Sustainable Ventilation Strategies for a Medium-Sized Space with Regional Effect

Abstract

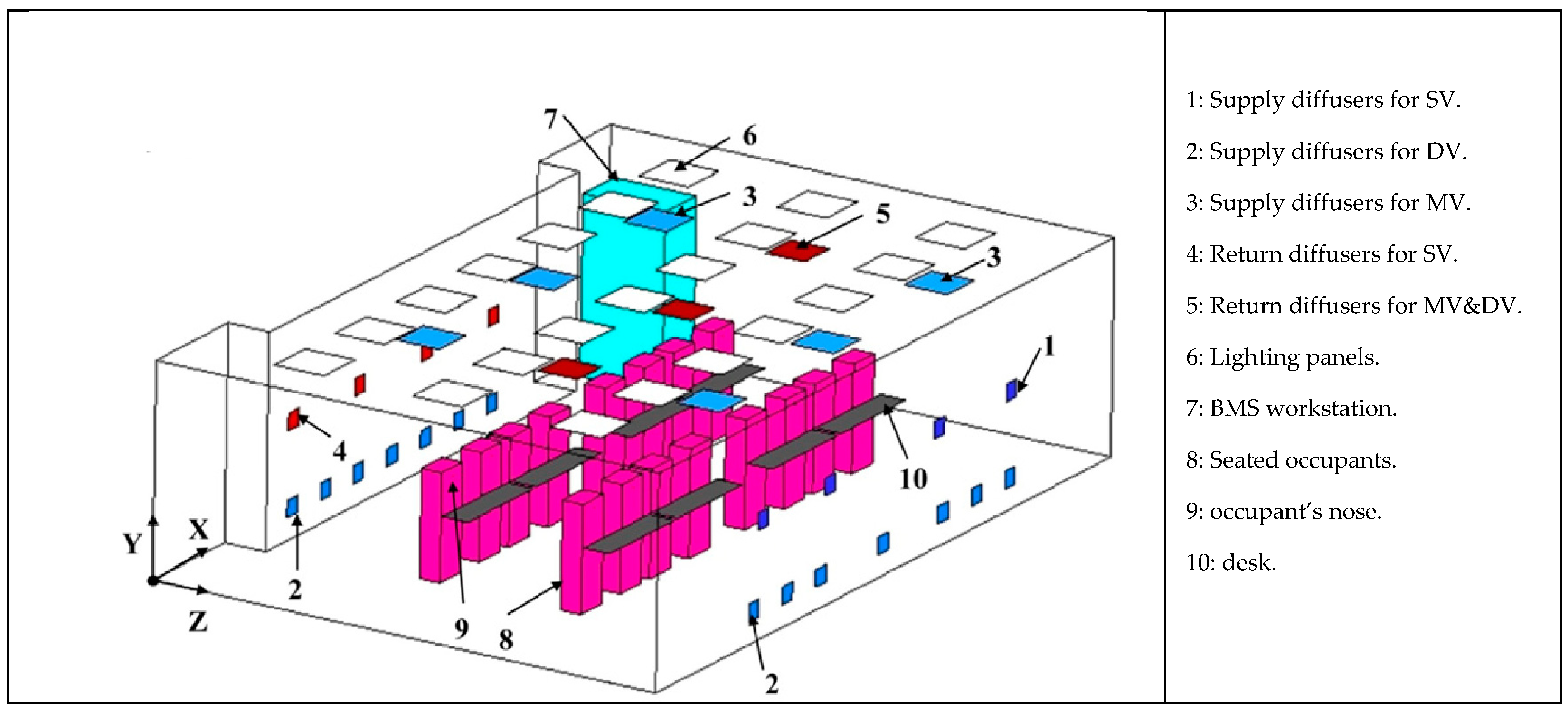

1. Regional Analysis for MV, DV, and SV

2. Research Methodology

2.1. Regional LCA Boundary for Comparison

2.2. Supply-and-Installation, Operation Phases in Various Regions

3. Regional Analysis for MV, DV, and SV

3.1. Supply-and-Installation Phase

3.1.1. Initial Cost

3.1.2. Cumulative Embedded Energy of Each System

3.2. Operation Phase

Energy Consumption of each system with regional effect

3.3. Regional LCA of Three Ventilation Systems for 20 Years

3.4. Regional LCC of three Ventilation Systems for 20 Service Years

- LCC (Yr-n): Total life-cycle cost in present value for n Service years.

- ICAHU: Initial cost for the AHU used in this study (See the items 1.1 to 1.7 in Table 1).

- ICDuct: Initial cost for the ductwork used in this study (See Table 1).

- OC: Operating cost for the selected ventilation system annually.

- MC: Maintenance cost for the selected ventilation system.

- n = number of service years in 5,10,15 & 20.

- I = annual discount rate, iHK & iGD = 0.025 (i.e., 2.5%) in HKSAR & Guangdong

- k = inflation rate, kHK = 0.023 (2.3%) in HKSAR, kGD = 0.0435 (4.35%) in Guangdong

4. Discussion

4.1. The Regional Effect in the Supply-and-Installation Phase

4.2. Regional Effect in the Operation Phase

4.3. Regional LCA and LCC

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AHU | Air handling Unit |

| CO2 | Carbon dioxide |

| DDC | Direct digital controller |

| DV | Displacement ventilation |

| DV(HK) | Displacement ventilation method in HKSAR |

| DV/MV(HK) | Percentage difference between DV in comparing with MV in HKSAR |

| DV(GD) | Displacement ventilation method in Guangdong |

| DV/MV(GD) | Percentage difference between DV in comparing with MV in Guangdong |

| ELCD | European Life Cycle Database |

| EMSD | Electrical and Mechanical Services Department |

| HKEPD | HKSAR Environmental Protection Department |

| HK$ | Hong Kong dollar |

| HKSAR | Hong Kong Special Administration Region |

| HVAC | Heating, ventilation and air conditioning |

| i | Annual discount rate (%) |

| IC | Initial cost (HK$) |

| ICE | Inventory of carbon & energy |

| k | Inflation rate (%) |

| LCA | Life cycle assessment |

| LCC | Life cycle cost |

| LCCDV(HK) | Life cycle cost of displacement ventilation method in HKSAR |

| LCCDV(GD) | Life cycle cost of displacement ventilation method in Guangdong |

| LCCDV/MV(HK) | Percentage difference between LCCDV(HK) in comparing with LCCMV(HK) in HKSAR |

| LCCDV/MV(GD) | Percentage difference between LCCDV(GD) in comparing with LCCMV(GD) in Guangdong |

| LCCMV(HK) | Life cycle cost of mixing ventilation method in HKSAR |

| LCCMV(GD) | Life cycle cost of mixing ventilation method in Guangdong |

| LCCSV(HK) | Life cycle cost of stratum ventilation method in HKSAR |

| LCCSV(GD) | Percentage difference between LCCSV(GD) in comparing with LCCMV(GD) in Guangdong |

| LCCSV/MV(HK) | Percentage difference between LCCSV(HK) in comparing with LCCMV(HK) in HKSAR |

| LCCSV/MV(GD) | Percentage difference between LCCSV(GD) in comparing with LCCMV(GD) in Guangdong |

| LCI | Life cycle inventory |

| LEED | Leadership in energy and environmental design |

| n | Number of years |

| PV | Present value |

| SAG | SAG Supply air grille |

| SV | Stratum ventilation |

| SV(HK) | Stratum ventilation in HKSAR |

| SV(GD) | Stratum ventilation in Guangdong |

| SV/MV(HK) | Percentage difference between DV in comparing with MV in HKSAR |

| SV/MV(GD) | Percentage difference between DV in comparing with MV in Guangdong |

| RAL | Return air louvre |

| MC | Maintenance cost (HK$) |

| NPV | Net Present value |

| OC | Operation cost (HK$) |

| TRNSYS | TRaNsient system simulation |

| USEPA | United states environmental protection agency |

References

- Cubi, E.; Doluweera, G.; Bergerson, J. Incorporation of electricity GHG emissions intensity variability into building environmental assessment. Appl. Energy 2015, 159, 62–69. [Google Scholar] [CrossRef]

- Xiao, H.; Wei, Q.; Jiang, Y. The reality and statistical distribution of energy consumption in office buildings in China. Energy Build. 2012, 50, 259–265. [Google Scholar] [CrossRef]

- IPCC Summary for Policymakers of IPCC Special Report on Global Warming of 1.5 °C Approved by Governments. Available online: https://www.ipcc.ch/2018/10/08/summary-for-policymakers-of-ipcc-special-report-on-global-warming-of-1-5c-approved-by-governments/ (accessed on 3 February 2020).

- Outline of the 14th Five-Year Plan. For National Economic and Social Development of the People’s Republic of China; The government of the People’s Republic of China: Beijing, China, 2021.

- Dong, F.; Bian, Z.; Yu, B.; Wang, Y.; Zhang, S.; Li, J.; Su, B.; Long, R. Can land urbanization help to achieve CO2 intensity reduction target or hinder it? Evidence from China. Resour. Conserv. Recycl. 2018, 134, 206–215. [Google Scholar] [CrossRef]

- Wu, C.B.; Huang, G.H.; Xin, B.G.; Chen, J.K. Scenario analysis of carbon emissions’ anti-driving effect on Qingdao’s energy structure adjustment with an optimization model, Part I: Carbon emissions peak value prediction. J. Clean. Prod. 2018, 172, 466–474. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Dong, F.; Hua, Y.; Yu, B. Peak carbon emissions in China: Status, key factors and countermeasures—A literature review. Sustainability 2018, 10, 2895. [Google Scholar] [CrossRef]

- Dong, F.; Wang, Y.; Su, B.; Hua, Y.; Zhang, Y. The process of peak CO2 emissions in developed economies: A perspective of industrialization and urbanization. Resour. Conserv. Recycl. 2019, 141, 61–75. [Google Scholar] [CrossRef]

- Energy Saving Policy Plan for Hong Kong’s Built Environment 2015-2025+; Environment Bureau of HKSAR: Hong Kong, China, 2015.

- Kapsalaki, M.; Leal, V.; Santamouris, M. A methodology for economic efficient design of Net Zero Energy Buildings. Energy Build. 2012, 55, 765–778. [Google Scholar] [CrossRef]

- HKEMSD Hong Kong Energy End-use Data 2020. Available online: http://www.emsd.gov.hk/emsd/e_download/pee/HKEEUD2020.pdf (accessed on 1 April 2021).

- ISO. ISO 14040: Environmental management–Life Cycle Assessment—Principles and Framework; Int. Organ. Stand.: Geneva, Switzerland, 2006. [Google Scholar]

- Heinonen, J.; Säynäjoki, A.; Junnonen, J.M.; Pöyry, A.; Junnila, S. Pre-use phase LCA of a multi-story residential building: Can greenhouse gas emissions be used as a more general environmental performance indicator? Build. Environ. 2016, 95, 116–125. [Google Scholar] [CrossRef]

- Kajikawa, Y.; Inoue, T.; Goh, T.N. Analysis of building environment assessment frameworks and their implications for sustainability indicators. Sustain. Sci. 2011, 6, 233–246. [Google Scholar] [CrossRef]

- Leadership in Energy and Environmental Design (LEED). Available online: https://www.usgbc.org/leed (accessed on 3 February 2020).

- Building Research Establishment Environmental Assessment Method (BREEAM). Available online: https://www.breeam.com/ (accessed on 3 February 2020).

- Green Star in Australia. Available online: https://new.gbca.org.au/green-star/ (accessed on 3 February 2020).

- Life Cycle Assessment (LCA) and Life Cycle Cost (LCC) Tool for Commercial Building Developments in Hong Kong; Electrical and Mechanical Services Department of HKSAR: Hong Kong, China, 2006.

- Green Mark in Singapore. Available online: https://www.bca.gov.sg/greenmark/green_mark_buildings.html (accessed on 4 February 2020).

- Cole, R.J.; Valdebenito, M.J. The importation of building environmental certification systems: International usages of BREEAM and LEED. Build. Res. Inf. 2013, 41, 662–676. [Google Scholar] [CrossRef]

- Schweber, L. The effect of BREEAM on clients and construction professionals. Build. Res. Inf. 2013, 41, 129–145. [Google Scholar] [CrossRef]

- Hernandez, P.; Kenny, P. Development of a methodology for life cycle building energy ratings. Energy Policy 2011, 39, 3779–3788. [Google Scholar] [CrossRef]

- Consultancy Study on Life Cycle Energy Analysis of Building Construction—An. Introduction to Life Cycle energy Assessment (LCEA) of Building Deelopments, a Report Submitted by Ove Arup and Partners; Consultancy Agreement No. CAO L013; Electrical and Mechanical Services Department of HKSAR: Hong Kong, China, 2006.

- Fong, A.M.-L. A Study of Thermal Comfort and Cost Effectiveness of Stratum Ventilation; De Montfort University: Leicester, UK, 2014. [Google Scholar]

- Fong, M.L.; Lin, Z.; Fong, K.F.; Hanby, V.; Greenough, R. Life cycle assessment for three ventilation methods. Build. Environ. 2017, 116, 73–88. [Google Scholar] [CrossRef]

- Ecoinvent-Life Cycle Inventory Database. Available online: https://www.ecoinvent.org/database/database.html (accessed on 3 February 2020).

- European Reference Life Cycle Database (ELCD). Available online: https://eplca.jrc.ec.europa.eu/index.html#menu1 (accessed on 3 February 2020).

- eBalance User Manunal (Chinese Version 3.0); Integrated Knowledge for our Environment: Beijing, China, 2012.

- Ibn-Mohammed, T.; Greenough, R.; Taylor, S.; Ozawa-Meida, L.; Acquaye, A. Integrating economic considerations with operational and embodied emissions into a decision support system for the optimal ranking of building retrofit options. Build. Environ. 2014, 72, 82–101. [Google Scholar] [CrossRef]

- Han, G.; Srebric, J.; Enache-Pommer, E. Variability of optimal solutions for building components based on comprehensive life cycle cost analysis. Energy Build. 2014, 79, 223–231. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A. Life cycle primary energy analysis of residential buildings. Energy Build. 2010, 42, 210–220. [Google Scholar] [CrossRef]

- Bevington, R.; Rosenfeld, A.H. Energy for buildings and homes. Sci. Am. 1990, 263, 76–87. [Google Scholar] [CrossRef]

- Yuan, Y.; Jin, Z. Life cycle assessment of building energy in big-data era: Theory and framework. In Proceedings of the 2015 International Conference on Network and Information Systems for Computers, Wuhan, China, 23–25 January 2015. [Google Scholar]

- Lindberg, K.B.; Doorman, G.; Fischer, D.; Korpås, M.; Ånestad, A.; Sartori, I. Methodology for optimal energy system design of Zero Energy Buildings using mixed-integer linear programming. Energy Build. 2016, 127, 194–205. [Google Scholar] [CrossRef]

- Fong, M.L.; Lin, Z.; Fong, K.F.; Chow, T.T.; Yao, T. Evaluation of thermal comfort conditions in a classroom with three ventilation methods. Indoor Air 2011, 21, 231–239. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Gassó, S.; Forcada, N.; Roca, X.; Fuertes, A. A methodology for predicting the severity of environmental impacts related to the construction process of residential buildings. Build. Environ. 2009, 44, 558–571. [Google Scholar] [CrossRef]

- Sodagar, B.; Fieldson, R. Towards a sustainable construction practice. Constr. Inf. Q. 2007, 18, 76–82. [Google Scholar]

- Erlandsson, M.; Borg, M. Generic LCA-methodology applicable for buildings, constructions and operation services—today practice and development needs. Build. Environ. 2003, 38, 919–938. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Available online: https://www.epa.gov/aboutepa (accessed on 4 February 2020).

- Lin, Z.; Chow, T.T.; Tsang, C.F.; Fong, K.F.; Chan, L.S. Stratum ventilation—A potential solution to elevated indoor temperatures. Build. Environ. 2009, 44, 2256–2269. [Google Scholar] [CrossRef]

- Wang, X.; Lin, Z. An experimental investigation into the pull-down performances with different air distributions. Appl. Therm. Eng. 2015, 91, 151–162. [Google Scholar] [CrossRef]

- Cheng, Y.; Lin, Z. Experimental study of airflow characteristics of stratum ventilation in a multi-occupant room with comparison to mixing ventilation and displacement ventilation. Indoor Air 2015, 25, 662–671. [Google Scholar] [CrossRef]

- Chai, J.; Huang, P.; Sun, Y. Differential evolution-based system design optimization for net zero energy buildings under climate change. Sustain. Cities Soc. 2020, 55, 102037. [Google Scholar] [CrossRef]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Varun Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Wegener Sleeswijk, A. Regional LCA in a global perspective. A basis for spatially differentiated environmental life cycle assessment. Int. J. Life Cycle Assess. 2011, 16, 106–112. [Google Scholar] [CrossRef]

- Tabatabaie, S.M.H.; Bolte, J.P.; Murthy, G.S. A regional scale modeling framework combining biogeochemical model with life cycle and economic analysis for integrated assessment of cropping systems. Sci. Total Environ. 2018, 625, 428–439. [Google Scholar] [CrossRef] [PubMed]

- Klein, S.A. TRNSYS 17: A Transient System Simulation Program; Solar Energy Laboratory University: Wisconsin, MA, USA, 2010. [Google Scholar]

- Project Cost in Guangdong. Available online: https://gd.zjtcn.com/ (accessed on 4 February 2020).

- Planning and Management Office of Pearl River Delta urban agglomeration Comprehensive quota of installation works in Guangdong Province 2010. Available online: http://de.yusuan.com/page_content.asp?content=397 (accessed on 1 October 2020).

- Hong Kong Environmental Protection Department (HKEPD). Available online: https://www.epd.gov.hk/epd/mobile/english/environmentinhk/waste/waste_maincontent.html (accessed on 4 February 2020).

- Practice Note for Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers ADV-19; Building Department of HKSAR: Hong Kong, China, 2021.

- Athena Regional LCA Software Tools. Available online: http://www.athenasmi.org/our-software-data/lca-databases/ (accessed on 4 February 2020).

- The BEES (Building for Environmental and Economic Sustainability) Software. Available online: https://www.nist.gov/services-resources/software/bees (accessed on 4 February 2020).

- Envest 2 Environmental Impact Assessment & Whole Life. Available online: https://www.bregroup.com/products/tools/impact-lca/ (accessed on 4 February 2020).

- Fong, M.L.; Hanby, V.; Greenough, R.; Lin, Z.; Cheng, Y. Acceptance of thermal conditions and energy use of three ventilation strategies with six exhaust configurations for the classroom. Build. Environ. 2015, 94, 606–619. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort: Analysis and Application in Environmental Engineering; McGraw Hill: New York, NY, USA, 1972. [Google Scholar]

- ISO. ISO 7730: Ergonomics of the Thermal Environment Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- The American Society of Heat, Refrigerating and Air-Conditioning Engineers. Thermal Environmental Conditions for Human Occupancy; ASHRAE Stand.: Atlanta, GA, USA, 2013. [Google Scholar]

- Lee, C.K.; Fong, K.F.; Lin, Z.; Chow, T.T. Year-round energy saving potential of stratum ventilated classrooms with temperature and humidity control. HVACR Res. 2013, 19, 986–991. [Google Scholar] [CrossRef]

- Lin, Z.; Lee, C.K.; Fong, S.; Chow, T.T.; Yao, T.; Chan, A.L.S. Comparison of annual energy performances with different ventilation methods for cooling. Energy Build. 2011, 43, 130–136. [Google Scholar] [CrossRef]

- Hales, D. Renewables 2018 Global Status Report. Available online: https://opus.cloud.lib.uts.edu.au/bitstream/10453/142688/2/GSR2018_Full-Report_English.pdf (accessed on 1 April 2021).

| Item | General Description of Each Construction Materials | HKSAR | Guangdong | ||

|---|---|---|---|---|---|

| HK$/Unit | HK$ | RMB$/Unit | RMB$ | ||

| 1.1 | 1 × air handling unit completed 1 × 450 L/s supply air fan | 50,000 | 50,000 | 11,118 | 11,118 |

| 1.2 | 1 set of framework support for ceiling mounted AHU | 6000 | 6000 | 5000 | 5000 |

| 1.3 | 2 × duct silencers | 4000 | 8000 | 2000 | 4000 |

| 1.4 | 26 m chilled water pipework | 450 | 11,700 | 286 | 8580 |

| 1.5 | 20 m condensate drain pipework | 320 | 6400 | 161 | 3220 |

| 1.6 | 1 set of electrical power control | 50,000 | 50,000 | 40,000 | 40,000 |

| 1.7 | 1 set of Direct Digital Controller (DDC) control equipment completed with necessarily valves and sensors. | 70,000 | 70,000 | 43,637 | 43,637 |

| 2.1MV | 45 m2 air ductworks with accessories (for MV) | 300 | 13,500 | 131 | 5895 |

| 2.2MV | 45 m2 thermal insulation for air ductwork (for MV) | 180 | 8100 | 240 | 10,800 |

| 2.3MV | 6 × Supply Air Grille (For MV) | 460 | 2760 | 350 | 2100 |

| 2.4MV | 3 × Return Air Louver (For MV) | 507 | 1520 | 350 | 1050 |

| 3.1DV | 29 m2 air ductworks with accessories (for DV) | 300 | 8700 | 131 | 3930 |

| 3.2DV | 29 m2 thermal insulation for air ductwork (for DV) | 200 | 5800 | 240 | 7200 |

| 3.3DV | 8 × Supply Air Grille (for DV) | 230 | 1840 | 350 | 2800 |

| 3.4DV | 3 × Return Air Louver (for DV) | 310 | 930 | 350 | 1050 |

| 4.1SV | 43 m2 air ductworks with accessories (for SV) | 300 | 12,900 | 131 | 5633 |

| 4.2SV | 43 m2 thermal insulation for air ductwork (for SV) | 200 | 8600 | 232 | 9976 |

| 4.3SV | 4 × Supply Air Grille (for SV) | 277 | 1110 | 250 | 1000 |

| 4.4SV | 4 × Return Air Louver (for SV) | 350 | 1400 | 250 | 1000 |

| Initial Cost, IC (HK$) for three ventilation systems | |||||

| HKSAR | Guangdong *1 | ||||

| ICMV | Items of 1.1 + 1.2 + 1.3 + 1.4 + 1.5 +1. 6 + 1.7 + 2.1MV + 2.2MV + 2.3MV + 2.4MV: = | HK$227,980 (Base) *2 | RMB¥135,400 or HK$162,480 (Base) *2 [−28.73%] *3 | ||

| ICDV | Items of 1.1 + 1.2 + 1.3 + 1.4 + 1.5 + 1.6 + 1.7 + 3.1DV + 3.2DV + 3.3DV + 3.4DV = | HK$219,370 (−3.78%) *2 | RMB¥130,535 or HK$156,642 (−3.59%) *2 [−28.59%] *3 | ||

| ICSV | Items of 1.1 + 1.2 + 1.3 + 1.4 + 1.5 + 1.6 + 1.7 + 4.1SV + 4.2SV + 4.3SV + 4.4SV = | HK$226,110 (−0.82%) *2 | RMB¥133,164 or HK$159,797 (−1.65%) *2 [−29.33%] *3 | ||

| General Description of Each Major Component in Various Systems | Mass (kg) | Embedded Energy (MJ) [Mass, kg × Energy Intensity *1, MJ/kg] | Embedded Carbon(kg CO2-eq) | |

|---|---|---|---|---|

| (1.1) Air Handling Unit: | 222 | 14,482 | 1100 | |

| (1.2) Accessories of MV: | 45 m2 × 2 mm galvanized iron air ductwork | 708 | 10,129 | 585 |

| 45 m2 × 13 mm fiberglass insulation | 281 | 8901 | 694 | |

| 45 m2 × 0.1 mm aluminum foil insulation for ductwork | 12 | 2564 | 220 | |

| 3.24 m2 × 3 mm aluminum for supply & return diffuser | 26 | 5332 | 458 | |

| Cumulative energy of MV, (1.1) + (1.2): | 1249 | 41,408 (Base) | 3057 (base) | |

| (1.3) Accessories of DV: | 30 m2 × 2 mm galvanized iron air ductwork | 472 | 6752 | 390 |

| 30 m2 × 13 mm fiberglass insulation | 187 | 5934 | 462 | |

| 30 m2 × 0.1 mm aluminum foil insulation for ductwork | 8 | 1709 | 147 | |

| 1.80 m2 × 3 mm aluminum for supply & return diffuser | 15 | 3076 | 263 | |

| Cumulative energy of DV, (1.1) + (1.3): | 904 | 31,953 (−22.83%) | 2364 (−22.68%) | |

| (1.4) Accessories of SV: | 43 m2 × 2 mm galvanized iron air ductwork | 679 | 9678 | 559 |

| 43 m2 × 13 mm fiberglass insulation | 268 | 8505 | 663 | |

| 43 m2 × 0.1 mm aluminum foil insulation in ductwork | 12 | 2450 | 210 | |

| 0.72 m2 × 3 mm aluminum for supply & return diffuser | 6 | 1231 | 107 | |

| Cumulative energy of SV, (1.1) + (1.4): | 1187 | 36,346 (−12.22%) | 2639 (−13.69%) | |

| Ventilation System | Total Weight of Ventilation System (kg or Ton) | Embedded Energy Factor * (MJ/Ton·km) | Distance (km) | Embedded Energy (MJ) | ||

|---|---|---|---|---|---|---|

| HKSAR | Guangdong | HKSAR | Guangdong | |||

| Mixing (MV) | 1249 or 1.249 | 2.474 | 150 | 20 | 464 | 62 |

| Displacement (DV) | 904 or 0.904 | 2.474 | 150 | 20 | 336 | 45 |

| Stratum (SV) | 1187 or 1.187 | 2.474 | 150 | 20 | 441 | 59 |

| Ventilation System | Cumulative Embedded Energy of AHU See Table 2 + Transportation See Table 3, MJ | Total Embedded Energy #1, MJ | Total Cumulative Embedded Energy, kWh #2 | Annual CO2 Emission, kg CO2-eq #3 | ||||

|---|---|---|---|---|---|---|---|---|

| HKSAR | Guangdong | HKSA-R | Guangdong | HKSAR | Guangdong | HKSAR (base) | Guangdong (% diff.) | |

| MV | 41,408 + 464 | 41,408 + 62 | 41,872 | 41,470 | 11,640 | 11,529 | 6286 | 7263 (+15.55%) |

| DV | 31,953 + 336 | 31,953 + 45 | 32,289 | 31,998 | 8976 | 8895 | 4847 | 5604 (+15.62%) |

| SV | 36,346 + 441 | 36,346 + 59 | 36,787 | 36,405 | 10,227 | 10,121 | 5522 | 6376 (+15.46%) |

| Outdoor Temperature, Celsius | HKSAR | Guangdong |

|---|---|---|

| Summer Design, Dry Bulb | 35 | 35.1 |

| Summer Coincident, Wet Bulb | 29 | 26.3 |

| Summer Daily Range | 4.5 | 6.9 |

| Winter Design, Dry Bulb | 7 | 5.8 |

| Winter Coincident, Wet Bulb | 4.6 | 2 |

| Ventilation System | Room Temp.*1 (°C) | Supply Air Temp. (°C) | Chiller Water Temp. | Chiller (kWh) | Fan & Pump (kWh) | Total Power *2 (kWh) | % diff. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Low. (°C) | Upp. (°C) | HKSAR | Guangdong | HKSAR | Guangdong | [a] HKSAR | [b] Guangdong | {[b]−[a]/[a]} | |||

| MV | 24.6 | 13.5 | 7 | 12.5 | 12,103 | 11,664 | 9426 | 8738 | 21,529 (Base) | 20,402 | −5.2% |

| DV | 25.1 | 15.4 | 10 | 15.5 | 7798 | 7559 | 8697 | 8149 | 16,495 (−23.38%) | 15,707 (−23.01%) | −4.8% |

| SV | 27.3 | 17.5 | 12.5 | 17.5 | 4709 | 4678 | 8519 | 8012 | 13,228 (−38.56%) | 12,690 (−37.80%) | −4.1% |

| Ventilation System | [a] CO2 Emission in Supply and Installation Phase See Table 4, kg CO2-eq | [b] CO2 Emission in Operation Phase See Table 6 , kg CO2-eq | Total CO2 Emission at the End of Service Years [a] + n x [b] *1 | |||

|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | |||

| (1) MVHK | 6286 | 11,626 | 64,416 | 122,546 | 180,676 | 238,806 |

| (2) MVGD | 7263 | 12,853 | 71,528 | 135,793 | 200,058 | 264,323 |

| %diff. with (2)/(1) *3 | [15.55%] | [10.55%] | [11.04%] | [10.81%] | [10.73%] | [10.69%] |

| (3) DVHK | 4847 | 8907 | 49,382 | 93,917 | 138,452 | 182,987 |

| DV/MV(HK) *2 | (−33.26%) | (−30.70%) | (−30.96%) | (−30.84%) | (−30.79%) | (−30.77%) |

| (4) DVGD | 5604 | 9896 | 55,084 | 104,564 | 154,044 | 203,524 |

| DV/MV(GD) *2 | (−22.84%) | (−23.01%) | (−22.99%) | (−23.00%) | (−23.00%) | (−23.00%) |

| % diff. with (4)/(3) *3 | [15.62%] | [11.10%] | [11.55%] | [11.34%] | [11.26%] | [11.22%] |

| (5) SVHK | 5522 | 7143 | 41,237 | 76,952 | 112,667 | 148,382 |

| SV/MV(HK) | (−23.97%) | (−44.43%) | (−42.35%) | (−43.33%) | (−43.68%) | (−43.86%) |

| (6) SVGD | 6376 | 7994 | 46,346 | 86,316 | 126,286 | 166,256 |

| SV/MV(GD) *2 | (−12.21%) | (−37.80%) | (−35.21%) | (−36.44%) | (−36.88%) | (−37.10%) |

| % diff. with (6)/(5) *3 | [15.46%] | [11.91%] | [12.39%] | [12.17%] | [+12.09%] | [12.05%] |

| a. Present Value (PV) Factor for LCC Analysis in “n” Service Vears | ||||

| Region | n = 5 | n = 10 | n = 15 | n = 20 |

| HKSAR | 4.8590 | 9.6709 | 14.4359 | 19.1547 |

| Guandong | 5.0573 | 10.5879 | 16.6358 | 23.2496 |

| b. Present Value (HK$) of the Initial Cost of Three Ventilation System | ||||

| Region | Mixing ventilation (MV) | Displacement ventilation (DV) | Stratum ventilation (SV) | |

| HKSAR | 227,980 | 219,370 | 226,110 | |

| Guandong | 162,480 | 156,642 | 159,797 | |

| c. Present Value (PV) of Operation and Maintenance Cost in “n” Service Years | ||||

| Ventilation System | n= 5 | n = 10 | n = 15 | n = 20 |

| O&MCMV(HK) | 173,807 | 345,926 | 516,371 | 685,161 |

| O&MCMV(GD) | 122,561 | 256,590 | 403,158 | 563,439 |

| O&MCDV(HK) | 144,026 | 286,653 | 427,894 | 567,762 |

| O&MCDV(GD) | 103,932 | 217,588 | 341,878 | 477,797 |

| O&MCSV(HK) | 127,694 | 254,147 | 379,371 | 503,378 |

| O&MCSV(GD) | 94,054 | 196,907 | 309,383 | 432,383 |

| d | ||||

| Item | Net Present Value (NPV) in “n” Service Years | |||

| n = 5 | n = 10 | n = 15 | n = 20 | |

| Life Cycle Cost *1, HK$ for Mixing Ventilation, as a reference case for comparison | ||||

| LCCMV(HK) | 401,787 | 573,906 | 744,351 | 913,141 |

| LCCMV(GD) | 285,041 | 419,070 | 565,638 | 725,919 |

| Life Cycle Cost *1, HK$ for Displacement Ventilation | ||||

| LCCDV(HK) | 363,396 | 506,023 | 647,264 | 787,132 |

| [% difference of LCC DV/MV(HK)] | [−9.56%] | [−11.83%] | [−13.04%] | [−13.80%] |

| LCCDV(GD) | 260,574 | 374,230 | 498,520 | 634,439 |

| [% difference of LCCDV/MV(GD)] | [−8.58%] | [−10.70%] | [−11.87%] | [−12.60%] |

| Life Cycle Cost *1, HK$ for Stratum Ventilation | ||||

| LCCSV(HK) | 353,804 | 480,257 | 605,481 | 729,488 |

| [% difference of LCCSV/MV(HK)] | [−11.94%] | [−16.32%] | [−18.66%] | [−20.11%] |

| LCCSV(DG) | 253,850 | 356,704 | 469,180 | 592,180 |

| [% difference of LCCSV/MV(GD)] | [−10.94%] | [−14.88%] | [−17.05%] | [−18.42%] |

| Item | Regional LCC Compare with the various Service Years | |||

|---|---|---|---|---|

| 5 | 10 | 15 | 20 | |

| Regional LCC of Mixing Ventilation in HKSAR and Guangdong | ||||

| LCCMV(HK) | $401,787 | $573,906 | $744,351 | $913,141 |

| LCCMV(GD) | $285,041 | $419,070 | $565,638 | $725,919 |

| % difference of MV in Guangdong | −29.06% | −26.98% | −24.01% | −20.50% |

| Regional LCC of Displacement Ventilation in HKSAR and Guangdong | ||||

| LCCDV(HK) | $363,396 | $506,023 | $647,264 | $787,132 |

| LCCDV(GD) | $260,574 | $374,230 | $498,520 | $634,439 |

| % difference of DV in Guangdong | −28.29% | −26.04% | −22.98% | −19.40% |

| Regional LCC of Stratum Ventilation in HKSAR and Guangdong | ||||

| LCCSV(HK) | $353,804 | $480,257 | $605,481 | $729,488 |

| LCCSV(GD) | $253,850 | $356,704 | $469,180 | $592,180 |

| % difference of SV in Guangdong | −28.25% | −25.73% | −22.51% | −18.82% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fong, M.-L.A. Sustainable Ventilation Strategies for a Medium-Sized Space with Regional Effect. Sustainability 2021, 13, 4651. https://doi.org/10.3390/su13094651

Fong M-LA. Sustainable Ventilation Strategies for a Medium-Sized Space with Regional Effect. Sustainability. 2021; 13(9):4651. https://doi.org/10.3390/su13094651

Chicago/Turabian StyleFong, Ming-Lun Alan. 2021. "Sustainable Ventilation Strategies for a Medium-Sized Space with Regional Effect" Sustainability 13, no. 9: 4651. https://doi.org/10.3390/su13094651

APA StyleFong, M.-L. A. (2021). Sustainable Ventilation Strategies for a Medium-Sized Space with Regional Effect. Sustainability, 13(9), 4651. https://doi.org/10.3390/su13094651