buy eggs from me because the good and reliable quality, and the customers prefer freshness. With the increase in regular, local customers recognizing that eggs are local products of Ban Klang, I feel confident that I will be able to survive”, according to the field notes of the interview with KI.

5. Conclusions

The long history of chicken layer farms in Ban Klang indicated the ability of farmers to adapt to dynamic socioeconomic conditions, market variations, and external influences (e.g., new policies and legislations). The viability of these farms has been promoted via rice farming, farm management, the distribution of farm products, and the support of the local community and consumers. The viability of the small chicken layer farms in Ban Klang has also been affected by their interactions with large agribusinesses (i.e., the chicken breeds, the concentrated feeds, vaccinations). While these smallholders have struggled to maintain their independence, commercial and industrialized production has provided unexpected benefits and opportunities for smallholders.

The production practices of Ban Klang chicken layer farms were unique and have evolved as a result of environmental, social, and cultural sustainability in a number of aspects. Small chicken layer farmers located outside of Ban Klang should consider adopting some of their practices, such as using local materials for barn construction, cage-free barn design with natural airflow, cooperative feed solutions to reduce costs and dangerous emissions, etc.

Ban Klang chicken layer farmers should also consider changes to their current practices, particularly those that are expensive or not environmentally sound. Maize grown in northern mountainous zones has caused forest degradation and the collapse of ecosystem services, and the fish meal and crushed shellfish used in their feed blend have to be transported across a significant distance. The feed cooperative should develop alternative feed blends while considering sustainable, green practices and adaptations.

Although the chicken layer farms of Ban Klang provided few local employment opportunities, they were well-integrated into the local fresh food network. Therefore, Ban Klang chicken layer farms indirectly generated further employment opportunities via their supply points, such as food stalls, grocers, mobile egg sellers, and regional wholesale. In addition to enhancing the local economy, chicken layer farms and local food retailers can ensure food access and security for their local community.

Finally, we recommend two practical suggestions from our study. Since chicken layer farms have adapted and evolved despite their setbacks, such as avian influenza and the financial crisis, their persistence indicates they may be joining an agricultural niche, such as organic farming. During our discussions with participants, some mentioned organic farming, but there were technical limitations preventing them from adopting more organic practices. The size of the farms in Ban Klang could permit further developments for organic farming. In addition, the efforts to manage the feeds via a cooperative could lead to developing alternative, organic feeds. We recommend that government agencies and local businesses engage with local farmers to pilot an organic approach to chicken layer farming.

Secondly, local products were popular in and around Ban Klang, which benefited both the community and the shareholders. We recommend promoting the health benefits of local products. One approach would be to monitor and ensure the production process and limit any risks to consumer health while ensuring that these observations were visible to consumers. In addition, the local producers could promote “institutional consumption”, such as hospital cafeterias, school lunches, food for monks, etc. With the support of local governments and policy makers, local food producers could expand their markets into these institutions and provide healthy, local nourishment for their populations.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su14105997/s1, Semi-Structured Interview Guides.

Author Contributions

Conceptualization, B.P. and M.S.; structure of the manuscript and analysis, B.P. and M.S.; writing—original draft, B.P.; writing—review and editing, M.S. and B.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Thailand Science Research and Innovation (TSRI) and Khon Kean University, grant number RSA6280099, and the article processing charges (APC) were funded by Mahidol University, Thailand.

Institutional Review Board Statement

This study was conducted in accordance with the Declaration of Helsinki and approved by the Khon Kaen University Ethics Committee in Human Research based on the Declaration of Helsinki and the ICH Good Clinical Practice Guideline, and it was approved on 19 January 2020, for studies involving humans (reference no. HE623130, institutional review board number: IRB00008614).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The sponsor had no role in the design of the study; in the collection, analysis, or interpretation of the data; in the writing of the manuscript; or in the decision to publish the results.

References

- Holt-Giménez, E.; Altieri, M.A. Agroecology, Food Sovereignty, and the New Green Revolution. Agroecol. Sustain. Food Syst. 2013, 37, 90–102. [Google Scholar] [CrossRef]

- Friedmann, H.; McMichael, P. Agriculture and the State System. Sociol. Rural. 1989, 29, 93–117. [Google Scholar] [CrossRef]

- Deller, S.C.; Lamie, D.; Stickel, M. Local Foods Systems and Community Economic Development. Community Dev. 2017, 48, 612–638. [Google Scholar] [CrossRef]

- Martinez, S.; Vogel, S.J.; Martinez, S.; Hand, M.; Da Pra, M.; Pollack, S.; Ralston, K.; Smith, T.; Vogel, S.; Clark, S.; et al. Local Food Systems: Concepts, Impacts, and Issues; United States Department of Agriculture (USDA), Economic Research Service: Washington, DC, USA, 2010; pp. 1–87. [Google Scholar]

- Mount, P. Growing Local Food: Scale and Local Food Systems Governance. Agric. Hum. Values 2012, 29, 107–121. [Google Scholar] [CrossRef]

- Sage, C. The Interconnected Challenges for Food Security from a Food Regimes Perspective: Energy, Climate and Malconsumption. J. Rural Stud. 2013, 29, 71–80. [Google Scholar] [CrossRef]

- Wang, C.K. East Asian Food Regimes: Agrarian Warriors, Edamame Beans and Spatial Topologies of Food Regimes in East Asia. Peasant Stud. 2018, 45, 739–756. [Google Scholar] [CrossRef]

- Enthoven, L.; Van Den Broeck, G. Local Food Systems: Reviewing Two Decades of Research. Agric. Syst. 2021, 193, 103226. [Google Scholar] [CrossRef]

- Getz, A. Urban Foodsheds. Permac. Act. 1991, 24, 26–27. [Google Scholar]

- Schreiber, K.; Hickey, M.G.; Metson, S.G.; Robinson, E.B.; MacDonald, K.G. Quantifying the Foodshed: A Systematic Review of Urban Food Flow and Local Food Self-Sufficiency Research. Environ. Res. Lett. 2021, 16, 023003. [Google Scholar] [CrossRef]

- Feenstra, G.W. Local Food Systems and Sustainable Communities. Am. J. Altern. Agric. 1997, 12, 28–36. [Google Scholar] [CrossRef]

- Kneafsey, M.; Venn, L.; Schmutz, U.; Balázs, B.; Trenchard, L.; Wood, E.T.; Bos, E.; Sutton, G.; Blackett, M. Short Food Supply Chains and Local Food Systems in the EU. A State of Play of Their Socio-Economic Characteristics; European Commission, Joint Research Centre: Sevilla, Spain, 2013; ISBN 9789279292880. [Google Scholar]

- Chase, L.; Grubinger, V. Food, Farms and Community: Exploring Food Systems; University of New Hampshire Press: Durham, NH, USA, 2014; ISBN 9781611684216. [Google Scholar]

- Groenewald, S.F.; van den Berg, M.M. Smallholder Livelihood Adaptation in the Context of Neoliberal Policy Reforms: A Case of Maize Farmers in Southern Veracruz, Mexico. J. Dev. Stud. 2012, 48, 429–444. [Google Scholar] [CrossRef] [Green Version]

- International Fund for Agricultural Development (IFAD). Smallholders, Food Security, and the Environment; IFAD: Rome, Italy, 2013. [Google Scholar]

- Ricciardi, V.; Ramankutty, N.; Mehrabi, Z.; Jarvis, L.; Chookolingo, B. How Much of the World’s Food Do Smallholders Produce? Glob. Food Sec. 2018, 17, 64–72. [Google Scholar] [CrossRef]

- Ansah, E.O.; Kaplowitz, M.D.; Lupi, F.; Kerr, J.; Offei, E.; Kaplowitz, M.D.; Lupi, F.; Kerr, J. Agroecology and Sustainable Food Systems Smallholder Participation and Procedural Compliance with Sustainable Cocoa Certification Programs. Agroecol. Sustain. Food Syst. 2020, 44, 54–87. [Google Scholar] [CrossRef]

- Rigg, J.; Salamanca, A.; Thompson, E.C.; Asia, E. The Puzzle of East and Southeast Asia’s Persistent Smallholder. J. Rural Stud. 2016, 43, 118–133. [Google Scholar] [CrossRef]

- Bebbington, A. Capitals and Capabilities: A Framework for Analyzing Peasant Viability, Rural Livelihoods and Poverty. World Dev. 1999, 27, 2021–2044. [Google Scholar] [CrossRef]

- Katre, A.; Bertossi, T.; Clarke-Sather, A.; Parsatoon, M. Agroecological Transition: A Territorial Examination of the Simultaneity of Limited Farmer Livelihoods and Food Insecurity. Sustainability 2022, 14, 3160. [Google Scholar] [CrossRef]

- Working Conditions of the Population by Business Type in the Northeast. Available online: https://www.bot.or.th/App/BTWS_STAT/statistics/ReportPage.aspx?reportID=730&language=th (accessed on 14 March 2022).

- Falvey, L. Thai Agriculture: Golden Cradle of Millennia; Kasetsart University Press: Nonthaburi, Thailand, 2000; ISBN 9745538167. [Google Scholar]

- Thompson, E.; Rigg, J.; Gillen, J. Asian Smallholders in Comparative Perspective; Amsterdam University Press B.V.: Amsterdam, The Netherlands, 2019; ISBN 9789462988170. [Google Scholar]

- Bernstein, H. Food Regimes and Food Regime Analysis: A Selective Survey. In Proceedings of the International Academic Conference, BRICS Initiatives for Critical Agrarian Studies (BICAS), Chiang Mai, Thailand, 5–6 June 2015. [Google Scholar]

- Rambo, A.T. The Agrarian Transformation in Northeastern Thailand: A Review of Recent Research. Southeast. Asian Stud. 2017, 6, 211–246. [Google Scholar] [CrossRef]

- Office of the National Economic and Social Development Council. Poverty and Inequity Report 2019; Office of the Prime Minister: Bangkok, Thailand, 2020. [Google Scholar]

- Eggs Profile. Available online: https://www.agmrc.org/commodities-products/livestock/poultry/eggs-profile (accessed on 15 March 2022).

- Global Egg Production Continues to Grow. Available online: https://www.internationalegg.com/resource/global-egg-production-continues-to-grow/#:~:text=There%20is%20a%20large%20varia-tion,eggs%20per%20person%20per%20year (accessed on 18 March 2022).

- Garnett, T. Cooking Up a Storm: Food, Greenhouse Gas Emissions and Our Changing Climate; Centre for Environmental Strategy, University of Surrey: Surrey, UK, 2008. [Google Scholar]

- Gunnarsson, S.; Segerkvist, K.A.; Göransson, L.; Hansson, H.; Sonesson, U. Systematic Mapping of Research on Farm-Level Sustainability in Egg and Chicken Meat Production. Environ. Rev. 2020, 12, 3033. [Google Scholar] [CrossRef] [Green Version]

- Wegerif, M.C.A. Exploring Sustainable Urban Food Provisioning: The Case of Eggs in Dar Es Salaam. Sustainability 2014, 6, 3747–3779. [Google Scholar] [CrossRef] [Green Version]

- The FoodPrint of Eggs: A Foodprint Report. Available online: https://foodprint.org/reports/the-foodprint-of-eggs/ (accessed on 14 March 2022).

- Pelletier, N.; Ibarburu, M.; Xin, H. A Carbon Footprint Analysis of Egg Production and Processing Supply Chains in the Midwestern United States. J. Clean. Prod. 2013, 54, 108–114. [Google Scholar] [CrossRef]

- Ioan, B.; Kumaran, R.M.; Larissa, B.; Anca, N.; Lucian, G.; Gheorghe, F.; Horia, T.; Ioan, B.; Mircea-iosif, R. A Panel Data Analysis on Sustainable Economic Growth in India, Brazil, and Romania. J. Risk Financ. Manag. 2020, 13, 170. [Google Scholar] [CrossRef]

- Batrancea, I.; Batrancea, L.; Rathnaswamy, M.M.; Tulai, H. Greening the Financial System in USA, Canada and Brazil: A Panel Data Analysis. Mathematics 2020, 8, 2217. [Google Scholar] [CrossRef]

- Vaarst, M.; Escudero, A.G.; Chappell, M.J.; Brinkley, C.; Nijbroek, R.; Arraes, N.A.M.; Andreasen, L.; Gattinger, A.; De Almeida, G.F.; Bossio, D.; et al. Exploring the Concept of Agroecological Food Systems in a City-Region Context. Agroecol. Sustain. Food Syst. 2018, 42, 686–711. [Google Scholar] [CrossRef]

- Stein, J.A.; Santini, F. The Sustainability of “Local” Food: A Review for Policy-Makers. Rev. Agric. Food Environ. Stud. 2021, 103, 77–89. [Google Scholar] [CrossRef]

- Suwanvajokkasikit Animal Research and Development. The Study and Analysis Project of Egg Production and Marketing Structure Egg Production Cost Structure: Executive Summary; Livestock Development: Nonthaburi, Thailand, 2012. [Google Scholar]

- Husbandry Data in 2020. Available online: http://docimage.dld.go.th/FILEROOM/CABDLD_BOOKSHELF2/DRAWER26/GENERAL/DATA0000/00000082.PDF (accessed on 13 March 2022).

- Kitiwong, K.; Saeliw, K. Production and Marketing of Egg in Thailand. Khon Kaen Agric. J. 2019, 47, 889–894. [Google Scholar]

- Good Agricultural Practices for Layer Farm. Available online: https://www.acfs.go.th/standard/download/GAP_Layer_Farm(G)_2562.pdf (accessed on 13 March 2022).

- Egg Price Stabilization in Thailand. Available online: http://extension.dld.go.th/th1/index.php?option=com_content&view=section&id=7&Itemid=108 (accessed on 20 April 2022).

- Sampantamit, T.; Ho, L.; Lachat, C.; Sutummawong, N. Aquaculture Production and Its Environmental Sustainability in Thailand: Challenges and Potential Solutions. Sustainability 2020, 12, 2010. [Google Scholar] [CrossRef] [Green Version]

- Kasem, S.; Thapa, G.B. Sustainable Development Policies and Achievements in the Context of the Agriculture Sector in Thailand. Sustain. Dev. 2012, 20, 98–114. [Google Scholar] [CrossRef]

- Digital Research Information Center. Available online: https://dric.nrct.go.th/Search/index#top (accessed on 20 March 2022).

- Hsieh, F.H.; Shannon, E. Three Approaches to Qualitative Content Analysis. Qual. Health Res. 2014, 15, 1277–1288. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).