Life Cycle Assessment of Protected Strawberry Productions in Central Italy

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal of the Study

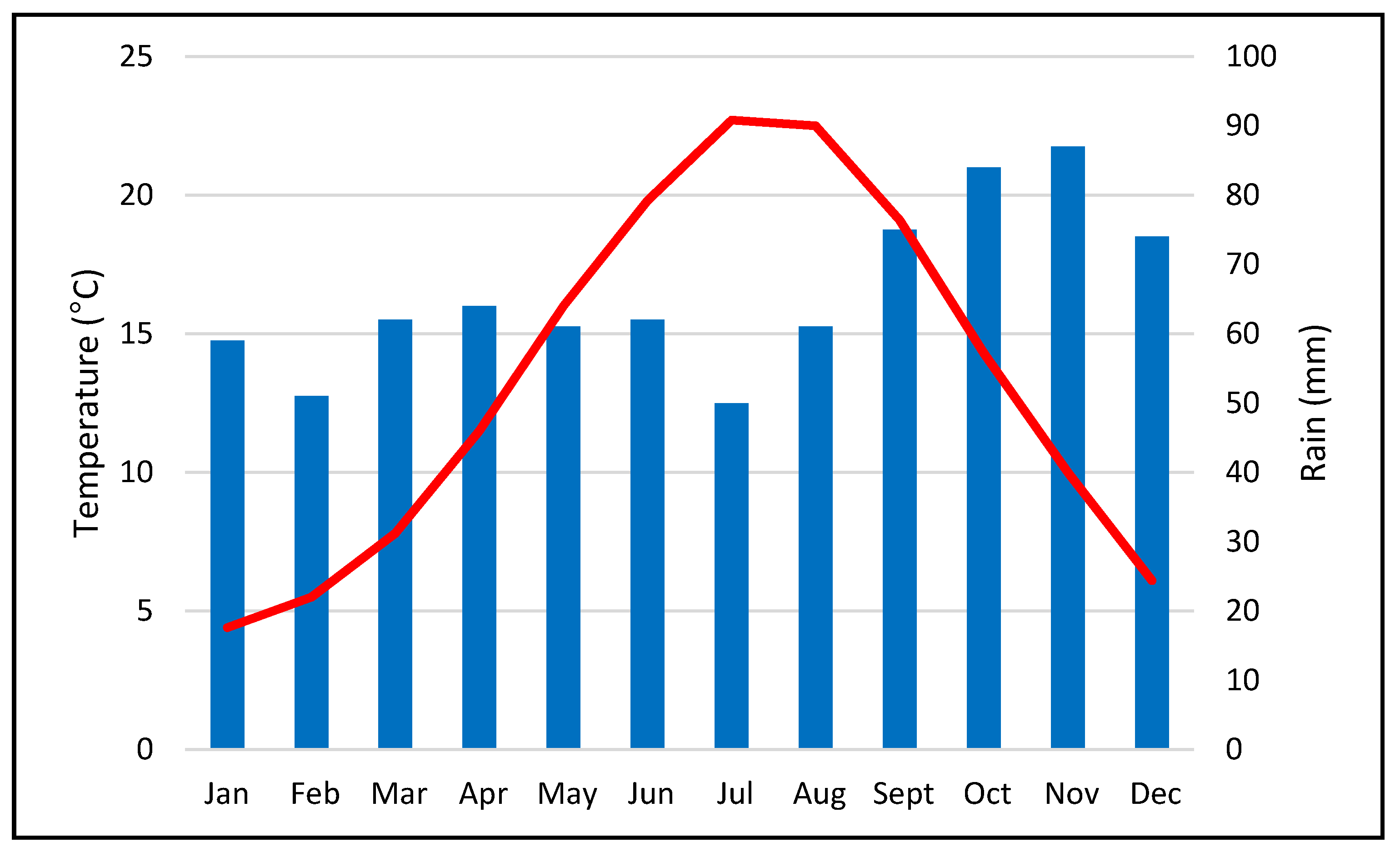

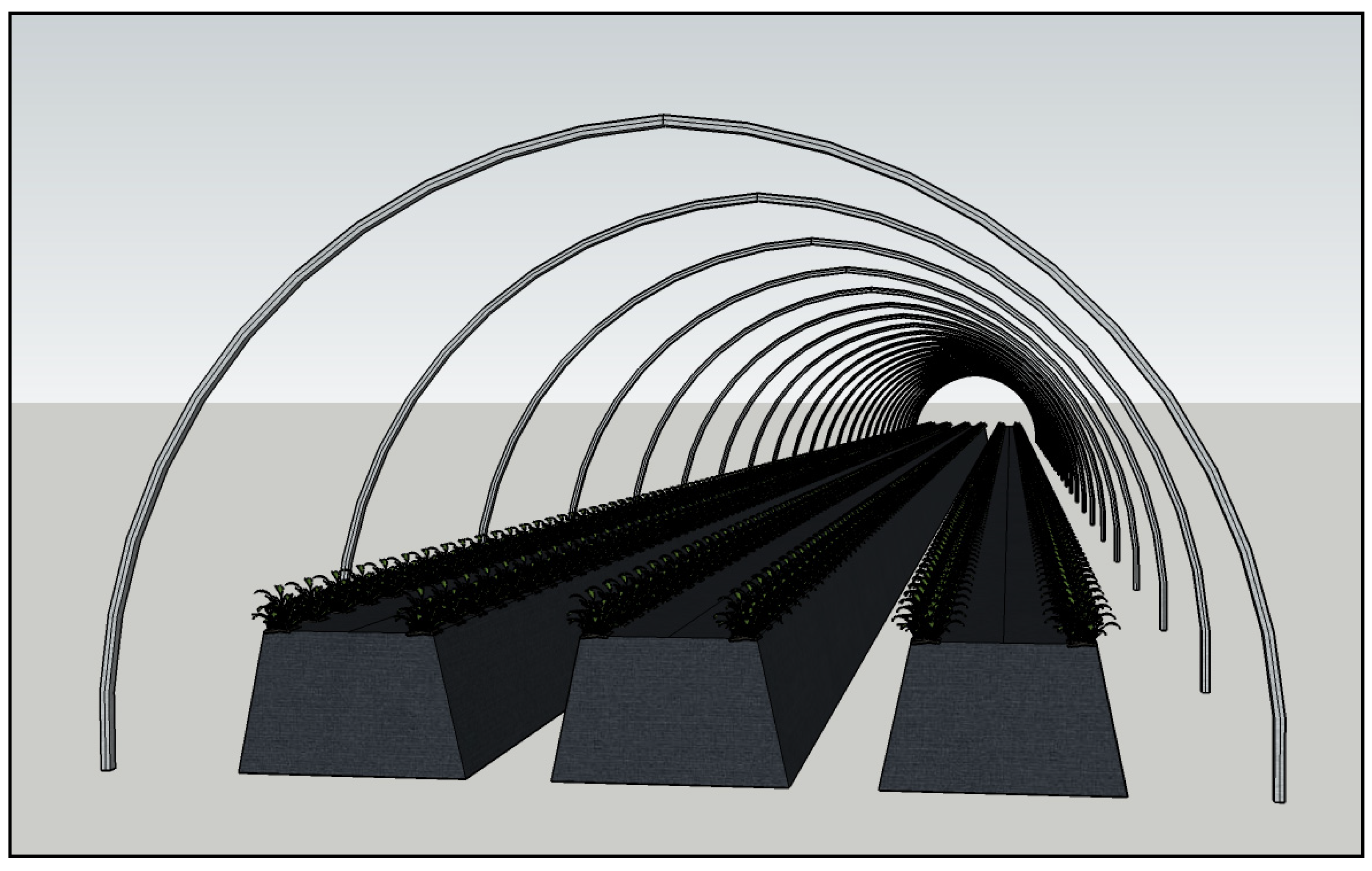

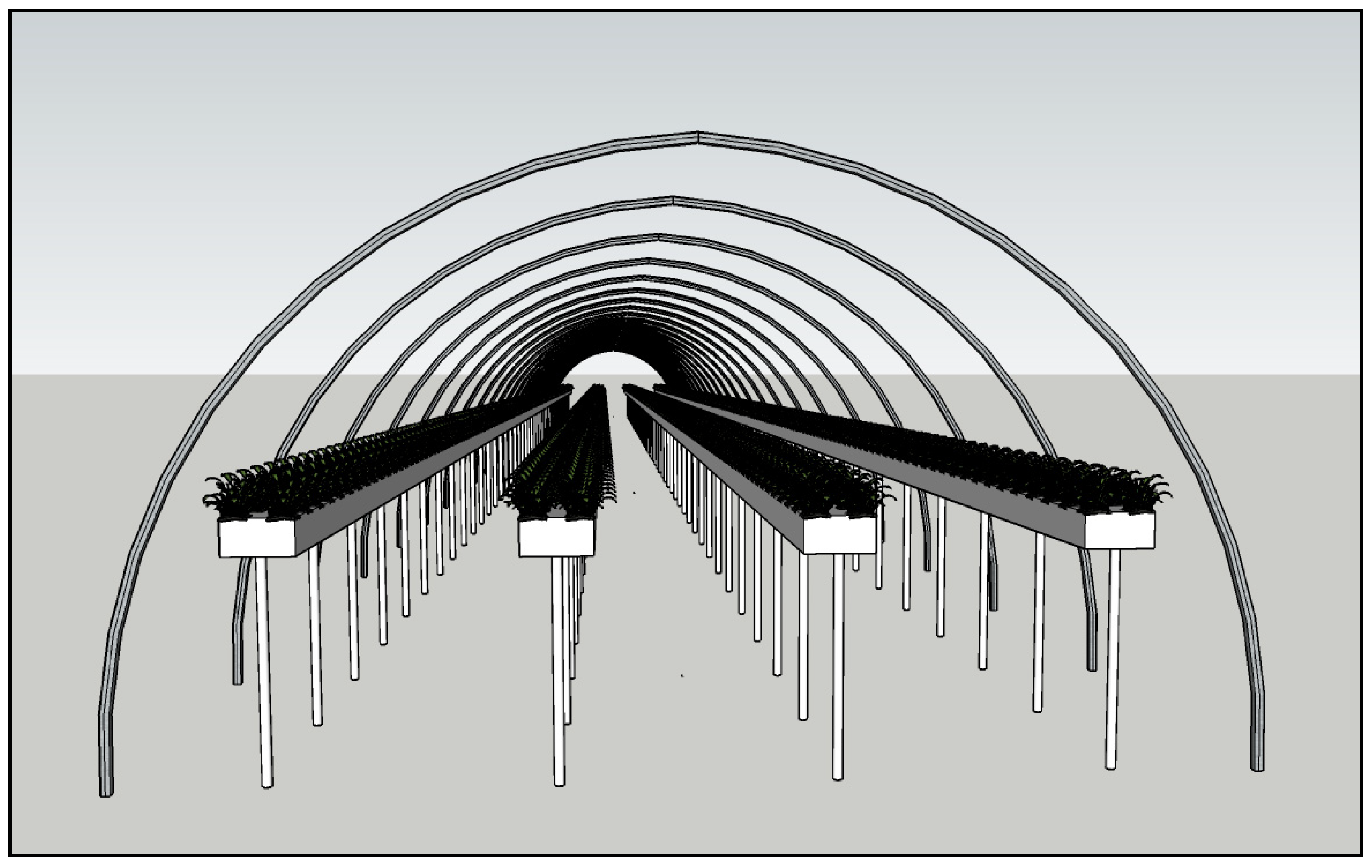

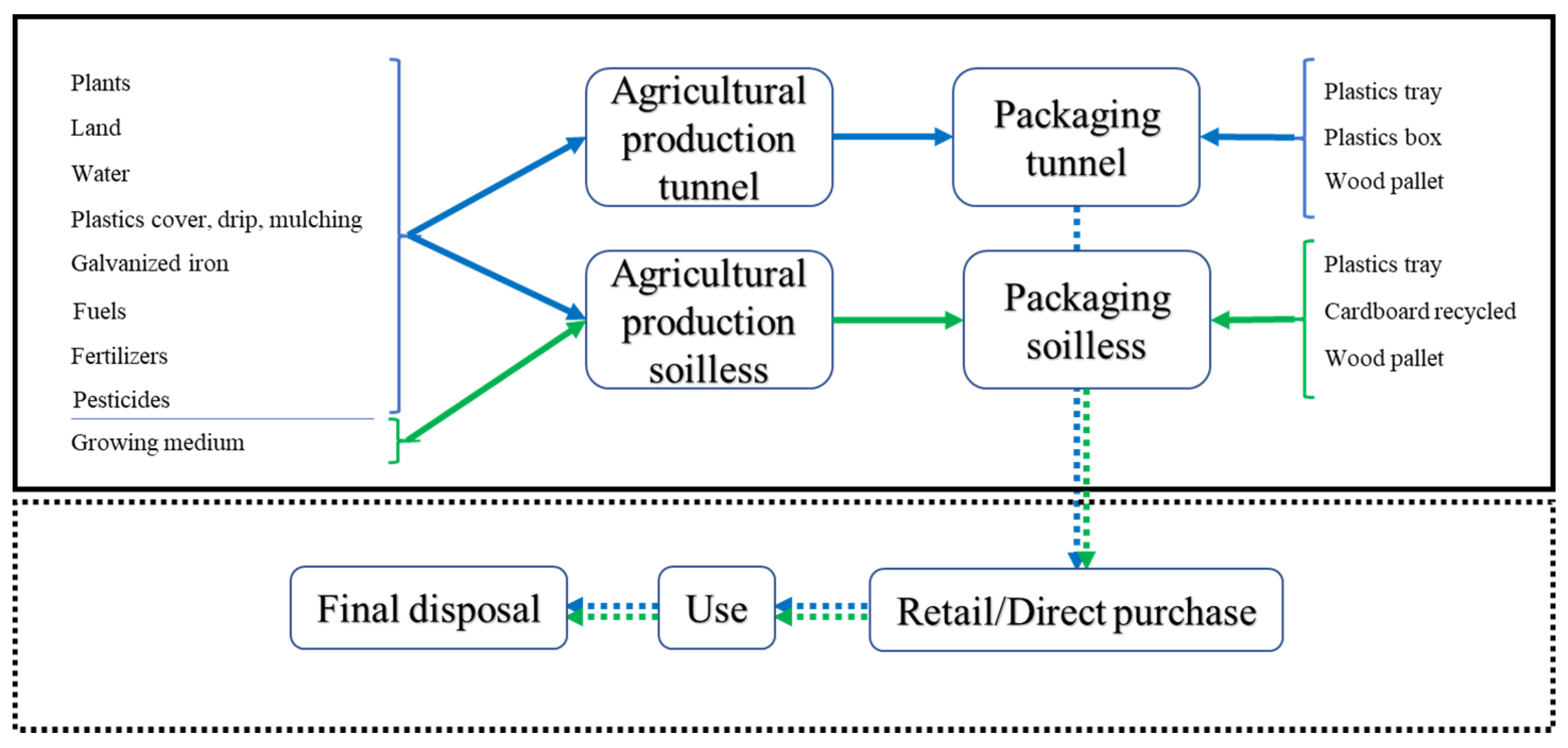

2.2. System Description

2.3. System Function, Functional Unit, and Reference Flow

2.4. Calculations, Allocation, and Emission Models

2.5. LCIA Method and Software

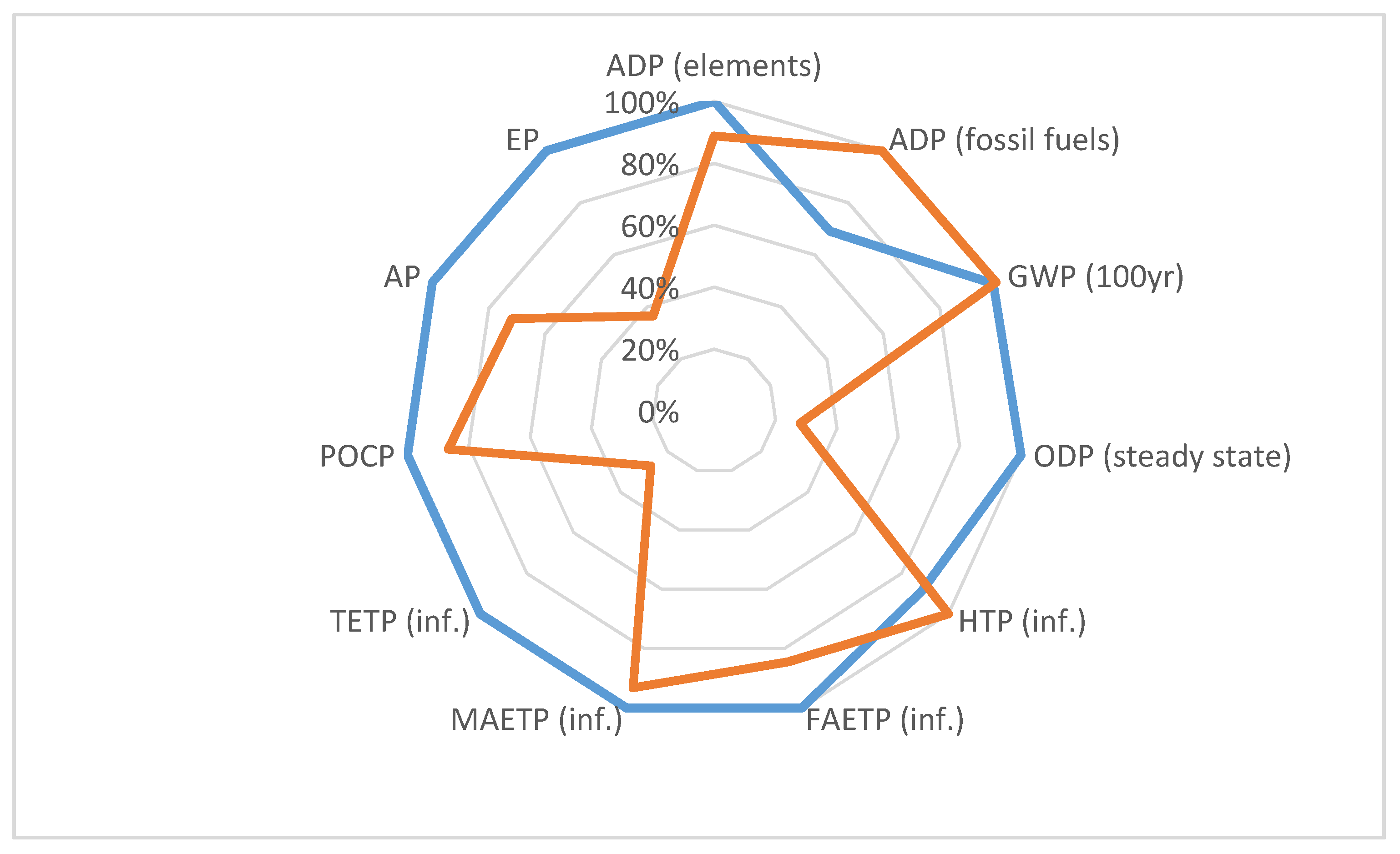

3. Results

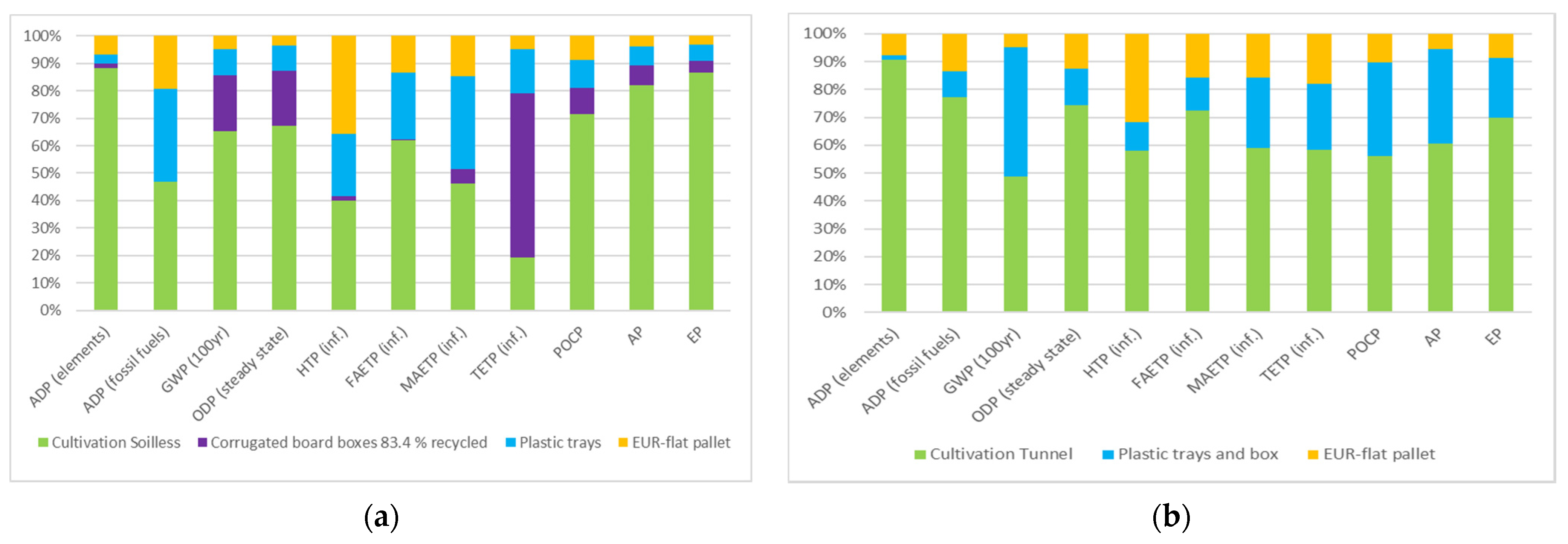

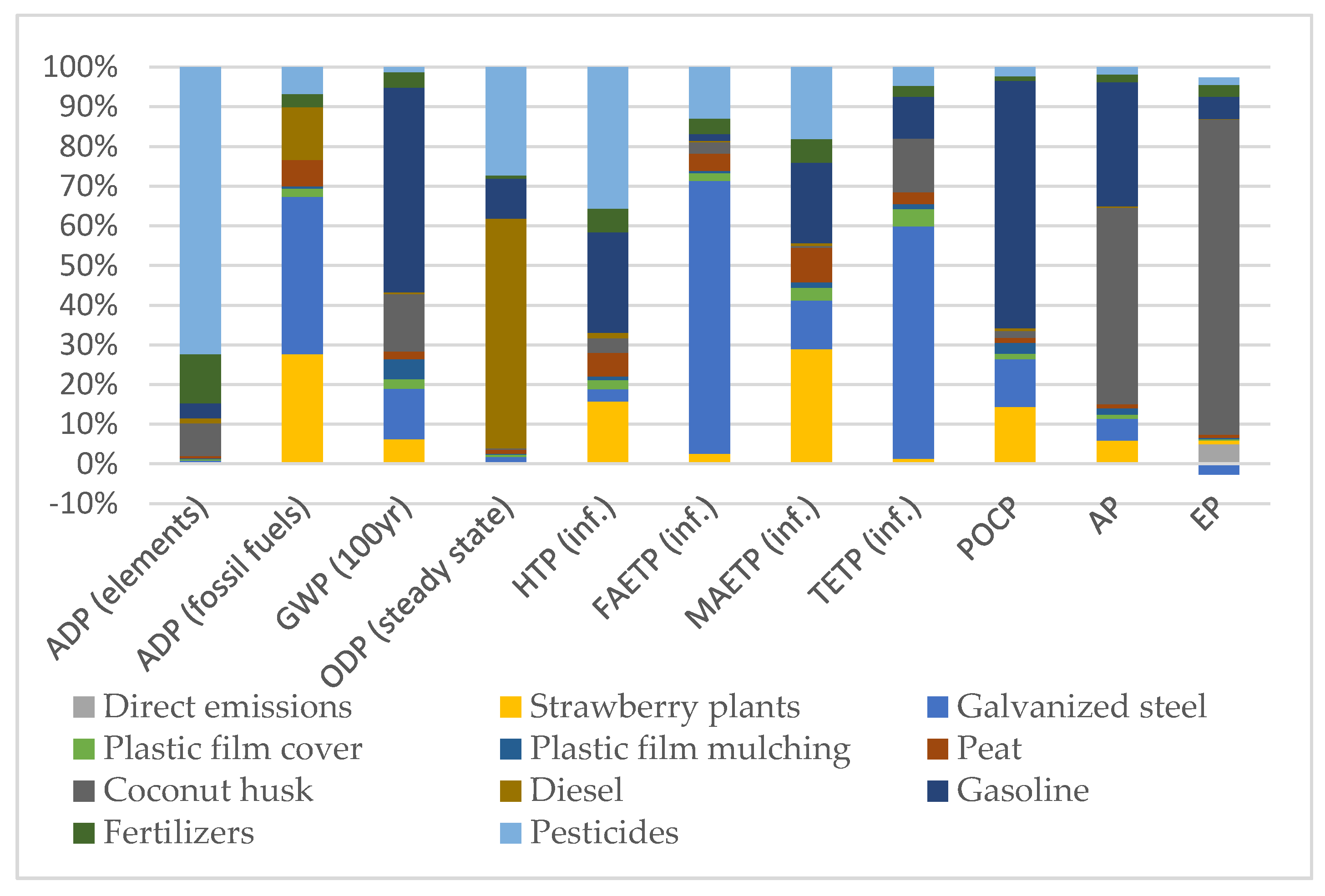

Contribution Analysis

4. Discussions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IPCC. Climate Change 2013 the Physical Science Basis; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; p. 1535. [Google Scholar]

- United Nations Environment Programme. Emissions Gap Report 2019; UNEP: Nairobi, Kenya, 2019. [Google Scholar]

- United Nations. Emissions Gap Emissions Gap Report 2020; UNEP: Nairobi, Kenya, 2020. [Google Scholar]

- UNEP. The Six Sector Solution to Climate Change n.d. Available online: https://www.unep.org/interactive/six-sector-solution-climate-change/ (accessed on 3 March 2021).

- Drew, J.; Cleghorn, C.; Macmillan, A.; Mizdrak, A. Healthy and Climate-Friendly Eating Patterns in the New Zealand Context. Environ. Heal Perspect. 2020, 128, 017007. [Google Scholar] [CrossRef]

- Unioncamere. Consumatori Sempre più Attenti Alla Sostenibilità 2011. Available online: http://www.unioncamere.gov.it/csr/P42A177C154S153/Consumatori-sempre-piu-attenti-alla-sostenibilita.htm (accessed on 3 March 2021).

- Mipaaf. Dati Biologico 2018. 2018. Available online: https://www.politicheagricole.it/flex/cm/pages/ServeBLOB.php/L/IT/IDPagina/14394 (accessed on 3 March 2021).

- Khoshnevisan, B.; Shariati, H.M.; Rafiee, S.; Mousazadeh, H. Comparison of energy consumption and GHG emissions of open field and greenhouse strawberry production. Renew. Sustain. Energy Rev. 2014, 29, 316–324. [Google Scholar] [CrossRef]

- Eren, O.; Baran, M.F.; Gokdogan, O. Determination of greenhouse gas emissions (GHG) in the production of different fruits in Turkey. Fresenius Environ. Bull. 2019, 28, 464–472. [Google Scholar]

- Andreotti, C.; Antoniacci, L.; Aranda, J.L.; Babini, A.R.; Baruzzi, G.; Baudino, M. Fragola nel mondo, Coltura e Cultura; n.d. Available online: https://www.colturaecultura.it/content/fragola-nel-mondo (accessed on 25 April 2021).

- Giampieri, F.; Forbes-Hernandez, T.Y.; Gasparrini, M.; Alvarez-Suarez, J.M.; Afrin, S.; Bompadre, S.; Quiles, J.L.; Mezzetti, B.; Battino, M. Strawberry as a Health Promoter: An Evidence Based Review. Food Funct. 2015, 6, 1386–1398. [Google Scholar] [CrossRef]

- Mazzoni, L.; Giampieri, F.; Suarez, J.M.A.; Gasparrini, M.; Mezzetti, B.; Hernandez, T.Y.F.; Battino, M.A. Isolation of strawberry anthocyanin-rich fractions and their mechanisms of action against murine breast cancer cell lines. Food Funct. 2019, 10, 7103–7120. [Google Scholar] [CrossRef] [PubMed]

- ISMEA. FILIERA FRUTTA FRESCA: Scheda di settore. 2020. Available online: http://www.ismeamercati.it/flex/cm/pages/ServeAttachment.php/L/IT/D/2%252F4%252Fb%252FD.5f56e7f9a5d8ff6e87d9/P/BLOB%3AID%3D3508/E/pdf (accessed on 25 April 2021).

- Holt, R.R.; Zuelch, M.L.; Charoenwoodhipong, P.; Al-Dashti, Y.A.; Hackman, R.M.; Keen, C.L. Effects of short-term consumption of strawberry powder on select parameters of vascular health in adolescent males. Food Funct. 2020, 11, 32–44. [Google Scholar] [CrossRef]

- Tabatabaie, S.M.H.; Murthy, G.S. Cradle to farm gate life cycle assessment of strawberry production in the United States. J. Clean. Prod. 2016, 127, 548–554. [Google Scholar] [CrossRef]

- Valiante, D.; Sirtori, I.; Cossa, S.; Corengia, L.; Pedretti, M.; Cavallaro, L.; Vignoli, L.; Galvagni, A.; Gomarasca, S.; Pesce, G.R.; et al. Environmental impact of strawberry production in Italy and Switzerland with different cultivation practices. Sci. Total. Environ. 2019, 664, 249–261. [Google Scholar] [CrossRef]

- Fritegotto, S. Fragola, coltivare in Sicilia con la tecnica del fuori suolo 2017. Available online: https://coltureprotette.edagricole.it/orticoltura/coltivare-sicilia-la-tecnica-del-suolo/ (accessed on 25 April 2021).

- Song, L.; Zhong, Z.; Han, Y.; Zheng, Q.; Qin, Y.; Wu, Q.; He, X.; Pan, C. Dissipation of sixteen pesticide residues from various applications of commercial formulations on strawberry and their risk assessment under greenhouse conditions. Ecotoxicol. Environ. Saf. 2020, 188, 109842. [Google Scholar] [CrossRef] [PubMed]

- Ilari, A.; Duca, D. Energy and environmental sustainability of nursery step finalized to “fresh cut” salad production by means of LCA. Int. J. Life Cycle Assess. 2018, 23, 800–810. [Google Scholar] [CrossRef]

- ISTAT. I.Stat, Data And Microdata on Horticultural Cultivation (Strawberry 2016–2019); Istituto nazionale di statistica: Rome, Italy, 2020. [Google Scholar]

- Muley, A.B.; Singhal, R.S. Extension of postharvest shelf life of strawberries (Fragaria ananassa) using a coating of chitosan-whey protein isolate conjugate. Food Chem. 2020, 329, 127213. [Google Scholar] [CrossRef] [PubMed]

- Rivas-Martínez, S.; Rivas-Sáenz, S.; Penas-Merino, A. Worldwide bioclimatic classification system. Glob Geobot 2011, 1, 1–638. [Google Scholar]

- ISO. ISO 14044-2006, Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. ISO 14040-2006, Environmental Management—Life cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Rilegno. Rapporto 2018. Available online: http://www.rilegno.org/wp-content/uploads/2018/08/Rapporto-2018-completo.pdf (accessed on 25 April 2021).

- Boulard, T.; Raeppel, C.; Brun, R.; Lecompte, F.; Hayer, F.; Carmassi, G.; Gaillard, G. Environmental impact of greenhouse tomato production in France. Agron. Sustain. Dev. 2011, 31, 757–777. [Google Scholar] [CrossRef]

- Antón, A.; Castells, F.; Montero, J.; Huijbregts, M. Comparison of toxicological impacts of integrated and chemical pest management in Mediterranean greenhouses. Chemosphere 2004, 54, 1225–1235. [Google Scholar] [CrossRef] [PubMed]

- Sedilot, C.; Degas, L.; Le Quillec, S.; Brajeul, E.; Grasselly, D. Management of greenhouse effluents: A status report for France. Infos-Ctifl 2002, 181, 50–52. [Google Scholar]

- Lecompte, F.; Bressoud, F.; Pares, L.; De Bruyne, F. Root and nitrate distribution as related to the critical plant N status of a fertigated tomato crop. J. Hortic. Sci. Biotechnol. 2008, 83, 223–231. [Google Scholar] [CrossRef]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment; Operational guide to the ISO standards. I: LCA in perspective. IIa: Guide. IIb: Operational annex. III: Scientific background; Kluwer Academic Publishers: Dordrecht, Holland, 2002. [Google Scholar]

- Cerutti, A.K.; Beccaro, G.L.; Bruun, S.; Bosco, S.; Donno, D.; Notarnicola, B.; Bounous, G. Life cycle assessment application in the fruit sector: State of the art and recommendations for environmental declarations of fruit products. J. Clean. Prod. 2014, 73, 125–135. [Google Scholar] [CrossRef]

- van Oers, L.; de Koning, A.; Guinée, J.B.; Huppes, G. Abiotic Resource Depletion in LCA—As an Illustrative the Extraction Rates of 14 Minerals Were Compared to Their Stocks in the Natural Environment (thus Excluding Stocks in the Economy). Mineral Stocks Were Here Defined in Three Different Ways: 2002:75. Available online: https://www.leidenuniv.nl/cml/ssp/projects/lca2/report_abiotic_depletion_web.pdf (accessed on 25 April 2021).

- Myhre, G.; Shindell, D.; Bréon, F.-M.; Collins, W.; Fuglestvedt, J.; Huang, J.; Koch, D.; Lamarque, J.-F.; Lee, D.; Mendoza, B.; et al. 2013: Anthropogenic and Natural Radiative Forcing. In Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F., Qin, D., Plattner, G.-K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013. [Google Scholar]

- WMO. Scientific assessment of ozone depletion: 2003. In Global Ozone Research and Monitoring Project—Report No. XX; WMO: Geneva, Switzerland, 2003. [Google Scholar]

- Huijbregts, M.; Thissen, U.; Guinée, J.; Jager, T.; Kalf, D.; Van De Meent, D.; Ragas, A.; Sleeswijk, A.W.; Reijnders, L. Priority assessment of toxic substances in life cycle assessment. Part I: Calculation of toxicity potentials for 181 substances with the nested multi-media fate, exposure and effects model USES-LCA. Chemosphere 2000, 41, 541–573. [Google Scholar] [CrossRef]

- E Jenkin, M.; Hayman, G.D. Photochemical ozone creation potentials for oxygenated volatile organic compounds: Sensitivity to variations in kinetic and mechanistic parameters. Atmos. Environ. 1999, 33, 1275–1293. [Google Scholar] [CrossRef]

- Derwent, R.G.; Jenkin, M.E.; Saunders, S.M.; Pilling, M.J. Photochemical ozone creation potentials for organic compounds in northwest Europe calculated with a master chemical mechanism. Atmos. Environ. 1998, 32, 2429–2441. [Google Scholar] [CrossRef]

- Huijbregts, M. Life-Cycle Impact Assessment of Acidifying and Eutrophying Air Pollutants 1999. Available online: https://p2infohouse.org/ref/37/36502.pdf (accessed on 25 April 2021).

- Khoshnevisan, B.; Rafiee, S.; Mousazadeh, H. Environmental impact assessment of open field and greenhouse strawberry production. Eur. J. Agron. 2013, 50, 29–37. [Google Scholar] [CrossRef]

- Peano, C.; Baudino, C.; Tecco, N.; Girgenti, V. Green marketing tools for fruit growers associated groups: Application of the Life Cycle Assessment (LCA) for strawberries and berry fruits ecobranding in northern Italy. J. Clean. Prod. 2015, 104, 59–67. [Google Scholar] [CrossRef]

- Gunady, M.G.; Biswas, W.; Solah, V.A.; James, A.P. Evaluating the global warming potential of the fresh produce supply chain for strawberries, romaine/cos lettuces (Lactuca sativa), and button mushrooms (Agaricus bisporus) in Western Australia using life cycle assessment (LCA). J. Clean. Prod. 2012, 28, 81–87. [Google Scholar] [CrossRef]

- Yoshikawa, N.; Amano, K.; Shimada, K. Evaluation of environmental load on friuts and vegetables consumption and its reduction potential. Environ. Syst. Res. 2007, 35, 499–509. [Google Scholar] [CrossRef]

- Mertenat, A.; Diener, S.; Zurbrügg, C. Black Soldier Fly biowaste treatment—Assessment of global warming potential. Waste Manag. 2019, 84, 173–181. [Google Scholar] [CrossRef] [PubMed]

| (a) Life cycle inventory table for mulched soil tunnel production (all data are expressed per the functional unit of 1 kg of fresh packed strawberry). | ||||

| Input/Output | Tunnel | Description/Compartment | ||

| Plants (p) | 1.25 | |||

| Land occupation (ha) | 2.08 × 10−5 | |||

| Plastics PE (kg) 1 | 1.35 × 10−2 | Greenhouse | ||

| Galvanized iron (kg) 1 | 1.27 × 10−2 | |||

| Mulching film/bag (kg) 1 | 1.32 × 10−2 | Mulching film | ||

| Drip irrigation pipes (kg) 1 | 1.25 × 10−2 | Irrigation | ||

| Field operations diesel (l) | 6.67 × 10−3 | |||

| Mulching film laying diesel (l) | 4.17 × 10−3 | Field operations | ||

| Water (m3) | 8.77 × 10−1 | Irrigation | ||

| Plastic tray (RPET) (kg) 3 | 1.60 × 10−2 | |||

| Plastic box (HDPE) (kg) | 7.50 × 10−2 | |||

| Wood pallet EPAL 1200 × 800 (p) 3 | 3.46 × 10−3 | Packaging | ||

| Wood pallet EPAL 1200 × 800 (kg) 3 | 8.53 × 10−2 | |||

| Nails pallet EPAL 90 mm (kg) 3 | 2.23 × 10−2 | |||

| Nails pallet EPAL 70 mm (kg) 3 | 1.74 × 10−2 | |||

| Nails pallet EPAL 55 mm (kg) 3 | 9.25 × 10−3 | |||

| Pesticide1 (kg) | 1.14 × 10−5 | Spinosad | 5.00 × 10−6 | |

| Pesticide2 (kg) | 2.50 × 10−4 | Bacillus subtilis | 3.92 × 10−6 | |

| Pesticide3 (l) | 2.31 × 10−5 | Azoxystrobin | 5.20 × 10−6 | |

| Pesticide4 (kg) | 3.34 × 10−5 | Cyprodinil | 1.25 × 10−5 | |

| Fludioxonil | 8.32 × 10−6 | |||

| Pesticide5 (l) | 1.03 × 10−5 | Penconazole | 1.04 × 10−6 | Plant protection products |

| Pesticide6 (l) | 8.56 × 10−5 | Sulfur | 4.38 × 10−5 | |

| Pesticide7 (l) | 1.00 × 10−5 | Clofentezine | 4.16 × 10−6 | |

| Pesticide8 (l) | 1.59 × 10−5 | Penconazole | 3.00 × 10−7 | |

| Water for pesticides (m3) 4 | 1.67 × 10−4 | |||

| Organic nitrogen fertilizer (kg) 4 | 5.56 × 10−2 | 7-2/3-1/2 NPK | ||

| Ammonium nitrate and Isobutylidenediurea (IBDU) fertilizer (kg) 4 | 2.78 × 10−2 | 15-9-15 NPK | ||

| Ammonium and ureic fertilizer (kg) 4 | 3.09 × 10−3 | 10-52-10 NPK | ||

| Ammonium nitrate and ureic fertilizer(kg) 4 | 3.09 × 10−3 | 20-20-20 NPK | Fertilizers (solid) | |

| Ammonium nitrate fertilizer(kg) 4 | 1.53 × 10−3 | 12-30-12 NPK | ||

| Ammonium nitrate fertilizer(kg) 4 | 1.24 × 10−2 | 10-10-30/23-6-10 NPK | ||

| Ammonium nitrate fertilizer(kg) 4 | 2.28 × 10−3 | 16-5-25 NPK | ||

| Calcium nitrate (kg) 4 | 1.03 × 10−3 | 15.5 N | ||

| (b) Life cycle inventory table for soilless tunnel production (all data are expressed per the functional unit of 1 kg of fresh packed strawberry). | ||||

| Input/Output | Soilless | Description/Compartment | ||

| Plants (p) | 1.33 | |||

| Land occupation (ha) | 1.33 × 10−5 | |||

| Plastics PE (kg) 1 | 4.80 × 10−3 | Greenhouse | ||

| Galvanized iron (kg) 1 | 2.02 × 10−2 | |||

| Mulching film/bag (kg) 1 | 1.33 × 10−2 | Growing bag | ||

| Peat 60% (kg) 2 | 4.00 × 10−1 | Growing medium | ||

| Coconut fiber 40% (kg) 2 | 2.67 × 10−1 | |||

| Field operations diesel (l) | 4.27 × 10−3 | |||

| Field operations petrol (l) | 3.84 × 10−3 | |||

| Water (m3) | 3.45 × 10−1 | Irrigation | ||

| Plastic tray (RPET) (kg) 3 | 4.00 × 10−2 | |||

| Recycled cardboard (kg) 3 | 1.40 × 10−1 | |||

| Wood pallet EPAL 1200 × 800 (p) 3 | 3.46 × 10−3 | Packaging | ||

| Wood pallet EPAL 1200 × 800 (kg) 3 | 8.53 × 10−2 | |||

| Nails pallet EPAL 90 mm (kg) 3 | 2.23 × 10−2 | |||

| Nails pallet EPAL 70 mm (kg) 3 | 1.74 × 10−2 | |||

| Nails pallet EPAL 55 mm (kg) 3 | 9.25 × 10−3 | |||

| Pesticide1 (l) 5 | 1.79 × 10−5 | Acetamiprid | 8.34 × 10−7 | |

| Pesticide2 (kg) 5 | 6.27 × 10−5 | Boscalid | 1.19 × 10−5 | |

| Pyraclostrobin | 2.99 × 10−6 | |||

| Pesticide3 (l) 5 | 9.99 × 10−6 | Bifenazate | 4.36 × 10−6 | |

| Pesticide4 (l) 5 | 9.31 × 10−6 | Piretrina | 3.56 × 10−7 | |

| Pesticide5 (l) 5 | 1.02 × 10−5 | Fluopyram | 2.18 × 10−6 | |

| Trifloxystrobin | 2.18 × 10−6 | |||

| Pesticide6 (l) 5 | 2.74 × 10−5 | Sulfur | 1.40 × 10−5 | |

| Pesticide7 (l) 5 | 1.40 × 10−5 | Bupirimate | 3.34 × 10−6 | |

| Pesticide8 (kg) 5 | 2.14 × 10−5 | Azoxystrobin | 5.32 × 10−6 | |

| Pesticide9 (kg) 5 | 2.14 × 10−5 | Cyprodinil | 8.00 × 10−6 | Plant protection products |

| Fludioxonil | 5.32 × 10−6 | |||

| Pesticide10 (kg) 5 | 1.33 × 10−4 | Potassium bicarbonate | 5.66 × 10−5 | |

| Pesticide11 (kg) 5 | 4.00 × 10−6 | Tau-fluvalinate | 9.60 × 10−7 | |

| Pesticide12 (l) 5 | 6.57 × 10−6 | Penconazole | 6.66 × 10−7 | |

| Pesticide13 (l) 5 | 8.45 × 10−6 | Quinoxyfen | 3.48 × 10−7 | |

| Myclobutanil | 3.48 × 10−7 | |||

| Pesticide14 (l) 5 | 9.60 × 10−6 | Clofentezine | 4.00 × 10−6 | |

| Pesticide15 (l) 5 | 7.25 × 10−5 | Copper | 1.45 × 10−5 | |

| Pesticide16 (l) 5 | 1.34 × 10−4 | Potassium salts of fatty acids | 6.40 × 10−5 | |

| Pesticide17 (l) 5 | 2.17 × 10−5 | Azadirachtin A | 5.20 × 10−7 | |

| Water for pesticides (m3) 5 | 2.37 × 10−4 | |||

| Nitric acid (kg) 5 | 3.60 × 10−3 | |||

| Calcium ammonium nitrate (kg) 5 | 5.47 × 10−3 | |||

| Single superphosphate (kg) 5 | 5.47 × 10−3 | Fertilizers (soluble) | ||

| Potassium sulfate (kg) 5 | 2.27 × 10−3 | |||

| Magnesium sulfate (kg) 5 | 8.00 × 10−4 | |||

| Category | Unit | Soilless | Tunnel |

|---|---|---|---|

| ADP (elements) | kg Sb eq | 1.72 × 10−6 | 1.52 × 10−6 |

| ADP (fossil fuels) | MJ eq | 3.46 | 5.01 |

| GWP (100yr) | kg CO2 eq | 7.85 × 10−1 | 7.78 × 10−1 |

| ODP (steady state) | kg CFC-11 eq | 5.62 × 10−8 | 1.57 × 10−8 |

| HTP (inf.) | kg 1,4-DB eq | 1.13 × 10−1 | 1.28 × 10−1 |

| FAETP (inf.) | kg 1,4-DB eq | 8.09 × 10−2 | 6.83 × 10−2 |

| MAETP (inf.) | kg 1,4-DB eq | 2.38 × 102 | 2.22 × 102 |

| TETP (inf.) | kg 1,4-DB eq | 6.43 × 10−4 | 1.74 × 10−4 |

| POCP | kg C2H2 eq | 2.90 × 10−4 | 2.52 × 10−4 |

| AP | kg SO2 eq | 6.20 × 10−3 | 4.45 × 10−3 |

| EP | kg PO43- eq | 2.05 × 10−3 | 7.48 × 10−4 |

| Category | Unit | Cultivation Soilless | Corrugated Board Boxes 83.4% Recycled | Plastic Trays | EUR-Flat Pallet |

|---|---|---|---|---|---|

| ADP (elements) | % | 88.2 | 1.7 | 3.3 | 6.7 |

| ADP (fossil fuels) | % | 46.8 | 0.0 | 33. 8 | 19.4 |

| GWP (100 yr) | % | 65.2 | 20.5 | 9.3 | 4.9 |

| ODP (steady state) | % | 67.2 | 20.2 | 9.1 | 3.5 |

| HTP (inf.) | % | 39.9 | 1.6 | 22. 7 | 35.8 |

| FAETP (inf.) | % | 61.9 | 0.3 | 24.5 | 13.3 |

| MAETP (inf.) | % | 46.2 | 5.1 | 34.1 | 14.6 |

| TETP (inf.) | % | 19.3 | 59.9 | 15.9 | 4.9 |

| POCP | % | 71.4 | 9.7 | 10.1 | 8.9 |

| AP | % | 82.2 | 6.9 | 7.0 | 4.0 |

| EP | % | 86.5% | 4.5% | 5.8% | 3.2% |

| Category | Unit | Cultivation Tunnel | Plastic Trays and Box | EUR-Flat Pallet |

|---|---|---|---|---|

| ADP (elements) | % | 90.6 | 1.8 | 7.6 |

| ADP (fossil fuels) | % | 77.3 | 9.3 | 13.4 |

| GWP (100 yr) | % | 48.7% | 46.3% | 5.0% |

| ODP (steady state) | % | 74.4 | 13.0 | 12.5 |

| HTP (inf.) | % | 58.1 | 10.1 | 31. 8 |

| FAETP (inf.) | % | 72.6 | 11.7 | 15. 8 |

| MAETP (inf.) | % | 59.0 | 25.4 | 15.6 |

| TETP (inf.) | % | 58.4 | 23.6 | 18.1 |

| POCP | % | 56.0% | 33.8% | 10.2% |

| AP | % | 60.5% | 34.0% | 5.5% |

| EP | % | 69.9% | 21.3% | 8.8% |

| Reference | Country | Crop | Production System | Growing Cycle | kg CO2 eq/kg Fresh Product |

|---|---|---|---|---|---|

| Valiante et al., 2019 [16] | CH | strawberry | GH | 1yr | 1.868 |

| strawberry | |||||

| Valiante et al., 2019 [16] | IT | strawberry | OF | 2yr | 0.182 |

| strawberry | 3 yr | 0.212 | |||

| Khoshnevisan et al., 2013 [39] | IR | strawberry | GH (tunnel) | 1yr | 0.585 |

| strawberry | OF | 1yr | 0.695 | ||

| Khoshnevisan et al., 2014 [8] | IR | strawberry | GH (tunnel) | 0.484 | |

| strawberry | OF | 0.147 | |||

| Peano et al., 2015 [40] | IT | strawberry | OF | 1yr | 0.324 |

| raspberry | OF | 1yr | 0.192 | ||

| blueberry | OF | 1yr | 0.168 | ||

| Tabatabaie et al., 2016 [15] | US | strawberry California | 1.75 | ||

| strawberry Florida | 2.5 | ||||

| strawberry North Carolina | 5.48 | ||||

| strawberry Oregon | 2.21 | ||||

| Gunady et al., 2012 [41] | AU | strawberry | OF | 2.23 | |

| Yoshikawa et al., 2008 [42] | JP | strawberry | GH | 4.8 | |

| Current study | IT | strawberry | Tunnel | 0.778 | |

| Current study | IT | strawberry | Tunnel soilless | 0.785 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilari, A.; Toscano, G.; Boakye-Yiadom, K.A.; Duca, D.; Foppa Pedretti, E. Life Cycle Assessment of Protected Strawberry Productions in Central Italy. Sustainability 2021, 13, 4879. https://doi.org/10.3390/su13094879

Ilari A, Toscano G, Boakye-Yiadom KA, Duca D, Foppa Pedretti E. Life Cycle Assessment of Protected Strawberry Productions in Central Italy. Sustainability. 2021; 13(9):4879. https://doi.org/10.3390/su13094879

Chicago/Turabian StyleIlari, Alessio, Giuseppe Toscano, Kofi Armah Boakye-Yiadom, Daniele Duca, and Ester Foppa Pedretti. 2021. "Life Cycle Assessment of Protected Strawberry Productions in Central Italy" Sustainability 13, no. 9: 4879. https://doi.org/10.3390/su13094879

APA StyleIlari, A., Toscano, G., Boakye-Yiadom, K. A., Duca, D., & Foppa Pedretti, E. (2021). Life Cycle Assessment of Protected Strawberry Productions in Central Italy. Sustainability, 13(9), 4879. https://doi.org/10.3390/su13094879