Smart Steaming: A New Flexible Paradigm for Synchromodal Logistics

Abstract

1. Introduction

2. Background and Established Practices: Towards a Smart Steaming Paradigm

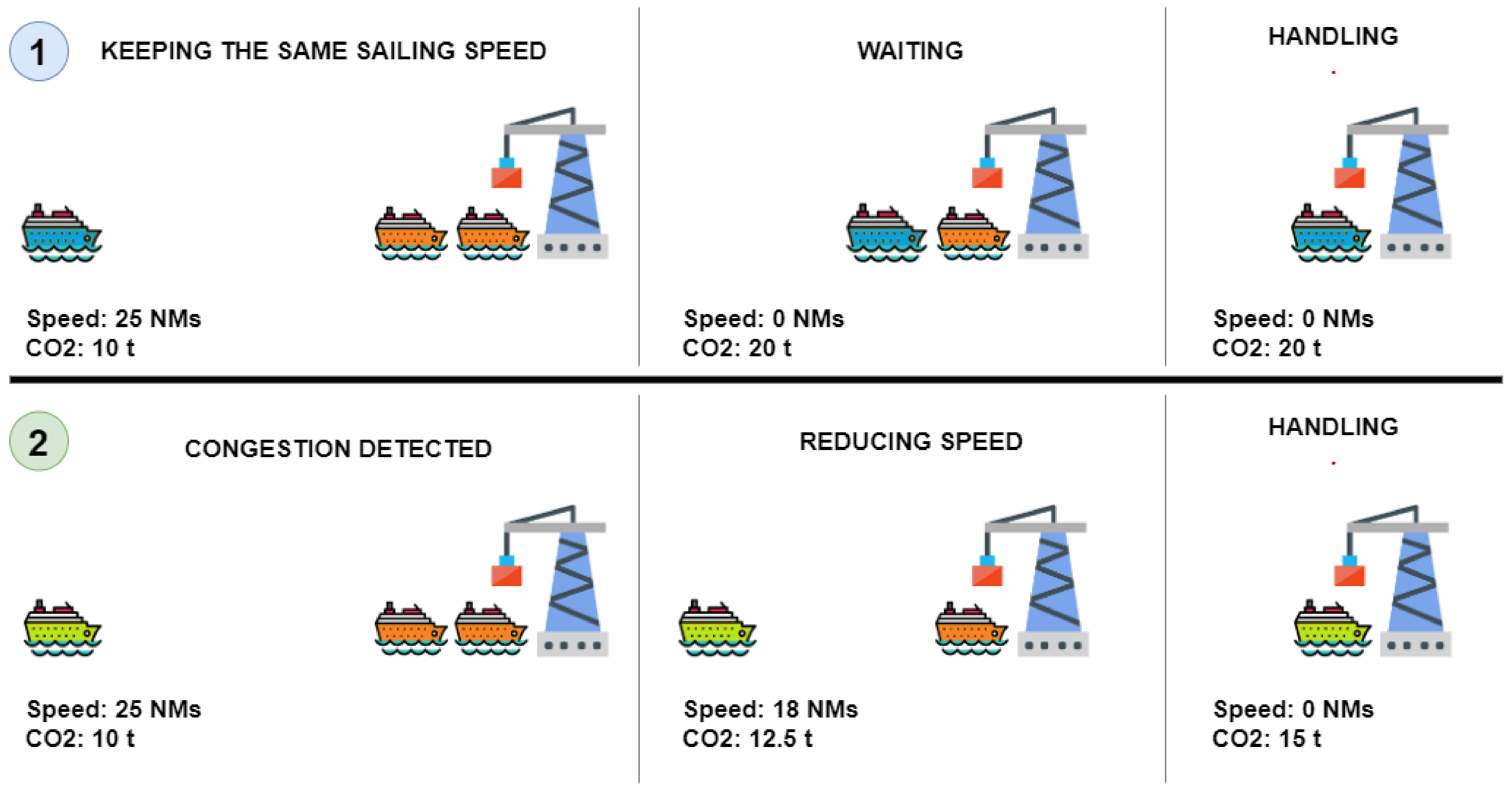

2.1. Slow Steaming

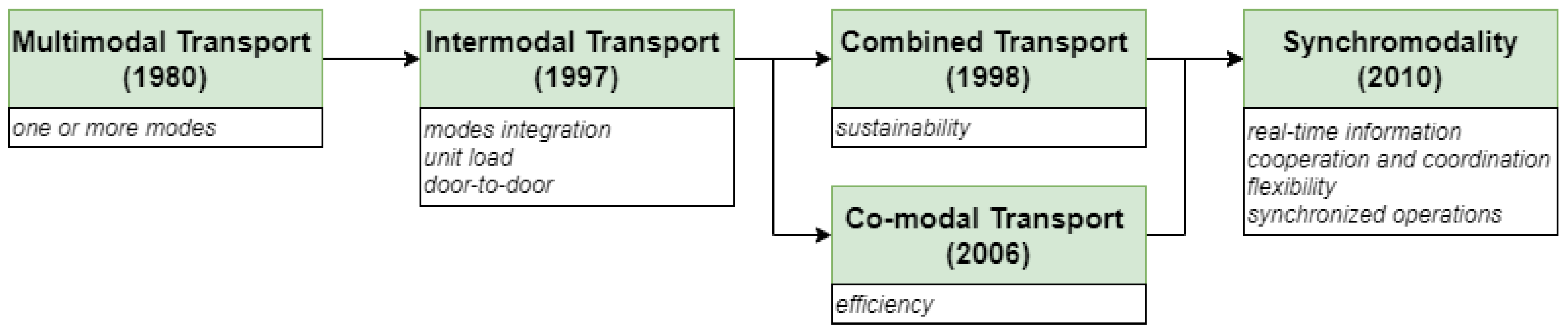

2.2. Synchromodality

- real-time information management,

- service flexibility,

- stakeholders cooperation and coordination, and

- synchronization of the operations.

2.3. Fuel Consumption Models

- travel-related: travel distance and times;

- weather-related: temperature, humidity, and wind effects;

- vehicle-related: engine, loading, vehicle speed, and acceleration;

- roadway-related: physical characteristics as the grade, the surface roughness, and the horizontal curvature;

- traffic-related: traffic flows and signals; and

- driver-related: driver’s behavior and aggressiveness (e.g., hard acceleration and deceleration).

- vehicle-related: number of wagons, payload per wagon, locomotive type (e.g., diesel engine, electric engine), and rolling and aerodynamic performance;

- railway-related: condition of the railway and altitude profile along the route; and

- travel-related: average speed, trip distance, and number of stops.

- vehicle-related: shape, size, numbers of containers loaded, cargo weight, displacement, and fuel type;

- weather-related: wave conditions, wind force, and current intensity; and

- speed-related: sailing speed and acceleration.

2.4. Speed Optimization Problems

3. Smart Steaming: Main Features and Advantages

- having a global real-time view of the logistics network;

- adjusting the speed of different types of vehicles in real-time;

- synchronizing operations by coordinating stakeholders;

- adopting re-planning procedures typical of synchromodality; and

- optimizing the global performance of its logistics network, ensuring that the cooperation leads benefits to all the stakeholders.

4. Smart Steaming Implementation in Real Settings

4.1. Environmental Policies

4.2. Operational Limitations on Implementing Smart Steaming

5. Decision-Making and Optimization Problems under Smart Steaming Strategies

5.1. Handling Uncertainty

5.2. Network Design

5.3. Operational and Real-Time Planning

6. Conclusions and Future Research

- We gave an overview of four relevant topics for understanding the logistics context and the current practices. In particular, we described slow steaming and its limits in synchromodal logistics, the impact factors for the fuel consumption of the different transportation modes, and the existing approaches to speed optimization problems.

- We presented the paradigm of smart steaming and how it overcomes the current practices’ limits to address synchromodal logistics settings better. Its main features are a global real-time view of the operations and the adoption of re-planning procedures (such as re-routing, re-scheduling, or dynamic speed adjustments).

- We highlighted smart steaming benefits to deal with emissions regulations and the operational limits for its implementation.

- We discussed how to address decision-making problems faced under smart steaming at different planning levels, focusing on handling uncertainty and optimization paradigms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tiwari, S.; Wee, H.M.; Zhou, Y.; Tjoeng, L. Freight consolidation and containerization strategy under business as usual scenario & carbon tax regulation. J. Clean. Prod. 2021, 279, 123270. [Google Scholar]

- Woo, J.K.; Moon, D.S.H. The effects of slow steaming on the environmental performance in liner shipping. Marit. Policy Manag. 2014, 41, 176–191. [Google Scholar] [CrossRef]

- Notteboom, T.; Cariou, P. Slow steaming in container liner shipping: Is there any impact on fuel surcharge practices? Int. J. Logist. Manag. 2013, 24, 73–86. [Google Scholar] [CrossRef]

- Giusti, R.; Manerba, D.; Bruno, G.; Tadei, R. Synchromodal logistics: An overview of critical success factors, enabling technologies, and open research issues. Transp. Res. Part E Logist. Transp. Rev. 2019, 129, 92–110. [Google Scholar] [CrossRef]

- Perboli, G.; Musso, S.; Rosano, M.; Tadei, R.; Godel, M. Synchro-modality and slow steaming: New business perspectives in freight transportation. Sustainability 2017, 9, 1843. [Google Scholar] [CrossRef]

- Pfoser, S.; Treiblmaier, H.; Schauer, O. Critical Success Factors of Synchromodality: Results from a Case Study and Literature Review. Transp. Res. Procedia 2016, 14, 1463–1471. [Google Scholar] [CrossRef]

- Qu, W.; Rezaei, J.; Maknoon, Y.; Tavasszy, L. Hinterland freight transportation replanning model under the framework of synchromodality. Transp. Res. Part E Logist. Transp. Rev. 2019, 131, 308–328. [Google Scholar] [CrossRef]

- Yin, J.; Fan, L.; Yang, Z.; Li, K.X. Slow steaming of liner trade: Its economic and environmental impacts. Marit. Policy Manag. 2014, 41, 149–158. [Google Scholar] [CrossRef]

- Maloni, M.; Paul, J.A.; Gligor, D.M. Slow steaming impacts on ocean carriers and shippers. Marit. Econ. Logist. 2013, 15, 151–171. [Google Scholar] [CrossRef]

- Tai, H.H.; Lin, D.Y. Comparing the unit emissions of daily frequency and slow steaming strategies on trunk route deployment in international container shipping. Transp. Res. Part D Transp. Environ. 2013, 21, 26–31. [Google Scholar] [CrossRef]

- Tezdogan, T.; Incecik, A.; Turan, O.; Kellett, P. Assessing the Impact of a Slow Steaming Approach on Reducing the Fuel Consumption of a Containership Advancing in Head Seas. Transp. Res. Procedia 2016, 14, 1659–1668. [Google Scholar] [CrossRef][Green Version]

- Finnsgård, C.; Kalantari, J.; Roso, V.; Woxenius, J. The Shipper’s perspective on slow steaming—Study of Six Swedish companies. Transp. Policy 2020, 86, 44–49. [Google Scholar] [CrossRef]

- Meyer, J.; Stahlbock, R.; Voss, S. Slow Steaming in Container Shipping. In Proceedings of the 2012 45th Hawaii International Conference on System Sciences, Maui, HI, USA, 4–7 January 2012; pp. 1306–1314. [Google Scholar]

- Cariou, P. Is slow steaming a sustainable means of reducing CO2 emissions from container shipping? Transp. Res. Part D Transp. Environ. 2011, 16, 260–264. [Google Scholar] [CrossRef]

- Psaraftis, H.; Kontovas, C. Slow Steaming in Maritime Transportation: Fundamentals, Trade-offs, and Decision Models. In Handbook of Ocean Container Transport Logistics; Springer: Cham, Switzerland, 2015; pp. 315–358. [Google Scholar]

- Mander, S. Slow steaming and a new dawn for wind propulsion: A multi-level analysis of two low carbon shipping transitions. Mar. Policy 2017, 75, 210–216. [Google Scholar] [CrossRef]

- Fan, L.; Huang, L. Analysis of the Incentive for Slow Steaming in Chinese Sulfur Emission Control Areas. Transp. Res. Rec. 2019, 2673, 165–175. [Google Scholar] [CrossRef]

- Fan, L.; Gu, B. Impacts of the Increasingly Strict Sulfur Limit on Compliance Option Choices: The Case Study of Chinese SECA. Sustainability 2019, 12, 165. [Google Scholar] [CrossRef]

- Hämäläinen, E. Can slow steaming lower cost impacts of sulphur directive—Shippers’ perspective. World Rev. Intermodal Transp. Res. 2014, 5, 59–79. [Google Scholar] [CrossRef]

- Raza, Z.; Woxenius, J.; Finnsgård, C. Slow Steaming as Part of SECA Compliance Strategies among RoRo and RoPax Shipping Companies. Sustainability 2019, 11, 1435. [Google Scholar] [CrossRef]

- Wu, W.M. The optimal speed in container shipping: Theory and empirical evidence. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101903. [Google Scholar] [CrossRef]

- Cepeda, M.F.S.; Assis, L.; Marujo, L.; Caprace, J. Effects of slow steaming strategies on a ship fleet. Mar. Syst. Ocean. Technol. 2017, 12, 178–186. [Google Scholar] [CrossRef]

- Psaraftis, H.N.; Kontovas, C.A. Balancing the economic and environmental performance of maritime transportation. Transp. Res. Part D Transp. Environ. 2010, 15, 458–462. [Google Scholar] [CrossRef]

- Ferrari, C.; Parola, F.; Tei, A. Determinants of slow steaming and implications on service patterns. Marit. Policy Manag. 2015, 42, 636–652. [Google Scholar] [CrossRef]

- Mallidis, I.; Iakovou, E.; Dekker, R.; Vlachos, D. The impact of slow steaming on the carriers’ and shippers’ costs: The case of a global logistics network. Transp. Res. Part E Logist. Transp. Rev. 2018, 111, 18–39. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, Z.; Li, D.; Peng, X. Impact Analysis of Slow Steaming on Inland River Container Freight Supply Chain. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 8430–8434. [Google Scholar]

- Le, L.T.; Lee, G.; Park, K.S.; Kim, H. Neural network-based fuel consumption estimation for container ships in Korea. Marit. Policy Manag. 2020, 47, 615–632. [Google Scholar] [CrossRef]

- Psaraftis, H. Speed Optimization for Sustainable Shipping. In Sustainable Shipping: A Cross-Disciplinary View; Springer: Berlin/Heidelberg, Germany, 2019; pp. 339–374. [Google Scholar]

- Lee, C.Y.; Lee, H.L.; Zhang, J. The impact of slow ocean steaming on delivery reliability and fuel consumption. Transp. Res. Part E Logist. Transp. Rev. 2015, 76, 176–190. [Google Scholar] [CrossRef]

- Reis, V. Should we keep on renaming a +35-year-old baby? J. Transp. Geogr. 2015, 46, 173–179. [Google Scholar] [CrossRef]

- Van Riessen, B.; Negenborn, R.; Dekker, R.; Lodewijks, G. Service Network Design for an Intermodal Container Network with Flexible due Dates/Times and the Possibility of Using Subcontracted Transport; Econometric Institute Research Papers EI2013-17, Erasmus University Rotterdam, Erasmus School of Economics (ESE), Econometric Institute: Rotterdam, The Netherlands, 2013. [Google Scholar]

- Ambra, T.; Caris, A.; Macharis, C. Should I Stay or Should I Go? Assessing Intermodal and Synchromodal Resilience from a Decentralized Perspective. Sustainability 2019, 11, 1765. [Google Scholar] [CrossRef]

- Tavasszy, L.A.; Behdani, B.; Konings, R. Intermodality and Synchromodality. In Ports and Networks; Strategies, Operations and Perspectives; Geerlings, H., Kuipers, B., Zuidwijk, R., Eds.; Routledge: London, UK, 2017; Chapter 16. [Google Scholar]

- van Riessen, B.; Negenborn, R.R.; Dekker, R. Synchromodal container transportation: An overview of current topics and research opportunities. Lect. Notes Comput. Sci. 2015, 9335, 386–397. [Google Scholar]

- Dong, C.; Boute, R.; McKinnon, A.; Verelst, M. Investigating synchromodality from a supply chain perspective. Transp. Res. Part D Transp. Environ. 2018, 61, 42–57. [Google Scholar] [CrossRef]

- Guo, W.; van Blokland, W.B.; Lodewijks, G. Survey on characteristics and challenges of synchromodal transportation in global cold chains. Lect. Notes Comput. Sci. 2017, 10572 LNCS, 420–434. [Google Scholar]

- Lin, X.; Negenborn, R.R.; Lodewijks, G. Towards Quality-aware Control of Perishable Goods in Synchromodal Transport Networks. IFAC-PapersOnLine 2016, 49, 132–137. [Google Scholar] [CrossRef]

- Nabais, J.L.; Negenborn, R.R.; Carmona-Benítez, R.; Botto, M.A. Cooperative relations among intermodal hubs and transport providers at freight networks using an MPC approach. Lect. Notes Comput. Sci. 2015, 9335, 478–494. [Google Scholar]

- Giusti, R.; Iorfida, C.; Li, Y.; Manerba, D.; Musso, S.; Perboli, G.; Tadei, R.; Yuan, S. Sustainable and De-Stressed International Supply-Chains Through the SYNCHRO-NET Approach. Sustainability 2019, 11, 1083. [Google Scholar] [CrossRef]

- Giusti, R.; Manerba, D.; Perboli, G.; Tadei, R.; Yuan, S. A New Open-source System for Strategic Freight Logistics Planning: The SYNCHRO-NET Optimization Tools. Transp. Res. Procedia 2018, 30, 245–254. [Google Scholar] [CrossRef]

- Holfeld, D.; Iorfida, C.; Koya, M.; Manerba, D.; Stephens, J.; Tadei, R.; Werner, F. SYNCHRO-NET: A powerful and innovative synchro-modal supply chain eco-NET. In Proceedings of the Transport Research Arena (TRA), Vienna, Austria, 16–19 April 2018. [Google Scholar]

- Holfeld, D.; Simroth, A.; Li, Y.; Manerba, D.; Tadei, R. Risk Analysis for synchro-modal freight transportation: The SYNCHRO-NET approach. In Proceedings of the Odysseus—7th International Workshop on Freight Transportation and Logistics, Cagliari, Italy, 3–8 June 2018. [Google Scholar]

- Ben-Chaim, M.; Shmerling, E.; Kuperman, A. Analytic Modeling of Vehicle Fuel Consumption. Energies 2013, 6, 117–127. [Google Scholar] [CrossRef]

- Zhou, M.; Jin, H.; Wang, W. A review of vehicle fuel consumption models to evaluate eco-driving and eco-routing. Transp. Res. Part D Transp. Environ. 2016, 49, 203–218. [Google Scholar] [CrossRef]

- Demir, E.; Bektaş, T.; Laporte, G. A comparative analysis of several vehicle emission models for road freight transportation. Transp. Res. Part D Transp. Environ. 2011, 16, 347–357. [Google Scholar] [CrossRef]

- Heinold, A. Comparing emission estimation models for rail freight transportation. Transp. Res. Part D Transp. Environ. 2020, 86, 102468. [Google Scholar] [CrossRef]

- Feng, X.; Sun, Q.; Liu, L.; Li, M. Assessing Energy Consumption of High-speed Trains based on Mechanical Energy. Procedia Soc. Behav. Sci. 2014, 138, 783–790. [Google Scholar] [CrossRef][Green Version]

- Le, L.T.; Lee, G.; Kim, H.; Woo, S.H. Voyage-based statistical fuel consumption models of ocean-going container ships in Korea. Marit. Policy Manag. 2020, 47, 304–331. [Google Scholar] [CrossRef]

- Baumel, C.; Hurburgh, C.; Lee, T.; Agriculture, I.; Station, H.E.E. Estimates of Total Fuel Consumption in Transporting Grain from Iowa to Major Grain-importing Countries by Alternative Modes and Routes; Number 77 in Special Report; Iowa State University, Agricultural and Home Economics Experiment Station: Ames, IA, USA, 1985. [Google Scholar]

- Shobayo, P.; van Hassel, E. Container barge congestion and handling in large seaports: A theoretical agent-based modeling approach. J. Shipp. Trade 2019, 4, 4. [Google Scholar] [CrossRef]

- Sung, I.; Nielsen, P. Speed optimization algorithm with routing to minimize fuel consumption under time-dependent travel conditions. Prod. Manuf. Res. 2020, 8, 1–19. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, J.; Fan, Y.; Kuang, H. An Expected Utility-Based Optimization of Slow Steaming in Sulphur Emission Control Areas by Applying Big Data Analytics. IEEE Access 2020, 8, 3646–3655. [Google Scholar] [CrossRef]

- Yuzhe, Z.; Zhou, J.; Fan, Y.; Kuang, H. Sailing Speed Optimization Model for Slow Steaming Considering Loss Aversion Mechanism. J. Adv. Transp. 2020, 2020. [Google Scholar] [CrossRef]

- Wong, E.Y.; Tai, A.H.; Lau, H.Y.; Raman, M. An utility-based decision support sustainability model in slow steaming maritime operations. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 57–69. [Google Scholar] [CrossRef]

- Li, X.; Sun, B.; Guo, C.; Du, W.; Li, Y. Speed optimization of a container ship on a given route considering voluntary speed loss and emissions. Appl. Ocean. Res. 2020, 94, 101995. [Google Scholar] [CrossRef]

- Tezdogan, T.; Demirel, Y.; Kellett, P.; Khorasanchi, M.; Incecik, A.; Turan, O. Full-scale unsteady RANS CFD simulations of ship behaviour and performance in head seas due to slow steaming. Ocean. Eng. 2015, 97, 186–206. [Google Scholar] [CrossRef]

- Rahman, A.; Yang, Z.; Bonsall, S.B.; Wang, J. A Proposed Rule-based bayesian Reasoning Appoarch for Analysing Steaming Modes on Containerships. J. Marit. Res. 2012, 9, 27–32. [Google Scholar]

- Wang, H.; Lang, X.; Mao, W.; Zhang, D.; Storhaug, G. Effectiveness of 2D optimization algorithms considering voluntary speed reduction under uncertain metocean conditions. Ocean. Eng. 2020, 200, 107063. [Google Scholar] [CrossRef]

- Bektaş, T.; Laporte, G. The Pollution-Routing Problem. Transp. Res. Part B Methodol. 2011, 45, 1232–1250. [Google Scholar] [CrossRef]

- Kumar, R.S.; Kondapaneni, K.; Dixit, V.; Goswami, A.; Thakur, L.; Tiwari, M. Multi-objective modeling of production and pollution routing problem with time window: A self-learning particle swarm optimization approach. Comput. Ind. Eng. 2016, 99, 29–40. [Google Scholar] [CrossRef]

- Ren, X.; Huang, H.; Feng, S.; Liang, G. An improved variable neighborhood search for bi-objective mixed-energy fleet vehicle routing problem. J. Clean. Prod. 2020, 275, 124155. [Google Scholar] [CrossRef]

- Eshtehadi, R.; Fathian, M.; Demir, E. Robust solutions to the pollution-routing problem with demand and travel time uncertainty. Transp. Res. Part D Transp. Environ. 2017, 51, 351–363. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Goli, A.; Faridnia, A.; Soltani, M.; Weber, G.W. Multi-objective optimization for the reliable pollution-routing problem with cross-dock selection using Pareto-based algorithms. J. Clean. Prod. 2020, 276, 122927. [Google Scholar] [CrossRef]

- Hoen, K.M.R.; Tan, T.; Fransoo, J.C.; van Houtum, G.J. Effect of carbon emission regulations on transport mode selection under stochastic demand. Flex. Serv. Manuf. J. 2014, 26, 170–195. [Google Scholar] [CrossRef]

- An, S.; Li, B.; Song, D.; Chen, X. Green credit financing versus trade credit financing in a supply chain with carbon emission limits. Eur. J. Oper. Res. 2020, 292, 125–142. [Google Scholar] [CrossRef]

- Tsao, Y.C. Design of a carbon-efficient supply-chain network under trade credits. Int. J. Syst. Sci. Oper. Logist. 2015, 2, 177–186. [Google Scholar] [CrossRef]

- Baranzini, A.; Goldemberg, J.; Speck, S. A future for carbon taxes. Ecol. Econ. 2000, 32, 395–412. [Google Scholar] [CrossRef]

- Rotaris, L.; Danielis, R. The willingness to pay for a carbon tax in Italy. Transp. Res. Part D Transp. Environ. 2019, 67, 659–673. [Google Scholar] [CrossRef]

- McHale, M.R.; Gregory McPherson, E.; Burke, I.C. The potential of urban tree plantings to be cost effective in carbon credit markets. Urban For. Urban Green. 2007, 6, 49–60. [Google Scholar] [CrossRef]

- Narassimhan, E.; Gallagher, K.S.; Koester, S.; Alejo, J.R. Carbon pricing in practice: A review of existing emissions trading systems. Clim. Policy 2018, 18, 967–991. [Google Scholar] [CrossRef]

- Bialystocki, N.; Konovessis, D. On the estimation of ship’s fuel consumption and speed curve: A statistical approach. J. Ocean. Eng. Sci. 2016, 1, 157–166. [Google Scholar] [CrossRef]

- Notteboom, T.E.; Vernimmen, B. The effect of high fuel costs on liner service configuration in container shipping. J. Transp. Geogr. 2009, 17, 325–337. [Google Scholar] [CrossRef]

- Kruse, C.J.; Warner, J.E.; Olson, L.E. A Modal Comparison of Domestic Freight Transportation Effects on the General Public: 2001–2014; Technical Report; Texas A&M Transportation Institute: Bryan, TX, USA, 2017. [Google Scholar]

- King, A.J.; Wallace, S. Modeling with Stochastic Programming; Springer Series in Operations Research and Financial Engineering; Springer: New York, NY, USA, 2012. [Google Scholar]

- Crainic, T.G.; Giusti, R.; Manerba, D.; Tadei, R. The Synchronized Location-Transshipment Problem. Transp. Res. Procedia 2021, 52, 43–50. [Google Scholar] [CrossRef]

- Giusti, R.; Manerba, D.; Tadei, R. Multiperiod transshipment location–allocation problem with flow synchronization under stochastic handling operations. Networks 2020. [Google Scholar] [CrossRef]

- Birge, J.R.; Louveaux, F.V. Introduction to Stochastic Programming; Springer: New York, NY, USA, 1997. [Google Scholar]

- Ben-Tal, A.; Ghaoui, L.E.; Nemirovski, A. Robust Optimization; Princeton University Press: Princeton, NJ, USA, 2009. [Google Scholar]

- Hrus̆ovský, M.; Demir, E.; Jammernegg, W.; Van Woensel, T. Real-time disruption management approach for intermodal freight transportation. J. Clean. Prod. 2021, 280, 124826. [Google Scholar] [CrossRef]

- Jaillet, P.; Wagner, M.R. Online Optimization—An Introduction. In Risk and Optimization in an Uncertain World; INFORMS: Catonsville, MD, USA, 2010; Chapter 6; pp. 142–152. [Google Scholar]

- Puterman, M.L. Markov Decision Processes: Discrete Stochastic Dynamic Programming; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1994. [Google Scholar]

- Hentenryck, P.V.; Bent, R. Online Stochastic Combinatorial Optimization; The MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giusti, R.; Manerba, D.; Tadei, R. Smart Steaming: A New Flexible Paradigm for Synchromodal Logistics. Sustainability 2021, 13, 4635. https://doi.org/10.3390/su13094635

Giusti R, Manerba D, Tadei R. Smart Steaming: A New Flexible Paradigm for Synchromodal Logistics. Sustainability. 2021; 13(9):4635. https://doi.org/10.3390/su13094635

Chicago/Turabian StyleGiusti, Riccardo, Daniele Manerba, and Roberto Tadei. 2021. "Smart Steaming: A New Flexible Paradigm for Synchromodal Logistics" Sustainability 13, no. 9: 4635. https://doi.org/10.3390/su13094635

APA StyleGiusti, R., Manerba, D., & Tadei, R. (2021). Smart Steaming: A New Flexible Paradigm for Synchromodal Logistics. Sustainability, 13(9), 4635. https://doi.org/10.3390/su13094635