Abstract

Lean principles and sustainability are considered important terms in business. Solar firms are witnessing great competition to fulfill energy requirements, suffering from a huge amount of waste, negatively affecting the sustainability dimensions. Thus, the aim of the study is to build a framework for solar energy firms to achieve sustainability through adopting lean principles, which will help to fix many problems as waste and costs. The method included reviewing the literature to explore the founding of the relation between the two terms, and using a questionnaire that was directed to the responsible people in Turkish solar energy firms. The results of the survey were analyzed to: (1) Find out what the responsible people think about the two terms lean and sustainability; (2) Measure the probable relationship between lean principles and sustainability dimensions by applying a linear regression test; (3) Use the results of point number two to build the framework. The result showed there was a high level of relative importance about the two terms from the point of view of managers and experts in solar firms. In addition, the study found a relationship between adopting pull and flow principles of lean, and achieving economic and social dimensions of sustainability, this finding is represented in a framework.

1. Introduction

In recent years, businesses have been under increasing pressure to find a way to manage their operations responsibly regarding their environmental and societal impacts. This has inspired companies and researchers to find ways to implement sustainable processes. The importance of sustainability caught considerable attention after the report of the United Nations’ World Commission on Environment and Development in 1987 with the title “Our common future”, which focused on the relationship between society, resources, and the environment through a long-term environmental perspective to achieve sustainability [1]. Sustainable Development means “meeting the needs of the present without compromising the ability of future generations to meet their own needs” [2]. In return, the term “lean” that Toyota Motor introduced in 1950 continued to evolve in a manner commensurate with the progress made in the field of operations management, which was represented in two main stages. The first stage was represented by working to keep the continuous improving of quality until the beginning of the 1990s, and then continuous working on the quality, cost, and the delivery side in the late 1990s, reaching to the second stage that has been concerned with customer value since 2000 due to the increasing interest in sustainability in that time period, especially with regard to the field of operations management. Scientists also began to study the compatibility and synergy between the traditional lean and sustainability [3]. The increased interest in sustainability and the increased attention towards improving the environmental sector has made environmental sustainability a primary goal in the strategies of organizations, with the necessity to go along with each of the goals of traditional organizations represented in increasing profitability and efficiency [4], which is involved under green industrialization that is considered an important way in the path of achieving sustainable development in the industrial sector. As a system it does not require the increased use of natural resources for expansion and growth. Lean holds the same principle in manufacturing and management operations [1].

In parallel, academics have studied the possible relationships between the adoption of lean and green production outcomes. The link between lean production and sustainable development has been called the lean–green manufacturing approach, which combines lean practices focused on customers’ demand, and green practices focused on reducing the business’ environmental impact, Nevertheless, lean–green manufacturing is still a new practice, lacking a clear and structured research definition; lean is “a systematic approach to process improvement. The method is based on finding and reducing waste coupled with continuous improvement”; in addition, using lean to produce renewable energy products will make the costs low, help the investment of capital to be more efficient, provide products in the shortest possible lead time, and ensure the continued growth of the industry [5].

Some scholars argue that lean firms can achieve environmental performance improvements since lean and green may have elements in common as both are focusing on reducing waste and increasing the efficiency of production processes [6].

Various countries’ economies are reliant on the energy market, and any improvements in this field can be seen in economic stability, sustainability, production, education, and health care, among other things. Since its activities are very distinct from those of other manufacturers, the energy industry is one of the industries that face a strong challenge in terms of efficiency and transformation to lean compared with other manufacturing [7], and solar energy is one of these types of industry. In addition, the problem of high waste in the industry represents an obstacle in achieving sustainability from both the environmental and economic dimensions. Despite the role of solar energy in raising the economic return and helping to achieve the required value for the customer, the increase in growth in this sector created a new challenge represented by the large amount of waste in it. According to the joint report of International Renewable Energy Agency (IRENA) and the International Energy Agency Photovoltaic Power Systems Program (IEA-PVPS) the waste of this sector will achieve 78 million ton [8]. This huge amount of waste will negatively affect access to sustainability as it results in a large loss of resources, which is reflected in multiple negative ways, such as economic loss. Thus, the work to get rid of problems that surround the solar energy sector will support it and reduce the cost of production and, as a result, consumers are encouraged to use it, this will help in achieving sustainability goals. One of the methods is the using of lean, according to its contributions in this field. Despite the ability of lean operation to solve a wide range of sustainability matters, when defined correctly, the benefits are not fully explored in many industrial sectors or in a wide range of cases study [9].

This study will add an important contribution to the solar sector in Turkey. The country has a good opportunity to investigate in solar energy sector, with sunshine per day equal to 7.5 h and solar radiation equal to 4.2 kWh/m2 per day. As a result of the geographical location, the solar energy sector is at the top with wind energy in the energy market in Turkey and, as a renewable energy resource to achieve Turkey’s goal in 2023, Turkey is among the largest developing solar markets. By the year 2018, the amount of installed solar collector area in Turkey was calculated as almost 20,200.000 m2; in addition, Turkey’s policies supported the solar sector as a result of Turkey’s needs to increase energy supply security and to meet the growing need for energy because of the increase in the population and ongoing economic development. That is why Turkey is working to develop this sector as a part of the goal to achieve 100% renewable energy powered electricity in 2050 [10].

The contribution of the study will be through developing a framework to clear the relationship between lean principles and sustainability dimensions, making the application of lean in this sector easier as well as achieving sustainability, which today is one of the most important goals for many firms around the world, and to obtain the benefits through fixing the many problems of waste and cost.

Thus, this study aims to build a framework for solar energy firms to adopt lean principles to achieve sustainability by studying companies in Turkey. The main purpose of this study is to work to achieve the sustainability of solar firms and measure the awareness of responsible people in companies of this sector towards lean principles and sustainability implementation.

This article is organized in six sections: the Section 1 introduces the article’s motivation and goals, Section 2 presents a summarized literature review, Section 3 describes the proposed approach, in Section 4 the results are presented, and the discussion is included in Section 5. Finally, in Section 6 the conclusions are outlined.

2. Literature Review

2.1. Lean and Sustainability: An Overview

The topic of lean became common through a book, “The Machine That Changed the World,” The lean concept is defined in many ways, because lean is still evolving [11]. Lean manufacturing is a common means of continuous improvement that has reshaped global manufacturing processes, practices, and principles.

It revolves around a philosophy of continuous performance improvement through systematic waste disposal on the manufacturing floor [12]. A review of the literature agreed that the main principles of lean are (Value, Value Stream, Flow, Pull, and Perfection) [13], the principles were presented to address the many challenges that arose inside and between business units as a result of variances in company culture and management thought process [12]. The basis of the lean management philosophy is that the overall performance of an enterprise must be directed into a logical and singular system with the main objective of providing value to clients, and indicating that a lean process alone cannot be the source of all benefits [11].

In parallel, the concept of sustainability started to be popular after the Brundtland report in 1987 (WCED, 1987), which was interested in the conflict between humanity’s desire for a better existence on the one hand and nature’s constraints on the other. Over time, the notion has come to be reinterpreted as embracing three dimensions: social, economic, and environmental. There are many definitions for Sustainability, and the popular one of (WCED) in (1987) is: “economic development that meets the needs of the present generation without compromising the ability of future generation to meet their own needs.” [14]. Sustainability aims to create mechanisms that contribute to maximizing profits while preserving environmental aspects, as well as the need for communities while preserving the rights and protection of employees [11].

Although many studies have supported the importance of using lean to improve the flow of operations, there are still many problems in its application. Perhaps the most important limitations are its weakness in dealing with variance and the lack of consideration for human aspects, in addition to the operational focus being confined to the workshop floor [15]. There are also a number of other problems represented by complaints from trade unions and the increase in the responsibilities of employees in companies without an appropriate increase in terms of salaries. These problems are the result of a misunderstanding of the mechanism of the way lean works, and these problems appear more clearly in small and medium companies [16]. The reason for these problems is not related to lean as much as to the need to understand how it works. According to [17], the correct application of lean depends largely on the level of understanding of senior management in companies of its work mechanisms and the correct way to implement it, with the need for an understanding between senior management in companies and workers to work together in order to create an image of the integrated application of it, in addition to the need for developing long-term employees and leaders.

Many researchers advocate that lean is fundamentally linked to sustainability [18], because lean supports the following points, which are considered as the main goals of sustainability, such as reducing cost, emission reduction, creating economic value, improving the condition of work, as is explained further in Section 2.2.1. In fact, even today, the correlation between lean and sustainability is still not conclusive, and, also, the relationship is not well known between these two terms [19]. Reviewing the literature showed that there are differences between various sectors about the influences of lean on sustainability. However, there are many sectors that need to be studied to evaluate the relationship between the two terms, as the situation in the solar energy sector in Turkey shows. Reviewing the literature showed that no framework to explain the relationship between lean principles and sustainability dimensions in the solar sector was found; however, the positive impact of adopting lean to reduce waste and, as a result, increase the efficiency, was proved through certain studies.

This shows the probability of finding a relationship between lean principles and sustainability dimensions and that the effect is not a coincidence. However, even today there are different opinions about the relationship between lean and sustainability, which will be explained in the next parts.

2.2. Lean and Sustainability Relationship through Different Studies

The attention on the relationship between lean principles and sustainability development led the researchers to study the effect of lean to achieve sustainability and the degree of the relationships between them. In fact, there are differing viewpoints in the literature on the relationship between lean and sustainability. This statement can be divided into the following: (1) Studies support that lean achieves the sustainability agenda, (2) Studies advocate that lean does not match the main sustainability agenda, (3) Studies claim the integration between lean and sustainability; these points will be demonstrated in detail in the following section.

2.2.1. Lean Achieves Sustainability Agenda

In general, the studies support the idea that lean is achieving the sustainability goals, that is lean is removing waste and optimizing the whole operation. One research study found that lean promotes sustainability in manufacturing through an energy-saving and emission-reduction strategy [20], and, according to another piece of research, it is possible to create environmental benefits alongside economic value, for example, eco-friendly goods are less expensive to manufacture as lean and green methods are incorporated into the design and service delivery processes [21]. A study that analyzed sustainability reporting, found that adopting lean in different companies increases the quality of the work conditions [19], another study of analysis and synthesis models found in a selected research, reported that integrating lean–green policies is an effective way to maintain and expand a greener manufacturing operation [22]. A study about a solar power plant found that smart lean manufacturing improves the efficiency through the reduction in waste and non-value added activities [7]. Another study, which examined the interaction between the principles of lean and sustainability on the AEC industry, showed that by adopting those principles in terms of optimizing processes and stakeholders’ quality of life, reducing all forms of wastes, the tracking and self-evaluation for performance growth, and marketing challenges, lean and sustainability production could have a virtually identical agenda [5].

2.2.2. That Lean Does Not Match the Main Sustainability Agenda

Other researchers have argued that lean does not match the main agenda of sustainability. A study to evaluate the relationships in the Iberian Peninsula adopted the view that the relationships remain poorly understood and were dispersed by various sustainability indicators because their results found that the evidence that lean manufacturing is linked to any of the sustainability foundations was inconclusive [19]. A study using a green–lean simulation model claimed that implementing lean methods has a negligible impact on the company’s environmental results [23], while another study reported that lean alone cannot achieve the sustainability targets or address all of the sustainability matters [24]. This is because the matters of increasing production in the sector of renewable energy, increasing the salary remuneration, or increasing the turnover were not identified [19].

2.2.3. The Integration between Lean and Sustainability

Some researchers have attempted to incorporate sustainability into the lean concept to maximize its gains; a study about integrating sustainability and lean reported that “Sustainability and leanness are organizational approach concepts for more efficient activities and increased competitiveness” [25], and, in another study, the authors suggested the use of lean strategies to improve sustainable manufacturing with an effect on the environment since the study’s research results showed that integrating the two dimensions enhanced the system’s performance and led to the growth of a sustainable company [26]. Another study reported that lean is the first step towards achieving sustainability. They even declared that environmental sustainability is the next step in the lean philosophy to minimize the product’s negative impact on the environment and safe resources, and this was what was happening in the Japanese auto industry; they were beginning to use lean toward currently hybrid engines and vehicles with recycled components [27].

In conclusion, we can notice that there are various opinions about the relationship between the two terms, but, at the same time, many researchers support the idea of the ability to find an interaction and an alignment between lean and sustainability goals. Thus, to build a framework that aims to adopt the use of lean principles to achieve sustainability in the solar energy firms in Turkey, there must be a set of steps to follow to make sure that there is a relationship between the two terms in this sector. These steps will be explained in the methodology used in the paper.

2.3. Influence of Lean in Sustainability Dimension

This section focuses on the degree to which the use of Lean can improve the results of sustainability factors. As pointed out in this research, the views differed among researchers about the impact of the application of lean on sustainability and the relationship between them. In general, some companies have succeeded in achieving better results and higher competitiveness through the application of lean principles, while others have not been able to achieve these results as they have not been able to maintain medium- and long-term results [28].

The following paragraphs outline some of the most important recent contributions made by a group of scholars to explain the lean–sustainability area, the main influences are summarized.

2.3.1. Influence of Adopting Lean in Social Dimension

Despite the importance of the social dimension as one of the main dimensions of sustainability, this dimension has not been sufficiently studied, as referred on the study of [5] to the need to pay attention to the social dimension as a goal affecting the situation in the environmental dimension side. The result of reviewing the literature showed that applying lean appeared to impact some sectors of the social dimension, such as increasing the quality of work [29,30] and increasing the employee’s engagement in decision making [30].

2.3.2. Influence of Adopting Lean in Environmental Dimension

Many studies supported the view that environmental management is greater in the firms adopting lean in their progress: adopting lean will help in increasing performance, as well as helping the decrease in industrial waste [28,31] energy saving, and emission reduction [20]. Despite that, we notice that no references were found about the effect of lean on environmental sustainability in renewable energy companies [19].

2.3.3. Influence of Adopting Lean in Economic Dimension

Economic performance, which is assessed by productivity, cost reduction, revenue, profit, cash flow, and business growth, is one of the pillars of sustainable performance. Achieving inclusive sustainability through the lean approach enables institutions to emphasize reaching economic sustainability [32]. When reviewing the literature, the results showed that applying lean would help to maximize the profit [33], increase the performances of the process, and decrease the operational cost [34]. However, there are few references about the effect of lean in the economic dimension and, even for the turnover impact, no references were discovered [19].

2.4. Hypothesis Development

To achieve the goal of the study we tried to find concrete facts about the effect of each principle of lean on the three dimensions of sustainability to propose the relationship in the solar sector. To develop the hypothesis, we need to come first to the definitions of each factor of lean and sustainability. The lean principles are defined, according to [35], as the following: Value is the “capability provided to customer at the right time at an appropriate price, as defined in each case by the customer.” The Value stream is the “specific activities required to design, order, and provide a specific product, from concept to launch, order to delivery, and raw materials into the hands of the customer.” Flow is defined as the “progressive achievement of tasks along the value stream so that a product proceeds from design to launch, order to delivery and raw materials into the hands of the customer with no stoppages, scrap or backflows.” The fourth lean principle of Pull is defined as a “system of cascading production and delivery instructions from downstream to upstream in which nothing is produced by the upstream supplier until the downstream customer signals a need.” The fifth principle of lean is Perfection, which is defined as the “complete elimination of Muda so that all activities along a value stream create value.” The sustainability dimensions are defined as the following: The social dimension, in fact, has no agreement to define it [36], but we can summarize the most common ideas of the social dimension in that it aims to establish justice and equality between the community to reach an acceptable degree of satisfaction. On the other hand, the environmental dimension aspects are focused on efficiency, reducing waste and pollution, and using renewable energy, and is defined as a way that enables organizations to value the influence of their operations on the environment [37]. The economic dimension is defined as: “In the economic debate, sustainable development is most often described as the need to maintain a permanent income for humankind, generated from non-declining capital stocks” [38], and following on from this:

- The relation between Value and Sustainability dimensions:

According to the definitions of the value and sustainability dimensions, we notice that the effect of value in the social dimension is shown with employees being involved in work decisions, which creates a high level of satisfaction and enhances the service performance [39]. Moreover, through increasing quality and efficiency a high level of customer satisfaction is found, which is reflected in the increasing of the economic return [40], and the relationship between the value and environmental dimensions is shown in the reduction in the need for re-working by making quality control a job for every worker [30]. Thus, H1, H2, and H3 were formulated:

Hypothesis 1 (H1).

There is a significant relationship between adopting value on lean and achieving social indicators on sustainability in solar energy sector.

Hypothesis 2 (H2).

There is a significant relationship between adopting value on lean and achieving economic indicators on sustainability in solar energy sector.

Hypothesis 3 (H3).

There is a significant relationship between adopting value on lean and achieving environmental indicators on sustainability in solar energy sector.

- 2.

- The relation between Value stream and Sustainability dimensions:

The effect of the value stream on the social dimension was found by enhancing the work environment and improving training programs [41]. Additionally, a relationship with the economic dimension was found through reducing unwanted activities such as reducing unnecessary testing in the clinical practice [42]. In addition, the elimination of hidden and unwanted activities gave a positive effect to the environmental dimension, as shown in the situation in a case study of (Plymouth Tube) through the decrease in lubrication use by 1400 gallons [30]. Thus H4, H5, and H6 were formulated.

Hypothesis 4 (H4).

There is a significant relationship between adopting value stream on lean and achieving social indicator in sustainability in solar energy sector.

Hypothesis 5 (H5).

There is a significant relationship between adopting value stream on lean and achieving economic indicator in sustainabilityin solar energy sector.

Hypothesis 6 (H6).

There is a significant relationship between adopting value stream on lean and achieving environmental indicator in sustainabilityin solar energy sector.

- 3.

- The relation between Flow and Sustainability dimensions:

With regards to the effect of flow, a positive effect was found between flow and creating an awareness among the employees about the plans for the job [13]. In a study to build a lean and green model for a production cell by adopting the flow principle in the processes, a positive impact was found to reduce resource use as an environmental aspect and reduce the total cost, which improved the economic side [33]. As a result H7, H8, and H9 were formulated

Hypothesis 7 (H7).

There is a significant relationship between adopting flow on lean and achieving social indicator in sustainabilityin solar energy sector.

Hypothesis 8 (H8).

There is a significant relationship between adopting flow on lean and achieving economic indicator in sustainabilityin solar energy sector.

Hypothesis 9 (H9).

There is a significant relationship between adopting flow on lean and achieving environmental indicator in sustainabilityin solar energy sector.

- 4.

- Pull and Sustainability dimensions:

The pull approach works through many effects that support the sustainability dimension, such as lowering of work-in-process, the elimination of potential waste from damaged products, and working for lesser floor space utilization. The reduction in waste is presented as a positive effect to the environmental dimension [30]. The application of pull alongside value stream principles to reduce waste management gave benefits on the economic and environment dimensions, according to [43]. The same study proposed that the work’s in depth results would help companies to identify the accurate impact of their waste improvement plan and enhance it in different dimensions: social, economic, and environmental. According to these facts H10, H11, and H12 were formulated.

Hypothesis 10 (H10).

There is a significant relationship between adopting pull on lean and achieving social indicator in sustainabilityin solar energy sector.

Hypothesis 11 (H11).

There is a significant relationship between adopting pull on lean and achieving economic indicator in sustainabilityin solar energy sector.

Hypothesis 12 (H12).

There is a significant relationship between adopting pull on lean and achieving environmental indicator in sustainabilityin solar energy sector.

- 5.

- Perfection and sustainability:

According to the definition of perfection, we can show clearly that this principle means working towards perfection; in addition, it encourages continuous improvement through the investment in new opportunities [12]. Adopting this principle is a way to achieve the sustainability dimensions depending on its effect in supplying the customer’s product. The principle of perfection also enhances the performance by selecting suitable delivery techniques and forces all organizational levels to work for continuous improvement [37]. As a result, H13, H14, and H15 were formulated.

Hypothesis 13 (H13).

There is a significant relationship between adopting perfection in lean and achieving social indicator in sustainabilityin solar energy sector.

Hypothesis 14 (H14).

There is a significant relationship between adopting perfection in lean and achieving economic indicator in sustainabilityin solar energy sector.

Hypothesis 15 (H15).

There is a significant relationship between adopting perfection in lean and achieving environmental indicator in sustainabilityin solar energy sector.

3. Materials and Methods

To achieve the aim of the study and to build the framework, a set of steps with a specific method for every single step is used. Initially, the references were reviewed in order to determine the factors that should be studied for both terms of the study; the factors that were adopted are the five factors of lean mentioned before (Value, Value Stream, Flow, Pull, and Perfection) as independent factors, and another three factors of sustainability (Social, Economic and Environment) as a dependent factors, which are shown in Table 1.

Table 1.

Shows the Factors for Lean and Sustainability.

In order to create the questionnaire that was used to conduct this study, the essential points to be inquired about each factor were identified.

In addition, the questions were presented to a group of experts who have experience in the subject of the study to develop the questions and find the best formulation for them, taking into consideration the most important aspects to be focused on, and investigating through the opinions presented by them to ensure that the questions would be useful for reaching the goal of the study.

After that, the questionnaire was directed to responsible persons (Managers, Experts) in the solar energy companies in Turkey to fill out the questionnaire because of their direct participation in the work process, also, because of their sufficient knowledge and experience they had about their companies. The questionnaire was directed in two stages: The first used the answers to test the reliability by using Cronbach’s Alpha test. Values ≥ 0.7 were accepted by researchers, according to the rule-of-thumb, to determine the strength of association as a good value [44], as shown in Table 2, and determine which questions would be adopted in the questionnaire. The second step started by using the final copy of the questionnaire and using the information that was received as a database for analysis, using SPSS_v25. The survey contained a total of 44 questions as shown in Appendix A, these questions included eight questions as descriptive ones about the companies. The descriptive questions were divided into two types, five of them as structured questions with predetermined response options, while the rest of the questions were structured as open response options. The other 36 questions were about the factors of the two terms, with 3–5 questions for every single factor of lean and sustainability, questions were structured with predetermined response options by using five-point Likert scales ranging from “strongly disagree” to “strongly agree”. The scales of responses are shown in Table 3.

Table 2.

Shows the strength of association according to the rule-of-thumb.

Table 3.

Shows the Likert Scale.

The purpose of the survey was to answer the hypotheses formulated through reviewing the literature. The hypotheses were established to scout the significant relationships between respondents at (α = 0.05) about adopting lean in the solar energy sector and achieving sustainability through the five main principles of lean (value, value stream, flow, pull, and perfection). Each one of these main factors was divided into three hypotheses to examine the significant relationships between the factors and the sustainability indicators for the three dimensions of sustainability, separately shown in Section 2.4. The indicators for the sustainability dimensions were, for example, increase profit as economic indicator and decrease operational costs as economic dimension; decrease energy consumption or use renewable energy resources, and decrease industrial waste as the indicators for the environmental dimensions; develop the work conditions and environment, and increase the participations of employees in the decision making as a social dimension).

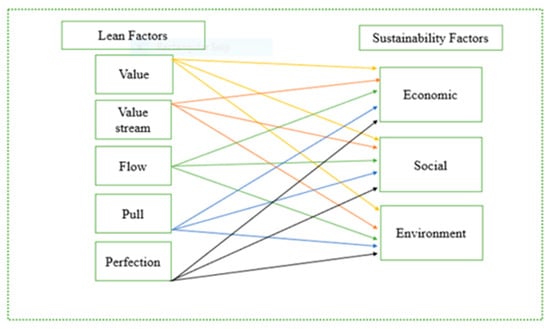

The result of analyzing the responses will lead to accepting or rejecting the hypothesis according to the (sig.) values, if these are less than (0.05) it means there is a significant relationship at (α = 0.05) between these factors and there is success on adopting lean to achieve sustainability in solar energy firms in Turkey The hypotheses can be illustrated through the following conceptual framework shown in Figure 1.

Figure 1.

Shows the conceptual model.

The hypotheses were examined by applying linear regression analysis on the survey responses. In addition, the importance of using the survey was to identify which tools of “lean” and “sustainability” concepts are used within the companies, to measure what the responsible people in these companies think about these two terms, and to measure the perception towards implementation of lean and sustainability principles by calculating the means of the Likert scale’s levels of agreement as shown in Table 4, and measuring the means of answers, then comparing the means of answers with the Likert scale’s levels of agreement.

Table 4.

Shows the mean of Likert scale level of agreement.

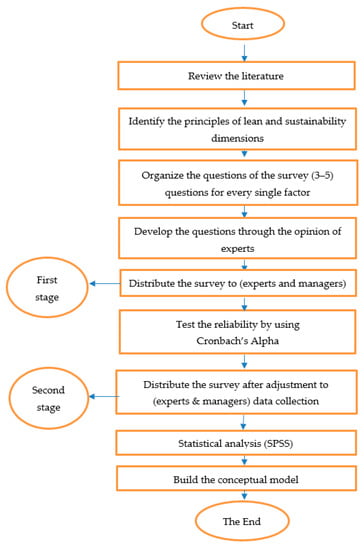

By adopting the abovementioned steps, the researchers designed the final view of the framework. The steps of the methodology are described in the flow chart shown in Figure 2.

Figure 2.

Overview of the methodology of the study.

4. Results

The values for the reliability test of the questionnaire ranged between 0.723 and 0.823 for all of the eight factors of lean and sustainability measured. As shown in Table 5, the values can be considered as acceptable results and the strength of association for these values ranged between good and very good values, according to the rule-of-thumb [44].

Table 5.

Evaluation of the stability of the tool using Cronbach’s Alpha.

According to the analysis of the total of (35) valid answers that were received from the solar energy firms, the results showed a high level of relative importance towards the implementation of both lean and sustainability principles in solar firms. The Value factor in lean and the Environmental factor in sustainability gave the highest levels of agreement (Strongly Agree) and the other factors in lean and sustainability gave a level of relative importance (Agree), as shown in Table 6, on the scale that ranges in five degrees of agreement (Strongly disagree, Disagree, Neutral, Agree, Strongly Agree).

Table 6.

The level of relative importance of lean and sustainability factors.

Calculating the items’ means of lean principles and sustainability dimensions gave the results in Table 7 and Table 8, respectively.

Table 7.

Shows the mean and standard deviation of lean principles.

Table 8.

Shows the mean and standard deviation of sustainability dimensions.

Table 7 shows the means of the lean principles, The means of the value items that are concerned about improving the value for the customer, identifying defective items, identifying the waste to improve the quality and cost, as well as sharing the responsibility with all the workers, ranged between 4.28–4.53 on the Likert scale for items 1, 2, 3, and 4, respectively. The means of the Value Stream items, which were about minimizing the waste in materials, transportation time, inventory level, lot size, machine time, and using tools to measure the speed of the project, ranged between 4.06–4.52 in the Likert scale of the items 5, 6, 7, and 8, respectively; the means of both Value and Value Stream were considered as good values. The Flow items that were directed to mapping the flow of materials to identify the non-added value, map flow as organizational culture, idle time, and work just in time ranged between 3.78–4.25 on the Likert scale for the items 9, 10, 11, 12, and 13, respectively; all the means showed good values, and the minimum means were for the items 12 and 13 compared with the others, which were about the issues of idle time and just in time. Additionally, Pull items, meaning contained aspects as ordered materials, low inventory, clear job, the time spend in each order, adopting new management tools, ranged between 3.69–4.28 on the Likert scale in the items 14, 15, 16, 17, and 18, respectively, which are considered as good mean values. The minimum means of pull items were for 17 and 18 compared with the others, which were about the issues of minimizing the required time in progressing the orders and adopting new management tools to improve the speed of work and minimizing waste and cost. For Perfection items that were concerned about improving the procedure by actively involving employees, team work, and using the new management practice to deal with quality and improving the communication system, the means ranged between 3.72–4.13 on the Likert scale for the items 19, 20, 21, and 22, respectively. All mean results showed good values, the minimum mean of the perfection items was for item 21 compared with the others, which was about depending on management tools that deal with the perfection of the quality and waste ratios. The minimum mean values mentioned above in Flow, Pull and Perfection refer to the belief that the responsible people in solar firms are not familiar with these item as much as with the others.

Table 8 shows the means of the sustainability dimensions. The items about the social dimension that are about enhancing work conditions, communication in a team, employees skills, and work opportunities, showed good values with means ranging between 3.53–4.34 on the Likert scale for the items 23, 24, 25, 26, and 27, respectively. The minimum mean compared with the other items was for item 25, which concerned the equality in the opportunity between workers. The items about the environmental dimension, which were about minimizing the resource waste, reducing energy use, reduced emissions, energy type use, and using green materials, showed good values and ranged between 4.13–4.66 on the Likert scale for the items 28, 29, 30, 31, and 32, respectively. In addition, the results of the economic dimension of sustainability, which involved using local resources, job creation, and the sustainable value of properties and tracts of land, showed good means, which ranged between 3.88–4.22 on the Likert scale for the items 33, 34, 35, and 36, respectively. The minimum mean between them was for the item number 34, which was about job creation. The reason behind the low means of the items that we referred to is the unfamiliarity of the responsible people with these items as much as with others.

Moreover, the results of the correlation between the items of each factor of lean and sustainability showed a relationship between them; so, the items for each factor seem to be related to each other, as shown in Appendix B and Appendix C, for the lean factor items and the sustainability factor items, respectively.

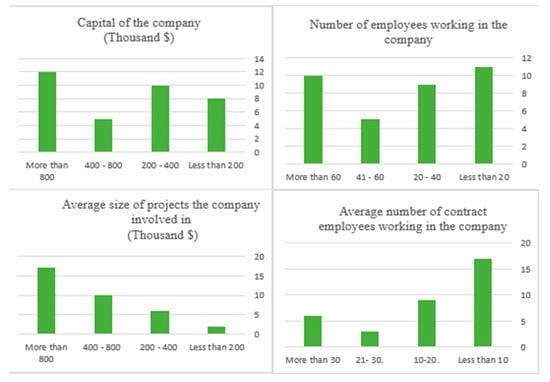

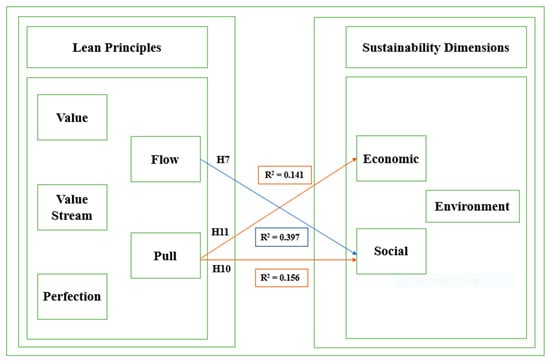

The descriptive analysis for the respondents shows the different demographical information, as shown in Figure 3 and Figure 4. On the other hand, the results of the linear regression analysis to measure the relationships between the lean and sustainability factors found a significant effect for the Pull and Flow factors of lean with the Social and Economic factors of sustainability: the values of (P) between (Flow and Social), (Pull and Social), and (Pull and Economic) were less than (0.05) as shown in Table 9.

Figure 3.

Shows the descriptive information about position of the responders, company’s field of work, company experience, and companies’ location distribution).

Figure 4.

Shows the descriptive information about Capital of the company (USD Thousand), average size of projects the company involved in (USD Thousand), number of employees working in the company, and average number of contract employees working in the company.

Table 9.

Regression analysis to explain the effects of independent factors.

While there was no significant effect found of lean factors on the Environment factor in sustainability, Value, Value Stream, and Perfection also showed no significant impact on any of the three sustainability factors; so, we can only accept H7, H10, and H11, and reject the other hypotheses, in return accepting the alternative hypotheses as a result of not finding any significant relationship, as shown in Figure 5. This explains the final framework about the type of the relationship between the factors of the two terms of the study (lean and sustainability).

Figure 5.

The final framework of the study.

5. Discussion

The findings of the study showed a high level of agreement from the point of view of the responsible people on solar firms towards all the factors of lean and sustainability in the study, which means there is a high level of awareness about the importance of these factors and incorporation of them in the processes of solar firms. The high level of awareness should make it easier to implement these factors in solar energy firms. This point could be considered as a positive one for the firms in this sector because many sectors still need to pay more attention to the importance of these two terms, which makes the implementation of these terms harder, Additionally, all the means of the items for the two terms lean and sustainability showed a good level, however, the weakest items were the result of the unfamiliarity of the responsible people with these items as much as with others. However, this can be improved through increasing the awareness about the importance of these items to achieve better outcomes.

Despite the different views among scientists about the relationship between lean and sustainability, the results showed that there are interrelationships between them in the solar energy sector and that this may be due to the lean role in addressing many problems that negatively affect achieving sustainability, such as minimizing the waste in solar power plants [7] and minimizing the cost [13]. In addition, the role of lean is important in many other aspects of the interests of society, such as raising efficiency [45], due to the methodology that lean follows in dealing with these issues.

The results found a significant effect of the implementation of some of the lean principles (Flow and Pull) on other factors of sustainability (Economic and Social); this effect helps to achieve the sustainability. The relationship with the social dimension that was found is considered an interesting result because many researchers have neglected the relationship between lean principles and social dimensions, which has caused an unclear view about the importance of this dimension, Additionally, the results correspond with many researchers’ results about the relationship between lean and sustainability, and the ability of lean to achieve or influence sustainability dimensions in a positive way. The relations found between Flow and Social dimensions and Pull with Social and Economic dimensions on the other side support the results on the benefit of adopting lean to achieve sustainability dimensions. Moreover, the results of the study support the opinions about the importance of studying each sector separately because of the different correlations between different sectors. For example, the correlations in the study showed a correlation between the Pull principle with both dimensions of sustainability, Economic and Social but no correlation with the Environmental dimension was found, while, in another study, the results showed a correlation between the Pull principle with the Economic and Environmental dimensions and, at the same time, no correlation with the Social dimension was found [43]. The relationships found in the study between the factors are as follows:

- Lean Manufacturing and Economic Sustainability:

The correlation that was discovered was the effect of the Pull factor on the Economic factor in sustainability. The apparent effect is the possibility of achieving an increase in profits and a decrease in the working capital thanks to reducing the inventory and decreasing the requirement space as one of the procedures that the pull works on according to its tools just in time (JIT). Lean, with these strategies, works to reduce the additional costs at the same time as continuing the work. Thus, it is similar to the goal of economic sustainability, which works to support the long-term growth and preservation of financial resources. However, finding this correlation is the first step towards achieving economic sustainability as companies must work on applying lean tools correctly in order to achieve economic sustainability; on the other hand, the economic result of this application of the lean tools are not immediate in most cases. The main reason that led to the failure of many companies in various sectors to reach the goal of achieving or developing economic sustainability was that these companies did not follow the right way of implementing the lean tools.

- 2.

- Lean Manufacturing and Social Sustainability:

The discovered correlation between the Pull and Flow factors of lean besides the Social sustainability dimension represents the possibility of improvement and development in the Social dimension of sustainability when applying lean tools. Lean works to preserve the safety of workers; at the same time, it tends to make work successful when all participants share the responsibility of developing the work and completing the tasks in a better way: this makes workers feel positive about the importance of their role and status at work and not just because they are only task executives. As a result, this facilitates work for the managers and responsible persons in companies as well, improving the general situation of the work, facilitating the implementation of tasks, and creating higher efficiency. In a way, the effort that is made is a collective effort to finish the tasks in the company. On the other hand, lean is interested in finding programs and tools that contribute to arranging, facilitating, and developing work to carry out their duties. The tools used in lean manufacturing are concerned with creating a better atmosphere of work more than their quest to reduce the number of jobs, and this matter contributes to removing the fears that some workers may have about implementing lean in their companies. However, the role of lean in achieving or improving societal sustainability depends on its successful application, as lean is a double-edged tool in this matter. Using it in the wrong way may add obstacles to employees and lead to tension in the general atmosphere of work.

- 3.

- Lean and Environmental Sustainability:

No correlation was found between these two dimensions in the solar energy companies, and this result is similar to the results obtained in other types of renewable energy companies. Lean aims to reduce waste and energy use, as well as reduce the use of resources, these tasks are considered environmentally friendly tasks. Still, the lack of interconnection between the two dimensions may be because they work in parallel, which does not allow for any intersection between them. However, some expectations indicate that the development of both dimensions may lead them to a stage where they will move in one line towards achieving the goal of both environmental sustainability and lean.

6. Conclusions

The study’s main aim is to find a model that helps solar energy companies in Turkey to reach sustainability by using lean principles. The scientific contribution of this paper is to explore the way for solar energy companies to achieve the sustainable development that companies in various sectors are seeking today, which is witnessing a great competition in the market to achieve it. The study worked by exploring the lean factors that help in achieving sustainability in this sector and understanding which sustainable dimensions can be reached by applying lean principles. Moreover, the study measured how the responsible persons in solar energy companies think about the importance of the implementation of both terms (lean and sustainability) in this sector. The results showed a high level of awareness about understanding the importance of these two terms and, at the same time, shed light on some points that can be developed to give better outcomes as the issues were related to minimizing the required time. This awareness will help managers use these results to understand the positive return of the integration of lean and sustainability. The studies proved the possibility of achieving both dimensions of sustainability (Economic and Social) due to implementing the two factors of Lean (Pull and Flow). Although there was no direct correlation between lean and environmental sustainability found in the study, this does not necessarily mean there is a distance between these two topics. Still, it may indicate that they follow a parallel path, and this is what was found from the literature review about the path of lean and sustainability towards the environmental sustainability dimension. However, the framework created by this study that clarified the correlation between the use of lean factors and achieving sustainability, is considered just a step in the direction of reaching the goal of the companies to achieve the benefits of adopting sustainability in their progress.

A group of studies must be made to determine the level of the actual impact of the implementation of lean in supporting both Economic and Social dimensions, knowing which tools of lean will give better results, and the level of benefit that companies will obtain in this sector by achieving both of the Economic and Social dimensions of sustainability.

Author Contributions

Conceptualization, B.A. and Z.A.; methodology, B.A. and Z.A; validation, B.A. and Z.A.; formal analysis, B.A.; resources, B.A. and Z.A; data collection, B.A.; writing—original draft preparation, B.A.; writing—review and editing, B.A and Z.A.; supervision, Z.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research study received no external funding.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. The Questionnaire

Dear:

First of all, I would like to thank you for your valuable time and effort that will be allocated in filling this survey.

This survey aims to build a framework for Solar energy firms to adopt Lean principles to achieve sustainability in Turkey.

Lean practices are based on improving the value of final product and eliminating waste through all processes of a project and the sustainability is development that meets the needs of the present without compromising the ability of future generations to meet their own needs.

This information in this survey will be used only for academic research, with a complete commitment to absolute confidence.

Researchers

Section 1: Profile of company:

- 1-

- Your position in the company:

- 2-

- Company’s location:

- 3-

- Company experience:

☐ Less than 5 years ☐ From (5–10) years ☐ From (11–15) ☐ More than 15 years.

- 4-

- Capital of the company (Thousand $) is:

☐ Less than 200 ☐ 200–400 ☐ 400–800 ☐ More than 800.

- 5-

- Average size of projects the company involved in (Thousand $) is:

☐ less than 200 ☐ 200–400 ☐ 400–800 ☐ more than 800.

- 6-

- The number of employees working in the company is:

☐ 1–less than 20 ☐ 20–less than 40 ☐ 40–less than 60 ☐ more than 60.

- 7-

- Average number of contract employees working in the company is:

☐ 1-less than 10 ☐ 10-less than 20 ☐ 20-less than 30 ☐ more than 30

- 8-

- What is the company’s field of work?

☐ Selling the Solar panels ☐ Installation of Solar Panels ☐ Manufacturing of Solar panels.

Section 2:

These factors examine the implementation of lean principles and sustainability in the company, please put (√) to the degree to which you agree with these statements.

| Rank. | QUESTION | Strongly Disagree | Disagree | Neutral | Agree | Strongly Agree |

| 1- | Your company is ready to do any change in the project, to improve the value for the customer. | |||||

| 2- | Defective items (human and machine error) are identified promptly to take corrective action. | |||||

| 3- | Identifying wastes through new management practices is vital for improving the quality, cost and time. | |||||

| 4- | It is vital that the quality of the project will be the responsibility of each person in the project | |||||

| 5- | Your company is interested in minimizing wastes in materials, conveying of materials and labor, transportation, and inventory level, waiting time, over production, over processing. | |||||

| 6- | Lot sizes are maintained at the minimum possible level. | |||||

| 7- | Machine set-up and Machine down times are maintained at the minimum possible level | |||||

| 8- | Your company follow special tools or standard for measuring the speed of the project. | |||||

| 9- | Mapping the flow of material and information of any activity, helps to identify the non-added value activity | |||||

| 10- | Material flow is adhered to consistently throughout the daily work activities | |||||

| 11- | Make flow evident through organizational culture | |||||

| 12- | Strive to cut back to zero the amount of time any work is sitting idle or waiting for someone to work on it | |||||

| 13- | Material, equipment, and other resources are provided in a “just in time” manner when needed | |||||

| 14- | Materials are ordered as close as possible to exact needs | |||||

| 15- | Strive for possible low level of (even stockless) material inventory | |||||

| 16- | Clear job contents, work time, material requirements, among other information are prepared before releasing a work task to a crew | |||||

| 17- | Amount of time spent in processing each order is maintained at the minimum possible level | |||||

| 18- | New management tools that improve quality, speed, cost and waste are essential to improve competitive advantage. | |||||

| 19- | Employees actively involved in providing suggestions for continuous improvement | |||||

| 20- | Quality teams are operating in an effective manner | |||||

| 21- | Your company depends on management practices that deal with quality and reduce wastes ratios in order to achieve high earnings ratios. | |||||

| 22- | Good vertical and horizontal communication systems reduce the time for decision taking. | |||||

| 23- | The company consulting local people. | |||||

| 24- | Your company follow new means of communications to improve the work of individuals within a team | |||||

| 25- | Equal employment opportunities existence. | |||||

| 26- | Work conditions are essential to improve the work. | |||||

| 27- | Enhance employee skills and retention them | |||||

| 28- | Intelligent selection and use of raw materials to minimize the resource wastes. | |||||

| 29- | Reduction of office energy and water usage. | |||||

| 30- | Reduced emissions of pollutants to prevent the Global warming | |||||

| 31- | Using Sustainable or renewable energy technologies. | |||||

| 32- | Using Green material in project design. | |||||

| 33- | Sustainable values of properties and tracts of land. | |||||

| 34- | Job creation for all sectors Combined | |||||

| 35- | Use of local resources. | |||||

| 36- | Creating employment during and after the project. |

Appendix B. Shows the Correlations between the Items of Each Principle of Lean

| Item | Va1 | Va2 | Va3 | Va4 | VS5 | VS6 | VS7 | VS8 | FL9 | FL10 | FL11 | FL12 | FL13 | Pu14 | Pu15 | Pu16 | Pu17 | Pu18 | Pe19 | Pe20 | Pe21 | Pe22 |

| Va1 | 1 | 0.198 | 0.304 | 0.454 ** | 0.056 | −0.05 | −0.01 | 0.189 | −0.08 | −0.02 | 0.262 | −0.00 | −0.10 | −0.20 | −0.13 | −0.12 | 0.088 | 0.133 | 0.158 | −0.15 | −0.03 | 0.017 |

| Va2 | 0.198 | 1 | 0.591 ** | 0.131 | 0.291 | 0.339 | 0.187 | 0.358 * | 0.242 | 0.117 | −0.03 | −0.01 | 0.040 | 0.169 | −0.04 | 0.128 | 0.097 | 0.014 | 0.148 | 0.337 | 0.305 | 0.378 * |

| Va3 | 0.304 | 0.591 ** | 1 | 0.334 | 0.051 | 0.081 | −0.01 | 0.244 | 0.047 | 0.365 * | 0.021 | −0.05 | 0.145 | 0.109 | −0.29 | −0.11 | −0.03 | −0.00 | −0.01 | 0.195 | 0.284 | 0.129 |

| Va4 | 0.454 ** | 0.131 | 0.334 | 1 | 0.195 | 0.381 * | −0.03 | 0.373 * | −0.03 | 0.449 ** | .408 * | −0.05 | 0.258 | 0.005 | −0.13 | −0.18 | 0.129 | 0.327 | 0.020 | 0.156 | 0.253 | 0.258 |

| VS5 | 0.056 | 0.291 | 0.051 | 0.195 | 1 | 0.675 ** | 0.292 | 0.505 ** | 0.138 | 0.132 | 0.007 | −0.24 | 0.115 | 0.373 * | 0.269 | 0.414 * | 0.278 | 0.134 | 0.477 ** | 0.518 ** | 0.553 ** | 0.748 ** |

| VS6 | −0.05 | 0.339 | 0.081 | 0.381 * | 0.675 ** | 1 | 0.320 | 0.470 ** | 0.198 | 0.142 | 0.032 | −0.01 | 0.033 | 0.262 | 0.054 | 0.219 | 0.271 | 0.119 | 0.313 | 0.500 ** | 0.406 * | 0.592 ** |

| VS7 | −0.01 | 0.187 | −0.017 | −0.034 | 0.292 | 0.320 | 1 | 0.148 | 0.527 ** | −0.07 | 0.015 | 0.034 | −0.08 | 0.232 | 0.250 | 0.086 | 0.347 | 0.162 | −0.12 | −0.05 | −0.14 | 0.248 |

| VS8 | 0.189 | 0.358 * | 0.244 | 0.373 * | 0.505 ** | 0.470 ** | 0.148 | 1 | 0.028 | 0.253 | 0.264 | 0.021 | 0.176 | 0.293 | 0.163 | 0.221 | 0.424 * | 0.292 | 0.188 | 0.165 | 0.253 | 0.355 * |

| FL9 | −0.08 | 0.242 | 0.047 | −0.032 | 0.138 | 0.198 | 0.527 ** | 0.028 | 1 | 0.462 ** | 0.130 | 0.501 ** | 0.391 * | 0.397 * | 0.194 | 0.191 | 0.375 * | 0.359 * | 0.061 | 0.107 | −0.18 | 0.235 |

| FL10 | −0.02 | 0.117 | .365 * | 0.449 ** | 0.132 | 0.142 | −0.07 | 0.253 | 0.462 ** | 1 | 0.505 ** | 0.246 | 0.738 ** | 0.339 | 0.024 | 0.162 | 0.347 | 0.432 * | −0.04 | 0.294 | 0.193 | 0.194 |

| FL11 | 0.262 | −0.03 | 0.021 | 0.408 * | 0.007 | 0.032 | 0.015 | 0.264 | 0.130 | 0.505 ** | 1 | 0.088 | 0.266 | 0.019 | 0.190 | −0.24 | 0.412 * | 0.461 ** | −0.06 | −0.05 | 0.098 | −0.105 |

| FL12 | −0.00 | −0.01 | −0.056 | −0.052 | −0.24 | −0.01 | 0.034 | 0.021 | 0.501 ** | 0.246 | 0.088 | 1 | 0.320 | 0.099 | −0.01 | 0.015 | 0.151 | 0.257 | 0.305 | 0.040 | −0.33 | −0.047 |

| FL13 | −0.10 | 0.040 | 0.145 | 0.258 | 0.115 | 0.033 | −0.08 | 0.176 | 0.391 * | 0.738 ** | 0.266 | 0.320 | 1 | 0.525 ** | 0.289 | 0.462 ** | 0.354 * | 0.500 ** | 0.036 | 0.285 | 0.075 | 0.206 |

| Pu14 | −0.20 | 0.169 | 0.109 | 0.005 | 0.373 * | 0.262 | 0.232 | 0.293 | 0.397 * | 0.339 | 0.019 | 0.099 | 0.525 ** | 1 | 0.593 ** | 0.532 ** | 0.449 ** | 0.274 | 0.063 | 0.055 | 0.031 | 0.225 |

| Pu15 | −0.14 | −0.04 | −0.290 | −0.133 | 0.269 | 0.054 | 0.250 | 0.163 | 0.194 | 0.024 | 0.190 | −0.01 | 0.289 | 0.593 ** | 1 | 0.335 | 0.590 ** | 0.298 | −0.01 | −0.24 | 0.013 | −0.007 |

| Pu16 | −0.12 | 0.128 | −0.116 | −0.185 | 0.414 * | 0.219 | 0.086 | 0.221 | 0.191 | 0.162 | −0.24 | 0.015 | 0.462 ** | 0.532 ** | 0.335 | 1 | 0.195 | 0.070 | 0.282 | 0.247 | 0.037 | 0.301 |

| Pu17 | 0.088 | 0.097 | −0.034 | 0.129 | 0.278 | 0.271 | 0.347 | 0.424 * | 0.375 * | 0.347 | 0.412 * | 0.151 | 0.354 * | 0.449 ** | 0.590 ** | 0.195 | 1 | 0.510 ** | −0.07 | −0.16 | −0.15 | 0.116 |

| Pu18 | 0.133 | 0.014 | −0.008 | 0.327 | 0.134 | 0.119 | 0.162 | 0.292 | 0.359 * | 0.432 * | 0.461 ** | 0.257 | .500 ** | 0.274 | 0.298 | 0.070 | .510 ** | 1 | 0.094 | 0.009 | −0.09 | 0.082 |

| Pe19 | 0.158 | 0.148 | −0.010 | 0.020 | 0.477 ** | 0.313 | −0.12 | 0.188 | 0.061 | −0.04 | −0.06 | 0.305 | 0.036 | 0.063 | −0.01 | 0.282 | −0.07 | 0.094 | 1 | 0.488 ** | 0.368 * | 0.443 * |

| Pe20 | −0.15 | 0.337 | 0.195 | 0.156 | 0.518 ** | 0.500 ** | −0.05 | 0.165 | 0.107 | 0.294 | −0.05 | 0.040 | 0.285 | 0.055 | −0.24 | 0.247 | −0.16 | 0.009 | 0.488 ** | 1 | 0.641 ** | 0.628 ** |

| Pe21 | −0.03 | 0.305 | 0.284 | 0.253 | 0.553 ** | 0.406 * | −0.14 | 0.253 | −0.18 | 0.193 | 0.098 | −0.33 | 0.075 | 0.031 | 0.013 | 0.037 | −0.15 | −0.09 | 0.368 * | 0.641 ** | 1 | 0.563 ** |

| Pe22 | 0.017 | 0.378 * | 0.129 | 0.258 | 0.748 ** | 0.592 ** | 0.248 | 0.355 * | 0.235 | 0.194 | −0.10 | −0.04 | 0.206 | 0.225 | −0.00 | 0.301 | 0.116 | 0.082 | 0.443 * | 0.628 ** | 0.563 ** | 1 |

| **, Correlation is significant at the 0.01 level (2-tailed). *, Correlation is significant at the 0.05 level (2-tailed). | ||||||||||||||||||||||

Appendix C. Shows the Correlations between the Items of Each Dimension of Sustainability

| Rank. | Soc23 | Soc24 | Soc25 | Soc26 | Soc27 | Env28 | Env29 | Env30 | Env31 | Env32 | Eco33 | Eco34 | Eco35 | Eco36 |

| Soc23 | 1 | 0.259 | 0.629 ** | 0.338 | 0.283 | −0.196 | 0.063 | 0.095 | −0.187 | 0.185 | 0.068 | 0.164 | 0.211 | 0.067 |

| Soc24 | 0.259 | 1 | 0.385 * | 0.306 | 0.527 ** | 0.183 | 0.201 | 0.244 | 0.384 * | 0.321 | 0.127 | 0.232 | 0.087 | 0.483 ** |

| Soc25 | 0.629 ** | 0.385 * | 1 | 0.236 | 0.346 | −0.132 | −0.010 | 0.065 | −0.131 | 0.037 | 0.051 | 0.138 | 0.019 | 0.103 |

| Soc26 | 0.338 | 0.306 | 0.236 | 1 | 0.535 ** | 0.076 | 0.281 | 0.235 | 0.165 | 0.178 | 0.046 | 0.444 * | 0.422 * | 0.244 |

| Soc27 | 0.283 | 0.527 ** | 0.346 | 0.535 ** | 1 | 0.148 | 0.104 | 0.213 | 0.234 | 0.027 | 0.328 | 0.241 | 0.310 | 0.343 |

| Env28 | −0.196 | 0.183 | −0.132 | 0.076 | 0.148 | 1 | 0.443 * | 0.453 ** | 0.452 ** | 0.331 | 0.437 * | 0.496 ** | 0.255 | 0.243 |

| Env29 | 0.063 | 0.201 | −0.010 | 0.281 | 0.104 | 0.443 * | 1 | 0.635 ** | 0.237 | 0.495 ** | 0.207 | 0.322 | 0.142 | 0.425 * |

| Env30 | 0.095 | 0.244 | 0.065 | 0.235 | 0.213 | 0.453 ** | 0.635 ** | 1 | 0.321 | 0.373 * | 0.346 | 0.291 | 0.344 | 0.243 |

| Env31 | −0.187 | 0.384 * | −0.131 | 0.165 | 0.234 | 0.452 ** | 0.237 | 0.321 | 1 | 0.146 | 0.163 | 0.233 | 0.233 | 0.504 ** |

| Env32 | 0.185 | 0.321 | 0.037 | 0.178 | 0.027 | 0.331 | 0.495 ** | 0.373 * | 0.146 | 1 | 0.256 | 0.512 ** | 0.344 | 0.417 * |

| Eco33 | 0.068 | 0.127 | 0.051 | 0.046 | 0.328 | 0.437 * | 0.207 | 0.346 | 0.163 | 0.256 | 1 | 0.293 | 0.495 ** | 0.486 ** |

| Eco34 | 0.164 | 0.232 | 0.138 | 0.444 * | 0.241 | 0.496 ** | 0.322 | 0.291 | 0.233 | 0.512 ** | 0.293 | 1 | 0.482 ** | 0.285 |

| Eco35 | 0.211 | 0.087 | 0.019 | 0.422 * | 0.310 | 0.255 | 0.142 | 0.344 | 0.233 | 0.344 | 0.495 ** | 0.482 ** | 1 | 0.334 |

| Eco36 | 0.067 | 0.483 ** | 0.103 | 0.244 | 0.343 | 0.243 | 0.425 * | 0.243 | 0.504 ** | 0.417 * | 0.486 ** | 0.285 | 0.334 | 1 |

| **, Correlation is significant at the 0.01 level (2-tailed). *, Correlation is significant at the 0.05 level (2-tailed). | ||||||||||||||

References

- Krut, R.; Munis, K. Sustainable Industrial Development. In Sustainable Measures; Routledge: London, UK, 2019; pp. 426–437. [Google Scholar] [CrossRef]

- Kim, A. Sustainable Development and Environmental Values. Soc. Ekol. 2000, 9, 149–162. [Google Scholar]

- Resta, B.; Dotti, S.; Gaiardelli, P.; Boffelli, A. Lean Manufacturing and Sustainability: An Integrated View. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Iguassu Falls, Brazil, 3–7 September 2016; Springer: Cham, Switzerland, 2016; pp. 659–666. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Lean and Green-a Systematic Review of the State of the Art Literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef] [Green Version]

- Khodeir, L.M.; Othman, R. Examining the Interaction between Lean and Sustainability Principles in the Management Process of AEC Industry. Ain Shams Eng. J. 2018, 9, 1627–1634. [Google Scholar] [CrossRef]

- King, A.A.; Lenox, M.J. Lean and Green? An Empirical Examination of the Relationship between Lean Production and Environmental Performance. Prod. Oper. Manag. 2001, 10, 244–256. [Google Scholar] [CrossRef]

- Albezuirat, M.K.; Hussain, M.I.; Ahmad, R.; Zulkepli, N.N. Improving the Efficiency of Solar Power Plants Through Smart Lean IJREER Improving the Efficiency of Solar Power Plants Through Smart Lean Manufacturing Assessment. Int. J. Renew. Energy Eng. Res. 2020, 1, 10–29. [Google Scholar]

- Weckend, S.; Wade, A.; Heath, G.A. End of Life Management: Solar Photovoltaic Panels; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016. [Google Scholar]

- Piercy, N.; Rich, N. The relationship between lean operations and sustainable operations. Int. J. Oper. Prod. Manag. 2015, 35, 282–315. [Google Scholar] [CrossRef]

- Kilickaplan, A.; Bogdanov, D.; Peker, O.; Caldera, U.; Aghahosseini, A.; Breyer, C. An Energy Transition Pathway for Turkey to Achieve 100% Renewable Energy Powered Electricity, Desalination and Non-Energetic Industrial Gas Demand Sectors by 2050. Sol. Energy 2017, 158, 218–235. [Google Scholar] [CrossRef]

- Cherra, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The Integration of Lean Manufacturing, Six Sigma and Sustainability: A Literature Review and Future Research Directions for Developing a specific model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Thangarajoo, Y. Lean Thinking: An Overview. Ind. Eng. Manag. 2015, 4, 2169-0316. [Google Scholar]

- Obaid, A.M.W. Towards Enhancement of Lean Practices in the West Bank Construction Industry. Ph.D. Thesis, Al-Najah National University, Nablus, Palestine, 2016. [Google Scholar]

- Herrero, M.; Ibáñez, E. Green Processes and Sustainability: An Overview on the Extraction of High Added-Value Products from Seaweeds and Microalgae. J. Supercrit. Fluids 2015, 96, 211–216. [Google Scholar] [CrossRef]

- Keitany, P.; Riwo-Abudho, M. Effects of lean production on organizational performance: A case study of flour producing company in Kenya. Eur. J. Logist. Purch. Supply Chain Manag. 2014, 2, 1–14. [Google Scholar]

- Cowger, G. Half measures gets less than half results. Mech. Eng. Mag. ASME 2016, 138, 30–35. [Google Scholar] [CrossRef] [Green Version]

- Dombrowski, U.; Mielke, T. Lean leadership: Fundamental principles and their application. Procedia CIRP 2013, 7, 569–574. [Google Scholar] [CrossRef] [Green Version]

- Mollenkopf, D.; Stolze, H.; Tate, W.L.; Ueltschy, M. Green, lean, and global supply chains. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 14–41. [Google Scholar] [CrossRef]

- Varela, L.; Araújo, A.; Ávila, P.; Castro, H.; Putnik, G. Evaluation of the Relation between Lean Manufacturing, Industry 4.0, and Sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef] [Green Version]

- Cai, W.; Lai, K.; Liu, C.; Wei, F.; Ma, M.; Jia, S.; Jiang, Z.; Lv, L. Promoting Sustainability of Manufacturing Industry through the Lean Energy-Saving and Emission-Reduction Strategy. Sci. Total Environ. 2019, 665, 23–32. [Google Scholar] [CrossRef]

- Kumar, M.; Rodrigues, V.S. Synergetic Effect of Lean and Green on Innovation: A Resource-Based Perspective. Int. J. Prod. Econ. 2020, 219, 469–479. [Google Scholar] [CrossRef]

- Abreu, M.F.; Alves, A.C.; Moreira, F. Lean-Green Models for Eco-Efficient and Sustainable Production. Energy 2017, 137, 846–853. [Google Scholar] [CrossRef]

- Golzarpoor, H.; González, V. A Green-Lean Simulation Model for Assessing Environmental and Production Waste in Construction. In Proceedings of the 21th Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013; pp. 845–854. [Google Scholar]

- Inman, R.A.; Green, K.W. Lean and Green Combine to Impact Environmental and Operational Performance. Int. J. Prod. Res. 2018, 56, 4802–4818. [Google Scholar] [CrossRef]

- Tăucean, I.; Tămășilă, M.; Ivascu, L.; Miclea, Ș.; Negruț, M. Integrating Sustainability and Lean: SLIM Method and Enterprise Game Proposed. Sustainability 2019, 11, 2103. [Google Scholar] [CrossRef] [Green Version]

- Florescu, A.; Barabaş, B. Integrating the Lean Concept in Sustainable Manufacturing Development. IOP Conf. Ser. Mater. Sci. Eng. 2018, 399, 012018. [Google Scholar] [CrossRef]

- Carneiro, S.B.D.M.; Campos, I.B.; Lins, D.M.D.O.; Barros Neto, J.D.P. Lean and green: A relationship matrix. Annual Conference of the International Group for Lean Construction. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Souza, J.P.E.; Alves, J.M. Lean-Integrated Management System: A Model for Sustainability Improvement. J. Clean. Prod. 2018, 172, 2667–2682. [Google Scholar] [CrossRef]

- Ioppolo, G.; Cucurachi, S.; Salomone, R.; Saija, G.; Ciraolo, L. Industrial Ecology and Environmental Lean Management: Lights and Shadows. Sustainability 2014, 6, 6362–6376. [Google Scholar] [CrossRef] [Green Version]

- Vinodh, S.; Arvind, K.R.; Somanaathan, M. Tools and Techniques for Enabling Sustainability through Lean Initiatives. Clean Technol. Environ. Policy 2011, 13, 469–479. [Google Scholar] [CrossRef]

- Gupta, V.; Narayanamurthy, G.; Acharya, P. Can Lean Lead to Green? Assessment of Radial Tyre Manufacturing Processes Using System Dynamics Modelling. Comput. Oper. Res. 2018, 89, 284–306. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; De, D.; Chowdhury, S.; Abdelaziz, F. Ben. The Impact of Lean Management Practices and Sustainably-Oriented Innovation on Sustainability Performance of Small and Medium-Sized Enterprises: Empirical Evidence from the UK. Br. J. Manag. 2020, 31, 141–161. [Google Scholar] [CrossRef]

- Brasco, A.; Found, P.; Moura, A. A Lean & Green Model for a Production Cell. J. Clean. Prod. 2014, 85, 19–30. [Google Scholar]

- Díaz-Reza, J.R.; García-Alcaraz, J.L.; Martínez-Loya, V.; Blanco-Fernández, J.; Jiménez-Macías, E.; Avelar-Sosa, L. The Effect of SMED on Benefits Gained in Maquiladora Industry. Sustainability 2016, 8, 1237. [Google Scholar] [CrossRef] [Green Version]

- Weigel, A.L. A Book Review: Lean Thinking by Womack and Jones. Rev. Lit. Arts Am. 2000. Available online: http://web.mit.edu/esd.83/www/notebook/WomackJones.PDF (accessed on 10 July 2021).

- Nugraheni, A.; Priyambodo, T.; Kusworo, H.; Sutikno, B. The Social Dimension of Sustainable Development: Defining Tourism Social Sustainability. In Proceedings of the 1st International Conference on Engineering, Science, and Commerce, ICESC 2019, Labuan Bajo, Indonesia, 18–19 October 2019. [Google Scholar] [CrossRef] [Green Version]

- Othman, A.A.E.; Ghaly, M.A.; Zainul Abidin, N. Lean Principles: An Innovative Approach for Achieving Sustainability in the Egyptian Construction Industry. Organ. Technol. Manag. Constr. Int. J. 2014, 6, 917–932. [Google Scholar] [CrossRef]

- Spangenberg, J.H. Economic Sustainability of the Economy: Concepts and Indicators. Int. J. Sustain. Dev. 2005, 8, 47–64. [Google Scholar] [CrossRef]

- Lee, C.; An, M.; Noh, Y. The Social Dimension of Service Workers’ Job Satisfaction: The Perspective of Flight Attendants. J. Serv. Sci. Manag. 2012, 05, 160–170. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Fernández, R.; Iniesta-Bonillo, M.Á. Efficiency and Quality as Economic Dimensions of Perceived Value: Conceptualization, Measurement, and Effect on Satisfaction. J. Retail. Consum. Serv. 2009, 16, 425–433. [Google Scholar] [CrossRef]

- Hartini, S.; Manurung, J.; Rumita, R. Sustainable-Value Stream Mapping to Improve Manufacturing Sustainability Performance: Case Study in a Natural Dye Batik SME’s. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1072, 012066. [Google Scholar] [CrossRef]

- Vegting, I.L.; Van Beneden, M.; Kramer, M.H.H.; Thijs, A.; Kostense, P.J.; Nanayakkara, P.W.B. How to Save Costs by Reducing Unnecessary Testing: Lean Thinking in Clinical Practice. Eur. J. Intern. Med. 2012, 23, 70–75. [Google Scholar] [CrossRef]

- Minh, N.D.; Nguyen, N.D.; Cuong, P.K. Applying lean tools and principles to reduce cost of waste management: An empirical research in Vietnam. Manag. Prod. Eng. Rev. 2019, 10, 37–49. [Google Scholar]

- Hair, J.F.; Celsi, M.; Money, A.; Samouel, P.; Page, M. The Essentials of Business Research Method, 3rd ed.; Routledge: New York, NY, USA, 2016; Available online: http://digitalcommons.kennesaw.edu/facbooks2016/2 (accessed on 15 July 2021).

- Moyano-Fuentes, J.; Maqueira-Marín, J.M.; Martínez-Jurado, P.J.; Sacristán-Díaz, M. Extending lean management along the supply chain: Impact on efficiency. J. Manuf. Technol. Manag. 2021, 32, 63–84. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).