1. Introduction

The UN Environment Programme (UNEP) defines marine litter as ‘any persistent, manufactured or processed solid material discarded, disposed of or abandoned in the marine and coastal environment’ [

1]. Marine plastics, representing 60 to 80% of overall marine litter [

2,

3], originate from various land- and sea-based sources and have a broad range of detrimental environmental, economic, safety, health and cultural impacts [

4,

5,

6,

7,

8]. In the past, successful efforts have been made to reduce losses and leakage from industry and dumping of ship-generated wastes [

9]. Nonetheless, the rapid increase in global plastic production combined with poor waste collection in many regions is leading to an ever-increasing number of plastic items and fragments found in marine systems, in rivers and on the shores [

9,

10,

11,

12]. The people most affected by marine plastic litter are those living in marginalized rural communities within marine biodiversity hotspots of the developing world. In Southeast Asia, for example, a large part of the population depends on the fishery sector. At the same time, Indonesia, the Philippines, Thailand and Vietnam, together with China, are responsible for more than half of the plastics from land-based sources reaching the oceans [

13]. According to Jambeck et al. [

14], a combined strategy of better waste management to reduce the share of mismanaged waste in the 10 top-ranked countries contributing to marine plastic litter and a waste reduction in high income countries could lead to a 77% reduction of annual plastic waste input into the oceans.

With respect to global governance on marine litter, various international bodies and initiatives have called for urgent action to tackle the marine plastic litter issue, such as the 2030 Agenda for Sustainable Development and the UN Sustainable Development Goals [

15], the Global Partnership on Marine Litter (GPML) [

16], the Group of Seven [

17] and the Group of Twenty [

18] Countries, to name only a few. Additionally, the International Convention for the Prevention of Pollution from Ships (MARPOL) and the regional sea conventions, such as the Barcelona Convention for the Protection of the Mediterranean, play a pivotal role, as they involve legally binding rules for their member states.

One key forum for preventing marine plastic litter is the UN Environment Assembly (UNEA). At the third UNEA session in 2018, the Ad-Hoc Open-Ended Expert Group (AHEG) on Marine Litter and Microplastics was set up, in accordance with previously adopted UNEA resolutions [

19]. At the AHEG’s first meeting, the lack of knowledge about the best available technologies and best environmental practices was identified as one of the numerous barriers to address marine plastic litter faced by developing countries [

20]. At the AHEG-4 meeting in 2020, the importance of technologies was stressed, for instance, with respect to innovative ways of data collection on the trajectory of plastic waste from source to sea (e.g., via earth observation), for cleaning up the legacy of waste and marine plastic litter in coastal areas and dumpsites, and for the prevention of future waste generation [

21].

Available scientific studies and reports focus mostly on the impacts of marine litter [

4,

7,

22] and/or on policies and laws, awareness-raising initiatives and behavioral change approaches [

23,

24,

25,

26,

27,

28,

29,

30]. The UNEP report “Marine plastic debris and microplastics: global lessons and research to inspire action and guide policy change” [

31], for example, summarizes the state of knowledge on the sources, fate and effects of marine plastics debris and microplastics and describes approaches to address this issue. GPML has collected and assessed the experiences of countries that have introduced bans and regulations on single-use plastics, serving as a tool for policymakers who intend to introduce measures to regulate the production and use of disposable plastics [

32]. However, there is only a limited number of systematic reviews on technological solutions to prevent or reduce marine litter in both the scientific and the ‘grey’ literature. Dijkstra et al. [

33], for example, focus on start-ups and recent developments of solutions tackling marine plastic pollution. Schmaltz et al. [

34] made a comprehensive inventory of technologies currently used or in development to prevent the leakage of plastic pollution or collect existing plastic pollution.

However, none of these include an assessment on the suitability of the deployment of these technologies, either in general or in the specific context of developing countries. Therefore, the overall goal of this study is to provide an overview on currently available technologies to tackle marine plastic litter to potentially be applied in developing countries. The first objective of this review is to collect and describe different types of currently available technological solutions for marine plastic litter prevention including their technology readiness level and the “source-to-sea” point of intervention. The second objective is to identify suitable solutions for potential deployment in developing countries.

2. Materials and Methods

To assure global coverage in the gathering of data and information, a dedicated sub-platform called “GreenHouse” was set up by Ubuntoo [

35], an existing online database for environmental solutions. Ubuntoo systematically collects and updates on organizations, movements, and technologies that provide innovative solutions to plastic pollution, food waste, and sustainable fashion.

This newly developed GreenHouse is coordinated by one of the co-authors, Venkatesh Kini, who is one of the Ubuntoo co-founders focusing on collecting technological solutions to prevent or reduce marine litter along the plastics value chain.

Technologies for the detection and capture of litter and integrated waste management solutions comprising several steps along the value chain were also considered. Being a major source of marine litter, solutions to tackle riverine and beach litter were included, too. Technologies related to wastewater treatment or the impact remediation of marine litter were not considered. Primary microplastics (e.g., from tire abrasion or textiles) are not within the scope.

In this newly developed GreenHouse platform, technologies suitable to the prevention or reduction of plastic marine litter are called ‘solutions’. These solutions were sourced from existing solutions from the Ubuntoo database, via expert judgement and from public campaigns via professional social networks. In addition, a call for contributions was released by UNEP addressing the members of the Ad-Hoc Open-Ended Expert Group (AHEG) on Marine Litter and Microplastics.

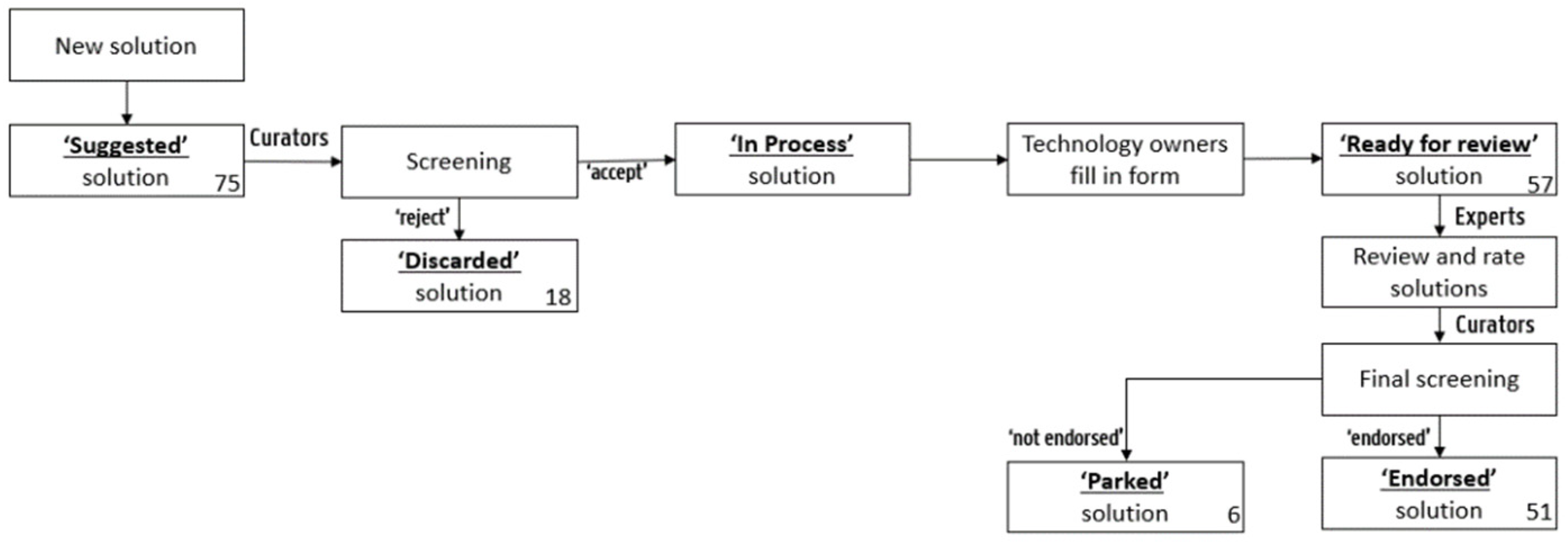

The collected potential solutions were assessed based on the flowchart displayed in

Figure 1.

Throughout the assessment (

Figure 1) the solutions received the consecutive statuses: ‘suggested’, ‘discarded’, ‘in process’, ‘ready for review’ and finally ‘parked’ or ‘endorsed’. For each solution status, a different task (e.g., screening, reviewing, etc.) was carried out. Depending on the task to be executed, different “roles” (curator, expert and technology owners) were assigned: the authors acted as the so-called ‘curators’, moving solutions from one status to the next when ready. The technology owners were granted access only to complete the technical content for their own solutions. The experts were thoughtfully chosen professionals from different organizations (e.g., Alliance to End Plastic Waste, Circular Plastics Alliance, UNEP), who were invited to review solutions on the GreenHouse platform in their field of expertise. The names of the 13 experts are confidential.

Each potential solution enters the system as ‘suggested’, at which point they undergo a first screening by the curators. The curators will either ‘accept’ or ‘reject’ the solution, causing them to move to the ‘in process’ or the ‘discarded’ solution status, respectively. Discarded solutions were those considered out of scope with regard to the prevention or recovery of marine litter. Typically, such solutions used marine plastics as a raw material, but did not contribute to the effective litter reduction as a technology (e.g., sunglasses made of marine waste). The assessment process continued with the ‘in process’ solutions only. Technology owners of these ‘in process’ solutions were invited to fill in a form with custom fields about detailed specifications (deployment regions, cost, energy requirement, etc.). Only solutions for which the technology owners explicitly agreed to be assessed through the form were included for further consideration and placed as ‘ready for review’ solutions. ‘Ready for review’ solutions were then reviewed by a minimum of three experts each. This was achieved through a form which includes a rating system between 0 (unsuitable solution) and 5 (excellent solution) and a mandatory comment section to motivate their scores. Additionally, the curators conducted interviews with the experts to identify the most promising solutions with respect to aspects that pose particular challenges to technology deployment in developing countries, such as the availability of qualified staff, access to electricity and other relevant infrastructure, cost, access to funding and unclear financial sustainability, and community involvement, to name only a few. A clear plan for follow-up treatment of the collected plastic debris is considered to be of high importance and also the environmental and societal impacts of newly deployed technological solutions are key factors to be considered.

Based on the different reviews, each solution received a total score. Finally, each solution was either ‘endorsed’ or ‘not endorsed’ into, respectively, an ‘endorsed’ or ‘parked’ solution status during a final screening completed by the curators. The final list of ‘endorsed’ solutions contained 51 solutions.

3. Results

The following section broadly describes the identified technological solutions and provides a comparative evaluation of the available types of technologies, including illustrative examples.

3.1. Broad Description of Available Technological Solutions to Prevent or Reduce Marine Plastic Litter

In total, 24 out of the 75 initially submitted technologies (32%) were rejected, either because they were considered out of scope due to a missing expression of interest by the technology owners or because they scored under 2 (out of 5). Overall, 8% of the solutions were assessed with an average score of 2 to 3, 40% with a score of 3 to 4, 19% with a score of 4 to 5 (19%) and 1% with exactly 5 (

Figure 2). On this basis, 51 technological solutions for marine litter prevention or reduction were shortlisted, which are available on the market or under development.

In terms of maturity, 4% of all reviewed solutions are at technology readiness level (TRL) 2 and 3 (prototype stage), 6% at TRL 4 and 5 (development stage), 14% at TRL 6 and 7 (pilot stage), 22% at TRL 8 (scale up) and 55% at TRL 9 (in market). The great majority (91%) of the shortlisted 51 solutions is at pilot stage or higher.

From this, it can be concluded that there is a variety of technological solutions available on the market. In order to enable local decision-makers to select them, it is important to gain further insight into the specific properties and applicability of the listed technologies. The main reasons why some of the solutions scored low was either due to an unsustainable business model or lack of any following steps in the plastics value chain, i.e., without a solid plan on what to do with the captured litter. Some just declared that it will depend on the local waste infrastructure, which is problematic as in many developing countries even basic waste infrastructure is absent or insufficient.

In contrast, the higher-ranked technologies also have an implementation plan in place, including a link towards the local community or a specific outreach strategy to raise awareness, such as Project STOP. Instead of being ‘stand-alone’ technologies, they create strong partnerships involving important local and global actors, public sector, private businesses, NGOs and citizens. The initiatives Ping Me! and Net-Works, for instance, cooperate with local fishermen to track or recover fishing gear. Plastic Bank shows that job creation and financial incentives are convincing arguments for private individuals to get involved, where people receive money in exchange for collected plastics. They also involve local businesses to accept the new plastic-based currency for payment. To avoid power supply issues, the rather simple mechanical solutions or technology powered by solar or hydro energy scored higher, such as the Trash Wheel or StormX.

An important shortcoming encountered is the low maturity of some of the proposed solutions without presenting a convincing plan to reach the next TRL, and also without a sustainable business plan. On the other hand, some of the more mature cleanup devices (e.g., Barber) and recycling technologies (e.g., Plastix) do not provide detailed investment and operating costs due to corporate confidentiality considerations, which would, however, be important information for users in developing countries.

The full list of all shortlisted solutions (51 in total) can be found in the

supplementary information. Collection systems represent the biggest share with 51%, out of which about 23% are land-based (mainly beach cleanup solutions); the rest refer to the capture of litter from water, that is, from rivers and streams (42%) and from the sea (35%), as shown in

Figure 3.

Almost half of the latter focus on recovering fishing gear. The second biggest group with 25% comprises treatment and processing technologies, either as a stand-alone solution (30%) or, more commonly, in combination with a first litter capturing step. Ten percent offer digital solutions (e.g., a citizen app to reduce plastic footprint, global fundraising campaigns to organize cleanups, virtual currency for plastic waste). Another 8% focus on remote sensing and the detection of litter. The 6% labeled as “other” include, for instance, integrated waste management solutions.

With respect to the stage in the source-to-sea movement, 37% of the endorsed solutions are sea-based, 29% are used in rivers or streams and 24% are land-based (

Figure 4). For 10%, the application is not specified, mainly for the digital solutions and waste-detection methods. This is interesting insofar as the report on technical and financial resources to tackle marine plastic litter found litter in and around rivers often not extensively discussed, while inland sources, the sea–land interface and the sea are well-covered [

21]. For the availability of technologies, this ratio appears to be quite balanced.

3.2. Comparative Evaluation of Different Types of Technologies

In the following sections, different types of technologies are compared. For each stage in the source-to-sea spectrum—land, rivers and streams, and sea—two illustrative examples are described in detail, which were rated by the experts with 4 or above and for which technology owners provided detailed specifications.

3.2.1. Rivers and Streams

According to Lebreton et al. [

36], up to 19% of plastic litter entering the oceans originates from rivers; 88 to 95% of it from 10 rivers, eight in Asia and two in Africa [

37]. The present study gathered 15 technologies designed to collect and recover plastic litter from streams and rivers. Most of these solutions were either at pilot stage (2) or already implemented (11). The average rating for these solutions was 3.3, of which two were considered by our experts amongst the most promising: Trash Wheel and Storm X. Based on data provided by the technology owners, the average cost per ton for collection and recovery for all solutions was USD

$600, including the capital and operating costs but not including any downstream processing costs.

Extrapolating this to the total volume of plastic litter flowing through rivers and streams—0.5 million tons as reported by Eunomia Research & Consulting Ltd. [

38] to maximum 2.3 million tons according to Lebreton, Van Der Zwet, Damsteeg, Slat, Andrady and Reisser [

36]—results in a total annual cost of between USD

$300 million and USD

$1.4 billion per annum for 100% litter recovery—noting that this is a hypothetical number, since the recovery efficiency will go down once it is expanded to rivers and streams with lower litter volume. Further study is needed to estimate the actual volume of recoverable plastic waste at reasonable costs.

These solutions require little manpower and can be installed, maintained and operated with unskilled manpower. River cleanup technologies such as this capture plastic waste before it enters the oceans.

Illustrative Examples: StormX Netting Trash Trap and Trash Wheel

StormX

TM is a passive capturing system for stormwater runoff that captures both floatable and non-floatable trash (up to 5-mm in size) into a collection netting system. It is used as “first flush” on pipe outfalls, structures and in channels where the current of the water will direct the waste into downstream trash traps. However, it cannot be used in water where aquatic life is present. The system requires no energy other than the natural current or flow. The overall price, together with installation requirements, maintenance and operation needs, and the capturing capacity depends on the diameter size (ranging from 0.5 to 3 m) and net length needed for a specific location. The prices range from USD

$4000 to 30,000 for a diameter of 0.5 to 3 m, respectively. A small-sized StormX

TM can be installed by two semi-skilled workers within one hour. Due to its size and weight, the installation of a large-sized StormX

TM can require mechanical lifting and placement assistance. To prevent flooding, StormX

TM is equipped with overflows and bypass options. Depending on the StormX

TM size and the amount of trash collected, either two unskilled workers or a truck-mounted crane is required to empty the collection nets. StormX

TM has been in use for over 15 years, and the company reports zero failures [

39,

40].

The experts consider StormX a very easy and efficient system to filter waste at sewers and pipe outfalls. It is a fully proven solution and is currently being used in different geographical regions.

Trash Wheel is a stationary active technology which collects floating waste from flowing waterways provided by the company Clearwater Mills. It first collects waste via a floating platform equipped with a conveyor belt and waterwheel and then stores the collected waste on a dumpster situated on a barge. While the floating platform is kept stationary through pilings, a vessel pushes the barge to a disposal area once the dumpsters are full. Both stationary platform and barge are equipped with a covering structure with solar panels on top, which protects the equipment and prevents the collected waste from being carried away by the wind.

The Trash Wheel directs floating waste through containment booms to the conveyer belt, which removes the waste from the water to the dumpsters on the barge. The conveyer belt is mechanically powered by renewable energy sources, namely solar-powered pumps and the water current. The pumps, the trash flow and the dumpster level can either be controlled via manual operation or through a remote control and monitoring system (internet-based). Depending on the weather conditions and amount of collected waste, one to two semi-skilled persons are needed to transfer and transport the full dumpsters. The needed technical assistance and training to operate and maintain the Trash Wheel is provided by Clearwater Mills. The cost for operation (including transport and disposal of waste) and maintenance amount to approximately USD $750 per ton. The total cost from feasibility assessment to installation is significant and lies between USD $382,500 and 895,000, depending on the location.

The Trash Wheel on Jones Falls River, installed in 2014, has a floating platform of 15.8 m by 7.3 m, which is equipped with a 11 m long conveyer and 4.3 m diameter waterwheel. The collection capacity amounts to more than 22 tons of waste per day (more than 8000 tons per year), with an actual annual collection of 200 ton of solid waste from the Jones Falls River. Depending on the dimensions of the waterways, ClearWater Mills provides both larger and smaller Trash Wheel models. Currently, there are three Trash Wheels operating in Baltimore and the collected waste from the three Thrash Wheel modes are used for energy recovery [

41,

42].

The experts consider the Trash Wheel a very promising and effective technology that can capture high volumes of waste in harbors, estuaries, coastal areas, rivers and canals. It could help prevent a lot of floating plastics from entering the marine environment. The installation can be scaled according to local requirements.

3.2.2. Sea-Based

Sea-based sources contributing to marine plastic litter are estimated to account for 1.75 million tons of a total 12 million tons entering the oceans each year, with about 1.15 million tons of fishing litter and 0.6 of million tons of shipping litter. Only 1% of marine plastics are found floating at or near the ocean surface, with a global concentration of less than 1 kg/km

2 on average [

38].

Near Offshore

A group of technologies have been developed to recover plastic from harbors, lakes and areas of the ocean within easy reach of land. These include autonomous, floating trash collection devices, such as Seabin, that return to shore when full, and passive trawling systems, such as Thomsea, that are attached to fishing boats. This study shortlisted 19 such solutions, with an average expert rating of 3.7. Most of the solutions were either at the pilot stage (3), scale-up (3) or already in market (12).

The advantage of these solutions is that the return logistics cost of collected debris is lower than solutions that collect litter from the open oceans, and most plastic waste gets captured before it spreads out to the sea or disintegrates on land by the action of waves. The average cost of these solutions works out to roughly USD $400 per ton of collected plastic waste. There are no reliable peer-reviewed studies of the volume of plastic litter floating in near offshore waters, but anecdotal evidence suggests that it is a significant volume.

Illustrative Examples: Seabin Smart Tech and Thomsea

Seabin Smart Tech provides a solution for both the cleanup and prevention of marine litter [

43]. A Seabin unit is a floating device that passively captures marine litter. It is installed in strategic upstream locations, such as rivers, ports, marinas and city foreshores. Each unit filters 600,000 L of water per day for microplastics, oil, surface pollutants and general plastics including plastic fibers. Currently, the global average capture is 3.9 kg per day or 1.4 tons of marine litter per year. In total, with over 860 Seabins in the water, across 52 countries, the daily capture amounts to 3.6 tons per day and 500 million liters of water filtered per day. To operate one Seabin unit, one non-skilled person is required. Currently, the marine litter captured is the responsibility of the marinas, ports and yacht club clients. With funding, however, Seabin aims to assume responsibility of the waste for a fully transparent closed-loop cycle. Operating one unit costs AUD

$3.3 per day, corresponding to about USD

$2.6 per day (March 2021). This translates into a cost of USD

$662 per ton of captured plastic waste. The units are also solar compatible to reduce energy consumption. An updated version of Seabin is currently in production and will incorporate underwater sensors to monitor electrical conductivity, dissolvable oxygen and water temperature as baseline data. The sensor technology is also designed as an appendage to be swapped out for other more relevant sensors to that region. Seabin is now offering services for cities and governments, which not only includes the daily empties and quarterly maintenance, but also the weekly data sets for the Pollution Index

®.

The Pollution Index

® program is operational in 19 countries with a network of 71 volunteers uploading data sets weekly of the information that the Seabin smart tech is capturing. This program is used as a monitoring system platform to measure, predict and interpret the health of waterways. Combined with the Pollution Index

® data monitoring program, the Seabin Foundation has designed education and community initiatives. Currently, a Pollution Index

® data app is being developed [

44].

In the experts’ opinion, the technology is well-considered and very promising. However, the current capacity is still not in relation to the volumes that need to be captured in high-leakage areas.

Thomsea provides a patented anti-pollution trawl net which collects floating waste from the sea, such as algae, petroleum and solid waste such as plastics and plants [

45].

The trawls are U-shaped floating devices and can be positioned on the coast or transported to the open sea by boats. The nets can be used by fishing vessels, amphibious oyster barges and conventional maritime vessels. Nets are available in three different sizes, starting from 40 kg up to several tons maximum capacity.

The small size (T1) has a maximum capacity of 40 to 50 kg. At least one unskilled person, ideally a fisherman, and a little boat (or paddle, kayak, marine drone, etc.) is needed to deploy one trawl of this size.

The medium size (T2) is the most versatile solution, and it can capture between 500 to 1000 kg of plastic waste depending on the size of plastic particles. The total capacity would be two tons of hydrocarbons. A boat with 50 horsepower is needed to use one trawl of this size. A minimum of two semi-skilled persons, ideally fishermen, and a crane are required to empty the trawl.

The big size (T8) can capture between two to three tons of plastic waste depending on the size of plastic particles. The total capacity would be eight tons of hydrocarbons. A boat with 250 horse powers is needed to deploy one trawl of this size. Between four and six persons are required, half of which should be semi-skilled, ideally fishermen. A crane is needed to empty the trawl. For all sizes, the maintenance cost is close to zero. The operational costs depend on the personnel cost in a specific country. In terms of energy input, only the energy for the boat drive is needed. This solution only concerns the collection of floating marine litter, while the follow-up treatment of collected debris depends on the cooperation partners and available infrastructure [

46].

The cost per ton of captured litter will depend on the overall amount of floating plastic litter and its density; however, it is to be expected that this solution is rather inexpensive: assuming a lifetime of about 10 years, T1 would cost between USD $15–150 per cleaned up ton of plastic (assuming an average daily collection of 5 to 50 kg). Slightly higher costs are to be expected for T2 and T3 (with a minimum daily capture of 500 kg). The cost for fuel and personnel has to be added (own calculations).

According to the experts’ opinion, this is one of the only existing and working solutions for coastal cleanups; its implementation seems to be relatively easy and quick. Although very labor-intensive it is actively collecting waste. A strong argument to use this solution is the involvement of local fishermen whose knowledge can be of great use. They are usually motivated to contribute to save their marine environment.

Open Oceans

Much attention has been drawn to the issue of plastic waste floating in the ocean gyres. However, the average concentration of plastic waste in these gyres is rather low due to a high dispersion rate, making the collection of the litter very difficult. Eunomia Research & Consulting Ltd. [

38] reports concentrations of maximum 18 kg/km

2 for floating plastics near the ocean surfaces, compared to 70 kg/km

2 on the sea floor.

Estimates are that the volume of waste floating in the biggest gyre, in the Pacific Ocean, are 79,000 tons inside an area of 1.6 million km

2 [

47], less than 0.6% of the estimated 12.2 million tons of litter entering the oceans each year.

Many technology solutions have been proposed to collect these particles, usually involving boats that can be self-powered by pyrolyzing the litter, or through solar power. However, none appear to have been implemented, and in the opinion of our experts, are unlikely to be economically scaled, because of the high initial capital cost, relatively costly return logistics and the low volume of collection. The most well-known solution, the Ocean Cleanup, did not agree to be evaluated for this study. However, based on publicly available data, it does not appear to have successfully operated its technology. The economics are not easily accessible on their website.

Due to the fact that both the overall amount of floating plastic and the concentration of litter is relatively low, these expensive approaches are not considered first-choice solutions by this paper’s authors.

3.2.3. Land-Based

Jambeck, Geyer, Wilcox, Siegler, Perryman, Andrady, Narayan and Law [

14] estimate that the sources contributing the highest share to marine plastic litter are land-based: About nine (of total 12) million tons of mismanaged plastic waste per year enter the oceans from beaches and coastlines around the world, again predominantly from Asian countries. Another 0.5 million tons are added from inland sources.

Beaches and Coastlines

Globally, the average concentration of litter found on beaches amounts to 2000 kg/km

2. Partly, this litter may have been released directly, and other plastics may have been washed up from the sea [

38].

Technological solutions to clean beaches and shorelines include machines that capture plastic and other trash, such as Barber; specialize in granulates, such as Nurdle; or Plastic Bank, which combines human-powered collection with a blockchain-enabled revenue model that provides a living wage to the collectors. This study shortlisted five solutions in this category, and they received an average rating of 3.4.

Among these, the Plastic Bank was the highest rated, proving that a scalable, low-cost model (USD $480 per ton) to clean beaches and coastal areas in well-populated areas in developing countries is feasible. However, the combined volume of plastic recovered by the five solutions evaluated by this study amounted to only a maximum of 60,000 tons per year, less than 0.5% of the annual volume of litter flowing into the oceans. For these solutions to create a meaningful impact, significant seed funding needs to be provided. Scaling solutions such as Plastic Bank to achieve 1 million tons of plastic waste collection per year would cost USD $500 million.

The challenge is that these solutions cannot be scaled to remote uninhabited islands such as the Henderson Islands, where a research group found large volumes of plastic litter washed up on the beach [

48]. Further research would need to be carried out to estimate the potential volume of plastic litter that can be economically captured by scaling solutions such as Plastic Bank, and the volume of litter that probably lies unrecovered in remote beaches.

Illustrative Example: Plastic Bank

Plastic Bank’s

® goal is a closed-loop plastic supply chain, including consumer to business return of plastic into the sourcing and manufacturing phases [

49]. Founded in 2013, the company builds recycling ecosystems in coastal communities and reprocesses the materials for reintroduction into the global manufacturing supply chain. Collectors receive a premium for the materials they collect, which helps them provide for their families. Plastic Bank’s proprietary blockchain platform secures the entire transaction and provides real-time data visualization—allowing for transparency, traceability, and rapid scalability. The collected material, called Social Plastic

®, can be easily reintegrated into products and packaging as part of a closed-loop supply chain, as reported by the company [

50]. Plastic Bank has opened over 320 collection branches in five countries. So far, the recycling ecosystems have collected over 13 million kg of plastic (over 650 million plastic bottles), and engaged over 20,000 collectors globally, providing opportunities to improve their lives. Collected quantities have been constantly increasing, with currently 1 million kg of plastic per month being collected across different countries. Only in July 2020, 1.2 million kg were collected. One-hundred percent of the plastic material collected in Plastic Bank recycling ecosystems is sent to processors and is recycled. No material is sent to landfill.

Collection numbers and the chain of custody are verified using the company’s proprietary blockchain platform. To expand the reach of Plastic Bank a mobile application was designed, opening up opportunities for people with varying levels of education and qualification to run a recycling business. Anyone operating a recyclable materials exchange business can use the Plastic Bank application to run their business through a basic smartphone. This includes plastic, glass, metal, paper and liquid material exchanges. Official Plastic Bank branches and certified Plastic Bank partners can qualify to contribute to Social Plastic orders and distribute Plastic Bank’s digital bonus rewards directly to registered members. These special incentive programs provide a substantial value increase to collectors and the local community while significantly increasing local recycling rates.

Processors with the equipment to bale-flake or pelletize recycled plastics can also participate in Social Plastic orders and bonus reward programs by enrolling their own collection networks to become Plastic Bank certified. To complete the full ecosystem, businesses of all kinds can use the application’s free point-of-sale and store management system on their basic smartphone to accept Plastic Bank’s digital rewards as an alternative to cash payments. This commonly includes grocery stores, transportation services, cooperative banks, and other local vendors who sell various products to members [

50].

Plastic Bank currently has over 20,000 registered members and employs 80 staff members across five countries. The global team, from headquarters to in-country staff, are trained sales, marketing, operations, technology, and finance professionals. Plastic Bank collectors’ skillset varies as some collect material part-time in addition to their other jobs, while others choose to be full-time collectors.

Plastic Bank’s blockchain-powered platform is accessed using a simple smartphone, ensuring inclusivity for the branch managers and collector community. Plastic Bank’s platform does not use Bitcoin (or any other cryptocurrency) or require mining (or any other energy-intensive proof-of-work consensus process). An assumed amount of 12,000 tons of collected plastics would result in a cost of about USD $480 per ton (own calculations).

According to the experts’ opinion, this system is an excellent way to capture plastic waste and has served as an example to many. First, it targets unmanaged waste before they enter waterbodies or oceans. Second, it exploits blockchain technologies to connect waste collector and recycling companies with a limited carbon footprint. Third, it generates revenues for local communities. However, the system should be closely monitored and certified to ensure full traceability of the “social” plastics.

Integrated Waste Management

Sound waste management practices, including the collection, treatment and disposal infrastructure, are the key to preventing and reducing marine litter. The seven shortlisted solutions (with an average score of 3.6) provide holistic concepts on setting up waste collection schemes and build collaborations with recyclers and producers to make use of the collected plastic litter. All but one are already in the market. Among these, Project STOP was the highest rated, mainly due to its involvement of local communities.

Illustrative Example: Project STOP

Project STOP is an initiative, co-founded by the companies Borealis and SYSTEMIQ, that seeks to establish a resilient, comprehensive and economically sustainable waste management system in southeast Asian areas with high ocean pollution [

51].

The approach of project STOP follows four steps, from scoping over preparation and design to implementation and scaling up a waste management system. In the first step, cities with about 100,000 to 150,000 residents without a waste management system, are selected and assessed for ocean pollution, given that the local government shows sufficient interest and support. In the second step, a waste management system for the selected city is designed. This involves baseline assessments, stakeholder agreements and cooperation with different waste management experts. In the third step, the waste management system is implemented in the city. During the first three to four years, the city receives technical and operational support from experienced waste management experts. In addition, approximately 80 new jobs are created in waste management (collecting, sorting, organic waste processing and general management). Finally, in the fourth step, the waste management system is scaled up and expanded to new regions.

Generally, an average Indonesian city with about 100,000 residents generates around 1500 tons of plastic waste per year. Project STOP aims to collect the total amount of generated waste. The capture rate, depending on the facility, amounts to 40 to 70%. The captured plastic litter is sold to plastic aggregators and recyclers. If no market is available, the waste will be disposed of at the landfill.

Project STOP spends an average of USD $1.4 million per 100,000 inhabitants, which includes expenses for collection infrastructure (e.g., for household bins, vehicles), behavior-change campaigns (e.g., for source separation of waste), composting plants, government training and beach and river cleanups. The collection and sorting cost amounts to approximately USD $30–40 per ton of captured litter.

Currently, project STOP reports many strategic corporate and government partners. At the time of publication, it operates in the Indonesian coastal cities of Muncar, Lekok, Ngulign, and Jembrana (Bali) [

51,

52]. In the future, Project STOP aims to establish new solutions and models that can be rapidly scaled-up across the whole plastic value chain, from the use of plastic to waste collection and recycling, focusing on areas where there is a need to improve the management of plastic waste.

According to the experts, project STOP is a promising and sufficiently well-backed project that has proven its effectiveness and scalability to other regions by already delivering good results in Indonesia.

To summarize,

Table 1 shows an overview of the different types of technologies and the illustrative examples, which were rated by the experts with 4 or above.

4. Discussion: Solutions for Developing Countries

A wide range of technological solutions to tackle marine plastic litter is either available or under development.

As reviewed by the experts, the most impactful, proven, and cost-effective solutions are those that capture marine litter in streams and rivers, beaches and coastlines, and near offshore locations, including those that focus on fishing gear. Solutions to capture plastic litter from the open oceans are yet to be proven.

The present study gathered 15 technologies designed to collect and recover plastic litter from streams and rivers. They are able to capture plastic waste before it enters the oceans, at a stage when it has not been degraded or broken up into microplastics and can still be reprocessed economically. These solutions require little manpower and can be installed, maintained and operated with unskilled manpower. Most of these solutions were either at the pilot stage (2) or already implemented (11). The average cost per ton for the collection and recovery for all solutions was USD $600, including the capital and operating costs.

A group of technologies have been developed to recover plastic from harbors, lakes and areas of the ocean within easy reach of land. This study shortlisted 19 such solutions, with most of them being either at pilot stage (3), scale-up (3) or already in market (12). The advantage of these solutions is that the return logistics cost of collected debris is lower than solutions that collect litter from the open oceans, and most plastic waste gets captured before it spreads out to the sea or disintegrates on land by the action of waves. The average cost of these solutions amounts to roughly USD $400 per ton of collected plastic waste. The biggest share of mismanaged plastic waste is believed to enter the oceans from land, namely from beaches and coastlines. Technological solutions to clean up beaches and shorelines include machines that capture plastic and other waste or combine human powered collection with a revenue model for the collectors. This study shortlisted five solutions in this category. However, the combined volume of plastic recovered by these types of solutions are currently very low. For these solutions to create a meaningful impact, significant seed funding needs to be provided.

Factors that will determine whether a solution can potentially be deployed in developing countries include the potential lack of highly educated staff, limited access to electricity and other relevant infrastructure, limited access to funding and unclear financial sustainability, and the inclusion of local stakeholders. Additionally, the environmental and societal impacts of newly deployed technological solutions have to be considered.

Simple mechanical solutions or technology powered by solar or hydro energy, such as the Trash Wheel or StormX, could be easily transferred to developing countries, as they are self-sufficient for their energy and do not require connection to an electricity grid or the constant supply of fuel. These solutions typically also can be run by low-skill workers, with operations limited, for example, to the emptying of captured waste reservoirs or regular monitoring. Furthermore, such solutions score excellently in terms of environmental soundness in terms of energy used. However, any impact on riverine or marine ecosystems is often not documented or researched.

Successful solutions are often not ‘stand-alone’ technologies but provide for their integration into society. Technology owners typically have put strategic effort onto the implementation, either by establishing a link towards the local community and/or developing a specific outreach strategy to raise awareness. In line with Dijkstra, van Beukering and Brouwer [

33], it was found that many businesses including cleanup and collection offer innovative approaches to raise funding to support waste management. They rely on people power from the local communities to participate in waste management activities. Cooperation with local communities can take different forms, e.g., with fishermen to recover fishing gear or with private individuals acting as waste collectors. Individuals performing cleanups—be it as volunteers or as paid workers—cannot solve the plastic pollution problem alone. Nevertheless, those cleanups have ecological benefits far beyond the aesthetic improvements. In addition to that, cleanups may also show a behavioral impact and improved awareness as they expose the litter problem first-hand.

Some of the more complex machines and recycling technology already operate in developed countries. Possible bottlenecks for their transfer to developing countries remain to be studied. During the survey, not much information on investment and operating cost was provided by these technology owners due to corporate confidentiality considerations. Aspects that deserve more attention in the future include cost transparency and environmental soundness—especially with regard to the impacts on ecosystems.

Often, the disposal of plastic debris collected during beach or ocean cleanups faces a lack of infrastructure for waste management and/or recycling, particularly in developing countries. Technology providers who did think about the following steps in the value chain either manufacture their own products (e.g., fishing nets, slippers, bracelets or carpet tiles), collaborate with big corporations (e.g., Henkel) or are connected to a sufficiently established local waste management system.

Although little research has been carried out on that topic, it is commonly accepted that the quality of plastics for recycling is lower when recovered from oceans, as compared to plastics of riverine origin. The highest quality is to be expected from municipally collected and potentially source-separated post-consumer plastic waste.

This is why the actual mechanical recycling of garbage from the ocean into new products is feasible, but typically less cost-effective than for separately collected waste on land. The recovered plastic litter contains salt (if collected from the ocean), sludge, and other contaminants such as lead, which is a common additive for marine polypropylene ropes [

53]. Therefore, the recovered waste requires special pre-treatment technologies such as sorting, cutting, lead separation, crushing, and desalting [

53].

Nonetheless, mechanical recycling remains the most ubiquitous recycling pathway for plastics and is relatively low-tech in terms of required infrastructure. The emerging technologies of thermo-chemical recycling, ranging from effective depolymerization to pyrolysis and gasification, require not just high-energy inputs but also reactor technology which is only economically feasible at volumes of around 100,000 tons per year. This technology is not available at the small scale (nor for a low cost) and as such, it is highly questionable if it would be a suitable route to explore for developing countries.

5. Conclusions

Twelve out of the top 20 countries with the biggest amounts of mismanaged waste, and hence a big potential for leakage into waterways, are labeled as low or lower-middle income [

14]. The goal of this study was to provide an overview on currently available technologies to tackle marine plastic litter and to assess their potential deployment in developing countries. A wide range of techno-commercial solutions are available to address the problem of marine plastic litter. A total of 51 out of initially 75 submitted solutions along the plastics value chain, including the detection and capture of litter, were assessed by independent experts.

Most of the solutions shortlisted and evaluated by this paper were at an advanced stage of commercialization—TRL 6 and beyond. However, none have achieved sufficient scale to make even a small dent in the problem. Some of the most promising solutions have already been tested or are operating in a similar context as in the target countries. Out of the shortlisted 51 solutions, collection and cleanup systems represent the biggest share with 51%. A quarter include processing and treatment technologies, either as a stand-alone solution (30%) or, more commonly, in combination with a first litter capturing step. Ten percent offer digital solutions, e.g., virtual currency for plastic waste. The rest focuses on the detection of waste and integrated waste management solutions. With respect to the stage in the source-to-sea movement, 37% of the endorsed solutions are sea-based, 29% are used in rivers or streams and 24% are land-based. This represents a misbalance insofar as the main share of marine plastic litter—80%—is assumed to originate from land-based sources [

14].

The authors conclude that technologies tackling land-based sources of marine plastic litter are most cost-effective and hence should be considered first choice solutions. With beaches and coastlines being litter hotspots and by far the biggest contributors to the overall amount of ocean plastics, these solutions are relatively inexpensive and yield the highest quality of captured plastics, which implies better recyclability and higher revenues later on in the value chain.

Reduction of plastic usage, adopting reusable packaging or package free products, recycling, and most importantly, investing in modern waste management infrastructure in developing markets are the only long-term solutions.

In the short term, the most promising palliative (collection, recovery and reprocessing) solutions for developing countries combine technology with people-oriented practices, require no energy or run on their own energy sources, connect throughout the plastics value chain with a convincing valorization plan for captured debris, create jobs and other financial incentives for local communities to participate and involve all relevant actors.

The technologies presented in this work can serve as promising complements that can work in combination with policy efforts and upstream innovations for product design, production processes and business models to tackle marine plastic pollution [

54]. Due to the size of the problem and its systemic nature, however, these local actions have not yet resulted in a clear reduction of the problem. There is a need for further concerted action, with coordination over the national borders and with impact across the value chain. Only a systemic transition towards sustainable materials management, including a reduction of the material intensity of our society, will be able to mitigate the marine litter problem. The size and systemic nature of this challenge should not hold us back from setting up small-scale or local activities to initiate the change. Through global coordination and feedback, the local activities can be replicated and upscaled to result in a worldwide systemic change.