The Experimental Timber–UHPC Composite Bridge

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Program

2.2. Material Characteristics

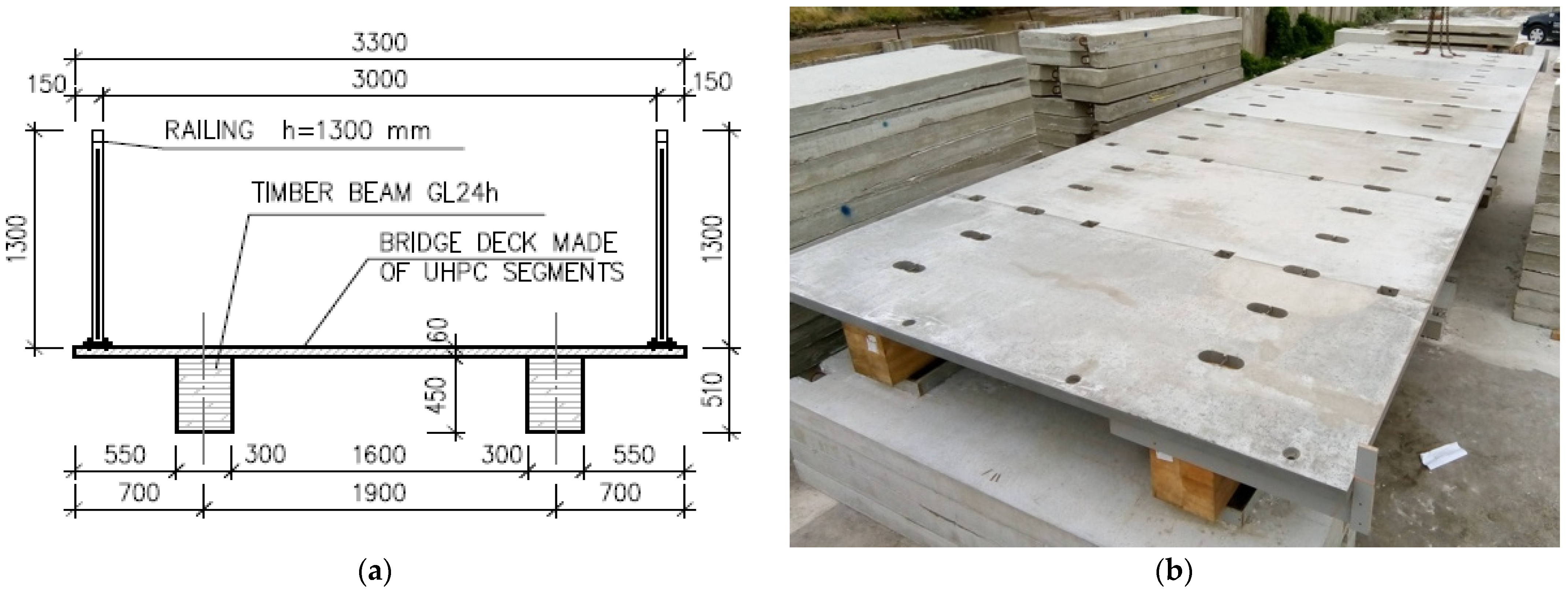

2.3. Experimental Structure

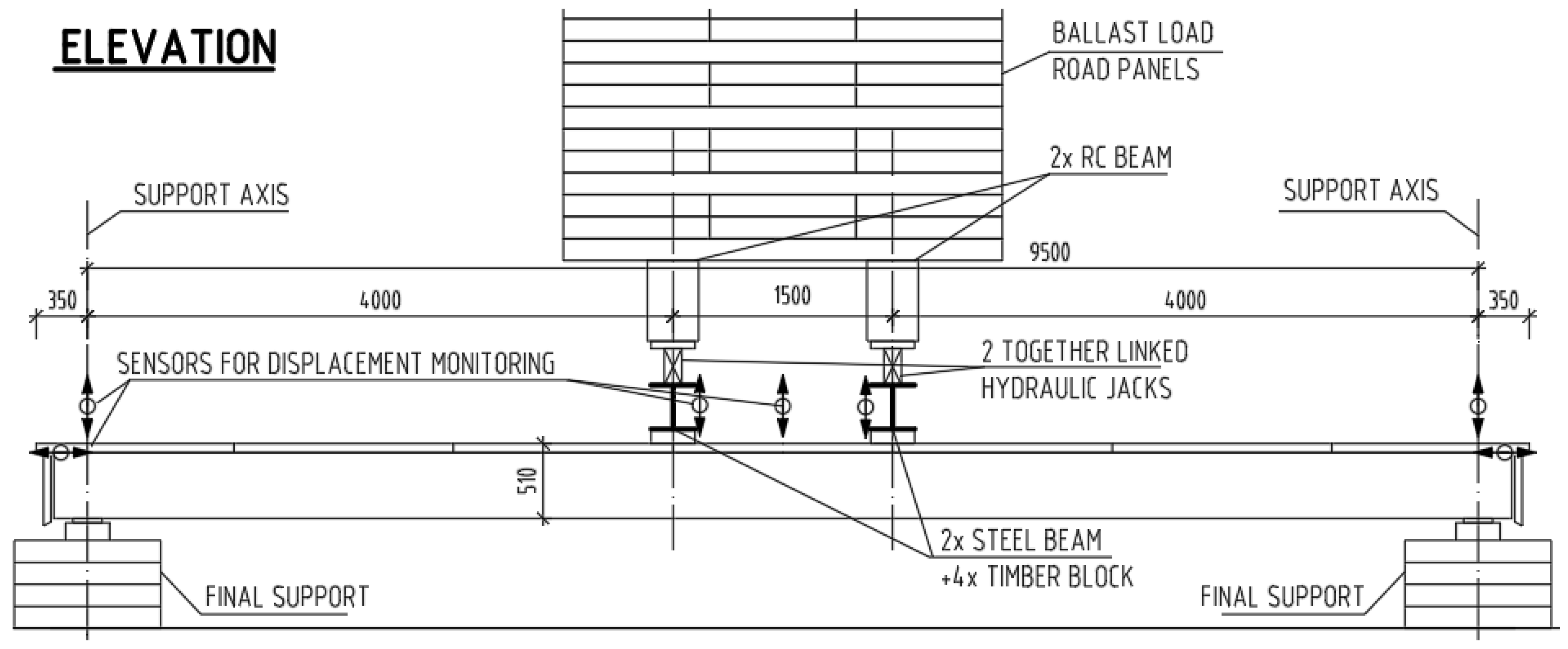

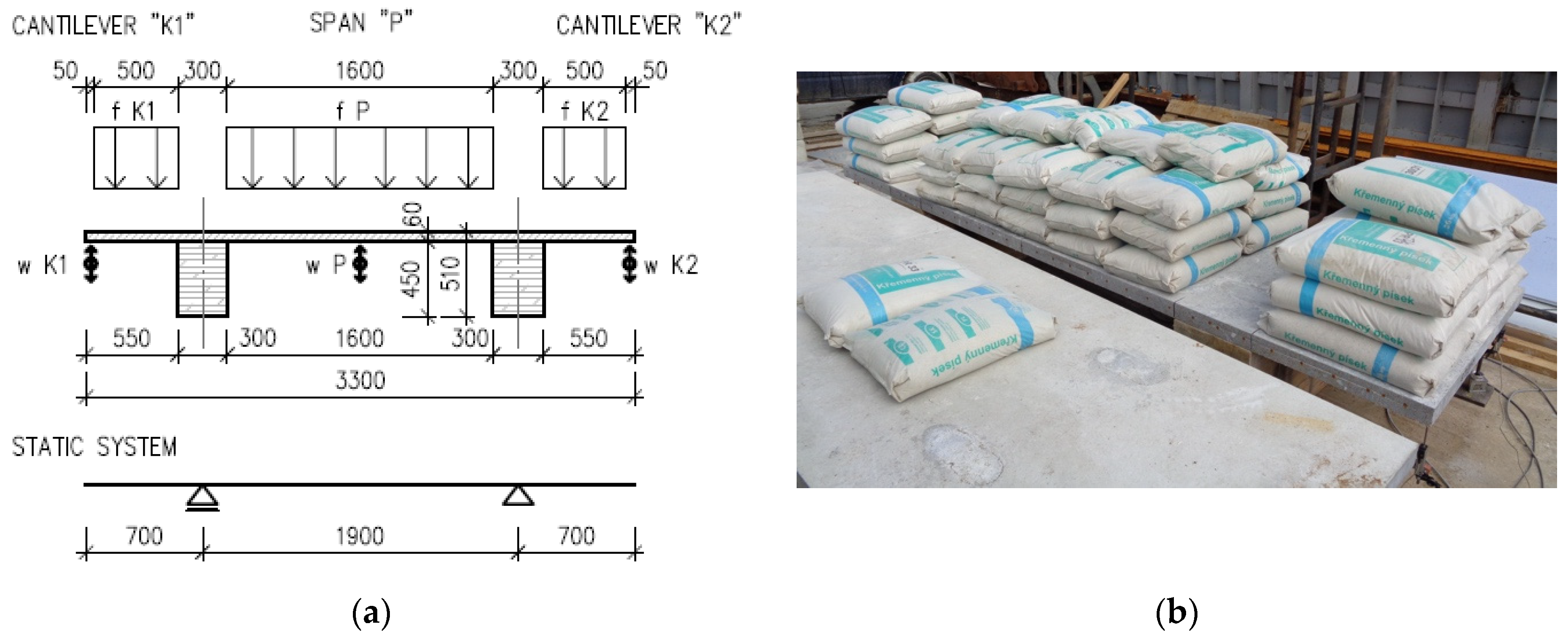

2.4. Load Test of the Experimental Structure

3. Results

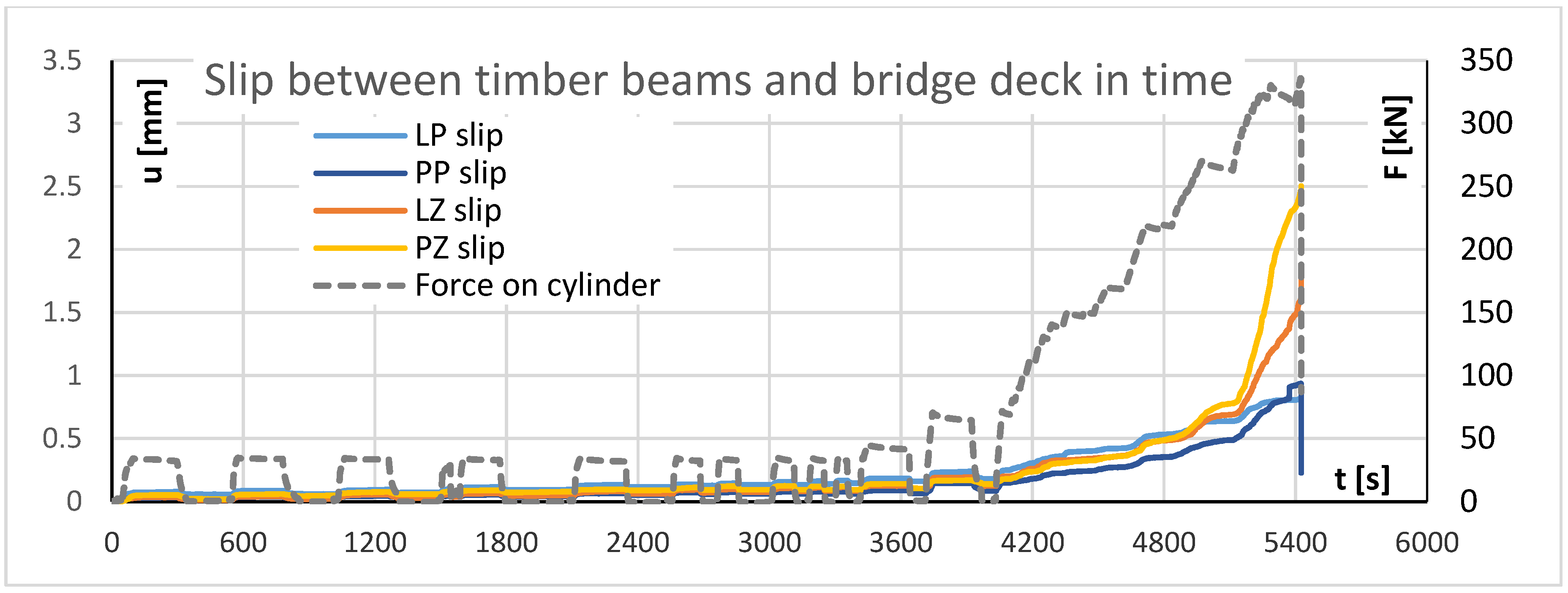

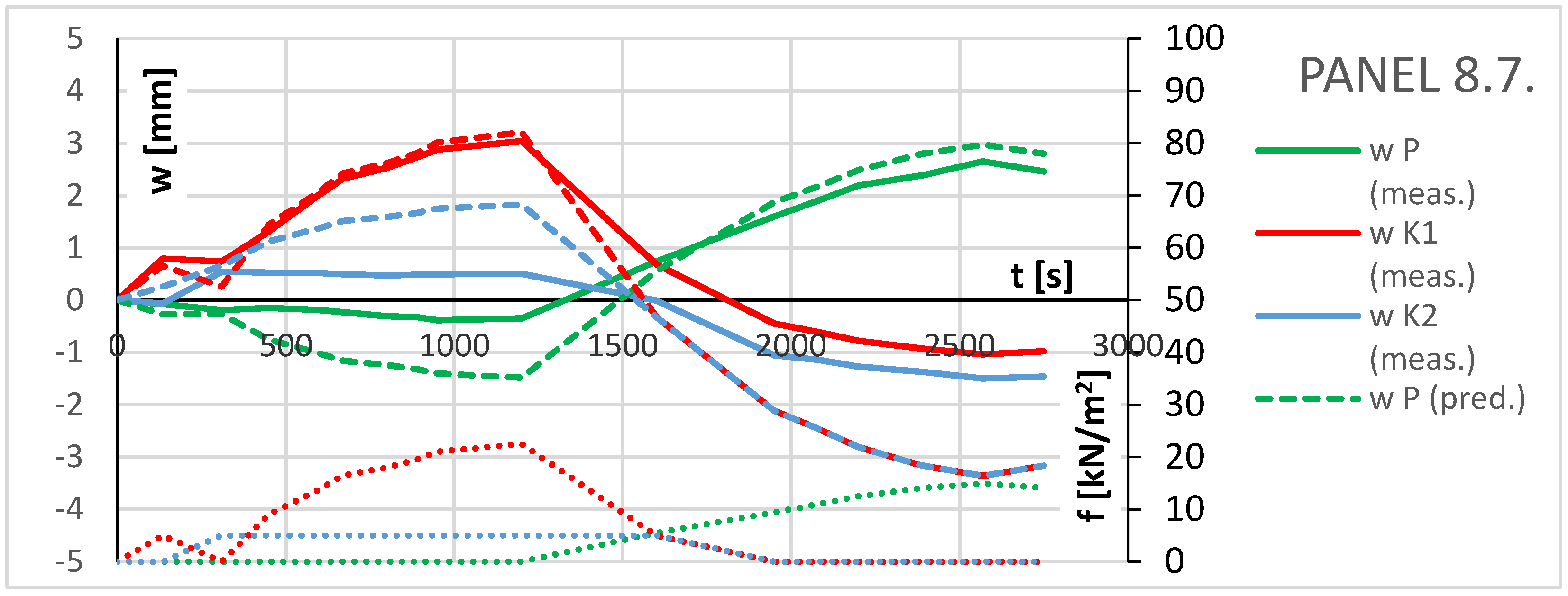

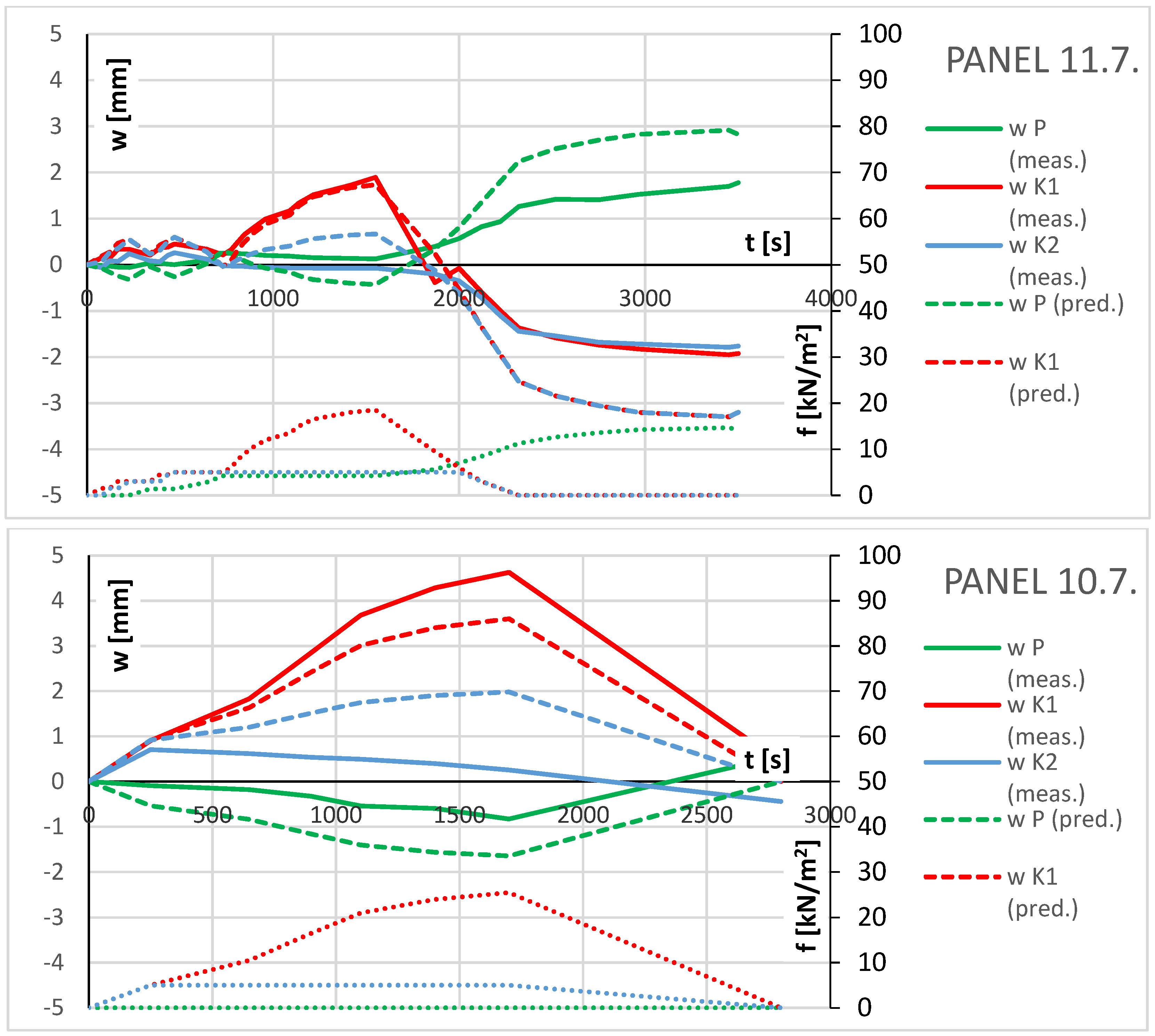

3.1. Load Test on the Experimental Structure

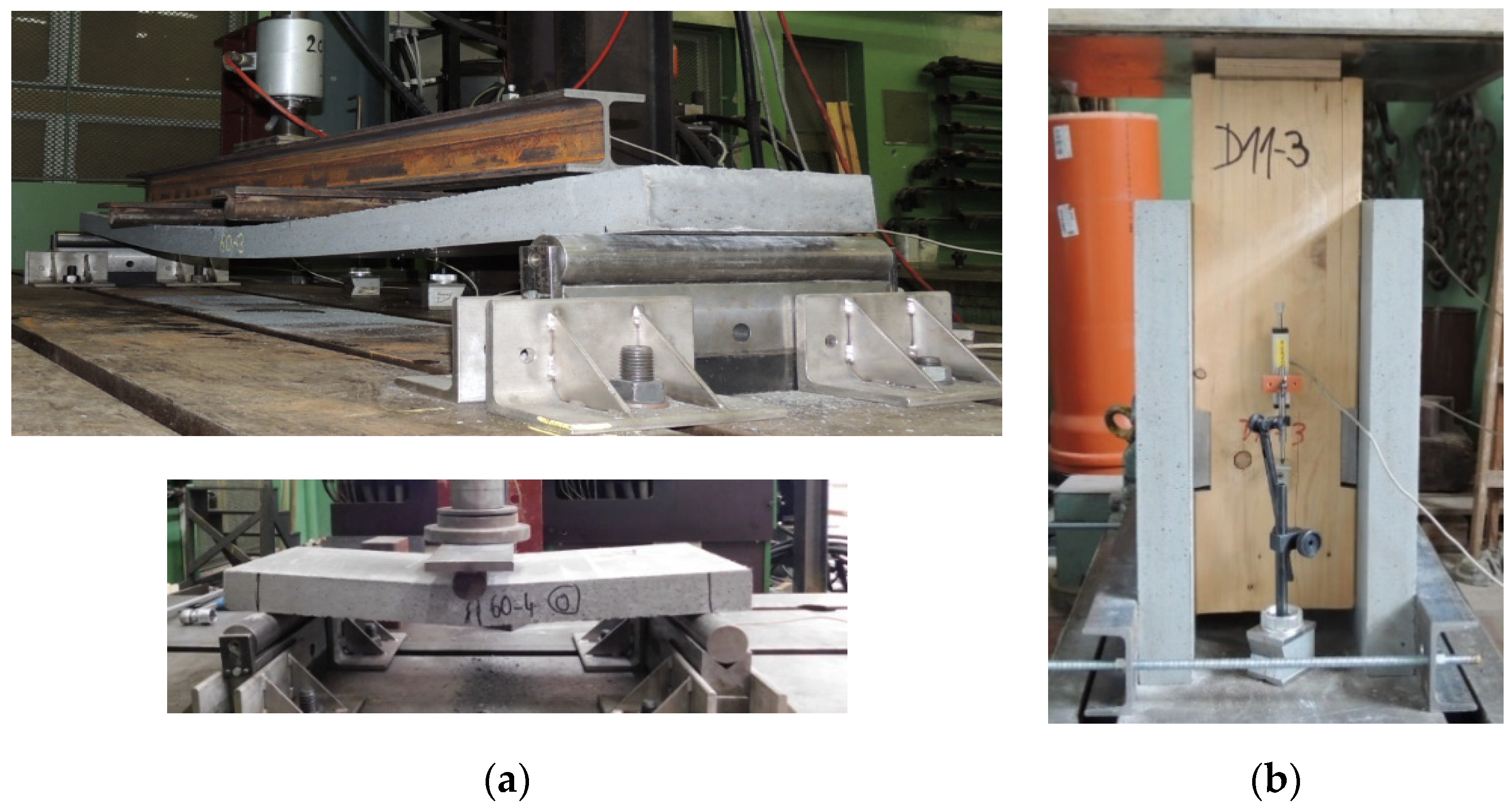

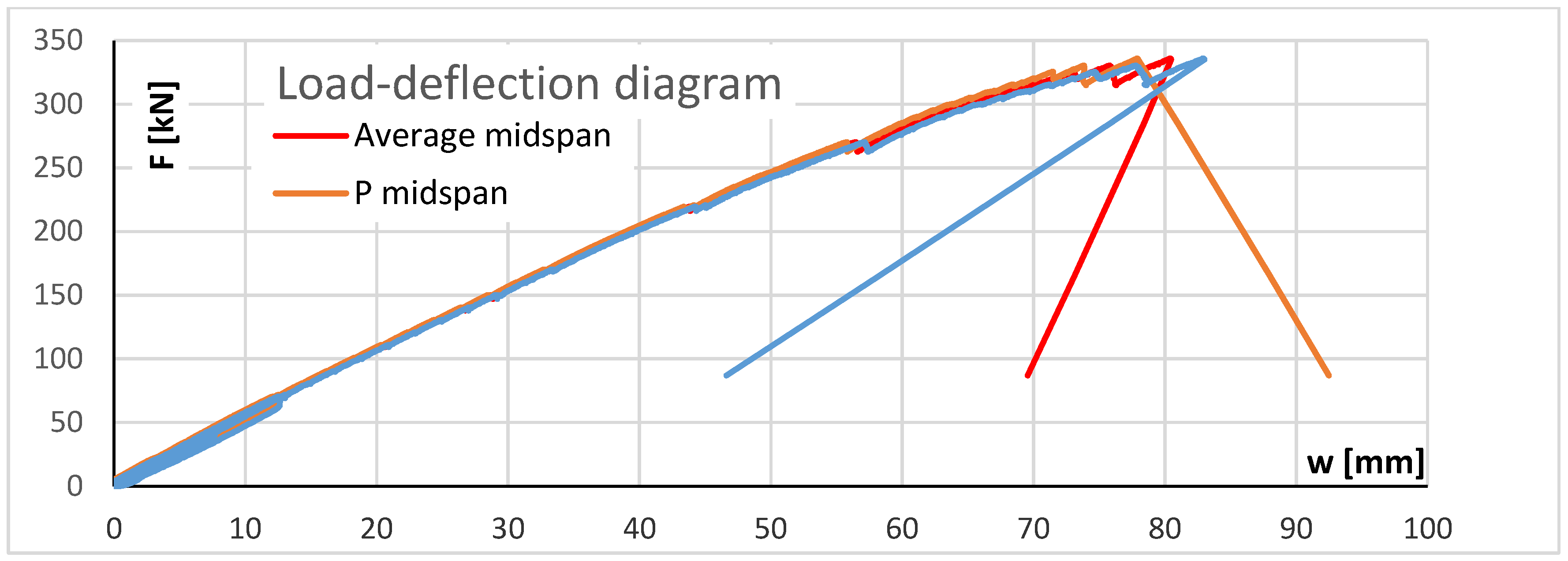

3.2. Load Test on Bridge Deck Segments

4. Discussion

4.1. Load Test on the Experimental Structure

4.2. Load Test on Bridge Deck Segments

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Ceccotti, A. Composite concrete-timber structures. Prog. Struct. Eng. Mater. 2002, 4, 264–275. [Google Scholar] [CrossRef]

- Yeoh, D.; Fragiacomo, M.; De Francheschi, M.; Koh, H.B. The state-of-the-art on timber-concrete composite structures—A literature review. J. Struct. Eng. 2011. [Google Scholar] [CrossRef]

- Rodrigues, J.; Dias, A.; Providencia, P. Timber-Concrete Composite Bridges: State-of-the-Art Review. BioResources 2013, 8, 6630–6649. [Google Scholar] [CrossRef] [Green Version]

- Simon, A. Brücken in Holz-Beton-Verbundbauweise—Renaissance Einer Genialen Idee: Vortrag, VSVI Mecklenburg Vorpommern; Seminar Brückenbau: Linstow, Germany, 2012. [Google Scholar]

- Kuklík, P.; Nechanický, P.; Kuklíková, A. Development of prefabricated timber-concrete composite floors. In Materials and Joints in Timber Structures; Aicher, S., Reinhardt, H.W., Garrecht, H., Eds.; RILEM Bookseries; Springer: Dordrecht, The Netherlands, 2014; Volume 9, ISBN 978-94-007-7811-5. [Google Scholar]

- Fragiacomo, M.; Lukaszewska, E. Development of Prefabricated Timber-Concrete Composite Floor Systems. Proc. Inst. Civ. Eng. Struct. Build. 2011, 164, 117–129. [Google Scholar] [CrossRef] [Green Version]

- Crocetti, R.; Sartori, T.; Tomasi, R.J. Innovative Timber-Concrete Composite Structures with Prefabricated FRC Slabs. Struct. Eng. 2015, 141, 04014224. [Google Scholar] [CrossRef]

- Set of Methodologies for Material Testing of UHPC and for Design Elements Made of UHPC, Output of Project TACR TA01010269; Klokner Institute CTU in Prague: Prague, Czech Republic, 2015.

- AFGC Ultra High Performance Fibre-Reinforced Concrete: Interim Recommendations; Revised Edition; AFGC Publication: Paris, France, 2013.

- Beton-Kalender. Teil 2, IX Ultrahochfester Beton UHPC; Ernst & Sohn: Berlin, Germany, 2013; pp. 117–240. [Google Scholar]

- Hájek, P.; Kynclová, M.; Fiala, C. Timber–UHPC composite floor structures—Environmental study. In Proceedings of the 3rd International Symposium on UHPC in Kassel in Germany, Kassel, Germany, 9–11 March 2012; ISBN 978-3-86219-265-6. [Google Scholar]

- Fragiacomo, M.; Gregori, A.; Xue, J.; Demartino, C.; Toso, M. Timber-concrete composite bridges: Three case studies. J. Traffic Transp. Eng. 2018, 5, 429–438. [Google Scholar] [CrossRef]

- Vítek, J.L.; Čítek, D. Joints of precast structures using UHPC. Solid State Phenom. 2017, 259, 164–169. [Google Scholar] [CrossRef]

- Vítek, J.L.; Čítek, D.; Coufal, R. UHPC Joints of Precast Elements. In Fibre Concrete 2013: Technology, Design, Application; CTU in Prague, Faculty of Civil Engineering: Prague, Czech Republic, 2013; pp. 407–414. [Google Scholar]

- Holý, M.; Vráblík, L. The Timber-Precast UHPC Composite Connection. Solid State Phenom. 2018, 272, 21–27. [Google Scholar] [CrossRef]

- Holý, M.; Tej, P.; Vráblík, L. Development of a timber-precast UHPFRC connection. In CONCRETE Innovations in Materials, Design and Structures, Proceedings of the Fib Symposium 2019, Kraków, Poland, 27–29 May 2019; Fédération Internationale du Béton: Lausanne, Switzerland, 2019; pp. 698–705. ISSN 2617-4820. ISBN 978-2-940643-00-4. [Google Scholar]

- Holý, M.; Vráblík, L. Push-out shear tests for timber-UHPC composite footbridge. In Proceedings of the 12th International Fib PhD Symposium in Civil Engineering, Fib Ph.D. Symposia, Prague, Czech Republic, 29–31 August 2018; Volume 12, pp. 195–202, ISBN 978-80-01-06401-6. [Google Scholar]

- Duque, L.F.M.; Varga, I.; Graybeal, B.A. Fibre reinforcement influence on the tensile response of UHPFRC. In Proceedings of the First International Interactive Symposium on UHPC—2016, Des Moines, IA, USA, 18–20 July 2016. [Google Scholar]

- Kolísko, J.; Rydval, M.; Huňka, P. UHPC—Assessment of steel fibre distribution and matrix homogeneity. In Fib Symposium TEL-AVIV 2013 Engineering a Concrete Future: Technology, Modeling & Construction—Proceedings; IACIE: Tel Aviv, Israel, 2013; pp. 113–116. [Google Scholar]

- Holý, M.; Čítek, D.; Tej, P.; Vráblík, L. Material properties of thin UHPC slabs used for timber-concrete composite bridge. In Proceedings of the 10th International Conference on Short and Medium Span Bridges (SMSB 2018), Quebec, QC, Canada, 30 July–3 August 2018. [Google Scholar]

- Holý, M.; Čítek, D.; Tej, P.; Vráblík, L. Flexural strength of thin slabs made of UHPFRC. In Proceedings of the 25th Concrete Days 2018; Solid State Phenomena; Trans Tech Publications: Curich, Switzerland, 2019; Volume 292, pp. 224–229. ISSN 1662-9779. ISBN 978-3-0357-1459-3. [Google Scholar]

- Kolísko, J.; Huňka, P.; Rydval, M.; Kostelecká, M. Development of UHPC from materials available in Czech Republic. In Proceedings of the CESB13, Prague, Czech Republic, 26–28 June 2013; pp. 385–388. [Google Scholar]

- Kolísko, J.; Čítek, D.; Tej, P.; Rydval, M. Production of Footbridge with Double Curvature Made of UHPC. In Proceedings of the IOP Conference Series-Materials Science and Engineering 246, Prague, Czech Republic, 13–16 September 2017. [Google Scholar] [CrossRef]

- Kněž, P.; Tej, P.; Čítek, D.; Kolísko, J. Design of Footbridge with Double Curvature Made of UHPC. In Proceedings of the IOP Conference Series-Materials Science and Engineering 246, Prague, Czech Republic, 13–16 September 2017. [Google Scholar] [CrossRef]

- ČSN EN 14080. Timber Structures—Glued Laminated Timber and Glued Solid Timber—Requirements (Czech Version of European Standard EN 14080:2013). 2013. Available online: https://csnonline.agentura-cas.cz/Detailnormy.aspx?k=94094 (accessed on 1 November 2013).

- ČSN EN 1990. Eurocode: Basis of Structural Design (Czech Version of European Standard EN 1990:2002). 2004. Available online: https://csnonline.agentura-cas.cz/Detailnormy.aspx?k=69473 (accessed on 1 April 2004).

- Rautenstrauch, K.; Grosse, M.; Lehmann, S.; Hartnack, R. Modellierung und baupraktische Bemessung von Holz-Verbund-Decken mit mineralischen Deckschichten unter Berücksichtigungneuartiger Verbindungsmittel. In Holz-Beton-Verbund; Bauwerk: Berlin, Germany, 2004; pp. 31–54. [Google Scholar]

- Holý, M. Optimization of Timber-UHPC Composite Bridges. Ph.D. Thesis, CTU, Prague, Czech Republic, 2020. [Google Scholar]

| Material Property | Mean Value | Number of Specimens | Coefficient of Variation | Standard Deviation | |

|---|---|---|---|---|---|

| Density | 2450 | kg/m3 | 48 | 0.84% | 20.6 |

| Compressive strength (cubes a = 100 mm) | 144.2 | MPa | 36 | 11.4% | 16.4 |

| Compressive strength (cylinder Ø150 mm) | 131.0 | MPa | 15 | 10.6% | 13.9 |

| Modulus of elasticity | 49.6 | GPa | 15 | 3.70% | 1.8 |

| Timber Grade | Density According to Standards [25] | Density Determined Experimentally |

|---|---|---|

| ρmean (kg/m3) | ρmean,real (kg/m3) | |

| GL24h | 420 | 422 |

| Characteristic value of bending strength, fm,k | 24.0 | MPa |

| Characteristic value of tension strength parallel to grain, ft,0,k | 19.2 | MPa |

| Characteristic value of shear strength, fv,k | 3.5 | MPa |

| Mean value of modulus of elasticity parallel to grain, E0,g,mean | 11.5 | GPa |

| Load Comb. | fd | M | V | W |

|---|---|---|---|---|

| (kN/m) | (kNm) | (kN) | (mm) | |

| 6.10 | 31.04 | 350 | 147 | 18.5 |

| Characteristic | 22.99 | 259 | 109 | 13.7 |

| Frequent | 13.99 | 158 | 66 | 8.3 |

| Load Comb. | g | G | F | M | V | w | wnet,calc | wnet,meas |

|---|---|---|---|---|---|---|---|---|

| (kN/m) | (kN) | (kN) | (kNm) | (kN) | (mm) | (mm) | (mm) | |

| M—6.10 | 6.16 | 3 | 67.1 | 350 | 99 | 17.3 | 13.0 | 12.4 |

| M—char. | 6.16 | 3 | 44.5 | 259 | 77 | 12.9 | 8.6 | 7.5 |

| V—frequent | 6.16 | 3 | 34 | 217 | 66 | 10.8 | 6.6 | 6.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Holý, M.; Čítek, D.; Tej, P.; Vráblík, L. The Experimental Timber–UHPC Composite Bridge. Sustainability 2021, 13, 4895. https://doi.org/10.3390/su13094895

Holý M, Čítek D, Tej P, Vráblík L. The Experimental Timber–UHPC Composite Bridge. Sustainability. 2021; 13(9):4895. https://doi.org/10.3390/su13094895

Chicago/Turabian StyleHolý, Milan, David Čítek, Petr Tej, and Lukáš Vráblík. 2021. "The Experimental Timber–UHPC Composite Bridge" Sustainability 13, no. 9: 4895. https://doi.org/10.3390/su13094895

APA StyleHolý, M., Čítek, D., Tej, P., & Vráblík, L. (2021). The Experimental Timber–UHPC Composite Bridge. Sustainability, 13(9), 4895. https://doi.org/10.3390/su13094895