Functionalization of Smart Recycled Asphalt Mixtures: A Sustainability Scientific and Pedagogical Approach

Abstract

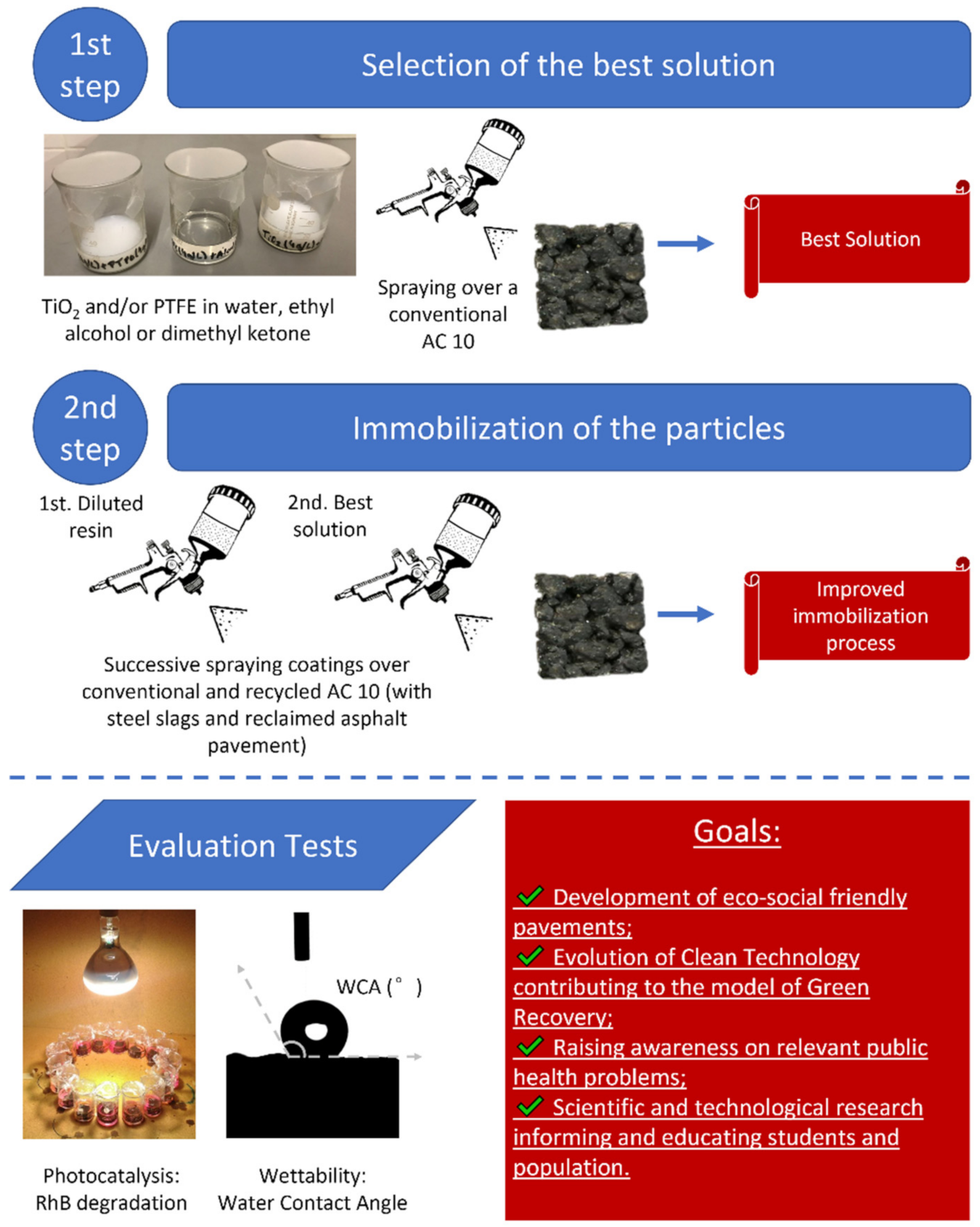

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation for the First Step (Selection of Best Solution)

2.3. Sample Preparation for the Second Step (Immobilization of the Particles)

2.4. Photocatalytic Efficiency Test

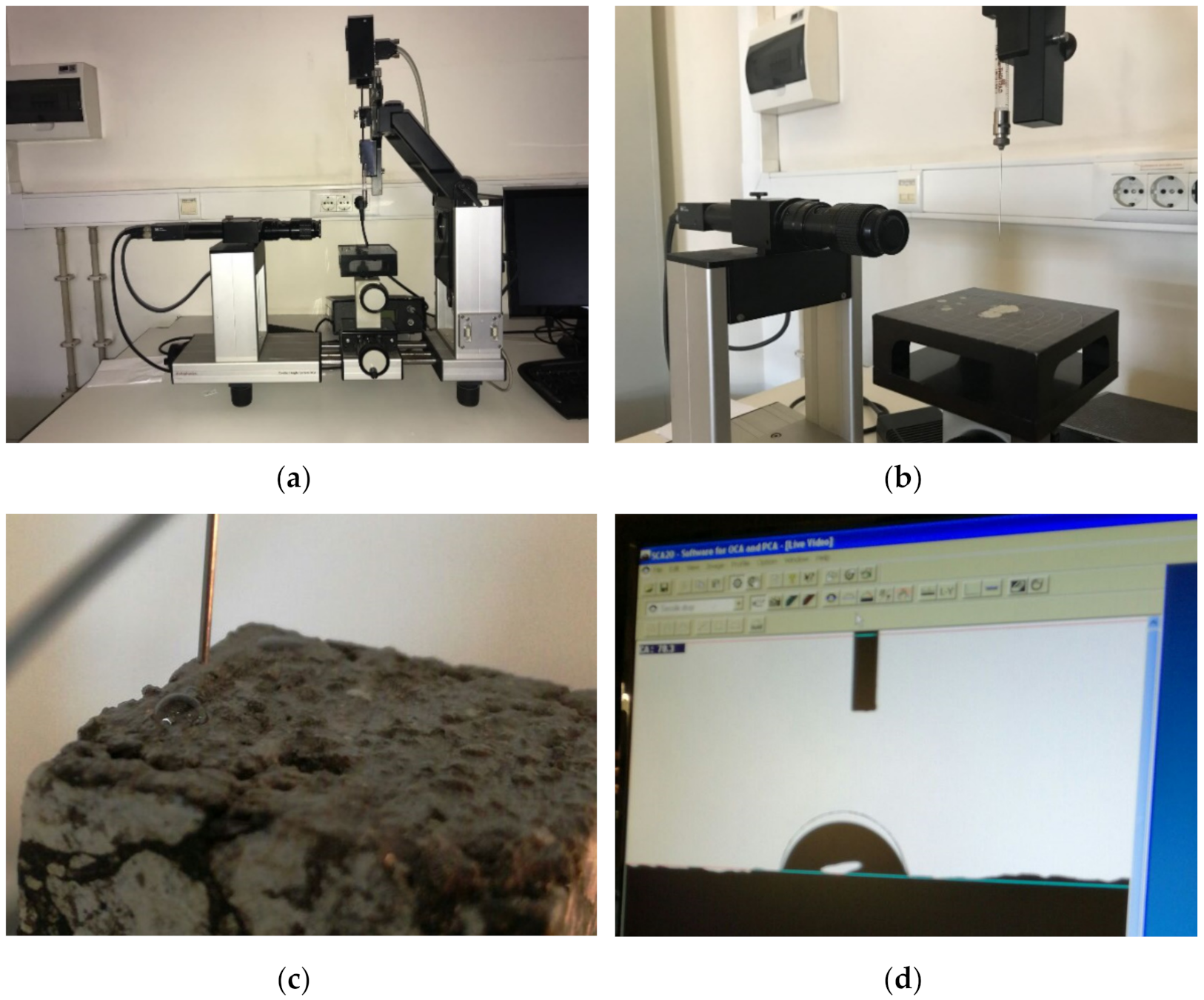

2.5. Water Contact Angle Test

3. Results

3.1. Selection of Best Solution

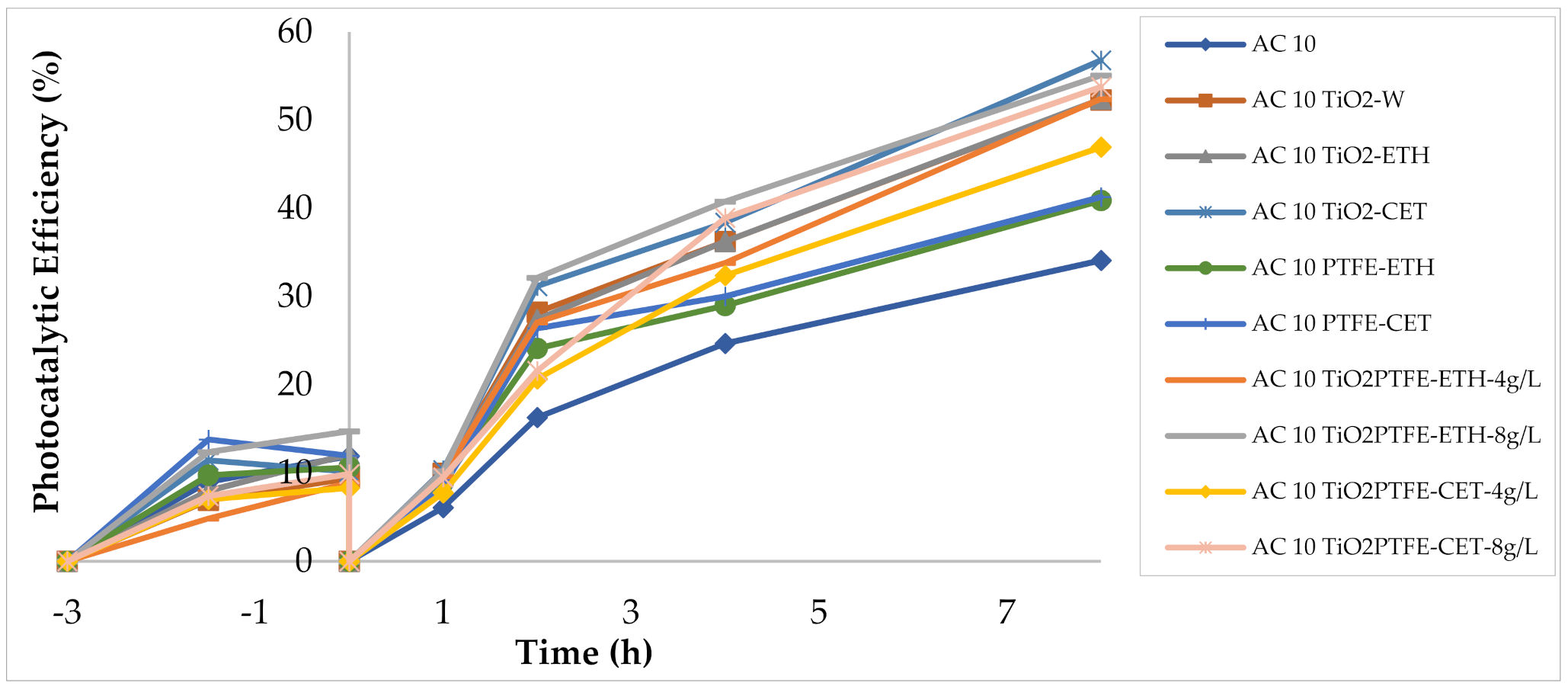

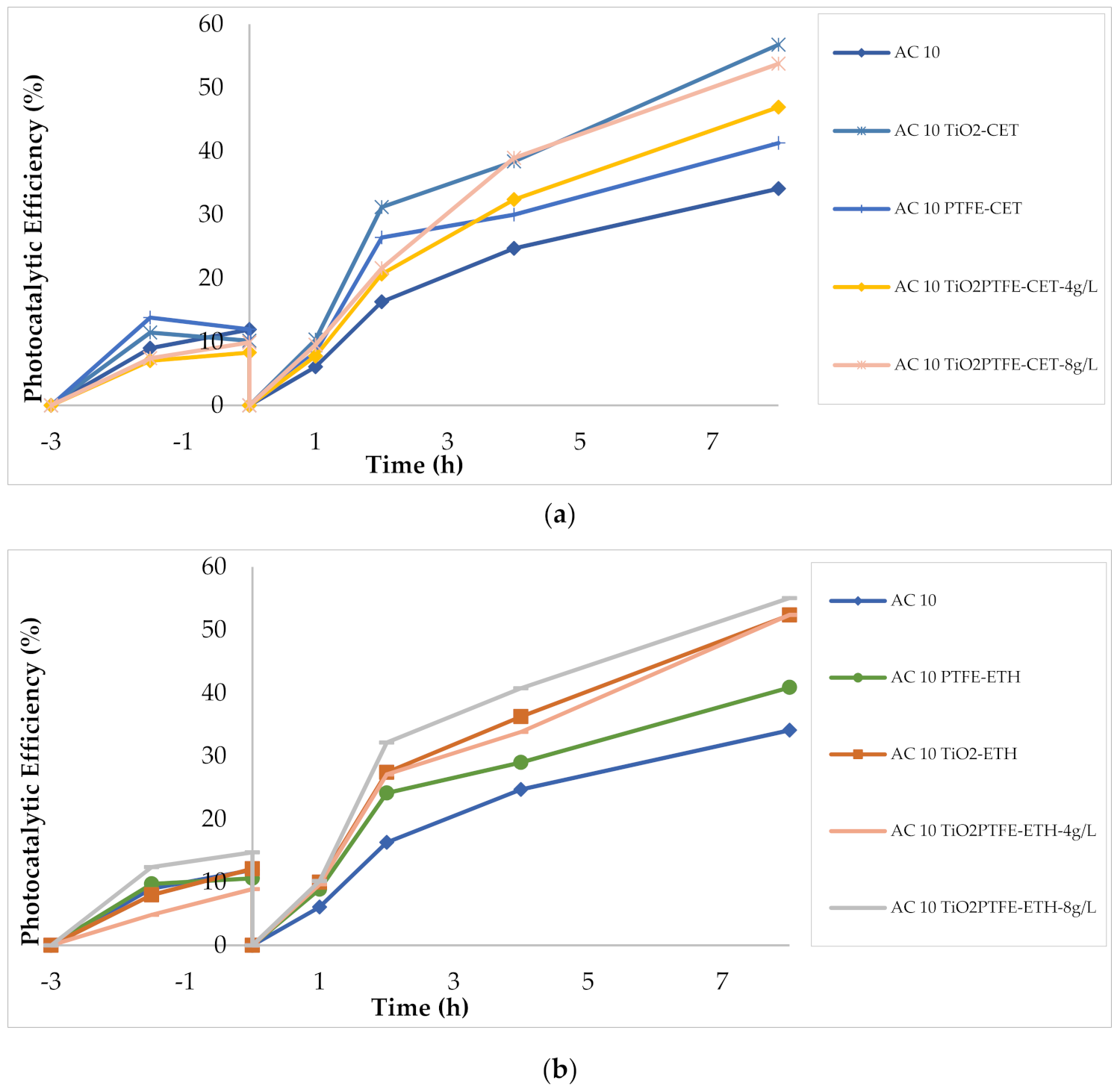

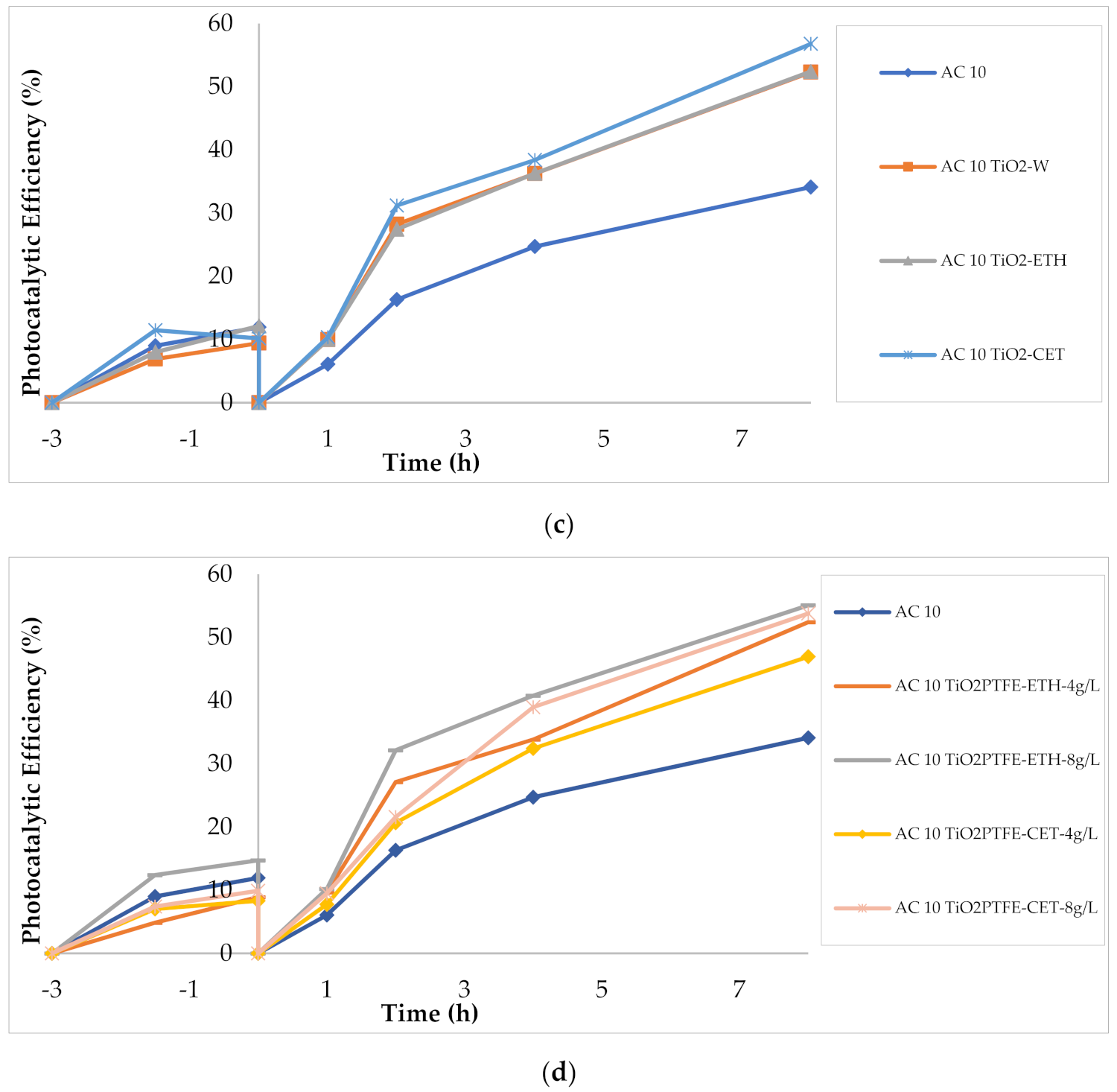

3.1.1. Photocatalytic Efficiency

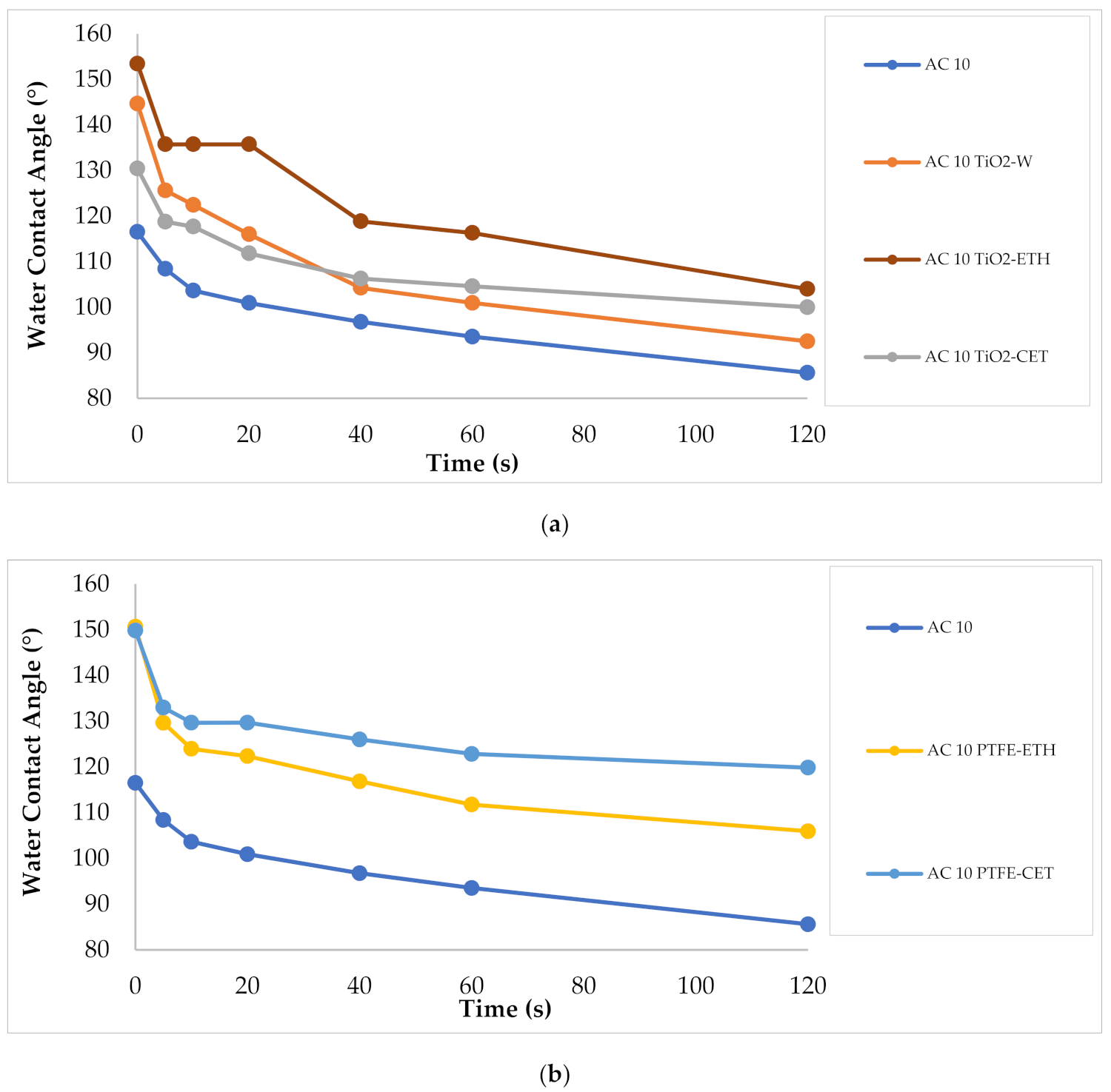

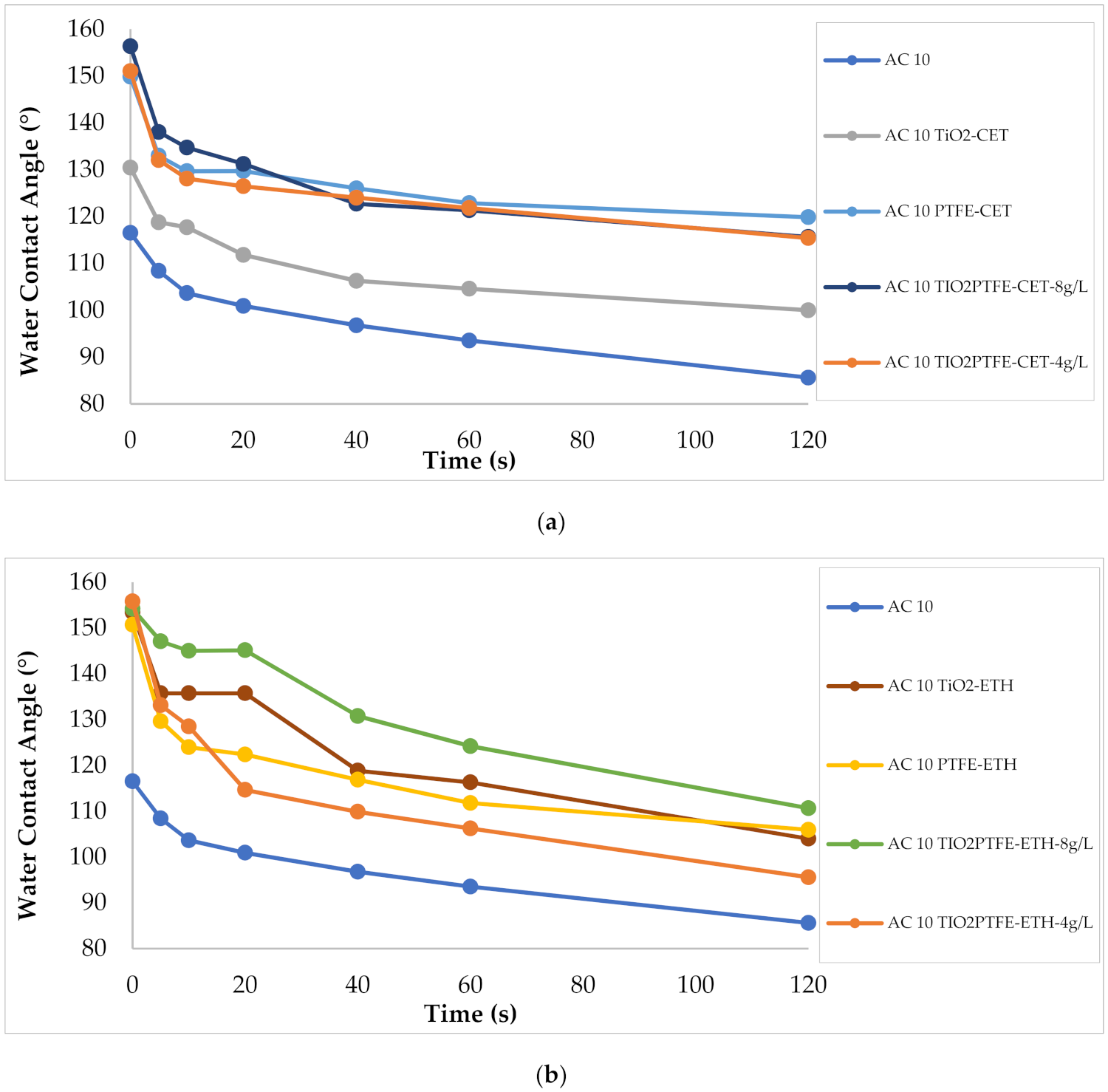

3.1.2. Water Contact Angle (Wettability)

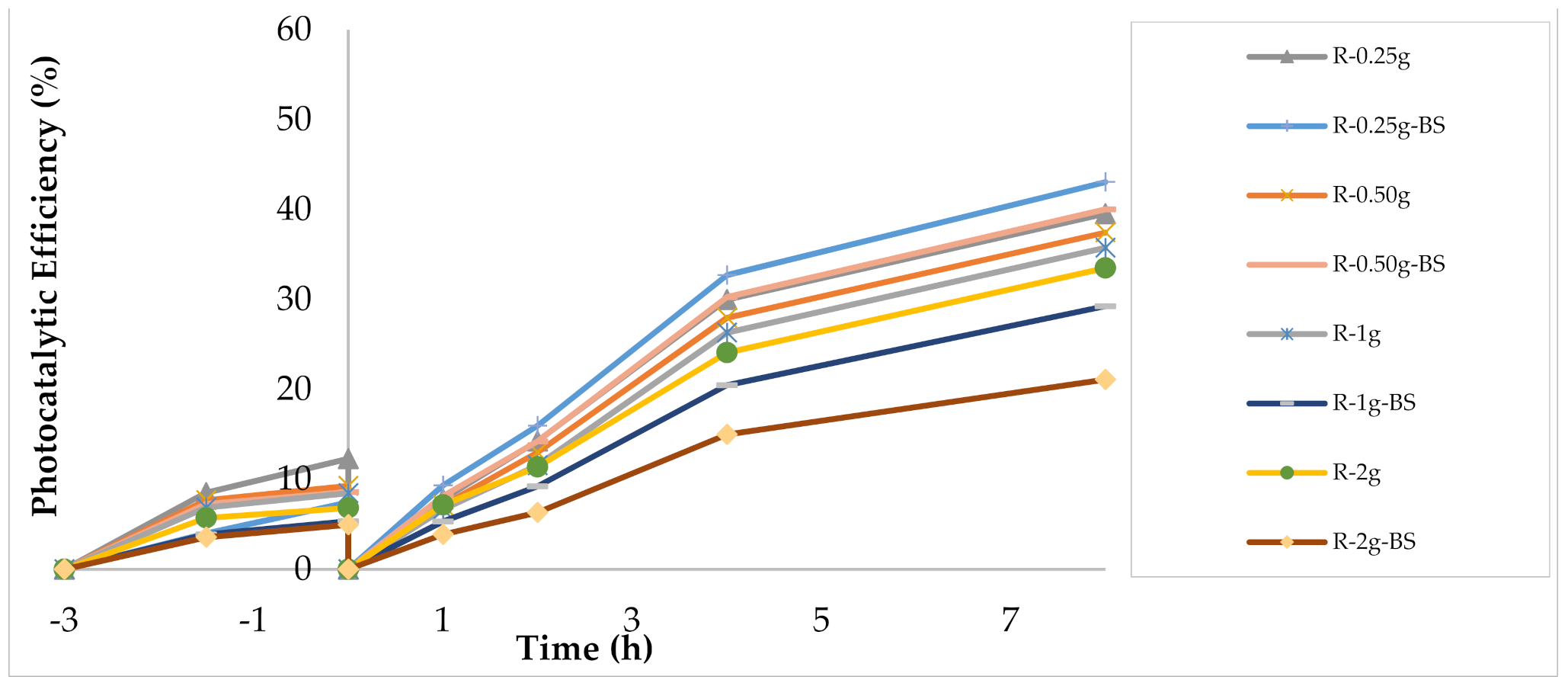

3.2. Immobilization of BS on Recycled and Conventional Asphalt Mixtures

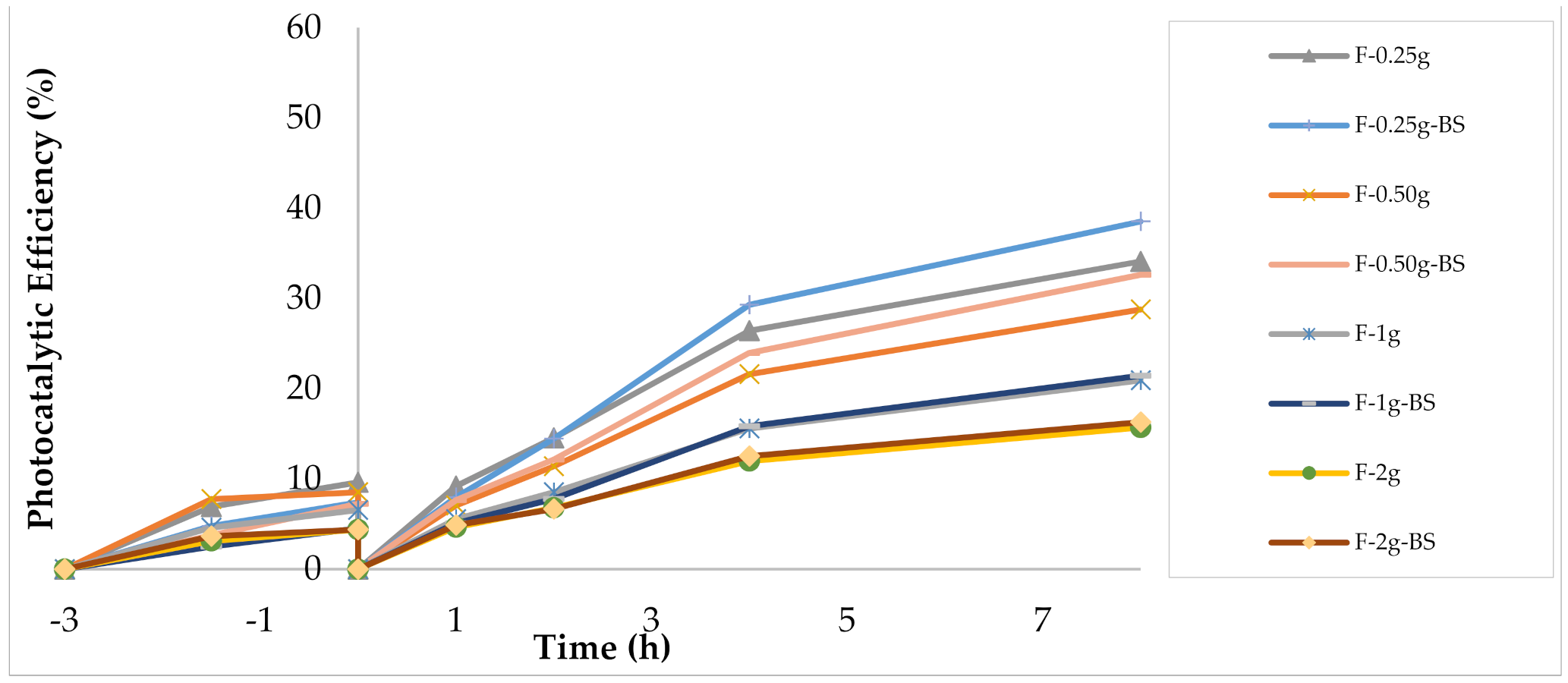

3.2.1. Photocatalytic Efficiency

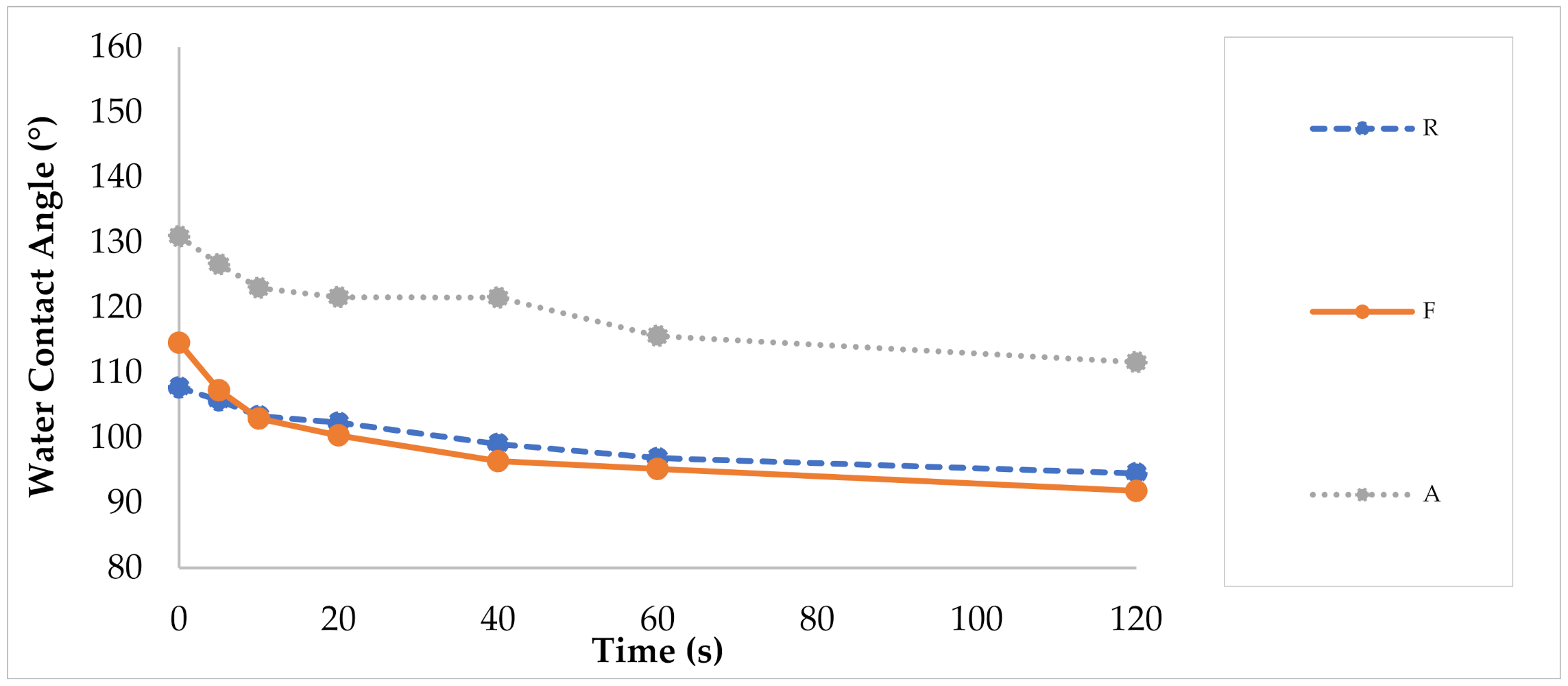

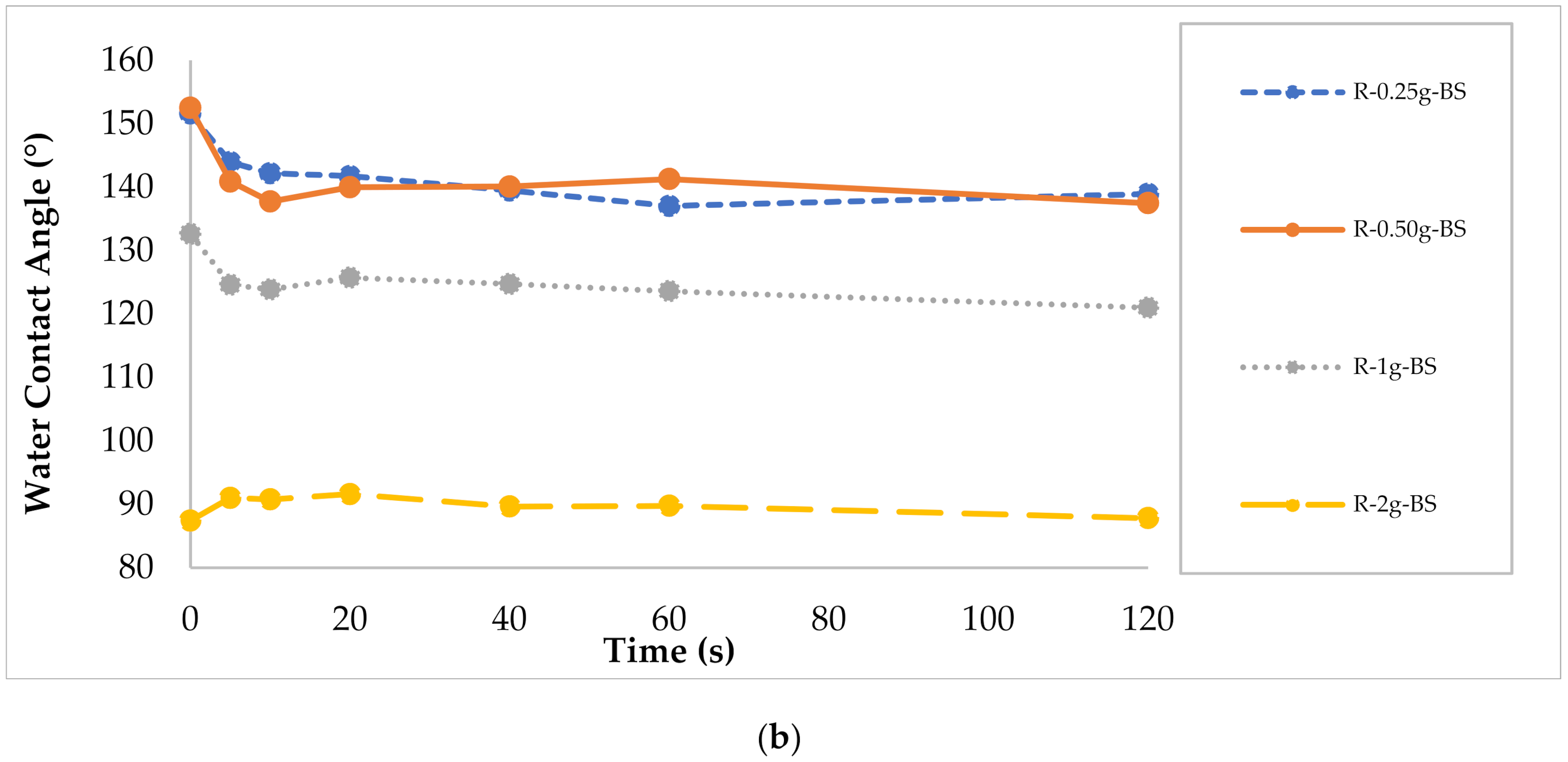

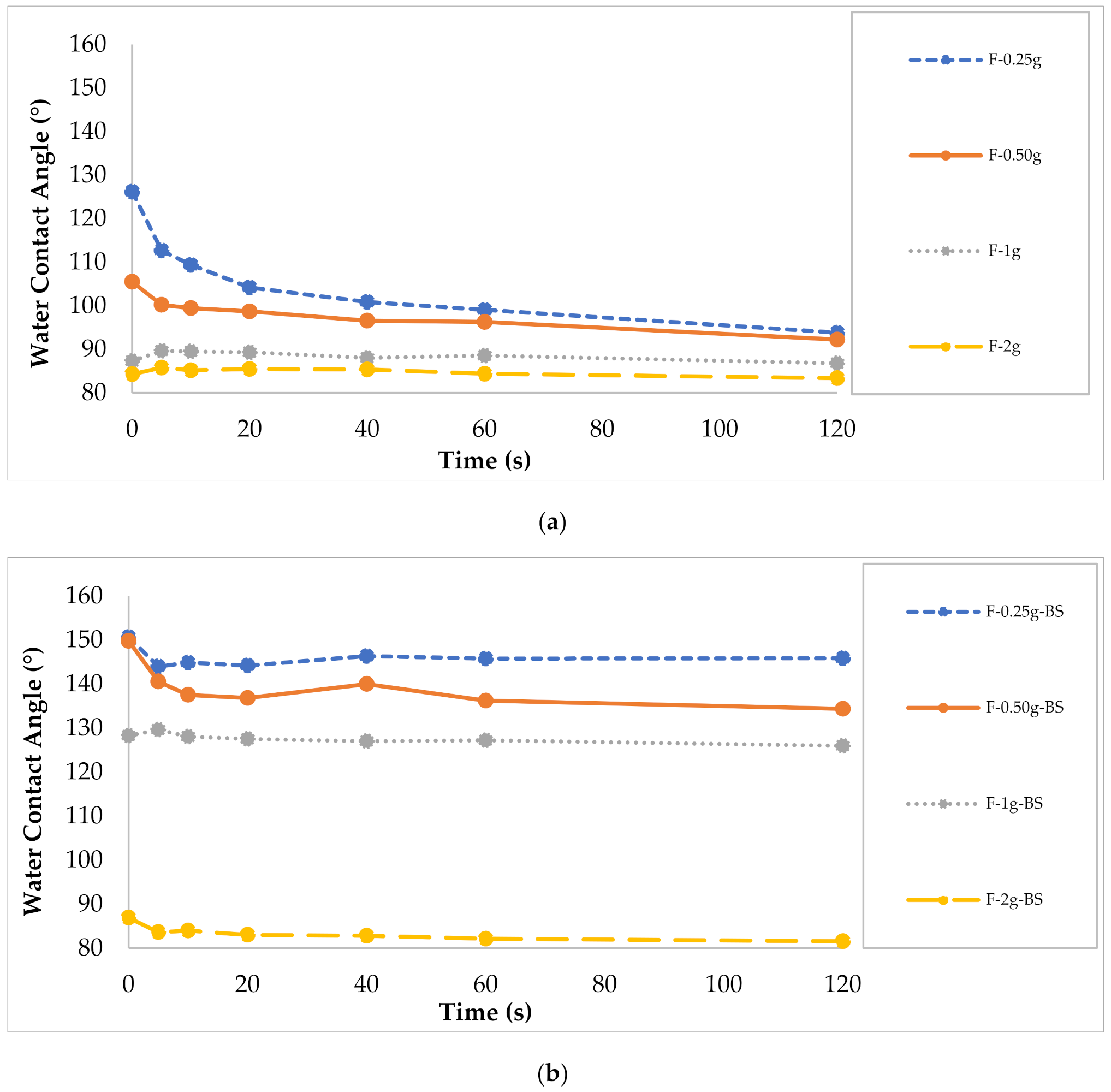

3.2.2. Water Contact Angle (Wettability)

3.2.3. Effect of the Asphalt Mixture on Photocatalysis and Wettability after Functionalization Process

4. Conclusions

- For photocatalysis, the best solutions evaluated in this research were TiO2-CET and TiO2-PTFE under an ethyl alcohol medium with a concentration of 8 g/L (AC 10 TiO2PTFE-ETH-8g/L). The treatments TiO2-ETH, PTFE-ETH, PTFE-CET, TiO2PTFE-ETH, and TiO2PTFE-CET provided superhydrophobic capability.

- Concerning both capabilities, the treatment TiO2PTFE-ETH-8g/L was the best considering the WCA and the second one regarding photocatalysis; therefore it was selected as the best solution.

- The spraying of the diluted resin decreased the photocatalytic efficiency. The highest results were with 0.25g-BS for all the asphalt mixtures. The spraying of the resin reduces the WCA. The superhydrophobic capability was achieved for the samples with 0.25 and 0.50 g with BS for R and F mixtures. Mixture A achieved the superhydrophobic capability only for 0.25 g of resin.

- Recycled and conventional asphalt mixtures were functionalized with superhydrophobic capability. The asphalt mixture with reclaimed asphalt pavement was more effective than the mixture with steel slags after the functionalization by the diluted resin and the BS. For the photocatalysis, the Mixture A was also less effective than these ones. The conventional Mixture R presented the best photocatalytic results. For the lowest resin amount, all the mixtures achieved superhydrophobicity and performed similarly regarding wettability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Health Organization. WHO Global Air Quality Guidelines. Particulate Matter (PM2.5 and PM10), Ozone, Nitrogen Dioxide, Sulfur Dioxide and Carbon Monoxide; World Health Organization: Geneva, Switzerland, 2021; ISBN 978-92-4-003422-8. [Google Scholar]

- Giunta, M.; Lo Bosco, D.; Leonardi, G.; Scopelliti, F. Estimation of Gas and Dust Emissions in Construction Sites of a Motorway Project. Sustainability 2019, 11, 7218. [Google Scholar] [CrossRef] [Green Version]

- Giunta, M. Assessment of the Impact of CO, NOx and PM10 on Air Quality during Road Construction and Operation Phases. Sustainability 2020, 12, 549. [Google Scholar] [CrossRef]

- Giunta, M. Assessment of the environmental impact of road construction: Modelling and prediction of fine particulate matter emissions. Build. Environ. 2020, 176, 106865. [Google Scholar] [CrossRef]

- Segundo, I.R.; Freitas, E.; Branco, V.T.F.C.; Landi, S.; Costa, M.F.; Carneiro, J.O. Review and analysis of advances in functionalized, smart, and multifunctional asphalt mixtures. Renew. Sustain. Energy Rev. 2021, 151, 111552. [Google Scholar] [CrossRef]

- Zabihi-Mobarakeh, H.; Nezamzadeh-Ejhieh, A. Application of supported TiO2 onto Iranian clinoptilolite nanoparticles in the photodegradation of mixture of aniline and 2, 4-dinitroaniline aqueous solution. J. Ind. Eng. Chem. 2015, 26, 315–321. [Google Scholar] [CrossRef]

- Nezamzadeh-Ejhieh, A.; Bahrami, M. Investigation of the photocatalytic activity of supported ZnO–TiO2 on clinoptilolite nano-particles towards photodegradation of wastewater-contained phenol. Desalin. Water Treat. 2015, 55, 1096–1104. [Google Scholar] [CrossRef]

- Rocha Segundo, I.; Freitas, E.; Landi Jr, S.; Costa, M.F.M.; Carneiro, J.O. Smart, Photocatalytic and Self-Cleaning Asphalt Mixtures: A Literature Review. Coatings 2019, 9, 696. [Google Scholar] [CrossRef] [Green Version]

- Carneiro, J.O.O.; Azevedo, S.; Teixeira, V.; Fernandes, F.; Freitas, E.; Silva, H.; Oliveira, J. Development of photocatalytic asphalt mixtures by the deposition and volumetric incorporation of TiO2 nanoparticles. Constr. Build. Mater. 2013, 38, 594–601. [Google Scholar] [CrossRef]

- Yu, H.; Dai, W.; Qian, G.; Gong, X.; Zhou, D.; Li, X.; Zhou, X. The NOx degradation performance of nano-TiO2 coating for asphalt pavement. Nanomaterials 2020, 10, 897. [Google Scholar] [CrossRef]

- Bocci, E.; Riderelli, L.; Fava, G.; Bocci, M. Durability of NO Oxidation Effectiveness of Pavement Surfaces Treated with Photocatalytic Titanium Dioxide. Arab. J. Sci. Eng. 2016, 1–7. [Google Scholar] [CrossRef]

- Dell’Antonio Cadorin, N.; Victor Staub de Melo, J.; Borba Broering, W.; Luiz Manfro, A.; Salgado Barra, B. Asphalt nanocomposite with titanium dioxide: Mechanical, rheological and photoactivity performance. Constr. Build. Mater. 2021, 289, 18–25. [Google Scholar] [CrossRef]

- Trujillo-Valladolid, M.; Alcántar-Vázquez, B.; Ramírez-Zamora, R.M.; Ossa-López, A. Influence of aging on the physicochemical behavior of photocatalytic asphalt cements subjected to the natural environment. Constr. Build. Mater. 2021, 295, 123597. [Google Scholar] [CrossRef]

- Fakhri, M.; Shahryari, E. The effects of nano zinc oxide (ZnO) and nano reduced graphene oxide (RGO) on moisture susceptibility property of stone mastic asphalt (SMA). Case Stud. Constr. Mater. 2021, 15, e00655. [Google Scholar] [CrossRef]

- Chen, C.; Tang, B.; Cao, X.; Gu, F.; Huang, W. Enhanced photocatalytic decomposition of NO on portland cement concrete pavement using nano-TiO2 suspension. Constr. Build. Mater. 2021, 275, 122135. [Google Scholar] [CrossRef]

- Cao, X.; Deng, M.; Tang, B.; Ding, Y.; Yang, X. Development of photocatalytic chip seal for nitric oxide removal on the surface of pavement using g-C3N4/TiO2 composite. Road Mater. Pavement Des. 2021, 22, 1178–1194. [Google Scholar] [CrossRef]

- Yang, J.; Muhammad, Y.; Yang, C.; Liu, Y.; Su, Z.; Wei, Y.; Li, J. Preparation of TiO2/PS-rGO incorporated SBS modified asphalt with enhanced resistance against ultraviolet aging. Constr. Build. Mater. 2021, 276, 121461. [Google Scholar] [CrossRef]

- Jensen, H.; Pedersen, P.D. Real-life Field Studies of the NOx Removing Properties of Photocatalytic Surfaces in Roskilde and Copenhagen Airport, Denmark. J. Photocatal. 2020, 2, 71–81. [Google Scholar] [CrossRef]

- Fernández-Pampillón, J.; Palacios, M.; Núñez, L.; Pujadas, M.; Sanchez, B.; Santiago, J.L.; Martilli, A. NOx depolluting performance of photocatalytic materials in an urban area—Part I: Monitoring ambient impact. Atmos. Environ. 2021, 251. [Google Scholar] [CrossRef]

- Sanchez, B.; Santiago, J.L.; Martilli, A.; Palacios, M.; Núñez, L.; Pujadas, M.; Fernández-Pampillón, J. NOx depolluting performance of photocatalytic materials in an urban area—Part II: Assessment through Computational Fluid Dynamics simulations. Atmos. Environ. 2021, 246. [Google Scholar] [CrossRef]

- Dalhat, M.A. Water resistance and characteristics of asphalt surfaces treated with micronized-recycled-polypropylene waste: Super-hydrophobicity. Constr. Build. Mater. 2021, 285, 122870. [Google Scholar] [CrossRef]

- Lee, E.; Kim, D.H. Simple fabrication of asphalt-based superhydrophobic surface with controllable wetting transition from Cassie-Baxter to Wenzel wetting state. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625, 126927. [Google Scholar] [CrossRef]

- Baheri, F.T.; Poulikakos, L.D.; Poulikakos, D.; Schutzius, T.M. Ice adhesion behavior of heterogeneous bituminous surfaces. Cold Reg. Sci. Technol. 2021, 192, 103405. [Google Scholar] [CrossRef]

- Wu, C.; Li, L.; Wang, W.; Gu, Z.; Li, H.; Lin, X.; Wang, H. Coating on Asphalt Pavement. Nanomaterials 2021, 11, 1–19. [Google Scholar]

- Rocha Segundo, I.; Ferreira, C.; Freitas, E.F.; Carneiro, J.O.; Fernandes, F.; Júnior, S.L.; Costa, M.F.; Landi Júnior, S.; Costa, M.F. Assessment of photocatalytic, superhydrophobic and self-cleaning properties on hot mix asphalts coated with TiO2 and/or ZnO aqueous solutions. Constr. Build. Mater. 2018, 166, 36–44. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Qu, L.; He, B.; Dai, K.; Fang, Z.; Zhu, R. Study on effectiveness of anti-icing and deicing performance of super-hydrophobic asphalt concrete. Constr. Build. Mater. 2018, 191, 270–280. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K.; Sassani, A. Superhydrophobic Coatings on Asphalt Concrete Surfaces. Transp. Res. Rec. J. Transp. Res. Board 2016, 2551, 10–17. [Google Scholar] [CrossRef]

- Nascimento, J.H.O.; Pereira, P.; Freitas, E.; Fernandes, F. Development and characterization of a superhydrophobic and anti-ice asphaltic nanostructured material for road pavements. In Proceedings of the 7th International Conference on Maintenance and Rehabilitation of Pavements and Technological Control, Auckland, New Zealand, 28–30 August 2012. [Google Scholar]

- Peng, C.; Zhang, H.; You, Z.; Xu, F.; Jiang, G.; Lv, S.; Zhang, R. Preparation and anti-icing properties of a superhydrophobic silicone coating on asphalt mixture. Constr. Build. Mater. 2018, 189, 227–235. [Google Scholar] [CrossRef]

- Torres de Rosso, L.; Victor Staub de Melo, J. Impact of incorporating recycled glass on the photocatalytic capacity of paving concrete blocks. Constr. Build. Mater. 2020, 259, 119778. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, W.; Jin, R.; Shen, J.; Smallbone, K.; Yan, C.; Hu, L. Experimental investigation of photocatalytic effects of concrete in air purification adopting entire concrete waste reuse model. J. Hazard. Mater. 2018, 353, 421–430. [Google Scholar] [CrossRef]

- Praticò, F.G.; Vaiana, R.; Giunta, M. Sustainable Rehabilitation of Porous European Mixes. In Proceedings of the ICSDC 2011; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 535–541. [Google Scholar]

- Praticò, F.G.; Giunta, M.; Mistretta, M.; Gulotta, T.M. Energy and Environmental Life Cycle Assessment of Sustainable Pavement Materials and Technologies for Urban Roads. Sustainability 2020, 12, 704. [Google Scholar] [CrossRef] [Green Version]

- Rocha Segundo, I.; Landi Jr., S.; Oliveira, S.M.B.; de Freitas, E.F.; Carneiro, J.A.O. Photocatalytic Asphalt Mixtures: Mechanical Performance and Impacts of Traffic and Weathering Abrasion on Photocatalytic Efficiency. Catal. Today 2018. [Google Scholar] [CrossRef]

- Akhtar Hossain, M. Effect of Water Submergence on the Characteristics of Bituminous Mixes Using Reclaimed Asphalt Pavement. Eur. J. Biophys. 2018, 6, 1. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Leng, Z.; Hüben, M.; Oeser, M.; Steinauer, B. Photocatalytic pavements with epoxy-bonded TiO2-containing spreading material. Constr. Build. Mater. 2016, 107, 44–51. [Google Scholar] [CrossRef]

- Zhang, W.; Xiao, X.; Zeng, X.; Li, Y.; Zheng, L.; Wan, C. Enhanced photocatalytic activity of TiO2 nanoparticles using SnS2/RGO hybrid as co-catalyst: DFT study and photocatalytic mechanism. J. Alloys Compd. 2016, 685, 774–783. [Google Scholar] [CrossRef]

- Madhukar, B.; Wiener, J.; Militky, J.; Rwawiire, S.; Mishra, R.; Jacob, K.I.; Wang, Y.; Kale, B.M.; Wiener, J.; Militky, J.; et al. Coating of cellulose-TiO2 nanoparticles on cotton fabric for durable photocatalytic self-cleaning and stiffness. Carbohydr. Polym. 2016, 150, 107–113. [Google Scholar] [CrossRef]

- Zahabizadeh, B.; Segundo, I.R.; Pereira, J.; Freitas, E.; Camões, A.; Tavares, C.J.; Teixeira, V.; Cunha, V.M.C.F.; Costa, M.F.M.; Carneiro, J.O. Development of Photocatalytic 3D-Printed Cementitious Mortars: Influence of the Curing, Spraying Time Gaps and TiO2 Coating Rates. Buildings 2021, 11, 381. [Google Scholar] [CrossRef]

- Rocha Segundo, I.; Freitas, E.; Costa, M.F.; Carneiro, J. Incorporation of steel slag and reclaimed asphalt into pavement surface layers. In Proceedings of the 5th International Conference WASTES: Solutions, Treatments and Opportunities, Lisbon, Portugal, 4–6 September 2019. [Google Scholar]

- Gao, J.; Sha, A.; Wang, Z.; Tong, Z.; Liu, Z. Utilization of steel slag as aggregate in asphalt mixtures for microwave deicing. J. Clean. Prod. 2017, 152, 429–442. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Q.; Wu, S.; Shang, F. Microwave heating of steel slag asphalt mixture. Key Eng. Mater. 2014, 599, 193–197. [Google Scholar] [CrossRef]

| Asphalt Mix | % 4/10 | % 0/4 | % Filler | % RAP 0/6 | % SS 0/10 | % Binder | % Virgin Binder | MBD (g/cm3) | BD (g/cm3) | VC (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| R | 68 | 28 | 4 | - | - | 5.5 | 5.5 | 2.428 | 2.305 | 5.1 |

| F | 67 | - | 3 | 30 | - | 5.4 | 3.5 | 2.446 | 2.334 | 4.6 |

| A | 42 | 25 | 3 | - | 30 | 5.4 | 5.5 | 2.676 | 2.569 | 4.0 |

| Mixture | TiO2 (g/L) | PTFE (g/L) | Solvent |

|---|---|---|---|

| AC 10 | - | - | - |

| AC 10 TiO2-W | 4 | - | water |

| AC 10 TiO2-ETH | 4 | ethyl alcohol | |

| AC 10 TiO2-CET | 4 | dimethyl ketone | |

| AC 10 PTFE-ETH | - | 4 | ethyl alcohol |

| AC 10 PTFE-CET | - | 4 | dimethyl ketone |

| AC 10 TiO2PTFE-ETH-4g/L | 2 | 2 | ethyl alcohol |

| AC 10 TiO2PTFE-ETH-8g/L | 4 | 4 | ethyl alcohol |

| AC 10 TiO2PTFE-CET-4g/L | 2 | 2 | dimethyl ketone |

| AC 10 TiO2PTFE-CET-8g/L | 4 | 4 | dimethyl ketone |

| Sample | Mixture | Diluted Resin (mg/cm2) | BS (mL/cm2) |

|---|---|---|---|

| R 0.25g | Reference | 0.10 | - |

| R 0.25g-BS | 8 | ||

| R 0.5g | 0.20 | - | |

| R 0.5g-BS | 8 | ||

| R 1g | 0.40 | - | |

| R 1g-BS | 8 | ||

| R 2g | 0.80 | - | |

| R 2g-BS | 8 | ||

| F 0.25g | with RAP | 0.10 | - |

| F 0.25g-BS | 8 | ||

| F 0.5g | 0.20 | - | |

| F 0.5g-BS | 8 | ||

| F 1g | 0.40 | - | |

| F 1g-BS | 8 | ||

| F 2g | 0.80 | - | |

| F 2g-BS | 8 | ||

| A 0.25g | with SS | 0.10 | - |

| A 0.25g-BS | 8 | ||

| A 0.5g | 0.20 | - | |

| A 0.5g-BS | 8 | ||

| A 1g | 0.40 | - | |

| A 1g-BS | 8 | ||

| A 2g | 0.80 | - | |

| A 2g-BS | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segundo, I.R.; Zahabizadeh, B.; Landi, S., Jr.; Lima, O., Jr.; Afonso, C.; Borinelli, J.; Freitas, E.; Cunha, V.M.C.F.; Teixeira, V.; Costa, M.F.M.; et al. Functionalization of Smart Recycled Asphalt Mixtures: A Sustainability Scientific and Pedagogical Approach. Sustainability 2022, 14, 573. https://doi.org/10.3390/su14010573

Segundo IR, Zahabizadeh B, Landi S Jr., Lima O Jr., Afonso C, Borinelli J, Freitas E, Cunha VMCF, Teixeira V, Costa MFM, et al. Functionalization of Smart Recycled Asphalt Mixtures: A Sustainability Scientific and Pedagogical Approach. Sustainability. 2022; 14(1):573. https://doi.org/10.3390/su14010573

Chicago/Turabian StyleSegundo, Iran Rocha, Behzad Zahabizadeh, Salmon Landi, Jr., Orlando Lima, Jr., Cátia Afonso, Jaffer Borinelli, Elisabete Freitas, Vítor M. C. F. Cunha, Vasco Teixeira, Manuel F. M. Costa, and et al. 2022. "Functionalization of Smart Recycled Asphalt Mixtures: A Sustainability Scientific and Pedagogical Approach" Sustainability 14, no. 1: 573. https://doi.org/10.3390/su14010573

APA StyleSegundo, I. R., Zahabizadeh, B., Landi, S., Jr., Lima, O., Jr., Afonso, C., Borinelli, J., Freitas, E., Cunha, V. M. C. F., Teixeira, V., Costa, M. F. M., & Carneiro, J. O. (2022). Functionalization of Smart Recycled Asphalt Mixtures: A Sustainability Scientific and Pedagogical Approach. Sustainability, 14(1), 573. https://doi.org/10.3390/su14010573