Innovative Building Technology Implemented into Facades with Active Thermal Protection

Abstract

:1. Introduction

2. Current State of Technical Solutions

3. Basic Calculation for Dimensioning

- Structure A—consists of a reinforced concrete load bearing structure 200 mm thick (reinforced concrete), which is insulated from the outside with polystyrene 120 mm thick. The ATP would be placed in a layer of mortar bed between the load-bearing wall and the insulation, shown in Figure 6;

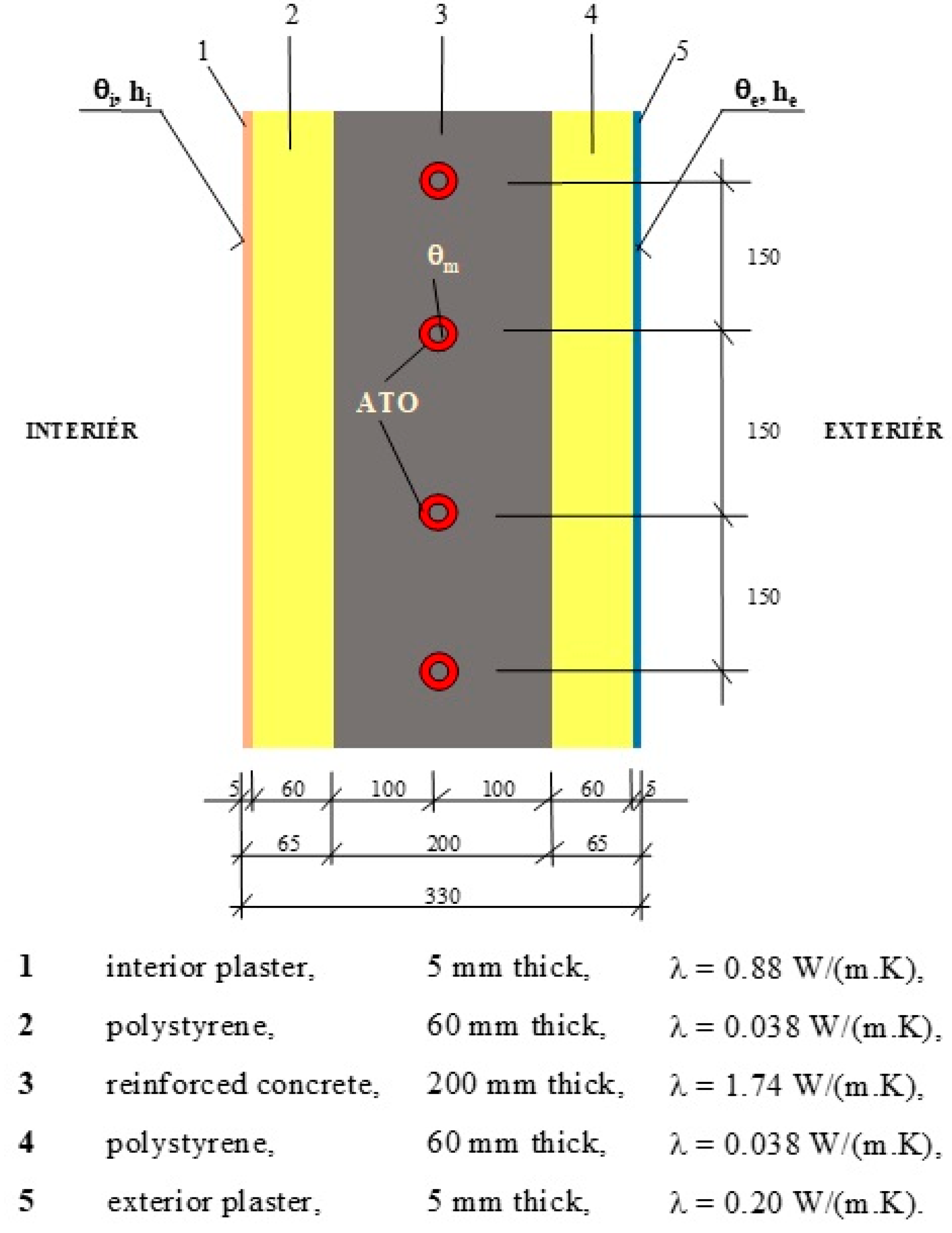

- Structure B—consists of a reinforced concrete load bearing structure 200 mm thick, which is insulated on the exterior and interior side with polystyrene 60 mm thick. The ATP would be located in the middle of the load bearing structure, shown in Figure 7;

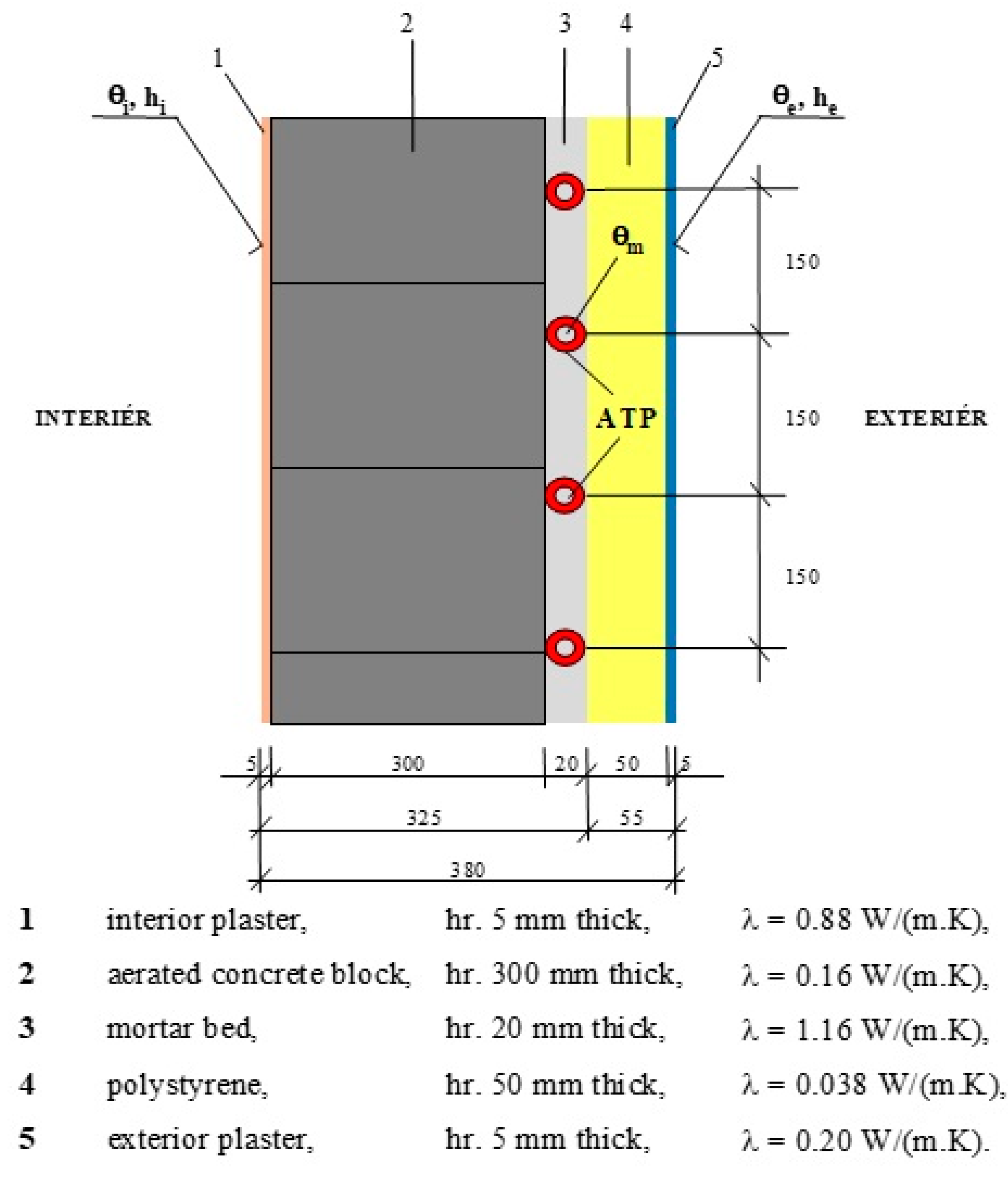

- Structure C—consists of aerated concrete blocks (PBT) 300 mm thick and insulated from the exterior with polystyrene 50 mm thick. The ATP would be placed in between, shown in Figure 8.

- Air flow, as the air is warmer in the higher positions and colder in the lower positions;

- Radiation as a consequence of the heat exchange of a given structure with all other room structures.

- Air flow mostly along the structure due to wind;

- Building structure A consists of the interior in front of the ATP made of a material with high thermal conductivity and low thermal resistance (reinforced concrete) and behind the ATP towards the exterior made of a material with low thermal conductivity and high thermal resistance (polystyrene). As a result, a higher surface temperature in the interior, a higher heat flux toward the interior and a lower heat flux toward the exterior are achieved compared to structures B and C. Surface temperature θp e.g., at mean temperature of the working medium θm = 35 °C in the ATP pipe starts at 26.61 °C, while at structure B = 21.03 °C and structure C = 20.90 °C. The heat flux toward the interior at θm = 35 °C is 52.896 W/m2. Compared to structure B (8260 W/m2), this value is more than 6 times higher and compared to structure C (7166 W/m2) more than 7 times higher. The heat flux toward the exterior is by almost half lower than with structure B. The difference is even greater compared to structure C;

- Building structures B and C consist of materials with low thermal conductivity and high thermal resistance in front of and behind the ATP. The heat flow toward the interior is considerably limited, compared to structure A the values are significantly lower. A higher average temperature in the pipe axis (θd) is generated in the layer where the ATP is located. However, as the temperature in the ATP pipe increases, the surface temperature in the interior increases only minimally. For example, in structure C, at the mean temperature of the working medium θm = 25 °C the surface temperature is θp = 20.30 °C, at θm = 45 °C θp = 21.49 °C. The heat flux toward the exterior is higher.

4. Research and Development of Facade Systems with Active Thermal Protection

4.1. Focus of Research

- (a)

- Heat/cold sources for energy systems—heating, hot water preparation, ventilation, and cooling—were stable, independent of variable and unpredictable solar and geothermic energy accumulated in large-capacity, especially in ground heat storage;

- (b)

- The requirements for buildings with nearly zero energy demand have been met;

- (c)

- RES are used as much as possible and the best possible accumulation of heat/cold from these sources is ensured;

- (d)

- The implementation of active thermal protection has been simplified;

- (e)

- The advantages of contact thermal insulation system have been economically effectively combined with energy systems—thermal barrier, heating, cooling, heat accumulation and recuperation, capture of solar and ambient energy and use of recuperative ventilation—in multifunctional building-energy constructions of buildings;

- (f)

- A compact heat station with a separate control system was designed to regulate, measure, and optimize the energy demand in the building;

- (g)

- A reliable exact calculation methodology was developed for the design, calculation, selection, and assessment of all components of the combined building and energy systems of a building.

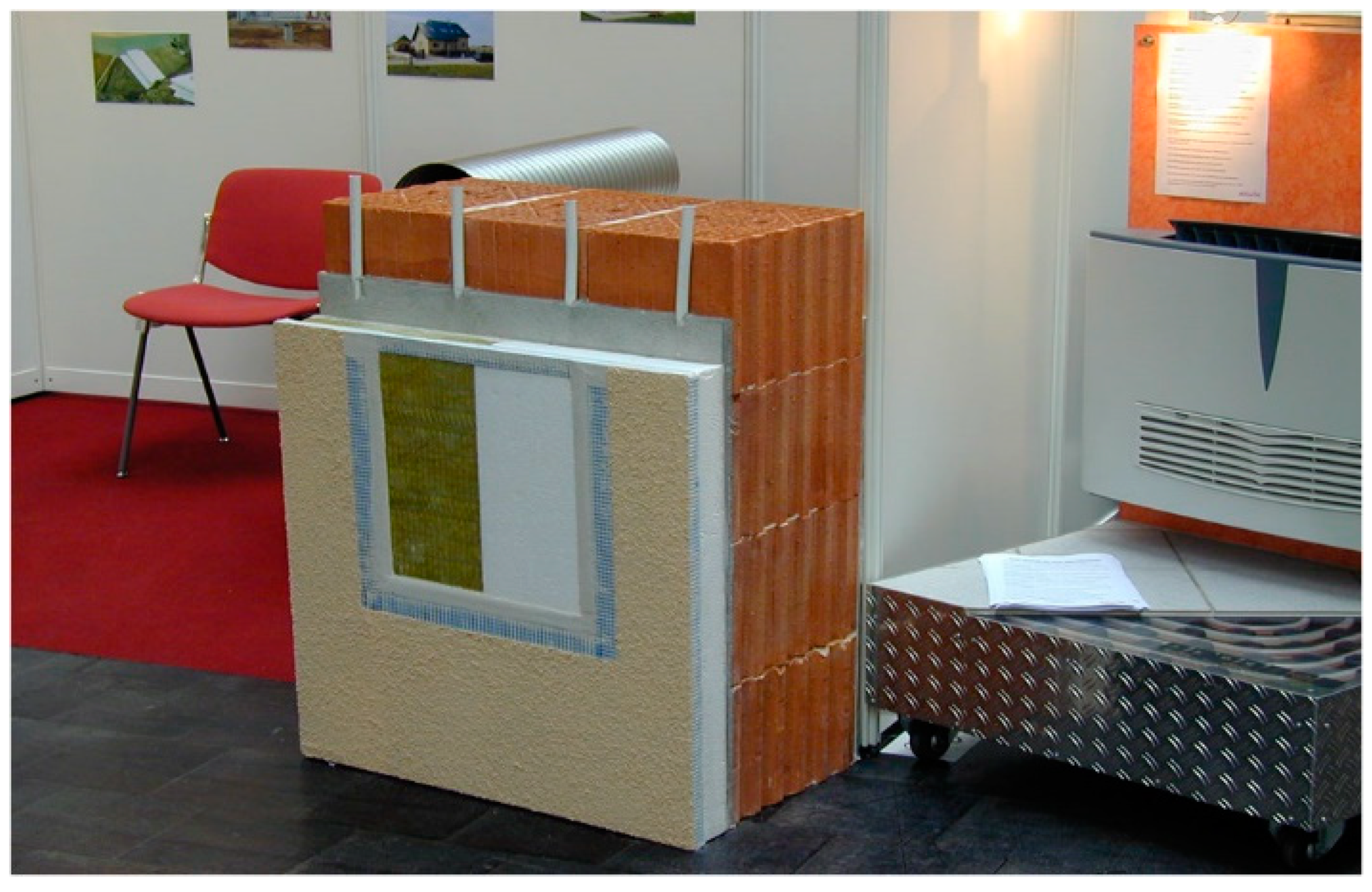

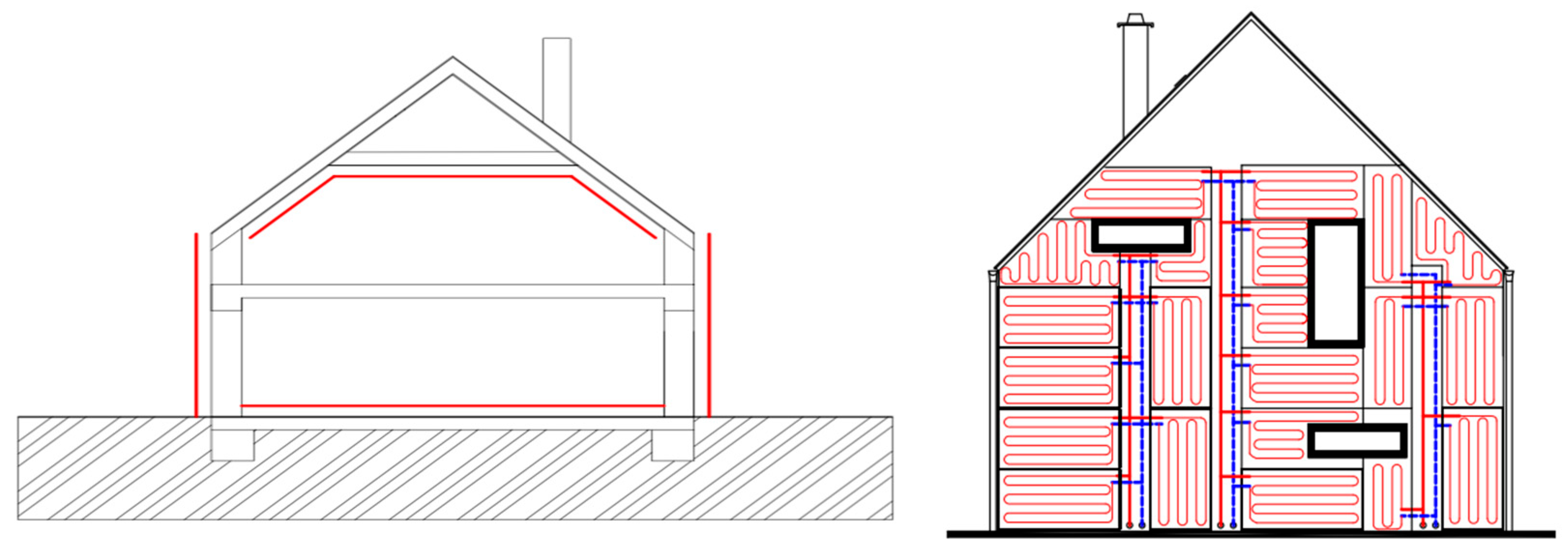

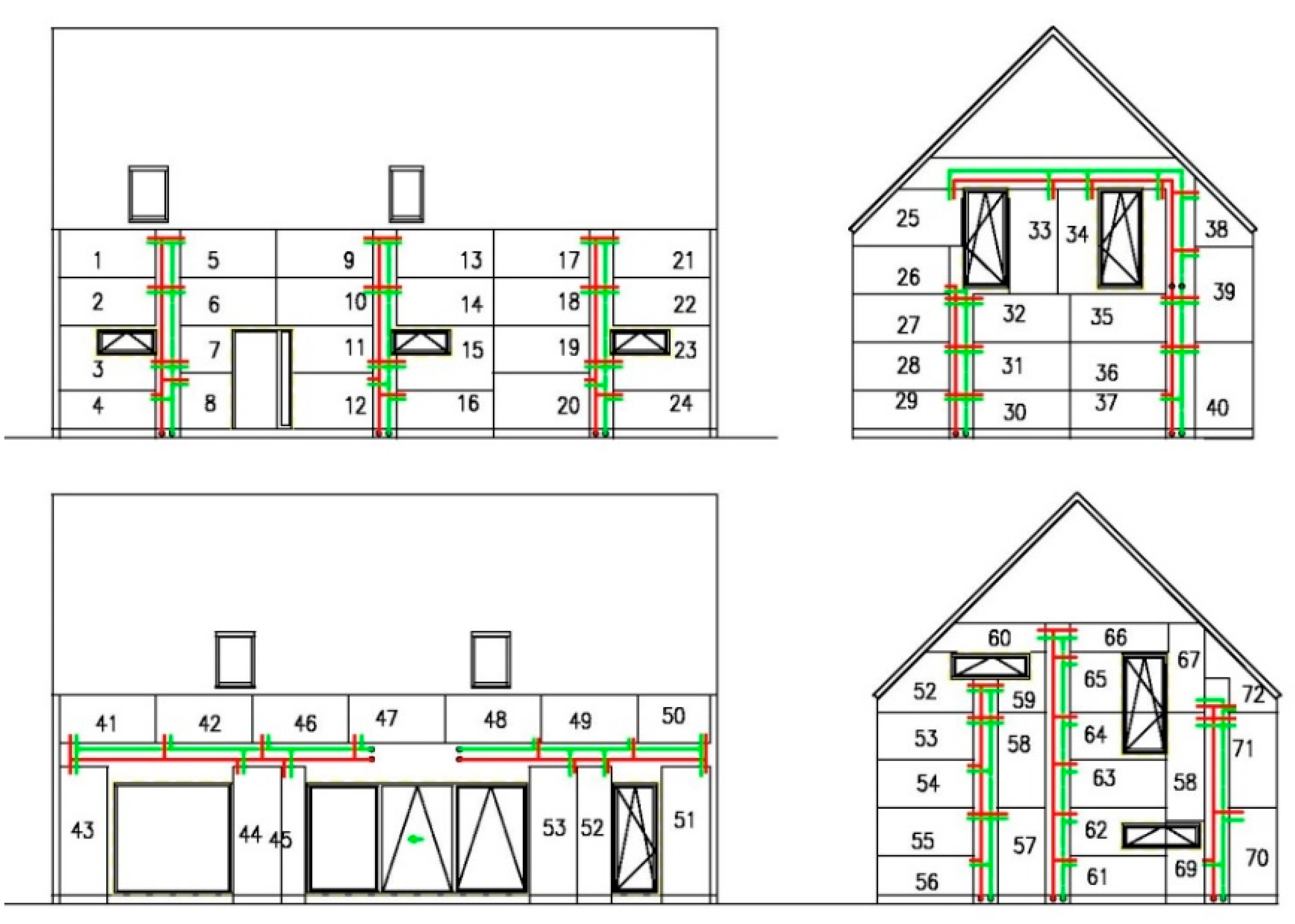

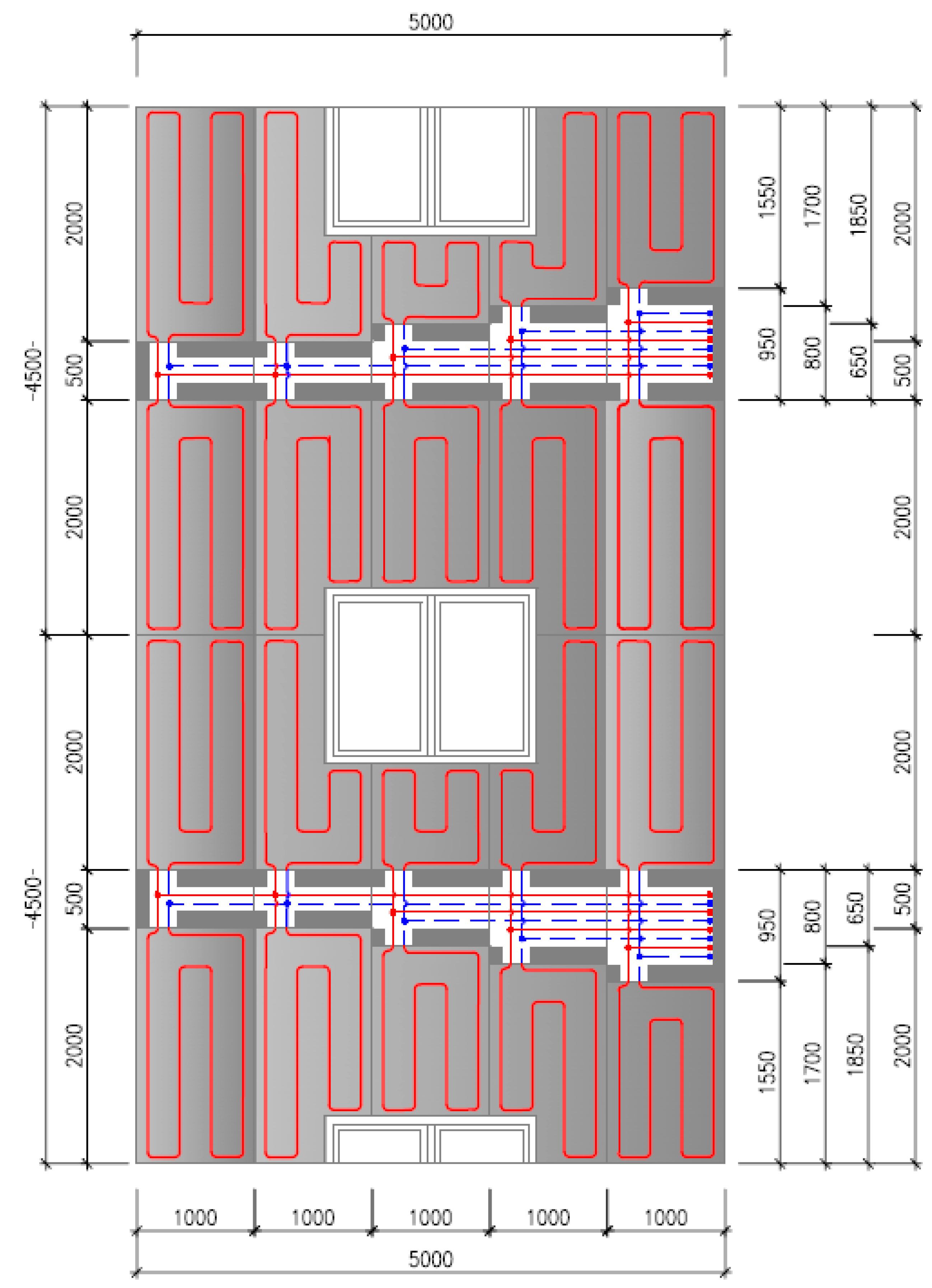

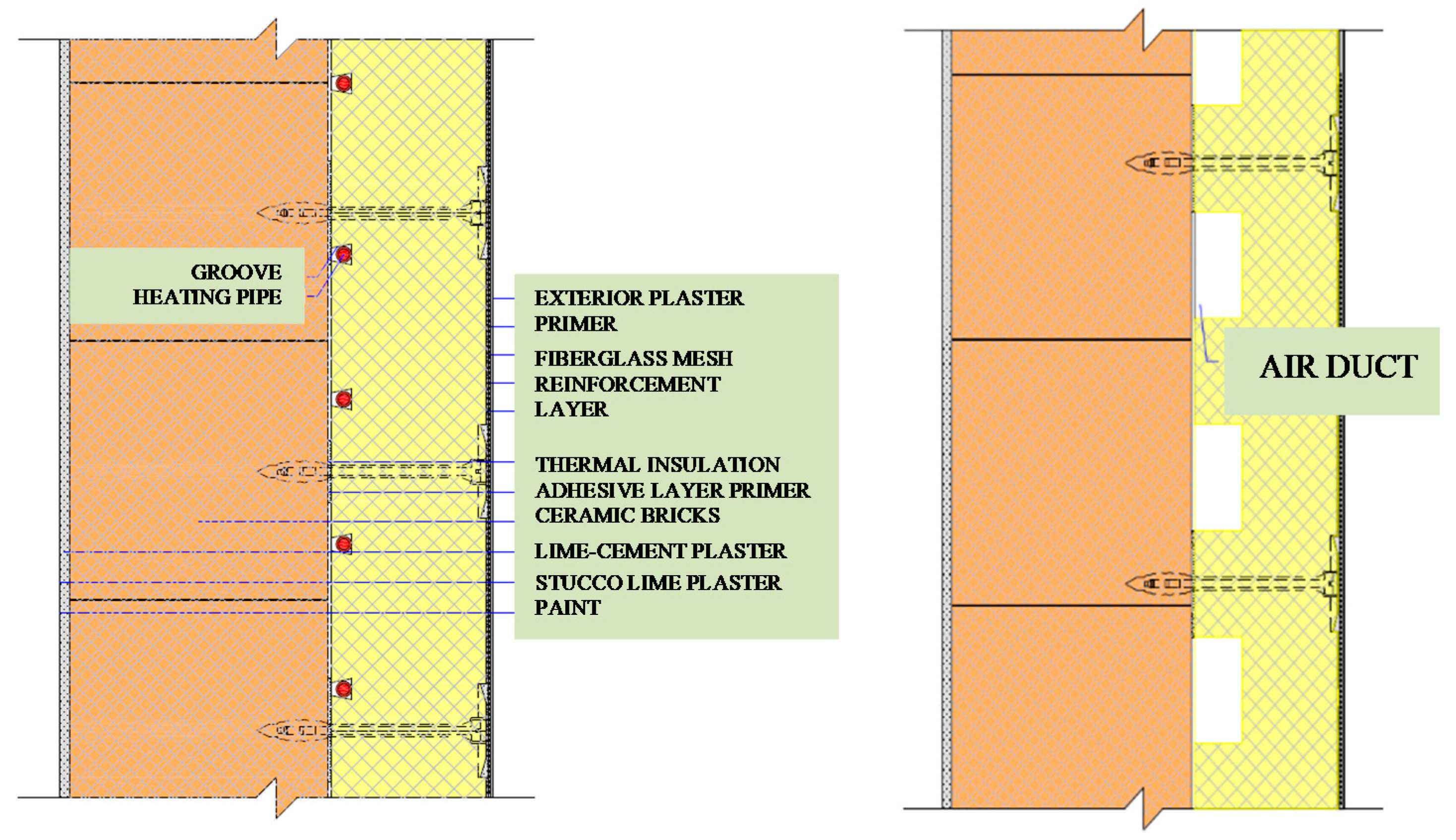

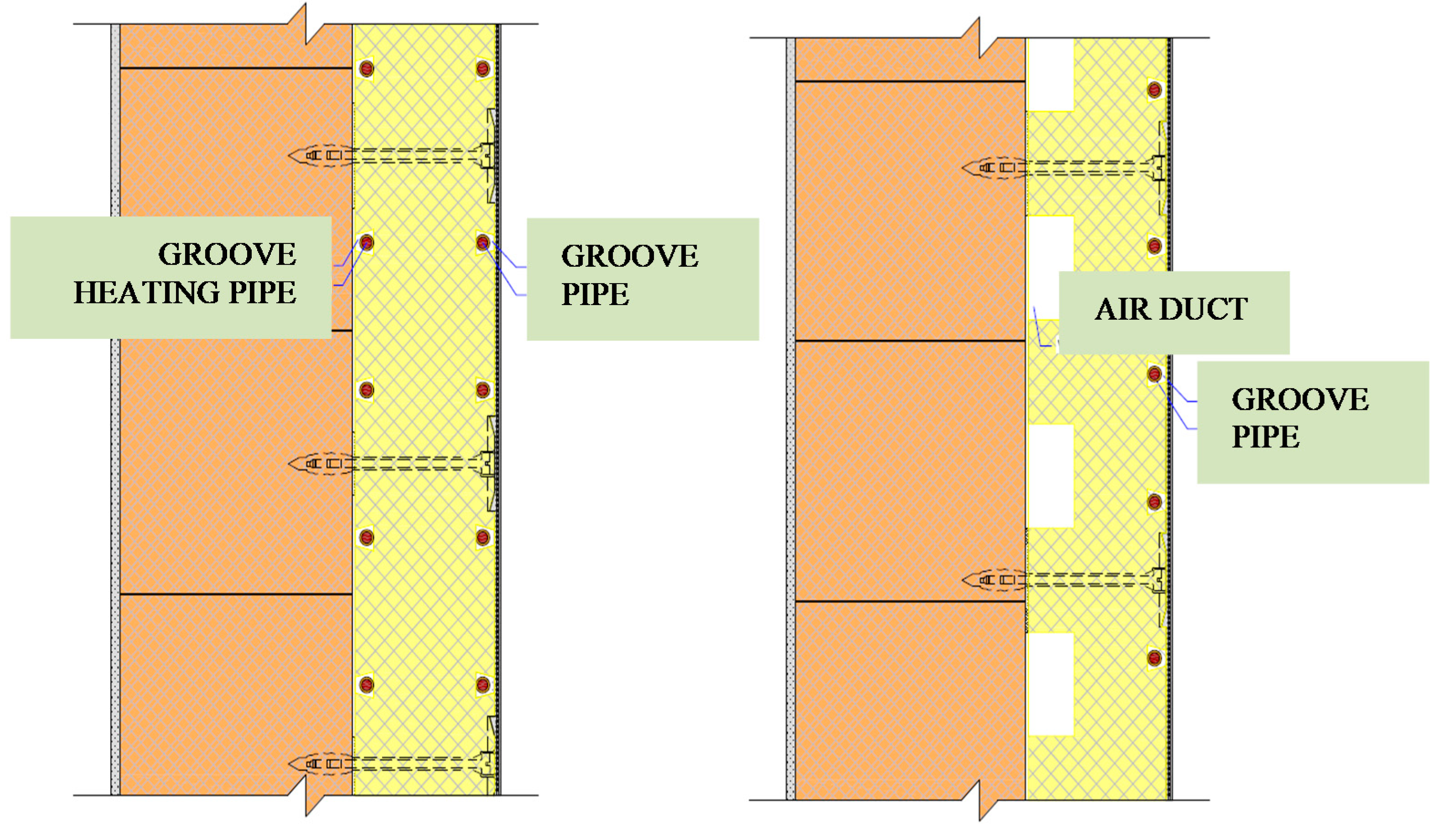

4.2. Description of Innovation

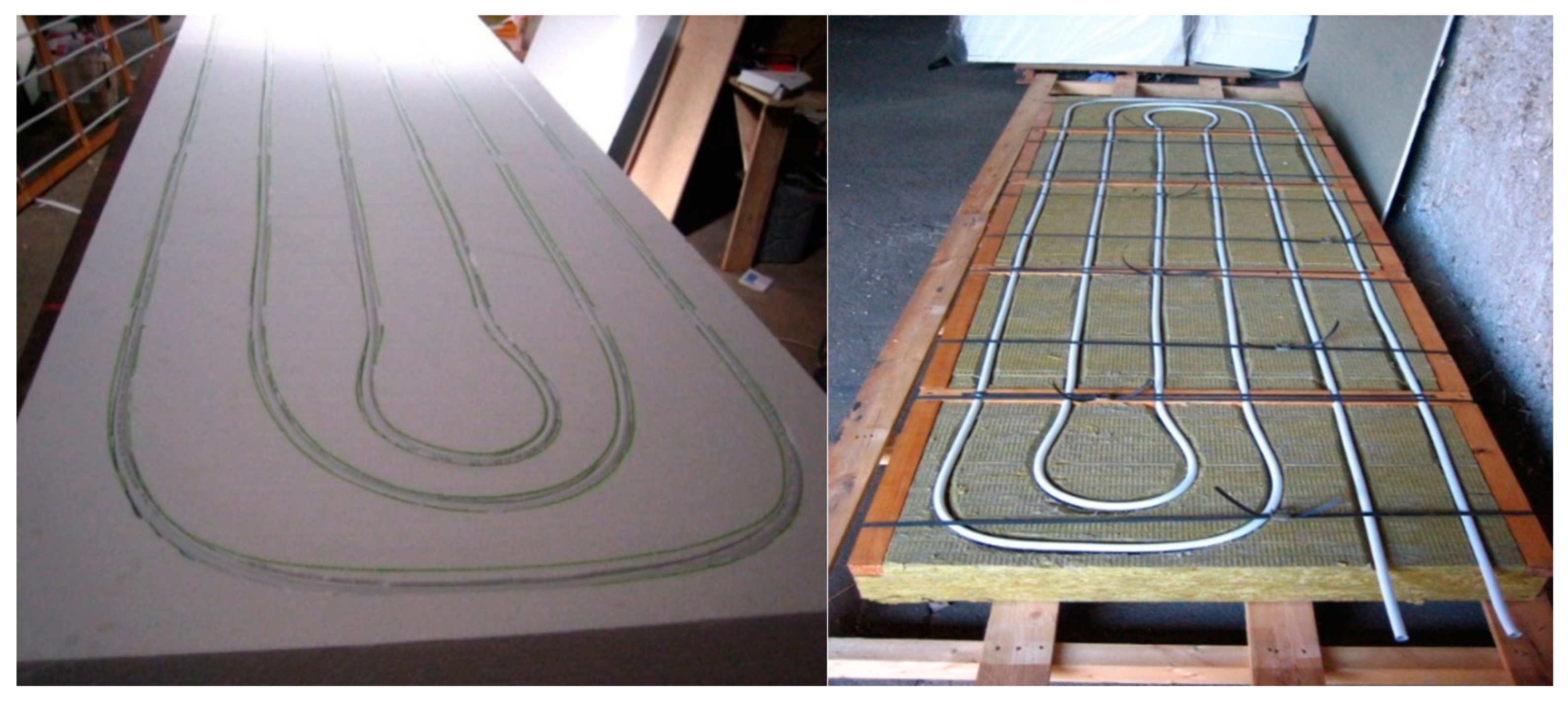

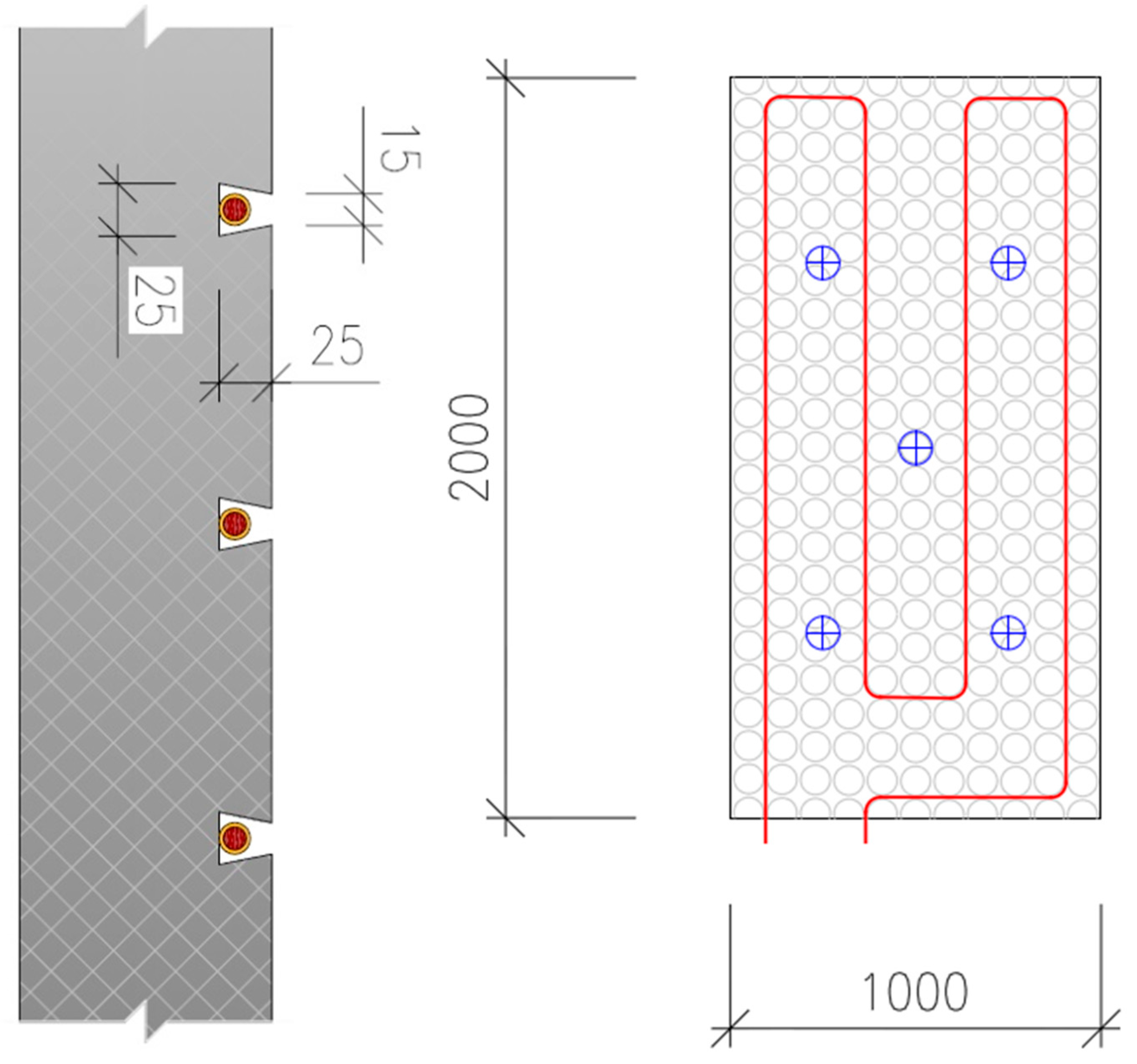

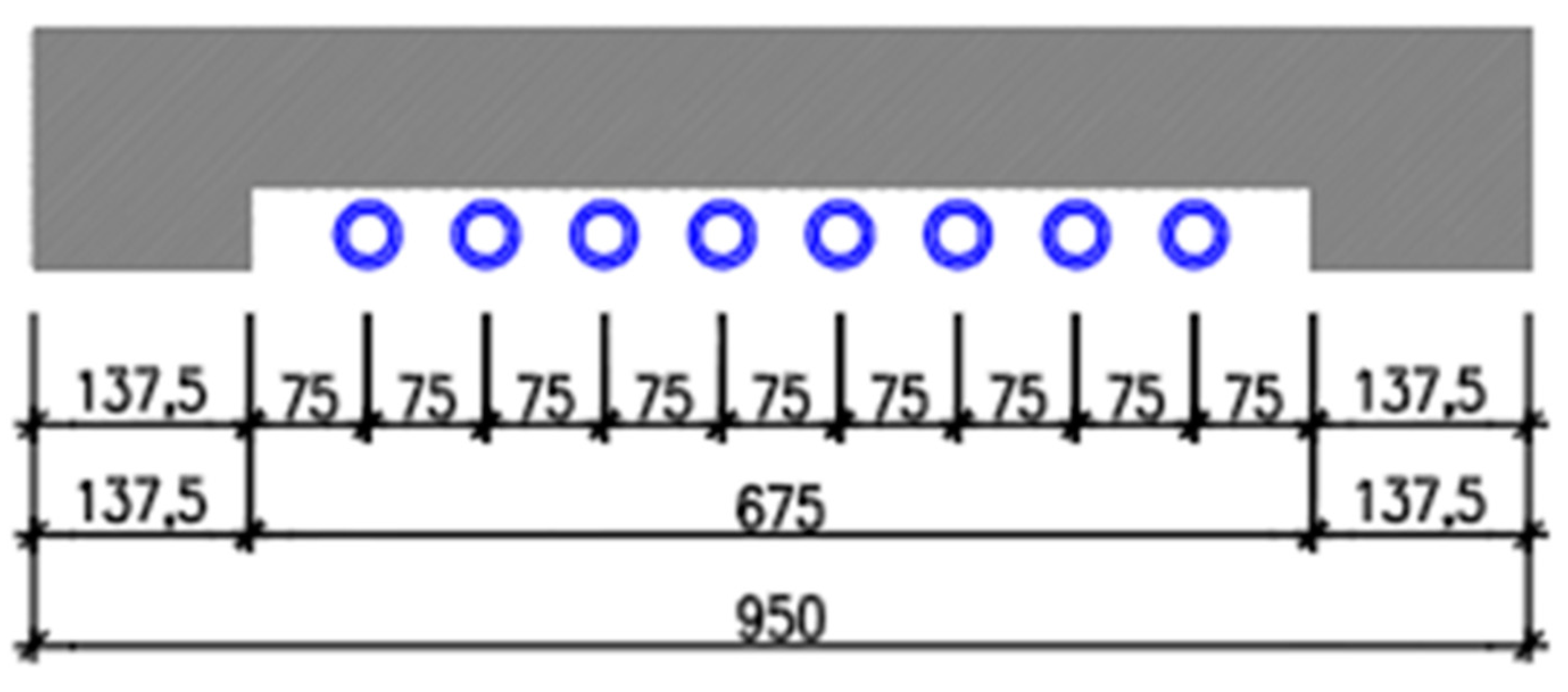

4.3. Technology of Production of Thermal Insulation Panels with Active Regulation of Heat Transfer

5. Discussion

5.1. Thermal Insulation Panels with Active Regulation of Heat Transfer with Integrated Active Area—Register for Heating and Cooling with Liquid or Gas as the Heat Carrier

5.2. Thermal Insulation Panels with Active Regulation of Heat Transfer with Integrated Active Area—Register Collecting Solar Energy and Energy of the Surrounding Environment, with Liquid or Gas as the Heat Carrier

5.3. Thermal Insulation Panels with Active Regulation of Heat Transfer with the Function of ATP (Heating and Cooling) and Active Area—Register Collecting Solar Energy and Energy of the Surrounding Environment, with Liquid or Gas as the Heat Carrier

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2018.156.01.0075.01.ENG (accessed on 14 March 2021).

- Šimko, M.; Krajčík, M.; Šikula, O.; Šimko, P.; Kalús, D. Insulation panels for active control of heat transfer in walls operated as space heating or as a thermal barrier: Numerical simulations and experiments. Energy Build. 2018, 158, 135–146. [Google Scholar] [CrossRef]

- Kalús, D.; Šimko, M.; Galváneková, M. Intelligent Facade System with Active Thermal Protection; Scholars’ Press: Stuttgart, Germany, 2014; p. 56. [Google Scholar]

- Krajčík, M.; Šikula, O. The possibilities and limitations of using radiant wall cooling in new and retrofitted existing buildings. Appl. Thermal Eng. 2020, 164, 114490. [Google Scholar] [CrossRef]

- Krajčík, M.; Šikula, O. Heat storage efficiency and effective thermal output: Indicators of thermal response and output of radiant heating and cooling systems. Energy Build. 2020, 229, 110524. [Google Scholar] [CrossRef]

- Oravec, J.; Šikula, O.; Krajčík, M.; Müslüm, A.; Mohapl, M. A comparative study on the applicability of six radiant floor, wall, and ceiling heating systems based on thermal performance analysis. J. Build. Eng. 2021, 36, 102133. [Google Scholar] [CrossRef]

- Krajčík, M.; Šikula, O. The possibilities of application of radiant wall cooling in existing buildings as a part of their retrofit. E3S Web Conf. 2019, 111, 7. [Google Scholar] [CrossRef]

- Tunçbileka, E.; Müslüm, A.; Krajčík, M.; Nižetić, S.; Karabay, H. Thermal performance based optimization of an office wall containing PCM under intermittent cooling operation. Appl. Thermal Eng. 2020, 179, 115750. [Google Scholar] [CrossRef]

- Zhu, Q.; Xu, X.; Gao, J.; Xiao, F. A semi-Dynamic simplified therm model of active pipe embedded building envelope based on frequency finite difference method. Int. J. Thermal Sci. 2015, 88, 170–179. [Google Scholar] [CrossRef]

- Christlieb, X.W. Gestión Térmica de una Vivienda con Mínimo Consumo de Energía–Proyecto de Fin de CARRERA; Universidad Pontificia Comillas: Madrid, Spain, 2007. [Google Scholar]

- Krzaczeka, M.; Kowalczuk, Z. Thermal Barrier as a technique of indirect heating and cooling for residential buildings. Int. J. Devoted Investig. Energy Use Effic. Build. Energy Build. 2011, 43, 823–837. [Google Scholar] [CrossRef]

- Babiak, J.; Olesen, B.W.; Petráš, D. Low Temperature Heating and High Temperature Cooling; Guidebook No 7; REHVA: Brussels, Belgium, 2007; p. 115. [Google Scholar]

- Kalús, D. EUROPEAN PATENT EP 2 572 057 B1: Heat Insulating Panel with Active Regulation of Heat Transition. In Bulletin 2014/42 European Patent Office, Slovak Republic. 2014; p. 67. Available online: https://wbr.indprop.gov.sk/WebRegistre/EPPatentPreSR/Detail/11716446.7 (accessed on 6 April 2021).

- Kalús, D. UTILITY MODEL SK 5725 Y1 (UTILITY MODEL): Tepelnoizolačný Panel pre Systémy s Aktívnym Riadením Prechodu Tepla. [Thermal Insulation Panel for Systems with Active Heat Transfer Control.] In Vestník ÚPV SR No.: 4/2011, Slovak Republic. 2011; p. 63. Available online: https://wbr.indprop.gov.sk/WebRegistre/UzitkovyVzor/Detail/5031-2010 (accessed on 6 April 2021).

- Krecké, E.D. Energetické Zariadenie Budov. [Energy Equipment of Buildings.] In Vestník ÚPV SR č.: 11/2005. Patent SK 284 751, 3 November 2005. [Google Scholar]

- ISOMAX. Available online: http://www.isomax.sk (accessed on 14 March 2021).

- Available online: http://www.isomax-terrasol.eu (accessed on 14 March 2021).

- ISOMAX–Technische Information. Available online: http://www.isomax-terrasol.eu/fileadmin/_migrated/content_uploads/ISOMAX-TerraSol-Technologie-DE.pdf (accessed on 6 April 2021).

- Cvíčela, M. Analysis of Wall Energy Systems. Master’s Thesis, Faculty of Civil Engineering, Slovak University of Technology in Bratislava, Bratislava, Slovakia, 2011; p. 119, SVF-13422-17675. [Google Scholar]

- Kalús, D.; Gašparík, J.; Janík, P.; Kubica, M.; Šťastný, P. Research Project HZ PG73/2011-Experimental Measurements, Analysis, and Determination of the Optimal Rate of Use of Renewable Energy Sources on a Prototype of a Family House EB2020 with Nearly Zero Energy Demand; Department of Building Services, Faculty of Civil Engineering, Slovak University of Technology in Bratislava: Bratislava, Slovakia, 2011–2013. [Google Scholar]

- Janík, P. Optimization of Energy Systems with Long-Term Heat Accumulation. Master’s Thesis, Faculty of Civil Engineering, Slovak University of Technology in Bratislava, Bratislava, Slovakia, 2013; p. 185, SvF-13422-16657. [Google Scholar]

- Petráš, D.; Lulkovičová, O.; Takács, J.; Füri, B. Nízkoteplotné Vykurovanie a Obnoviteľné Zdroje Energie; JAGA: Bratislava, Slovakia, 2001; p. 271. [Google Scholar]

- Petráš, D.; Lulkovičová, O.; Füri, B.; Takács, J. Nízkoteplotní Vytápění a Obnovitelné Zdroje Energie; JAGA Group: Bratislava, Slovakia, 2008; p. 216. [Google Scholar]

- STN 06 0312: Ústredné Sálavé Vykurovanie so Zabetónovanými Rúrkami. Projektovanie a Montáž. [Radiation Central Heating with Concreted Tubes. Projection and Installation]. Available online: https://normy.unms.sk/eshop/public/standard_detail.aspx?id=52393 (accessed on 6 April 2021).

- Kalús, D. UTILITY MODEL SK 5729 Y1 (UTILITY MODEL): Samonosný Tepelnoizolačný Panel pre Systémy s Aktívnym Riadením Prechodu Tepla. [Self-Supporting Thermal Insulation Panel for Systems with Active Heat Transfer Control.] In Vestník ÚPV SR No.: 4/2011, Slovak Republic. 2011; p. 32. Available online: https://wbr.indprop.gov.sk/WebRegistre/UzitkovyVzor/Detail/5030-2010 (accessed on 6 April 2021).

- Kalús, D. UTILITY MODEL SK 5749 Y1 (UTILITY MODEL): Spôsob Prevádzky Kombinovaného Stavebno-Energetického Systému Budov a Zariadenie. [Method of Operation of a Combined Construction-Energy System of Buildings and Equipment.] In Vestník ÚPV SR No.: 5/2011, Slovak Republic. 2011. Available online: https://wbr.indprop.gov.sk/WebRegistre/UzitkovyVzor/Detail/5027-2010 (accessed on 6 April 2021).

- Kalús, D. Research Project HZ 04-309-05-Design of a Passive House Using Solar and Geothermic Energy; Department of Building Services, Faculty of Civil Engineering, Slovak University of Technology in Bratislava: Bratislava, Slovakia, 2006. [Google Scholar]

- Kalús, D. Research Project HZ 04-310-05-Assessment of Thermal Comfort State in an Experimental House; Slovak Republic, Department of Building Services, Faculty of Civil Engineering, Slovak University of Technology in Bratislava: Bratislava, Slovakia, 2006. [Google Scholar]

- Kalús, D. Research Project HZ 04-142-07-Assessment of Thermal Comfort State in an Experimental House; Department of Building Services, Faculty of Civil Engineering, Slovak University of Technology in Bratislava: Bratislava, Slovakia, 2007. [Google Scholar]

- Kalús, D. Research Project HZ PR10/2015-Analysis of Energy, Economic, Environmental Aspects and Experimental Measurements of Compact Equipment of Energy Systems for the Application of Renewable Energy Sources; Department of Building Services, Faculty of Civil Engineering, Slovak University of Technology in Bratislava: Bratislava, Slovakia, 2015. [Google Scholar]

- Šimko, M. Energy Efficiency in Buildings with Systems with Active Thermal Protection. Master’s Thesis, Faculty of Civil Engineering, Slovak University of Technology in Bratislava, Bratislava, Slovakia, 2017; p. 152, SvF-13422-49350. [Google Scholar]

- Available online: https://www.asb.sk/stavebnictvo/zateplenie/expandovany-polystyren-pouzivany-na-zateplovanie-je-environmentalne-vhodny-material (accessed on 6 April 2021).

- STN 73 2901/01: Zhotovovanie vonkajších tepelno-izolačných kontaktných systémov ETICS. 2015. Available online: https://www.stavomat.com/--13-87-stn-73-2901-2015-zhotovovanie-vonkajsich-tepelnoizolacnych-kontaktnych-systemov-etics- (accessed on 6 April 2021).

| θe (°C) | θi (°C) | θm (°C) | θd (°C) | θp (°C) | q (W/m2) | Q″ (W/m2) | |

|---|---|---|---|---|---|---|---|

| Structure A | −11 | 20 | 20 | 20.00 | 20.00 | 0.000 | 3.390 |

| −11 | 20 | 25 | 24.33 | 22.20 | 17.632 | 4.723 | |

| −11 | 20 | 30 | 28.66 | 24.41 | 35.264 | 6.055 | |

| −11 | 20 | 35 | 32.99 | 26.61 | 52.896 | 7.388 | |

| −11 | 20 | 40 | 37.32 | 28.82 | 70.528 | 8.721 | |

| −11 | 20 | 45 | 41.65 | 31.02 | 88.160 | 10.054 | |

| Structure B | −11 | 20 | 20 | 20.00 | 20.00 | 0.000 | 6.375 |

| −11 | 20 | 25 | 24.87 | 20.34 | 2.753 | 9.190 | |

| −11 | 20 | 30 | 29.73 | 20.69 | 5.507 | 12.006 | |

| −11 | 20 | 35 | 34.60 | 21.03 | 8.260 | 14.822 | |

| −11 | 20 | 40 | 39.46 | 21.38 | 11.014 | 17.637 | |

| −11 | 20 | 45 | 44.33 | 21.72 | 13.767 | 20.453 | |

| Structure C | −11 | 20 | 20 | 20.00 | 20.00 | 0.000 | 7.827 |

| −11 | 20 | 25 | 24.79 | 20.30 | 2.389 | 11.231 | |

| −11 | 20 | 30 | 29.58 | 20.60 | 4.777 | 14.635 | |

| −11 | 20 | 35 | 34.37 | 20.90 | 7.166 | 18.039 | |

| −11 | 20 | 40 | 39.16 | 21.19 | 9.555 | 21.443 | |

| −11 | 20 | 45 | 43.96 | 21.49 | 11.944 | 24.847 |

| θe (°C) | θi (°C) | θm (°C) | θd (°C) | θp (°C) | q (W/m2) | q″ (W/m2) | |

|---|---|---|---|---|---|---|---|

| Structure A | 32 | 26 | 16 | 17.34 | 21.59 | −35.264 | −12.508 |

| 32 | 26 | 17 | 18.20 | 22.03 | −31.738 | −12.242 | |

| 32 | 26 | 18 | 19.07 | 22.47 | −28.211 | −11.975 | |

| 32 | 26 | 19 | 19.94 | 22.91 | −24.685 | −11.708 | |

| 32 | 26 | 20 | 20.80 | 23.36 | −21.164 | −11.101 | |

| 32 | 26 | 21 | 21.67 | 23.80 | −17.632 | −11.175 | |

| Structure B | 32 | 26 | 16 | 16.27 | 25.31 | −5.507 | −24.140 |

| 32 | 26 | 17 | 17.24 | 25.38 | −4.956 | −23.576 | |

| 32 | 26 | 18 | 18.22 | 25.45 | −4.406 | −23.013 | |

| 32 | 26 | 19 | 19.19 | 25.52 | −3.855 | −22.450 | |

| 32 | 26 | 20 | 20.16 | 25.59 | −3.304 | −21.887 | |

| 32 | 26 | 21 | 21.13 | 25.66 | −2.753 | −21.324 | |

| Structure C | 32 | 26 | 16 | 16.42 | 25.40 | −4.777 | −29.533 |

| 32 | 26 | 17 | 17.38 | 25.46 | −4.300 | −28.852 | |

| 32 | 26 | 18 | 18.33 | 25.52 | −3.822 | −28.171 | |

| 32 | 26 | 19 | 19.29 | 25.58 | −3.344 | −27.490 | |

| 32 | 26 | 20 | 20.25 | 25.64 | −2.866 | −26.810 | |

| 32 | 26 | 21 | 21.21 | 25.70 | −2.389 | −26.129 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalús, D.; Gašparík, J.; Janík, P.; Kubica, M.; Šťastný, P. Innovative Building Technology Implemented into Facades with Active Thermal Protection. Sustainability 2021, 13, 4438. https://doi.org/10.3390/su13084438

Kalús D, Gašparík J, Janík P, Kubica M, Šťastný P. Innovative Building Technology Implemented into Facades with Active Thermal Protection. Sustainability. 2021; 13(8):4438. https://doi.org/10.3390/su13084438

Chicago/Turabian StyleKalús, Daniel, Jozef Gašparík, Peter Janík, Matej Kubica, and Patrik Šťastný. 2021. "Innovative Building Technology Implemented into Facades with Active Thermal Protection" Sustainability 13, no. 8: 4438. https://doi.org/10.3390/su13084438

APA StyleKalús, D., Gašparík, J., Janík, P., Kubica, M., & Šťastný, P. (2021). Innovative Building Technology Implemented into Facades with Active Thermal Protection. Sustainability, 13(8), 4438. https://doi.org/10.3390/su13084438