An Exploratory Study of How Latecomers Transform Strategic Path in Catch-Up Cycle

Abstract

1. Introduction

2. Literature and Research Framework

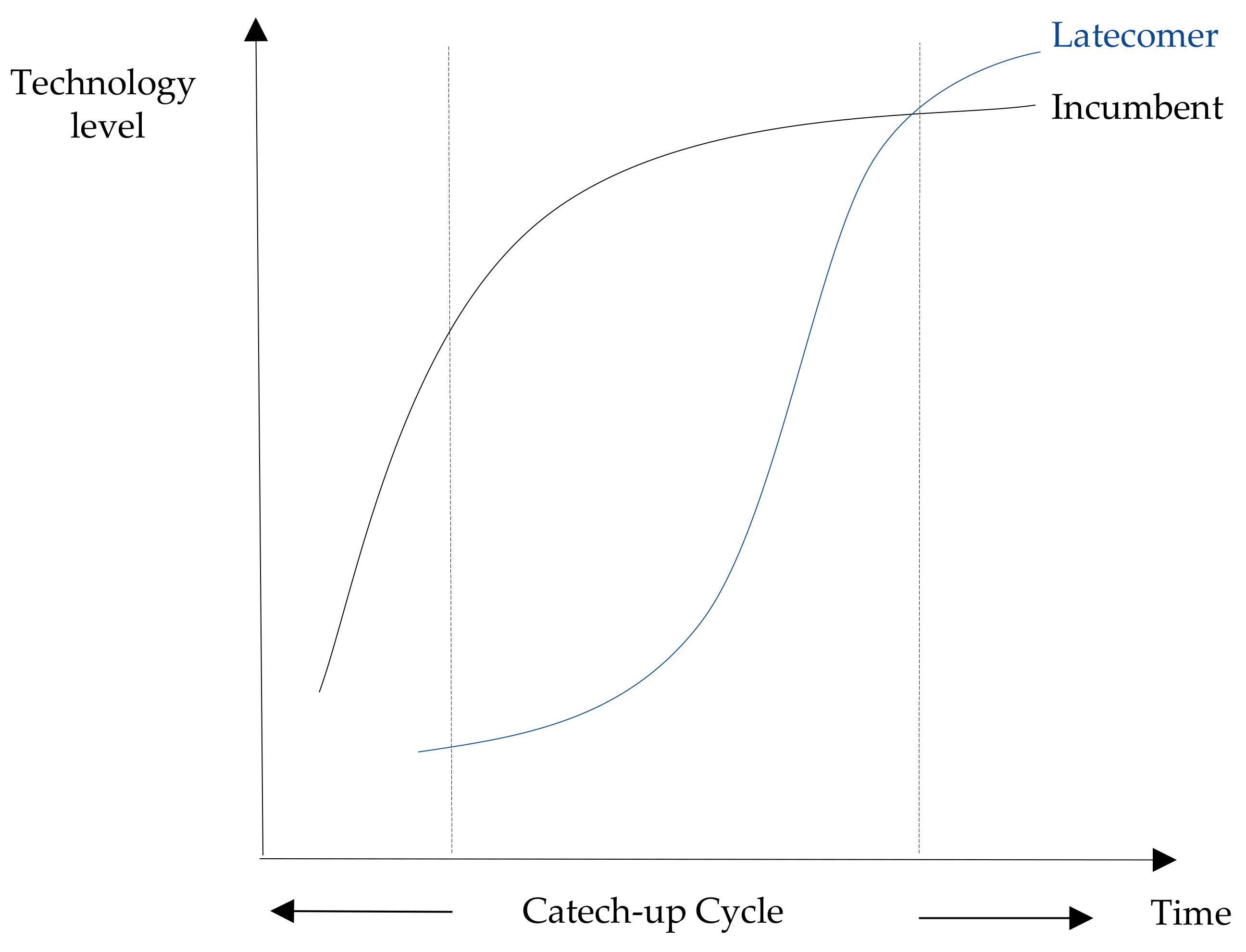

2.1. Catch-Up Cycle

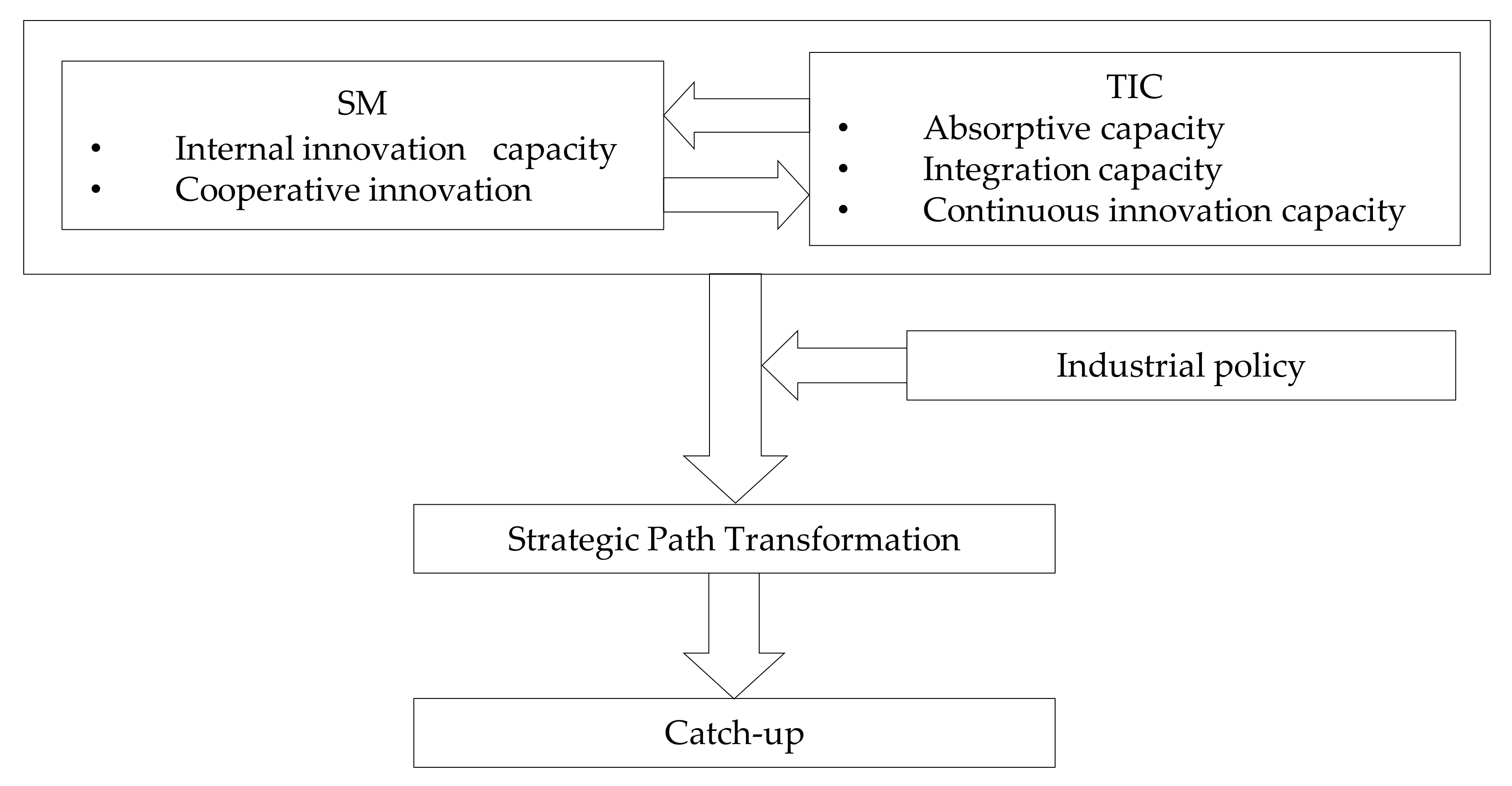

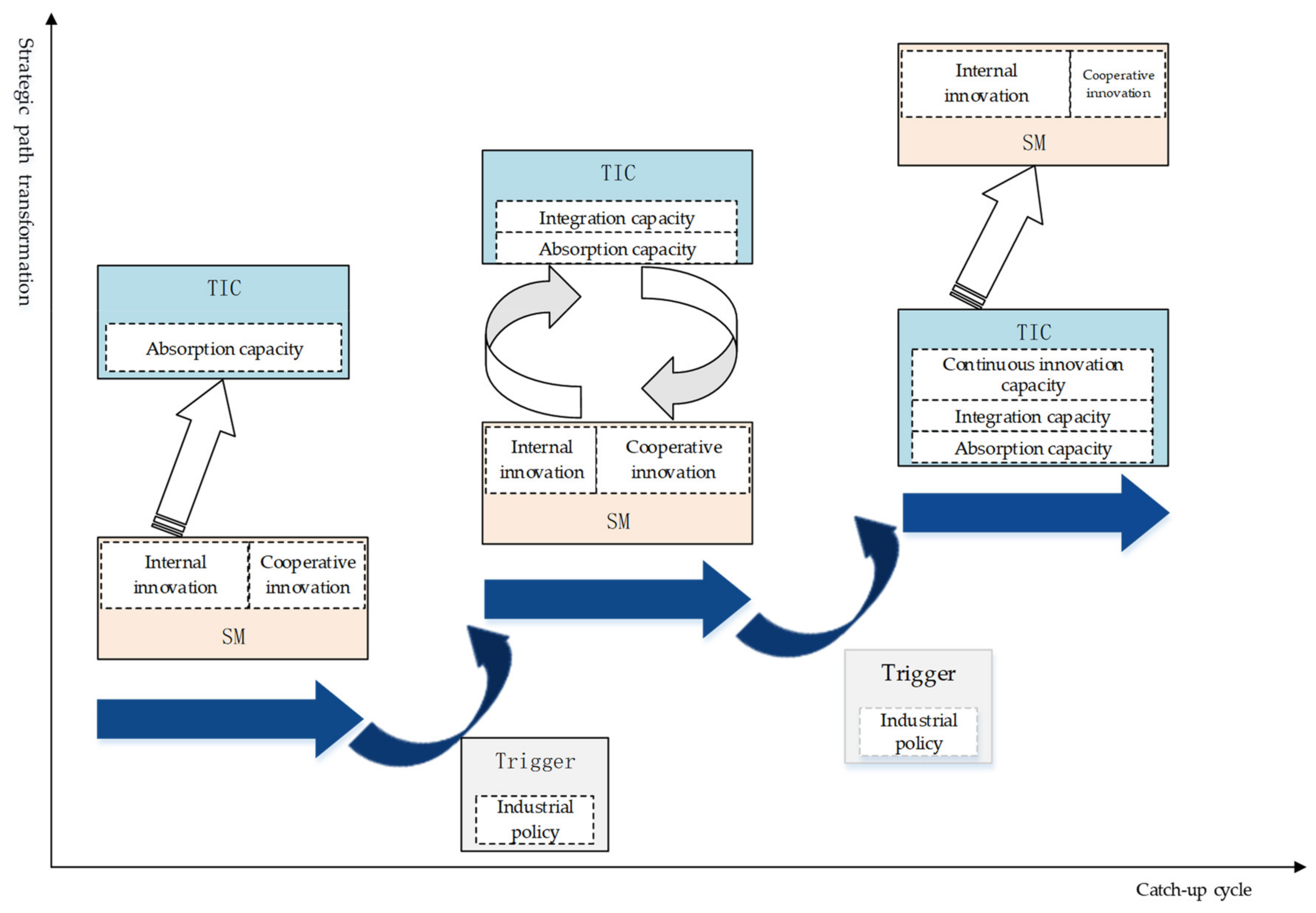

2.2. Strategic Path Transformation

2.3. SM and TIC

2.4. Industrial Policy

2.5. Analysis Framework

3. Method

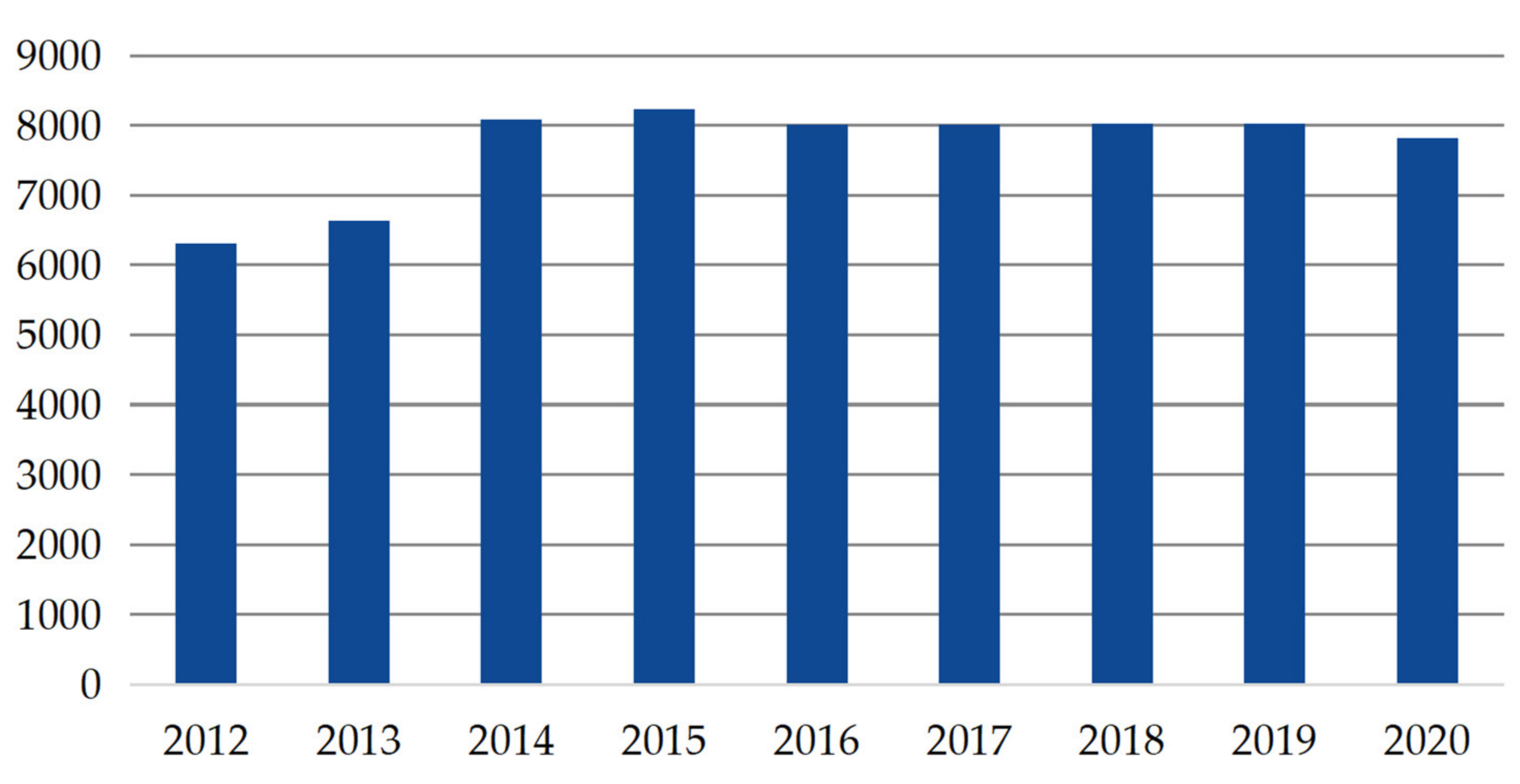

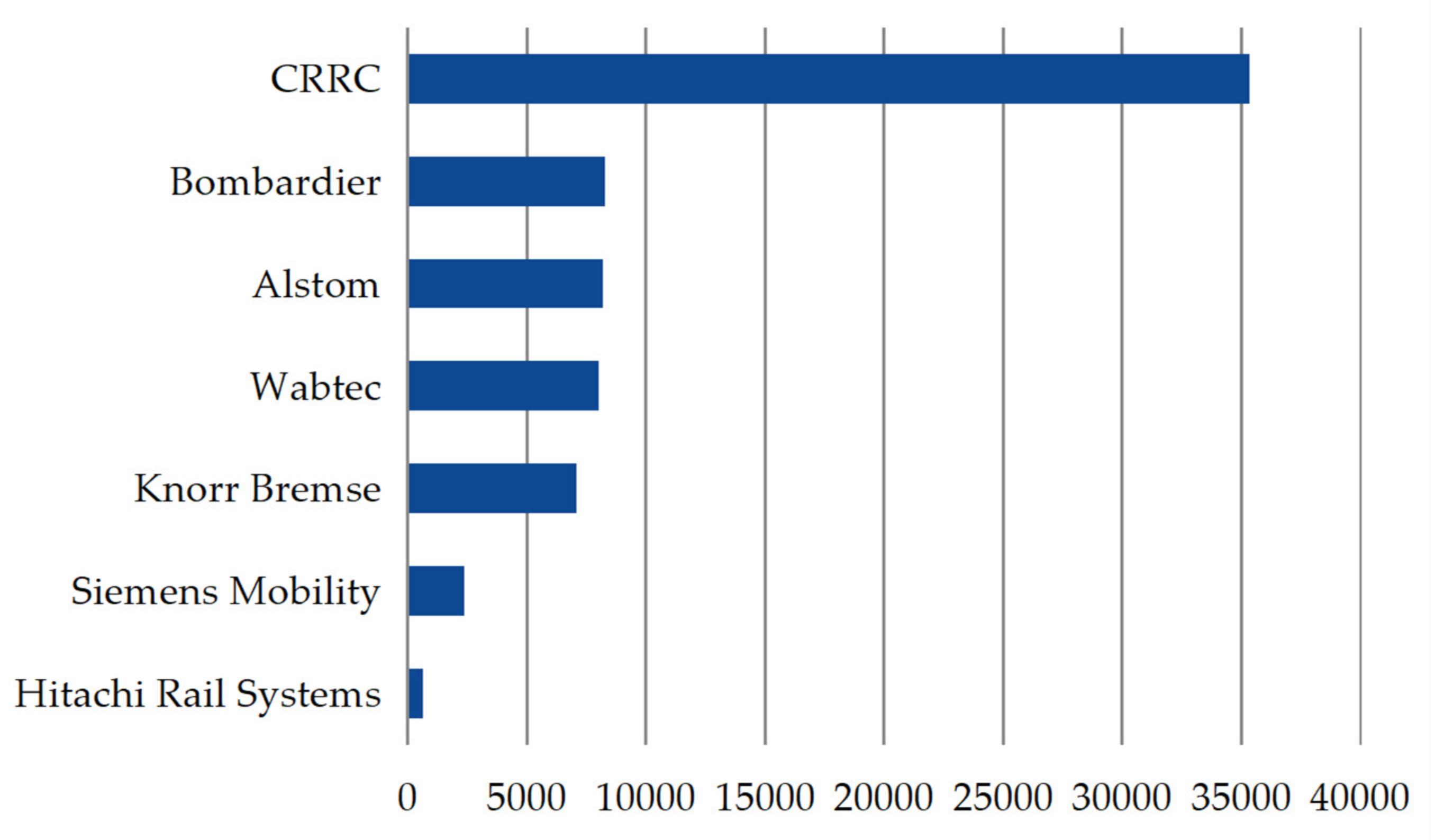

3.1. Case Selection

- Representativeness. A powered car train set can be divided into Diesel Multiple Unit (DMU) and Electric Multiple Unit (EMU) according to the type of power. CRRC’s products were mainly DMU in the early stage and then gradually replaced by EMU. CRRC has now become the world’s largest and technologically advanced railway vehicle manufacturer by catching-up, and the most prominent international competitor.

- Integrity. The development of CRRC started from imitating the units of the former Soviet Union, benefiting from the continuous development of a high-speed network under the background of China’s transitional economy [65]. It has now developed into a world-leading manufacturer in production scale, product level, and R&D and test capabilities. This process fully interprets the strategic path’s transformation process in manufacturers’ catch-up cycle in emerging economies.

- Correlation. CRRC has experienced the whole process of strategic path transformation; SM changes between internal innovation and cooperative innovation; TIC has improved in various periods of technological development. A large number of supportive policies targeted at competitive industrial advantages have operated successively. These are closely related to the research theme.

3.2. Data Collection

3.3. Data Analysis Method

4. Findings

4.1. Original Strategic Path

4.1.1. Industrial Policy Fosters Absorption Capacity of TIC

4.1.2. Interaction between SM (Internal Innovation) and TIC (Absorption Capacity)

4.1.3. Interaction between SM (Cooperative Innovation) and TIC (Absorption Capacity)

4.2. First Transformation of Strategic Path: Mismatch between SM and TIC

4.2.1. Improvement of TIC

4.2.2. Mismatch between Improved TIC and Original SM

4.2.3. Adjustment of Industrial Policy

4.3. New Strategic Path

4.3.1. Industrial Policy Enhances Integration Capacity of TIC

4.3.2. Interaction between SM (Cooperative Innovation) and TIC (Integration Capacity)

4.3.3. Interaction between SM (Internal Innovation) and TIC (Integration Capacity)

4.4. Second Transformation of Strategic Path: Re-Mismatch between SM and TIC

4.4.1. Further Improvement of TIC (Continuous Innovation Capacity)

4.4.2. Mismatch between Further Improved TIC and SM

4.4.3. Adjustment of Industrial Policy

4.5. Recent Strategic Path

4.5.1. Industrial Policy Strengthens Continuous Innovation Capacity of TIC

4.5.2. Interaction between SM (Internal Innovation) and TIC (Continuous Innovation Capacity)

4.5.3. Interaction between SM (Cooperative Innovation) and TIC (Continuous Innovation Capacity)

5. Discussion

5.1. Impetus: Interaction between SM and TIC

5.2. Trigger: Industrial Policy

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Nomenclature | Full Names | Note |

|---|---|---|

| CRRC | China Railway Rolling Stock Corporation | Analyses object of the case study. |

| EMU | Electric Multiple Unit | Specific analysis units of the case study. |

| SM | Strategic mode | The decisions of the corporate innovation asset portfolio. Including internal innovation and cooperative innovation. |

| TIC | Technological innovation capability | The capability of firms to improve technological innovation. Including absorption capacity, integration capacity, and continuous innovation capacity. |

Appendix B

- Strategic mode (SM)

- Catch-up cycle

References

- Lee, K.; Franco, M. Catch-up cycles and changes in industrial leadership: Windows of opportunity and responses of firms and countries in the evolution of sectoral systems. Res. Policy 2017, 46, 338–351. [Google Scholar] [CrossRef]

- Figueiredo, P.N. Beyond technological catch-up: An empirical investigation of further innovative capability accumulation outcomes in latecomer firms with evidence from Brazil. J. Eng. Technol. Manag. 2014, 31, 73–102. [Google Scholar] [CrossRef]

- Choi, Y.; Cui, L.; Li, Y. Focused and ambidextrous catch-up strategies of emerging economy multinationals. Int. Bus. Rev. 2019, 29, 101567. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, J.; Xiong, J. Windows of Opportunity in Catch-Up: Research Trends and Prospects. Manag. Rev. 2020, 32, 151–164. [Google Scholar]

- Cui, L.; Fan, D.; Liu, X. Where to Seek Strategic Assets for Competitive Catch-up? A configurational study of emerging multinational enterprises expanding into foreign strategic factor markets. Organ. Stud. 2016, 38, 1059–1083. [Google Scholar] [CrossRef]

- Lee, K.; Jee, H. Rise of latecomers and catch-up cycles in the world steel industry. Res. Policy 2017, 46, 365–375. [Google Scholar] [CrossRef]

- Sakata, I.; Sasaki, H. Scientific Catch-Up in Asian Economies: A Case Study for Solar Cell. Nat. Resour. 2013, 4, 134–141. [Google Scholar] [CrossRef]

- Guo, Y.; Zheng, G. How do firms upgrade capabilities for systemic catch-up in the open innovation context? A multiple-case study of three leading home appliance companies in China. Technol. Forecast. Soc. Chang. 2019, 144, 36–48. [Google Scholar] [CrossRef]

- Guan, J.C.; Yam, R.C.M.; Mok, C.K. A study of the relationship between competitiveness and technological innovation capability based on DEA models. Eur. J. Oper. Res. 2006, 170, 971–986. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, M.Y.; Dodgson, M. Windows of Opportunity, Technological Innovation, and Globalization: Huawei’s Global Catch-up. Acad. Manag. Annu. Meet. Proc. 2016, 1, 12872. [Google Scholar] [CrossRef][Green Version]

- Keun, L.; Xudong, G.; Xibao, L. Industrial catch-up in China: A sectoral systems of innovation perspective. J. Reg. Econ. Soc. 2017, 10, 59–76. [Google Scholar]

- Lee, M.K. Knowledge diffusion, market segmentation and technological catch-up: The case of the telecommunication industry in China. Res. Policy 2005, 34, 759–783. [Google Scholar]

- Baker, T.; Nelson, R.E. Creating Something from Nothing: Resource Construction through Entrepreneurial Bricolage. Adm. Sci. Q. 2005, 50, 329–366. [Google Scholar] [CrossRef]

- Lee, K.; Lim, C.; Song, W. Emerging digital technology as a window of opportunity and technological leapfrogging: Catch-up in digital TV by the Korean firms. Int. J. Technol. Manag. 2005, 29, 40–63. [Google Scholar] [CrossRef]

- Park, K.-H.; Lee, K. Linking the technological regime to the technological catch-up: Analyzing Korea and Taiwan using the US patent data. Ind. Corp. Chang. 2006, 15, 715–753. [Google Scholar] [CrossRef]

- Egbetokun, A.A. Interactive learning and firm-level capabilities in latecomer settings: The Nigerian manufacturing industry. Technol. Soc. Chang. 2015, 99, 231–241. [Google Scholar] [CrossRef]

- Lang, T.M.; Lin, S.H.; Vy, T.N.T. Mediate effect of technology innovation capabilities investment capability and firm performance in Vietnam. Procedia Soc. Behav. Sci. 2012, 40, 817–829. [Google Scholar] [CrossRef]

- Gao, X. A latecomer’s strategy to promote a technology standard: The case of Datang and TD-SCDMA. Res. Policy 2014, 43, 597–607. [Google Scholar] [CrossRef]

- Kang, K.; Hahn, J.; Dec, P. Learning Effects of Domain, Technology, and Customer Knowledge in Information Systems De-velopment: An Empirical Study. Inf. Syst. Res. 2017, 28, 797–811. [Google Scholar] [CrossRef]

- Suddaby, R.; Seidl, D.; Le, J.K. Strategic Organization Strategy-as-practice meets neo-institutional theory. Strateg. Organ. 2013, 11, 329–344. [Google Scholar] [CrossRef]

- Chuang, Y.S. Learning and International Knowledge Transfer in Latecomer Firms: The Case of Taiwan’s Flat Panel Display Industry. IEEE Trans. Eng. Manag. 2014, 61, 261–274. [Google Scholar] [CrossRef]

- Zhang, H.; Shi, Y.; Liu, J.; Wu, X. How do technology strategies affect the catch-up progress of high-tech latecomers? Evidence from two Chinese research-institute-transformed telecommunications firms. J. Bus. Res. 2021, 122, 805–821. [Google Scholar] [CrossRef]

- André, S.; Clarysse, B.; Knockaert, M. Building absorptive capacity to organize inbound open innovation in traditional industries. Technovation 2010, 30, 130–141. [Google Scholar]

- Lee, K.; Song, J. When and How Can Latecomers’ Path-creating Catch-up Be Successful? A Case Study on Interchangeable-lens Camera Industry. J. Strat. Manag. 2012, 15, 95–135. [Google Scholar] [CrossRef]

- Lu, F. Break through the Fog: Reveal the Origin of Chinese High-Speed Railway Technology Advances. Manag. World 2019, 35, 164–194, 200. [Google Scholar]

- Tang, M.; Sun, H. China’s High-Speed Railway Development History. High-Speed Rail; Shanghai Scientific and Technological Literature Press: Shanghai, China, 2019; Volume 12, pp. 385–424. [Google Scholar]

- Xintong, W.; Liang, M.; Jin, C. Theoretical Construction of Holistic Innovation: Lessons from China’s High-Speed Rail Industry. Sci. Sci. Manag. S. T. 2020, 41, 66–82. [Google Scholar]

- Mei, L.; Zhang, N. Transformer in Navigation: Diverse Government Roles for Open Innovation in China’s High-speed Rail. Long Range Plan. 2020, 22, 344–370. [Google Scholar]

- Wang, X.; Huang, S.; Zou, T. Effects of the high speed rail network on China’s regional tourism development. Tour. Manag. Perspect. 2012, 1, 34–38. [Google Scholar] [CrossRef]

- Landesmann, M.A.; Stoellinger, R. Structural change, trade and global production networks: An ’appropriate industrial policy’ for peripheral and catching-up economies. Struct. Chang. Econ. Dyn. 2019, 48, 7–23. [Google Scholar] [CrossRef]

- Yap, O.F. A Strategic Model of Economic Performance and Democratization in South Korea and Taiwan. Br. J. Political Sci. 2011, 42, 213–239. [Google Scholar] [CrossRef]

- Kim, D.B.; Park, M.J. Latecomers’ path-creating catch-up strategy in ICT industry: The effect of market disparity and gov-ernment dependence. J. Entrep. Emerg. Econ. 2019, 11, 234–257. [Google Scholar] [CrossRef]

- Bruno, T.; Frank, W. Incumbent actors, guided search paths, and landmark projects in infra-system transitions: Re-thinking Strategic Niche Management with a case study of French tramway diffusion (1971–2016). Res. Policy 2019, 48, 1412–1428. [Google Scholar]

- Seo, E.Y.; Choung, J.Y.; Hwang, H.R. The Changing Patterns of Knowledge Production of Catch-Up Firms During the Forg-ing-Ahead Period: Case Study of Samsung Electronics Co. IEEE Trans. Eng. Manag. 2019, 66, 621–635. [Google Scholar] [CrossRef]

- Kodama, M.; Shibata, T. Strategy transformation through strategic innovation capability-a case study of Fanuc. RD Manag. 2014, 44, 75–103. [Google Scholar] [CrossRef]

- Choi, D.G.; Hyun, O.-S.; Hong, J.-I.; Kang, B.-G. Standards as catalyst for national innovation and performance—A capability assessment framework for latecomer countries. Total Qual. Manag. Bus. Excel. 2014, 25, 969–985. [Google Scholar] [CrossRef][Green Version]

- Mishina, Y.; Block, E.S.; Mannor, M.J. The path dependence of organizational reputation: How social judgment influences assessments of capability and character. Strat. Manag. J. 2011, 33, 459–477. [Google Scholar] [CrossRef]

- Altenburg, T.; Wilfried, L. Industrial Policy in Developing Countries; Edward Elgar Publishing: Cheltenham, UK, 2015; pp. 436–451. [Google Scholar]

- López-Cabarcos, M.Á.; Srinivasan, S.; Vázquez-Rodríguez, P. The role of product innovation and customer centricity in transforming tacit and explicit knowledge into profitability. J. Knowl. Manag. 2020, 24, 1037–1057. [Google Scholar] [CrossRef]

- Wenzel, M. Path dependence and the stabilization of strategic premises: How the funeral industry buries itself. Acad. Manag. Annu. Meet. Proc. 2015, 1, 15370. [Google Scholar] [CrossRef]

- Akman, G.; Cengiz, Y. Innovative Capability, Innovation Strategy and Market Orientation: An Empirical Analysis in Turkish Software Industry. Int. J. Innov. Manag. 2008, 12, 69–111. [Google Scholar] [CrossRef]

- Shin, J.-S. Dynamic catch-up strategy, capability expansion and changing windows of opportunity in the memory industry. Res. Policy 2017, 46, 404–416. [Google Scholar] [CrossRef]

- Pang, C.; Wang, Q.; Li, Y. Integrative capability, business model innovation and performance: Contingent effect of business strategy. Eur. J. Innov. Manag. 2019, 22, 208–230. [Google Scholar] [CrossRef]

- Taggart, J.H. Strategy shifts in MNC subsidiaries. Strateg. Manag. J. 2015, 19, 663–681. [Google Scholar] [CrossRef]

- Yang, W. Research on Enterprise Internationalization Strategy Based on Path Dependence Theory: Literature Review and Future Prospect. Am. J. Ind. Bus. Manag. 2017, 7, 1229–1243. [Google Scholar] [CrossRef][Green Version]

- Lau, A.K.W.; Lo, W. Absorptive capacity, technological innovation capability and innovation performance: An empirical study in Hong Kong. Int. J. Technol. Manag. 2019, 80, 107–129. [Google Scholar] [CrossRef]

- Teece, D.J. Dynamic Capabilities and Entrepreneurial Management in Large Organizations: Toward a Theory of The (entre-preneurial) Firm. Eur. Econ. Rev. 2016, 7, 202–216. [Google Scholar] [CrossRef]

- Li, J.; Kozhikode, R.K. Knowledge management and innovation strategy: The challenge for latecomers in emerging economies. Asia Pac. J. Manag. 2008, 25, 429–450. [Google Scholar] [CrossRef]

- Nair, S.R.; Demirbag, M.; Mellahi, K. Reverse Knowledge Transfer from Overseas Acquisitions: A Survey of Indian MNEs. Manag. Int. Rev. 2015, 55, 277–301. [Google Scholar] [CrossRef]

- Guo, F.; Cui, L.; Zou, B. Knowledge Search and Firm Innovation: The Moderating Role of Organizational Aspirations. Acad. Manag. Annu. Meet. Proc. 2019, 1, 12047. [Google Scholar] [CrossRef]

- Lema, R.; Fu, X.; Rabellotti, R. Green windows of opportunity: Latecomer development in the age of transformation toward sustainability. Ind. Corp. Chang. 2021, 29, 1193–1209. [Google Scholar] [CrossRef]

- Donge, V.; Kees, J. The Politics of African Industrial Policy: A Comparative Perspective. J. Dev. Stud. 2016, 95, 191–221. [Google Scholar]

- Chen, J.; Xie, L. Industrial policy, structural transformation and economic growth: Evidence from China. Front. Bus. Res. China 2019, 13, 449–467. [Google Scholar] [CrossRef]

- Pack, H.; Saggi, K. The Case for Industrial Policy: A Critical Survey; World Bank Group: Washington, DC, USA, 2006; Volume 3022, pp. 368–379. [Google Scholar] [CrossRef]

- Cozzolino, A.; Verona, G.; Rothaermel, F.T. Unpacking the Disruption Process: New Technology, Business Models, and Incumbent Adaptation. J. Manag. Stud. 2018, 55, 1166–1202. [Google Scholar] [CrossRef]

- Sergio, L.G. Strategizing by the government: Can industrial policy create firm-level competitive advantage? Strateg. Manag. J. 2015, 36, 97–112. [Google Scholar]

- Lee, K. The Art of Economic Catch-Up; Cambridge University Press: Cambridge, UK, 2019; pp. 34–37. [Google Scholar]

- Mathews, J.A. Latecomer strategies for catching-up: The cases of renewable energies and the LED program. Int. J. Technol. Learn. Innov. Dev. 2007, 1, 34–42. [Google Scholar] [CrossRef]

- Meyer, K.E. Catch-Up and Leapfrogging: Emerging Economy Multinational Enterprises on the Global Stage. Int. J. Econ. Bus. 2018, 25, 19–30. [Google Scholar] [CrossRef]

- Wang, P.; Kwak, J.; Lee, H. The latecomer strategy for global ICT standardization: Indigenous innovation and its dilemma. Telecommun. Policy 2014, 38, 933–943. [Google Scholar] [CrossRef]

- Thietart, R.-A. Strategy dynamics: Agency, path dependency, and self-organized emergence. Strat. Manag. J. 2015, 37, 774–792. [Google Scholar] [CrossRef]

- Laursen, K.; Salter, A. Open for innovation: The role of openness in explaining innovation performance among UK manu-facturing firms. Strat. Manag. J. 2010, 27, 131–150. [Google Scholar] [CrossRef]

- Paulo, N.; Figueire, D. Government Policies and Sources of Latecomer Firms’ Capability Building: A Learning Story from Brazil. Oxf. Dev. Stud. 2008, 36, 59–88. [Google Scholar]

- Yin, R.K. Case Study Research and Applications: Design and Methods; Sage Publications: London, UK, 2011. [Google Scholar]

- Yun, J.J.; Won, D.; Park, K. Dynamics from open innovation to evolutionary change. J. Open Innov. Technol. Mark. Complex. 2016, 2, 1–22. [Google Scholar] [CrossRef]

- Liu, Y. High-Tech Ventures’ Innovation and Influences of Institutional Voids: A Comparative Study of Two High–Tech Parks in China. J. Chin. Entrep. 2011, 3, 112–133. [Google Scholar] [CrossRef]

- Maielli, G. Explaining Organizational Paths through the Concept of Hegemony: Evidence from the Italian Car Industry. Organ. Stud. 2015, 36, 491–511. [Google Scholar] [CrossRef]

- Miller, K.; McAdam, R.; Moffett, S.; Alexander, A.T.; Puthusserry, P. Knowledge transfer in university quadruple helix ecosystems: An absorptive capacity perspective. RD Manag. 2016, 46, 383–399. [Google Scholar] [CrossRef]

- Liping, X.; Danyang, X. Foreign technology import and domestic innovation growth: Complementary or replacement: A perspective of heterogeneous absorbency. Chin. Ind. Econ. 2016, 9, 75–92. [Google Scholar]

- Sumrit, D.; Anuntavoranich, P. Using Dematel Method to Analyze the Causal Relations on Technological Innovation Capa-bility Evaluation Factors in Thai Technology-Based Firms. Int. Trans. J. Eng. Manag. Appl. Sci. Technol. 2013, 2, 81–103. [Google Scholar]

- Zhao, Y.; Wong, P.; Subramanian, A.; Hang, C. Technology licensing and innovation performance: Evidence from Chinese latecomers in high-tech industries. J. Chin. Econ. Bus. Stud. 2014, 12, 125–147. [Google Scholar] [CrossRef]

- Sydow, J.; Schreyögg, G. Organizational Path Dependence. Int. Encycl. Soc. Behav. Sci. 2015, 385–389. [Google Scholar] [CrossRef]

- Handayani, T.L. Measuring innovation best practices: Improvement of an innovation index integrating threshold and synergy effects. Technovation 2008, 28, 838–854. [Google Scholar]

- Xie, X.; Zeng, S.; Tam, C.M. How does cooperative innovation affect innovation performance? Evidence from Chinese firms. Technol. Anal. Strat. Manag. 2013, 25, 939–956. [Google Scholar] [CrossRef]

- Tan, B.; Ng, E.; Jiang, J. The Process of Technology Leapfrogging: Case Analysis of the National ICT Infrastructure Devel-opment Journey of Azerbaijan. Int. J. Inf. Manag. 2018, 38, 311–316. [Google Scholar] [CrossRef]

- Long, P.D.; My, D.T.H. Rapid and Sustainable Growth in Vietnam: Lessons from the “Miracle” East Asia. J. Manag. Inf. Decis. Sci. 2020, 23, 123–146. [Google Scholar]

| Source Code | Type | Source | Content |

|---|---|---|---|

| E1 | Interviews | Managers and technical experts of CRRC | Interview records and documents provided by the interviewees. |

| E2 | Reports and bulletin | CRRC/National Railway Administration website | Annual reports and interim reports; Railway Statistics Bulletin. |

| E3 | National experimental platforms | China State Railway | Information about national key scientific research projects and national key Laboratories. |

| E4 | Policy documents and industry reports | National Railway Administration | Policy documents and industry reports including national strategies, industrial policies, science and technology innovation policies, foreign policies, plans, industry standards, regulations, etc. |

| E5 | Publications | China national knowledge infrastructure; National Press and Publication Administration | Papers, dissertations, and monographs about CRRC and China high-speed railway. |

| E6 | Videos | China Central Television | Documentaries, news reports, and interpretation about history and construction outline of China high-speed railway. |

| Constructs | Measures Variable | Keywords |

|---|---|---|

| SM | Internal innovation Cooperative innovation | High proportion of R&D expenses in sales; high proportion of R&D staff; |

| Cooperate in R&D, purchase of technology, technology licensing, technology authorization, technology consulting, innovation investment; | ||

| TIC | Absorption capacity Integration capacity Continuous innovation capacity | Fast mastering of the production process, Well utilize technical knowledge; |

| Strong product system integration, prescriptive technical integration process; | ||

| Adequate technicians, advanced product, internal R&D as a main technology source | ||

| Industrial policy | Target Methods | Capacity expansion, speed up, independent R&D, independent brand, leapfrog development |

| Catch-up | Catch-up performance | Technical level, the proportion of new product, market share of core products, number of Patents |

| Time | Stages | Content |

|---|---|---|

| 1994–2003 | Exploration stage | Independent development of main models; Exploration of valuable experience for EMU manufacturing. |

| 2004–2014 | Localization stage | Cooperation with Japan, Canada, France, and Germany, and began to produce CRH series EMU. |

| 2015–present | Standardization stage | Distinctive and comprehensive Chinese standard system. Higher than European and Japanese standards in function and construction. |

| Theoretical Dimension | Secondary Construct | Evidence | Code Source |

|---|---|---|---|

| SM | Internal innovation |

| E1, E5, E6 |

| Cooperative innovation |

| E1, E5, E6 | |

| TIC | Absorption capacity |

| E1, E2, E3 |

| Industrial policy | Promote absorption capacity |

| E1, E4, E6 |

| Catch-up | Catch-up performance |

| E2,E5,E6 |

| Theoretical Dimension | Secondary Construct | Evidence | Code Source |

|---|---|---|---|

| TIC | Improvement |

| E1, E2, E3, |

| Interaction between SM and TIC | Mismatch |

| E5, E5, |

| Industrial policy | Adjustment |

| E2, E4, E6 |

| Theoretical Dimension | Secondary Construct | Evidence | Code Source |

|---|---|---|---|

| SM | Internal innovation |

| |

| E1, E5, E6 | ||

| Cooperative innovation |

| E1, E5, E6 | |

| TIC | Integration capacity |

| E1, E2, E3 |

| Industrial policy | Enhance integration capacity |

| E1, E4, E6 |

| Catch-up | Catch-up performance |

| E2,E5,E6 |

| Theoretical Dimension | Secondary Construct | Evidence | Code Source |

|---|---|---|---|

| TIC | Further improvement |

| E1,E2,E3 |

| Interaction between SM and TIC | Mismatch |

| E1,E6 |

| Industrial policy | Adjustment |

| E2,E4,E6 |

| Theoretical Dimension | Secondary Construct | Evidence | Code Source |

|---|---|---|---|

| SM | Internal innovation |

| E1, E5, E6 |

| Cooperative innovation |

| E1, E5, E6 | |

| TIC | Continuous innovation capacity |

| E1, E2, E3 |

| Industrial policy | Strengthen continuous innovationcapacity |

| E1, E4, E6 |

| Catch-up | Catch-up performance |

| E2,E5,E6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wang, H. An Exploratory Study of How Latecomers Transform Strategic Path in Catch-Up Cycle. Sustainability 2021, 13, 4929. https://doi.org/10.3390/su13094929

Li X, Wang H. An Exploratory Study of How Latecomers Transform Strategic Path in Catch-Up Cycle. Sustainability. 2021; 13(9):4929. https://doi.org/10.3390/su13094929

Chicago/Turabian StyleLi, Xiaoli, and Hongqi Wang. 2021. "An Exploratory Study of How Latecomers Transform Strategic Path in Catch-Up Cycle" Sustainability 13, no. 9: 4929. https://doi.org/10.3390/su13094929

APA StyleLi, X., & Wang, H. (2021). An Exploratory Study of How Latecomers Transform Strategic Path in Catch-Up Cycle. Sustainability, 13(9), 4929. https://doi.org/10.3390/su13094929