Abstract

The optimization of mechanized construction processes has a very important impact on economic and environmental sustainability. Our analyses evaluate key factors that affect the quality, environment, and economics of mechanized earth processes. This paper also presents approaches in this area in Slovakia and abroad, and existing mathematical models for the optimal design of earthmoving machinery. The main goals of our paper are the proposal of a method of machine selection for excavation including a multi-criteria optimization method with software support and application and verification of this method in a model example. A total of nine scientific methods applied in our paper are analyzed. The key results of the research work in terms of the set goals are given in the Conclusion, where the key research results are summarized. The results of the research work presented in the paper have a direct impact on economic and environmental sustainability, which can be achieved already in the phase of construction preparation. Applications of information technologies in multi-criteria optimization of the selection of construction machines for earth processes enables their use in the BIM (building information modeling) model.

1. Introduction

The optimization of mechanized construction processes has a very important impact on economic and environmental sustainability. In our paper, all key factors that affect the quality, environment, and economics of mechanized earth processes are analyzed. The main research goals of our paper are the proposal of a method of machine selection for the excavation including a multi-criteria optimization system with software support and the application and verification of this method in a selected model example. Nine scientific methods applied in our paper are analyzed. There are several experts interested in this topic in Slovakia and abroad. Most of them are focused on modeling, simulation, and optimization methods concerning the mechanized construction processes [1,2,3,4,5,6], and have influenced the proposal of multi-criteria optimization described in our contribution. Although many authors deal with this issue, there are possibilities for further progress in this topic, such as extending the application to excavations with the use of different types of construction machines, focusing on the criteria of optimality: quality of machine selection, time, fuel consumption and costs, software development for quick decisions, and determining the weighting factor according to the requirements of investors.

The key results of the research work in terms of the set goals are given in the conclusion where our key research results are summarized. The aim of our paper is to bring new knowledge to the subject area for science in the field of construction and to help construction practice effectively select the optimal design of machines in terms of process duration, fuel consumption, and total costs. As part of this work, another plan is to design suitable software that would increase these effects. The results of the research work presented in the paper have a direct impact on economic and environmental sustainability, which can already be achieved in the phase of construction preparation. Applications of information technologies in multi-criteria optimization of selecting construction machines for earth processes enable their use in the BIM (building information modeling) model. This contribution is used in a construction-technological project when the construction planner decides on the optimal use of construction machinery, in our case for earth processes. The outputs of this paper are a supporting process for 5D BIM (construction budget) and 6D BIM (construction technology and quality). The results of the work presented in this paper have a direct impact on economic [7] and environmental sustainability [8,9,10], which can be achieved in the phase of construction preparation. As part of this research work, another plan is to design suitable software to increase these effects. Edmundas Kazimieras Zavadskas in [11] analyzes sustainability in construction engineering. This publication is mainly concentrated in five areas: sustainable architecture; construction/reconstruction technology and sustainable construction materials; construction economics, including investments, supply, contracting and costs calculation; infrastructure planning and assessment; and project risk perception, analysis, and assessment, with an emphasis on sustainability. The significance and importance of our research lie in the fact that there are many possible solutions for the implementation of mechanized earth processes, as well as a large number of construction machines. Thanks to the proposed software, the design of our method creates an opportunity for the construction preparer in a relatively short time to choose a construction machine variant that will be able to perform work from a qualitative and quantitative point of view according to the delivered construction project, meet time requirements for the construction process, and find a construction machine variant, that would be optimal in terms of overall process costs and in terms of minimizing energy intensity, which is important from an environmental point of view. To simplify practical use, it was necessary to develop a large number of mathematical models; to concentrate a large amount of input data in terms of quality of work, economics, and energy; and to process everything using the proposed software. When choosing an optimal machine, the construction preparer can choose scales for the individual optimality criteria (time, costs, energy) and thus, in accordance with the investor’s request, make the mechanized construction process as efficient as possible.

2. Analysis of Factors and Machines Useful for Earth Processes

Earth processes consist of various activities that result in earth structures. The standard of activities is written in technical standard STN 73 3050 “Earth works, common regulations [7].” We can divide basic processes into [8] transport and spread of excavating product, compacting of embankments, loading, transport, and unloading. The technological properties of soils include mine-ability and disconnecting, natural gradient, bulk density, bulkage, and moisture. The seven classes of soils from the point of its mine-ability include [12]:

- Bulk soils taken by a shovel or loader;

- Bulk soils disconnected by a spade or loader;

- Pit soils disconnected by a picker, excavator;

- Crumbly soils disconnected by a wedge, excavator;

- Easy demolition consolidated soils disconnected by a ripper, large excavator, demolitions;

- Hard demolition consolidated soils disconnected by a hard ripper, demolitions;

- Very hard demolition consolidated soils disconnected by demolitions.

According to the shape of the excavation, we can divide excavation into the surface and deepening (shaft, ditch, deepening cutting, groove). The factors that influence the excavation realization are softness and properties of disconnecting earth; type, shape, and range of excavation; the climatic and hydro-geological conditions affecting excavation; health, occupation, and safety requirements; and environmental requirements. For effective machine selection for earth processes, we must take into account these factors [12,13]: characteristics of earth material (Table 1); type of excavation (Table 2), and location of the excavation area (Table 3).

Table 1.

Choice of machines suitable for groundworks according to the categorization of earth and type and location of the excavation [13].

Table 2.

Choice of machinery for excavation removal according to the transport distance [13].

Table 3.

Selection of machines for earth processes according to operation process conducted.

Legend for Table 1: 1. Excavator with black shoe; 2. Excavator with a front shovel; 3. Excavator with a loading shovel; 4. Excavator with towed buckets; 5. Excavator with a grapple; 6. Bucket excavator; 7. Wheel excavator; 8. Wheel loader; 9. Crawler loader; 10. Wheel dozer; 11. Crawler dozer; 12. Grader; 13. Scraper.

Table 2 shows the effective transport distance for basic machines for earth processes.

Table 3 illustrates the useful selection of machines for earth processes according to the operation process conducted.

Legend for Table 3: 01. Soil disconnecting; 02. Soil scooping; 03. Soil transporting 04. Soil foisting; 05. Soil loading; 06. Soil unloading and storage; 07. Soil grading; 08. Soil compaction; 09. Spray.

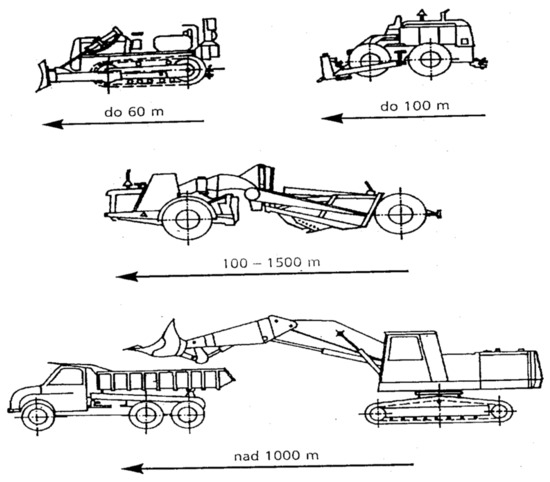

Figure 1 shows the optimal distance of construction machines for earth processes.

Figure 1.

Optimal distance of earth machines.

3. Scientific Methods Used

Our research used the following scientific methods and theories: scientific analysis, scientific synthesis, induction, deduction, comparison, abstraction, generalization, and multi-criteria optimization. The method of scientific analysis was used to investigate issues in Slovakia and abroad. Particularly important was the analysis of factors influencing the mechanized earth processes including parameters of construction machinery for earthworks. The criteria concerning the selection of construction machinery for earthworks and efficiency of use of construction machines for earth process were also analyzed. The method of scientific synthesis was used to propose a method for selecting construction machines for mechanized earth processes; to create mathematical models for determining the duration of mechanized construction work, fuel consumption, and total costs; to create software for the selection of construction machinery in terms of efficiency and investor requirements, and to formulate benefits for science and practice and overall conclusions. The method of induction is used to draw general scientific conclusions and theorems based on the evaluation of basic scientific data. Our study was implemented for formulating general research outputs on the basis of research results. The method of deduction is based on general assumptions and applies them to individual general or partial conclusions. Our contribution was implemented for formulating the benefits for practice and the overall conclusions. The method of comparison was implemented in the process of comparison of different variants of machines (scrapers) and realized earth processes from the points of production rate, cost, duration of the process, and fuel consumption. The method of abstraction was implemented in the process of the selection of important input data for the creation of mathematical models. The method of generalization was implemented in the process of the creation of the method of optimal machine selection according to the proposed criteria. Because the method of multi-criteria optimization is also the output of our paper, it is described in more detail in the next sub-chapter.

Multi-Criteria Optimization Method

Several authors have focused on multi-criteria analysis and implementation. J. Roston [14] defined an IT tool that allows for comparing different types of solutions based on mathematical calculations via the Monte Carlo method. The developed approach can help the investor to optimize their cash-flow schedule. The original method enables the client to select a construction project variant characterized by the best economical and sustainable parameters, while considering customers’ demands. Zhang J. [15] presents a construction stage and zone optimization model based on a data-driven analytical hierarchy process extended by D numbers (D-AHP) and an enhanced whale optimization algorithm (EWOA). The flow shop construction scheme is optimized by presenting an automatic flow shop construction scheme multi-criteria decision making (MCDM) method, which integrates the data-driven D-AHP with an improved construction simulation of a high rockfill dam (CSHRD). Slobodan B. Mickovski in [16] analyzes theory, practice and applications concerning sustainable geotechnics. Environmental sciences are becoming more and more detailed and sophisticated, with the natural phenomena and processes surrounding the civil engineering infrastructure being modeled, designed, monitored, and assessed in a more holistic way. E. K. Zavadskas [17] proposed multi-criteria decision-making techniques to improve sustainable engineering processes. The application of the developed new multi-criteria decision-making (MCDM) methods can be eliminated or decreased by decision-makers’ subjectivity, which leads to consistency or symmetry in the weight values of the criteria. The paper of S. A. Erdogan [18] is focused on a multi-criteria decision-making model to choose the best option for sustainable construction management. It identifies the main problems of construction management and discusses ways to solve them using multi-criteria methods. This paper presents a comprehensive set of criteria, which led to creating a decision-making model for construction management. The success of any activity and process depends fundamentally on the possibility of balancing (symmetry) needs and their satisfaction. According to H. Jin [19] in construction projects, the planning objectives include the safety and labor productivity of the activities, along with the cost influence affecting the overall performance of construction. To ensure the balance among safety, labor productivity and construction cost performance, all influencing factors associated with the construction objectives should be considered in temporary facility layout planning. The author proposes a novel multi-criteria temporary facility layout planning model that integrates analytic network process (ANP) modeling and simulation-based sensitivity evaluation, which effectively transforms the spatial layout planning problem into a mathematical decision problem. N. Rajagopalan [20] proposed a multi-criteria decision analysis using life cycle assessment and life cycle costing in circular building design. This article details a qualitative and a quantitative method to evaluate characteristics, such as circularity, adaptability, and reuse of building elements amongst others, to provide decision-makers, such as building clients, architects, investors, and policymakers, an objective way to assess the benefits and constraints of circular buildings and elements. Beibei Pang [21], in his paper firstly expands the structure of the multi-cloud service system and further constructs a multi-cloud multi-edge cloud (MCMEC) environment. To obtain an optimized cloud combination that can efficiently reduce energy consumption, money cost, and network latency, a skyline query mechanism is utilized for extracting the optimized cloud composition. Hubert Anysz et al. [22] analyzed new multi-criteria decision making with a cost criterion at the final stage (MCDM-CCAF). This method is based on the principle of Pareto optimal decisions. It is proposed to exclude the cost criterion from MCDM analysis and consider it at the final phase of the decision-making process.

The optimal selection of construction machines for construction processes is the responsibility of the construction preparer. This person, based on the supplied project of earth processes and products must design construction machines that meet quality and quantitative requirements. These machines must be suitable for the mechanized process, and it is necessary to look for optimal criteria (time, cost, and energy consumption). These key criteria are also presented in mathematical models of multi-criteria optimization. While optimization respects one parameter when selecting the most suitable variant of the machine set for the construction process, multi-criteria optimization simultaneously respects more, often conflicting parameters [13]. The following are the principles of multi-criteria optimization:

- Each parameter is assigned a different severity expressed by the weight of the parameter;

- Deterioration of any parameter must lead to an increase in the value of the multi-optimization indicator;

- The indicator of optimization of individual parameters must be implemented in such a way as to eliminate the influence of the choice of units;

- The values of the optimization indicator of individual parameters should not grow above all limits (the resulting multi-optimization indicator will not be sensitive to the choice of weighting factors);

- We choose the value of the optimization indicator of individual parameters so that the best variant has the lowest value of this indicator (performance and productivity-reciprocal values).

In our paper we used these parameters of multi-criteria optimization:

TIME (T) … (duration of the mechanized process);

ENERGY (E) … (consumption of fuel of the mechanized process);

COST (C) … total cost of the mechanized process.

Procedural steps:

- Definition of optimization indicators:

- 1.1

- Time indicator—TI (i):for i = 1 …. n, where:TI (i)—time indicator;Ti—total duration of the “i”th machine’s work;n—number of machines.

- 1.2

- Energy indicator—EI (i):for i = 1 … n, where:EI (i)—energy indicator;Ei—machine energy consumption;n—number of machines.

- 1.3

- Cost indicator—CI (i):for i = 1 … n, where:CI (i)—cost indicator;Ci—total cost of the “i”th machine´s work;n—number of machines.

- Definition of weighting factors:In our paper, we applied these weighting factors:

- 2.1.

- Weighting factor of time—WT as a percentage;

- 2.2.

- Weighting factor of energy—WE as a percentage;

- 2.3.

- Weighting factor of cost—WC as a percentage.

The sum of the weighting factors is equal to 100%. - Definition of multi-criteria optimization indicator—IMO(i):TI (i)—Time indicator;EI (i)—Energy indicator;CI (i)—Cost indicator;WT—Weighting factor of time (%);WE—Weighting factor of energy (%);WC—Weighting factor of cost (%).Note: the sum of the weighting factors is equal to 100%.

- The best variant (BV) of the machine set is determined by this formula:for i = 1 … n, where:IMOi—multi-criteria optimization indicator of “i”th machine.This method was applied in our paper in the model example.

4. The Proposal of the Machine Selection Optimizing (MSO) Method for Earth Processes Using Multi-Criteria Optimization with Software Support

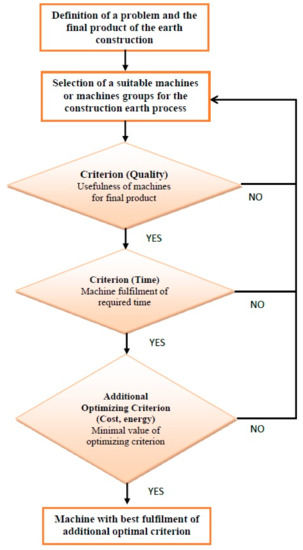

The “Machine Selection Optimizing Method” (MSO Method) consists of these steps (Figure 2):

Figure 2.

Machine Selection Optimizing (MSO) method.

- Definition of the construction problem and the final product of the construction processes:Description of activities: This phase includes the key definition of the construction problem and final product of mechanized earth processes and the definition of all important input data.

- Proposal of suitable machines or machines groups:Description of activities: In this phase, the main activity is the proposal of suitable machines for a given type of construction works. The criterion (the aspect of quality) is the usefulness of the machines to provide the defined earth product. Basic processes at this step are the analysis of the earth process and earth product; proposal of useful machines for the defined earth product; the selection of all necessary input data concerning the machines including information about technical parameters, cost, fuel consumption, etc. The output of this step is machines useful to realize the earth product.

- Assessment of machines in terms of required time:Description of activities: At this phase, all the proposed machines or machine groups are evaluated according to the time criterion. The first step is calculating the production rates of all proposed and useful machines, and then the duration of the process is calculated. Time is one of the key requirements of most investors. Basic processes at this step are the creation of a model of mechanized earth processes; the proposal of possible variants of machines for defined earth processes; the proposal of mathematical variables and creation of mathematical models for calculating the duration of mechanized earth processes; software calculation of the duration of work by selected machines; comparing selected machine variants to the time of work required.The output of this step is machines that fulfill the time requirement.

- Assessment of machines in terms of additional optimizing criteria:Description of activities: This phase includes all machines, that fulfill the time criterion evaluated according to additional optimizing criteria, for example, cost or energy aspects). Minimizing cost and the consumption of fuel of machines are very serious requirements of investors and the construction process suppliers. Basic processes at this step are the definition of mathematic variables concerning the optimization criteria (cost, energy); creation of mathematical models for calculation cost and energy consumption in the defined earth processes; software calculation of cost and energy consumption by the selected machines; comparing selected machine variants to cost and energy consumption results (the output from software). The output of this step and the optimal solution is the optimal machines from the point of cost and fuel consumption.The output of this step is a machine with minimal costs and energy consumption.

5. Application and Verification of This Optimal Method into a Model Example of Surface Excavation

The “Machine Selection Optimizing Method” (MSO method) was applied and verified in a model example, which evaluated machines for surface excavation.

Definition of a problem and the final product of the earth construction:

The problem concerns the implementation of surface excavation, specifically the leveling of the sloping terrain. The total volume of earthworks is 20,000 m3. The average distance between the center of gravity of the excavation and the center of gravity of the hopper is 1000 m. Basic input data:

Final product of construction earth process—surface excavation;

Total volume of earth work: 20,000 m3;

Earth: sandy loam;

The average distance of earth transport L = 1000 m;

Time of work—March.

Selection of suitable machines for the earth construction process:

Based on the information given in Table 1, Table 2 and Table 3 in Section 1 of the work, a scraper appears to be a suitable machine for implementing this excavation. In our model example, we chose five types of scrapers to implement the leveling of the terrain:

S1 (Model CAT 621K) [23];

S2 (Model Komatsu WS23S-1[24]);

S3 (Model TEREX TS 14 G) [25];

S4 (Model CAT 627G Auger) [26];

S5 (Model CAT 637G) [27].

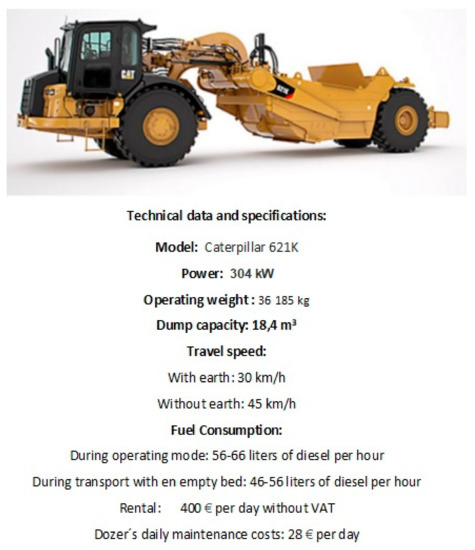

Technical data and specifications necessary for optimal selection of scrapers are described in [23,24,25,26,27,28,29]. This paper illustrates basic information concerning scraper S1. shown in Figure 3.

Figure 3.

Scraper S1: Cat 621K specification [23].

Assessment of scrapers in terms of required time and additional optimizing criteria:

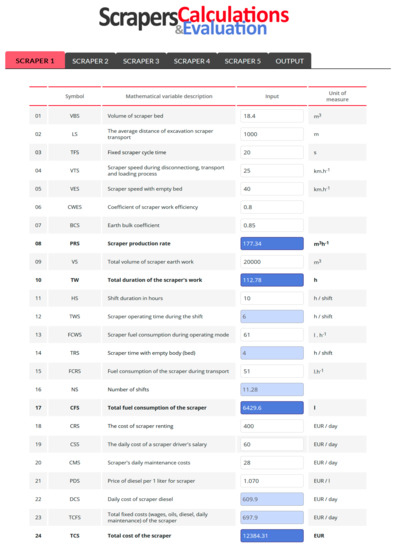

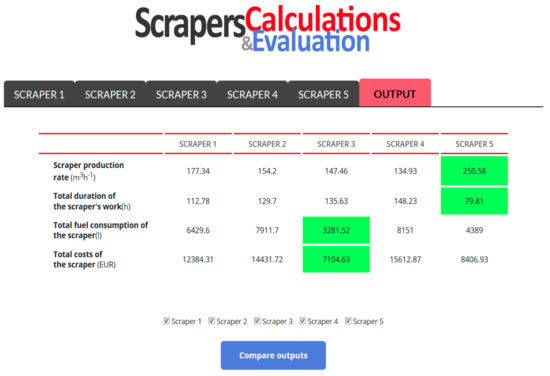

In this part, it is necessary to define all input data on the final product of earthworks, the earth itself, technical parameters of selected scrapers and to design mathematical models for determining the selected optimality criteria: duration of work (TIME), fuel consumption (ENERGY), and total costs (COST). Table 4 provides an overview of all inputs, mathematical quantities, and mathematical models for determining the time, fuel consumption, and costs for individual dozer variants. Calculation according to the proposed mathematical models and evaluation of scrapers was performed using the software Scrapers Calculation & Evaluation developed in the Center for Quality Management in Construction (CEMAKS) at the Department of Building Technology in Civil Engineering during our research work. The software Scrapers Calculations & Evaluation is an application based on JavaScript and HTML. Its purpose is to provide automatic calculation of key mathematical outputs of specific scrapers’ work and evaluate and identify the best scraper vehicle based on these main criteria: scraper production rate; total duration of the scraper’s work; total fuel consumption of the scraper, total costs of the scraper.

Table 4.

Mathematical quantities and mathematical models for determining the time, fuel consumption and costs for individual scraper variants.

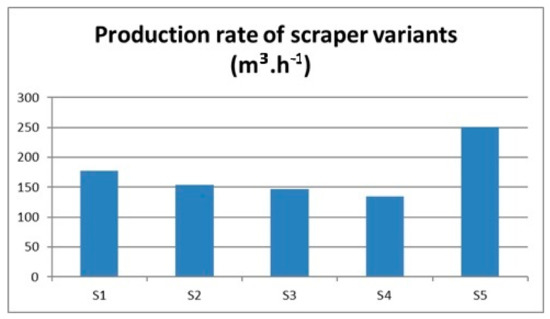

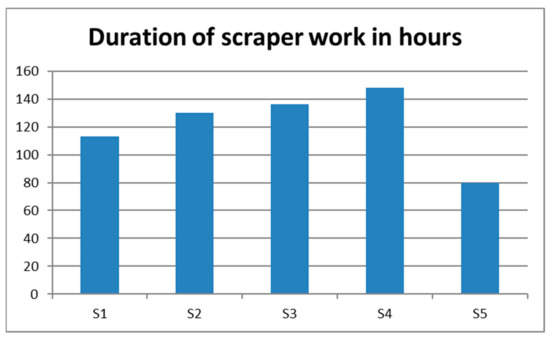

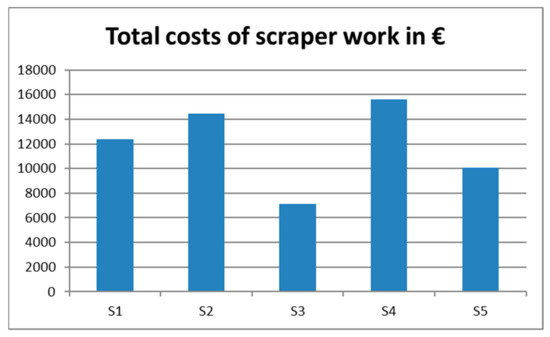

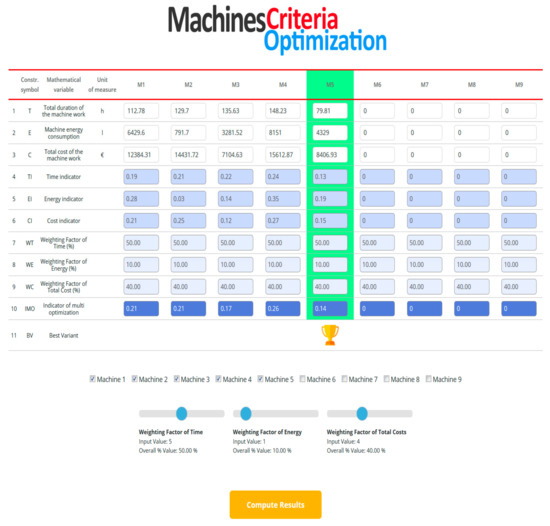

The user enters the inputs for a maximum of five scrapers. On an output screen, the user chooses which scrapers to compare (minimum of two, maximum of five). Optimal solutions based on the mentioned four criteria mentioned will be clearly marked on the output screen’s result table. Figure 4. illustrates the input data in the software for scraper variant S1. Figure 5 shows the overall evaluation of all five scraper variants in terms of production rate, time, fuel consumption, and total cost. Graphical interpretations of scraper variants evaluation concerning the production rate, duration of the process, fuel consumption, and total cost are included in Figure 6, Figure 7, Figure 8 and Figure 9. The principles of multi-criteria optimization are described in Section 2. Our paper applied this method in a model example: scrapers. We used the mechanized process duration (TIME criteria), the fuel consumption of mechanized processes (ENERGY criteria), and total costs of mechanized processes (COST criteria) as optimality criteria. Table 5 defines mathematical quantities and mathematical models for calculating optimality criteria. The calculation of the optimal solution is realized using software Machine Criteria Optimization developed within our research work at the Quality Management Centre in Construction (CEMAKS) at the Faculty of Civil Engineering SUT in Bratislava. Machines Criteria Optimization is an application based on JavaScript and HTML. Its purpose is to provide automatic calculation to compare machines’ work and choose the best variant, based on the main criteria and the weight assigned for each criterion. The user enters inputs for a maximum of nine machines. Then we can choose which machines to compare (minimum of two, maximum of nine) and enter the weight for each criterion. The calculated outputs are shown in the main table. In this table, the optimal variant is also clearly marked. Figure 10 shows outputs of multi-criteria optimization implemented into our model example: scrapers. When the weighting factors change, new optimal solutions appear immediately.

Figure 4.

Loading data of Scraper S1 in Scraper Calculation & Evaluation software.

Figure 5.

Overall evaluation of scraper variants from the point of view—production rate, duration of the process, fuel consumption, and total cost in Scraper Calculation & Evaluation software.

Figure 6.

Evaluation of scraper variants from the point of view of production rate.

Figure 7.

Evaluation of scraper variants from the point of view of duration of work (TIME CRITERION).

Figure 8.

Evaluation of scraper variants from the point of view of fuel consumption in liters (ENERGY CRITERION).

Figure 9.

E Evaluation of scraper variants from the point of view of total costs (COST CRITERION).

Table 5.

Definition of mathematical quantities and models to find the optimal solution.

Figure 10.

Outputs of multi-criteria optimization implemented into scrapers.

6. Multi-Criteria Optimization of Mechanized Earth Processes

The optimal selection machine method for earthworks using an automated system of machine evaluation will also find effects in the BIM system (building information modeling) application in the section-time planning (4D), billing (5D), and technological procedures and quality (6D). This thesis was prepared as a part of the scientific research project VEGA No. 1/0511/19.

7. Conclusions

A machine selection optimizing (MSO) method was implemented for surface excavation and proposed construction machines (model example: scrapers). Our research team prepared similar models and software for other construction machines [8], such as dozers or machine group excavators-trucks. This contribution proposes the method of machine selection for excavation, including a multi-criteria optimization system with software support; the application and verification of this method in a model example: scrapers; an analysis of factors influencing the technology of mechanized earth processes; a definition of mathematical variables, and models for calculating outputs such as production rates, the duration of the process, fuel consumption, and total cost for the selected excavation. Software for the effective selection of construction earth machines was developed in the Quality Management Centre in Construction (CEMAKS) at the Faculty of Civil Engineering SUT in Bratislava according to our proposal of mathematical models and next important input dates. We can see the effects of our proposed MSO method in the model example for surface excavation using multi-criteria optimization (time, cost, energy). This software will allow the simulation of various combinations of machines and, in a short time, evaluation of their effective deployment. In addition, construction planners can vary the weighting factor for process duration, fuel consumption, and total costs according to investor requirements. Using credible input data and the proposed software, we can quickly find an optimal solution. Several organizations in Slovakia and abroad have shown interest in the results of our research work, e.g., the LECTURA company from Germany, which provides a database of construction machines and is interested in software designed in our paper. Additionally, several renting organizations for construction machinery are interested in the results of our work. Due to the limited scope of this paper, we were only able to provide an example of only one model example and thus demonstrate the real application of our proposed method of selecting construction machinery. In our research work, we are also working on other applications, such as the design of machinery for deep excavations and excavation of excavators + vehicles using the queuing theory. The proposed method is universal in nature, but applications to various construction machines require new input data, new machine parameters, new mathematical models, and resulting software solutions. However, the steps are similar to those in our method. Improvements can be made in the search for other scientific methods that would lead to an even more accurate model of mechanized construction processes, and improvements can be made in exploring other software options for solving similar tasks.

Author Contributions

Conceptualization, J.G., V.M., P.Š. and S.S.; methodology, J.G., V.M. and S.S.; software, J.G.; validation, J.G., V.M., P.Š. and S.S.; formal analysis, J.G. and P.Š.; investigation, J.G. and S.S.; resources, J.G., V.M., P.Š. and S.S.; data curation, J.G.; writing—original draft preparation, J.G. and P.Š.; writing—review and editing, J.G. and P.Š.; visualization, J.G., V.M. and P.Š.; supervision, J.G. and V.M.; project administration, J.G.; funding acquisition, J.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by VEGA, grand number 1/0511/19. This paper was created as research work for VEGA No. 1/0511/19.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, H. Multi-objective simulation-optimization for earthmoving operations. Autom. Constr. 2008, 18, 79–86. [Google Scholar] [CrossRef]

- Martinez, J.C. STROBOSCOPE: State and Resource Based Simulation of Construction Operations. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 1996. [Google Scholar]

- Martinez, J. Earthmover-Simulation Tool for Earthwork Planning. In Proceedings of the 1998 Winter Simulation Conference, Washington, DC, USA, 13–16 December 1998; pp. 1263–1271. [Google Scholar] [CrossRef] [Green Version]

- Halphin, D.W. CYCLONE: A method for modeling job site processes. J. Constr. Div. 1977, 103, 489–499. [Google Scholar] [CrossRef]

- Shi, J.; AbouRizk, S. An Automated modeling System for Simulating Earthmoving Operations. J. Comput.-Aided Civ. Infrastruct. Eng. 1998, 13, 121–130. [Google Scholar] [CrossRef]

- Marzouk, M.; Moselhi, O. Multiobjective Optimization of Earthmoving Operations. J. Constr. Eng. Manag. 2004, 130, 105–113. [Google Scholar] [CrossRef]

- Mandičák, T.; Mésároš, P.; Spišáková, M. Impact of Information and Communication Technology on Sustainable Supply Chain and Cost Reducing of Waste Management in Slovak Construction. Sustainability 2021, 13, 7966. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M.; Pošiváková, T. Analysis of Selected Building Constructions Used in Industrial Construction in Terms of Sustainability Benefits. Sustainability 2018, 10, 4394. [Google Scholar] [CrossRef] [Green Version]

- Švajlenka, J.; Kozlovská, M. Perception of User Criteria in the Context of Sustainability of Modern Methods of Construction Based on Wood. Sustainability 2018, 10, 116. [Google Scholar] [CrossRef] [Green Version]

- Kantová, R. Evaluation of Construction Site Noise to Allow the Optimisation of Construction Processes and Construction Machinery Selection. Appl. Sci. 2021, 11, 4389. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Šaparauskas, J.; Antucheviciene, J. Sustainability in Construction Engineering. Sustainability 2018, 10, 2236. [Google Scholar] [CrossRef] [Green Version]

- STN 73 3050 Zemné Práce. Všeobecné Ustanovenia. [Earth Works, Common Regulations]. Available online: https://normy.unms.sk/eshop/public/standard_detail.aspx?id=69207 (accessed on 12 October 2021).

- Gašparík, J.; Alamro, B.I.M. Optimization of Mechanized Earth Processes, 1st ed.; Tribun EU: Brno, Czech Republic, 2020; 132p. [Google Scholar]

- Roston, J.; Kziazek-Nowak, M.; Nowak, P.; Zawistowaki, J. Cash-Flow Schedules Optimization within Life Cycle Costing (LCC). Sustainability 2020, 12, 8201. [Google Scholar] [CrossRef]

- Zhang, J.; Zhong, D.; Zhao, M.; Yu, J.; Lv, F. An Optimization Model for Construction Stage and Zone Plans of Rockfill Dams Based on the Enhanced Whale Optimization Algorithm. Energies 2019, 12, 466. [Google Scholar] [CrossRef] [Green Version]

- Mickovski, S.B. Sustainable Geotechnics—Theory, Practice, and Applications. Sustainability 2021, 13, 5286. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Pamucar, D.; Željko Stevic, Ž.; Mardani, A. Multi-Criteria Decision-Making Techniques for Improvement Sustainability Engineering Processes. Symmetry 2020, 12, 986. [Google Scholar] [CrossRef]

- Erdogan, A.A.; Šaparauskas, J.; Turskis, Z. A Multi-Criteria Decision-Making Model to Choose the Best Option for Sustainable Construction Management. Sustainability 2019, 11, 2239. [Google Scholar] [CrossRef] [Green Version]

- Jin, H.; Mingyuan Zhang, M.; Yuan, Y. Analytic Network Process-Based Multi-Criteria Decision Approach and Sensitivity Analysis for Temporary Facility Layout Planning in Construction Projects. Appl. Sci. 2018, 8, 2434. [Google Scholar] [CrossRef] [Green Version]

- Rajagopalan, N.; Brancart, S.; De Regel, S.; Paduart, A.; de Temmerman, N.; Debacker, W. Multi-Criteria Decision Analysis Using Life Cycle Assessment and Life Cycle Costing in Circular Building Design: A Case Study for Wall Partitioning Systems in the Circular Retrofit Lab. Sustainability 2021, 13, 5124. [Google Scholar] [CrossRef]

- Pang, B.; Hao, F.; Park, D.S.; De Maio, C. A Multi-Criteria Multi-Cloud Service Composition in Mobile Edge Computing. Sustainability 2020, 12, 7661. [Google Scholar] [CrossRef]

- Anysz, H.; Nicał, A.; Stevic, Ž.; Grzegorzewski, M.; Sikora, K. Pareto Optimal Decisions in Multi-Criteria Decision Making Explained with Construction Cost Cases. Symmetry 2021, 13, 46. [Google Scholar] [CrossRef]

- Scraper CAT 621K. Available online: https://www.cat.com/en_US/products/new/equipment/wheel-tractor-scrapers/open-bowl-scrapers/18576136.html (accessed on 11 October 2021).

- Scraper Komatsu WS23S-1. Available online: https://www.ritchiespecs.com/model/komatsu-ws23s-1-motor-scraper (accessed on 11 October 2021).

- Scraper TEREX TS 14 G. Available online: https://www.ritchiespecs.com/model/terex-ts14g-motor-scraper (accessed on 11 October 2021).

- Scraper CAT 627G Auger. Available online: https://www.lectura-specs.com/en/model/construction-machinery/scrapers-caterpillar/627g-auger-998750 (accessed on 11 October 2021).

- Scraper Model CAT 637G. Available online: https://www.ritchiespecs.com/model/caterpillar-637g-motor-scraper (accessed on 11 October 2021).

- Scrapers Renting. Available online: https://www.rentalyard.com/listings/construction-equipment/for-rent/list/category/1054/scrapers (accessed on 2 October 2021).

- Lectura-Machine Databases. Available online: https://www.lectura-specs.com/en (accessed on 11 October 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).