Energy Efficiency in Production of Swiftlet Edible Bird’s Nest

Abstract

:1. Introduction

- To examine the evaluation of the flow of energy consumption based on the different resources in EBN production;

- To investigate the GHG emission rate based on the different resources in EBN production;

- To assess the efficiency of energy consumption based on four inputs and one output in EBN production by using the DEA approach;

- To calculate the optimum energy and GHG emissions rate to reduce the consumption of energy and emission in EBN production;

- To analyze the potential determinants of the swiftlet ranches’ efficiency for improvement in energy savings and emissions reduction by using the Tobit regression estimation method.

2. Materials and Methods

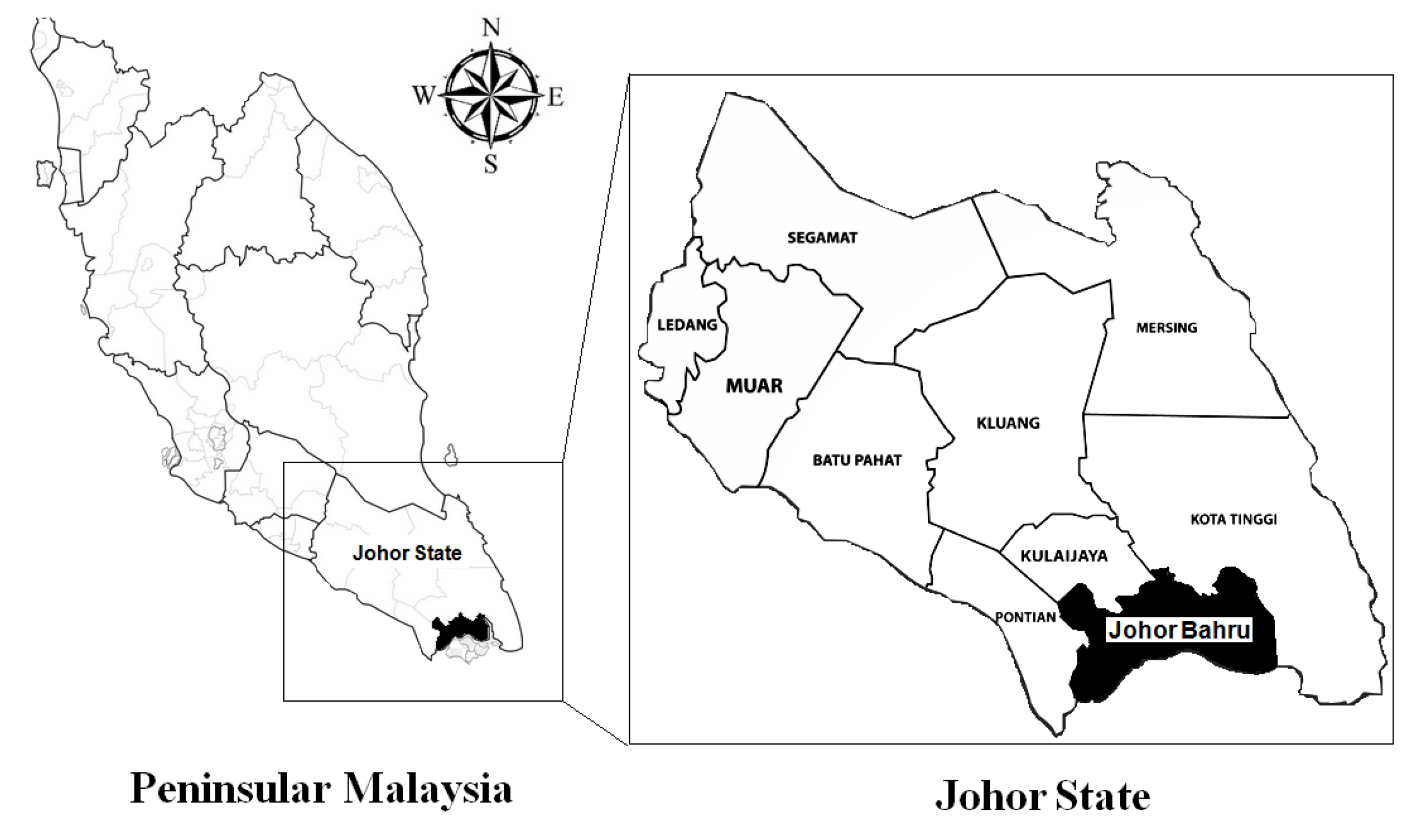

2.1. Collection of Data

2.2. Energy Equivalent in EBN Production

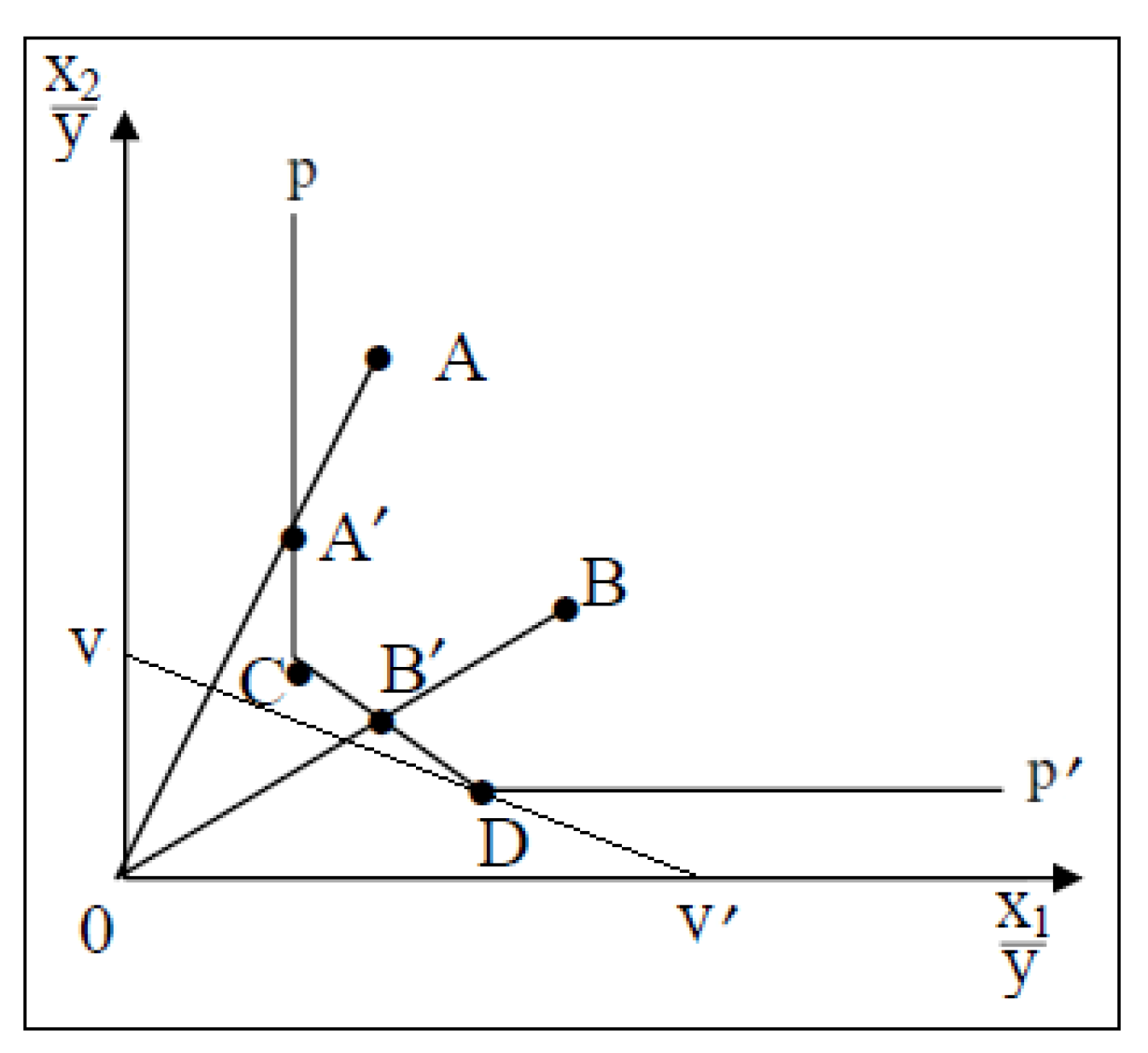

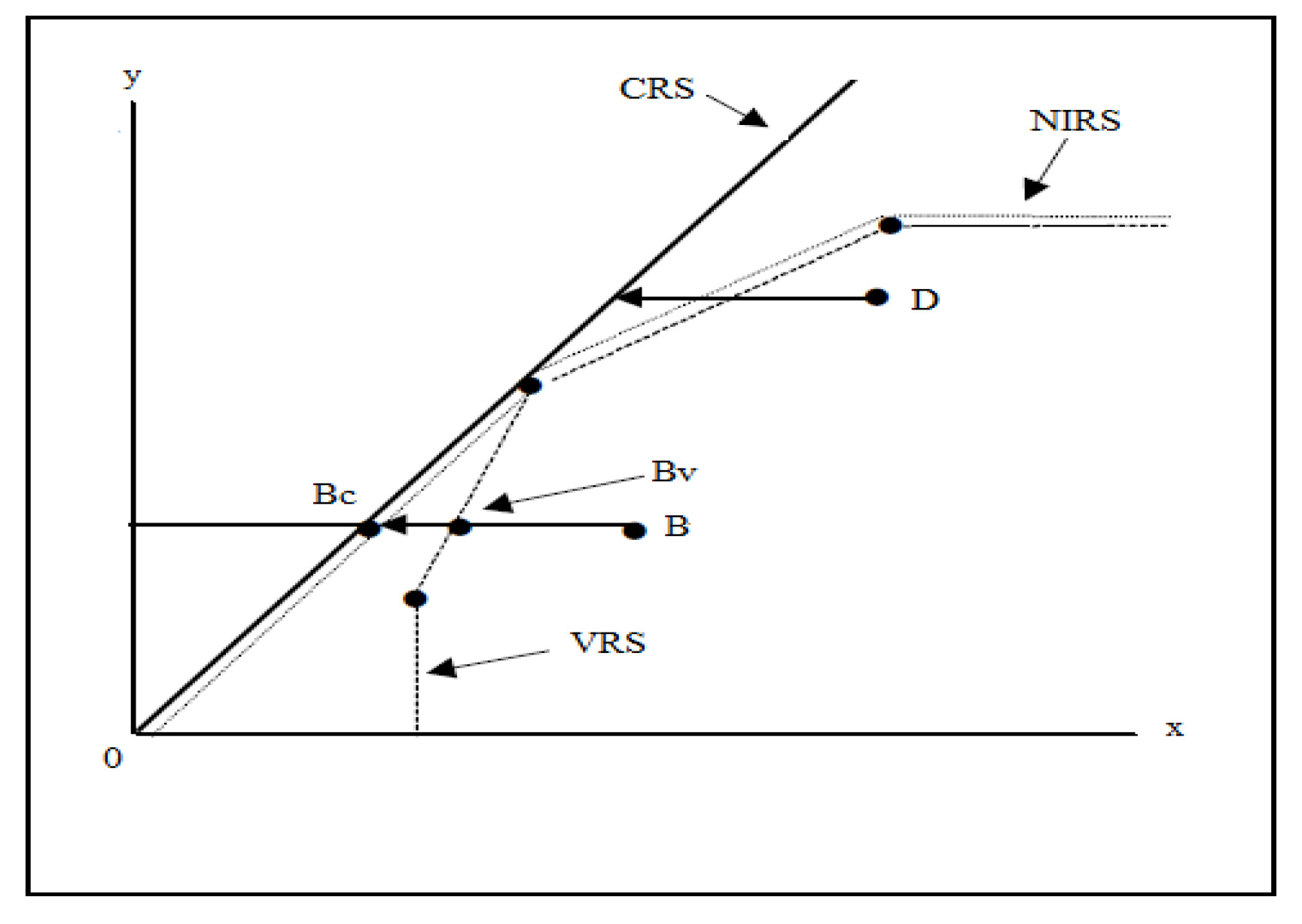

2.3. DEA Method for Efficiency Estimation

2.4. Emission of GHG in EBN Production

2.5. Tobit Regression Estimation Method

3. Results and Discussion

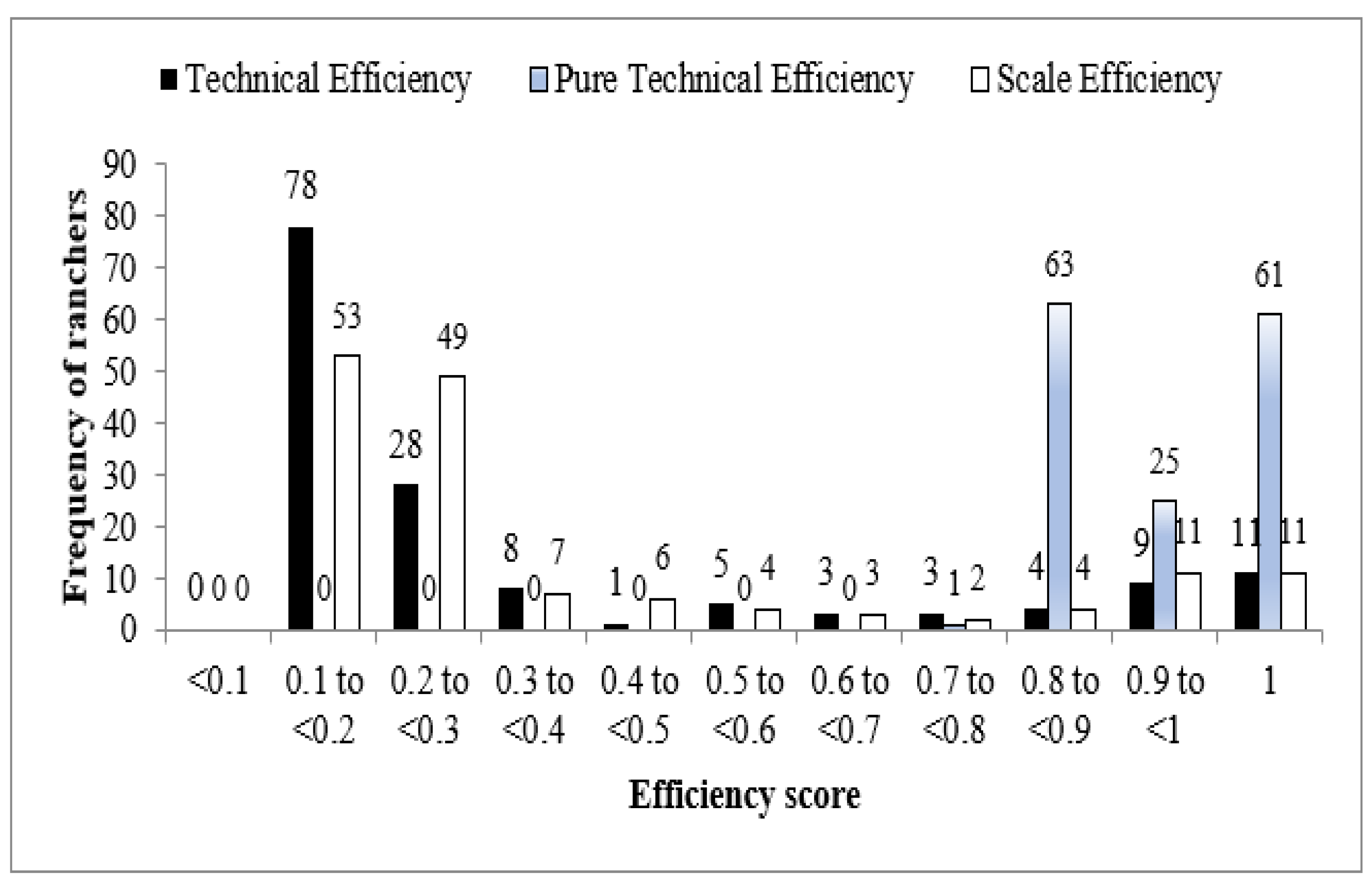

3.1. Ranch Efficiency

3.2. Ranking Ranch Efficiency

3.3. Pattern of Input Consumption in Efficient and Inefficient Ranches

3.4. Identifying Optimum Energy Requirement and Energy Savings to Avoid Wastage

3.5. Energy Indices Improvements

3.6. Optimum GHG Emission and Emission Reduction to Enhance Health Environment

3.7. Other Determinants on Ranches’ TE, PTE, and SE

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lim, C. Make Millions from Swiftlet Farming: A Definitive Guide; True Wealth Sdn Bhd Publication: Kuala Lumpur, Malaysia, 2006. [Google Scholar]

- Rabu, M.R.; Nazmi, M.S.M. Malaysia’s Edible Bird Nest (EBN) Industry. Economic and Technology Management Centre; Food and Fertilizer Technology Center for the Asian and Pacific Region Publications: Suva, Fiji, 2015. [Google Scholar]

- Anuar, A.; Ang, Y.P.; Nurul Zahirah, M.A.; Mokhtar Azizi, M.D. Investment in swiftlet hotels in Malaysia—Does ROI compensate investment risks? Afr. J. Bus. Manag. 2013, 7, 3936–3943. [Google Scholar]

- Nabavi-Pelesaraei, A.; Abdi, R.; Rafiee, S.; Bagheri, I. Determination of efficient and inefficient units for watermelon production-a case study: Gulian province of Iran. J. Saudi Soc. Agric. Sci. 2016, 15, 162–170. [Google Scholar] [CrossRef] [Green Version]

- Hatirli, S.A.; Ozkan, B.; Fert, C. Energy inputs and crop yield relationship in greenhouse tomato production. Renew. Energy 2006, 31, 427–438. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Nabavi-Pelesaraei, A.; Khanali, M.; Ghahderijani, M.; Chau, K.W. Application of data envelopment analysis approach for optimization of energy use and reduction of greenhouse gas emission in peanut production of Iran. J. Clean. Prod. 2018, 172, 1327–1335. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, H.Q.; Liu, S.S.; Zhang, H.B. Technological innovation, environmental regulation, and green total factor efficiency of industrial water resources. J. Clean. Prod. 2019, 211, 61–69. [Google Scholar] [CrossRef]

- Heidari, M.D.; Omid, M. Energy use patterns and econometric models of major greenhouse vegetable productions in Iran. Energy 2011, 36, 220–225. [Google Scholar] [CrossRef]

- Khoshroo, A.; Mulwa, R.; Emrouznejad, A.; Arabi, B. A non-parametric Data Envelopment Analysis approach for improving energy efficiency of grape production. Energy 2013, 63, 189–194. [Google Scholar] [CrossRef]

- Mousavi-Avval, S.H.; Rafiee, S.; Jafari, A.; Mohammadi, A. Optimization of energy consumption for soybean production using Data Envelopment Analysis (DEA) approach. Appl. Energy 2011, 88, 3765–3772. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Omid, M.; Mousazadeh, H. Applying Data Envelopment Analysis approach to improve energy efficiency and reduce GHG (greenhouse gas) emission of wheat production. Energy 2013, 58, 588–593. [Google Scholar] [CrossRef]

- Bolandnazar, E.; Keyhani, A.; Omid, M. Determination of efficient and inefficient greenhouse cucumber producers using Data Envelopment Analysis approach, a case study: Jiroft city in Iran. J. Clean. Prod. 2014, 79, 108–115. [Google Scholar] [CrossRef]

- Heidari, M.D.; Omid, M.; Akram, A. Optimization of energy consumption of broiler production farms using Data Envelopment Analysis Approach. Mod. Appl. Sci. 2011, 5, 69–78. [Google Scholar] [CrossRef] [Green Version]

- Amid, S.; Gundoshmian, T.M.; Shahgoli, G.; Rafiee, S. Energy use pattern and optimization of energy required for broiler production using data envelopment analysis. Inf. Processing Agric. 2016, 3, 83–91. [Google Scholar] [CrossRef] [Green Version]

- Sefeedpari, P. Assessment and optimization of energy consumption in dairy farm: Energy efficiency. Iran. J. Energy Environ. 2012, 3, 213–224. [Google Scholar] [CrossRef]

- Guo, L.; Wu, Y.; Liu, M.; Wang, B.; Ge, Y.; Chen, Y. Determination of edible bird’s nests by FTIR and SDS-PAGE coupled with multivariate analysis. Food Control 2017, 80, 259–266. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Abdi, R.; Rafiee, S.; Taromi, K. Applying data envelopment analysis approach to improve energy efficiency and reduce greenhouse gas emission of rice production. Eng. Agric. Environ. Food 2014, 7, 155–162. [Google Scholar] [CrossRef]

- Oryza, O. Birds Nest Extract; Oryza Oil and Fat Chemical Co., LTD: Ichinomiya-City, Japan, 2013. [Google Scholar]

- Cooper, W.W.; Seiford, L.M.; Zhu, J. Handbook on Data Envelopment Analysis; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Farrell, M.J. The measurement of productive efficiency. J. R. Stat. Soc. Assoc. 1957, 120, 253–281. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some models for estimating technical and scale efficiencies in data envelopment analysis. J. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar]

- Coelli, T.J.; Rao, D.S.P.; O’Donnell, C.J.; Battese, G.E. An Introduction to Efficiency and Productivity Analysis; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Asgharipour, M.R.; Mousavinik, S.M.; Enayat, F.F. Evaluation of energy input and greenhouse gases emissions from alfalfa production in the Sistan region, Iran. Energy Rep. 2016, 2, 135–140. [Google Scholar] [CrossRef] [Green Version]

- Wan Khairy, W.I.; Mohd Rafi, Y.; Azwan, A. The importance of technical knowledge in sustainability of Malay’s bird’s nest industry in Malaysia. J. Appl. Environ. Biol. Sci. 2015, 5, 190–196. [Google Scholar]

- Zulnaidah, M.; Shahwahid, M. An Economic Analysis of Swiftlet Edible Birds’ Nest Industry; Forestry Department Peninsular Malaysia, Kuala Lumpur Publications: Kuala Lumpur, Malaysia, 2012. [Google Scholar]

- Prehoda, E.W.; Pearce, J.M. Potential lives saved by replacing coal with solar photovoltaic electricity production in the U.S. Renew. Sustain. Energy Rev. 2017, 80, 710–715. [Google Scholar] [CrossRef] [Green Version]

- Hendri, S.C. Strategi Jitu Memikat Walet; PT AgroMedia Pustaka Publications: Jakarta Selatan, Indonesia, 2007. [Google Scholar]

| Items (Unit) | Energy Equivalent (MJ Unit−1) | Quantity Per Unit Area (Unit Sqft−1) | Total Energy Equivalent (MJ Sqft−1) | Total Energy Equivalent (%) | |

|---|---|---|---|---|---|

| A. Input | |||||

| 1. Human labor (h) | 1.96 | [6,9,14,17] | 0.00168 | 0.00330 | 0.24 |

| 2. Electricity (kWh) | 11.93 | [6,9,14] | 0.11556 | 1.37861 | 98.51 |

| 3. Water irrigation (m3) | 1.02 | [9,10] | 0.01444 | 0.01473 | 1.05 |

| 4. Pesticides (kg) | 101.20 | [9,10] | 0.00003 | 0.00289 | 0.21 |

| Total energy input (MJ) | 1.39952 | 100 | |||

| B. Output | |||||

| Edible bird’s nest (kg) | 15.65 | [18] | 0.00299 | 0.04678 | |

| Input (Unit) | GHG Coefficient (kgCo2eq Unit−1) | GHG Emissions (kgCo2eq Sqft−1) | GHG Emission (%) |

|---|---|---|---|

| 1. Electricity (kWh) | 0.608 [17] | 0.07026 | 99.79 |

| 2. Pesticides (kg) | 5.10 [11,24] | 0.00015 | 0.21 |

| Total GHG emissions (kg CO2eq.) | 5.708 | 0.07041 | 100 |

| Particular | CRS under CCR Model | VRS under BCC Model | |

|---|---|---|---|

| TE | PTE | SE | |

| Average | 0.35361 | 0.93071 | 0.37199 |

| SD | 0.29255 | 0.06626 | 0.29173 |

| Min | 0.14000 | 0.72900 | 0.14400 |

| Max | 1.00000 | 1.00000 | 1.00000 |

| Rank | Ranch No. | Frequency in Referent Set |

|---|---|---|

| 1 | 23 | 79 |

| 2 | 43 | 72 |

| 3 | 37 | 61 |

| 4 | 40 | 37 |

| 5 | 39 | 35 |

| 6 | 48 | 15 |

| 7 | 4 | 10 |

| 8 | 41 | 5 |

| 9 | 6 | 3 |

| 10 | 36 | 3 |

| Items (Unit) | 10 Most Efficient Ranches (MJ sqft−1) | Inefficient Ranches (MJ Sqft−1) | Difference (%) |

|---|---|---|---|

| A. Input. | |||

| 1. Human labor (h) | 0.00272 | 0.00359 | 24.13 |

| 2. Electricity (kWh) | 1.47423 | 1.47046 | −0.26 |

| 3. Water irrigation (m3) | 0.01560 | 0.01573 | 0.82 |

| 4. Pesticides (kg) | 0.00238 | 0.00314 | 24.28 |

| B. Output | |||

| 1. Edible bird’s nest (kg) | 0.12728 | 0.04347 | −192.78 |

| Items (Unit) | Optimum Energy Requirement (MJ Sqft−1) | Energy Saving (MJ Sqft−1) | Energy Saving (%) | Contribution to Total Energy Saving (%) |

|---|---|---|---|---|

| 1. Human labor (h) | 0.00105 | 0.00225 | 68.24 | 0.25 |

| 2. Electricity (kWh) | 0.49838 | 0.88022 | 63.85 | 98.47 |

| 3. Water irrigation (m3) | 0.00534 | 0.00939 | 63.77 | 1.05 |

| 4. Pesticides (kg) | 0.00084 | 0.00204 | 70.83 | 0.23 |

| Total energy input (MJ) | 0.50561 | 0.89391 | 63.87 | 100 |

| Items (Unit) | Unit | Present Quantity | Optimum Quantity | Difference (%) |

|---|---|---|---|---|

| Energy use efficiency | − | 910.47043 | 2520.16635 | 176.80 |

| Energy productivity | kg MJ−1 | 58.17702 | 161.03299 | 176.80 |

| Specific energy | MJ kg−1 | 0.01719 | 0.00621 | −63.87 |

| Net energy | MJ sqft−1 | 1272.82348 | 1273.71739 | 0.07 |

| Direct energy a | MJ sqft−1 | 0.00330 (0.24) | 0.00105 (0.21) | −68.24 |

| Indirect Energy b | MJ sqft−1 | 1.39622 (99.76) | 0.50456 (99.79) | −63.86 |

| Renewable Energy c | MJ sqft−1 | 0.01803 (1.29) | 0.00639 (1.26) | −64.59 |

| Non-renewable Energy d | MJ sqft−1 | 1.38149 (98.71) | 0.49923 (98.74) | −63.86 |

| Total Energy input | MJ sqft−1 | 1.39952 (100) | 0.50561 (100) | −63.87 |

| Items (Unit) | Optimum GHG Emissions (kgCo2eq Sqft−1) | Emission Reductions (kgCo2eq Sqft−1) | Emissions Reduction (%) | Contribution to Total Emissions Reduction (%) |

|---|---|---|---|---|

| 1. Electricity (kWh) | 0.02540 | 0.04486 | 63.85 | 99.76 |

| 2. Pesticides (kg) | 0.00004 | 0.00011 | 73.33 | 0.24 |

| Total GHG emissions (kgCo2eq) | 0.02544 | 0.04497 | 63.86 | 100 |

| Variable | TE | PTE | SE | |||

|---|---|---|---|---|---|---|

| Coefficient | t-Ratio | Coefficient | t-Ratio | Coefficient | t-Ratio | |

| C | −6.76255 *** | −3.06419 | 0.30832 | 0.31196 | −6.73695 *** | −3.11295 |

| Capital | −0.05930 | −0.27327 | 0.02686 | 0.27529 | −0.07368 | −0.34631 |

| Size | 0.05624 | 0.22803 | −0.17494 | −1.56546 | 0.10272 | 0.42478 |

| Plank | 1.50957 *** | 4.65127 | 0.41069 *** | 2.80334 | 1.45602 *** | 4.57479 |

| R2 | 0.47394 | 0.11519 | 0.49026 | |||

| Adj. R2 | 0.45943 | 0.09079 | 0.47620 | |||

| No. of Obs. | 150 | 150 | 150 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alpandi, R.M.; Kamarudin, F.; Wanke, P.; Muhammad Salam, M.S.; Iqbal Hussain, H. Energy Efficiency in Production of Swiftlet Edible Bird’s Nest. Sustainability 2022, 14, 5870. https://doi.org/10.3390/su14105870

Alpandi RM, Kamarudin F, Wanke P, Muhammad Salam MS, Iqbal Hussain H. Energy Efficiency in Production of Swiftlet Edible Bird’s Nest. Sustainability. 2022; 14(10):5870. https://doi.org/10.3390/su14105870

Chicago/Turabian StyleAlpandi, Rabiatul Munirah, Fakarudin Kamarudin, Peter Wanke, Muhammad Syafiq Muhammad Salam, and Hafezali Iqbal Hussain. 2022. "Energy Efficiency in Production of Swiftlet Edible Bird’s Nest" Sustainability 14, no. 10: 5870. https://doi.org/10.3390/su14105870

APA StyleAlpandi, R. M., Kamarudin, F., Wanke, P., Muhammad Salam, M. S., & Iqbal Hussain, H. (2022). Energy Efficiency in Production of Swiftlet Edible Bird’s Nest. Sustainability, 14(10), 5870. https://doi.org/10.3390/su14105870