Fly Ash from Thermal Conversion of Sludge as a Cement Substitute in Concrete Manufacturing

Abstract

1. Introduction

- limitation of the use of natural deposits, and thus savings in fossil fuels and natural resources and limitation of the devastation of the land surface as a result of the exploration of aggregates;

- reduction of the environmental pollution by reducing the emission of harmful gases (carbon dioxide);

- reduction of the amount of landfilled waste;

- recovery of land occupied by ash dumps.

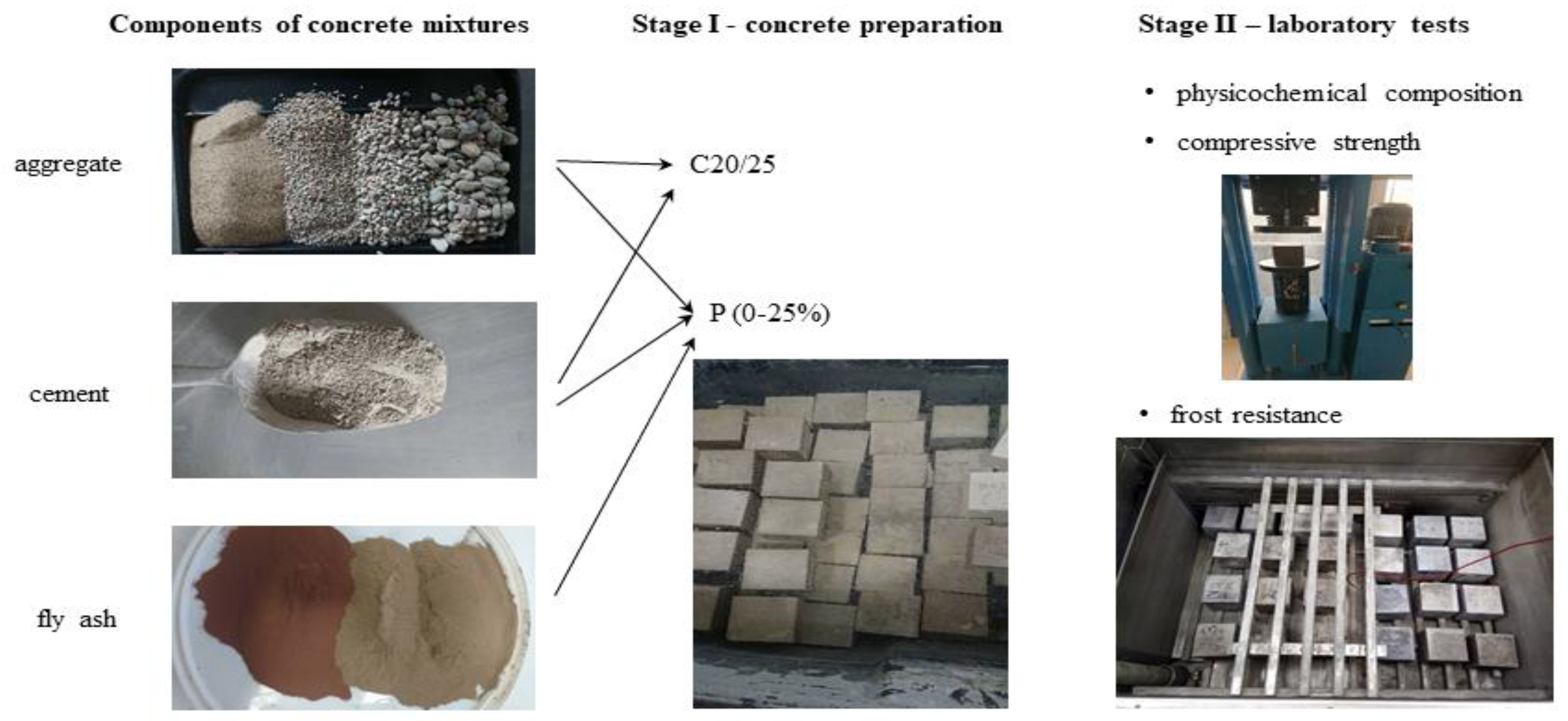

2. Materials and Methods

3. Results and Their Discussion

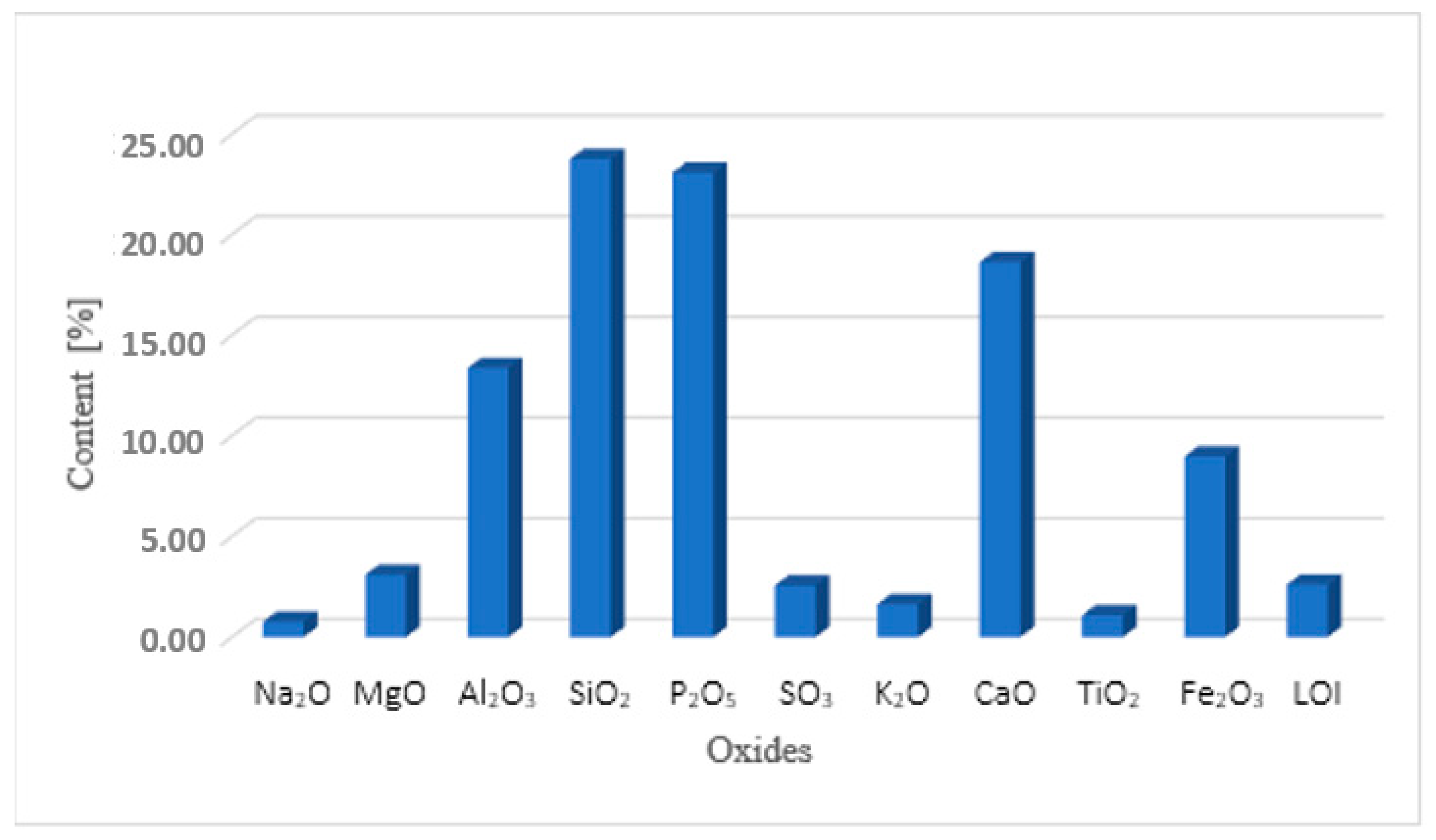

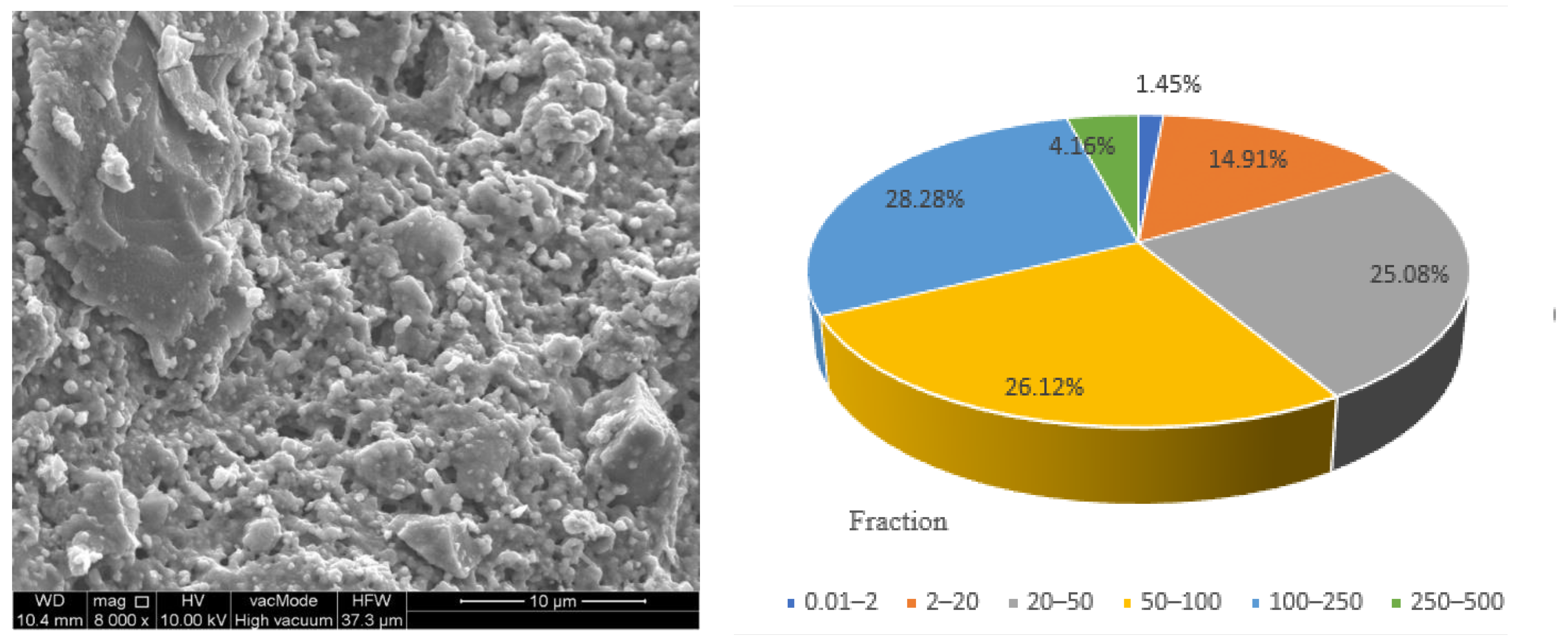

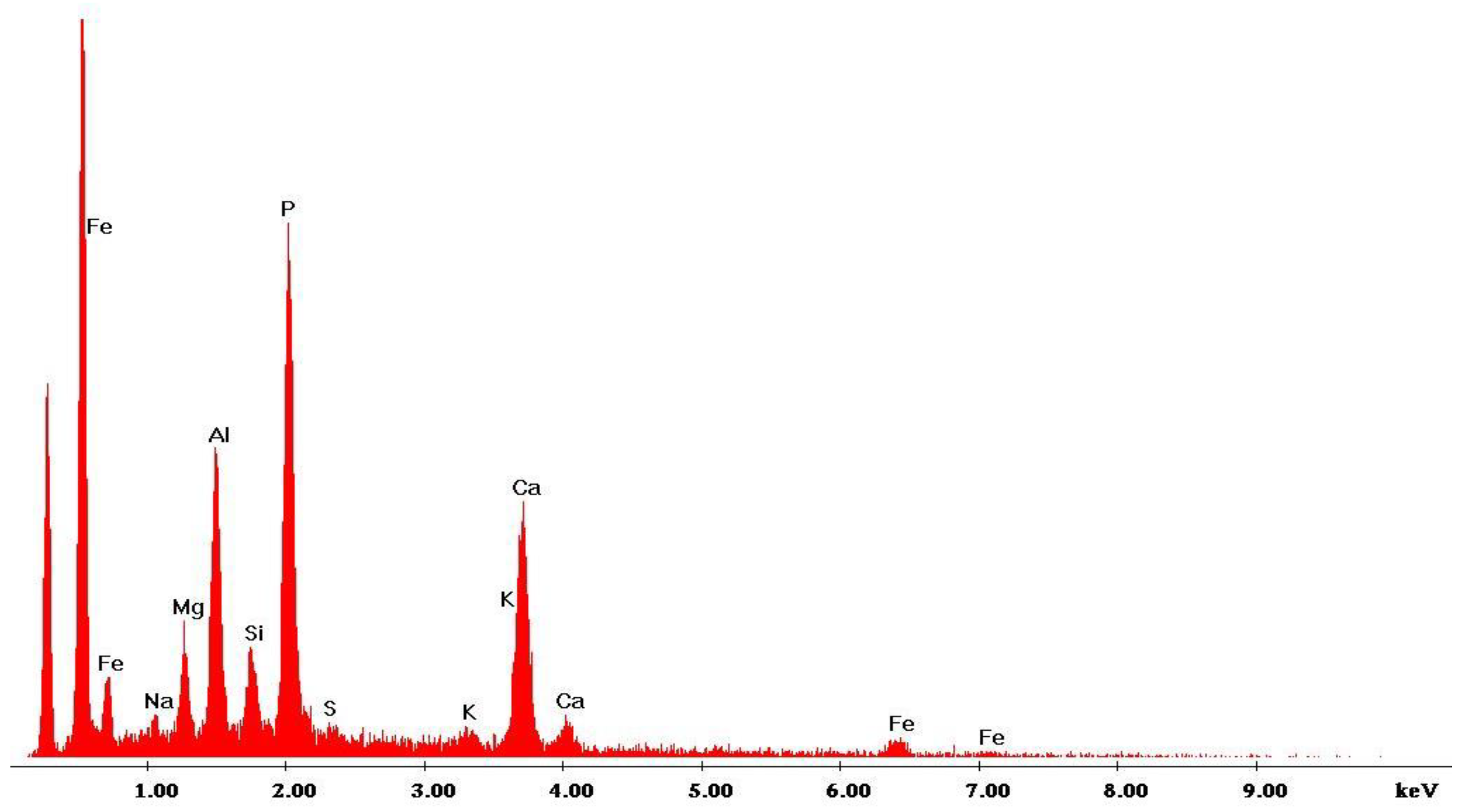

3.1. Physical and Chemical Properties of Fly Ash

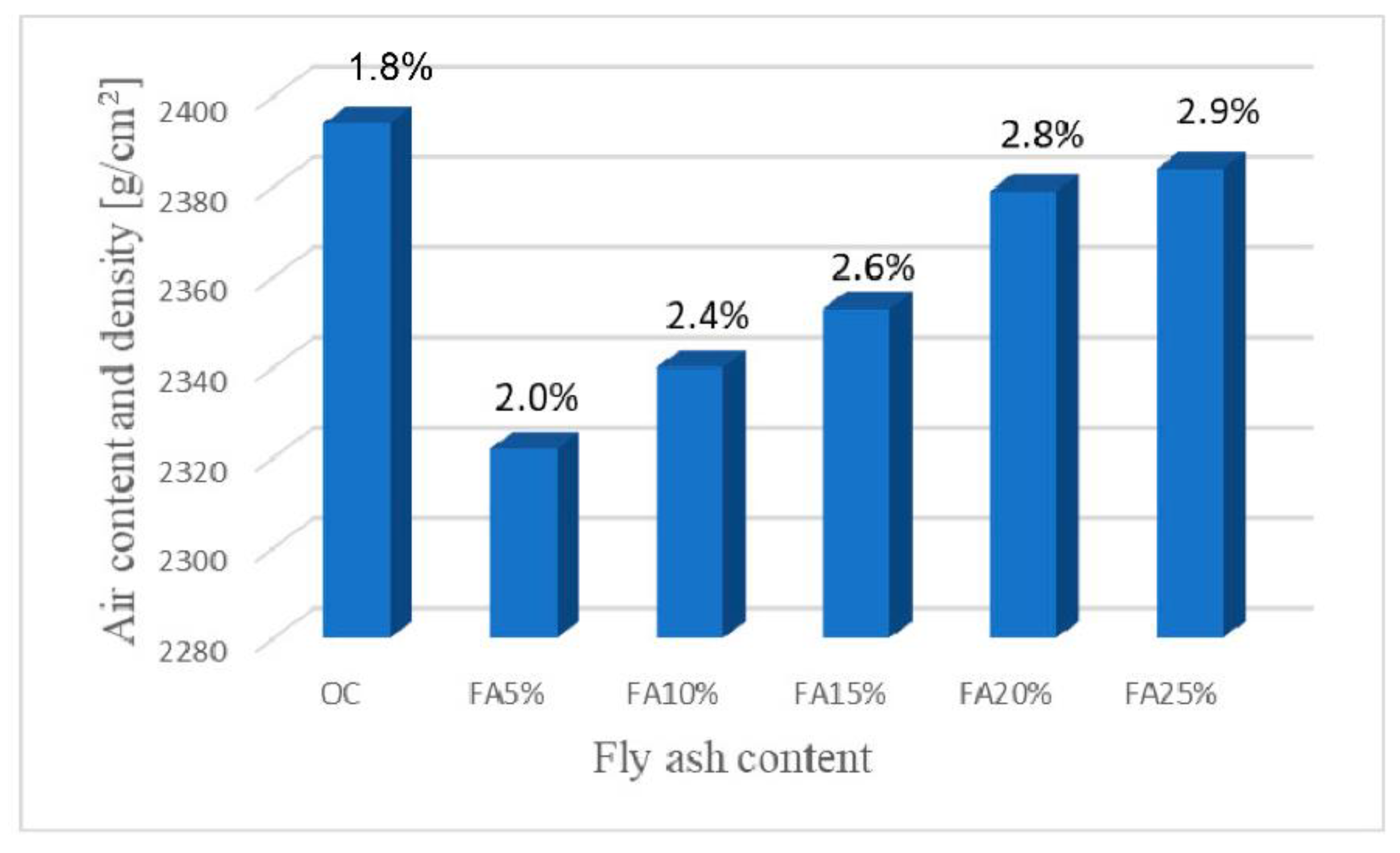

3.2. Properties of the Concrete Mix

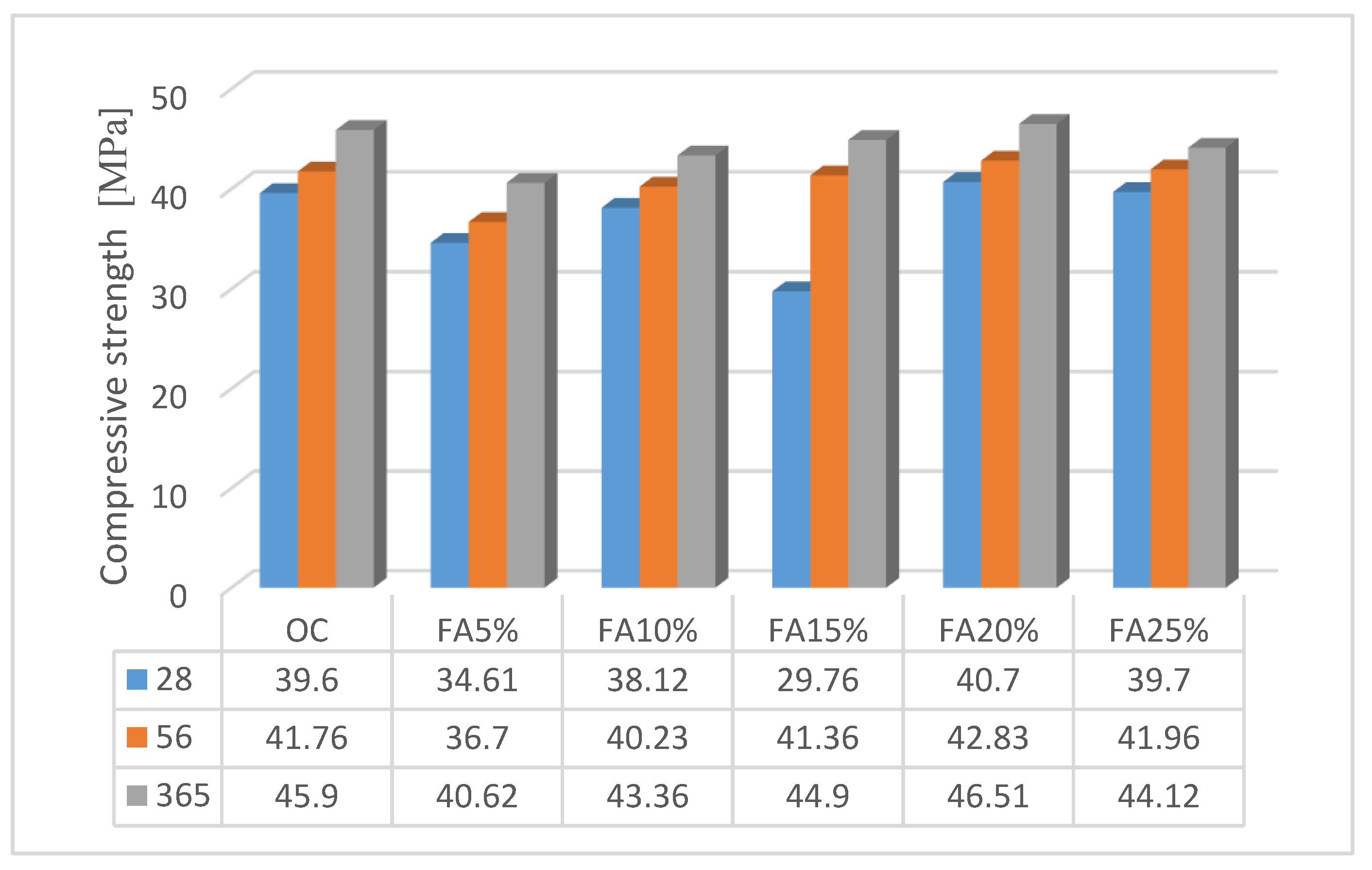

3.3. Compressive Strength

3.4. Frost Resistance

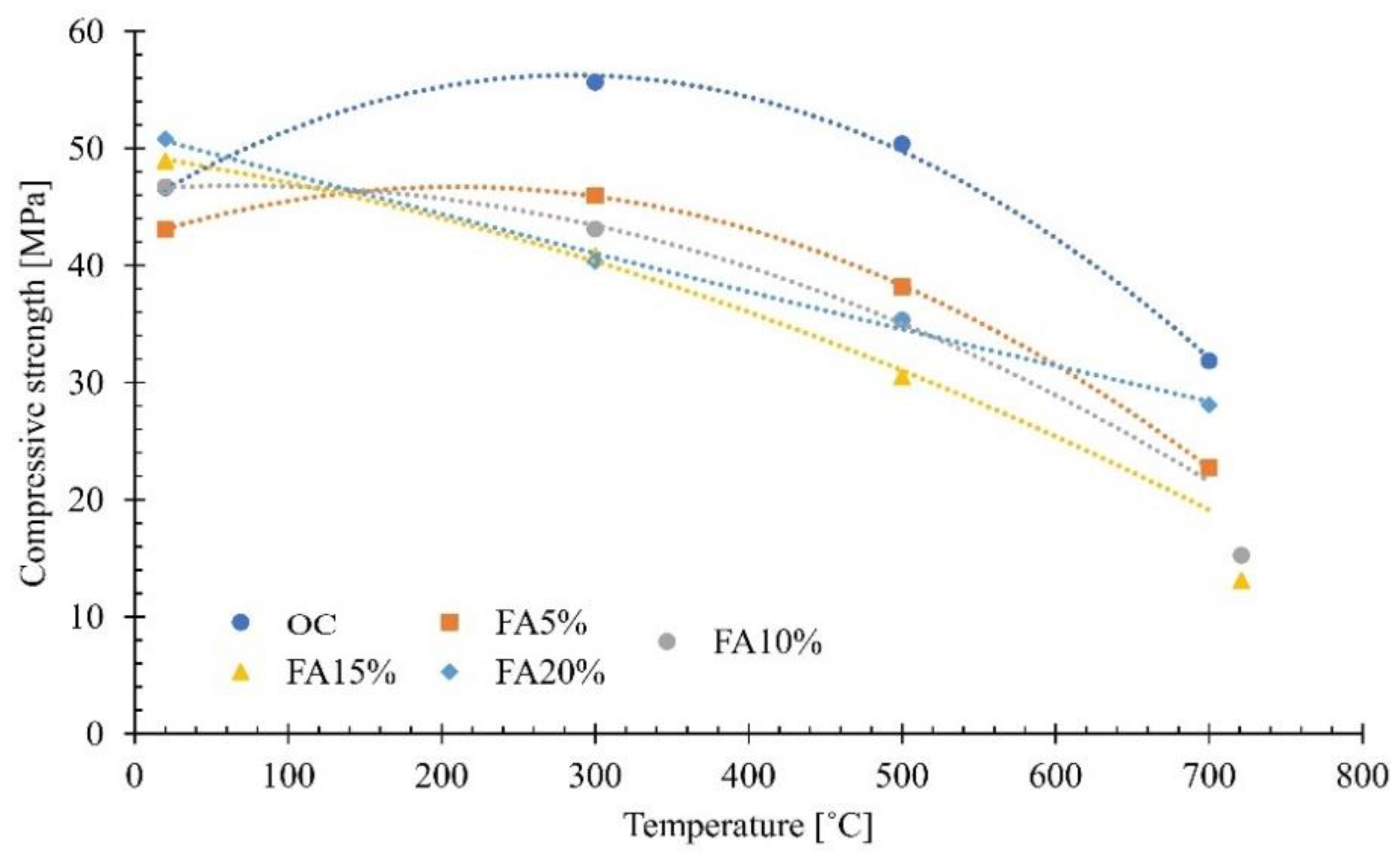

3.5. Material Model after Heating of Samples

4. Conclusions

- The generated waste—the fly ash from thermal conversion of sewage sludge used for the production of concrete positively affects its compressive strength and frost resistance.

- The concrete containing the fly ash from incineration of sewage sludge in its composition presented a compressive strength comparable to that of the reference concrete without additives. The ash can be used as a cement substitute if its content does not exceed 20%. The average compressive strength of concrete containing 20% of the fly ash from thermal conversion of sewage sludge after 28, 56 and 365 days of maturation was equal to 40.7 MPa, 42.8 MPa and 46.5 MPa, respectively.

- There is no typical composition and quality of municipal wastewater, and thus there is no typical composition of fly ash generated during thermal conversion of sewage sludge.

- The fly ash from thermal conversion of sewage sludge has a different physicochemical composition compared to the silica fly ash used in concrete technology and does not meet the requirements of PN-EN 450-1: 2012. The oxides of silicon, calcium, phosphorus and aluminum had the largest share in the composition of the ash samples.

- Concretes made with ash in the amount of 5%–25% are frost-resistant. The concrete containing ash from sewage sludge obtained satisfactory strength parameters after 150 freezing and thawing cycles.

- The action of high temperature damaged the structure of the tested concrete, and visible scratches and cracks appeared on its surface. After heating of the concrete samples at the temperature of 300 °C, an increase in compressive strength for the OC concrete by 9.1 MPa was recorded, and for the concrete samples FA5%—by 3.0 MPa. The temperature increase to 500 °C caused a decrease in strength in the range of 10% (FA5%)–37% (FA15%) in all cement composites. The concrete at the temperature of 700 °C presented a decrease in the range of 30% (OC) to 60% (FA15%) in relation to the samples made of the reference concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rocznik Statystyki Międzynarodowej (International Statistics Yearbook). Available online: https://stat.gov.pl/en/topics/statistical-yearbooks/statistical-yearbooks/concise-statistical-yearbook-of-poland-2020,1,21.html (accessed on 12 February 2021).

- IEA—Shaping a Secure and Sustainable Energy Future for All. Available online: www.iea.org (accessed on 12 February 2021).

- Deja, J.; Antosiak, B. Degree of progress of the fly ash reaction in alkali-activated fly-ash binders. Cem. Lime Concr. 2012, 17, 67–76. [Google Scholar]

- Ustawa z Dnia 14 Grudnia 2012 r. o Odpadach (Dz.U. 2013, poz. 21). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU2013000002 (accessed on 25 April 2019).

- Rozporządzenie Ministra Rozwoju z Dnia 21 Stycznia 2016 r. W Sprawie Wymagań Dotyczących Prowadzenia Procesu Termicznego Przekształcania Odpadów Oraz Sposobów Postępowania z Odpadami Powstałymi w Wyniku Tego Procesu. (Dz.U. 2016 poz. 108). Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20160000108 (accessed on 24 April 2019).

- Directive 2010/75/UE of the European Parliament and the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control). Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ%3AL%3A2010%3A334%3A0017%3A0119%3Aen%3APDF (accessed on 24 April 2019).

- Lin, D.F.; Luo, H.L.; Cheng, J.F.; Zhuang, M.L. Strengthening tiles manufactured with sewage sludge ash replacement by adding micro-carbon powder. Mater. Struct. 2016, 49, 3559–3567. [Google Scholar] [CrossRef]

- Lin, D.F.; Luo, H.L.; Lin, K.L.; Liu, Z.K. Effects of waste glass and waste foundry sand additions on reclaimed tiles containing sewage sludge ash. Environ. Technol. 2017, 38, 1–10. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S. Sewage sludge ash characteristics and potential for use in bricks, tiles and glass ceramics. Water Sci. Technol. 2016, 74, 17–29. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, S.; Tanaka, M.; Kaneko, T. Glass-ceramic from sewage sludge ash. J. Mater. Sci. 1997, 32, 1775–1779. [Google Scholar] [CrossRef]

- Park, Y.J.; Moon, S.O.; Heo, J. Crystalline phase control of glass ceramics obtained from sewage sludge fly ash. Ceram. Int. 2003, 29, 223–227. [Google Scholar] [CrossRef]

- Merino, I.; Arévalo, L.F.; Romero, F. Preparation and characterization of ceramic products by thermal treatment of sewage sludge ashes mixed with different additives. Waste Manag. 2007, 27, 1829–1844. [Google Scholar] [CrossRef] [PubMed]

- Piasta, W.; Lukawska, M. The effect of sewage sludge ash on properties of cement composites. Proc. Eng. 2016, 161, 1018–1024. [Google Scholar] [CrossRef]

- Vouk, D.; Nakic, D.; Stirmer, N.; Cheeseman, C.R. Use of sewage sludge ash in cementitious materials. Rev. Adv. Mater. Sci. 2017, 49, 158–170. [Google Scholar]

- Chakraborty, S.; Jo, B.W.; Jo, J.H.; Baloch, Z. Effectiveness of sewage sludge ash combined with waste pozzolanic minerals in developing sustainable construction material: An alternative approach for waste management. J. Clean. Prod. 2017, 153, 253–263. [Google Scholar] [CrossRef]

- Rutkowska, G.; Fronczyk, J.; Filipchuk, S. Influence of fly-ash properties from thermal transformation of sewage sludge on ordinary concrete parameters. Acta Sci. Pol. Archit. 2020, 19, 43–54. (In Polish) [Google Scholar] [CrossRef]

- Monzó, J.; Paya, J.; Borrachero, M.V.; Peris-Mora, E. Mechanical behavior of mortars containing sewage sludge ash (SSA) and Portland cements with different tricalcium aluminate content. Cem. Concr. Res. 1999, 29, 87–94. [Google Scholar] [CrossRef]

- Cyr, M.; Coutand, M.; Clastres, P. Technological and environmental behavior of sewage sludge ash (SSA) in cement-based materials. Cem. Concr. Res. 2007, 37, 1278–1289. [Google Scholar] [CrossRef]

- Lin, K.L.; Chang, W.C.; Lin, D.F.; Luo, H.L.; Tsai, M.C. Effects of nano-SiO2 and different ash particle sizes on sludge ash-cement mortar. J. Environ. Manag. 2008, 88, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Blanc, D.; Gautier, M.; Mehu, J.; Gourdon, R. Environmental and technical assessments of the potential utilization of sewage sludge ashes (SSAs) as secondary raw materials in construction. Waste Manag. 2013, 33, 1268–1275. [Google Scholar] [CrossRef] [PubMed]

- Ing, D.S.; Chin, S.C.; Guan, T.K.; Suil, A. The use of sewage sludge ash (SSA) as partial replacement of cement in concrete. ARPN J. Eng. Appl. Sci. 2016, 11, 3771–3775. [Google Scholar]

- Pinarli, V.; Kaymal, G. An innovative sludge disposal option—reuse of sludge ash by incorporation in construction materials. Environ. Technol. 1994, 15, 843–852. [Google Scholar] [CrossRef]

- Baeza-Broton, F.; Garces, P.; Paya, J.; Saval, J.M. Portland cement systems with addition of sewage sludge ash. Application in concretes for the manufacture of blocks. J. Clean. Prod. 2014, 82, 112–124. [Google Scholar] [CrossRef]

- Chang, F.; Lin, J.; Tsai, C.; Wang, K. Study on cement mortar and concrete made with sewage sludge ash. Water Sci. Technol. 2010, 62, 1689–1693. [Google Scholar] [CrossRef]

- Chen, Z.; Poon, C.S. Comparative studies on the effects of sewage sludge ash and fly ash on cement hydration and properties of cement mortars. Constr. Build. Mater. 2017, 154, 791–803. [Google Scholar] [CrossRef]

- Lin, K.-L.; Lin, C.-Y. Hydration characteristics of waste sludge ash utilized as raw cement material. Cem. Concr. Res. 2005, 35, 1999–2007. [Google Scholar] [CrossRef]

- Yen, C.L.; Tseng, D.H.; Lin, T.T. Characterization of eco-cement paste produced from waste sludges. Chemosphere 2011, 84, 220–226. [Google Scholar] [CrossRef]

- Ferreira, C.; Ribeiro, A.; Ottosen, L. Possible applications for municipal solid waste fly ash. J. Hazard. Mater. 2003, 96, 201–216. [Google Scholar] [CrossRef]

- Rutkowska, G.; Wichowski, P.; Fronczyk, J.; Franus, M.; Chalecki, M. Use of fly ashes from municipal sewage sludge combustion in production of ash concretes. Constr. Build. Mater. 2018, 188, 874–883. [Google Scholar] [CrossRef]

- Rutkowska, G.; Wichowski, P.; Franus, M.; Mendryk, M.; Fronczyk, J. Modification of ordinary concrete using fly ash from combustion of municipal sewage sludge. Materials 2020, 13, 487. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Li, J.S.; Poon, C.S. Combined use of sewage sludge ash and recycled glass cullet for the production of concrete blocks. J. Clean. Prod. 2018, 171, 1447–1459. [Google Scholar] [CrossRef]

- Lynn, C.J.; Dhir, R.K.; Ghataora, G.S.; West, R.P. Sewage sludge ash characteristics and potential for use in concrete. Constr. Build. Mater. 2015, 98, 767–779. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, C.; Sun, W. Fly ash effects: I. The morphological effect of fly ash. Cem. Concr. Res. 2003, 33, 2023–2029. [Google Scholar] [CrossRef]

- Yadav, S.; Agnihotri, S.; Gupta, S.; Tripathi, R. Incorporation of STP sludge and fly ash in brick manufacturing: An attempt to save the environment. Int. J. Adv. Res. Technol. 2014, 3, 138–144. [Google Scholar] [CrossRef]

- Yusur, R.O.; Noor, Z.Z.; Din, M.F.M.; Abba, A.H. Use of sewage sludge ash (SSA) in the production of cement and concrete—A review. Int. J. Glob. Environ. Issues 2012, 12, 214–228. [Google Scholar] [CrossRef]

- Bundyra-Oracz, G. Różnice między PN-88/B-06250 Beton zwykły i PN-EN 206-1: 2003 PN-EN 206+A1:2016-12 Beton. Część 1: Wymagania, właściwości, produkcja i zgodność. Pr. Inst. Tech. Bud. 2008, 37, 3–26. [Google Scholar]

- Jamroży, Z. Beton i Jego Technologie; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2015. [Google Scholar]

- PN-EN 197–1:2012. Cement. Part 1: Composition, Requirements and Compliance Criteria for Common Cements; Polish Standardization Committee: Warsaw, Poland, 2012. [Google Scholar]

- PN-EN 12350–6:2011. Testing of Fresh Concrete. Part 6: Density; Polish Standardization Committee: Warsaw, Poland, 2011. [Google Scholar]

- PN-EN 12350–2:2011. Testing of Fresh Concrete. Part 2. Slump Test; Polish Standardization Committee: Warsaw, Poland, 2011. [Google Scholar]

- PN-EN 12350–7:2011. Testing of Fresh Concrete. Part 7: Air Content-Pressure Method; Polish Standardization Committee: Warsaw, Poland, 2011. [Google Scholar]

- PN-EN 12390–3:2019–07. Testing of Hardened Concrete. Part 3: Compressive Strength of Test Specimens; Polish Standardization Committee: Warsaw, Poland, 2019. [Google Scholar]

- PN-B-06265:2004. Plain Concrete; Polish Standardization Committee: Warsaw, Poland, 2004. [Google Scholar]

- PN-EN 1363–2:2001. Fire Resistance Tests. Part 2: Alternative and Additional Procedures; Polish Standardization Committee: Warsaw, Poland, 2001. [Google Scholar]

- Czarnecki, L.; Łukowski, P. Model materiałowy betonów żywicznych. In Proceedings of the Scientific Technical Conference (Materiały Konferencji Naukowo-Technicznej) MATBUD’96, Kraków, Poland, 19–22 June 1996. [Google Scholar]

- British Standards Institution (BSI). Fly Ash for Concrete. Part 1: Definition, Specifications and Conformity Criteria; British Standards Institution: London, UK, 2012. [Google Scholar]

- ASTM C379–65T. Specification for Fly Ash for Use as a Pozzolanic Material with Lime; Polish Standardization Committee: Warsaw, Poland, 1996. [Google Scholar]

- Williams, P.T. Waste Treatment and Disposal, 2nd ed.; John Wiley & Sons: Chichester, UK, 2005. [Google Scholar]

- Tkaczewska, E. Właściwości cementów zawierających różne frakcje ziarnowe krzemionkowych popiołów lotnych. Drogi Mosty 2008, 4, 47–80. [Google Scholar]

- PN-EN 1097–7:2008. Determination of the Filler Density; Polish Standardization Committee: Warsaw, Poland, 2008. [Google Scholar]

- PN-EN 451–2:2017–06. Fly Ash Test Method-Determination of Fineness by Wet Sieving; Polish Standardization Committee: Warsaw, Poland, 2017. [Google Scholar]

- Rutkowska, G.; Ogrodnik, P.; Fronczyk, J.; Bilgin, A. Temperature influence on ordinary concrete modified with fly ash from thermally conversed municipal sewage sludge strength parameters. Materials 2020, 13, 5259. [Google Scholar] [CrossRef]

- Rutkowska, G. Fly ash from the thermal transformation of sewage as an additive to concrete. Acta Sci. Pol. Archit. 2020, 19, 93–104. (In Polish) [Google Scholar] [CrossRef]

- Małolepszy, J.; Tkaczewska, E. Influence of fly ashes from the co-combustion of coal and biomass on the hydration process and properties of cement. Concr. Days 2006, 23, 591–601. (In Polish) [Google Scholar]

- Wang, L.; He, T.S.; Zhou, Y.X. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Chen, Y.; Cen, G.P.; Cui, Y.H. Comparative study on the effect of synthetic fiber on the preparation and durability of airport pavement concrete. Constr. Build. Mater. 2018, 184, 34–44. [Google Scholar] [CrossRef]

| Fraction | Fraction Mixing Percentage Ratio (for Sand and Gravel) | Grain Composition [%] | |||

|---|---|---|---|---|---|

| I Stage | II Stage | III Stage | Sand | Gravel | |

| 0.0–0.125 | 32 | 1.37 | 0.44 | ||

| 0.0125–0.25 | 11.66 | 3.73 | |||

| 0.25–0.50 | 37.24 | 11.92 | |||

| 0.50–1.0 | 33.88 | 10.84 | |||

| 1.0–2.0 | 15.85 | 5.07 | |||

| 2.0–4.0 | 35 | 68 | 23.80 | ||

| 4.0–8.0 | 47 | 65 | 20.77 | ||

| 8.0–16.0 | 53 | 23.43 | |||

| The Share of Mineral Phases CEM I [5 mass] | |||

|---|---|---|---|

| C3S—61.9 | C2S—12.2 | C3A—7.6 | C4AF—4.0 |

| Blaine specific sur- face area [cm2/g] | Beginning of bin- ding time [min] | Compressive strength after 2 days [MPa] | Compressive strength after 28 days [MPa] |

| 3331 | 217 | 21.0 | 49.7 |

| Roasting Loss [%] | Sulfate Content SO3 [%] | Chloride Content Cl− [%] | Alkali Content Na2Oeq [%] | Silica Content SiO2 [%] |

|---|---|---|---|---|

| 3.19 | 3.19 | 0.05 | 0.72 | 20.21 |

| Al2O3 [%] | Fe2O3 [%] | CaO [%] | CaOw [%] | MgO [%] |

| 4.33 | 2.38 | 65.20 | 1.75 | 1.52 |

| Specification | Mass of Concrete Ingredients [kg/m3] | |||

|---|---|---|---|---|

| Aggregate | Water | Cement | Fly Ash | |

| Concrete OC | 1789.57 | 191.78 | 412.01 | |

| FA 5% Concrete with 5% of fly ash | 1789.57 | 191.78 | 391.41 | 20.60 |

| FA 10% Concrete with 10% of fly ash | 1789.57 | 191.78 | 370.81 | 41.20 |

| FA 15% Concrete with 15% of fly ash | 1789.57 | 191.78 | 350.21 | 61.80 |

| FA 20% Concrete with 20% of fly ash | 1789.57 | 191.78 | 329.61 | 82.40 |

| FA 25% Concrete with 25% of fly ash | 1789.57 | 191.78 | 309.01 | 103.00 |

| Research | Test Method |

|---|---|

| Particle size distribution | The analysis was performed based on the phenomenon of laser diffraction using the Mastersizer 3000 analyzer (Malvern Instruments). The measurement was carried out in a dispersing liquid (demineralized water) in the presence of an ultrasonic probe in order to break up larger aggregates of the tested samples. Grains with equivalent diameters ranging from 0.1 µm to 1000 µm were analyzed. |

| Morphology and chemical composition in the micro-area | The determination was performed by the EDAX scanning electron microscopy SEM Quanta 250 FEG FEI Company, with a system of chemical composition analysis based on the X-ray radiation energy dispersion—EDS (Energy Dispersive X-Ray Spectroscopy) |

| The chemical composition of the material | The composition was determined by the X-ray energy dispersion fluorescence (XRF) method on an Epsilon 3 spectrometer (Panalytical). The test was carried out in the measuring range of the elements Na—Am using an apparatus equipped with the Rh X-ray tube (9 W, 50 kV, 1 mA), 4096-channel spectrum analyzer, 6 measurement filters (Cu-500, Cu-300, Ti, Al-50, Al-200, Ag) and a high-resolution semiconductor SDD detector (50 µm thick beryllium window) cooled with a Peltier cell. |

| Mineral composition | The composition was determined using X-ray phase analysis (XRD). Measurements were made using the powder method using a Panalytical X’pertPRO MPD X-ray diffractometer with a PW 3020 goniometer. A copper tube (CuKα = 1.54178 Å) was used as a source of the X-ray emission. X’Pert Highscore software was used to process the diffraction data. Identification of mineral phases was based on the PDF-2 release 2010 database formalized by JCPDS-ICDD. |

| Pozzolanic activity | The determination was carried out in accordance with PN-EN 450-1: 2012 and ASTM C379-65T [46,47]. |

| No | Sample | Average Compressive Strength | Average Strength Decrease of Frozen Samples | Average Mass | Average Loss in Mass | ||

|---|---|---|---|---|---|---|---|

| before Freezing | after 150 Freeze–Thaw Cycles | before Freezing | after 150 Freeze–Thaw Cycles | ||||

| [MPa] | [MPa] | [%] | [g] | [g] | [%] | ||

| 1 | OC | 43.12 | 41.87 | −2.899 | 2366 | 2362 | 0.169 |

| 2 | FA5% | 37.87 | 35.99 | −4.964 | 2416 | 2409 | 0.289 |

| 3 | FA10% | 42.65 | 41.78 | −2.039 | 2361 | 2342 | 0.804 |

| 4 | FA15% | 43.90 | 43.12 | −1.777 | 2329 | 2331 | 0.086 |

| 5 | FA20% | 42.34 | 39.98 | −5.574 | 2378 | 2372 | 0.252 |

| 6 | FA25% | 41.33 | 38.76 | −6.218 | 2363 | 2357 | 0.254 |

| Predicted Parameter | Model Equation x—Temperature [°C] | Coefficient of Determination R2 |

|---|---|---|

| Compressive strength of OC [MPa] | fcm = −0.0001x2 + 0.0793x + 44.98 | 0.9974 |

| Compressive strength of FA5% [MPa] | fcm = −0.0001x2 + 0.0419x + 42.303 | 0.9999 |

| Compressive strength of FA10% [MPa] | fcm = −2.5775x2 + 4.518x + 44.693 | 0.9995 |

| Compressive strength of FA15% [MPa] | fcm = −0.765x2 − 6.097x + 55.86 | 0.9998 |

| Compressive strength of FA20% [MPa] | fcm = 0.8x2 − 11.304x + 60.91 | 0.9886 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rutkowska, G.; Chalecki, M.; Żółtowski, M. Fly Ash from Thermal Conversion of Sludge as a Cement Substitute in Concrete Manufacturing. Sustainability 2021, 13, 4182. https://doi.org/10.3390/su13084182

Rutkowska G, Chalecki M, Żółtowski M. Fly Ash from Thermal Conversion of Sludge as a Cement Substitute in Concrete Manufacturing. Sustainability. 2021; 13(8):4182. https://doi.org/10.3390/su13084182

Chicago/Turabian StyleRutkowska, Gabriela, Marek Chalecki, and Mariusz Żółtowski. 2021. "Fly Ash from Thermal Conversion of Sludge as a Cement Substitute in Concrete Manufacturing" Sustainability 13, no. 8: 4182. https://doi.org/10.3390/su13084182

APA StyleRutkowska, G., Chalecki, M., & Żółtowski, M. (2021). Fly Ash from Thermal Conversion of Sludge as a Cement Substitute in Concrete Manufacturing. Sustainability, 13(8), 4182. https://doi.org/10.3390/su13084182