Quantification of On-Farm Pomegranate Fruit Postharvest Losses and Waste, and Implications on Sustainability Indicators: South African Case Study

Abstract

1. Introduction

Status of Pomegranate Fruit Production and Losses in South Africa

2. Materials and Methods

2.1. Research Design

2.2. Research Method

2.3. Data Collection

2.4. Statistical Analysis

3. Results

3.1. Magnitude of Fruit Losses and Waste

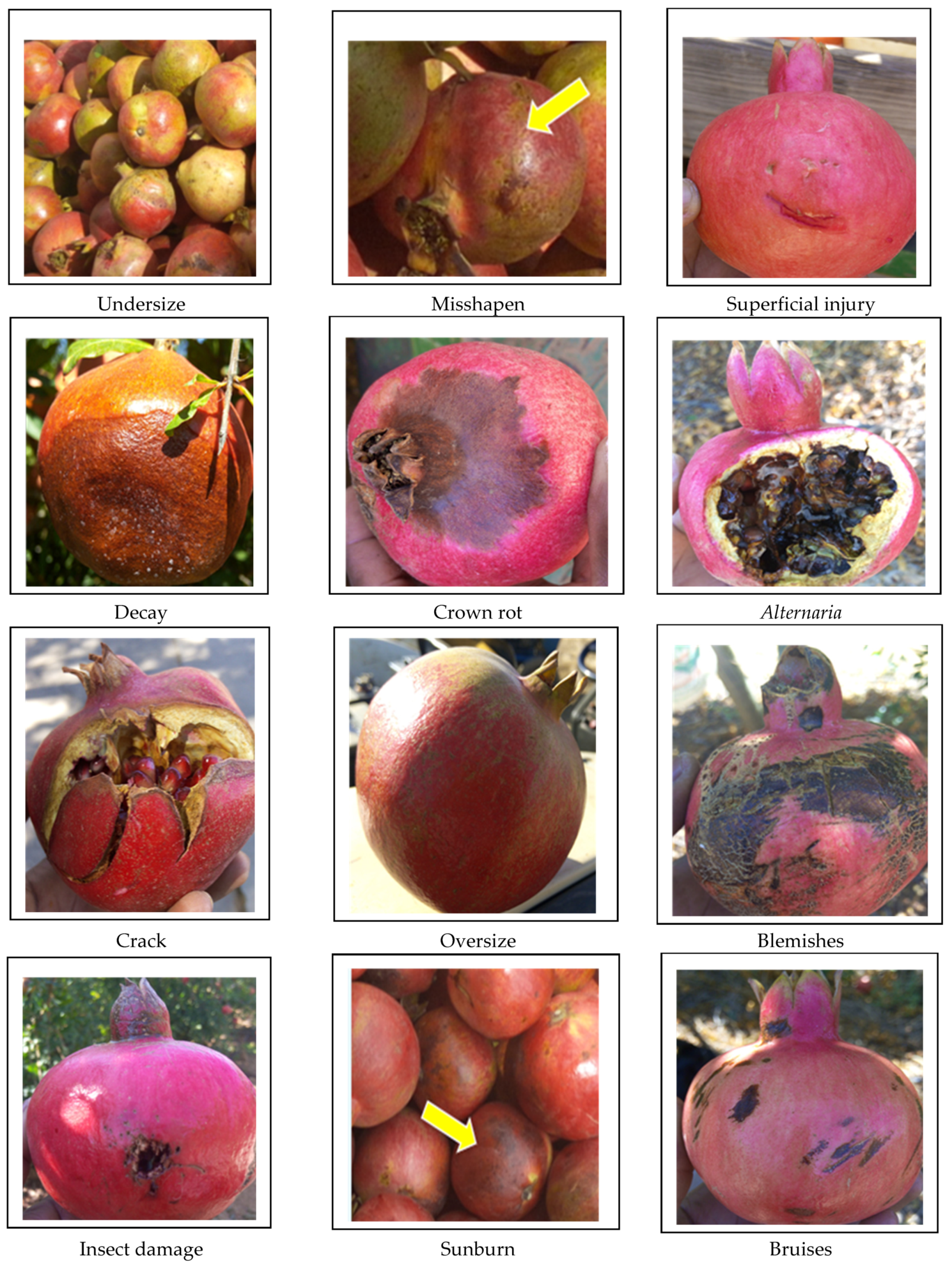

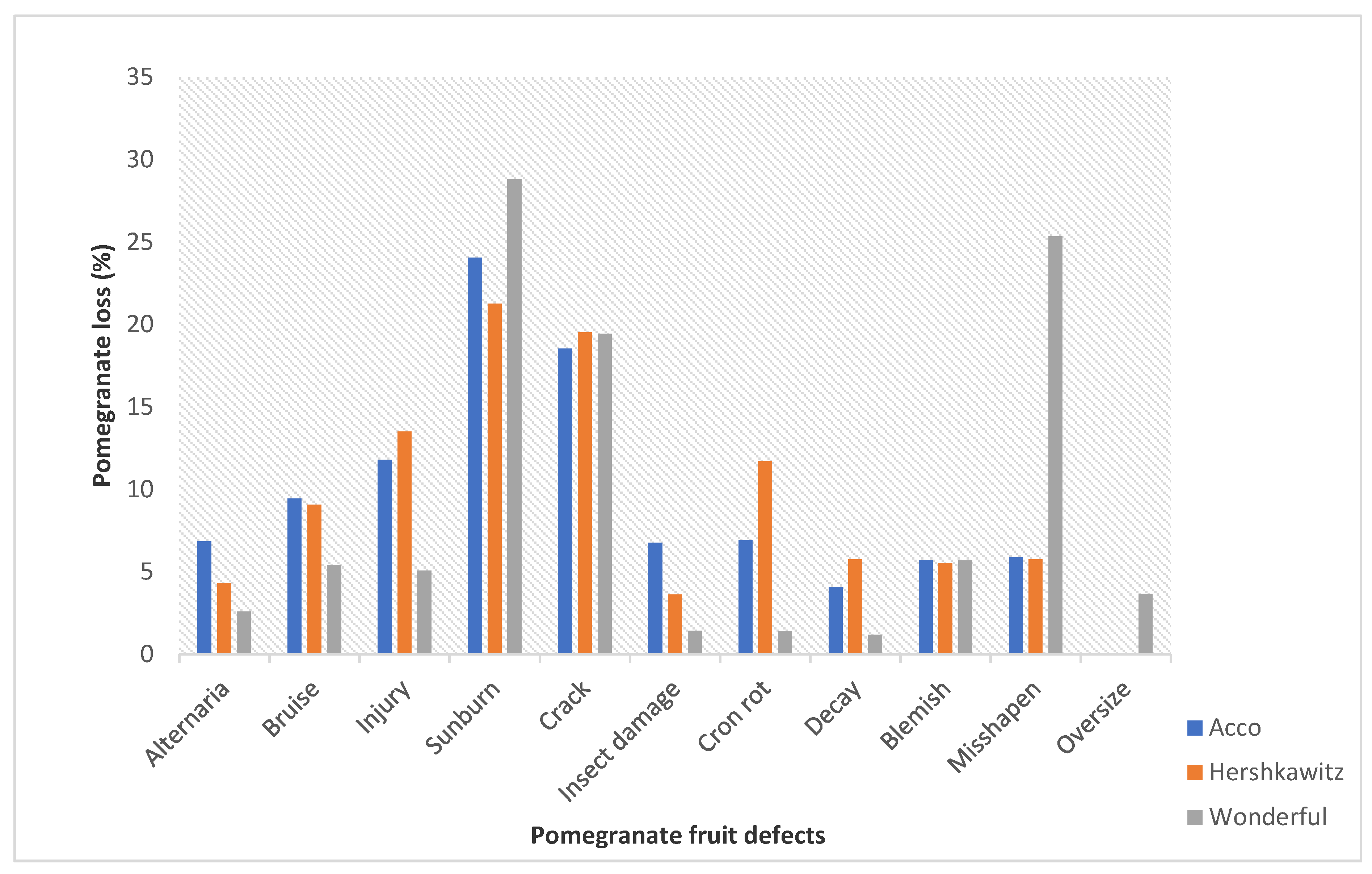

3.2. Causes of Farm Pomegranate Fruit Losses

3.2.1. Environmental Stress (Sunburn, Cracks and Splits)

Sunburn

Cracks and Splits

3.2.2. Mechanical and Physical Damage (Superficial Injuries, Bruise Damage and Blemish)

Superficial Injuries

Bruise Damage

Blemish

3.2.3. Biological Damage (Insect Damage)

Insect Damage

3.2.4. Microbial and Pathological Spoilage (Decay and Rots, Alternaria, Crown Rot)

Decay and Rots

Alternaria

Crown Rot

3.2.5. Irregular Fruit Size and Shape (Oversize, Undersize and Misshapen)

Oversize

Undersize and Misshapen

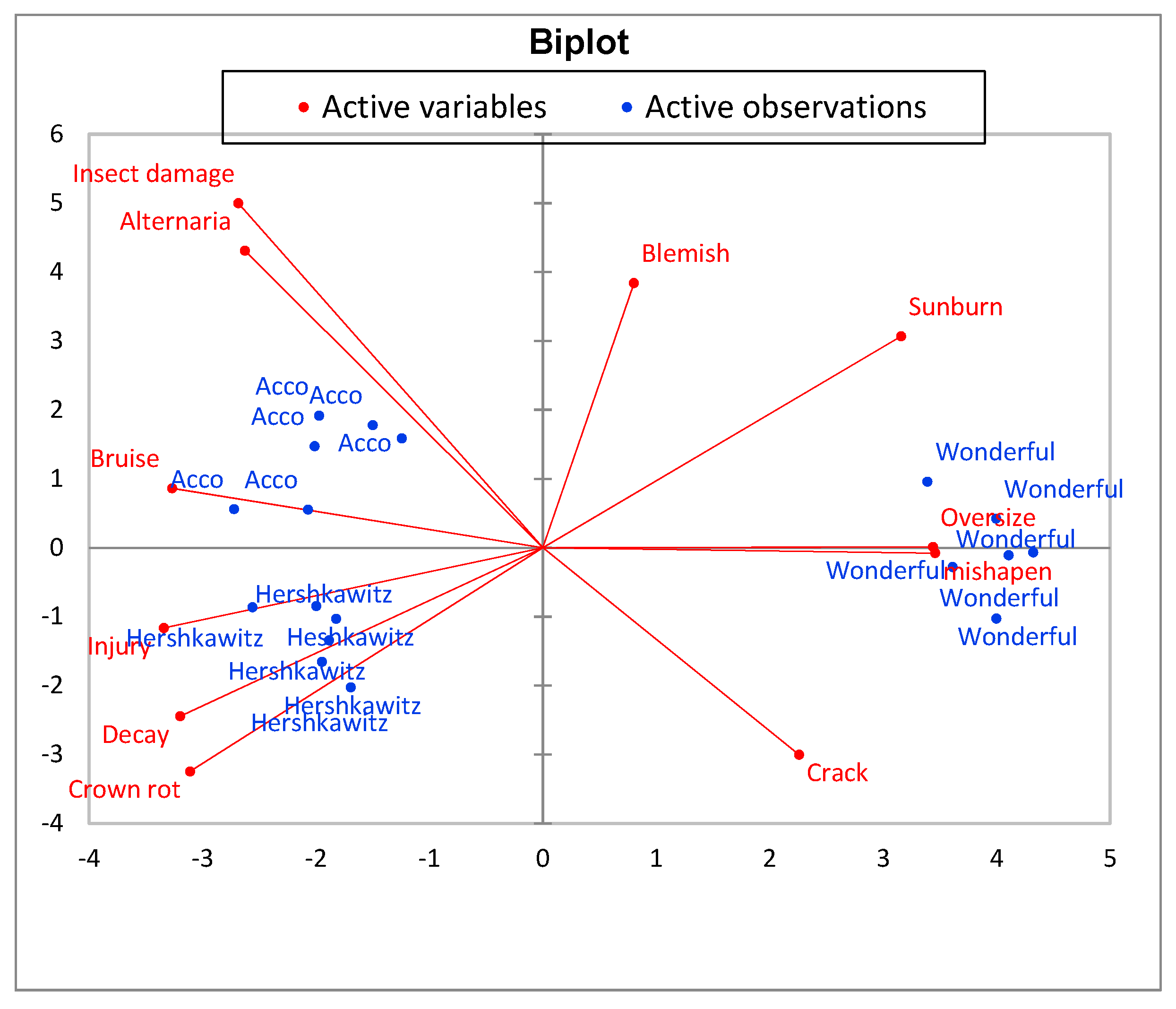

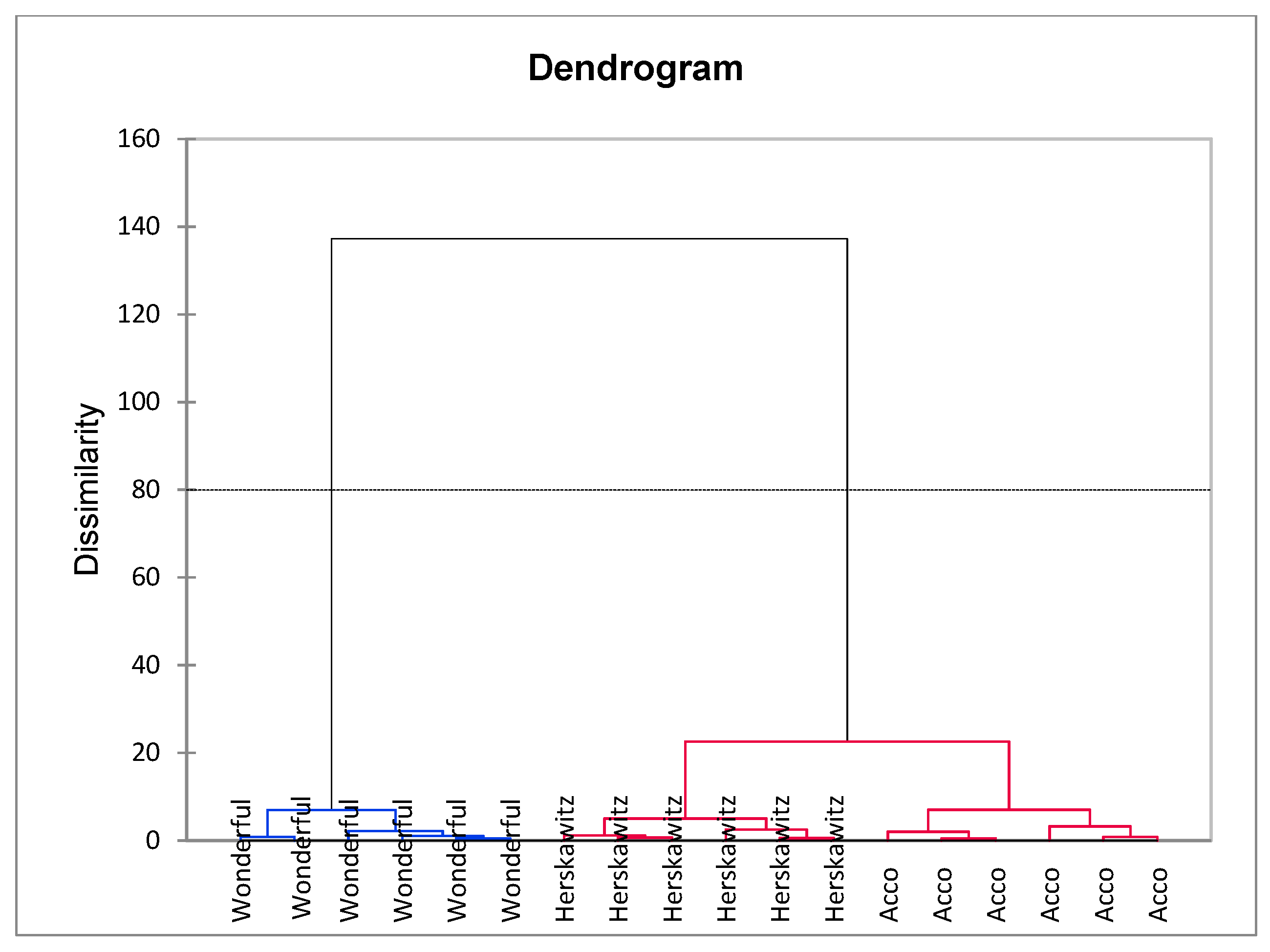

3.3. Comparative Analysis of Pomegranate Fruit Cultivars Based on Defects

4. Discussion

4.1. Economic, Environmental and Resource Impacts

4.2. Nutritional Impacts

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Health Organization (WHO). Fruit and Vegetables Promotion Initiative; Report of the Meeting; WHO: Geneva, Switzerland, 2003; pp. 25–27. Available online: https://www.who.int/dietphysicalactivity/publications/f&v_promotion_initiative_report.pdf (accessed on 20 June 2020).

- Keatinge, J.D.; Waliyar, F.; Jamnadas, R.H.; Moustafa, A.; Andrade, M.; Drechsel, P.; Hughes, J.D.A.; Kadirvel, P.; Luther, K. Relearning old lessons for the future of food—by bread alone no longer: Diversifying diets with fruit and vegetables. Crop Sci. 2010, 50, 51–62. [Google Scholar] [CrossRef]

- Paul, D.K.; Shaha, R.K. Nutrients, vitamins and minerals content in common citrus fruits in the northern region of Bangladesh. Pak. J. Biol. Sci. 2004, 7, 238–242. [Google Scholar] [CrossRef]

- Keatinge, J.D.H.; Yang, R.Y.; Hughes, J.D.A.; Easdown, W.J.; Holmer, R. The importance of vegetables in ensuring both food and nutritional security in attainment of the Millennium Development Goals. Food Secur. 2011, 3, 491–501. [Google Scholar] [CrossRef]

- Sagar, N.A.; Pareek, S.; Sharma, S.; Yahia, E.M.; Lobo, M.G. Fruit and vegetable waste: Bioactive compounds, their extraction, and possible utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef] [PubMed]

- Opara, L.U. Editorial: Postharvest technology for linking production to markets. Int. J. Postharvest Technol. Innov. 2006, 1, 139–141. [Google Scholar]

- Opara, U.L. High incidence of postharvest food losses is worsening global food and nutrition security. Int. J. Postharvest Technol. Innov. 2010, 2, 1–3. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Van Otterdijk, R.; Meybeck, A. Global food losses and food waste. In Proceedings of the Save Food Congress, Düsseldorf, Germany, 16 May 2011. [Google Scholar]

- Food and Agriculture Organisation of the United Nations (FAO). Food Wastage Footprint. Impacts on Natural Resources. Rome, Italy, 2013. Available online: http://www.fao.org/3/i3347e/i3347e.pdf (accessed on 3 May 2020).

- Oelofse, S.H.; Nahman, A. Estimating the magnitude of food waste generated in South Africa. Waste Manag. Res. 2013, 3, 80–86. [Google Scholar] [CrossRef]

- Kahramanoglu, I.; Usanmaz, S. Pomegranate Production and Marketing, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Kahramanoglu, I. Trends in pomegranate sector: Production, postharvest handling and marketing. Int. J. Agric. For. Life Sci. 2019, 3, 239–246. [Google Scholar]

- Mukama, M.; Ambaw, A.; Opara, U.L. A virtual prototyping approach for redesigning the vent-holes of packaging for handling pomegranate fruit–A short communication. J. Food Eng. 2020, 270, 1–5. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Harvest and postharvest factors affecting bruise damage of fresh fruits. Hortic. Plant J. 2019, 6, 1–13. [Google Scholar] [CrossRef]

- Arendse, E.; Fawole, O.A.; Magwaza, L.S.; Nieuwoudt, H.; Opara, U.L. Fourier transform near infrared diffuse reflectance spectroscopy and two spectral acquisition modes for evaluation of external and internal quality of intact pomegranate fruit. Postharvest Biol. Technol. 2018, 138, 91–98. [Google Scholar] [CrossRef]

- Belay, Z.A.; Caleb, O.J.; Opara, U.L. Enzyme kinetics modelling approach to evaluate the impact of high CO2 and super-atmospheric O2 concentrations on respiration rate of pomegranate arils. CyTA J. Food 2017, 15, 608–616. [Google Scholar] [CrossRef]

- Fawole, O.A.; Opara, U.L. Effects of storage temperature and duration on physiological responses of pomegranate fruit. Ind. Crops Prod. 2013, 47, 300–309. [Google Scholar] [CrossRef]

- Pomegranate Producers Association of South Africa (POMASA). Pomegranate Industry Overview: Statistics and Information. 2019. Available online: https://www.sapomegranate.co.za/statistics-and-information/pomegranate-industry-overview/ (accessed on 12 March 2020).

- Munhuweyi, K.; Lennox, C.L.; Meitz-Hopkins, J.C.; Caleb, O.J.; Opara, U.L. Major diseases of pomegranate (Punica granatum L.), their causes and management—A review. Sci. Hortic. 2016, 211, 126–139. [Google Scholar] [CrossRef]

- Lufu, R.; Ambaw, A.; Opara, U.L. The contribution of transpiration and respiration processes in the mass loss of pomegranate fruit (cv. Wonderful). Postharvest Biol. Technol. 2019, 157, 1–10. [Google Scholar] [CrossRef]

- Lufu, R.; Ambaw, A.; Opara, U.L. Water loss of fresh fruit: Influencing pre-harvest, harvest and postharvest factors. Sci. Hortic. 2020, 272, 1–16. [Google Scholar] [CrossRef]

- Rymon, D. Mapping features of the global pomegranate market. Acta Hortic. 2011, 890, 599–602. [Google Scholar] [CrossRef]

- Pomegranate Producers Association of South Africa (POMASA). Pomegranate Industry Overview: Statistics and Information. 2016. Available online: https://www.sapomegranate.co.za/statistics-and-information/pomegranate-industry-overview/ (accessed on 12 March 2020).

- Pomegranate Producers Association of South Africa (POMASA). Pomegranate Industry Overview: Statistics and Information. 2017. Available online: https://www.sapomegranate.co.za/statistics-and-information/pomegranate-industry-overview/ (accessed on 12 March 2020).

- Pomegranate Producers Association of South Africa (POMASA). Pomegranate Industry Overview: Statistics and Information. 2018. Available online: https://www.sapomegranate.co.za/statistics-and-information/pomegranate-industry-overview/ (accessed on 12 March 2020).

- Johnson, L.K.; Dunning, R.D.; Bloom, J.D.; Gunter, C.C.; Boyette, M.D.; Creamer, N.G. Estimating on-farm food loss at the field level: A methodology and applied case study on a North Carolina farm. Resour. Conserv. Recycl. 2018, 137, 243–250. [Google Scholar] [CrossRef]

- Johnson, L.K.; Dunning, R.D.; Gunter, C.C.; Bloom, J.D.; Boyette, M.D.; Creamer, N.G. Field measurement in vegetable crops indicates need for reevaluation of on-farm food loss estimates in North America. Agric. Syst. 2018, 167, 136–142. [Google Scholar] [CrossRef]

- Moller, H.; Hansen, O.J.; Svanes, E.; Hartikainen, H.; Silvennoinen, K.; Gustavsson, J.; Schneider, F.; Soethoudt, H.; Canali, M.; Politano, A.; et al. Standard Approach on Quantitative Techniques to Be Used to Estimate Food Waste Levels; Project Report FUSIONS; Ostfold Research: Krakeroy, Norway, 2014. [Google Scholar]

- Lipinski, B.; Hanson, C.; Lomax, J.; Kitinoja, L.; Waite, R.; Searchinger, T. Reducing Food Loss and Waste; Working Paper; World Resources Institute: Washington, DC, USA, 2013; Volume 1, pp. 1–40. [Google Scholar]

- Baker, G.A.; Gray, L.C.; Harwood, M.J.; Osland, T.J.; Tooley, J.B.C. On-farm food loss in northern and central California: Results of field survey measurements. Resour. Conserv. Recycl. 2019, 149, 541–549. [Google Scholar] [CrossRef]

- Dome, M.M.; Prusty, S. Determination of vegetable postharvest loss in the last-mile supply chain in Tanzania: A lean perspective. Int. J. Logist. Syst. Manag. 2017, 27, 133–150. [Google Scholar] [CrossRef]

- Opara, U.L.; Al-Ani, M.R. Antioxidant contents of pre-packed fresh-cut versus whole fruit and vegetables. Br. Food J. 2010, 112, 797–810. [Google Scholar] [CrossRef]

- Kumar, S.; Underhill, S.J. Smallholder Farmer Perceptions of Postharvest Loss and Its Determinants in Fijian Tomato Value Chains. Horticulturae 2019, 5, 74. [Google Scholar] [CrossRef]

- Musasa, S.T.; Mvumi, B.M.; Manditsera, F.A.; Chinhanga, J.; Musiyandaka, S.; Chigwedere, C. Postharvest orange losses and small-scale farmers’ perceptions on the loss causes in the fruit value chain: A case study of Rusitu Valley, Zimbabwe. Food Sci. Qual. Manag. 2013, 18, 1–8. [Google Scholar]

- Opara, L.U. Postharvest losses at the fresh produce retail chain in the Sultanate of Oman. In Proceedings of the Australian Postharvest Horticulture Conference, Brisbane, Australia, 1–3 October 2003; pp. 248–249. [Google Scholar]

- Food and Agriculture Organisation of the United Nations (FAO). Global Food Losses and Food Waste—Extent, Causes and Prevention; FAO: Rome, Italy, 2011; Available online: http://www.fao.org/3/mb060e/mb060e00.pdf (accessed on 3 March 2020).

- Hanson, C.; Lipinski, B.; Robertson, K.; Dias, D.; Gavilan, I.; Gréverath, P.; Ritter, S.; Fonseca, J.; Van Otterdijk, R.; Timmermans, T.; et al. Food Loss and Waste Accounting and Reporting Standard; World Resource Institute: Washington, DC, USA, 2016; Available online: https://www.wri.org/publication/food-loss-and-waste-accounting-and-reporting-standard (accessed on 29 March 2020).

- McKenzie, T.J.; Singh-Peterson, L.; Underhill, S.J. Quantifying postharvest loss and the implication of market-based decisions: A case study of two commercial domestic tomato supply chains in Queensland, Australia. Horticulturae 2017, 3, 44. [Google Scholar] [CrossRef]

- González, A.D.; Frostell, B.; Carlsson-Kanyama, A. Protein efficiency per unit energy and per unit greenhouse gas emissions: Potential contribution of diet choices to climate change mitigation. Food Policy 2011, 36, 562–570. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. The green, blue and grey water footprint of crops and derived crop products. Hydrol. Earth Syst. Sci. 2011, 15, 1577–1600. [Google Scholar] [CrossRef]

- Spiker, M.L.; Hiza, H.A.; Siddiqi, S.M.; Neff, R.A. Wasted food, wasted nutrients: Nutrient loss from wasted food in the United States and comparison to gaps in dietary intake. J. Acad. Nutr. Diet. 2017, 117, 1031–1040. [Google Scholar] [CrossRef] [PubMed]

- Sudharshan, G.M.; Anand, M.B. Marketing & Post-Harvest Losses in Fruits: Its Implications on Availability & Economy-A Study on Pomegranate in Karnataka. Int. J. Manag. Soc. Sci. Res. 2013, 2, 34–43. [Google Scholar]

- Jadhav, R.J.; Shaikh, N.B.; Pawar, K.B.; Mendhe, A.R.; Chaure, J.S. Assessment of post-harvest losses in banana under Jalgaon condition, in Maharashtra. Int. J. Chem. Stud. 2020, 8, 889–892. [Google Scholar] [CrossRef]

- Springael, J.; Paternoster, A.; Braet, J. Reducing postharvest losses of apples: Optimal transport routing (while minimizing total costs). Comput. Electron. Agric. 2018, 146, 136–144. [Google Scholar] [CrossRef]

- Aulakh, J.; Regmi, A. Post-Harvest Food Losses Estimation-Development of Consistent Methodology; FAO: Rome, Italy, 2013; Available online: http://www.fao.org/fileadmin/templates/ess/documents/meetings_and_workshops/GS_SAC_2013/Improving_methods_for_estimating_post_harvest_losses/Final_PHLs_Estimation_6-13-13.pdf (accessed on 20 April 2020).

- Weerakkody, P.; Jobling, J.; Infante, M.M.V.; Rogers, G. The effect of maturity, sunburn and the application of sunscreens on the internal and external qualities of pomegranate fruit grown in Australia. Sci. Hortic. 2010, 124, 57–61. [Google Scholar] [CrossRef]

- Yazici, K.; Kaynak, L. Effects of air temperature, relative humidity and solar radiation on fruit surface temperatures and sunburn damage in pomegranate (Punica granatum L. cv. Hicaznar. Acta Hortic. 2006, 818, 181–186. [Google Scholar] [CrossRef]

- Galindo, A.; Rodríguez, P.; Collado-González, J.; Cruz, Z.N.; Torrecillas, E.; Ondoño, S.; Corell, M.; Moriana, A.; Torrecillas, A. Rainfall intensifies fruit peel cracking in water stressed pomegranate trees. Agric. For. Meteorol. 2014, 194, 29–35. [Google Scholar] [CrossRef]

- Abd El-Rhman, I.E. Physiological studies on cracking phenomena of pomegranates. J. Appl. Sci. Res. 2010, 6, 696–703. [Google Scholar]

- Ahmed, B. Fruit cracking and yield of pomegranate as affected by borax with irrigation at different intervals. Ann. Agric. Res. 2009, 30, 148–149. [Google Scholar]

- Hepaksoy, S.; Aksoy, U.; Can, H.Z.; Ui, M.A. Determination of relationship between fruit cracking and some physiological responses, leaf characteristics and nutritional status of some pomegranate varieties. Options Méditerr. Sér. A 2000, 42, 87–92. [Google Scholar]

- Martinez-Romero, D.; Serrano, M.; Carbonell, A.; Castillo, S.; Riquelme, F.; Valero, D. Mechanical damage during fruit post-harvest handling: Technical and physiological implications. In Production Practices and Quality Assessment of Food Crops, 3rd ed.; Springer: Dordrecht, The Netherlands, 2004; pp. 233–252. [Google Scholar]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Investigating bruise susceptibility of pomegranate cultivars during postharvest handling. Afr. J. Rural Dev. 2017, 2, 33–39. [Google Scholar]

- Yahaya, S.M.; Mardiyya, A.Y. Review of Post-Harvest Losses of Fruits and Vegetables. Biomed. J. Sci. Tech. Res. 2019, 13, 10192–10200. [Google Scholar]

- Prusky, D. Reduction of the incidence of postharvest quality losses, and future prospects. Food Secur. 2011, 3, 463–474. [Google Scholar] [CrossRef]

- Wohlfarter, M.; Giliomee, J.H.; Venter, E. A survey of the arthropod pests associated with commercial pomegranates, Punica granatum (Lythraceae), in South Africa. Afr. Entomol. 2010, 18, 192–199. [Google Scholar] [CrossRef]

- Michailides, T.; Morgan, D.; Quist, M.; Reyes, H. Infection of pomegranate by Alternaria spp. causing black heart. Phytopathology 2008, 98, 105. [Google Scholar]

- Selvaggi, R.; Valenti, F. Assessment of Fruit and Vegetable Residues Suitable for Renewable Energy Production: GIS-Based Model for Developing New Frontiers within the Context of Circular Economy. Appl. Syst. Innov. 2021, 4, 10. [Google Scholar] [CrossRef]

- Bocca, F.; Di Donato, P.; Covino, D.; Poli, A. Food waste and bio-economy: A scenario for the Italian tomato market. J. Clean. Prod. 2019, 227, 424–433. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Method for Calculating Carbon Sequestration by Trees in Urban and Suburban Settings; Voluntary Reporting of Greenhouse Gases; U.S. Department of Energy, Energy Information Administration: Washington, DC, USA, 1998. Available online: https://www3.epa.gov/climatechange/Downloads/method-calculating-carbon-sequestration-trees-urban-and-suburban-settings.pdf (accessed on 17 July 2020).

- Gleick, P.H.; Iwra, M. Basic water requirements for human activities: Meeting basic needs. Water Int. 1996, 21, 83–92. [Google Scholar] [CrossRef]

- Grundy, M.M.L.; Edwards, C.H.; Mackie, A.R.; Gidley, M.J.; Butterworth, P.J.; Ellis, P.R. Re-evaluation of the mechanisms of dietary fibre and implications for macronutrient bioaccessibility, digestion and postprandial metabolism. Br. J. Nutr. 2016, 116, 816–833. [Google Scholar] [CrossRef] [PubMed]

- Smith, H.A.; Gonzalez, J.T.; Thompson, D.; Betts, J.A. Dietary carbohydrates, components of energy balance, and associated health outcomes. Nutr. Rev. 2017, 75, 783–797. [Google Scholar] [CrossRef]

- Evans, W.J.; Fisher, E.C.; Hoerr, R.A.; Young, V.R. Protein metabolism and endurance exercise. Physician Sportsmed. 1983, 11, 63–162. [Google Scholar] [CrossRef]

- Brussaard, J.H.; Brants, H.A.; Bouman, M.; Löwik, M.R. Iron intake and iron status among adults in the Netherlands. Eur. J. Clin. Nutr. 1997, 51, 51–58. [Google Scholar]

- Xu, X.; Chueh, C.C.; Yang, Z.; Rajagopal, A.; Xu, J.; Jo, S.B.; Jen, A.K.Y. Ascorbic acid as an effective antioxidant additive to enhance the efficiency and stability of Pb/Sn-based binary perovskite solar cells. Nano Energy 2017, 34, 392–398. [Google Scholar] [CrossRef]

- Flynn, A. The role of dietary calcium in bone health. Proc. Nutr. Soc. 2003, 62, 851–858. [Google Scholar] [CrossRef]

- Britton, J.; Pavord, I.; Richards, K.; Wisniewski, A.; Knox, A.; Lewis, S.; Tattersfield, A.; Weiss, S. Dietary magnesium, lung function, wheezing, and airway hyper-reactivity in a random adult population sample. Lancet 1994, 344, 357–362. [Google Scholar] [CrossRef]

- Chen, D.; Stegbauer, J.; Sparks, M.A.; Kohan, D.; Griffiths, R.; Herrera, M.; Gurley, S.B.; Coffman, T.M. Impact of angiotensin type 1A receptors in principal cells of the collecting duct on blood pressure and hypertension. Hypertension 2016, 67, 1291–1297. [Google Scholar] [CrossRef] [PubMed]

- Seifter, J.L. Body Fluid Compartments, Cell Membrane Ion Transport, Electrolyte Concentrations, and Acid-Base Balance. Semin. Nephrol. 2019, 39, 368–379. [Google Scholar] [CrossRef] [PubMed]

| Year | Wonderful | Hershkawitz | Acco | Reference * |

|---|---|---|---|---|

| 2016 | 1.0 | 14.0 | 2.0 | [23] |

| 2017 | 11.0 | 13.0 | 11.0 | [24] |

| 2018 | 7.0 | 8.0 | 9.0 | [25] |

| 2019 | 9.0 | 25.0 | 13.0 | [18] |

| Mean | 7.0 | 15.0 | 8.8 |

| Cultivar | Good Fruit | Discarded Fruit | Discarded Fruit (%) |

|---|---|---|---|

| Min–Max | Min–Max | Min–Max | |

| Acco | 7274–7330 | 1370–1432 | 15.8–16.5 |

| Hershkawitz | 7296–7373 | 1327–1404 | 15.3–16.2 |

| Wonderful | 5793–5825 | 1425–1457 | 19.7–20.1 |

| Defects | Alternaria | Bruise | Injury | Sunburn | Crack | Insect Damage | Crown Rot | Decay | Blemish | Misshapen | Oversize |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alternaria | 1 | ||||||||||

| Bruise | 0.774 | 1 | |||||||||

| Injury | 0.605 | 0.886 | 1 | ||||||||

| Sunburn | −0.456 | −0.760 | −0.904 | 1 | |||||||

| Crack | −0.510 | −0.553 | −0.546 | 0.453 | 1 | ||||||

| Insect damage | 0.943 | 0.806 | 0.657 | −0.440 | −0.641 | 1 | |||||

| Crown rot | 0.397 | 0.734 | 0.903 | −0.968 | −0.478 | 0.409 | 1 | ||||

| Decay | 0.488 | 0.769 | 0.873 | −0.953 | −0.543 | 0.471 | 0.957 | 1 | |||

| Blemish | −0.147 | −0.287 | −0.263 | 0.261 | −0.064 | −0.011 | −0.231 | −0.207 | 1 | ||

| Misshapen | −0.729 | −0.913 | −0.947 | 0.889 | 0.588 | −0.758 | −0.888 | −0.899 | 0.138 | 1 | |

| Oversize | −0.761 | −0.907 | −0.909 | 0.889 | 0.556 | −0.748 | −0.869 | −0.907 | 0.190 | 0.978 | 1 |

| Cultivar | ||||||||

|---|---|---|---|---|---|---|---|---|

| Defects | Acco (Mean) | Acco (Total) | Hershkawitz (Mean) | Hershkawitz (Total) | Wonderful (Mean) | Wonderful (Total) | Total | Loss (%) |

| Biological | ||||||||

| Insect damage (mean) | 95.17 ± 3.86 c * | 571 | 49.17 ± 4.02 a | 295 | 20.67 ± 2.76 b | 124 | ||

| Total | 571 | 295 | 124 | 990 | 3.92 | |||

| Irregular fruit size and shape | ||||||||

| Undersize/malformation | 83.00 ± 3.32 b | 498 | 78.17 ± 5.44 b | 469 | 366.00 ± 6.23 a | 2196 | ||

| Oversize | 0.00 ± 0.00 | 0 | 0.00 ± 0.00 | 0 | 52.50 ± 3.15 a | 315 | ||

| Total | 498 | 469 | 2511 | 3478 | 13.76 | |||

| Mechanical damage | ||||||||

| Bruise damage | 132.83 ± 5.46 a | 797 | 123.50 ± 3.25 a | 741 | 78.50 ± 3.39 b | 471 | ||

| Superficial injuries | 166.00 ± 10.13 a | 996 | 183.83 ± 5.06 a | 1103 | 73.17 ± 6.12 b | 439 | ||

| Total | 1793 | 1844 | 910 | 4547 | 17.99 | |||

| Environmental stress | ||||||||

| Sunburn | 338.33 ± 8.94 a | 2030 | 289.33 ± 5.38 b | 1736 | 415.83 ± 3.48 c | 2495 | ||

| Crack and splits | 261.00 ± 4.23 b | 1566 | 266.00 ± 4.20 ab | 1596 | 280.17 ± 5.57 a | 1681 | ||

| Total | 3596 | 3332 | 4176 | 11104 | 43.93 | |||

| Microbial and pathological | ||||||||

| Alternaria | 96.33 ± 2.26 c | 578 | 59.00 ± 3.28 a | 354 | 37.33 ± 2.79 b | 224 | ||

| Crown rot | 97.50 ± 5.86 a | 585 | 159.33 ±3.44 c | 956 | 20.00 ± 2.07 b | 120 | ||

| Decay and rots | 56.67 ± 2.93 a | 340 | 78.17 ± 3.22 c | 469 | 17.17 ± 2.57 b | 103 | ||

| Total | 1503 | 1779 | 447 | 3729 | 14.75 | |||

| Physical | ||||||||

| Blemish | 80.33 ± 5.59 a | 482 | 75.33 ± 4.78 a | 452 | 82.17 ± 4.48 a | 493 | ||

| Total | 482 | 452 | 493 | 1427 | 5.65 |

| Factor | Case Study Farm | South Africa | Global |

|---|---|---|---|

| Production area (ha) | 17.60 | 1024.00 | 98,701.29 |

| Production volume (tonnes) * | 677.60 | 39,424.00 | 3.80 × 106 |

| Average loss (%) | 17.38 | 17.38 | 17.38 |

| Retail price (R/kg) a | 89.99 | 89.99 | 89.99 |

| Estimated physical and economic losses | |||

| Physical loss (tonnes) | 117.76 | 6851.89 | 660,440.00 |

| Monetary loss (ZAR) | 10.50 × 106 | 616.60 × 106 | 59.43 × 109 |

| Environmental impacts | |||

| Estimated GHG emission (CO2 eq) b | 56.50 × 103 | 3288.00 × 103 | 317.01 × 106 |

| Estimated energy used (MJ) c | 718.00 × 103 | 41.79 × 106 | 4.02 × 109 |

| Resource impact | |||

| Water footprint (m3) d | 107.10 × 103 | 6235.20 × 103 | 601.00 × 106 |

| Equivalent land used to produce lost fruit (ha) | 3.00 | 177.97 | 17,174.02 |

| Case Study Farm | National (South Africa) | Global | |||||

|---|---|---|---|---|---|---|---|

| Nutrition Factor | Amount Lost (mg100−1 g) * | Nutritional Loss (per capita/day) ** | Amount Lost (mg100−1 g) * | Nutritional Loss (per capita/day) ** | Amount Lost (mg100−1 g) * | Nutritional Loss (per capita/day) ** | Role of Nutrient in Human Health |

| Fibre | 58.88 ## | 2.00 | 3425.94 ## | 137.00 | 330 × 103 ## | 13,224.00 | Digestibility [62] |

| Carbohydrate | 1165.82 ## | 9.00 | 67,833.71 ## | 522.00 | 654 × 104 ## | 50,353.00 | Energy source [63] |

| Protein | 164.86 ## | 4.00 | 9592.64 ## | 209.00 | 925 × 103 ## | 20,123.00 | Energy source [64] |

| Iron | 35.32 | 2.00 | 2055.56 | 114.00 | 198 × 103 | 11,020.00 | Oxygen transport [65] |

| Ascorbic acid | 1766.40 | 24.00 | 102,778.35 | 1370.00 | 991 × 104 | 132,240.00 | Antioxidant [66] |

| Calcium | 3532.80 | 4.00 | 205,556.70 | 206.00 | 198 × 105 | 19,836.00 | Bone formation [67] |

| Magnesium | 1413.12 | 5.00 | 82,222.68 | 265.00 | 793 × 104 | 25,595.00 | Better lung function [68] |

| Sodium | 471.04 | 1.00 | 27,407.56 | 14.00 | 264 × 104 | 1322.00 | Blood pressure regulation [69] |

| Potassium | 20,136.96 | 4.00 | 1,171,673.19 | 249.00 | 113 × 106 | 24,056.00 | Fluid regulation [70] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Opara, I.K.; Fawole, O.A.; Kelly, C.; Opara, U.L. Quantification of On-Farm Pomegranate Fruit Postharvest Losses and Waste, and Implications on Sustainability Indicators: South African Case Study. Sustainability 2021, 13, 5168. https://doi.org/10.3390/su13095168

Opara IK, Fawole OA, Kelly C, Opara UL. Quantification of On-Farm Pomegranate Fruit Postharvest Losses and Waste, and Implications on Sustainability Indicators: South African Case Study. Sustainability. 2021; 13(9):5168. https://doi.org/10.3390/su13095168

Chicago/Turabian StyleOpara, Ikechukwu Kingsley, Olaniyi Amos Fawole, Candice Kelly, and Umezuruike Linus Opara. 2021. "Quantification of On-Farm Pomegranate Fruit Postharvest Losses and Waste, and Implications on Sustainability Indicators: South African Case Study" Sustainability 13, no. 9: 5168. https://doi.org/10.3390/su13095168

APA StyleOpara, I. K., Fawole, O. A., Kelly, C., & Opara, U. L. (2021). Quantification of On-Farm Pomegranate Fruit Postharvest Losses and Waste, and Implications on Sustainability Indicators: South African Case Study. Sustainability, 13(9), 5168. https://doi.org/10.3390/su13095168