Environmental Problem Shifting Analysis of Pollution Control Units in a Coal-Fired Powerplant Based on Multiple Regression and LCA Methodology

Abstract

1. Introduction

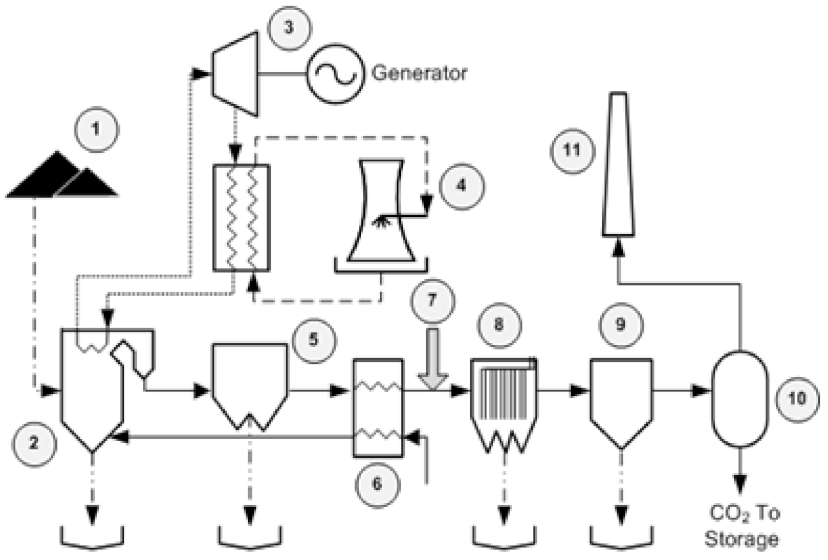

2. Methodology

3. Results and Discussion

3.1. Global Warming Potential (GWP)

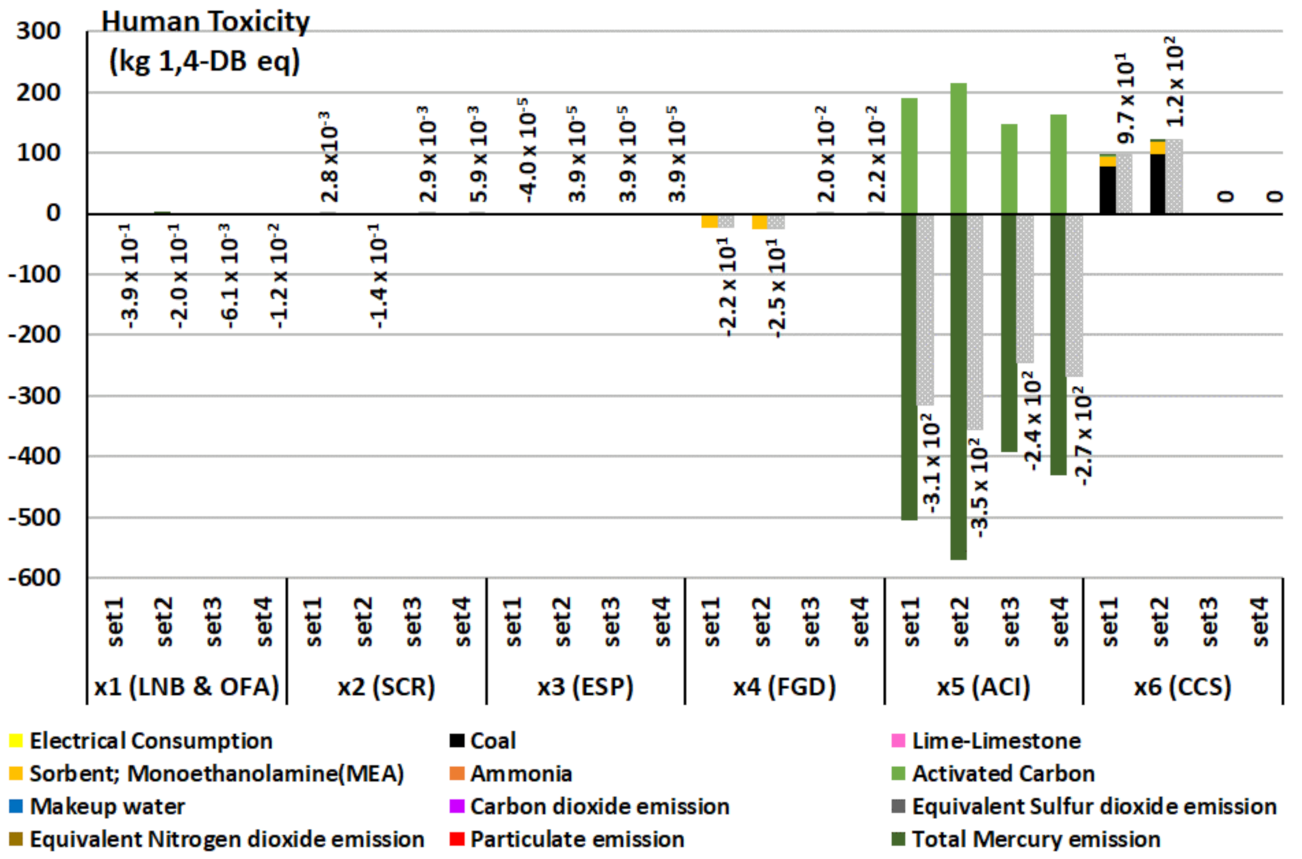

3.2. Human Toxicity (HT)

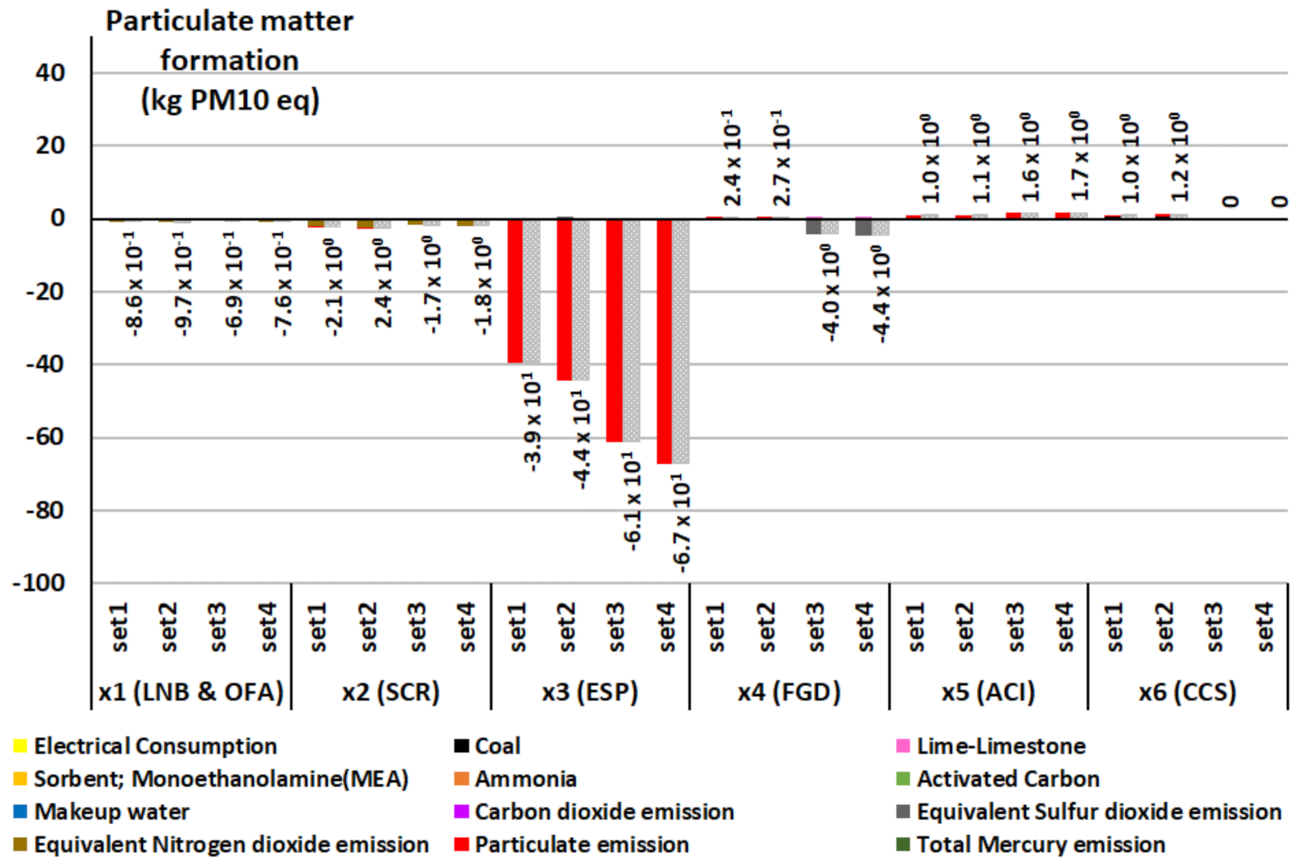

3.3. Particulate Matter (PM)

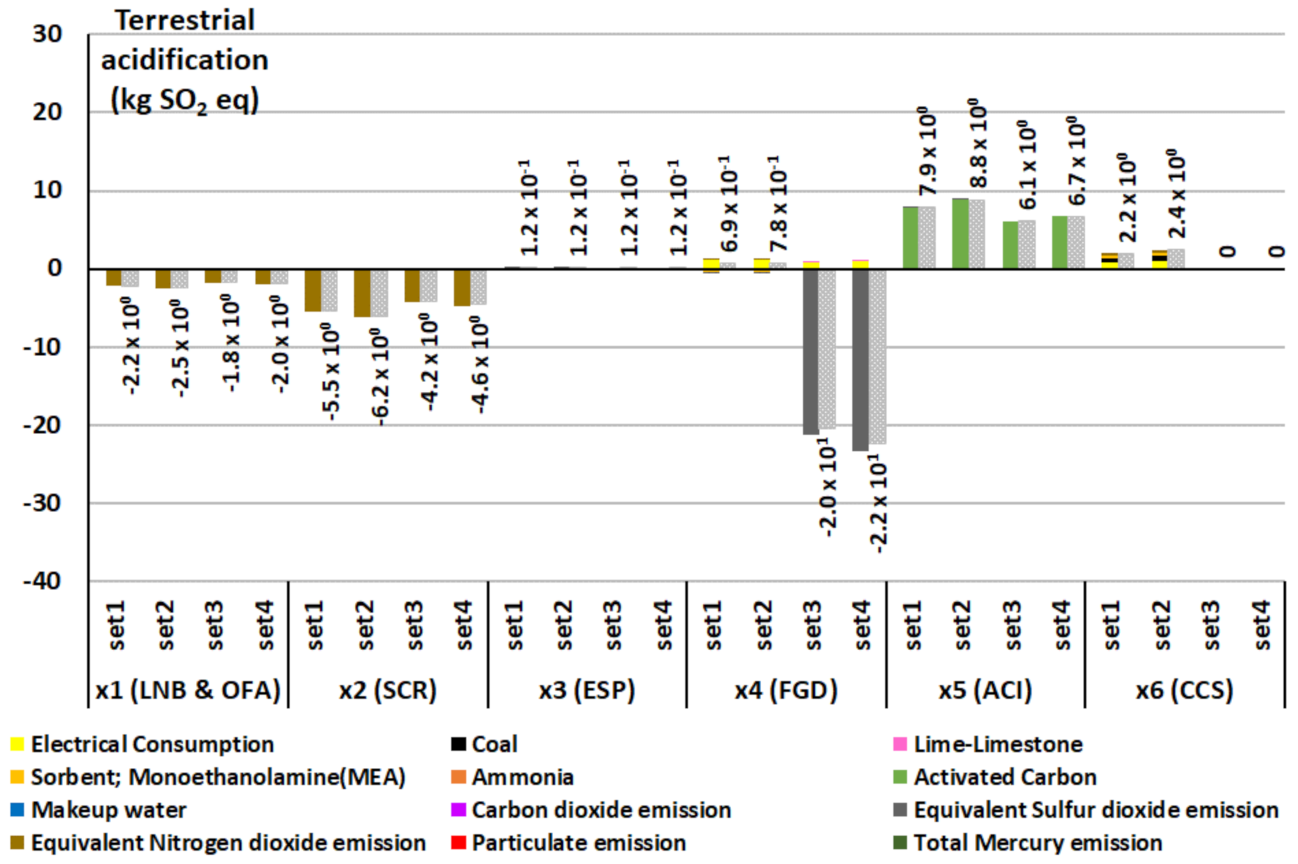

3.4. Acidification Potential (ADP)

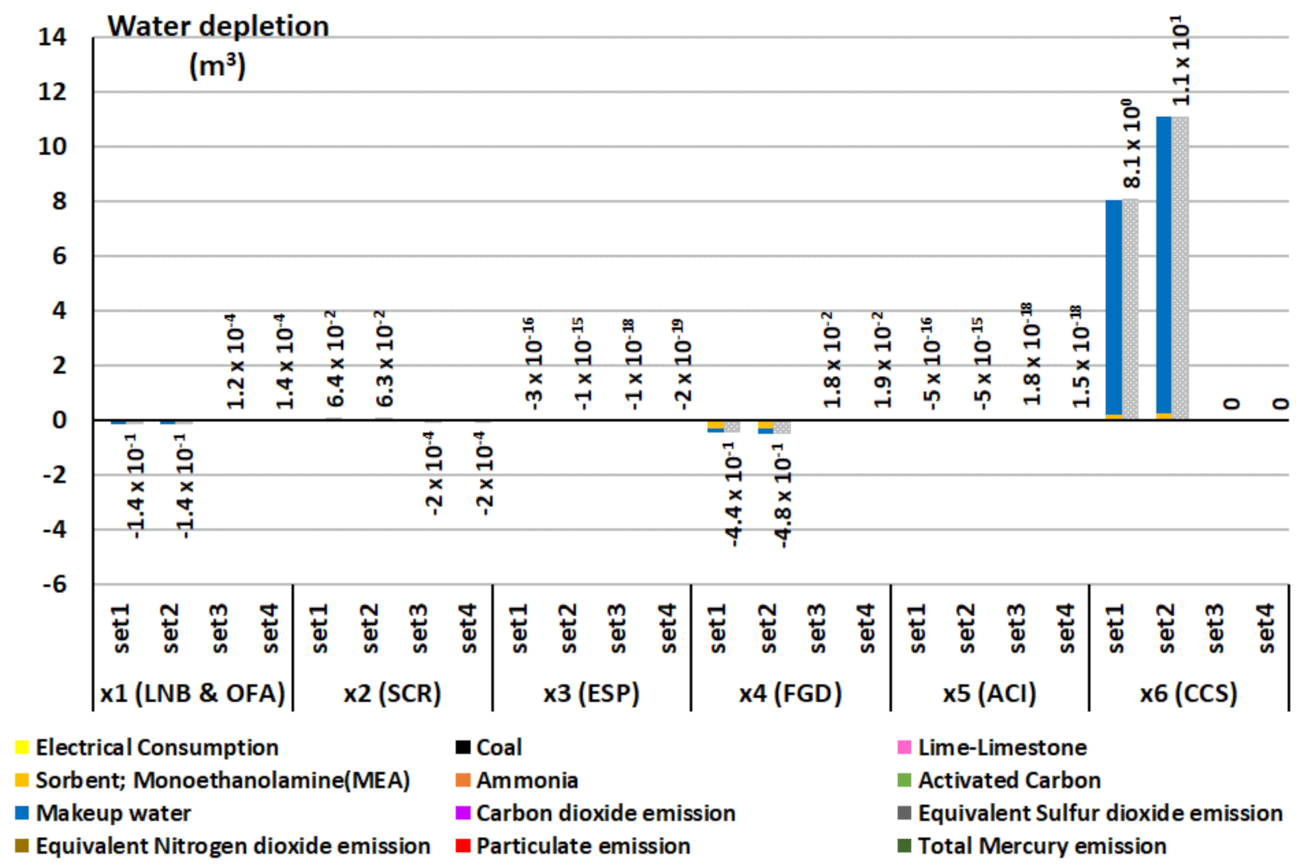

3.5. Water Depletion (WD)

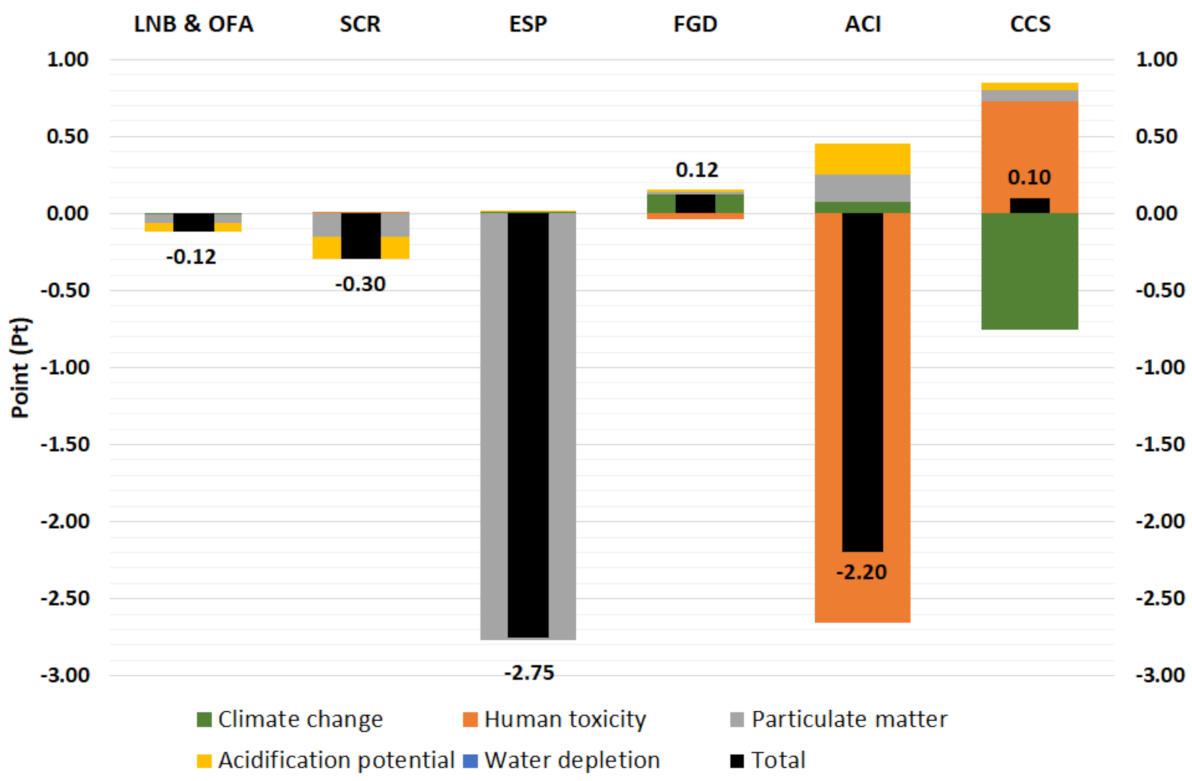

3.6. End-Point Impact Analysis (Pt)

3.7. Economic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Enerdata. Global Energy Statistical Yearbook. 2017. Available online: https://yearbook.enerdata.net/electricity/electricity-domestic-consumption-data.html (accessed on 31 January 2018).

- Li, M.; Zhang, D.; Li, C.-T.; Selin, N.E.; Karplus, V.J. Co-benefits of China’s climate policy for air quality and human health in China and transboundary regions in 2030. Environ. Res. Lett. 2019, 14, 084006. [Google Scholar] [CrossRef]

- Muller, N.Z.; Mendelsohn, R.; Nordhaus, W.D. Environmental Accounting for Pollution in the United States Economy. Am. Econ. Rev. 2011, 101, 1649–1675. [Google Scholar] [CrossRef]

- Jakob, M.; Steckel, J.C.; Jotzo, F.; Sovacool, B.K.; Cornelsen, L.; Chandra, R.; Edenhofer, O.; Holden, C.; Löschel, A.; Nace, T.; et al. The future of coal in a carbon-constrained climate. Nat. Clim. Chang. 2020, 10, 704–707. [Google Scholar] [CrossRef]

- Andrae, A.; Ab, S.K. Comparative screening life cycle impact assessment of renewable and fossil power supply for a radio base station site. Int. J. Green Technol. 2015, 1, 21–34. [Google Scholar] [CrossRef]

- Cristóbal, J.; Guillén-Gosálbez, G.; Jiménez, L.; Irabien, A. Optimization of global and local pollution control in electricity production from coal burning. Appl. Energy 2012, 92, 369–378. [Google Scholar] [CrossRef]

- Rigotto, R.M. The inclusion of health in environmental impact studies: Case report of a coal-fired power plant in Ceará State. Ciên. Saúde Colet. 2009, 14, 2049–2059. [Google Scholar] [CrossRef] [PubMed]

- Song, Q.; Li, J. Greenhouse gas emissions from the usage of typical e-products by households: A case study of China. Clim. Chang. 2015, 132, 615–629. [Google Scholar] [CrossRef]

- Zhou, J.S.; Luo, Z.Y.; Zhu, Y.Q.; Fang, M.X. Mercury Emission and its Controlling Pollutants in Coal-Fired Power Plants in China. In Advanced Topics in Science and Technology in China; Springer: Berlin, Germany, 2013. [Google Scholar]

- Shahzad, B.K.; Yousaf, M. Coal Fired Power Plants: Emission Problems and Controlling Techniques. J. Earth Sci. Clim. Chang. 2017, 8, 404. [Google Scholar] [CrossRef]

- Grahame, T.J.; Schlesinger, R.B. Health Effects of Airborne Particulate Matter: Do We Know Enough to Consider Regulating Specific Particle Types or Sources? Inhal. Toxicol. 2007, 19, 457–481. [Google Scholar] [CrossRef] [PubMed]

- Information Collection Request. Available online: http://www.epa.gov/ttn/atw/utility/utilitypg.html (accessed on 13 March 2019).

- Ribeiro, J.; Taffarel, S.R.; Sampaio, C.H.; Flores, D.; Silva, L.F. Mineral speciation and fate of some hazardous contaminants in coal waste pile from anthracite mining in Portugal. Int. J. Coal Geol. 2013, 109–110, 15–23. [Google Scholar] [CrossRef]

- Tian, H.Z.; Lu, L.; Hao, J.M.; Gao, J.J.; Cheng, K.; Liu, K.Y.; Qiu, P.P.; Zhu, C.Y. A Review of Key Hazardous Trace Elements in Chinese Coals: Abundance, Occurrence, Behavior during Coal Combustion and Their Environmental Impacts. Energy Fuels 2013, 27, 601–614. [Google Scholar] [CrossRef]

- GAINS. Greenhouse Gas and Air Pollution Interactions and Synergies - South Asia Program; International Institute of Applied Systems Analysis: Laxenburg, Austria, 2012; Available online: https://iiasa.ac.at/web/home/research/researchPrograms/air/Asia.html (accessed on 27 April 2019).

- Feeley, T.J.; Skone, T.J.; Stiegel, G.J.; McNemar, A.; Nemeth, M.; Schimmoller, B.; Murphy, J.T.; Manfredo, L. Water: A critical resource in the thermoelectric power industry. Energy 2008, 33, 1–11. [Google Scholar] [CrossRef]

- Wang, Z.; Cen, K.; Zhou, J.; Fan, J. Application and Economic Analysis of the Multi-Pollutants Removal Technology Incor-porated with Ozone Oxidization and Alkali Solution Adsorption. In Simultaneous Multi-Pollutants Removal in Flue Gas by Ozone; Springer: Berlin/Heidelberg, Germany, 2014; pp. 95–106. [Google Scholar]

- Wu, X.; Wu, K.; Zhang, Y.; Hong, Q.; Zheng, C.; Gao, X.; Cen, K. Comparative life cycle assessment and economic analysis of typical flue-gas cleaning processes of coal-fired power plants in China. J. Clean. Prod. 2017, 142, 3236–3242. [Google Scholar] [CrossRef]

- Córdoba, P. Status of Flue Gas Desulphurisation (FGD) systems from coal-fired power plants: Overview of the physic-chemical control processes of wet limestone FGDs. Fuel 2015, 144, 274–286. [Google Scholar] [CrossRef]

- Franco, A.; Diaz, A.R. The future challenges for “clean coal technologies”: Joining efficiency increase and pollutant emission control. Energy 2009, 34, 348–354. [Google Scholar] [CrossRef]

- Han, J.; Wang, L.; Li, J. Selection and application of technology of high efficient removal for flue gas of coal-fired power plant. J. Environ. Sci. Manag. 2011, 36, 86–89. Available online: http://search.cnki.net/down/default.aspx?filename=BFHJ201101024&dbcode=CJFD&year=2011&dflag=pdfdown (accessed on 2 September 2019).

- Pui, D.Y.; Chen, S.-C.; Zuo, Z. PM2.5 in China: Measurements, sources, visibility and health effects, and mitigation. Particuology 2014, 13, 1–26. [Google Scholar] [CrossRef]

- Mao, X.; Zeng, A.; Hu, T.; Xing, Y.; Zhou, J.; Liu, Z. Co-control of local air pollutants and CO2 from the Chinese coal-fired power industry. J. Clean. Prod. 2014, 67, 220–227. [Google Scholar] [CrossRef]

- Ma, S.; Chai, J.; Jiao, K.; Ma, L.; Zhu, S.; Wu, K. Environmental influence and countermeasures for high humidity flue gas discharging from power plants. Renew. Sustain. Energy Rev. 2017, 73, 225–235. [Google Scholar] [CrossRef]

- Xiong, Y.; Niu, Y.; Wang, X.; Tan, H. Pilot Study on In-depth Water Saving and Heat Recovery from Tail Flue Gas in Lignite-fired Power Plant. Energy Procedia 2014, 61, 2558–2561. [Google Scholar] [CrossRef]

- Wu, J. The development and application of SCR denitrification technology in power plant. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 100, p. 12033. [Google Scholar]

- Moretti, A.L.; Jones, C.S. Advanced Emissions Control Technologies for Coal-Fired Power Plants. Presented at Power-Gen Asia, Bangkok, Thailand. 2012. Available online: https://andymaypetrophysicist.files.wordpress.com/2017/01/advanced_emissions_control_coal_br-1886.pdf (accessed on 30 June 2019).

- Fang, J.; Jin, X.; Huang, K. Life cycle analysis of a combined CO2 capture and conversion membrane reactor. J. Membr. Sci. 2018, 549, 142–150. [Google Scholar] [CrossRef]

- Thitakamol, B.; Veawab, A.; Aroonwilas, A. Environmental impacts of absorption-based CO2 capture unit for post-combustion treatment of flue gas from coal-fired power plant. Int. J. Greenh. Gas. Control. 2007, 1, 318–342. [Google Scholar] [CrossRef]

- Mores, P.; Scenna, N.; Mussati, S. Post-combustion CO2 capture process: Equilibrium stage mathematical model of the chemical absorption of CO2 into monoethanolamine (MEA) aqueous solution. Chem. Eng. Res. Des. 2011, 89, 1587–1599. [Google Scholar] [CrossRef]

- Rodríguez, N.; Mussati, S.; Scenna, N.J. Optimization of post-combustion CO2 process using DEA–MDEA mixtures. Chem. Eng. Res. Des. 2011, 89, 1763–1773. [Google Scholar] [CrossRef]

- Zhao, B.; Yi, H.; Tang, X.; Li, Q.; Liu, D.; Gao, F. Copper modified activated coke for mercury removal from coal-fired flue gas. Chem. Eng. J. 2016, 286, 585–593. [Google Scholar] [CrossRef]

- Du, W.; Yin, L.; Zhuo, Y.; Xu, Q.; Zhang, L.; Chen, C. Performance of CuOx-neutral Al2O3 sorbents on mercury removal from simulated coal combustion flue gas. Fuel Process. Technol. 2015, 131, 403–408. [Google Scholar] [CrossRef]

- Liu, Y.X.; Zhang, J.; Sheng, C.D.; Zhang, Y.C.; Yuan, S.J. New research progress in sorbents for removal of mercury in coal-fired flue gas. Mod. Chem. Ind. 2008, 11, 19–25. Available online: https://pay.cnki.net/zscsdoc/download?flag=cnkispace&plat=cnkispace&filename=XDHG200811003&dbtype=CJFD&year=2008&dtype=pdf (accessed on 5 June 2019).

- Zheng, Y.; Jensen, A.D.; Windelin, C.; Jensen, F. Dynamic measurement of mercury adsorption and oxidation on activated carbon in simulated cement kiln flue gas. Fuel 2012, 93, 649–657. [Google Scholar] [CrossRef]

- Tan, Z.Q.; Sun, L.S.; Xiang, J.; Zeng, H.C.; Liu, Z.H.; Hu, S.; Qiu, J.R. Gas-phase elemental mercury removal by novel carbon-based sorbents. Carbon 2012, 50, 362–371. [Google Scholar] [CrossRef]

- Kim, R.E. Global governance: Problem shifting in the Anthropocene and the limits of international law. In Research Handbook on International Law and Natural Resources; Morgera, E., Kulovesi, K., Eds.; Edward Elgar Publishing: Cheltenham, UK, 2016. [Google Scholar]

- Yang, Y.; Bae, J.; Kim, J.; Suh, S. Replacing Gasoline with Corn Ethanol Results in Significant Environmental Problem-Shifting. Environ. Sci. Technol. 2012, 46, 3671–3678. [Google Scholar] [CrossRef] [PubMed]

- Capaz, R.S.; de Medeiros, E.M.; Falco, D.G.; Seabra, J.E.; Osseweijer, P.; Posada, J.A. Environmental trade-offs of renewable jet fuels in Brazil: Beyond the carbon footprint. Sci. Total. Environ. 2020, 714, 136696. [Google Scholar] [CrossRef]

- Williamson, P.; Wallace, D.W.; Law, C.S.; Boyd, P.W.; Collos, Y.; Croot, P.; Denman, K.; Riebesell, U.; Takeda, S.; Vivian, C. Ocean fertilization for geoengineering: A review of effectiveness, environmental impacts and emerging governance. Process. Saf. Environ. Prot. 2012, 90, 475–488. [Google Scholar] [CrossRef]

- Jones, N. Safeguarding Against Environmental Injustice: 1.5 °C Scenarios, Negative Emissions, and Unintended Consequences. Carbon Clim. Law Rev. 2018, 12, 23–30. [Google Scholar] [CrossRef]

- Xue, B.; Mitchell, B.; Geng, Y.; Ren, W.; Müller, K.; Ma, Z.; de Oliveira, J.A.P.; Fujita, T.; Tobias, M. A review on China’s pollutant emissions reduction assessment. Ecol. Indic. 2014, 38, 272–278. [Google Scholar] [CrossRef]

- Pehnt, M.; Henkel, J. Life cycle assessment of carbon dioxide capture and storage from lignite power plants. Int. J. Greenh. Gas. Control. 2009, 3, 49–66. [Google Scholar] [CrossRef]

- Sebastián, F.; Royo, J.; Gómez, M. Cofiring versus biomass-fired power plants: GHG (Greenhouse Gases) emissions savings comparison by means of LCA (Life Cycle Assessment) methodology. Energy 2011, 36, 2029–2037. [Google Scholar] [CrossRef]

- Oró, E.; Gil, A.; de Gracia, A.; Boer, D.; Cabeza, L.F. Comparative life cycle assessment of thermal energy storage systems for solar power plants. Renew. Energy 2012, 44, 166–173. [Google Scholar] [CrossRef]

- Hondo, H. Life cycle GHG emission analysis of power generation systems: Japanese case. Energy 2005, 30, 2042–2056. [Google Scholar] [CrossRef]

- Odeh, N.A.; Cockerill, T.T. Life cycle GHG assessment of fossil fuel power plants with carbon capture and storage. Energy Policy 2008, 36, 367–380. [Google Scholar] [CrossRef]

- Schakel, W.; Meerman, H.; Talaei, A.; Ramírez, A.; Faaij, A. Comparative life cycle assessment of biomass co-firing plants with carbon capture and storage. Appl. Energy 2014, 131, 441–467. [Google Scholar] [CrossRef]

- Viebahn, P.; Vallentin, D.; Höller, S. Prospects of carbon capture and storage (CCS) in India’s power sector—An integrated assessment. Appl. Energy 2014, 117, 62–75. [Google Scholar] [CrossRef]

- Van Caneghem, J.; De Greef, J.; Block, C.; Vandecasteele, C. NOx reduction in waste incinerators by selective catalytic reduction (SCR) instead of selective non catalytic reduction (SNCR) compared from a life cycle perspective: A case study. J. Clean. Prod. 2016, 112, 4452–4460. [Google Scholar] [CrossRef]

- Feng, C.; Gao, X.; Tang, Y.; Zhang, Y. Comparative life cycle environmental assessment of flue gas desulphurization technologies in China. J. Clean. Prod. 2014, 68, 81–92. [Google Scholar] [CrossRef]

- Mantripragada, H.C.; Zhai, H.; Rubin, E.S. Boundary Dam or Petra Nova—Which is a better model for CCS energy supply? Int. J. Greenh. Gas. Control. 2019, 82, 59–68. [Google Scholar] [CrossRef]

- Zhai, H.; Rubin, E.S. Systems Analysis of Physical Absorption of CO2 in Ionic Liquids for Pre-Combustion Carbon Capture. Environ. Sci. Technol. 2018, 52, 4996–5004. [Google Scholar] [CrossRef] [PubMed]

- Zhai, H.; Rubin, E.S. A Techno-Economic Assessment of Hybrid Cooling Systems for Coal- and Natural-Gas-Fired Power Plants with and without Carbon Capture and Storage. Environ. Sci. Technol. 2016, 50, 4127–4134. [Google Scholar] [CrossRef] [PubMed]

- Zhai, H.; Ou, Y.; Rubin, E.S. Opportunities for Decarbonizing Existing U.S. Coal-Fired Power Plants via CO2 Capture, Utilization and Storage. Environ. Sci. Technol. 2015, 49, 7571–7579. [Google Scholar] [CrossRef] [PubMed]

- Bell, R.D.; Buckingham, F.P. An overview of technologies for reduction of oxides of nitrogen from combustion furnaces. Alexandria: MPR Assoc 8 (2010): 2016. Available online: http://www.mrp.com/uploads/news/nox-reduction-coal-fired.pdf (accessed on 4 March 2019).

- Sorrels, J.L.; Randall, D.D.; Schaffner, K.S.; Fry, C.R. Selective Catalytic Reduction. In EPA Air Pollution Control Cost Manual; 2019. Available online: https://www3.epa.gov/ttn/ecas/docs/SCRCostManualchapter7thEdition_2016.pdf (accessed on 4 August 2019).

- United States Environmental Protection Agency, US.EPA. CAM Protocol for an ESP controlling PM from a Coal-Fired Boiler. 2016. Available online: https://www3.epa.gov/ttnemc01/cam/espcam.pdf (accessed on 4 March 2019).

- Air, P. Advanced Technologies for the Control of Sulfur Dioxide Emissions from Coal-Fired Boilers. 1999. Available online: https://pdfs.semanticscholar.org/4196/36dada5f3d2a235b99b834ebefb5a2f01d4a.pdf (accessed on 4 March 2019).

- Tan, L.; Shariff, A.; Lau, K.; Bustam, M. Factors affecting CO2 absorption efficiency in packed column: A review. J. Ind. Eng. Chem. 2012, 18, 1874–1883. [Google Scholar] [CrossRef]

- Rezaei, F.; Rownaghi, A.A.; Monjezi, S.; Lively, R.P.; Jones, C.W. SOx/NOx Removal from Flue Gas Streams by Solid Adsorbents: A Review of Current Challenges and Future Directions. Energy Fuels 2015, 29, 5467–5486. [Google Scholar] [CrossRef]

- Bamdad, H.; Hawboldt, K.; MacQuarrie, S. A review on common adsorbents for acid gases removal: Focus on biochar. Renew. Sustain. Energy Rev. 2018, 81, 1705–1720. [Google Scholar] [CrossRef]

- Valverde, J.; Sanchez-Jimenez, P.; Perez-Maqueda, L. Ca-looping for postcombustion CO2 capture: A comparative analysis on the performances of dolomite and limestone. Appl. Energy 2015, 138, 202–215. [Google Scholar] [CrossRef]

- Alade, A.O.; Amuda, O.S.; Bello, M.O. Life Cycle Inventory Analysis (LCIA) of production of activated carbons from selected agricultural materials. Pollution 2012, 44, 7275–7279. Available online: https://www.researchgate.net/publication/272973462_Life_Cycle_Inventory_Analysis_LCIA_of_production_of_activated_carbons_from_selected_agricultural_materials (accessed on 5 July 2019).

- Hjaila, K.; Baccar, R.; Sarrà, M.; Gasol, C.; Blánquez, P. Environmental impact associated with activated carbon preparation from olive-waste cake via life cycle assessment. J. Environ. Manag. 2013, 130, 242–247. [Google Scholar] [CrossRef] [PubMed]

- Yahya, M.A.; Al-Qodah, Z.; Ngah, C.Z. Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: A review. Renew. Sustain. Energy Rev. 2015, 46, 218–235. [Google Scholar] [CrossRef]

| Combustion Controls | |

|---|---|

| Fuel Type Coal | Coal |

| NOx Control | In-Furnace Controls |

| Post-Combustion Controls | |

| NOx Control | Hot-Side SCR |

| Mercury | Carbon Injection |

| Particulates | Cold-Side ESP |

| SO2 Control | Wet FGD |

| CO2 Capture | Amine System |

| Water and Solids Management | |

| Cooling System | Wet Cooling Tower |

| Wastewater | Ash Pond |

| Fly Ash Disposal | No Mixing |

| Gross Electrical Output (MW) | 650 |

| Capacity Factor (%) | 85 |

| Ambient Air Temp. (°C) | 27.91 |

| Ambient Pressure (MPa) | 0.1013 |

| Relative Humidity (%) | 73 |

| Coal Rank | Sub-Bituminous |

| Coal Name | Wyodak-Anderson |

| High Heating Value (kJ/kg) | 1.96 × 104 |

| Carbon (wt%) | 49.21 |

| Hydrogen (wt%) | 3.51 |

| Oxygen (wt%) | 11.67 |

| Sulfur (wt%) | 0.45 |

| Nitrogen (wt%) | 0.73 |

| Ash (wt%) | 6.31 |

| Moisture (wt%) | 28.09 |

| Independent Variable | Range (Min–Max), A or N/A | |

|---|---|---|

| x1 | Efficiency of in-furnace NOx control system (%) [56] | 60–65 |

| x2 | Efficiency of NOx control by SCR (%) [57] | 80–90 |

| x3 | Efficiency of PM control by ESP (%) [58] | 95–99.9 |

| x4 | Efficiency of SO2 control by FGD (%) [59] | 95–98 |

| x5 | Mercury control by carbon injection (%) | N/A * or completely removed |

| x6 | Efficiency of CO2 control by MEA absorption (%) [60] | A* or N/A, 90–96 |

| Dependent Variable | Unit | |

|---|---|---|

| Input | ||

| y1 | Electrical consumption | MW |

| y2 | Coal consumption | ton/h |

| y3 | Limestone consumption | ton/h |

| y4 | MEA consumption | ton/h |

| y5 | Ammonia consumption | ton/h |

| y6 | Activated carbon consumption | ton/h |

| y7 | Makeup water | ton/h |

| Output | ||

| y8 | CO2 emission | kg/h |

| y9 | SO2 emission | kg/h |

| y10 | NO2 emission | kg/h |

| y11 | PM emission | kg/h |

| y12 | Mercury emission | kg/h |

| Type of System | Number of Independent Variable/Number of Runs | |

|---|---|---|

| With Carbon Capture Unit | Without Carbon Capture Unit | |

| Supercritical | 6/64 (Set 1) | 5/32 (Set 3) |

| Ultra-supercritical | 6/64 (Set 2) | 5/32 (Set 4) |

| Dependent Variable | bi,1 | bi,2 | bi,3 | bi,4 | bi,5 | bi,6 | Interc. | Max/Min |

|---|---|---|---|---|---|---|---|---|

| y1 (MW) | −8.1 × 10−3 | 3.4 × 10−3 | 1.6 × 10−1 | 1.5 | 1.3 × 10−1 | 1.2 | −1.2 × 102 | 149.3/162.0 |

| y2 (T/h) | 0 | 0 | 0 | 0 | 0 | 1.4 | 2.2 × 102 | 347.5/355.8 |

| y3 (T/h) | 4.5 × 10−4 | −6.7 × 10−4 | 0 | 4.8 × 10−2 | 0 | 1.8 × 10−2 | −1.6 | 4.482/4.743 |

| y4 (T/h) | −4.5 × 10−4 | 0 | 0 | −2.6 × 10−2 | 0 | 1.9 × 10−2 | 2.3 | 1.392/1.585 |

| y5 (T/h) | −8.3 × 10−3 | 3.7 × 10−3 | 0 | 0 | 0 | 1.2 × 10−3 | 4.1 × 10−1 | 0.2737/0.3592 |

| y6 (T/h) | −1.1 × 10−5 | 5.4 × 10−6 | 0 | 2.8 × 10−6 | 1.5 × 10−1 | 9.5 × 10−4 | −4.4 × 10−2 | 0.0424/0.2021 |

| y7 (kg/h) | −1.3 × 10−1 | 6.4 × 10−2 | 0 | −1.9 × 10−1 | 0 | 7.9 | 1.4 × 103 | 2052/2102 |

| y8 (kg/h) | 9.1 × 10−1 | −3.6 × 10−1 | 0 | 1.0 | 0 | −6.2 × 103 | 6.2 × 105 | 25,737/62,845 |

| y9 (kg/h) | −4.6 × 10−4 | 8.7 × 10−4 | 5.2 × 10−5 | −4.1 × 10−2 | 2.6 × 10−4 | 1.5 × 10−3 | 4.2 | 0.3233/0.4683 |

| y10 (kg/h) | −3.9 | −9.8 | 0 | 1.3 × 10−3 | 0 | 5.8 × 10−1 | 1.2 × 103 | 90.09/210.8 |

| y11 (kg/h) | 0 | 0 | −3.9 × 101 | 0 | 9.8 × 10−1 | 4.0 × 10−1 | 3.9 × 103 | 3.871/200.1 |

| y12 (kg/h) | 0 | 0 | 0 | 0 | −8.9 × 10−3 | 4.5 × 10−5 | 1.2 × 10−2 | 0.0069/0.0161 |

| Dependent Variable | bi,1 | bi,2 | bi,3 | bi,4 | bi,5 | bi,6 | Interc. | Max/Min |

|---|---|---|---|---|---|---|---|---|

| y1(MW) | −5.0 × 10−3 | 2.5 × 10−3 | 1.6 × 10−1 | 1.7 | 1.3 × 10−1 | 1.4 | −1.4 × 102 | 166.9/181.4 |

| y2 (T/h) | 5.0 × 10−3 | −2.5 × 10−3 | 0 | 0 | 0 | 1.8 | 2.3 × 102 | 391.7/402.3 |

| y3 (T/h) | 4.5 × 10−4 | −7.0 × 10−4 | 0 | 5.4 × 10−2 | 0 | 2.3 × 10−2 | −2.1 | 5.053/5.362 |

| y4 (T/h) | −5.5 × 10−4 | 0 | 0 | −2.9 × 10−2 | 0 | 2.2 × 10−2 | 2.5 | 1.569/1.793 |

| y5 (T/h) | −9.4 × 10−3 | 4.1 × 10−3 | 0 | 0 | 0 | 1.6 × 10−3 | 4.4 × 10−1 | 0.3083/0.4061 |

| y6 (T/h) | −1.2 × 10−5 | 6.0 × 10−6 | 0 | 8.3 × 10−7 | 1.7 × 10−1 | 1.1 × 10−3 | −5.6 × 10−2 | 0.0478/0.2285 |

| y7 (kg/h) | −1.3 × 10−1 | 6.3 × 10−2 | 0 | −2.0 × 10−1 | 0 | 1.1 × 101 | 1.5 × 103 | 2494/2561 |

| y8 (kg/h) | 8.8 × 10−1 | −4.4 × 10−1 | 0 | 1.7 | 0 | −7.0 × 103 | 7.0 × 105 | 29,099/70,844 |

| y9 (kg/h) | −5.2 × 10−4 | 9.8 × 10−4 | 5.9 × 10−5 | −4.7 × 10−2 | 2.9 × 10−4 | 1.9 × 10−3 | 4.7 | 0.3645/0.5294 |

| y10 (kg/h) | −4.4 | −1.1 × 101 | 0 | 1.1 × 10−3 | 0 | 7.3 × 10−1 | 1.3 × 103 | 101.58/238.36 |

| y11 (kg/h) | 0 | 0 | −4.4 × 101 | 0 | 1.1 | 5.0 × 10−1 | 4.4 × 103 | 4.364/226.3 |

| y12 (kg/h) | 0 | 0 | 0 | 0 | −1.0 × 10−2 | 5.8 × 10−5 | 1.3 × 10−2 | 0.0078/0.0182 |

| Dependent Variable | bi,1 | bi,2 | bi,3 | bi,4 | bi,5 | Interc. | Max/Min |

|---|---|---|---|---|---|---|---|

| y1 (MW) | 0 | 0 | 1.6 × 10−1 | 1.2 | 8.8 × 10−2 | −7.9 × 101 | 46.8/51.2 |

| y2 (T/h) | 0 | 0 | 0 | 0 | 0 | 2.7 × 102 | 273.5 |

| y3 (T/h) | 2.5 × 10−4 | −4.2 × 10−4 | 0 | 3.7 × 10−2 | 0 | 2.8 × 10−2 | 3.528/3.645 |

| y4 (T/h) | - | - | - | - | - | - | -/- |

| y5 (T/h) | −6.5 × 10−3 | 2.8 × 10−3 | 0 | 0 | 0 | 4.1 × 10−1 | 0.2154/0.2761 |

| y6 (T/h) | −5.0 × 10−6 | 2.5 × 10−6 | 0 | 0 | 1.2 × 10−1 | 1.0 × 10−4 | 0/0.1197 |

| y7 (kg/h) | 0 | 0 | 0 | 0 | 0 | 1.4 × 103 | 1461/1459 |

| y8 (kg/h) | 0 | 0 | 0 | 0 | 0 | 4.9 × 105 | 494,567/494,550 |

| y9 (kg/h) | −6.4 × 10−2 | 1.3 × 10−1 | 0 | −2.1 × 101 | 0 | 2.1 × 103 | 50.90/116.20 |

| y10 (kg/h) | −3.1 | −7.7 | 0 | 0 | 0 | 9.6 × 102 | 71.77/164.12 |

| y11 (kg/h) | 0 | 0 | −6.1 × 101 | 0 | 1.5 | 6.1 × 103 | 6.094/307.6 |

| y12 (kg/h) | 0 | 0 | 0 | 0 | −6.9 × 10−3 | 1.2 × 10−2 | 0.0054/0.0124 |

| Dependent Variable | bi,1 | bi,2 | bi,3 | bi,4 | bi,5 | Interc. | Max/Min |

|---|---|---|---|---|---|---|---|

| y1 (MW) | 0 | 0 | 1.6 × 10−1 | 1.3 | 1.0 × 10−1 | −8.5 × 101 | 51.3/55.9 |

| y2 (T/h) | 0 | 0 | 0 | 0 | 0 | 3.0 × 102 | 300.2 |

| y3 (T/h) | 3.0 × 10−4 | −5.0 × 10−4 | 0 | 4.1 × 10−2 | 0 | 5.1 × 10−2 | 3.872/4.0 |

| y4 (T/h) | - | - | - | - | - | - | -/- |

| y5 (T/h) | −7.1 × 10−3 | 3.1 × 10−3 | 0 | 0 | 0 | 4.5 × 10−1 | 0.2363/0.3030 |

| y6 (T/h) | −1.0 × 10−5 | 5.0 × 10−6 | 0 | 0 | 1.3 × 10−1 | 2.0 × 10−4 | 0/1314 |

| y7 (kg/h) | 0 | 0 | 0 | 0 | 0 | 1.6 × 103 | 1631/1627 |

| y8 (kg/h) | 0 | 0 | 0 | 0 | 0 | 5.4 × 105 | 542,824/542,809 |

| y9 (kg/h) | −7.0 × 10−2 | 1.4 × 10−1 | 0 | −2.3 × 101 | 0 | 2.3 × 103 | 55.87/127.54 |

| y10 (kg/h) | −3.4 | −8.4 | 0 | 0 | 0 | 1.1 × 103 | 78.77/180.13 |

| y11 (kg/h) | 0 | 0 | −6.7 × 101 | 0 | 1.7 | 6.7 × 103 | 6.689/337.6 |

| y12 (kg/h) | 0 | 0 | 0 | 0 | −7.6 × 10−3 | 1.4 × 10−2 | 0.0060/0.0136 |

| Dependent Variable | GWP kg CO2-eq | HT kg 1,4-DB-eq | PM kg PM10-eq | ADP kg SO2-eq | WD m3 | Per Unit |

|---|---|---|---|---|---|---|

| y1 | 6.1 × 102 | 2.4 × 10−4 | 2.3 × 10−1 | 7.2 × 10−2 | 0 | MWh |

| y2 | 1.6 × 102 | 5.6 × 101 | 9.7 × 10−2 | 3.6 × 10−1 | 0 | ton |

| y3 | 6.5 | 5.3 × 10−1 | 8.7 × 10−3 | 3.2 × 10−2 | 0 | ton |

| y4 | 3.4 × 103 | 8.7 × 102 | 4.0 | 1.3 × 101 | 1.0 × 101 | ton |

| y5 | 3.1 × 102 | 0 | 3.4 × 10−2 | 9.0 × 10−2 | 0 | ton |

| y6 | 3.0 × 103 | 1.2 × 103 | 0 | 5.0 × 101 | 0 | ton |

| y7 | 0 | 0 | 0 | 0 | 1.0 | ton |

| y8 | 1.0 | 0 | 0 | 0 | 0 | kg |

| y9 | 0 | 0 | 2.0 × 10−1 | 1.0 | 0 | kg |

| y10 | 0 | 0 | 2.2 × 10−1 | 5.6 × 10−1 | 0 | kg |

| y11 | 0 | 0 | 1.0 | 0 | 0 | kg |

| y12 | 0 | 5.7 × 104 | 0 | 0 | 0 | kg |

| Unit | Fixed O&M * | Variable O&M | Annulized Capital | Total Annual Cost | ||||

|---|---|---|---|---|---|---|---|---|

| M$/yr ** | ||||||||

| w | w/o | w | w/o | w | w/o | w | w/o | |

| LNB & OFA | 0.139 | 0.139 | 0 | 0 | 1.048 | 1.048 | 1.187 | 1.187 |

| SCR | 0.848 | 0.751 | 2.386 | 1.602 | 3.714 | 3.097 | 6.948 | 5.45 |

| ACI | 0.086 | 0.086 | 0.034 | 0.021 | 0.009 | 0.011 | 0.129 | 0.118 |

| ESP | 1.039 | 0.962 | 3.508 | 2.511 | 5.726 | 4.590 | 10.27 | 8.063 |

| FGD | 11.24 | 9.812 | 14.35 | 7.358 | 20.11 | 16.71 | 45.70 | 33.88 |

| CCS | 18.98 | 0 | 98.11 | 0 | 80.30 | 0 | 187.4 | 0 |

| Base Plant | 26.68 | 23.93 | 45.31 | 64.68 | 117.3 | 101.4 | 189.3 | 190 |

| Land | 0 | 0 | 0 | 0 | 0.114 | 0.114 | 0.114 | 0.114 |

| Total | 59.01 | 35.68 | 163.7 | 76.17 | 228.3 | 126.9 | 451 | 238.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phungrassami, H.; Usubharatana, P. Environmental Problem Shifting Analysis of Pollution Control Units in a Coal-Fired Powerplant Based on Multiple Regression and LCA Methodology. Sustainability 2021, 13, 5142. https://doi.org/10.3390/su13095142

Phungrassami H, Usubharatana P. Environmental Problem Shifting Analysis of Pollution Control Units in a Coal-Fired Powerplant Based on Multiple Regression and LCA Methodology. Sustainability. 2021; 13(9):5142. https://doi.org/10.3390/su13095142

Chicago/Turabian StylePhungrassami, Harnpon, and Phairat Usubharatana. 2021. "Environmental Problem Shifting Analysis of Pollution Control Units in a Coal-Fired Powerplant Based on Multiple Regression and LCA Methodology" Sustainability 13, no. 9: 5142. https://doi.org/10.3390/su13095142

APA StylePhungrassami, H., & Usubharatana, P. (2021). Environmental Problem Shifting Analysis of Pollution Control Units in a Coal-Fired Powerplant Based on Multiple Regression and LCA Methodology. Sustainability, 13(9), 5142. https://doi.org/10.3390/su13095142