Abstract

Building insulation based on nanomaterials is considered one of the most effective means of reducing energy consumption in the hot desert climate. The application of an energy-efficient insulation system can significantly decrease the energy consumed via a building’s air-conditioning system during the summer. Hence, building insulation has become an interesting research topic, especially with regards to the use of insulation based on nanomaterials due to their low U-values. In the present study, the use of nano vacuum insulation panels (VIPs) or polystyrene foam in the walls enabled a significant reduction in the annual energy consumption, a savings of 23% compared to the uninsulated wall in a study in New Aswan City. The application of nanogel glazing to the windows (two layers of clear glass filled with the nanogel) achieved approximately 11% savings in annual energy. This savings, twice that obtained by using double-glazed windows, could be due to the low U-value of nanogel compared to the U-values of argon or air. The embedded nanogel layer between two layers of argon and two layers of single clear glass showed a significant reduction in annual energy consumption, saving 26% compared to the use of a single layer of glass. Moreover, the integration between this window and embedded walls with 50 mm of polystyrene foam exhibited a significant improvement of energy efficiency by 47.6% while presenting the lowest value of simple payback period (SPP). This research provides a way for buildings to be insulated to make them more energy efficient as well as attractive from the economic standpoint.

1. Introduction

The growth of the world’s population, with 200,000 new inhabitants being born daily, has resulted in a significant rise in global energy demand [1,2]. Two of the most significant challenges the world faces are rapid urbanization and climate change. The urban population in 2014 accounted for 54% of the total global population, up from 34% in 1960 and it continues to grow; furthermore, it is estimated that even in less developed countries, most people will soon be living in urban areas [3]. The Arab region is rapidly urbanizing, and according to 2015 estimates, urbanization is growing at an average rate of 2.5% per year. Currently, more than half of the Arab population (57%) lives in urban areas [4]. Moreover, it is estimated that by 2035, global energy-related CO2 emissions will exceed today’s levels by 20% [5], which in turn would lead to a significant increase in energy demand, especially for cooling purposes as temperatures rise [6]. Moreover, electricity consumed can be expected to increase in the industrial, transportation and building sectors [7,8].

Approximately 40% of the total energy consumed by the residential and commercial building sectors is used to heat or cool buildings, this being mainly due to the long periods people spend indoors as well as inadequate building insulation. This issue has become one of the obstacles in the development of society [8,9].

According to the principles of the Kyoto Pyramid, providing better thermally insulated buildings is one of the most efficient solutions to overcome high consumption of energy in buildings in cold and hot climates [10,11]. Traditional thermal insulating materials (e.g., polystyrene foam, polyurethane foam, glass wool, etc.) require considerable thickness (250 mm) and maximum thermal conductivity of 0.6 W/(m K) [12,13]. In hot climates with very intense solar radiation where the required thermal insulation thickness needs to be substantially increased, such high thickness decreases internal space in buildings and increases insulation costs. Therefore, the development of high-performance thermal insulation materials with low thickness and low thermal conductivity can increase energy efficiency at reduced costs.

Vacuum insulation panel (VIP) technique is considered a promising solution for providing high-performance thermal insulation in buildings due to their ultra-low thickness (5–50 mm) and very low thermal conductivity (0.002–0.004 W/(m K)) compared to conventional insulation materials; these values are ten times less than those of conventional insulation materials used in buildings today. Therefore, Vacuum insulation panels (VIPs) are considered by many to be the most suitable material for walls, roofs and floors in new and refurbished buildings where space is limited [14]. Brunner and Simmler [15] who implemented VIPs in a flat roof found that the initial thermal conductivity and expected lifespan were 0.0045 W/(m K) and 25 years, respectively. Araki, Kamoto [1] studied the use of VIP technique for high-temperature applications, and Jelle, Sveipe [16] investigated the retrofitting of old Norwegian buildings (timber frame construction) with VIPs.

Nanogel has come to be considered as one of the most promising nanomaterials to use in energy-efficient buildings and daylight systems [17,18]. Nanogels are nanoparticles made up of hydrophilic polymers that are physically or chemically cross-linked. These organic materials have been extensively used in numerous fields such as medicine, medical imaging and industry. The soluble materials have a uniform and wide surface area, with particle diameters ranging from tens to hundreds of nanometers. The material is highly porous and lightweight, with very low thermal conductivity of 0.004–0.01 W/(m K). It also has good optical transparency and high acoustic insulation. Nanogel is currently in use throughout the building insulation market [19] for filling between double-glazed (DG) windows, multiwall polycarbonate panels or methyl methacrylate panels. It can be used for facades, skylights, roofs and walls [20]. Granular nanogel is being used in a wide range of applications in daylighting systems and thermal insulation systems (e.g., in schools, commercial and industrial buildings, airports, etc.), especially in the U.S. and in Europe [8,17]. Buratti and Moretti [21], in an in-lab experiment on an aluminum frame window prototype with silica granular nanogel in the glazing interspace, found good acoustic properties and excellent thermal performance of the material.

Most research into nanomaterials as insulation solutions has been conducted in cold climates, with little research being done in hot climates. However, that is changing. Recently, Ihara, Gao [22] studied the effect of a translucent nanogel granulate glazing system in the spandrels of office buildings in three hot climate cities. The simulated results indicated that the nanogel could achieve lower energy consumption compared to double-glazed facades. Using nanogel in the windows and nano VIPs in the walls and roof, Rashwan, Farag [23] investigated the lower energy demand of an office building under Aswan weather conditions. They found approximately 60% of the energy lost through the high transparent windows. Recent studies have been undertaken in single- and multi-store office buildings in Al-Dammam, Saudi Arabia. The simulated results indicated that the nanogel in the windows and nano VIPs in the walls and roof could achieve lower energy consumption compared to conventional insulation. More energy was saved through the windows than through the walls in annual energy consumption [24,25]. One of the largest projects being implemented in Egypt is aimed at establishing in all governorates and new cities about 725,000 residential units, each consisting of two or three rooms that are fully finished [26]. These buildings are deployed all over Egypt without considering their environmental compatibility with the surroundings and climate, or the expected energy consumption in the cooling process. They are, therefore, likely to face problems in energy consumption, especially in the case of social housing buildings in New Aswan City that is known for its harsh climatic conditions [27,28].

The current study focused on the effect of nanogel glazing in windows and nano VIPs in external walls on energy consumption of residential building in New Aswan City, Egypt. The base case of this study consisted of 120 mm brick walls and 3 mm glass windows, for comparison with nano VIPs walls and nanogel glazed windows. Energy consumption was simulated using the Design Builder software.

2. Materials and Methods

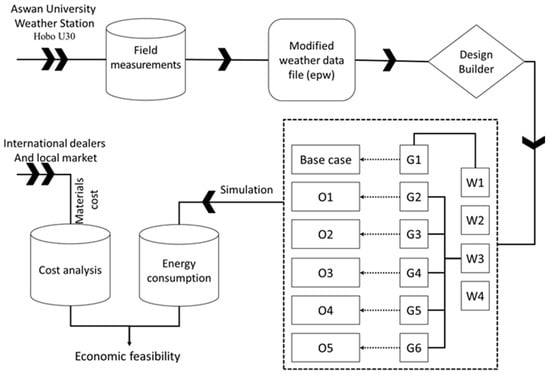

The study investigated the effects of using nano vacuum insulation panels and polystyrene foam in external walls, as well as different types of nano glazing in windows. The main objective of the present study was to investigate the use of these nanomaterials integrated into building components like walls and windows as a new approach to building insulation in New Aswan City under the current climatic conditions. The analysis went through three main steps in this respect. The first step dealt with the impact of materials used in walls on the energy consumption in social residential buildings. The second phase explored the influence of nano-glazing materials on energy consumption of the examined buildings. The third step involved integration of the two steps described above. The analysis was expanded to include their economic feasibility for Egyptian cities. Figure 1 shows the steps of the study which investigates four types of walls (W1, W2, W3 and W4), six types of glazing (G1–G6), and five integrated options (O1–O5) between the studied walls and glazing. Table 1 and Table 2 show the characteristics of the studied walls and glazing.

Figure 1.

The study framework.

Table 1.

Main characteristics of the external walls.

Table 2.

Characteristics of the windows.

2.1. Study Area

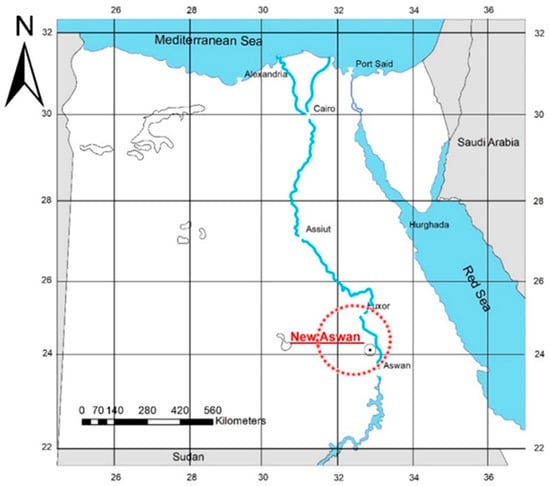

This paper had its focus on a hot arid climate in view of the increasing energy demand in this region since current climatic solutions involving green roofs, green facades and building insulation materials had not been fully satisfactory [29]. In Egypt, it is common for insulation materials not to be used in residential buildings constructed by citizens [30]. Even for buildings that had been constructed by the government, the traditional insulating materials used would have higher thermal conductivity than insulation premised on nanomaterials. Therefore, this study was conducted to investigate the effect of different nanomaterials on the energy demand in New Aswan city shown in Figure 2.

Figure 2.

Location of New Aswan city.

New Aswan city is located in the western part of the Nile Valley, 15 km away from the current city of Aswan. It is an example of a hot desert region in Egypt, with daytime temperatures exceeding 45 °C in summer, and dropping to below 15 °C in winter. Relative humidity is lowest in May and June (12%), while the highest values are recorded in December and January (36%, 34%, respectively) [31].

2.2. The Model Definition

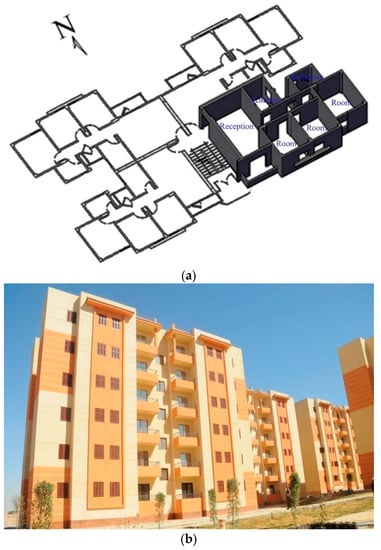

A model of a real residential building located in New Aswan City was used as shown in Figure 3. The building located within the social housing project was selected owing to its construction that utilized low-cost methods without consideration for climatic aspects. The building has six floors (four flats per floor) and an area of approximately 86 m2 per flat, and about 357 m2 for the whole building including the stair space. The floor height was 3 m, and the window-to-wall ratio was about 10%.

Figure 3.

The residential building models. (a) Ground floor isometric plan. (b) Building façade.

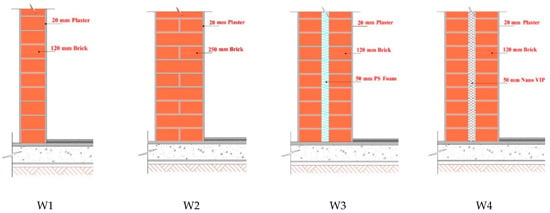

2.3. External Walls and Glass Specifications

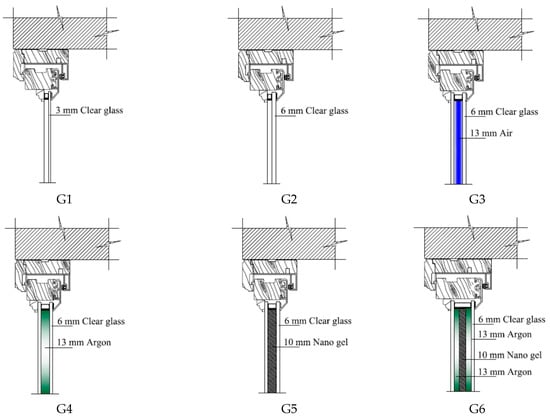

The wall construction system used in this study is presented in Table 1 and Figure 4, while the glazing system appears in Table 2 and Figure 5. The thermal properties for the construction materials used in the simulation program were obtained from the Egyptian Residential Energy Code (EREC), and Egyptian Specifications for Thermal Insulation Work Items [32,33,34]. The selected nano VIPs and nanogel glazing arrangements employed in this study were similar to those in the literature [23,25] with some modifications in the nanogel glazing [35,36]. The nano VIPs consisting of silica aerogel core sheathed in metallic film was used in the external walls. The nanogel glazing consisted of nano aerogel core sheathed by the glass panes. Nano aerogel has a thermal conductivity of (0.015 W/mK), whereas nano VIPs have a thermal conductivity of 0.003 W/mK. These insulations were used to minimize energy consumption and decrease energy costs.

Figure 4.

Characteristics of the wall sections.

Figure 5.

Cross-sections of windows.

In the wall sections shown in Figure 4, W1 and W2 refer to the popularly used construction systems. W3 depicts the use of conventional insulation materials while W4 depicts the use of nanomaterial-based insulation. In the window cross-sections shown in Figure 5, G1 and G2 are the common windows used, whereas G3, G4, G5 and G6 are the various categories of insulated windows.

2.4. Weather Data File

According to the official website of the US Department of Energy, the simulation software incorporates the 2002 epw file (Energy Plus Weather) for the Aswan climatic region. These, epw files are text-based CSV files containing a year’s worth of hourly weather variables for the studied location. However, to simulate a real situation, the weather data file available in the software was replaced by in-situ weather data file for Aswan climatic conditions (2019) obtained from a weather station (Hobo U30) as shown in Figure 6.

Figure 6.

The weather station at Aswan University (Hobo U30).

Since the EPW file of weather data could not be modified directly, it was first transformed to a Comma Separated Value file, CSV, in order to accept different extracted meteorological data from the weather station.

The weather station’s extracted input data included dry-bulb temperature, relative humidity, global radiation, wind speed and wind direction. While element software was used to calculate dew point and direct radiation.

The modified CSV was exported to a new EPW that was used as input data in Design Builder software after replacing those parameters in a new CSV.

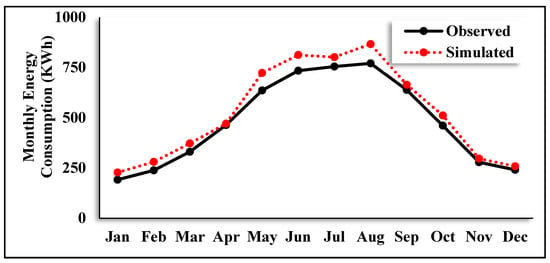

According to ASHRAE Guideline 14-2002, the simulation results were calibrated through modelling of the required parameters of the study site (i.e., comfort zone limits, lighting, building materials and heating, ventilation and air conditioning (HVAC) configurations). The electricity bills of the flat located on the third floor were used to compare the simulation results and actual energy consumption to represent the average power consumption of all the flats of the building. The average error of energy simulation results was found to be 10.19% (Figure 7), whereas the correlation coefficient between simulated and actual observed values was 0.995.

Figure 7.

The validation of simulation results.

2.5. The Simulation Procedures

Modelling was achieved using dynamic thermal simulation for different walls and windows with the Design Builder software in its fourth version (V.4.0.0.105). The base case of the study consisted of a non-insulated building (common in New Aswan City); the comparison cases consisted of different walls and glass windows, including new and common insulation used in Egypt, viz. PS insulation, double glazing, nano VIPs and nano gel glazing. The building plan was drawn using 2D AutoCAD and exported to the program to carry out the simulation test. The simulation hypothesis of the study building is shown in Table 3.

Table 3.

Specification of the simulation hypothesis of the study building.

The simulation was run to evaluate the annual energy consumption (AEC) for natural ventilation and HVAC. The AEC in kWh was evaluated based on the electricity consumed, lighting and HVAC systems according to the common lifestyle of the residents (taking into consideration holidays, work hours, etc.) [37].

Fixed schedules for energy use were used to monitor the scheduling in Design Builder and to define those activities in the simulations, such as occupancy times, appliances, lighting and HVAC application (in combination with the cooling and heating set points and comfort zone characteristics of each site).

The schedules were created using a set of fixed activities based on the traditional Egyptian lifestyle (holidays, work hours, etc.). According to recent population statistics, the average number of Egyptian family members is around five [38]. Egypt, on the other hand, observes a variety of holidays. Islamic holidays do not adhere to a strict calendar. As a result, they are difficult to define. Certain holidays were programmed into the software.

Furthermore, on Fridays and Saturdays, most government employees and other private businesses are closed. They report to work from 8:00 a.m. to 3:00 p.m. on the other days. The residents of the flat are assumed to be between the ages of 22 and 60. The majority of the unit residents will be away from home during work hours on weekdays. Otherwise, family members typically spend the majority of the day at home.

According to a previous study [37], the average lighting-power intensity for the living room and bedroom is 17, and 13 W/m2, respectively. Other spaces’ average lighting-power intensity is 9 W/m2. On the other hand, as shown in Table 4, appliances were set up for each residential unit, providing the Design Builder software with heat gain values.

Table 4.

Appliance operation scheduling for a typical residential unit [37].

The simulation procedures used a simple HVAC system configuration with a basic loads calculation algorithm for the heating and cooling systems (Energy Plus zone HVAC ideal loads). In the summer, when the temperature exceeds 29 °C, split air-conditioning units are used for the entire day till the room temperature drops below 25 °C; otherwise, natural ventilation is often used.

2.6. Electric Energy Prices

The energy consumption cost per flat per year was determined in Egyptian Pounds (EGP) at a rate set by the Egyptian Ministry of Electricity and Renewable Energy for the residential sector (Table 5).

Table 5.

The electricity price for residential buildings.

3. Results and Discussion

The results from the simulations for external wall and window construction in the Aswan climate were plotted for annual energy consumption, annual energy costs and annual energy saving per cent. To assess the effect of nanogel glazing and nano VIPs on the energy performance of the building, the energy simulation was executed with nanogel glazing and nano VIPs, and without the thermal insulation in the wall and windows according to the existing case in New Aswan city. The determined energy saved in all cases was compared to the base case.

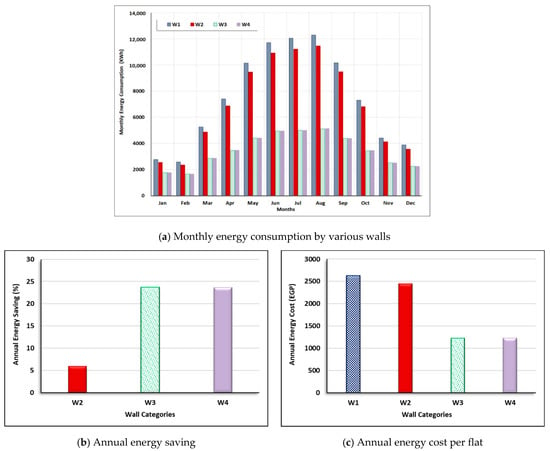

3.1. External Wall

The annual energy consumption, annual energy costs and annual energy savings of the building with various insulation walls are shown in Figure 8a–c. All three variables were sharply reduced using insulation wall-based- polystyrene foam (W3) and nano VIPs (W4) as compared to the commonly used walls in the building model (W1 and W2). It was also observed that approximately 23% of the energy was saved in the case of wall-based- PS foam and nano VIPs and the same annual energy consumption and savings in annual energy cost in both cases were obtained.

Figure 8.

Simulation results for external walls: energy consumption, savings and costs attributed to the choice of walls.

Mahdy and Nikolopoulou [36] and Moretti, Zinzi [39] studied the effect of various wall constructions on the building’s insulation in different regions and climates in Egypt. They indicated that the best annual energy consumption and annual cost savings could be achieved using wall based-PS foam in the hot climatic regions (e.g., Aswan City). Even though the PS and nano VIPs in the wall had almost the same reduction of annual energy consumption with a slight effectiveness for the nano VIPs which return to their lower thermal transmittance in comparison to the PS. Therefore, the PS was considered more suitable due to the low cost compared to that of the nano VIPs [24]. Nonetheless, while the nano VIPs are more expensive, a thin wall thickness is sufficient to reduce the amount of energy consumed.

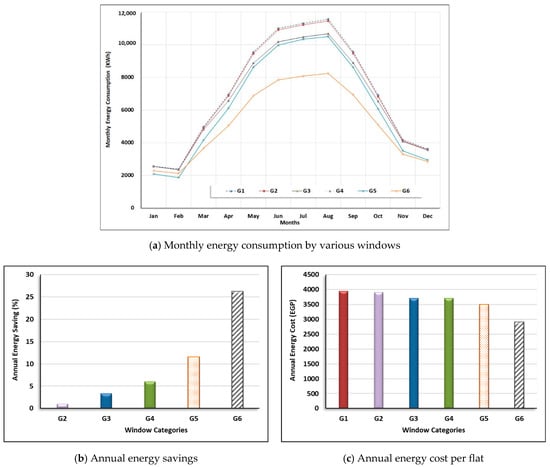

3.2. Insulation Windows

The simulation results for the various windows are shown in Figure 9a–c. The (G6) window (with nanogel and argon layers) gave the best results compared to other types of windows in terms of annual energy consumption, annual energy costs and annual energy savings. This window saved about 26% of annual energy relative to that of the (G1) window. The (G5) window (nanogel layer) showed about 11% saving in annual energy consumption. This percentage is higher than the value for the double-glazed window with air (G3) or argon (G4) layer in between the glass, achieving approximately, respectively, 3% and 5% savings in the annual energy consumption. The (G2) window (with thickened glass) had a minimal effect as only 1% on the energy was saved relative to the base case (G1). The high thermal insulation of nanogel based widows could be attributed to the low thermal conductivity of the nanogel as compared to argon or air. In addition, nanogel reduced airflow through small pores. The embedded air inside the nanopores led to a reduction in its thermal conductivity compared to free air at ambient pressure due to the condensed effect within the nanopores of nanogel [39].

Figure 9.

Simulation results for windows: energy consumption, savings and costs attributed to the choice of windows.

Furthermore, it was observed that the nanogel had lower heat transfer compared to the different types of double-glazed fillers. This may be due to the lower solar heat gain coefficient and U-value of nanogel (0.35 and 0.45 W/m2K, respectively) relative to simple double glazing (0.75 and 2.71 W/m2K, respectively). However, the visual transmittance of the double-glazed layer (0.92) was higher than that of nanogel glazing (0.3). This could increase the energy consumed by the lighting load even though the lighting load has a low impact on total energy consumption [25]. Despite the lighting energy has decreased by 27% on average, the energy needed for lighting in these buildings does not surpass 18.56% of the energy required for improving climatic conditions, which has decreased by 26%. As a result, total energy consumption has dropped by 20%. Interestingly, the (G6) construction that showed the best result in energy-saving (26%) might be due to the combination of low thermal conductivity of argon and nanogel. Even though (G6) has a greater thickness than the other windows studied, it has a low weight of less than 0.8 Kg, indicating the possibility of being applicable [25].

Schultz and Jensen [40] achieved an energy reduction of approximately 1200 kWh per year, which represented approximately 19% savings in the required annual heating in a family house in Denmark. This was achieved by replacing triple-layered argon-filled glazing with aerogel glazing. Huang and Niu [35] showed a 4% reduction in the annual space cooling of commercial buildings in the humid subtropical region by using silica aerogel filled between two layers of traditional single clear glass. Mujeebu, Ashraf [24] demonstrated that double glazed windows contributed considerably to the heat gain compared to nanogel glazing. They indicated that during the winter months, the heating load was reduced using double-glazed windows, while during the summer months, the cooling load was increased. A good contribution of nanogel glazing compared to the wall-based nano VIPs were mentioned by Rashwan, Farag [23] who studied the effect of wall-, windows- and coating- based nano insulation materials on heat transfer through the fabric of buildings. Gao, Jelle [41] demonstrated a significant reduction in U-value by incorporating aerogel granules into the cavity of double-glazing. They showed a 63% reduction in heat loss compared to a conventional double-glazing unit with the same interspace thickness. This study indicated the positive impact of window-based nanomaterials compared to conventional insulation materials. As well as it indicated the positive impact of using both Polystyrene as a conventional material and Nano-VIPs to improve the energy efficiency in buildings. Usage of these materials in the future would save money and energy.

3.3. The Effect of Integration between Insulation Based on Nanomaterials in the External Walls and Windows

In this phase, an integration between insulation based on nanomaterials in the external walls and windows was investigated. Six options were tested to improve energy efficiency as shown in Table 6. The base case that utilized common materials used in the existing social residential buildings was taken as a reference for comparison with the proposed alternative options. Since W3 (polystyrene foam) and W4 (nano VIPs) performed similarly in terms of energy-saving, the former was chosen for testing with the glazing options because of its lower cost.

Table 6.

Proposed options for integration between insulation based on nanomaterials in the external walls and windows.

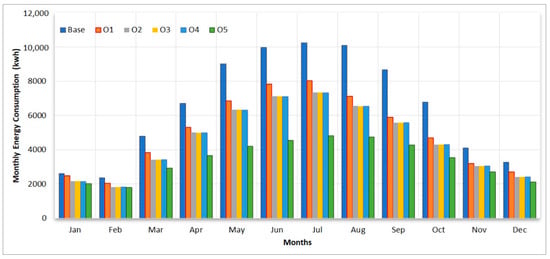

The analysis showed a clear reduction in annual energy consumption for all the tested options relative to the base. The impact of the options analyzed was manifested distinctly during the summer season, while the results during the winter period were attenuated, as shown in Figure 10. The findings can, in general, be summarized as follows:

Figure 10.

Simulation results for integration between the external walls and windows in terms of insulation based on nanomaterials.

- (O1) showed a decline in annual energy usage by around 24% relative to the base case, while (O2) showed a decrease of about 30.2% in annual energy consumption compared to the same base case.

- (O3) and (O4) showed almost the same impact as (O2). They contributed to an improvement in terms of energy efficiency with 30.3%, and 30.4%, respectively, in comparison with the base case.

- The most promising option was O5. Among all other options, it had the highest effect, improving energy efficiency by 47.6% compared to the base case.

3.4. Cost Analysis

Even though nano-insulation techniques are thought to be remarkable in terms of energy efficiency, economic performance and sustainability should also be considered. To support Egyptian architectural architects and decision-makers, a cost analysis was performed using the simple period of payback (SPP), which represents the length of time it takes to recover the cost of an investment. The additional investment needed for each studied option and the associated annual savings in energy costs are in Egyptian pounds (EGP). The additional investment and the simple period of payback (SPP, in the number of years) is deter-mined as follows:

Table 7 summarizes the unit costs (EGP/m2) of nanogel, and polystyrene foam according to current prices (aerogel and polystyrene foam costs were derived from international dealers and other costs were from the local market). Table 8 quantifies the total cost, the predicted annual energy cost, the annual savings and the SPP for the options.

Table 7.

Unit costs of materials.

Table 8.

Cost analysis summary for the proposed options.

Even though all options were appealing in terms of energy-saving efficiency, it was observed that O5 (polystyrene foam in wall and argon-nanogel glazed windows) had the lowest SPP of 17.0 years as well as the best performance in terms of energy savings efficiency. O2 (polystyrene foam in the wall and double-glazed windows filled with 13 mm air) exhibited the second most successful option among the proposed options with the second lowest SPP of 17.81 years. On the other hand, O1 (polystyrene foam in wall and 6 mm clear glass) showed energy-saving efficiency with SPP value of 19.23 years. In general, all the options examined are acceptable due to the current energy crisis in Egypt.

4. Conclusions

In this study, the effects of nano VIPs and PS in the wall and nanogel in the window were evaluated with respect to the annual energy consumption, annual energy cost and annual energy savings of residential buildings in a region with hot desert climate (New Aswan City—Egypt). The nano VIPs and the PS layer filled between two brick layers performed similarly with savings of about 23% annual energy as compared to the commonly used walls. The nanogel filling between two layers of clear glass saved approximately 11% energy relative to the commonly used glass, or twice that achieved by double glazing filled with argon. Interestingly, the nanogel layer filled between two layers of argon and two layers of glass sharply decreased the annual energy consumption by 26%. Five options were evaluated to improve both building insulation and energy efficiency. These options present the integration between the proposed windows and walls insulated with polystyrene foam, the most efficient wall insulation in terms of energy conservation and economic considerations. Building walls with polystyrene foam insulation integrated, and windows with argon and gel reduced energy consumption in social residential buildings by 47.6% while having the lowest SPP of 17 years. This study opens the way to encouraging the use of insulating materials, including nanomaterials, in the construction of energy-efficient buildings that cut down on energy costs. There is a necessity to develop nanomaterials used in thermal insulation of buildings with more in-depth economic studies to investigate the feasibility of using these materials in the present and future, especially in view of the impending climate change.

Author Contributions

M.H.H.A. and A.R. conceived the ideas and research design of this paper; M.H.H.A. and A.R. performed data analysis; A.A., M.H.H.A., and A.R. participated in acquiring the data; M.H.H.A. and A.R. developed and validated the model; A.A., M.H.H.A., and A.R. wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by TU Delft Open Access Program.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Not Applicable.

Conflicts of Interest

The authors declare no conflict of interests.

References

- Araki, K.; Kamoto, D.; Matsuoka, S.-I. Optimization about multilayer laminated film and getter device materials of vacuum insulation panel for using at high temperature. J. Mater. Process. Technol. 2009, 209, 271–282. [Google Scholar] [CrossRef]

- Johannesen, N.J.; Kolhe, M.; Goodwin, M. Relative evaluation of regression tools for urban area electrical energy demand forecasting. J. Clean. Prod. 2019, 218, 555–564. [Google Scholar] [CrossRef]

- Vasilakopoulou, K.; Kolokotsa, D.; Santamouris, M. Cities for Smart Environmental and Energy Futures: Urban heat Island Mitigation Techniques for Sustainable Cities. In Cities for Smart Environmental and Energy Futures; Springer: Berlin/Heidelberg, Germany, 2014; pp. 215–233. [Google Scholar]

- Wang, Q.; Su, M.; Li, R. The effects of energy prices, urbanization and economic growth on energy consumption per capita in 186 countries. J. Clean. Prod. 2019, 225, 1017–1032. [Google Scholar] [CrossRef]

- Zhou, N.; Price, L.; Dai, Y.; Creyts, J. A roadmap for China to peak carbon dioxide emissions and achieve a 20% share of non-fossil fuels in primary energy by 2030. Appl. Energy 2019, 239, 793–819. [Google Scholar] [CrossRef]

- Güneralp, B.; Zhou, Y.; Sha, L. Global scenarios of urban density and its impacts on building energy use through 2050. Natl. Acad. Sci. 2017, 114, 8945–8950. [Google Scholar] [CrossRef]

- King, D. A Global Apollo Programme to Combat Climate Change; London School of Economics and Political Science: London, UK, 2015. [Google Scholar]

- Buratti, C. Nano and Biotech Based Materials for Energy Building Efficiency; Springer International Publishers: Cham, Switzerland, 2016. [Google Scholar]

- Sharma, A.; Saaxena, A.; Venu, S. Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Edenhofer, O. Renewable Energy Sources and Climate Change Mitigation: Special Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Jelle, B.P.; Kalnæs, S.E. Nanotech Based Vacuum Insulation Panels for Building Applications. In Nano and Biotech Based Materials for Energy Building Efficiency; Springer: Berlin/Heidelberg, Germany, 2016; pp. 167–214. [Google Scholar]

- Fricke, J.; Heinemann, U.; Ebert, H. Vacuum insulation panels—From research to market. Vacuum 2008, 82, 680–690. [Google Scholar] [CrossRef]

- Yang, C.; Li, Y.J.; Gao, X.; Xu, L. A review of vacuum degradation research and the experimental outgassing research of the core material-PU foam on vacuum insulation panels. Phys. Procedia 2012, 32, 239–244. [Google Scholar] [CrossRef]

- Tenpierik, M.J. Vacuum Insulation Panels Applied in Building Constructions. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2010. [Google Scholar]

- Brunner, S.; Simmler, H. In situ performance assessment of vacuum insulation panels in a flat roof construction. Vacuum 2008, 82, 700–707. [Google Scholar] [CrossRef]

- Jelle, B.P. Moisture Robustness during Retrofitting of Timber Frame Walls with Vacuum Insulation Panels: Experimental and Theoretical Studies. In Hygrothermal Behavior, Building Pathology and Durability; Springer: Berlin/Heidelberg, Germany, 2013; pp. 183–210. [Google Scholar]

- Buratti, C.; Moretti, E.; Belloni, E. Nanogel Windows for Energy Building Efficiency. In Nano and Biotech Based Materials for Energy Building Efficiency; Springer: Berlin/Heidelberg, Germany, 2016; pp. 41–69. [Google Scholar]

- Zhao, Y.; Tang, G.; Du, M. Numerical study of radiative properties of nanoporous silica aerogel. Int. J. Therm. Sci. 2015, 89, 110–120. [Google Scholar] [CrossRef]

- Koebel, M.; Rigacci, A.; Achard, P. Aerogel-based thermal superinsulation: An overview. J. Sol-Gel Sci. Technol. 2012, 63, 315–339. [Google Scholar] [CrossRef]

- Rigacci, A.; Einarsrud, M.A.; Pirard, R. Improvement of the silica aerogel strengthening process for scaling-up monolithic tile production. J. Non-Cryst. Solids 2004, 350, 196–201. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E. Glazing systems with silica aerogel for energy savings in buildings. Appl. Energy 2012, 98, 396–403. [Google Scholar] [CrossRef]

- Ihara, T.; Gao, T.; Jelle, B.P. Aerogel granulate glazing facades and their application potential from an energy saving perspective. Appl. Energy 2015, 142, 179–191. [Google Scholar] [CrossRef]

- Rashwan, A.; Farag, O.; Moustafa, W.S. Energy performance analysis of integrating building envelopes with nanomaterials. Int. J. Sustain. Built Environ. 2013, 2, 209–223. [Google Scholar] [CrossRef]

- Mujeebu, M.A.; Ashraf, N.; Alsuwayigh, A. Energy performance and economic viability of nano aerogel glazing and nano vacuum insulation panel in multi-story office building. Energy 2016, 113, 949–956. [Google Scholar] [CrossRef]

- Mujeebu, M.A.; Ashraf, N.; Alsuwayigh, A.H. Effect of nano vacuum insulation panel and nanogel glazing on the energy performance of office building. Appl. Energy 2016, 173, 141–151. [Google Scholar] [CrossRef]

- Attia, S.; Shafik, Z.; Ibrahim, A. New Cities and Community Extensions in Egypt and the Middle East: Visions and Challenges; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Aly, A.M.; Hassn, M.H.; Rady, Y.R. The effect of using nano-materials in external openings on energy consumption in hot desert climate. J. Eng. Sci. 2020, 48, 468–477. [Google Scholar] [CrossRef]

- Ragab Abdel Radi, A. The impact of phase change materials on the buildings enegy efficiency in the hot desert areas the annexed rooms of the traffic building in new aswan city as a case study. JES J. Eng. Sci. 2020, 48, 302–316. [Google Scholar]

- Ragab, A.; Abdelrady, A. Impact of Green Roofs on Energy Demand for Cooling in Egyptian Buildings. Sustainability 2020, 12, 5729. [Google Scholar] [CrossRef]

- Hamdy, O.; Zhao, S.; Abd El-Atty, H.; Ragab, A.; Salem, M. Urban Areas Management in Developing Countries: Analysis of the Urban Areas Crossed with Risk of Storm Water Drains, Aswan-Egypt. Int. J. Urban Civ. Eng. 2020, 14, 96–102. [Google Scholar]

- Roberto, B.; Zhao, S.; Abd, H.; Ragab, A. Current Status and Future Developments of the ECMWF Ensemble Prediction System; ECMWF: Shinfield Park, UK, 1999. [Google Scholar]

- Hanna, G.B. Energy Efficiency Building Codes and Green Pyramid Rating System. In Renewable Energy in the Service of Mankind Vol I; Springer: Berlin/Heidelberg, Germany, 2015; pp. 597–608. [Google Scholar]

- Fahmy, M. Estimating the future energy efficiency and CO2 emissions of passive country housing applying domestic biogas reactor: A case study in Egypt. Ain Shams Eng. J. 2018, 9, 2599–2607. [Google Scholar] [CrossRef]

- Radwan, A.F.; Mahdy, M.M.; Rizk, H. Retrofitting of existing buildings to achieve better energy-efficiency in commercial building case study: Hospital in Egypt. Alex. Eng. J. 2016, 55, 3061–3071. [Google Scholar] [CrossRef]

- Huang, Y.; Niu, J.-L. Application of super-insulating translucent silica aerogel glazing system on commercial building envelope of humid subtropical climates–Impact on space cooling load. Energy 2015, 83, 316–325. [Google Scholar] [CrossRef]

- Mahdy, M.M.; Nikolopoulou, M. The cost of achieving thermal comfort via altering external walls specifications in Egypt, from construction to operation through different climate change scenarios. In Proceedings of the Building Simulation Conference, Chambery, France, 26–28 August 2013. [Google Scholar]

- Attia, S.; Evrard, A.; Gratia, E. Development of benchmark models for the Egyptian residential buildings sector. Appl. Energy 2012, 94, 270–284. [Google Scholar] [CrossRef]

- Osman, M. Population Situation Analysis; NFPA: Cairo, Egypt, 2016; p. 188. [Google Scholar]

- Moretti, E. Optical, thermal, and energy performance of advanced polycarbonate systems with granular aerogel. Energy Build. 2018, 166, 407–417. [Google Scholar] [CrossRef]

- Schultz, J.M.; Jensen, K.I. Evacuated aerogel glazings. Vacuum 2008, 82, 723–729. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.P.; Gustavsen, A.; Stefan, J. Aerogel-incorporated concrete: An experimental study. Constr. Build. Mater. 2014, 52, 130–136. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).