Strategies for Enhancing Construction Waste Recycling: A Usability Analysis

Abstract

1. Introduction

2. Methodology

2.1. Survey Development

- i.

- Research objective: Compare the usability of enhancement strategies for CWR.

- ii.

- iii.

- Keywords selection: ‘recycling’, ‘waste’, ‘construction’, and ‘project’. Articles with those keywords in their title, abstract, or keywords are included in the review. The exact search string is: TITLE-ABS-KEY (recycl* AND waste AND construction AND project). The search was on 4 May 2020, yielding 961 papers detected in total.

- iv.

- Selection of compatible articles: The main purpose of this process is to detect those papers aligned with the research subject. The researchers determined the inclusion and exclusion standards to support the selection criteria process. The search selects only articles and reviews papers written in English and published between 2000 and 2020 to ensure that all extracted information was up to date. Moreover, the search considers those only in the area of engineering, business, social science, economics, and decision making to make certain that most papers are related to the research area. Finally, only journals that published at least two articles were selected for the review process [33]. This process resulted in 167 papers from 34 journals. In addition, this process of filtering the SLR is similar to previous works in construction management research [10,29,34].The article selection process started with reading the titles and abstracts for all the papers and selecting papers with results directly related to the study objective. In this regard, the following inclusion standards were utilized to determine the papers: (1) the paper should be specifically related to construction waste recycling; (2) the paper should cover at least either the concept, process, or application of construction waste recycling in the construction projects; and (3) the paper should mention any discussion related to construction waste recycling. The articles that do not contain the criteria mentioned above were screened out. In addition, some papers that were not relevant were also excluded via screening. By following the inclusion standards, 123 papers were excluded. In addition, to ensure the reliability of the SLR, all researchers work together in the process of filtering and coding. In order to this process, only when the researchers agree that a paper does not meet the study’s inclusion standards can it be excluded. Additionally, if there are any conflicts of opinion, they will resolve via discussion between the researchers. At the end of this step, 44 papers were identified.

- v.

- Data extraction: In this stage, the SLR extracts the CWR enhancement strategies from the 44 papers within one month to finalize the whole process. In addition, all authors validated the latest sample to increase the validity standards.

| Code | Strategy | References |

|---|---|---|

| S01 | Raise project team awareness on CW | [39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54] |

| S02 | Adopt off-site construction practices (e.g., prefabrication) | [49,53,55,56,57,58,59] |

| S03 | Adopt on-site construction practices (e.g., mobile recycling) | [45,60,61,62,63] |

| S04 | Acquire certifications related to CW recycling from the government (e.g., green building, LEED) | [40,41,64,65] |

| S05 | Prepare dedicated spaces to sort CW | [56,66,67,68,69] |

| S06 | Organize temporary bins in each construction zone | [67,69,70] |

| S07 | Identify construction activities that produce recyclable materials | [39,40,71] |

| S08 | Adopt a database for collecting CW | [43,46,48,49,59,62,69,70] |

| S09 | Use information technology to facilitate CWR processes (e.g., website) | [39,48,49,72,73] |

| S10 | Use CW recycled materials as alternative construction materials | [54,55,57,74,75,76,77,78,79,80,81] |

| S11 | Satisfy the requirements of CWR processes | [42,48,67,68,77,82] |

| S12 | Enhance company policies related to CWR | [51,56,74] |

| S13 | Adhere to national legislations related to CWR | [51] |

2.2. Survey Participants

2.3. Survey Results and Analysis

2.3.1. Reliability Analysis

2.3.2. Mean Score Ranking and Normalization Technique

2.3.3. Agreement Analysis

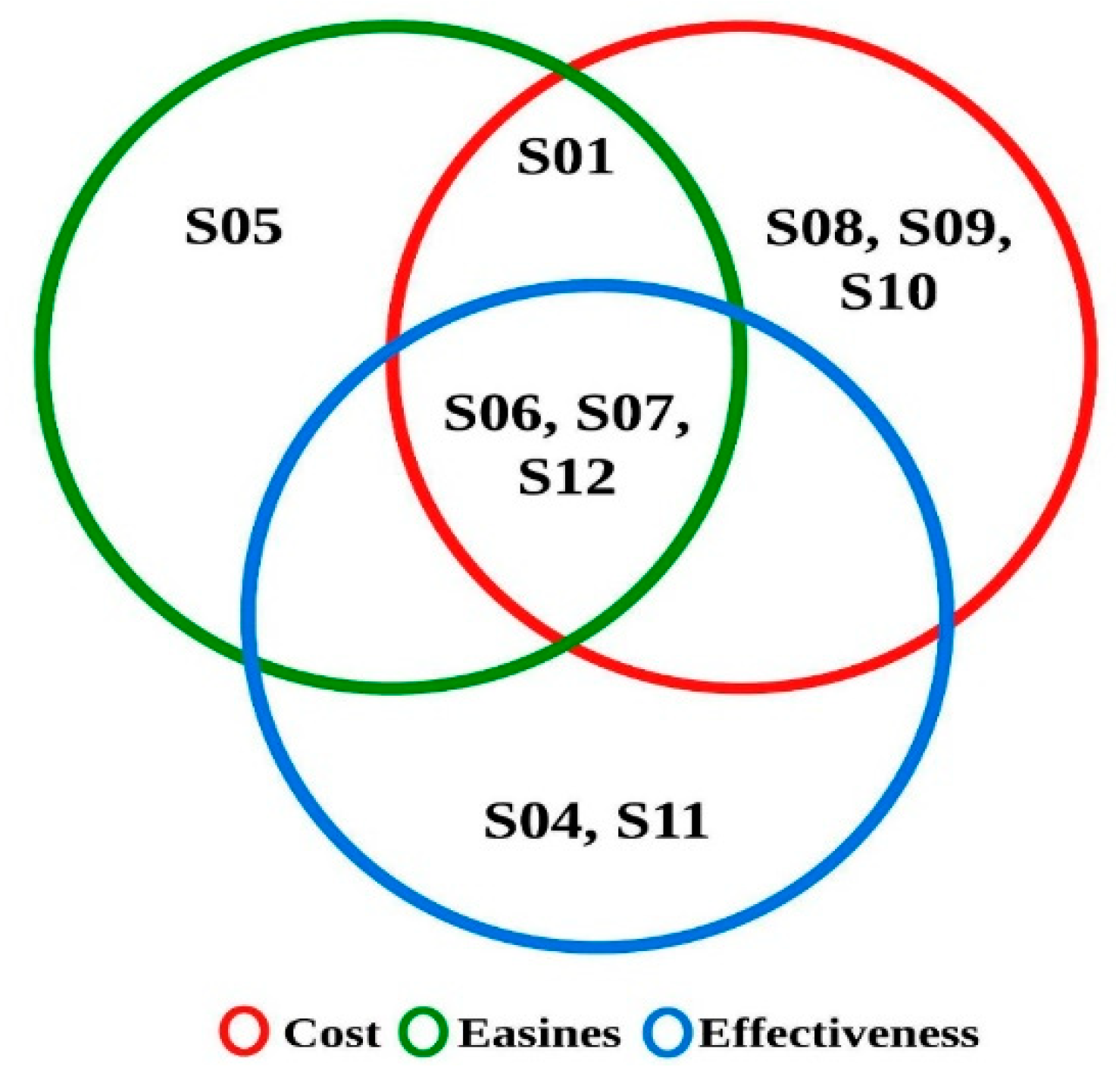

2.3.4. Overlap Analysis

2.3.5. Usability Analysis

2.3.6. Factor Analysis Using the Usability Index

3. Discussion

3.1. Easy, Cheap, and Effective Strategies

3.1.1. Organize Temporary Bins in Each Construction Zone (S06)

3.1.2. Identify Construction Activities That Produce Recyclable Materials (S07)

3.1.3. Enhance Company Policies Related to CWR (S12)

3.2. Effective but Not Cheap nor Easy Strategies

3.2.1. Acquire Certifications Related to CWR from the Government (S04)

3.2.2. Satisfy the Necessary Requirements of CWR Processes (S11)

3.3. Theoretical, Practical, and Managerial Implications

3.4. Study Limitations and Future Recommendations

4. Conclusions

- Thirteen strategies can target the enhancement of CWR rates in construction projects.

- Three out of those thirteen strategies can be considered relatively cheap, effective, and easy compared to the others. The strategies are: ‘organize temporary bins in each construction zone’ (S06), ‘identify construction activities that produce recyclable materials’ (S07), and ‘enhance company policies related to CWR’ (S12).

- Additionally, two others are rated as effective but not cheap or easy. The strategies are: ‘acquire certifications related to CWR from the government’ (S04) and ‘satisfy the necessary requirements of CWR processes’ (S11).

- The study proposed a formula for computing usability indexes using the cost, easiness, and effectiveness values.

- Factor analysis produced three-factor for the usability index’s list, which were named workplace laws and policy management (S13, S02, S10, S11, S05, S12, and S04), information technology and capability management (S08 and S09), workforce and workplace management (S01, S06, and S03).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Li, H.; Wong, C.T.C. An Application of Bar-Code System for Reducing Construction Wastes. Autom. Constr. 2002, 11, 521–533. [Google Scholar]

- Duarte, K.; Fernandes, P.; Baracho, N.; Majik, R.; Dias, S.; Dias, M. Assessment of Construction and Demolition Waste in Goa for Re-Use in New Construction. In Recent Trends in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2021; pp. 157–169. [Google Scholar]

- Jin, R.; Yuan, H.; Chen, Q. Science Mapping Approach to Assisting the Review of Construction and Demolition Waste Management Research Published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, D.; Zheng, D.; Guo, X.; Zhao, W. Construction Waste Landfill Volume Estimation Using Ground Penetrating Radar. Waste Manag. Res. 2022. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Webster, C.; Chen, K.; Zhang, X.; Chen, X. Computational Building Information Modelling for Construction Waste Management: Moving from Rhetoric to Reality. Renew. Sustain. Energy Rev. 2017, 68, 587–595. [Google Scholar] [CrossRef]

- Meng, Y.; Ling, T.C.; Mo, K.H. Recycling of Wastes for Value-Added Applications in Concrete Blocks: An Overview. Resour. Conserv. Recycl. 2018, 138, 298–312. [Google Scholar] [CrossRef]

- Bao, Z.; Lee, W.M.W.; Lu, W. Implementing On-Site Construction Waste Recycling in Hong Kong: Barriers and Facilitators. Sci. Total Environ. 2020, 747, 141091. [Google Scholar] [CrossRef]

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Shanawaz Uddin, A.S.M.; Salmiati, S.; Shahid, S. An Empirical Study of Construction and Demolition Waste Generation and Implication of Recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef]

- Bao, Z.; Lu, W. Developing Efficient Circularity for Construction and Demolition Waste Management in Fast Emerging Economies: Lessons Learned from Shenzhen, China. Sci. Total Environ. 2020, 724, 138264. [Google Scholar] [CrossRef]

- Omer, M.M.; Rahman, R.A.; Almutairi, S. Construction Waste Recycling: Enhancement Strategies and Organization Size. Phys. Chem. Earth 2022, 103114. [Google Scholar] [CrossRef]

- Negash, Y.T.; Hassan, A.M.; Tseng, M.L.; Wu, K.J.; Ali, M.H. Sustainable Construction and Demolition Waste Management in Somaliland: Regulatory Barriers Lead to Technical and Environmental Barriers. J. Clean. Prod. 2021, 297, 126717. [Google Scholar] [CrossRef]

- Ulubeyli, S.; Kazaz, A.; Arslan, V. Construction and Demolition Waste Recycling Plants Revisited: Management Issues. Procedia Eng. 2017, 172, 1190–1197. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Developing Strategies for Managing Construction and Demolition Wastes in Malaysia Based on the Concept of Circular Economy. J. Mater. Cycles Waste Manag. 2017, 19, 1144–1154. [Google Scholar] [CrossRef]

- Liljegren, E. Usability in a Medical Technology Context Assessment of Methods for Usability Evaluation of Medical Equipment. Int. J. Ind. Ergon. 2006, 36, 345–352. [Google Scholar] [CrossRef]

- ISO, W. 9241-11; Ergonomic Requirements for Office Work with Visual Display Terminals (VDTs). International Organization Standard: Geneva, Switzerland, 1998.

- Bao, Z.; Lu, W. A Decision-Support Framework for Planning Construction Waste Recycling: A Case Study of Shenzhen, China. J. Clean. Prod. 2021, 309, 127449. [Google Scholar] [CrossRef]

- Mak, T.M.W.; Yu, I.K.M.; Wang, L.; Hsu, S.C.; Tsang, D.C.W.; Li, C.N.; Yeung, T.L.Y.; Zhang, R.; Poon, C.S. Extended Theory of Planned Behaviour for Promoting Construction Waste Recycling in Hong Kong. Waste Manag. 2019, 83, 161–170. [Google Scholar] [CrossRef]

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An Empirical Study of Perceptions towards Construction and Demolition Waste Recycling and Reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A. Identifying and Managing Critical Waste Factors for Lean Construction Projects. Eng. Manag. J. 2019, 32, 2–13. [Google Scholar] [CrossRef]

- Caldera, S.; Ryley, T.; Zatyko, N. Enablers and Barriers for Creating a Marketplace for Construction and Demolition Waste: A Systematic Literature Review. Sustainability 2020, 12, 9931. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Financial and Economic Evaluation of Construction and Demolition Waste Recycling in Hanoi, Vietnam. Waste Manag. 2021, 131, 294–304. [Google Scholar] [CrossRef]

- Liu, J.; Gong, E.; Wang, X. Economic Benefits of Construction Waste Recycling Enterprises under Tax Incentive Policies. Environ. Sci. Pollut. Res. 2022, 29, 12574–12588. [Google Scholar] [CrossRef]

- Mohamed Shaffril, H.A.; Samsuddin, S.F.; Abu Samah, A. The ABC of Systematic Literature Review: The Basic Methodological Guidance for Beginners. Qual. Quant. 2021, 55, 1319–1346. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The Sage Handbook of Organizational Research Methods; Sage Publications Ltd.: Newbury Park, CA, USA, 2009. [Google Scholar]

- Creswell, J.W.; Creswell, J.D. Research Design: Qualitative, Quantitative, and Mixed Methods Approaches; Sage Publications Ltd.: Newbury Park, CA, USA, 2017; ISBN 1506386717. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Altman, D.; Antes, G.; Atkins, D.; Barbour, V.; Barrowman, N.; Berlin, J.A.; et al. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Ann. Intern. Med. 2009, 51, 264–269. [Google Scholar] [CrossRef] [PubMed]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Group, P. Reprint—Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Phys. Ther. 2009, 89, 873–880. [Google Scholar] [CrossRef] [PubMed]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A. Preferred Reporting Items for Systematic Review and Meta-Analysis Protocols (PRISMA-P) 2015 Statement. Syst. Rev. 2015, 4, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Radzi, A.R.; Rahman, R.A.; Doh, S.I. Decision Making in Highway Construction: A Systematic Review and Future Directions. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- Tijani, B.; Xiaohua, J.; Osei-Kyei, R. Critical Analysis of Mental Health Research among Construction Project Professionals. J. Eng. Des. Technol. 2020, 19, 467–496. [Google Scholar] [CrossRef]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, Web of Science, and Google Scholar: Strengths and Weaknesses. FASEB J. 2008, 22, 338–342. [Google Scholar] [CrossRef] [PubMed]

- Kumar Singh, V.; Singh, P.; Karmakar, M.; Leta, J.; Mayr, P.; Kumar Singh Vivek, V. The Journal Coverage of Web of Science, Scopus and Dimensions: A Comparative Analysis. Scientometrics 2021, 126, 5113–5142. [Google Scholar] [CrossRef]

- Amos, D.; Chan, A.P.C. Critical Analysis of Green Building Research Trend in Construction. J. Habitat Int. 2016, 57, 53–63. [Google Scholar]

- Zamani, S.H.; Rahman, R.A.; Fauzi, M.A.; Yusof, L.M. Government Pandemic Response Strategies for AEC Enterprises: Lessons from COVID-19. J. Eng. Des. Technol. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Göb, R.; McCollin, C.; Ramalhoto, M.F. Ordinal Methodology in the Analysis of Likert Scales. Qual. Quant. 2007, 41, 601–626. [Google Scholar] [CrossRef]

- Omer, M.M.; Rahman, R.A.; Almutairi, S. Strategies for Enhancing Construction Waste Recycling: A Fuzzy Synthetic Evaluation. In Proceedings of the the Construction Research Congress 2022, Arlington, Virginia, 9–12 March 2022; pp. 676–685. [Google Scholar] [CrossRef]

- Maurer, T.J.; Pierce, H.R. A Comparison of Likert Scale and Traditional Measures of Self-Efficacy. J. Appl. Psychol. 1998, 83, 324–329. [Google Scholar] [CrossRef]

- Dillman, D.A. Mail and Internet Surveys: The Tailored Design Method--2007 Update with New Internet, Visual, and Mixed-Mode Guide; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 1118044630. [Google Scholar]

- Durão, V.; Caixinhas, J.; Osório-Peters, S.; Den Boer, E.; Williams, I.D.; Curran, T.; Pertl, A. Zero-Waste Networks in Construction and Demolition in Portugal. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2014, 167, 153–168. [Google Scholar] [CrossRef]

- Chi, B.; Lu, W.; Ye, M.; Bao, Z.; Zhang, X. Construction Waste Minimization in Green Building: A Comparative Analysis of LEED-NC 2009 Certified Projects in the US and China. J. Clean. Prod. 2020, 256, 120749. [Google Scholar] [CrossRef]

- Arif, M.; Bendi, D.; Toma-Sabbagh, T.; Sutrisna, M. Construction Waste Management in India: An Exploratory Study. Constr. Innov. 2012, 12, 133–155. [Google Scholar] [CrossRef]

- Cha, H.S.; Kim, K.H.; Kim, C.K. Case Study on Selective Demolition Method for Refurbishing Deteriorated Residential Apartments. J. Constr. Eng. Manag. 2012, 138, 294–303. [Google Scholar] [CrossRef]

- Hobbs, G.; Adams, K.; Blackwell, M. Understanding and Predicting Construction Waste. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2011, 164, 239–245. [Google Scholar] [CrossRef]

- Cha, H.S.; Kim, J.; Han, J.Y. Identifying and Assessing Influence Factors on Improving Waste Management Performance for Building Construction Projects. J. Constr. Eng. Manag. 2009, 135, 647–656. [Google Scholar] [CrossRef]

- Davies, H. Site Waste Management-Do You Have a Plan? Build. Eng. 2008, 83, 20–21. [Google Scholar]

- Haselbach, L.M.; Bruner, S.U. Determining Construction Debris Recycling Dumpster Densities. J. Green Build. 2006, 1, 139–147. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Yang, X.; Amati, A.; Tukker, A. Life Cycle Greenhouse Gas Emission and Cost Analysis of Prefabricated Concrete Building Façade Elements. J. Ind. Ecol. 2020, 24, 1016–1030. [Google Scholar] [CrossRef]

- Wang, H.; Chen, D.; Duan, H.; Yin, F.; Niu, Y. Characterizing Urban Building Metabolism with a 4D-GIS Model: A Case Study in China. J. Clean. Prod. 2019, 228, 1446–1454. [Google Scholar] [CrossRef]

- Chidambaram, S. Application of Building Information Modelling for Reinforcement Waste Minimisation. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2019, 172, 3–13. [Google Scholar] [CrossRef]

- Arrigoni, A.; Beckett, C.T.S.; Ciancio, D.; Pelosato, R.; Dotelli, G.; Grillet, A.C. Rammed Earth Incorporating Recycled Concrete Aggregate: A Sustainable, Resistant and Breathable Construction Solution. Resour. Conserv. Recycl. 2018, 137, 11–20. [Google Scholar] [CrossRef]

- Gottsche, J.; Kelly, M. Assessing the Impact of Construction Waste Reduction on Selected Projects in Ireland. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2018, 171, 71–81. [Google Scholar] [CrossRef]

- Freitas, L.A.R.U.; Magrini, A. Waste Management in Industrial Construction: Investigating Contributions from Industrial Ecology. Sustainability 2017, 9, 1251. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-Cycle Energy Analysis of Prefabricated Building Components: An Input-Output-Based Hybrid Model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Lotfi, S.; Eggimann, M.; Wagner, E.; Mróz, R.; Deja, J. Performance of Recycled Aggregate Concrete Based on a New Concrete Recycling Technology. Constr. Build. Mater. 2015, 95, 243–256. [Google Scholar] [CrossRef]

- Silva, M.F.; Jayasinghe, L.B.; Waldmann, D.; Hertweck, F. Recyclable Architecture: Prefabricated and Recyclable Typologies. Sustainability 2020, 12, 1342. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Alshawi, M. Measuring the Impact of Prefabrication on Construction Waste Reduction: An Empirical Study in China. Resour. Conserv. Recycl. 2014, 91, 27–39. [Google Scholar] [CrossRef]

- Bjerregaard, M. Demolition Waste: Are We Doing Our Best? Proc. Inst. Civ. Eng. Waste Resour. Manag. 2008, 161, 45–49. [Google Scholar] [CrossRef]

- Chong, W.K.; Hermreck, C. Understanding Transportation Energy and Technical Metabolism of Construction Waste Recycling. Resour. Conserv. Recycl. 2010, 54, 579–590. [Google Scholar] [CrossRef]

- Poon, C.S.; Yu, A.T.W.; Ng, L.H. Comparison of Low-Waste Building Technologies Adopted in Public and Private Housing Projects in Hong Kong. Eng. Constr. Archit. Manag. 2003, 10, 88–98. [Google Scholar] [CrossRef]

- Lotfi, S.; Deja, J.; Rem, P.; Mróz, R.; Van Roekel, E.; Van Der Stelt, H. Mechanical Recycling of EOL Concrete into High-Grade Aggregates. Resour. Conserv. Recycl. 2014, 87, 117–125. [Google Scholar] [CrossRef]

- Dunlop, J. Sustainable Regeneration of Former Mackies Site, Belfast. Proc. Inst. Civ. Eng. Eng. Sustain. 2006, 159, 109–116. [Google Scholar] [CrossRef]

- Shen, L.Y.; Tam, V.W.Y.; Tam, C.M.; Drew, D. Mapping Approach for Examining Waste Management on Construction Sites. J. Constr. Eng. Manag. 2004, 130, 472–481. [Google Scholar] [CrossRef]

- McGrath, C. Waste Minimisation in Practice. Resour. Conserv. Recycl. 2001, 32, 227–238. [Google Scholar] [CrossRef]

- Keeton, J.M. The Road to Platinum Using the Usgbc’s Leed-Eb® Green Building Rating System to Retrofit the U.S. Environmental Protection Agency’s Region 10 Park Place Office Building. J. Green Build. 2010, 5, 55–75. [Google Scholar] [CrossRef]

- Wimalasena, B.A.D.S.; Madanayake, H.L.S.P.; Weerasinghe, I.P.T.R.; Ruwanpura, J.Y.; Hettiaratchi, J.P.A. Recycling as a Construction Waste Management Technique. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2010, 163, 49–58. [Google Scholar] [CrossRef]

- Li, J.; Liang, J.; Zuo, J.; Guo, H. Environmental Impact Assessment of Mobile Recycling of Demolition Waste in Shenzhen, China. J. Clean. Prod. 2020, 263, 121371. [Google Scholar] [CrossRef]

- Lu, M.; Lau, S.C.; Poon, C.S. Simulation Approach to Evaluating Cost Efficiency of Selective Demolition Practices: Case of Hong Kong’s Kai Tak Airport Demolition. J. Constr. Eng. Manag. 2009, 135, 448–457. [Google Scholar] [CrossRef]

- Huang, W.L.; Lin, D.H.; Chang, N.B.; Lin, K.S. Recycling of Construction and Demolition Waste via a Mechanical Sorting Process. Resour. Conserv. Recycl. 2002, 37, 23–37. [Google Scholar] [CrossRef]

- Lam, P.T.I.; Yu, A.T.W.; Wu, Z.; Poon, C.S. Methodology for Upstream Estimation of Construction Waste for New Building Projects. J. Clean. Prod. 2019, 230, 1003–1012. [Google Scholar] [CrossRef]

- Bakchan, A.; Faust, K.M.; Leite, F. Seven-Dimensional Automated Construction Waste Quantification and Management Framework: Integration with Project and Site Planning. Resour. Conserv. Recycl. 2019, 146, 462–474. [Google Scholar] [CrossRef]

- Kemp, I. The Benefits of Modular Structures Discussed by Ian Kemp of Caledonian Building Systems. Build. Eng. 2009, 84, 18. [Google Scholar]

- Alwan, Z.; Jones, P.; Holgate, P. Strategic Sustainable Development in the UK Construction Industry, through the Framework for Strategic Sustainable Development, Using Building Information Modelling. J. Clean. Prod. 2017, 140, 349–358. [Google Scholar] [CrossRef]

- de Souza, J. Recycle Your Construction Waste to Save Money and Reduce Your Environmental Impact. Build. Eng. Build. Eng. 2008, 83, 16. [Google Scholar]

- Mahpour, A. Prioritizing Barriers to Adopt Circular Economy in Construction and Demolition Waste Management. Resour. Conserv. Recycl. 2018, 134, 216–227. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, F.; Zhang, Y. Use of Building-Related Construction and Demolition Wastes in Highway Embankment: Laboratory and Field Evaluations. J. Clean. Prod. 2019, 230, 1051–1060. [Google Scholar] [CrossRef]

- Porras-Amores, C.; Astorqui, J.S.C.; Del Río Merino, M.; Villoria-Sáez, P.; Arrebola, C.V. Thermal Behavior of Traditional Lightweight Gypsum with Construction and Demolition Waste Materials. Dyna 2019, 94, 431–436. [Google Scholar] [CrossRef]

- Astorqui, J.S.C.; Del Río Merino, M.; Sáez, P.V.; Amores, C.P. Analysis of the Viability of Prefabricated Elements for Partitions Manufactured with Plaster and Eps from Waste Recycling. Dyna 2019, 94, 415–420. [Google Scholar] [CrossRef]

- Kamei, T.; Ahmed, A.; El Naggar, M.H. Performance of Ground Improvement Projects Incorporating Sustainable Reuse of Geo-Composite Wastes. Transp. Geotech. 2018, 14, 22–28. [Google Scholar] [CrossRef]

- Del Río Merino, M.; Astorqui, J.S.C.; Sáez, P.V.; Arrebola, C.V.; Sánchez, A.R.; Amores, C.P. Valorization of Building Retrofitting Waste as Alternative Materials in Gypsums. Open Constr. Build. Technol. J. 2017, 11, 334–342. [Google Scholar] [CrossRef][Green Version]

- Doan, D.T.; Chinda, T. Modeling Construction and Demolition Waste Recycling Program in Bangkok: Benefit and Cost Analysis. J. Constr. Eng. Manag. 2016, 142, 5016015. [Google Scholar] [CrossRef]

- Blengini, G.A. Life Cycle of Buildings, Demolition and Recycling Potential: A Case Study in Turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Hao, J.; Yuan, H.; Liu, J.; Chin, C.S.; Lu, W. A Model for Assessing the Economic Performance of Construction Waste Reduction. J. Clean. Prod. 2019, 232, 427–440. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakolan, M. Identifying Safety Archetypes of Construction Workers Using System Dynamics and Content Analysis. Saf. Sci. 2020, 129, 104831. [Google Scholar] [CrossRef]

- Wright, B.; Schwager, P.H. Online Survey Research: Can Response Factors Be Improved? J. Internet Commer. 2008, 7, 253–269. [Google Scholar] [CrossRef]

- Ott, R.L.; Longnecker, M.T. An Introduction to Statistical Methods and Data Analysis; Cengage Learning: Boston, MA, USA, 2015; ISBN 1305465520. [Google Scholar]

- Roscoe, J.T. Fundamental Research Statistics for the Behavioral Sciences; Holt, Rinehart and Winston: New York, NY, USA, 1975; ISBN 0030919347. [Google Scholar]

- Singh, K. Research Process. In Quantitative Social Research Methods; Sage Publisher India Pvt Ltd.: New Delhi, India, 2007; pp. 75–76. [Google Scholar]

- Darko, A.; Chan, A.P.C. Strategies to Promote Green Building Technologies Adoption in Developing Countries: The Case of Ghana. Build. Environ. 2018, 130, 74–84. [Google Scholar] [CrossRef]

- Lee, Z.P.; Rahman, R.A.; Doh, S.I. Critical Success Factors for Implementing Design-Build: Analysing Malaysian Public Projects. J. Eng. Des. Technol. 2021, 712, 012045. [Google Scholar] [CrossRef]

- Lee, Z.P.; Rahman, R.A.; Doh, S.I. Key Drivers for Adopting Design Build: A Comparative Study between Project Stakeholders. Phys. Chem. Earth, Parts A/B/C 2020, 120, 102945. [Google Scholar] [CrossRef]

- Adabre, M.A.; Chan, A.P.C. Critical Success Factors (CSFs) for Sustainable Affordable Housing. Build. Environ. 2019, 156, 203–214. [Google Scholar] [CrossRef]

- Hu, Y.; Chan, A.P.C.; Le, Y. Understanding the Determinants of Program Organization for Construction Megaproject Success: Case Study of the Shanghai Expo Construction. J. Manag. Eng. 2015, 31, 05014019. [Google Scholar] [CrossRef]

- Kruskal, W.H.; Wallis, W.A. Use of Ranks in One-Criterion Variance Analysis. J. Am. Stat. Assoc. 1952, 47, 583–621. [Google Scholar] [CrossRef]

- Dunn, O.J. Multiple Comparisons Using Rank Sums. Technometrics 1964, 6, 241–252. [Google Scholar] [CrossRef]

- Heberle, H.; Meirelles, G.V.; da Silva, F.R.; Telles, G.P.; Minghim, R. InteractiVenn: A Web-Based Tool for the Analysis of Sets through Venn Diagrams. BMC Bioinforma. 2015, 16, 169. [Google Scholar] [CrossRef]

- Brito, C.; Crespo, E.G.; Paulo, O.S. Modelling Wildlife Distributions: Logistic Multiple Regression vs Overlap Analysis. Ecography Cop. 1999, 22, 251–260. [Google Scholar] [CrossRef]

- Farouk, A.M.; Rahman, R.A.; Romali, N.S. Economic Analysis of Rehabilitation Approaches for Water Distribution Networks: Comparative Study between Egypt and Malaysia. J. Eng. Des. Technol. 2021; online ahead of print. [Google Scholar] [CrossRef]

- King, S.S.; Rahman, R.A.; Fauzi, M.A.; Haron, A.T. Critical Analysis of Pandemic Impact on AEC Organizations: The COVID-19 Case. J. Eng. Des. Technol. 2021, 20, 358–383. [Google Scholar] [CrossRef]

- Pallant, J. SPSS Survival Manual: A Step by Step Guide to Data Analysis Using IBM SPSS; Routledge: London, UK, 2020; ISBN 1000256235. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis: A Global Perspective, 7th ed.; Pearson Education: London, UK, 2010. [Google Scholar]

- Bartlett, M.S. A Note on the Multiplying Factors for Various χ2 Approximations. J. R. Stat. Soc. Ser. B 1954, 16, 296–298. [Google Scholar] [CrossRef]

- Kaiser, H.F. An Analytic Rotational Criterion for Factor Analysis. Amer. Psychol. 1955, 10, 438. [Google Scholar]

- Kline, P. An Easy Guide to Factor Analysis; Routledge: London, UK, 2014; ISBN 1315788136. [Google Scholar]

- Field, A. Discovering Statistics Using IBM SPSS Statistics; Sage Publications Ltd.: Newbury Park, CA, USA, 2013. [Google Scholar]

- Comrey, A.L.; Lee, H.B. A First Course in Factor Analysis; Psychology Press: London, UK, 2013; ISBN 1315827506. [Google Scholar]

- Gulghane, A.A.; Khandve, P. V Management for Construction Materials and Control of Construction Waste in Construction Industry: A Review. Int. J. Eng. Res. Appl. 2015, 5, 59–64. [Google Scholar]

- Ge, X.J.; Livesey, P.; Wang, J.; Huang, S.; He, X.; Zhang, C. Deconstruction Waste Management through 3d Reconstruction and Bim: A Case Study. Vis. Eng. 2017, 5, 13. [Google Scholar] [CrossRef]

- Liu, J.; Hua, Z.; Pang, Y.; Wang, X. Risk Sharing for PPP Project in Construction Waste Recycling Industry in China. Environ. Sci. Pollut. Res. 2021, 29, 12614–12628. [Google Scholar] [CrossRef]

- Kamal, M.F.M.; Affandi, H.M.; Sohimi, N.E.; Musid, N.H.A.; Ali, M.R.M.; Nashir, I.M. Malaysian Carbon Reduction and Environmental Sustainability Tool (MyCREST) Qualified Professional Training Assessment. J. Tech. Educ. Train. 2019, 11. [Google Scholar]

- Ohueri, C.C.; Enegbuma, W.I.; Habil, H. MyCREST Embedded Framework for Enhancing the Adoption of Green Office Building Development in Sarawak. Built Environ. Proj. Asset Manag. 2019, 10, 215–230. [Google Scholar] [CrossRef]

- Liu, H.; Long, H.; Li, X. Identification of Critical Factors in Construction and Demolition Waste Recycling by the Grey-DEMATEL Approach: A Chinese Perspective. Environ. Sci. Pollut. Res. 2020, 27, 8507–8525. [Google Scholar] [CrossRef]

- Poon, C.S.; Yu, A.T.W.; Wong, A.; Yip, R. Quantifying the Impact of Construction Waste Charging Scheme on Construction Waste Management in Hong Kong. J. Constr. Eng. Manag. 2013, 139, 466–479. [Google Scholar] [CrossRef]

- Badraddin, A.K.; Radzi, A.R.; Almutairi, S.; Rahman, R.A. Critical Success Factors for Concrete Recycling in Construction Projects. Sustainability 2022, 14, 3102. [Google Scholar] [CrossRef]

| Attributes | Categories | (n = 106) | Attributes | Categories | (n = 106) | ||

|---|---|---|---|---|---|---|---|

| n | % | n | % | ||||

| Position | Project Manager | 106 | 100.0 | Location | Central Region | 51 | 48.1 |

| Organization | Contractor | 63 | 59.4 | Southern Region | 20 | 18.9 | |

| Consultants | 22 | 20.8 | Northern region | 16 | 15.1 | ||

| Clients | 16 | 15.1 | East Malaysia | 15 | 14.2 | ||

| Other. | 5 | 10.7 | East Coast Region | 4 | 3.8 | ||

| Experience | 11–20 Years | 45 | 42.5 | Contractor Grade | Grade 7-No limit | 56 | 52.8 |

| Not applicable | 37 | 34.9 | |||||

| More than 20 years | 25 | 23.6 | Grade 1 | 4 | 3.8 | ||

| Grade 2 | 4 | 3.8 | |||||

| 6–10 years | 23 | 21.7 | Grade 6 | 2 | 1.9 | ||

| Grade 3 | 1 | 0.9 | |||||

| 1–5 years | 13 | 12.3 | Grade 4 | 1 | 0.9 | ||

| Grade 5 | 1 | 0.9 | |||||

| Code | All Respondents | Contractor | Consultants | Clients | Other | Kruskal–Wallis p-Value | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | NV | Rank | Mean | SD | Mean | SD | Mean | SD | Mean | SD | ||

| Cost | |||||||||||||

| S06 | 3.07 | 0.796 | 1.000 a | 1 | 2.97 | 0.822 | 3.09 | 0.684 | 3.38 | 0.885 | 3.20 | 0.447 | 0.476 |

| S07 | 2.99 | 0.724 | 0.906 a | 2 | 2.87 | 0.684 | 3.05 | 0.722 | 3.25 | 0.856 | 3.40 | 0.548 | 0.172 |

| S08 | 2.89 | 0.666 | 0.776 a | 3 | 2.78 | 0.683 | 2.95 | 0.635 | 3.19 | 0.655 | 3.00 | 0.000 | 0.124 |

| S01 | 2.85 | 0.728 | 0.729 a | 4 | 2.76 | 0.756 | 2.86 | 0.640 | 2.94 | 0.574 | 3.60 | 0.894 | 0.132 |

| S12 | 2.82 | 0.778 | 0.694 a | 5 | 2.70 | 0.687 | 3.00 | 0.976 | 2.88 | 0.806 | 3.40 | 0.548 | 0.148 |

| S10 | 2.81 | 0.794 | 0.682 a | 6 | 2.83 | 0.834 | 2.68 | 0.716 | 2.75 | 0.775 | 3.40 | 0.548 | 0.299 |

| S09 | 2.76 | 0.724 | 0.624 a | 7 | 2.76 | 0.777 | 2.73 | 0.631 | 2.75 | 0.683 | 3.00 | 0.707 | 0.866 |

| S05 | 2.63 | 0.760 | 0.459 | 8 | 2.67 | 0.762 | 2.45 | 0.739 | 2.56 | 0.814 | 3.20 | 0.447 | 0.142 |

| S03 | 2.55 | 0.745 | 0.353 | 9 | 2.46 | 0.800 | 2.77 | 0.685 | 2.56 | 0.629 | 2.60 | 0.548 | 0.242 |

| S13 | 2.54 | 0.706 | 0.341 | 10 | 2.48 | 0.715 | 2.36 | 0.658 | 2.94 | 0.680 | 2.80 | 0.447 | 0.058 |

| S02 | 2.53 | 0.693 | 0.329 | 11 | 2.54 | 0.714 | 2.50 | 0.598 | 2.38 | 0.806 | 3.00 | 0.000 | 0.095 |

| S11 | 2.52 | 0.693 | 0.318 | 12 | 2.49 | 0.693 | 2.45 | 0.671 | 2.69 | 0.793 | 2.60 | 0.548 | 0.939 |

| S04 | 2.26 | 0.694 | 0.000 | 13 | 2.33 | 0.741 | 2.14 | 0.640 | 2.13 | 0.619 | 2.40 | 0.548 | 0.536 |

| Effectiveness | |||||||||||||

| S06 | 3.58 | 0.850 | 1.000 a | 1 | 3.41 | 0.816 | 3.86 | 0.834 | 3.63 | 0.885 | 4.20 | 0.837 | 0.041 b |

| S04 | 3.57 | 0.805 | 0.960 a | 2 | 3.48 | 0.759 | 3.86 | 0.941 | 3.63 | 0.719 | 3.20 | 0.837 | 0.054 |

| S12 | 3.54 | 0.819 | 0.846 a | 3 | 3.46 | 0.858 | 3.73 | 0.767 | 3.50 | 0.816 | 3.80 | 0.447 | 0.475 |

| S07 | 3.53 | 0.907 | 0.808 a | 4 | 3.38 | 0.974 | 3.73 | 0.827 | 3.75 | 0.775 | 3.80 | 0.447 | 0.373 |

| S11 | 3.50 | 0.759 | 0.692 a | 5 | 3.41 | 0.816 | 3.77 | 0.752 | 3.50 | 0.516 | 3.40 | 0.548 | 0.203 |

| S03 | 3.46 | 0.917 | 0.538 | 6 | 3.25 | 0.933 | 3.82 | 0.958 | 3.69 | 0.704 | 3.80 | 0.447 | 0.062 |

| S01 | 3.45 | 0.947 | 0.500 | 7 | 3.27 | 0.954 | 3.77 | 0.922 | 3.63 | 0.957 | 3.80 | 0.447 | 0.107 |

| S13 | 3.45 | 0.917 | 0.500 | 8 | 3.35 | 0.953 | 3.91 | 0.921 | 3.31 | 0.602 | 3.20 | 0.837 | 0.093 |

| S05 | 3.44 | 0.895 | 0.462 | 9 | 3.27 | 0.954 | 3.55 | 0.671 | 3.75 | 0.856 | 4.20 | 0.447 | 0.036 b |

| S08 | 3.38 | 0.961 | 0.192 | 10 | 3.30 | 0.891 | 3.59 | 0.854 | 3.38 | 0.806 | 3.40 | 0.894 | 0.607 |

| S02 | 3.38 | 0.867 | 0.192 | 11 | 3.25 | 0.999 | 3.36 | 0.902 | 3.94 | 0.854 | 3.20 | 0.447 | 0.032 b |

| S09 | 3.34 | 0.925 | 0.038 | 12 | 3.21 | 1.003 | 3.73 | 0.767 | 3.31 | 0.704 | 3.40 | 0.894 | 0.193 |

| S10 | 3.33 | 1.021 | 0.000 | 13 | 3.13 | 1.070 | 3.45 | 1.101 | 3.88 | 0.500 | 3.60 | 0.548 | 0.037 b |

| Easiness | |||||||||||||

| S06 | 3.25 | 0.944 | 1.000 a | 1 | 3.17 | 0.871 | 3.14 | 1.207 | 3.44 | 0.814 | 4.00 | 0.707 | 0.148 |

| S07 | 3.02 | 0.828 | 0.733 a | 2 | 2.33 | 0.622 | 2.41 | 0.666 | 2.50 | 0.966 | 2.80 | 0.837 | 0.480 |

| S12 | 2.95 | 0.832 | 0.656 a | 3 | 2.81 | 0.859 | 3.14 | 0.834 | 3.06 | 0.680 | 3.60 | 0.548 | 0.055 |

| S05 | 2.94 | 0.934 | 0.644 a | 4 | 3.08 | 0.867 | 2.82 | 0.853 | 3.00 | 0.632 | 3.20 | 0.837 | 0.275 |

| S01 | 2.92 | 0.973 | 0.622 a | 5 | 2.54 | 0.668 | 2.59 | 0.796 | 2.81 | 0.655 | 3.20 | 0.447 | 0.590 |

| S09 | 2.86 | 0.856 | 0.544 | 6 | 2.78 | 0.906 | 2.91 | 0.921 | 2.75 | 0.931 | 3.40 | 0.894 | 0.225 |

| S08 | 2.84 | 0.745 | 0.522 | 7 | 2.84 | 0.884 | 2.86 | 0.941 | 3.31 | 1.138 | 3.00 | 1.581 | 0.380 |

| S03 | 2.83 | 0.910 | 0.511 | 8 | 2.40 | 0.730 | 2.59 | 0.908 | 2.63 | 0.806 | 3.20 | 0.447 | 0.504 |

| S02 | 2.81 | 0.896 | 0.489 | 9 | 2.86 | 0.931 | 2.95 | 0.999 | 3.06 | 0.929 | 3.60 | 0.548 | 0.667 |

| S10 | 2.62 | 0.798 | 0.267 | 10 | 2.75 | 0.695 | 3.05 | 0.785 | 2.81 | 0.834 | 3.20 | 0.837 | 0.651 |

| S11 | 2.62 | 0.696 | 0.267 | 11 | 2.81 | 0.877 | 2.82 | 1.053 | 2.69 | 0.793 | 3.20 | 0.837 | 0.128 |

| S13 | 2.51 | 0.784 | 0.133 | 12 | 2.89 | 0.845 | 3.00 | 0.690 | 2.50 | 1.033 | 3.00 | 1.000 | 0.122 |

| S04 | 2.40 | 0.699 | 0.000 | 13 | 2.62 | 0.812 | 2.55 | 0.739 | 2.81 | 0.750 | 2.40 | 1.140 | 0.675 |

| Code | Strategy | Contractors-Clients | Contractors-Consultants | Consultants-Clients |

|---|---|---|---|---|

| S06 | Organize temporary bins in each construction zone | 0.328 | 0.020 a | 0.359 |

| S05 | Prepare dedicated spaces to sort CW | 0.047 a | 0.339 | 0.331 |

| S02 | Adopt off-site construction practices | 0.005 a | 0.680 | 0.036 a |

| S10 | Use information technology to facilitate CWR processes | 0.006 a | 0.157 | 0.200 |

| Code | Strategy | Usability Index | Standard Deviation | NV | Rank |

|---|---|---|---|---|---|

| S06 | Organize temporary bins in each construction zone | 4.64 | 3.232 | 1.000 a | 1 |

| S07 | Identify construction activities that produce recyclable materials | 4.07 | 2.701 | 0.746 a | 2 |

| S12 | Enhance company policies related to CW | 3.84 | 2.750 | 0.644 a | 3 |

| S01 | Raise project team awareness on CW | 3.67 | 3.166 | 0.567 | 4 |

| S05 | Prepare dedicated spaces to sort CW | 3.42 | 2.474 | 0.456 | 5 |

| S08 | Adopt a database for collecting CW | 3.42 | 1.891 | 0.457 | 6 |

| S09 | Use information technology to facilitate CW recycling processes (e.g., website) | 3.24 | 1.850 | 0.376 | 7 |

| S10 | Use CW recycled materials as alternative construction materials | 3.18 | 2.751 | 0.347 | 8 |

| S03 | Adopt on-site construction practices (e.g., Mobile Recycling) | 3.09 | 1.724 | 0.310 | 9 |

| S02 | Adopt off-site construction practices (e.g., prefabrication) | 2.96 | 2.161 | 0.252 | 10 |

| S11 | Satisfy the requirements of CW recycling processes | 2.83 | 1.443 | 0.191 | 11 |

| S13 | Adhere to national legislations related to CW | 2.73 | 1.754 | 0.149 | 12 |

| S04 | Acquire certifications related to CWR from the government (e.g., Green Building, LEED) | 2.40 | 1.018 | 0.000 | 13 |

| Code | Strategy | Factor Loadings | Eigenvalue | PVE | CPVE | Cronbach’s Alpha |

|---|---|---|---|---|---|---|

| Factor 1: Workplace laws and policy management | — | 5.715 | 43.961 | 43.961 | 0.876 | |

| S13 | Adhere to national legislations related to CW | 0.886 | — | — | — | — |

| S02 | Adopt off-site construction practices (e.g., prefabrication) | 0.871 | — | — | — | — |

| S10 | Use CW recycled materials as alternative construction materials | 0.856 | — | — | — | — |

| S11 | Satisfy the requirements of CW recycling processes | 0.833 | — | — | — | — |

| S05 | Prepare dedicated spaces to sort CW | 0.787 | — | — | — | — |

| S12 | * Enhance company policies related to CW | 0.751 | — | — | — | — |

| S04 | Acquire certifications related to CWR from the government (e.g., Green Building, LEED) | 0.504 | — | — | — | — |

| S07 | * Identify construction activities that produce recyclable materials | 0.473 | — | — | — | — |

| Factor 2: Information technology and capability management | — | 1.941 | 14.929 | 58.890 | 0.716 | |

| S08 | Adopt a database for collecting CW | 0.835 | — | — | — | — |

| S09 | Use information technology to facilitate CW recycling processes (e.g., website) | 0.831 | — | — | — | — |

| Factor 3: Workforce and workplace management | — | 1.112 | 8.554 | 67.445 | 0.725 | |

| S01 | Raise project team awareness on CW | 0.711 | — | — | — | — |

| S06 | * Organize temporary bins in each construction zone | 0.674 | — | — | — | — |

| S03 | Adopt on-site construction practices (e.g., Mobile Recycling) | 0.585 | — | — | — | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omer, M.M.; Rahman, R.A.; Almutairi, S. Strategies for Enhancing Construction Waste Recycling: A Usability Analysis. Sustainability 2022, 14, 5907. https://doi.org/10.3390/su14105907

Omer MM, Rahman RA, Almutairi S. Strategies for Enhancing Construction Waste Recycling: A Usability Analysis. Sustainability. 2022; 14(10):5907. https://doi.org/10.3390/su14105907

Chicago/Turabian StyleOmer, Mazen M., Rahimi A. Rahman, and Saud Almutairi. 2022. "Strategies for Enhancing Construction Waste Recycling: A Usability Analysis" Sustainability 14, no. 10: 5907. https://doi.org/10.3390/su14105907

APA StyleOmer, M. M., Rahman, R. A., & Almutairi, S. (2022). Strategies for Enhancing Construction Waste Recycling: A Usability Analysis. Sustainability, 14(10), 5907. https://doi.org/10.3390/su14105907