1. Introduction

In Rwanda, about 75% of buildings are constructed with baked clay bricks [

1]. The industrial subsector Masterplan for Construction Materials for Rwanda identified an abundance of available local construction materials, such as clay, wood, sand, and stone [

2]. The hilly terrain of Rwanda creates a natural movement of surface water from the hills to the valley. Soils on the hills are generally stony, while clay and silt are washed from the highlands into the valleys, leaving large deposits of clay in some valleys. The efforts to utilize the existing local materials may well explain the popularity of baked clay bricks in the construction industry. While the formal brick industries are conscious of environmental issues posed by choice of firing materials by the use of rice or coffee husks (waste biomaterials), the informal local brick producers most often use wood with environmental effect on the forests. Furthermore, most firing burners are inefficient with incomplete combustion and substantial carbon emission. In the informal sector, the baked brick production can be seen to be cumbersome and labor intensive. Humanitarian News [

3] reported of environmental concern as brick makers quarry near banks destroying natural vegetation. Since poor people directly depend on natural resources and natural services for their survival, a clear link between poverty reduction and environmental degradation is established [

4].

While the baked bricks have firing issues, the cement stabilized soil blocks require 7 to 12% cement of content to produce a block of adequate resistance against surface erosion. The opinion that the addition of cement to earth raised fundamental sustainability questions against earth construction was laid to rest by the analysis made by Walker and Standards Australia [

5], which indicated that clay bricks consume between 1.0 and 7.0 GJ per ton, of which 80% to 90% is used in drying and firing, thus replacing firing with cement stabilization and reducing the energy consumed in the block production process by at least 50%.

Attempts were made at solving the limitations of ‘earth’ as a building material [

6,

7,

8,

9]. The prospect of durability of earth walls is dependent on how well the forces of erosion on its surface are resisted. This is of the utmost importance to social acceptability and the future of earthen architecture [

10]. Rammed earth and compressed earth are areas of focus of modern research in a continuous efforts to explore and improve sustainable earthen architecture.

The analysis of Egenti et al. [

11] is shown in

Table 1; it takes 43.5 kg of cement to produce blocks for 1 m

2 of compressed earth wall of 200 mm thickness with 12% stabilization. The subject of cement content in compressed earth walls, for desirable effect and durability should be addressed critically and minimized.

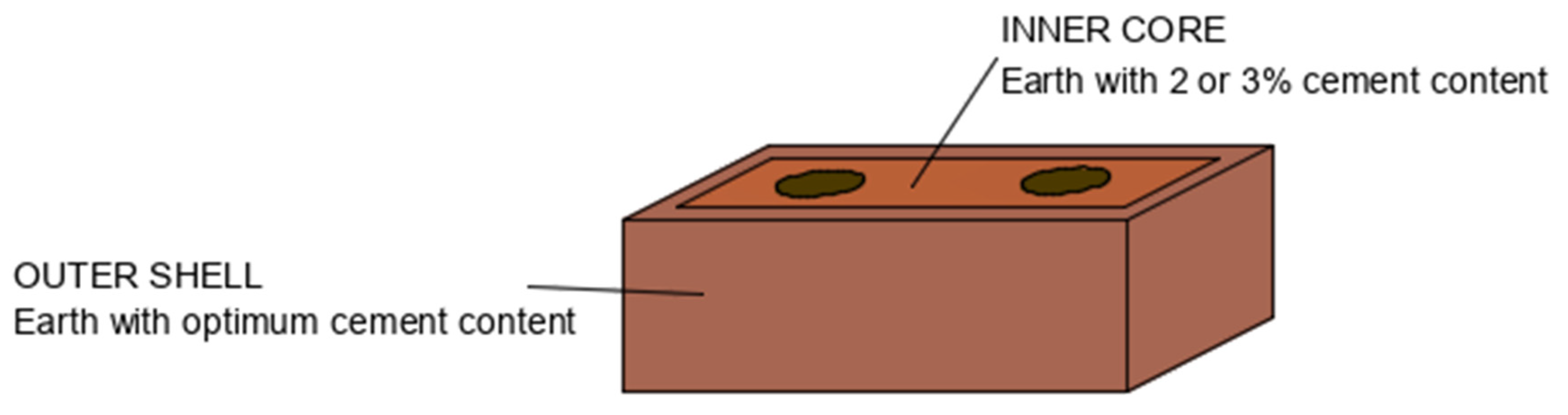

1.1. Shelled Compressed Earth Blocks

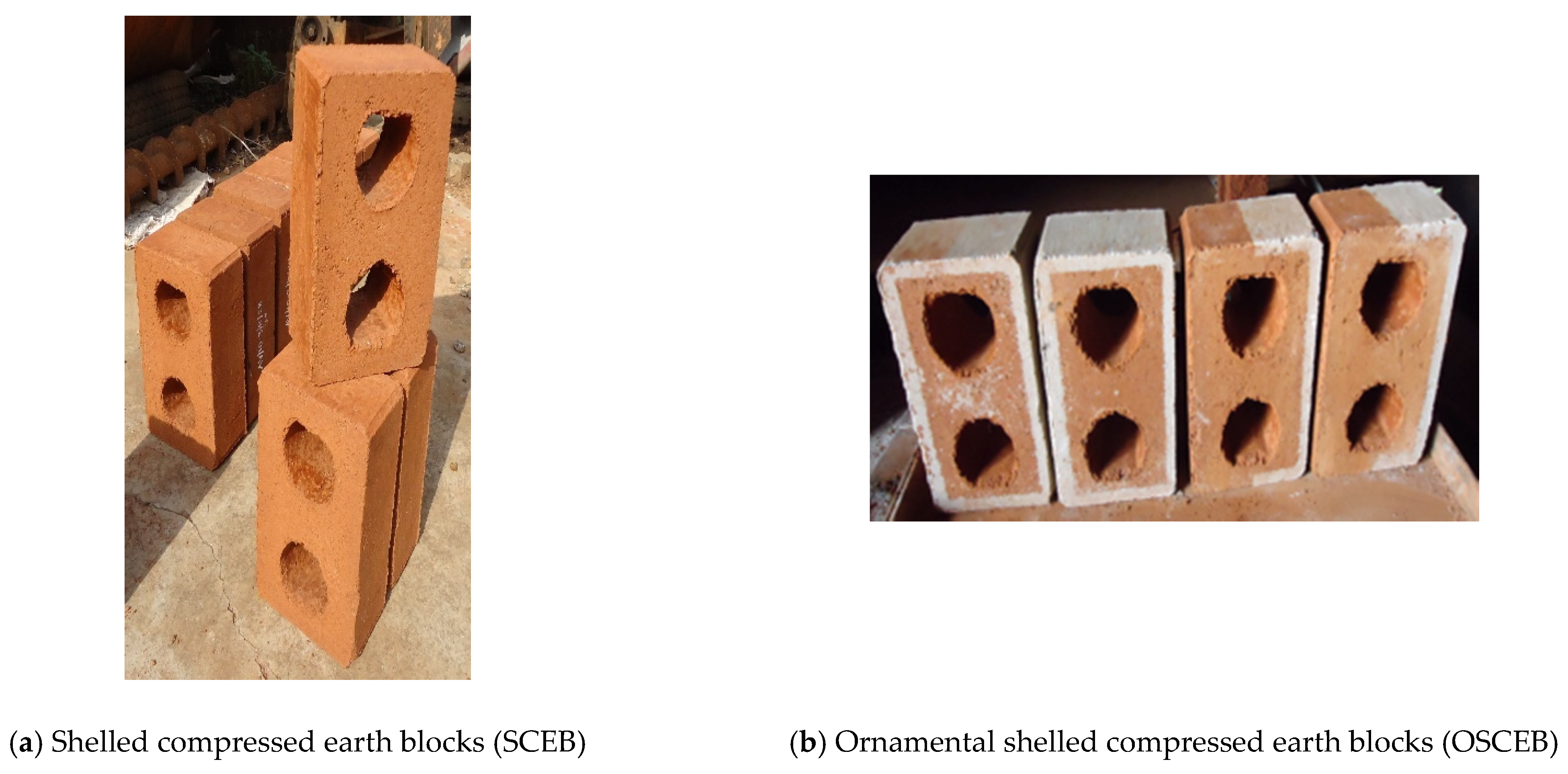

In a bid to reduce the amount of cement while maintaining quality of blocks, shelled compressed earth blocks (SCEB) was evolved by Egenti et al. [

12] as shown in

Figure 1. SCEB is a compressed earth block of two layers of different materials or percentages of cement content, compressed into a block. The inner layer/core may constitutes up to 60% of the total volume of a unit block and may be stabilized with 0–3% cement. The outer layer/shell of about 40% of total volume of unit block can be stabilized with higher (8–12%) cement content. All were mechanically compressed into a single unit block. The structure of SCEB and wall is illustrated in

Figure 1. The structure gives adequate strength and surface resistance to the exposed part of the earth block with less overall cement content and cost. A quality earthen architecture can be achieved with substantial reduction in cement with SCEB.

The SCEB wall is a framework of shell in a supportive and interwoven structure and the inner core in a protective confinement [

12].

1.2. Earth Walls in Urban and Rural Areas

Earth walls are environmentally friendly with less use of cement and low embodied energy. While the challenges and desired characteristics of compressed earth building are simple and few in rural areas, they are more demanding in the urban areas as shown in

Table 2.

This research aims to produce a model of compressed earth masonry units of high surface resistance with less cement and less weight for affordable and sustainable housing in Rwanda.

2. Materials and Methods

The materials and technique to explore or adopt are dependent on the environment and the ways relevant soil and natural deposits are constituted. Appropriate materials were fetched from locations in Rwanda and subjected to relevant standard tests.

2.1. Muhanzi Clay Soil

The clay soil sample used for this research work was taken from Muhanzi in the Muhanga district of Rwanda, a place popularly known for its production of fired bricks. Particle size distribution and plasticity index tests were conducted in accordance with BS EN ISO 17892-12:2018 [

13].

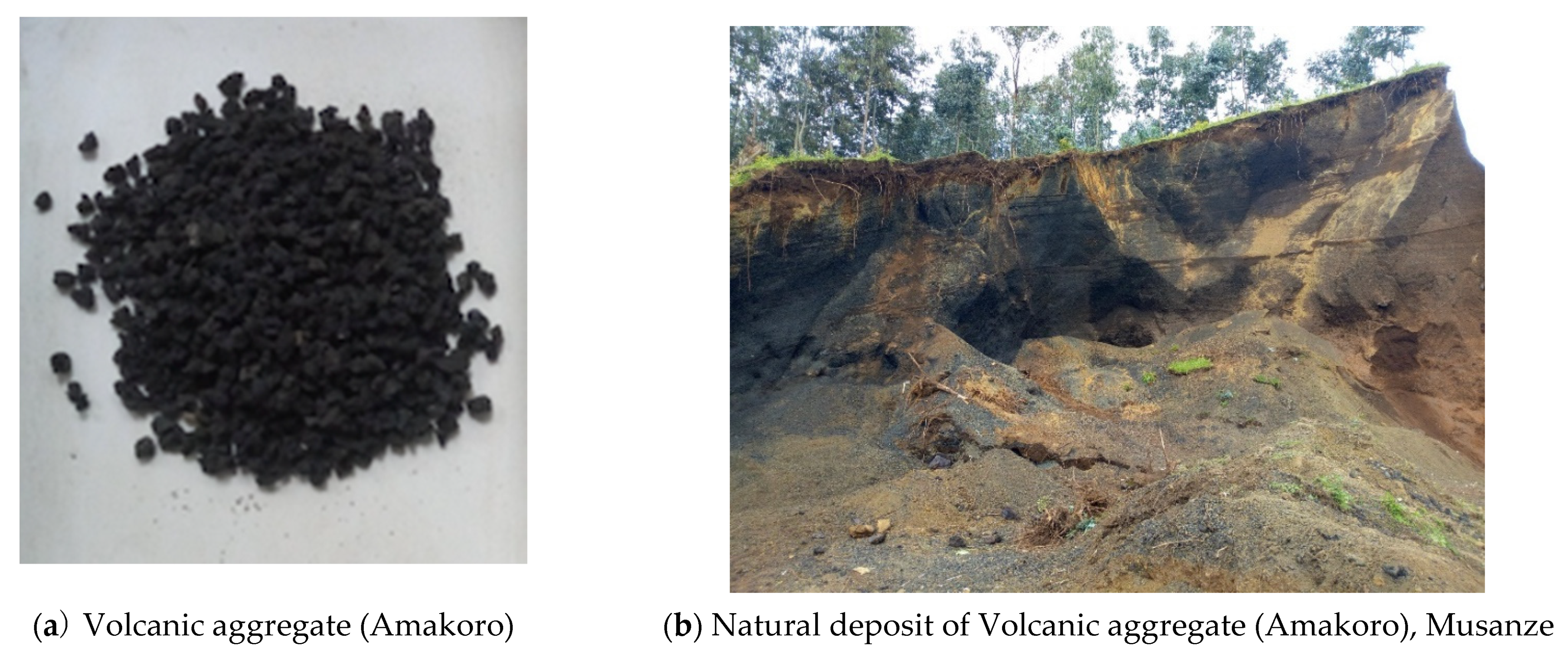

2.2. Volcanic Aggregate (Amakoro), Musanze

Samples of volcanic aggregate was collected from Musanze (shown in

Figure 2a) and used in this research as lightweight aggregate added to Muhanzi clay soil. The dramatic deposit of Volcanic sand/gravel in Musanze exists in two colors: black and golden yellow as shown if

Figure 2b. A mountain of loose volcanic aggregate were clean and ready for use. Local settlers used this material as aggregate for building works. The particle size distribution was conducted in accordance with BS EN ISO 17892-12:2018 [

13].

2.3. Research Design/Analytical Approach

A research design was proposed in

Table 3 and used within the framework of material requirements, available resources, past research works, and standards.

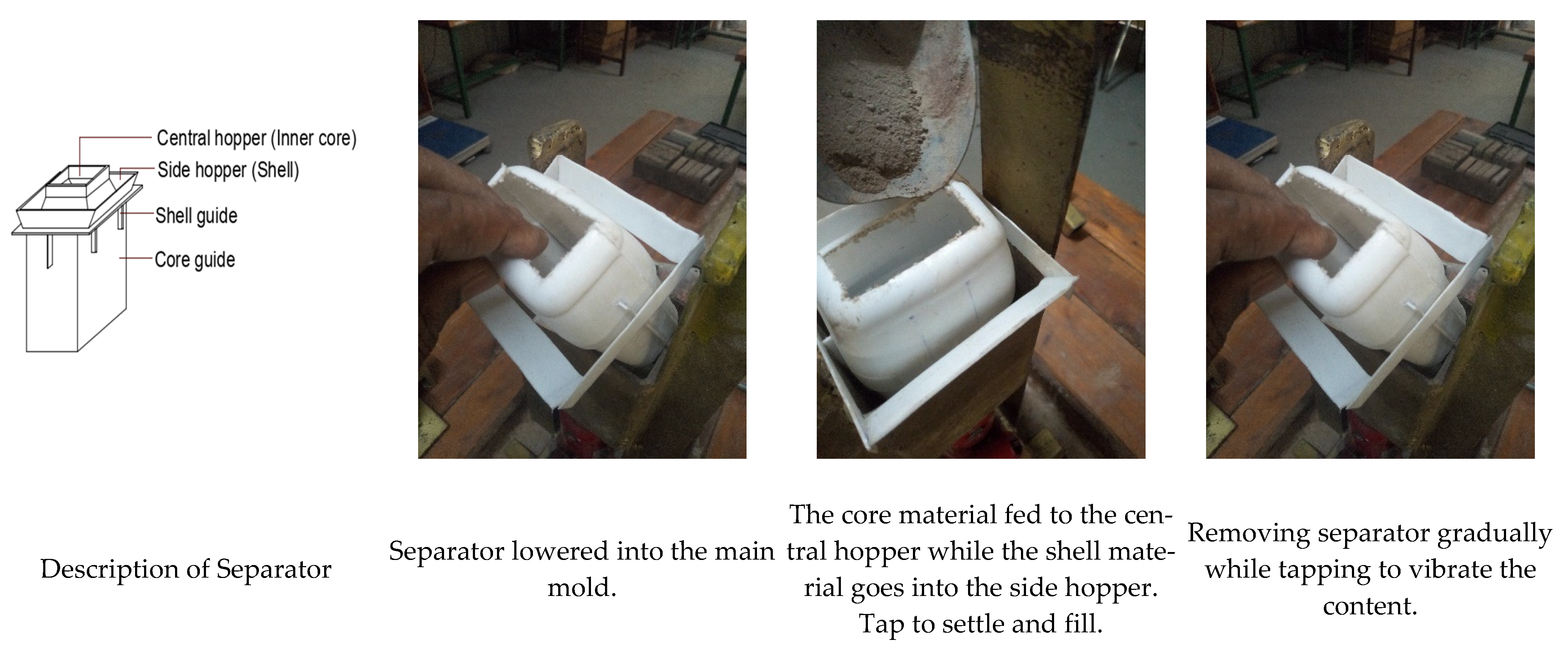

2.4. Mechanical Kit for Production of Laboratory Samples

A mechanical kit was fabricated for the production of laboratory samples of CEB with uniform compaction pressure. Standard masonry tests were conducted on specimens of SCEB. The mechanical kit, as shown in

Figure 3, was fabricated similar to an earlier one described in Egenti et al. [

12] and illustrated in

Figure 4.

2.5. Surface Resistance Test

Surface resistance of block was tested using ‘surface integrity test’ method in Egenti et al. [

11]—(a simple hand test, evolved by curiosity and found to be effective in assessment of surface resistance/integrity of clay based masonry unit).

3. Results

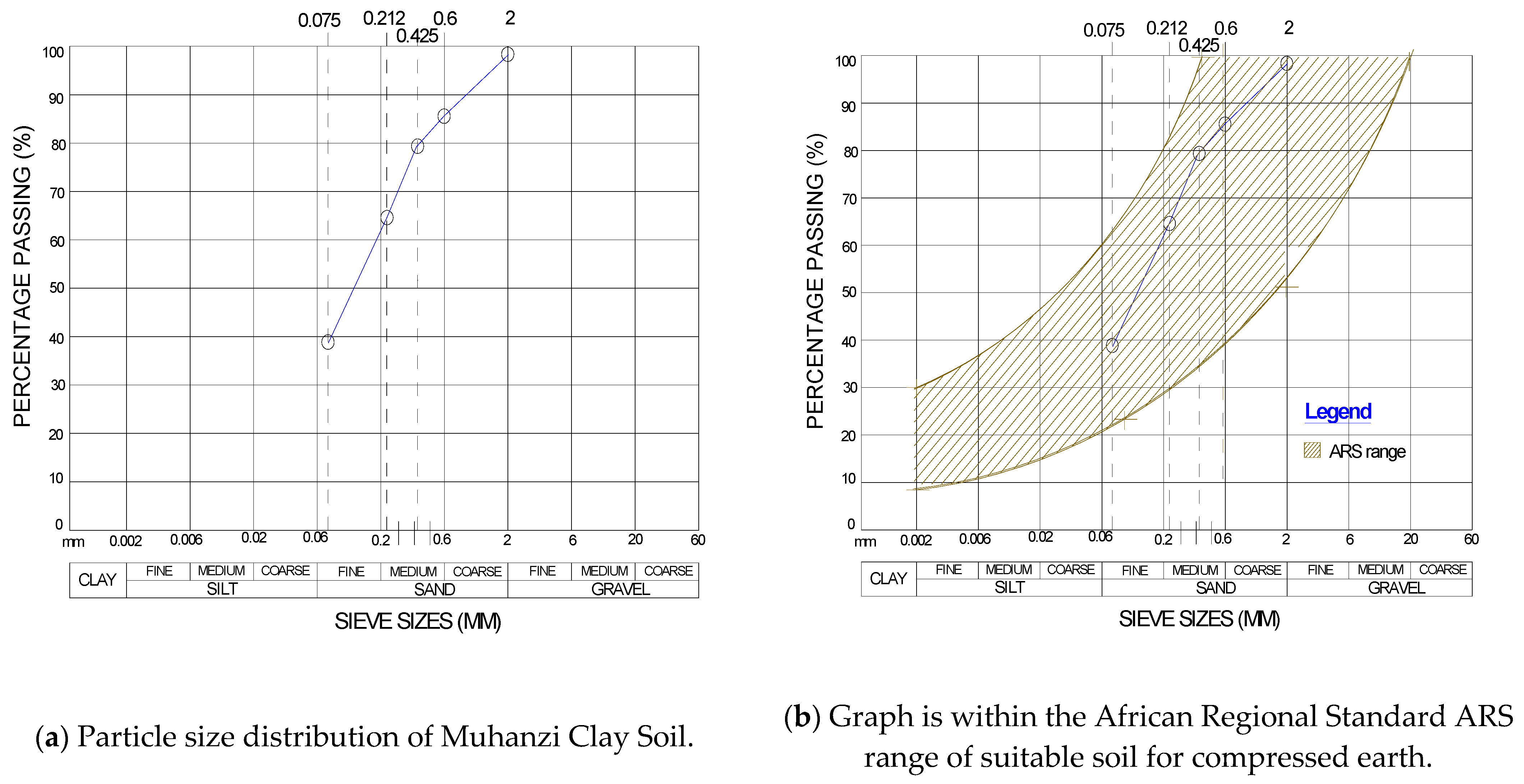

3.1. Particle Size Distribution and Plasticity Index of Muhanzi Clay Soil

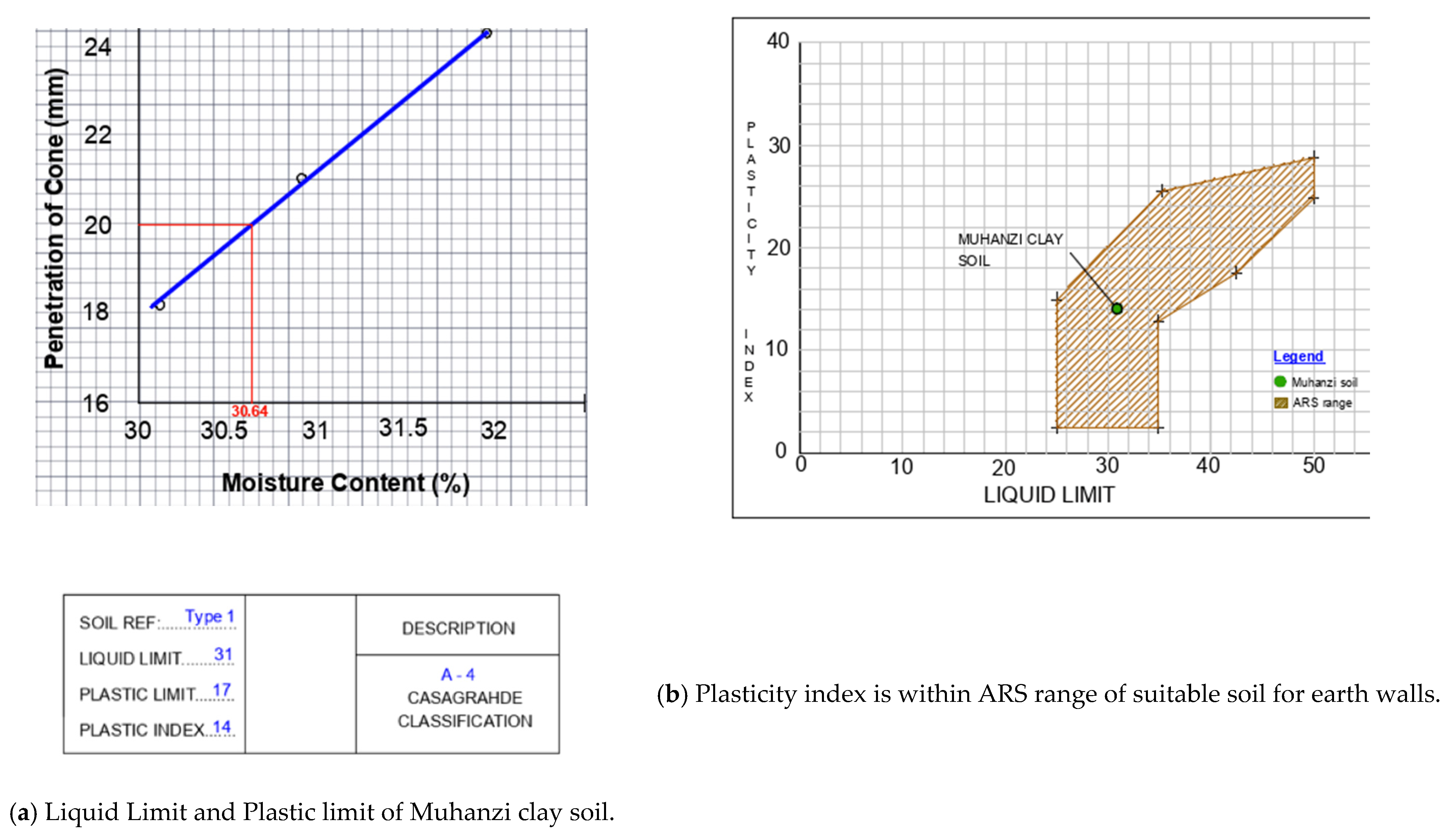

The particle size distribution of Muhanzi clay soil and its plasticity index are shown in

Figure 5 and

Figure 6. The Muhanzi clay soil is composed of about 40% of silt and clay, combined with 60% of sand in range of fine, medium, and coarse (

Figure 5a). The composition is within the African Regional Standards (ARS) range of suitable soil for compressed earth as shown in

Figure 5b. ARS are compressed earth blocks standards intended to guide earth construction activities in the African regions.

The liquid limit and plastic limits of Muhanzi clay soil were 31 and 17, respectively, as shown in

Figure 6a. The plasticity index of 14 falls within the ARS range of suitable soil for earth walls (

Figure 6b).

3.2. Particle Size Distribution of Volcanic Aggregate (Amakoro)

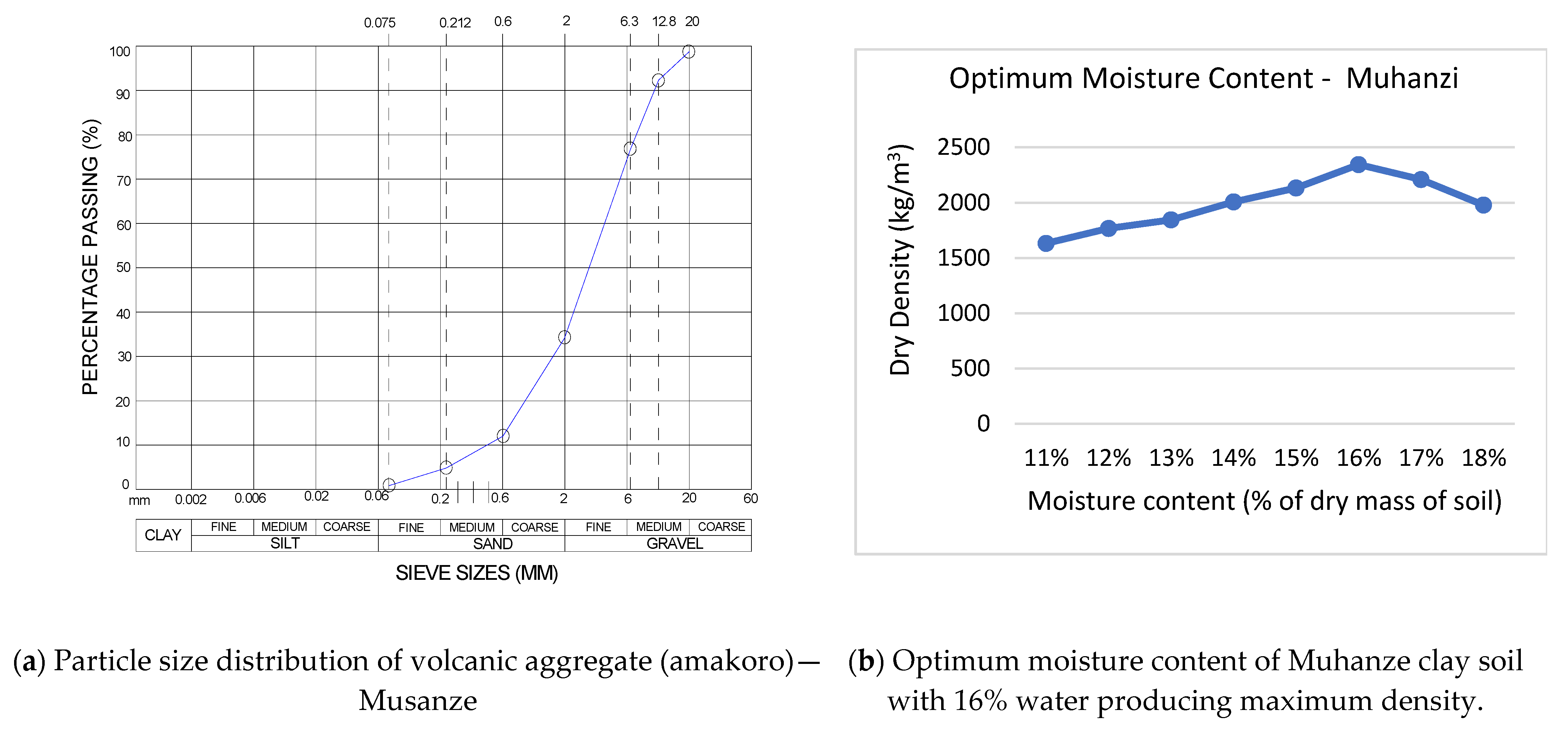

The composition of the volcanic aggregate ranged between fine sand and medium gravel, with a high (90%) proportion coarse sand, fine, and medium gravel, as shown in the results in

Figure 7a.

3.3. Optimum Moisture Content of Muhanzi Clay Soil

The result of the optimum moisture content test of Muhanzi clay soil shows that 16% gave the highest density as shown in

Figure 7b. The optimum moisture content was adopted in the preparation of all laboratory specimens.

3.4. Results for the Shell of SCEB

3.4.1. Optimum Cement Content

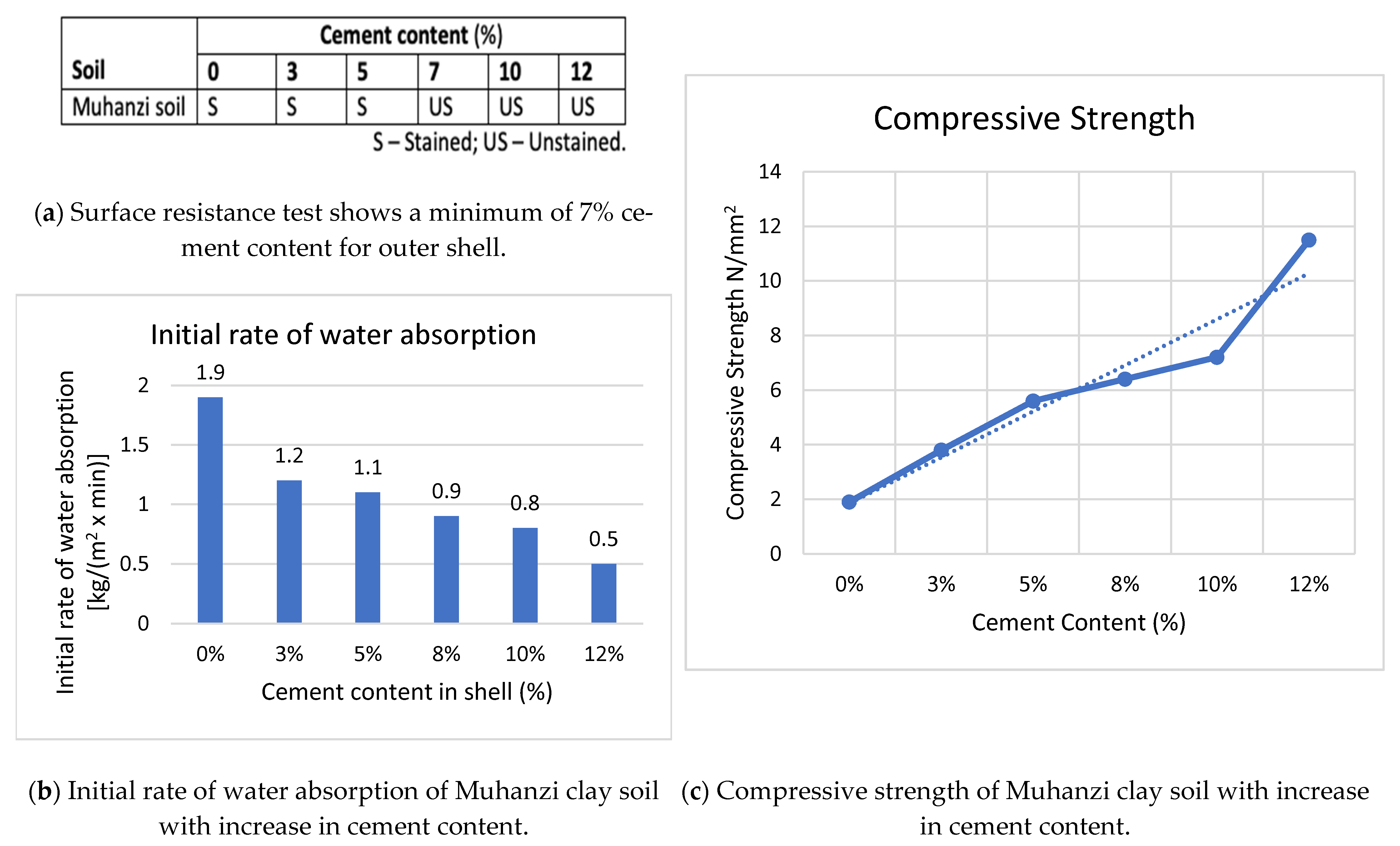

The optimum cement content was determined based on the result of the surface resistance test, as well as the compressive strength and water absorption tests.

3.4.2. Surface Resistance

Figure 8a shows that the minimum cement content for a durable, non-eroding surfaces of block made from Muhanzi clay soil is 7%. However, 8% cement content is appropriate as a factor of safety due to mixing.

3.4.3. Initial Rate of Water Absorption

The initial rate of water absorption reduced when cement content increased, as shown in

Figure 8b. The average absorption of 8% cement content is less than 15% absorption, which was a limit established by Abdullah et al. [

17].

3.4.4. Compressive Strength

The compressive strength increased when the cement content increased, as shown in

Figure 8c. Moreover, 8% passed the surface resistance test and gave a compressive strength of 6 N/mm

2, which is above average strength for earth masonry units.

3.5. Results for the Inner Core of SCEB

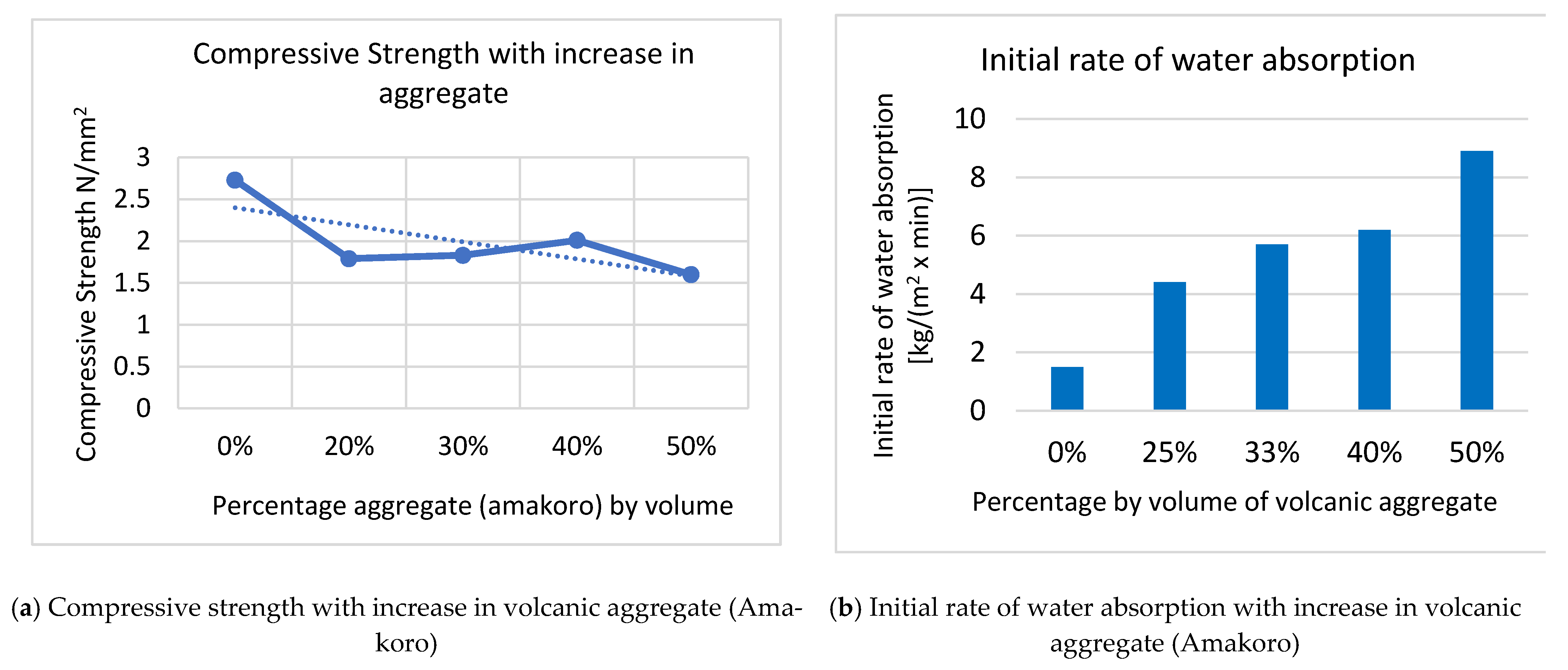

Optimum Aggregate Content

The compressive strength of compressed earth blocks reduced when the content of the volcanic aggregate increased, as shown in

Figure 9a. The cement content was 3% and the compaction pressure of the samples was 2.5 N/m

2. The initial rate of water absorption increased with increase in volcanic aggregate, as shown in

Figure 9b. A 33% volcanic aggregate with a 3% minimal cement content for a core of SCEB produced the minimum compressive strength of 2 N/mm

2 (

Figure 9a).

3.6. Summary of Results of Costs from Market Survey

The average cost per square meter of different wall materials in Rwanda are shown in

Table 4.

4. Analysis of a Model Masonry Unit

Following the above results, the shell of a model of SCEB from Muhanzi clay soil was found to contain 8% cement content and thus could be safely adopted for a good surface resistance of shell. A 3% cement content is typically adequate in the inner core of block. Furthermore, 33% volcanic aggregate (amakoro) in a core is adaptable. The research results and data were applied to a typical standard block in order to calculate quantity of cement used and weight reduction in a proposed model of SCEB.

Block Configuration

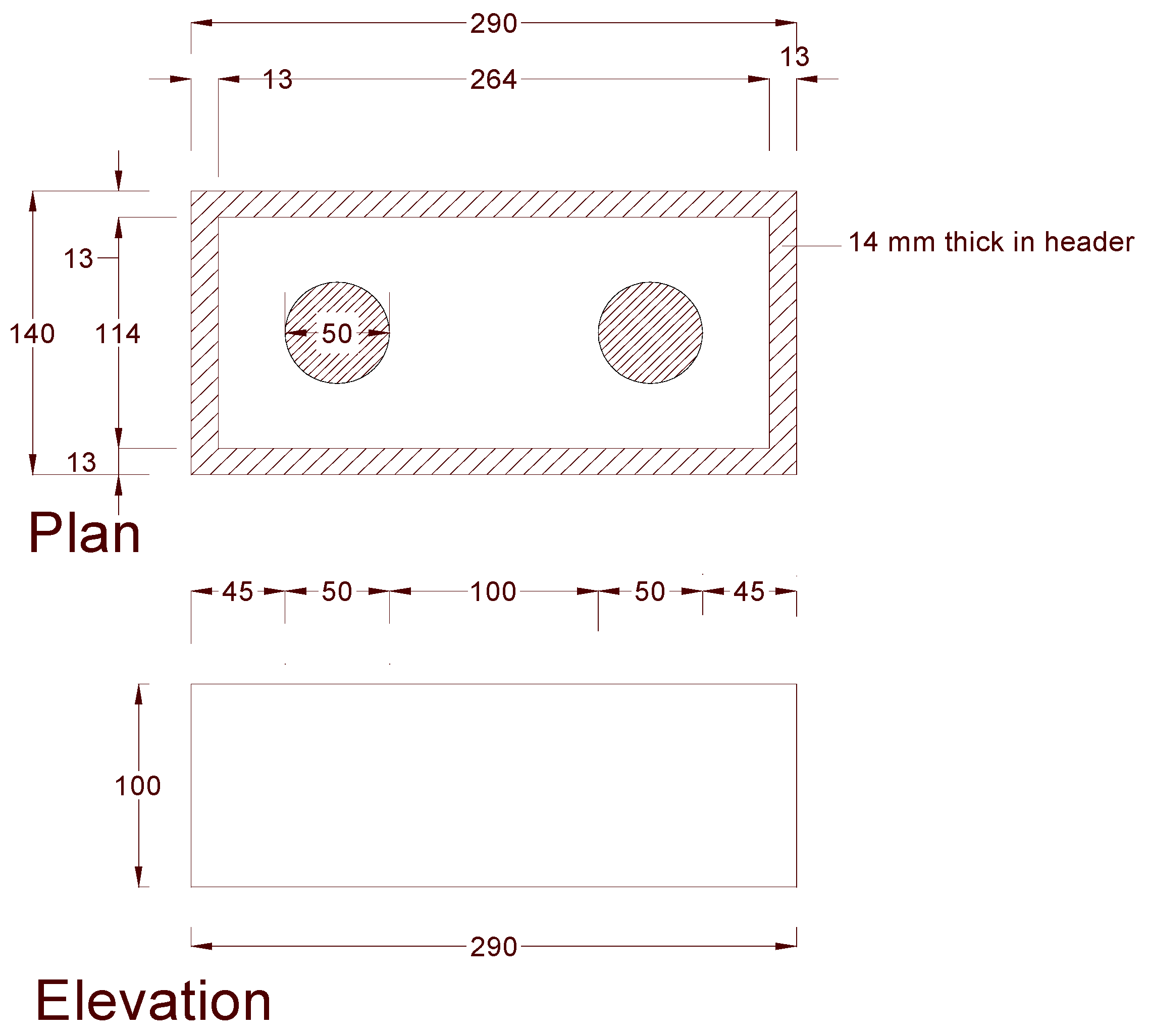

The regular CEB size is 295 × 140 × 90 mm ARS [

18] and can be adapted for 10 mm of a mortar joint with 290 × 140 × 100 mm block size. The dimensional structure of the block is as shown in

Figure 10.

The gross volume of the block is (290 × 140 × 100) mm = 4,060,000 mm3

Volume of void = 2 (π × 252 × 100) = 141,390 mm3 (3.5% of gross volume of block)

Volume of shell = 1,050,400 mm3 = (26% of gross volume of block)

Volume of inner core = 2,868,210 mm3 = (70.5% of gross volume of block).

Table 5 shows the summary of measurements and computation of the amount of cement required for the unit block of SCEB in comparison with CEB. The comparison of CEB and SCEB with the optimum volcanic aggregate content in the core is shown in

Table 6. The basic parameters for the calculations such as sample mass, sample cement content, and sample aggregate content were taken from the laboratory specimens of cubes cast and tested to research design requirements.

The above analysis shows that with the SCEB, the cement content of the model block was reduced by 60%. Furthermore, with 33% of volcanic aggregate in the core, a reduction in mass of 12% was achieved.

A comparison of the cost profile of different wall materials was analyzed as in

Table 7.

The estimated cost per square meter of a SCEB brick wall had a cost reduction of 54% compared to a sand-cement wall. Moreover, it had a 67% cost reduction compared to that of industrially fired bricks. The cost reduction of 25% over conventional CEB walls can be attributable to the reduction of cement in the core.

5. Architectural and Building Opportunities

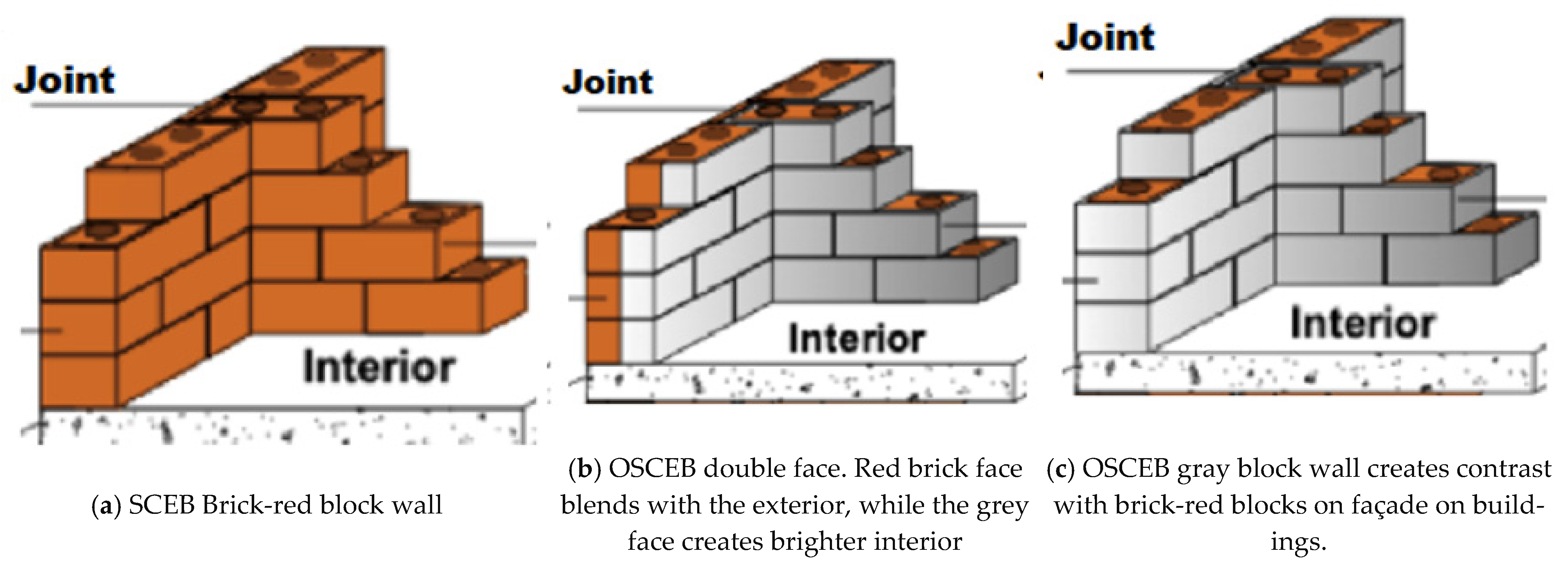

Beyond cement reduction, the concept of a shelled block provides the opportunity for ornamental SCEB (OSCEB). The OSCEB adopts a wide range of compressible earth materials such as Kaolin (white clay), grey clay soil, red clay soil, volcanic sand, etc., to make blocks of desirable colors, textures, and effects, as shown in

Figure 11. The possible application in earthen architecture is shown in

Figure 12.

6. Compressed Earth Buildings in Rural Areas

The task of using compressed earth for affordable housing in rural areas is less challenging than it is in urban areas. Rural environments may have the advantage of on-site mining of earth and a family and friends labor force for a self-help building process. The conventional compressed earth blocks with 3–5% cement content is adequate for building stability with no attachment to polished wall surfaces. The challenges of compressed earth in rural area is limited to the compressed earth presses and technical know-how. Cooperatives and governmental agencies can make compressed earth presses and trained personnel available at sectorial offices for use in various cells in their respective jurisdiction.

7. Conclusions

Enhancing compressed earth masonry units can provide an alternative wall construction systems to baked clay bricks with an appreciable effect on environment and cost. The challenges of conventional compressed earth masonry units were explored and a model of shelled compressed earth block was evolved with a 60% reduction in the use of cement. The reduction in cement without a reduction in comfort and aesthetic appeal balances the triple bottom line of sustainability, i.e., environment, economic, and sociocultural. In this study, the use of lightweight volcanic aggregate (amakoro) reduced the weight of the unit block by 12%, which further reduced with bigger blocks of larger inner core. The estimated cost of the SCEB wall compared to common wall materials showed a reduction of 15% over conventional compressed earth block wall and a 54% cost reduction over sand-cement block wall. Therefore, shelled compressed earth provides opportunities for ornamenting blocks with more architectural uses for affordable housing in urban areas. In rural areas, compressed earth presses and technical know-how can be made available for people to build their own houses.

Author Contributions

Conceptualization, C.E.; methodology, C.E. and J.K.; software, C.E.; validation, J.K.; formal analysis, C.E. and J.K.; investigation, C.E.; resources, C.E. and University of Rwanda; data curation, C.E.; writing—original draft preparation, C.E.; writing—review and editing, J.K.; visualization, C.E.; supervision, C.E. and J.K.; project administration, C.E.; funding acquisition, None. Both authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study conducted according to the guidelines of the Directorate of Research of the College of Science and Technology of University of Rwanda.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We would like to acknowledge the assistance of Clemence Hagenimana (Laboratory Technician, Concrete Laboratory of University of Rwanda) and Louis Dushimirimana (Laboratory Technician, Soil Laboratory of University of Rwanda) who helped to provide needed support for our laboratory works.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mbereyaho, L.; Twubahimana, J.D.; Mureramanzi, G. Strength characteristics of earth bricks application in construction. Int. Res. J. Eng. 2014, 2, 1–7. [Google Scholar]

- Ministry of Trade and Industry. Industrial Sub-Sector Masterplan for Construction Materials, Rwandan Ministry of Trade and Industry. Available online: https://rwandatrade.rw/media/MINICOM%20Construction%20Materials%20MasterPlan.pdf (accessed on 5 August 2020).

- Humanitarian News. Muvumba Gallery Forest Conservation Project. NonProfitBlogs. Available online: http://m.humanitariannews.org/20100810/muvumba-gallery-forest-conservation-project (accessed on 20 March 2021).

- Twagiramungu, F. Environmental Profile of Rwanda; Consultancy Report; European Commission: Kigali, Rwanda; 78p, 2006; Available online: http://www.vub.ac.be/klimostoolkit/sites/default/files/documents/rwanda-environmental-profile.pdf (accessed on 5 August 2020).

- Walker, P.; Standards Australia. The Australian Earth Building Handbook (HB195); Standards Australia International: Sydney, Australia, 2002. [Google Scholar]

- Ngowi, B.A. Improving the traditional earth construction: A case study of Botswana. Constr. Build. Mater. 1997, 11, 1–7. [Google Scholar] [CrossRef]

- Ikejiofor, U. If past traditions were building blocks: A perspective on low income housing development in Nigerian cities. Build. Environ. 1998, 34, 2. [Google Scholar] [CrossRef]

- Wekesa, B.; Steyn, C.; Otieno, F. The response of common building construction technologies to the urban poor and their environment. Build. Environ. 2010, 45, 10. [Google Scholar] [CrossRef]

- Galan-Marin, C.; Rivera-Gomez, C.; Petric, J. Clay-based composite stabilized with natural polymer and fibre. Constr. Build. Mater. 2010, 24, 1462–1468. [Google Scholar] [CrossRef]

- Egenti, C.; Khatib, J.M. Sustainability of Compressed Earth as a Construction Material. In Chapter 13 of Sustainability of Construction Materials, 2nd ed.; Khatib, J., Ed.; Woodhead Publishers (ELSEVIER): Cambridge, UK, 2016. [Google Scholar]

- Egenti, C.; Khatib, J.M.; Oloke, D. Appropriate Design and Construction of Earth Buildings: Contesting issues of protection against cost. Afr. J. Basic Appl. Sci. 2013, 5, 102–103. [Google Scholar]

- Egenti, C.; Khatib, J.M.; Oloke, D. Conceptualisation and Pilot Study of Shelled Compressed Earth Block for Sustainable Housing in Nigeria. Int. J. Sustain. Built Environ. 2014. Available online: http://www.sciencedirect.com/science/article/pii/S2212609014000223 (accessed on 6 July 2020).

- British Standard Institution. BS EN ISO 17892-12:2018 Methods of Tests for Soil for Civil Engineering Purposes. Classification Tests. BSI Group, 2018. Available online: http://www.bsi-global.com (accessed on 20 March 2020).

- Sehgal, S.B. A Text Book of Soil Mechanics; CBS Publishers and Distributors Pvt. Ltd.: New Delhi, India, 1984. [Google Scholar]

- British Standard Institution. BS EN 772-11:2011 Determination of Water Absorption of Aggregate Concrete, Autoclaved Aerated Concrete, Manufactured Stone and Natural Stone Masonry Units Die to Capillary Action and the Initial Rate of Water Absorption of Clay Masonry Units. BSI Group, 2011. Available online: http://www.bsi-global.com (accessed on 20 March 2012).

- British Standard Institution. BS EN 772-1:2011 Determination of Compressive Strength. BSI Group, 2011. Available online: http://www.bsi-global.com (accessed on 20 March 2012).

- Abdullah, A.H.; Nagapan, S.; Antonyova, A.; Rasiah, K.; Yunus, R.; Sohu, S. Strength and absorption rate of compressed stabilized earth bricks (CSEBs) due to different mixture ratios and degree of compaction. MATEC Web Conf. 2017, 103, 01028. [Google Scholar] [CrossRef]

- ARS. ARS 675:1996 Compressed Earth Blocks Technical Specifications for Facing Compressed Earth Blocks; African Regional Standards: Accra, Ghana, 1996; pp. 51–55. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).