An Evolutionary Game Research on Cooperation Mode of the NEV Power Battery Recycling and Gradient Utilization Alliance in the Context of China’s NEV Power Battery Retired Tide

Abstract

1. Intruction

2. Literature Review

2.1. Environmental and Economic Benefits of NEV Power Battery Recycling and Utilization

2.2. Strategy Optimization of NEV Power Battery Recycling and Utilization

2.3. The Impact of Policies on the Recycling and Utilization of NEV Power Batteries

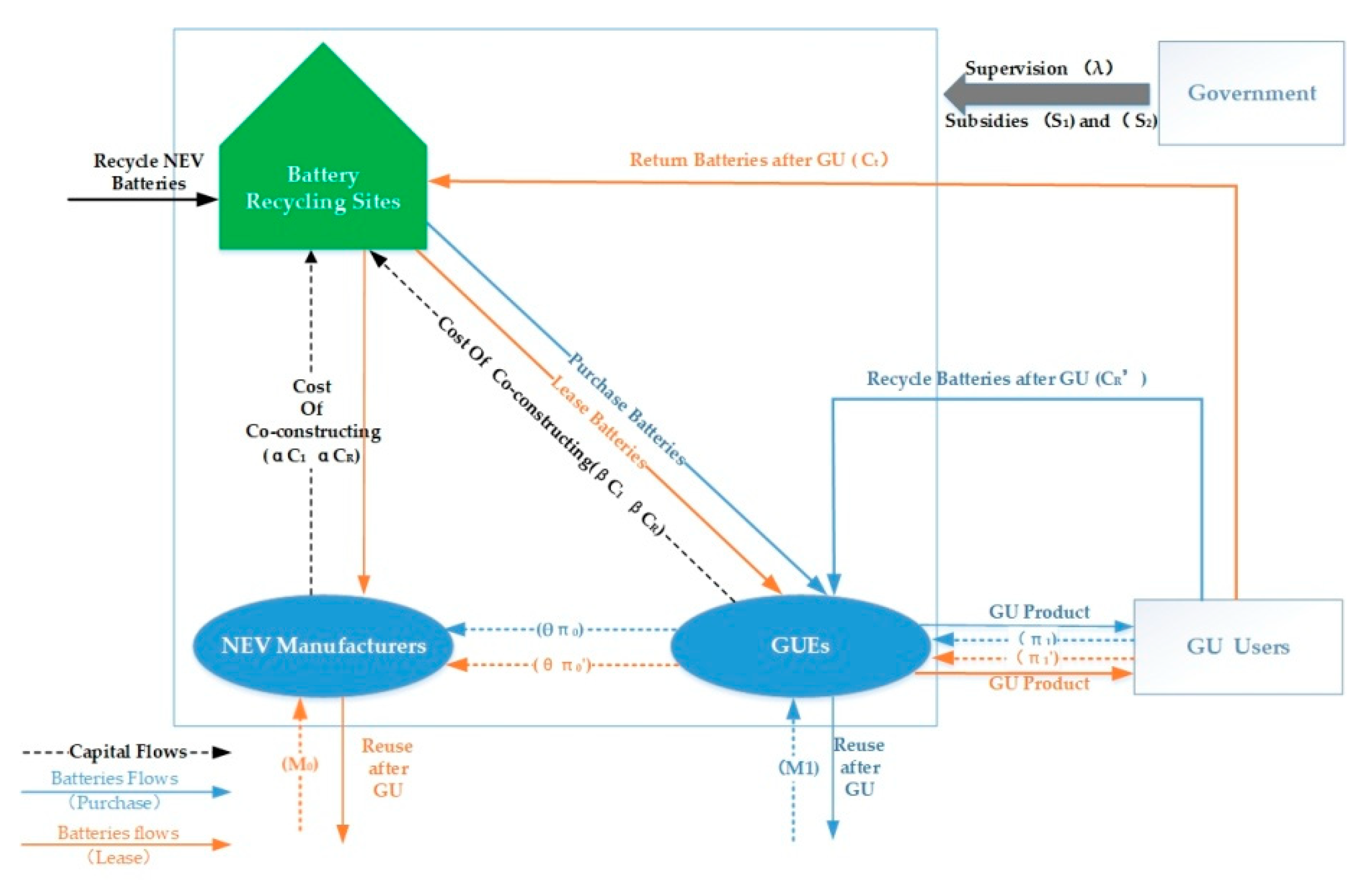

3. Evolutionary Game Model

3.1. Problem Description and Basic Assumptions

3.2. Parameter Setting and Payment Matrix

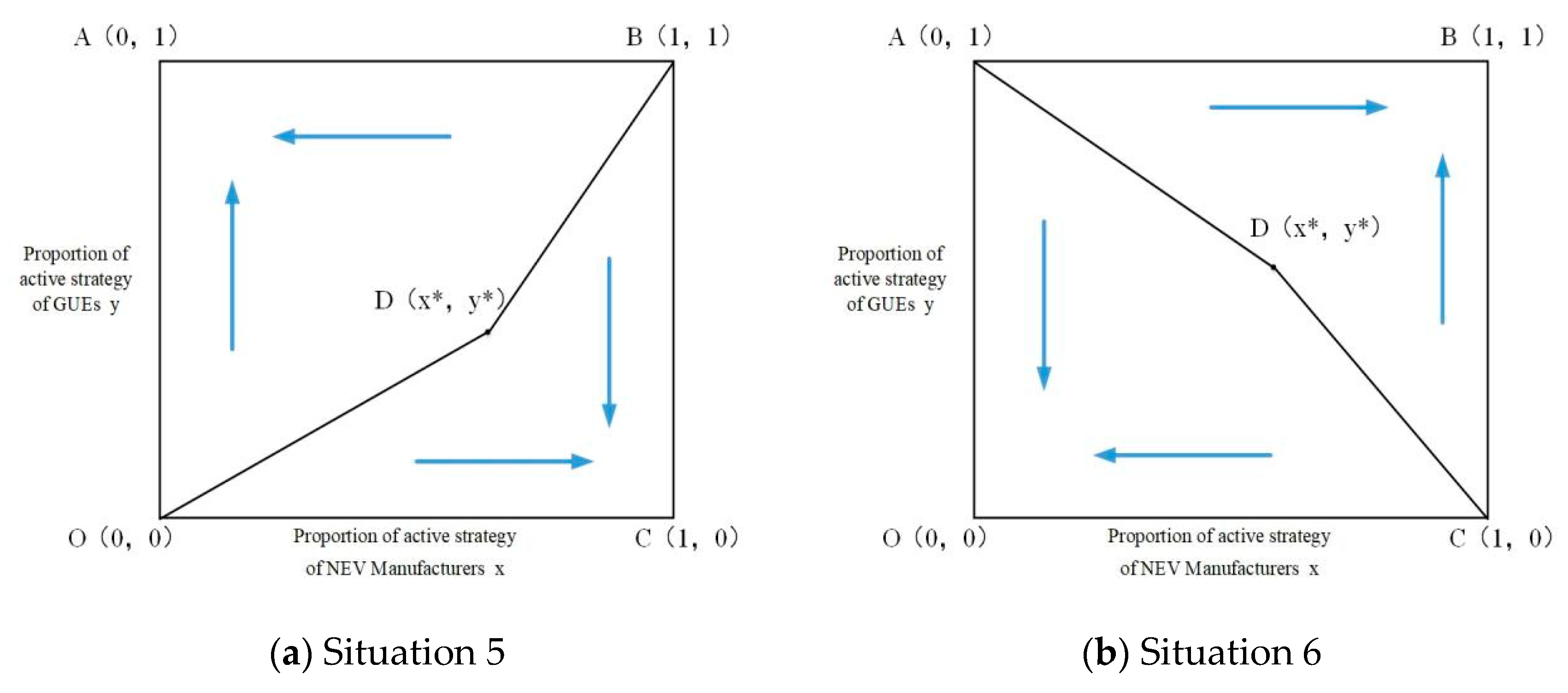

4. Analysis of Evolutionary Stable Strategies

5. Simulation and Analysis

5.1. Related Data

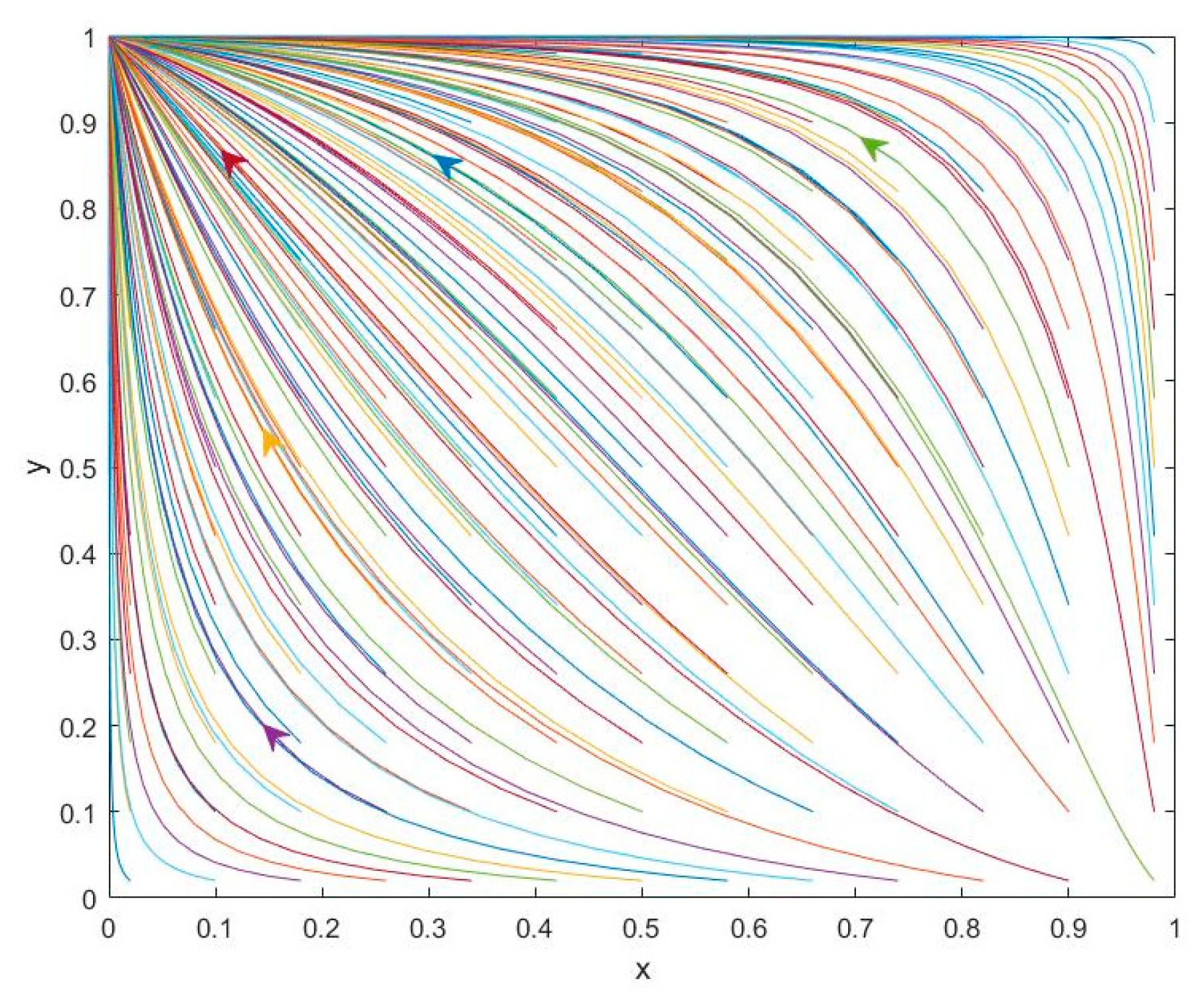

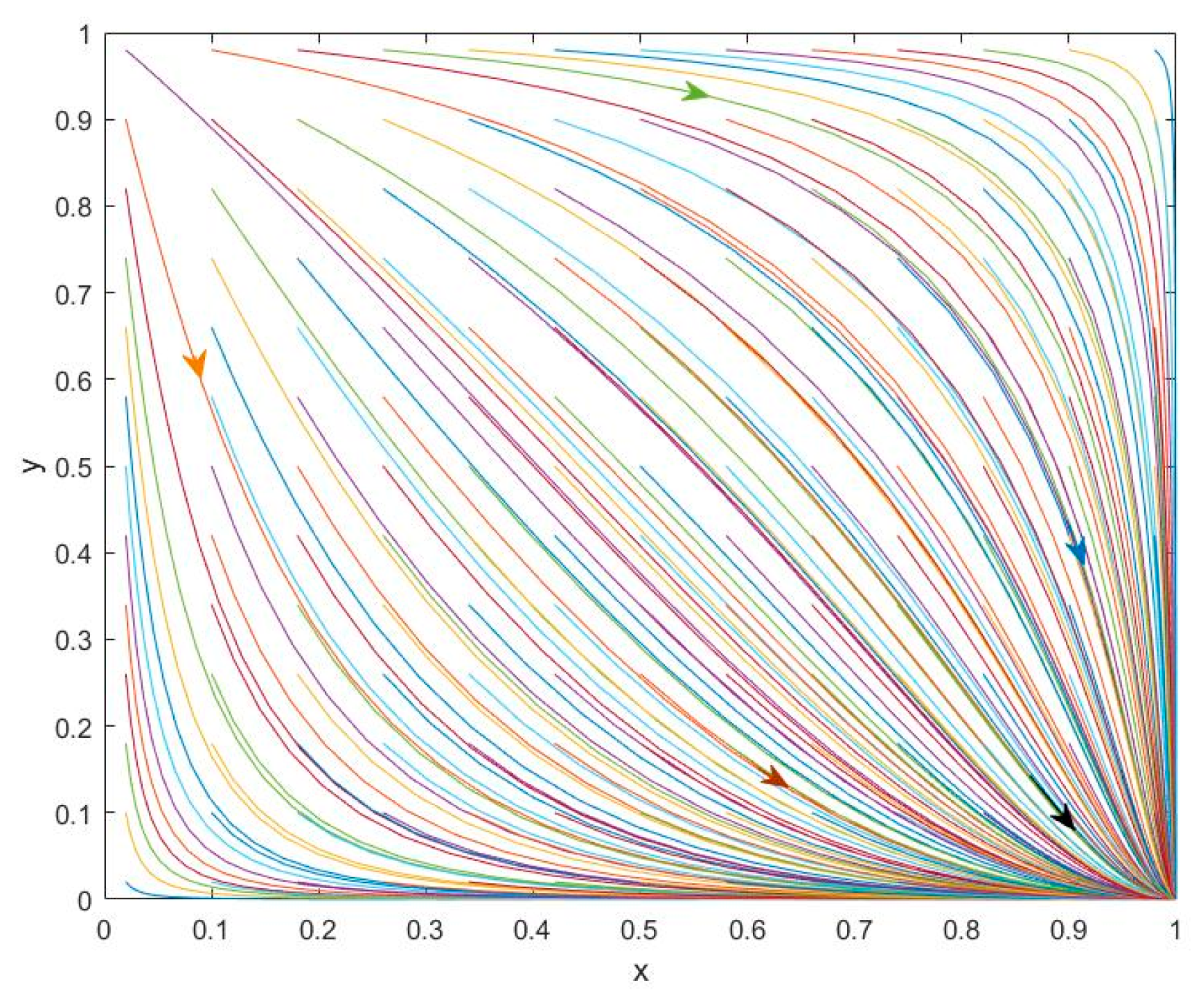

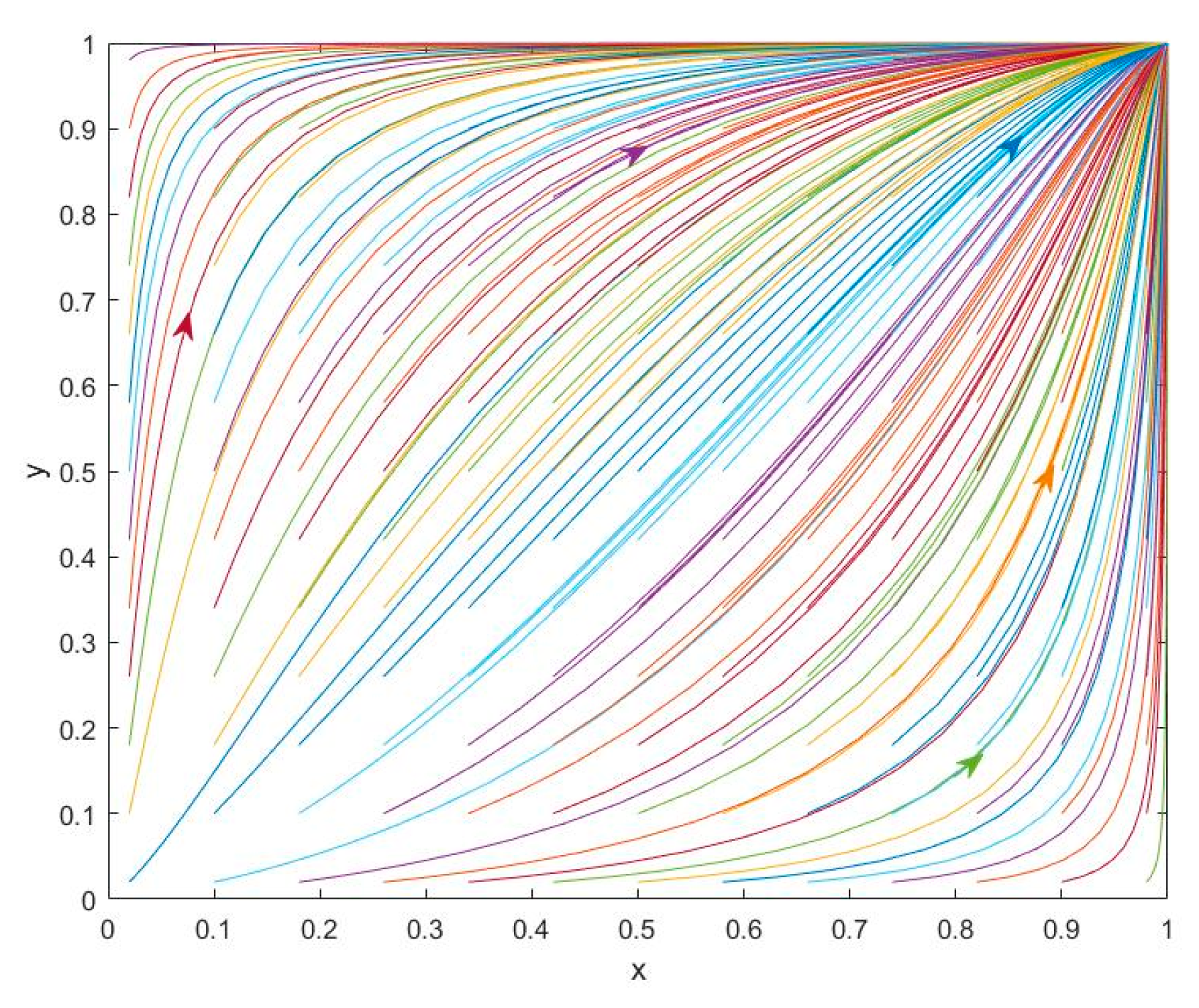

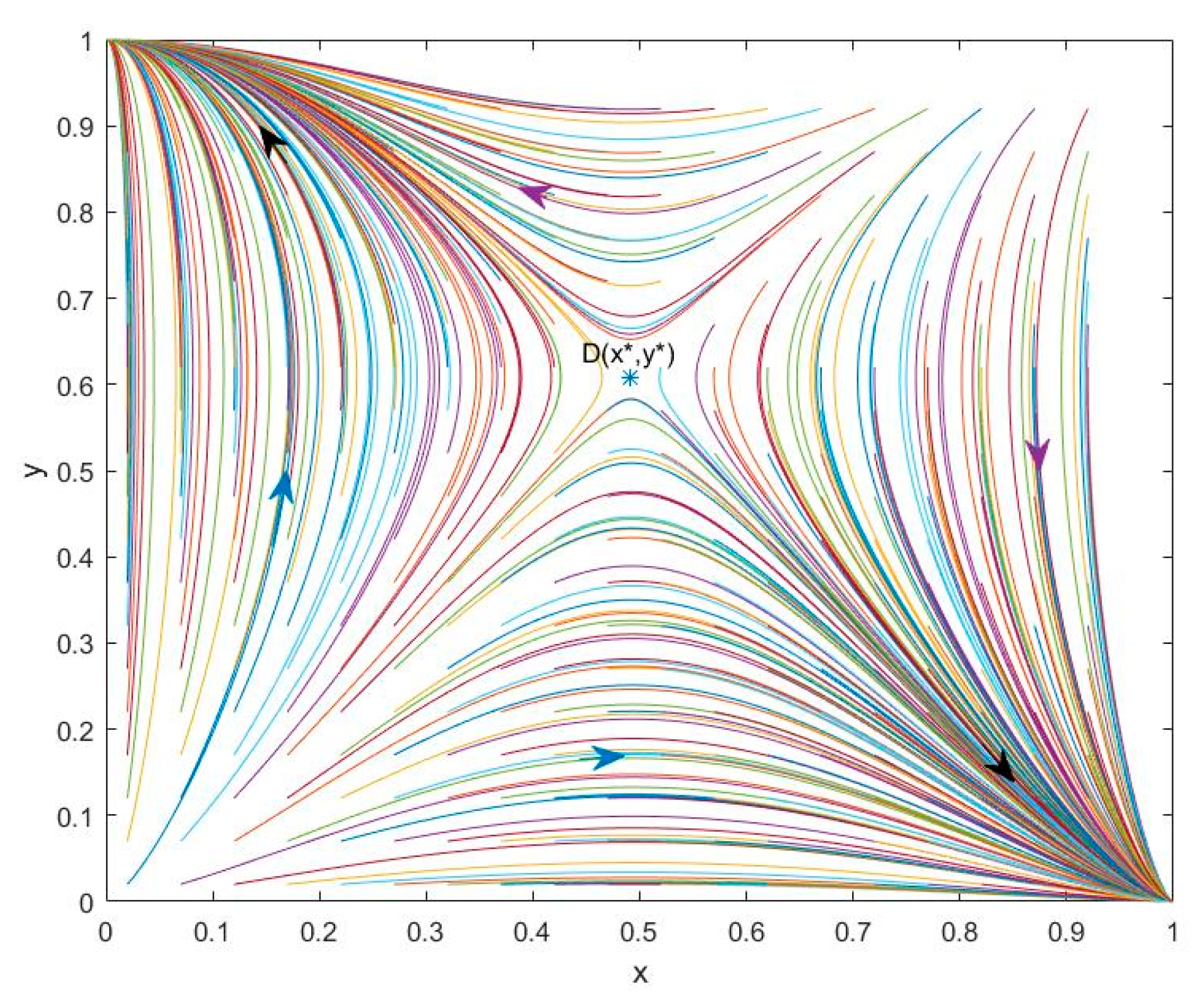

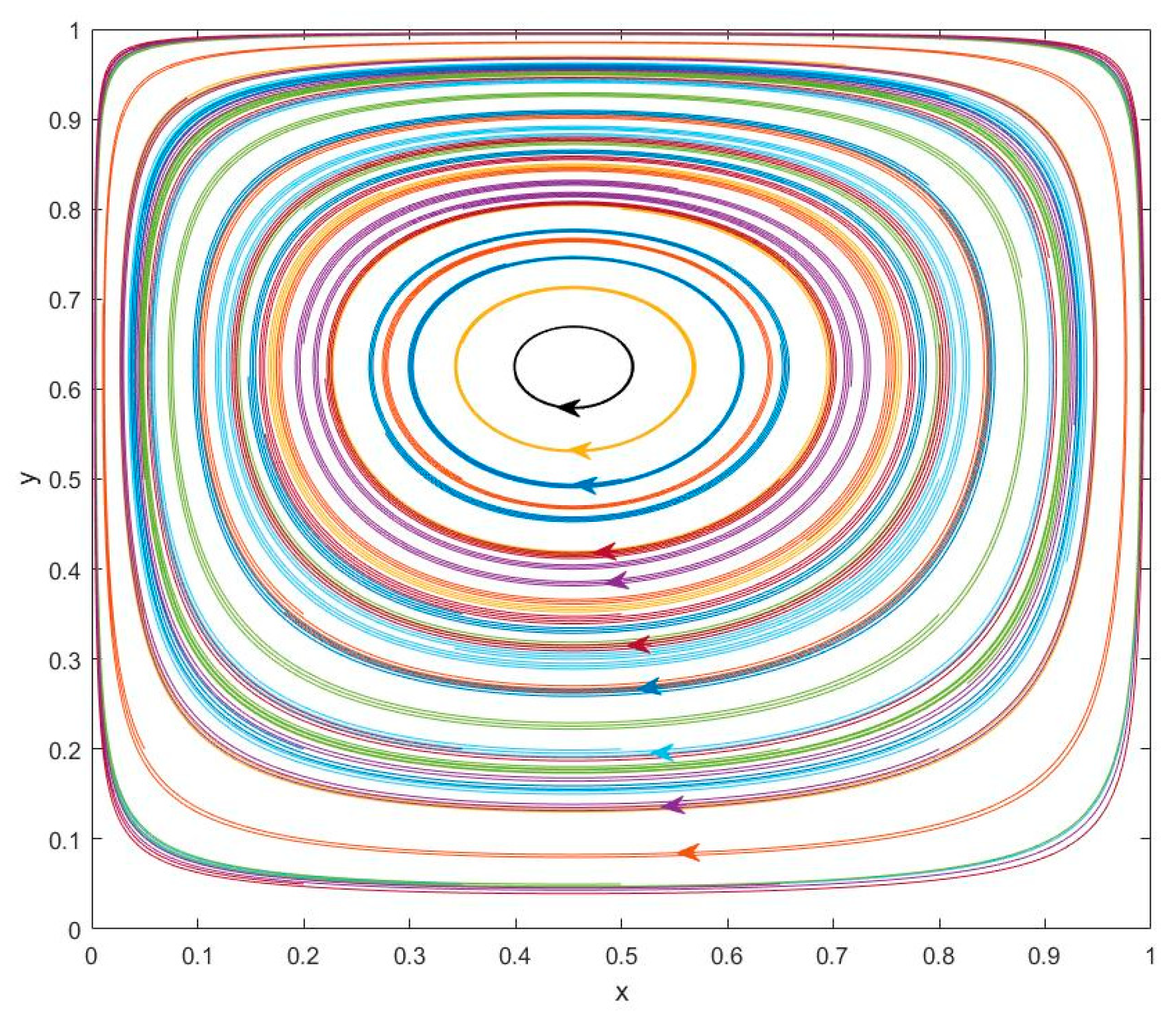

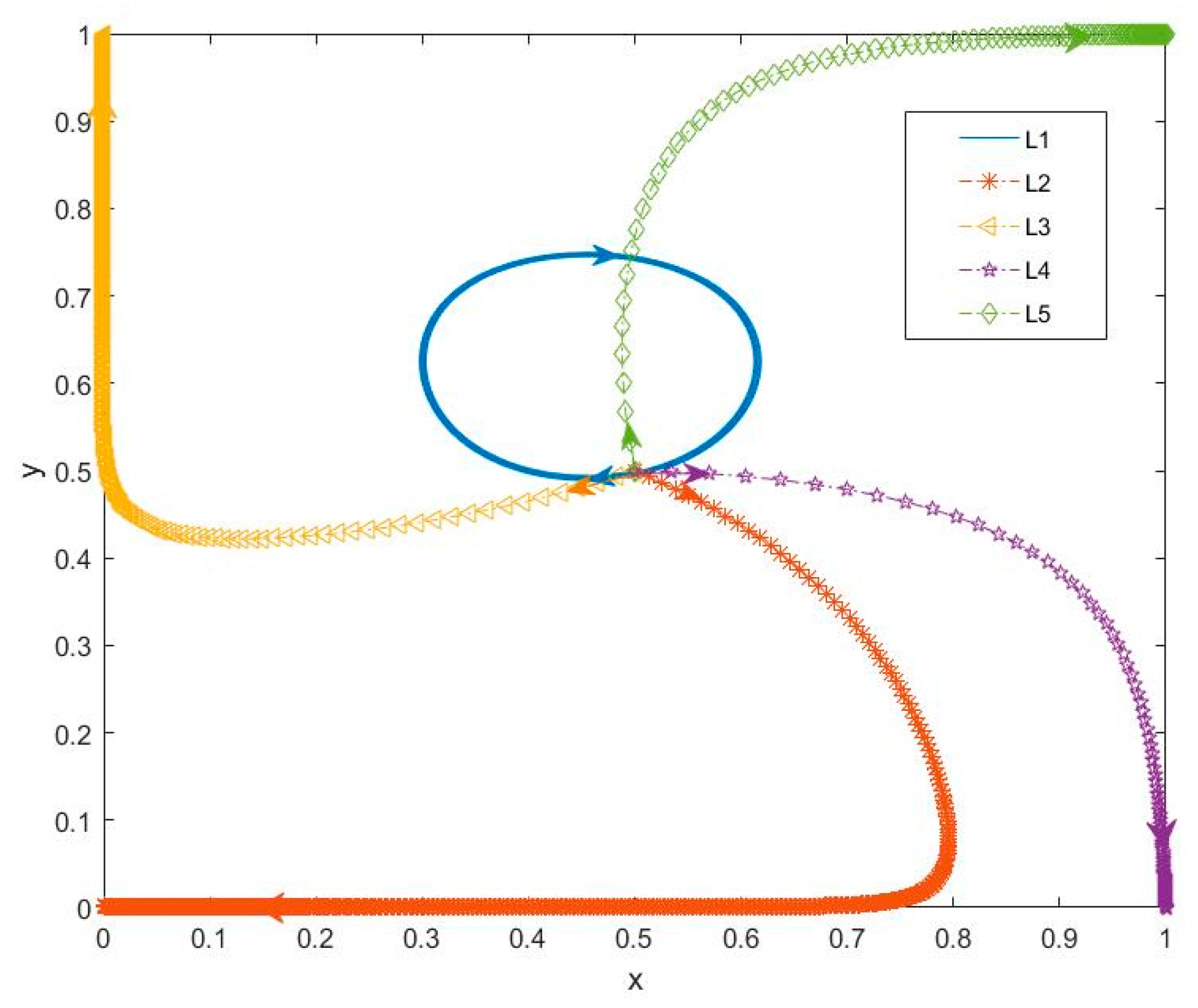

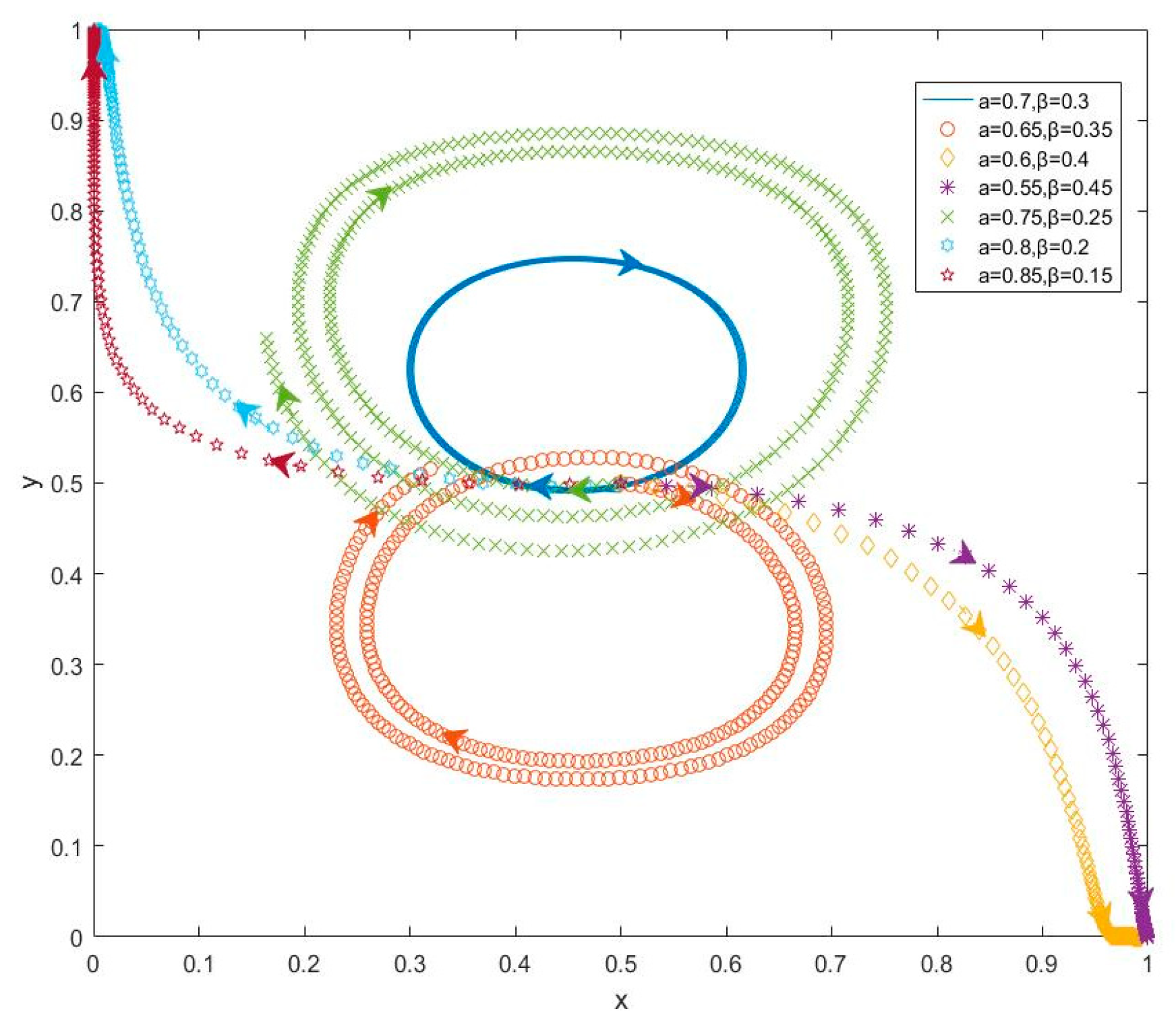

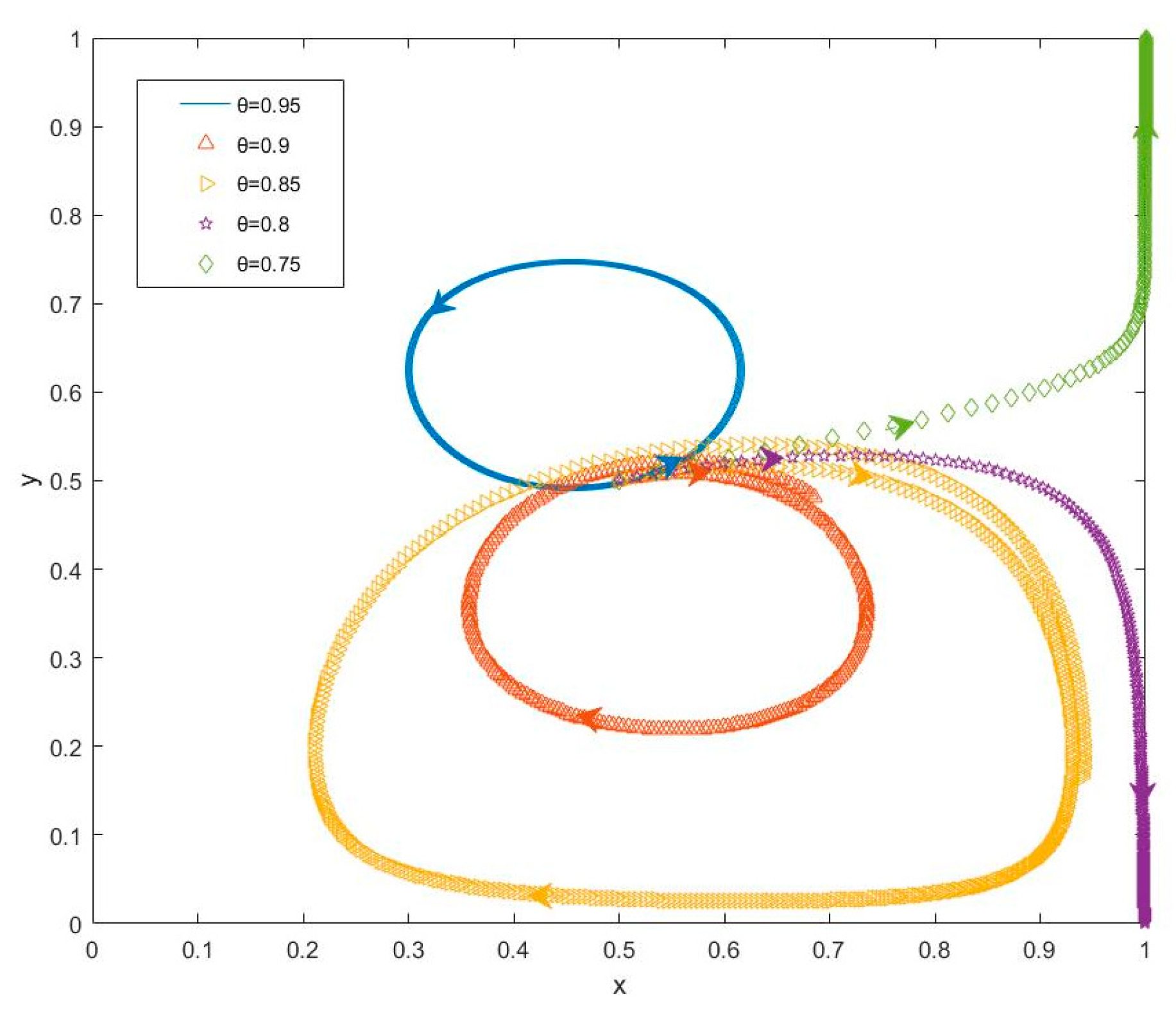

5.2. Impact of Initial Proportion on Evolutionary Results

5.3. Impact of Market Development on Evolutionary Results

5.4. Impact of Government Regulation on Evolutionary Results

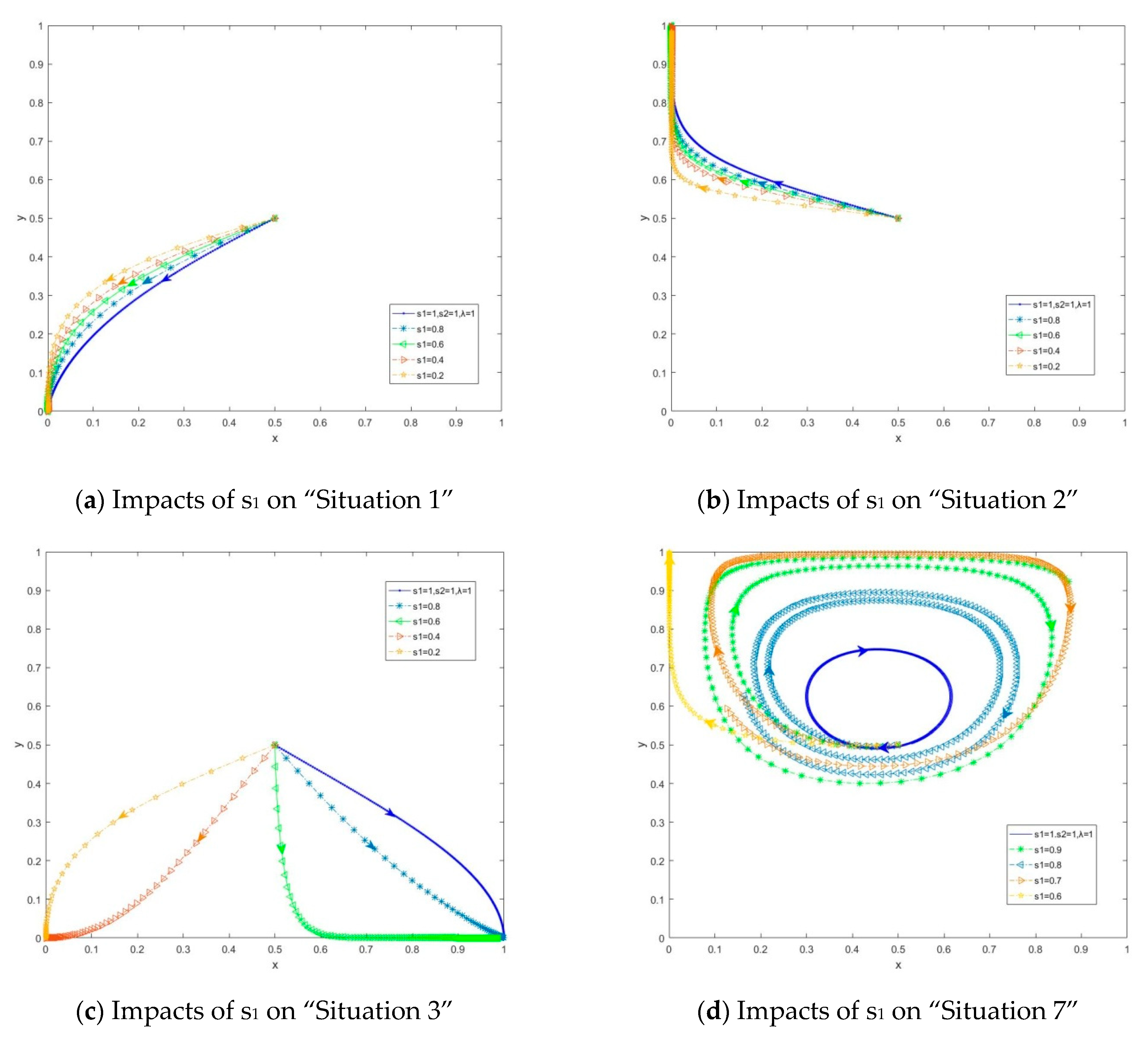

5.4.1. Impacts of Recycling Site Construction Subsidies (s1) on the Alliance Evolution

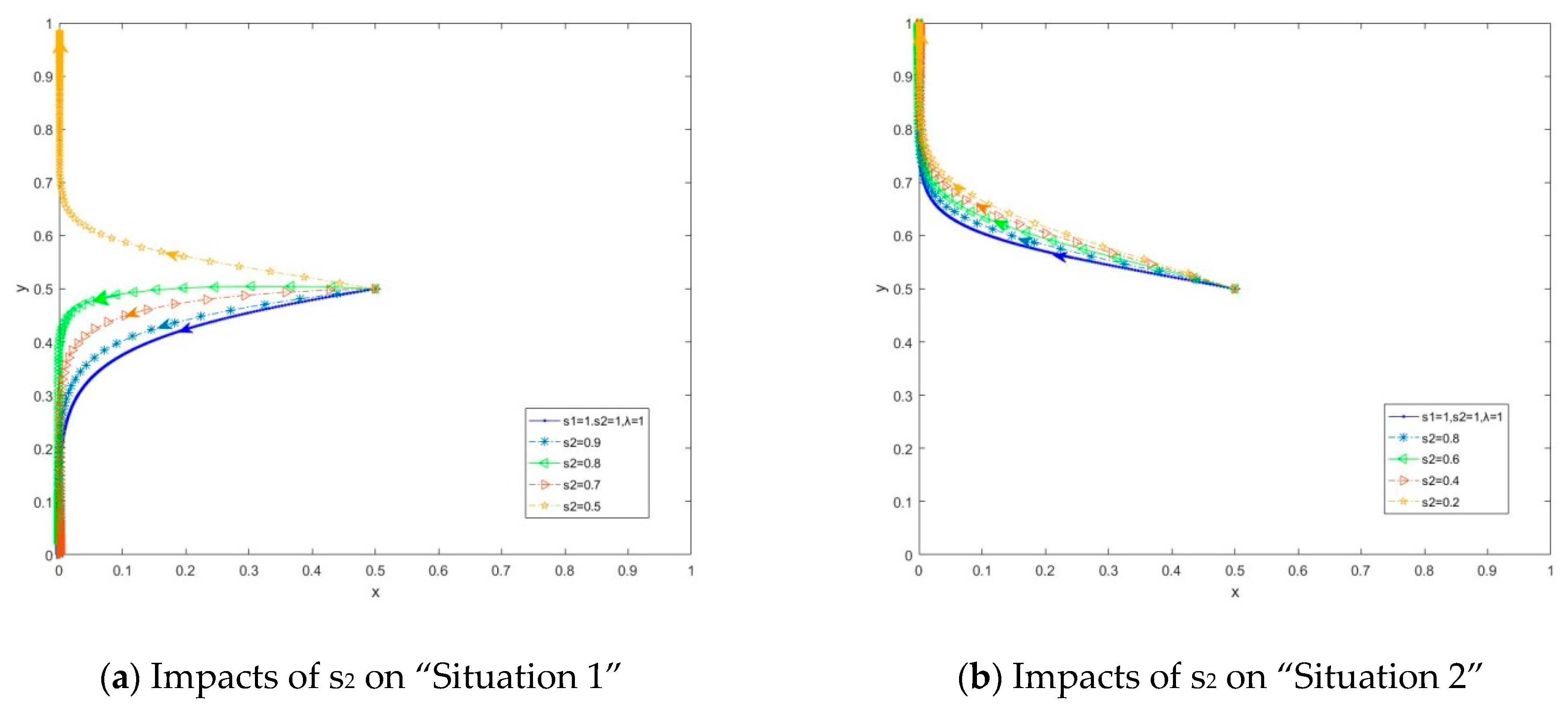

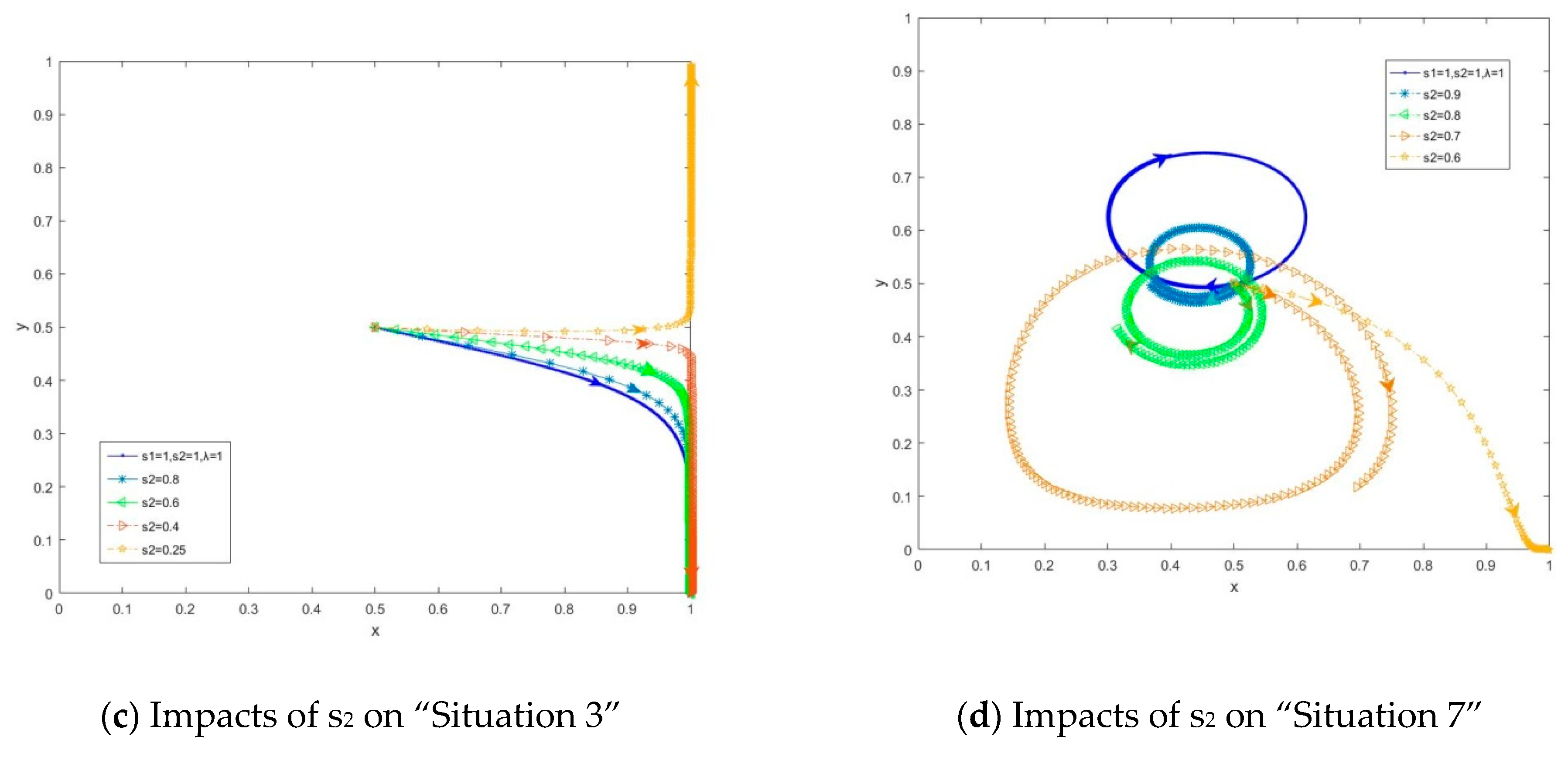

5.4.2. Impacts of Recycling Site Operation Subsidies (s2) on the Alliance Evolution

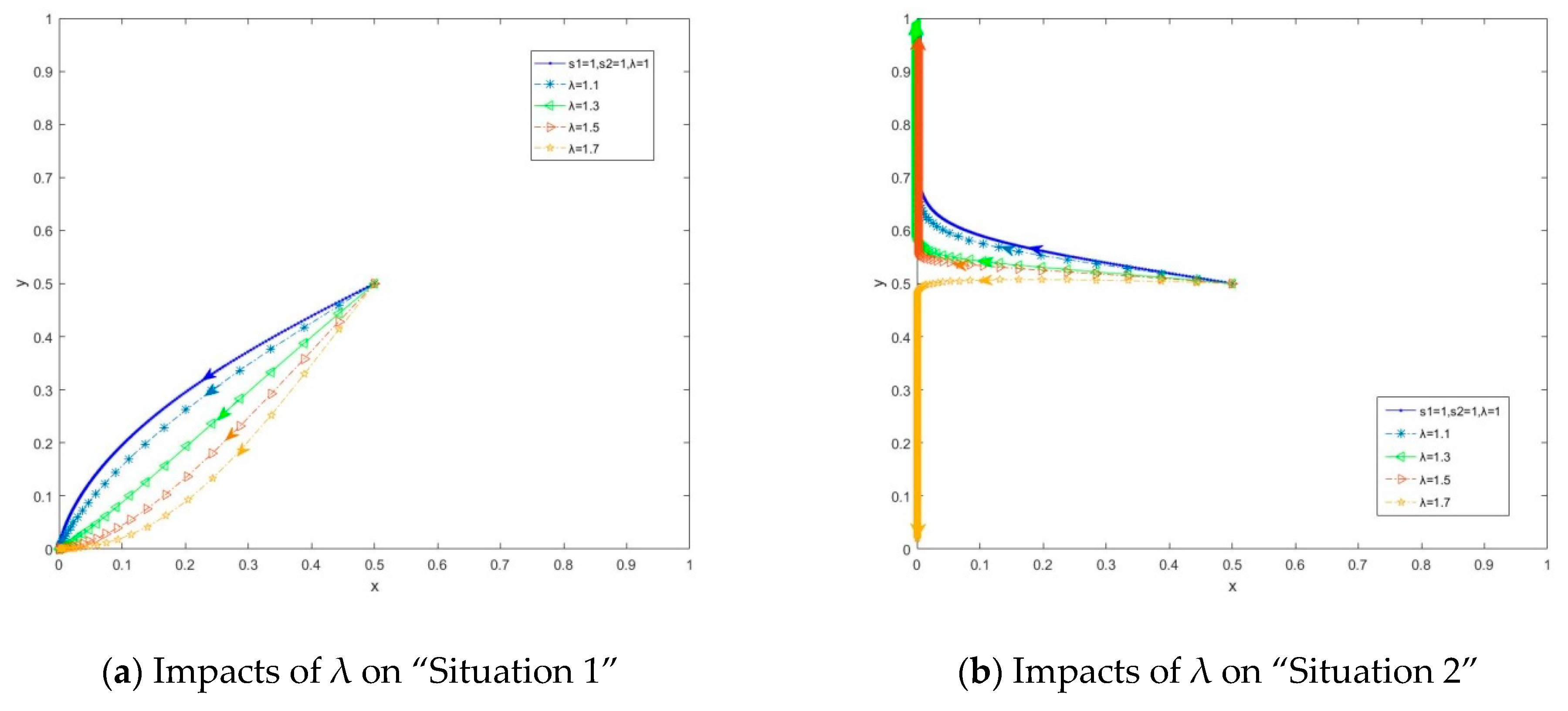

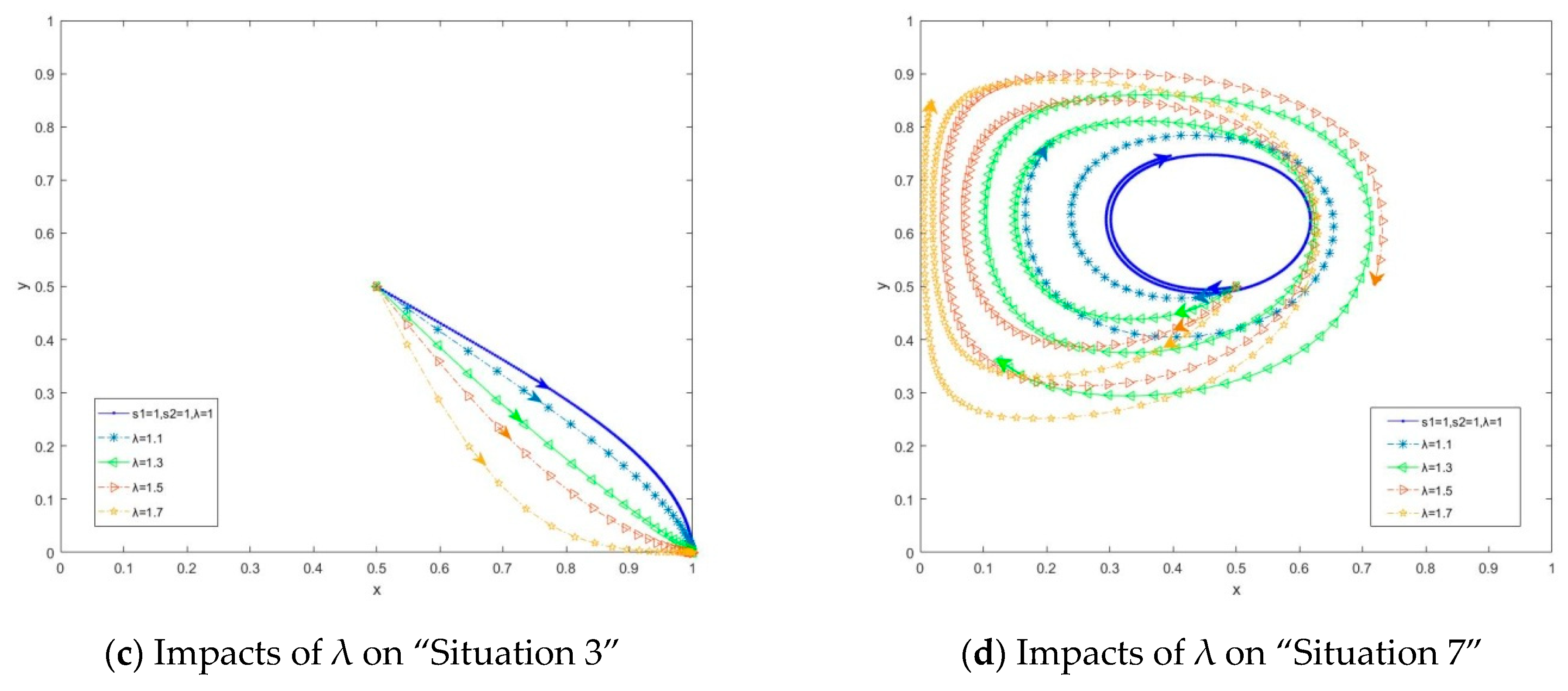

5.4.3. Impacts of Regulatory Intensity λ on Alliance Evolution

6. Conclusions and Management Implications

6.1. Conclusions

- (1)

- When certain conditions are met, the NEV power battery recycling and GU alliance can establish and maintain different types of competition and cooperation relationships. As the main subjects with battery-recycling responsibilities, NEV manufacturers focus on whether co-construction can save enough costs. GUEs are more concerned about whether they can make more profit by purchasing batteries than renting them. Under the condition of “Situations 1–4”, if the profit and loss situation is determined, regardless of the initial proportion of both sides in adopting active strategies, the cooperation mode formed by the members of the alliance will not change. Therefore, the guidance and regulation of these situations must only change the profit and loss of the subjects. Under the conditions of “Situation 5 and 6”, evolution paths and steady-state of the alliance should be guided according to not only the initial proportion of the subjects but also the profit and loss of the evolution process. Under the conditions of “Situation 7”, the alliance may enter an evolutionary deadlock. No matter how much time passes, the members in the alliance cannot form stable cooperation modes, and each subject continues testing and changing strategies, resulting in internal resource consumption.

- (2)

- When the evolution conditions are satisfied and the alliance can evolve to a steady-state, market development and government regulation can change the evolutionary paths and steady-state to some extent. However, the robustness of evolutionary systems to different parameters varies greatly under different conditions, and the sensitivity of subjects’ strategies to different types of parameters is also different. Under the market mechanism, raising the threshold of self-constructing of recycling sites (), reducing the co-construction costs of recycling sites (), saving the cost of operation (), and reducing the cost-sharing ratio during co-construction are effective means of encouraging NEV manufacturers to choose the “co-constructing” strategy. Reducing the battery-leasing price and increasing the GU income is necessary to encourage the GUEs to choose positive strategies, which accelerates the alliance to the ideal steady-state of “co-constructing” and “leasing”. When the market mechanism does not work, the government’s regulation measures, such as increasing the subsidies for the construction and operation of recycling sites and strengthening the supervision of illegal recycling channels, can increase the pace of forming stable cooperation in the alliance. However, the single regulation effect is not adequate. For example, only increasing the subsidies for the construction of recycling sites or increasing the supervision intensity cannot result in the alliance reaching the ideal win-win steady-state. However, it may cause an alliance subject who has a positive intention to eventually choose the negative strategy (as depicted in Figure 14c and Figure 16b). The increase in operation subsidies of recycling sites can only encourage the alliance to form an ideal steady-state of cooperation under the premise of “Situation 3” Therefore, the cooperative steady-state of “Situation 3” can be formed first through the guidance of market mechanism, then government regulation can promote the formation of the ideal stable state of cooperation.

- (3)

- When the alliance evolves into deadlock, measures in market mechanisms can break the deadlock and promote the alliance to evolve to a steady-state, such as reducing the battery purchase costs and leasing costs equidistantly, reducing the recycling site operating costs, reducing the GU yield gap between purchasing and leasing mode, adjusting the cost-sharing ratio, and providing preferential discounts to GUEs when co-constructing recycling sites. It is more effective to reduce the profit difference between purchasing and leasing mode and increase the preferential discount for the GUEs when co-constructing recycling site, which can directly promote the alliance evolve to the ideal steady-state of “co-constructing” and “leasing”. Concerning government regulations, increasing supervision has little effect on breaking the evolutionary deadlock. Increasing subsidies can only break the evolutionary deadlock if the subsidies are sufficiently large, but it cannot enable the alliance to evolve to the ideal state.

6.2. Management Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| (x,y) | Det J | Tr J |

|---|---|---|

| (0, 0) | ||

| (0, 1) | ||

| (1, 0) | ||

| (1, 1) | ||

| (x*,y*) |

References

- Gu, H.; Liu, Z.; Qing, Q. Optimal electric vehicle production strategy under subsidy and battery recycling. Energy Policy 2017, 109, 579–589. [Google Scholar] [CrossRef]

- Shao, Y.; Deng, X.; Qing, Q.; Wang, Y. Optimal Battery Recycling Strategy for Electric Vehicle under Government Subsidy in China. Sustainability 2018, 10, 4855. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, M. Development of a Two-Stage Pyrolysis Process for the End-Of-Life Nickel Cobalt Manganese Lithium Battery Recycling from Electric Vehicle. Sustainability 2020, 12, 9164. [Google Scholar] [CrossRef]

- China Merchants Securities. In-depth Report on Power Battery Recycling and Gradient Utilization Industry. Available online: http://chuneng.bjx.com.cn/news/20190801/996967.shtml (accessed on 12 March 2020).

- Liu, S.; Gong, D. Modeling and simulation on recycling of electric vehicle batteries—Using agent approach. Int. J. Simul. Model 2014, 13, 79–92. [Google Scholar] [CrossRef]

- Beaudet, A.; Larouche, F.; Amouzegar, K.; Bouchard, P.; Zaghib, K. Key Challenges and Opportunities for Recycling Electric Vehicle Battery Materials. Sustainability 2020, 12, 5837. [Google Scholar] [CrossRef]

- Tian, X.; Wu, Y.; Hou, P.; Liang, S.; Qu, S.; Xu, M.; Zuo, T. Environmental impact and economic assessment of secondary lead production: Comparison of main spent lead-acid battery recycling processes in China. J. Clean Prod. 2017, 144, 142–148. [Google Scholar] [CrossRef]

- Sun, H.; Wan, Y.; Zhang, L.; Zhou, Z. Evolutionary game of the green investment in a two-echelon supply chain under a government subsidy mechanism. J. Clean. Prod. 2019, 235, 1315–1326. [Google Scholar] [CrossRef]

- Guo, S.; Xiong, R.; Wang, K.; Sun, F. A novel echelon internal heating strategy of cold batteries for all-climate electric vehicles application. Appl. Energy 2018, 219, 256–263. [Google Scholar] [CrossRef]

- Gu, X.; Ieromonachou, P.; Zhou, L.; Tseng, M.L. Optimising quantity of manufacturing and remanufacturing in an electric vehicle battery closed-loop supply chain. Ind. Manag. Data Syst. 2017, 118, 283–302. [Google Scholar] [CrossRef]

- Khoshand, A.; Khanlari, K.; Abbasianjahromi, H.; Zoghi, M. Construction and demolition waste management: Fuzzy Analytic Hierarchy Process approach. Waste Manag. Res. 2020, 38, 773–782. [Google Scholar] [CrossRef]

- Qiao, F.; Lei, L. Environmental Analysis of Pure Electric Vehicle Battery Recycling and Utilization. Adv. Mater. Res. 2014, 955–959, 1987–1992. [Google Scholar] [CrossRef]

- Ministry of Industry and Information Technology, Ministry of Environmental Protection, Ministry of Transport, Ministry of Commerce, General Administration of Quality Supervision, Inspection and Quarantine, Energy Administration on Printing and Distributing. Interim Administration Measures of Recycling and Utilization of New Energy Vehicle Power Battery. Available online: https://www.miit.gov.cn/zwgk/zcwj/wjfb/zh/art/2020/art_459b0eb972964f68930bb39be9e92688.html (accessed on 15 December 2020).

- Interim Provisions on Traceability Management of Recycling and Utilization of Power Battery for New Energy Vehicles. Available online: https://www.miit.gov.cn/jgsj/jns/gzdt/art/2020/art_c1a708247cc54b068ea60ceaff0b044d.html (accessed on 15 December 2020).

- Announcement of the Ministry of Industry and Information Technology, PRC. Available online: https://www.miit.gov.cn/zwgk/zcwj/wjfb/gg/art/2020/art_556db04398224c2baf5d88fdf82121bd.html (accessed on 15 December 2020).

- To Solicit Public Opinions on the New Energy Vehicle Power Battery Gradient Utilization Management Measures (draft). Available online: https://www.miit.gov.cn/jgsj/jns/gzdt/art/2020/art_0faef15e1d9d4c10ab10ac940883dcb2.html (accessed on 15 December 2020).

- Kong, D.; Xia, Q.; Xue, Y.; Zhao, X. Effects of multi policies on electric vehicle diffusion under subsidy policy abolishment in China: A multi-actor perspective. Appl. Energy 2020, 266, 114887. [Google Scholar] [CrossRef]

- Sun, X.; Luo, X.; Zhang, Z.; Meng, F.; Yang, J. Life cycle assessment of lithium nickel cobalt manganese oxide (NCM) batteries for electric passenger vehicles. J. Clean. Prod. 2020, 273, 123006. [Google Scholar] [CrossRef]

- Li, X.; Mu, D.; Du, J.; Cao, J.; Zhao, F. Game-based system dynamics simulation of deposit-refund scheme for electric vehicle battery recycling in China. Resour. Conserv. Recycl. 2020, 157, 104788. [Google Scholar] [CrossRef]

- Li, M.; Yang, J.; Liang, S.; Hou, H.; Hu, J.; Liu, B.; Kumar, R.V. Review on clean recovery of discarded/spent lead-acid battery and trends of recycled products. J. Power Sources 2019, 436, 226853. [Google Scholar] [CrossRef]

- Rynne, O.; Lepage, D.; Aymé-Perrot, D.; Rochefort, D.; Dollé, M. Application of a Commercially-Available Fluorine-Free Thermoplastic Elastomer as a Binder for High-Power Li-Ion Battery Electrodes. J. Electrochem. Soc. 2019, 166, A1140–A1146. [Google Scholar] [CrossRef]

- Zhang, B.; Li, J.; Yue, X. Driving Mechanism of Power Battery Recycling Systems in Companies. Int. J. Environ. Res. Public Health 2020, 17, 8204. [Google Scholar] [CrossRef]

- Yu, H.; Solvang, W.D. A Stochastic Programming Approach with Improved Multi-Criteria Scenario-Based Solution Method for Sustainable Reverse Logistics Design of Waste Electrical and Electronic Equipment (WEEE). Sustainability 2016, 8, 1331. [Google Scholar] [CrossRef]

- Yun, L.; Linh, D.; Shui, L.; Peng, X.; Garg, A.; Le, M.L.P.; Asghari, S.; Sandoval, J. Metallurgical and mechanical methods for recycling of lithium-ion battery pack for electric vehicles. Resour. Conserv. Recycl. 2018, 136, 198–208. [Google Scholar] [CrossRef]

- Pan, H.Y.; Geng, Y.; Dong, H.J.; Ali, M.; Xiao, S.J. Sustainability evaluation of secondary lead production from spent lead acid batteries recycling. Resour. Conserv. Recycl. 2019, 140, 13–22. [Google Scholar] [CrossRef]

- Thiel, C.; Perujo, A.; Mercier, A. Cost and CO2 aspects of future vehicle options in Europe under new energy policy scenarios. Energy Policy 2010, 38, 7142–7151. [Google Scholar] [CrossRef]

- Kang, D.H.P.; Chen, M.; Ogunseitan, O.A. Potential environmental and human health impacts of rechargeable lithium batteries in electronic waste. Environ. Sci. Technol. 2013, 47, 5495–5503. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, J.; Wu, X.; Hu, Y.; Yu, W.; Wang, J.; Dong, J.; Li, M.; Liang, S.; Hu, J.; et al. A critical review on secondary lead recycling technology and its prospect. Renew. Sustain. Energy Rev. 2016, 61, 108–122. [Google Scholar] [CrossRef]

- Hung, Y.; Yin, L.; Wang, J.; Wang, C.; Tsai, C.; Kuo, Y. Recycling of spent nickel-cadmium battery using a thermal separation process. Environ. Prog. Sustain. Energy 2018, 37, 645–654. [Google Scholar] [CrossRef]

- Lee, J.; Kim, T.; Sung, M.; Vu, H.; Shin, K.N.; Ahn, J.W. An Integrative Approach to International Technology Transfer for Recycling Vietnam Coal Ash with Consideration of the Technological, Legal, and Network Perspectives. Sustainability 2020, 12, 771. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Anderson, P. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef] [PubMed]

- Miedema, J.H.; Moll, H.C. Lithium availability in the EU27 for battery-driven vehicles: The impact of recycling and substitution on the confrontation between supply and demand until2050. Resour. Policy 2013, 38, 204–211. [Google Scholar] [CrossRef]

- Gu, X.; Ieromonachou, P.; Zhou, L.; Tseng, M.L. Developing pricing strategy to optimise total profits in an electric vehicle battery closed loop supply chain. J. Clean. Prod. 2018, 203, 376–385. [Google Scholar] [CrossRef]

- Hao, H.; Qiao, Q.; Liu, Z.; Zhao, F. Impact of recycling on energy consumption and greenhouse gas emissions from electric vehicle production: The China 2025 case. Resour. Conserv. Recycl. 2017, 122, 114–125. [Google Scholar] [CrossRef]

- Ellingsen, L.A.; Hung, C.; Strømman, A.H. Identifying Key Assumptions and Differences in Life Cycle Assessment Studies of Lithium-Ion Traction Batteries with Focus on Greenhouse Gas Emissions. Transp. Res. Part D Transp. Environ. 2017, 55, 82–90. [Google Scholar] [CrossRef]

- Mayyas, A.; Steward, D.; Mann, M. The case for recycling: Overview and challenges in the material supply chain for automotive li-ion batteries. Sustain. Mater. Technol. 2019, 19, e00087. [Google Scholar] [CrossRef]

- Steward, D.; Mayyas, A.; Mann, M. Economics and Challenges of Li-Ion Battery Recycling from End-of-Life Vehicles. Proc. Manuf. 2019, 33, 272–279. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Pang, B.; Sun, B.; Kokko, A. Second Use Value of China’s New Energy Vehicle Battery: A View Based on Multi-Scenario Simulation. Sustainability 2020, 12, 341. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Tan, X. Research on the Classification Method for the Secondary Uses of Retired Lithium-ion Traction Batteries. Energy Procedia 2017, 105, 2843–2849. [Google Scholar] [CrossRef]

- Zhang, Q. The Current Status on the Recycling of Lead-acid Batteries in China. Int. J. Electrochem. Sci. 2013, 8, 6457–6466. [Google Scholar]

- Jung, M.; Wooyoung, J. The Impact of Electric Vehicle Demand and Battery Recycling on Price Dynamics of Lithium-Ion Battery Cathode Materials: A Vector Error Correction Model (VECM) Analysis. Sustainability 2018, 10, 2870. [Google Scholar]

- Wang, L.; Wang, X.; Yang, W. Optimal design of electric vehicle battery recycling network—From the perspective of electric vehicle manufacturers. Appl. Energy 2020, 275, 115328. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Li, Y.; Wang, G.; Li, Y. Recycling mechanisms and policy suggestions for spent electric vehicles’ power battery—A case of beijing. J. Clean. Prod. 2018, 186, 388–406. [Google Scholar] [CrossRef]

- Hong, X.; Xu, L.; Du, P.; Wang, W. Joint advertising, pricing and collection decisions in a closed–loop supply chain. Int. J. Prod. Econ. 2015, 167, 12–22. [Google Scholar] [CrossRef]

- Cheng, D.; Zhou, J.; Li, J.; Du, C.; Zhang, H. Analysis in Power Battery Gradient Utilization of Electric Vehicle. Adv. Mater. Res. 2012, 347–353, 555–559. [Google Scholar] [CrossRef]

- Sun, B.; Su, X.; Wang, D.; Zhang, L.; Liu, Y.; Yang, Y.; Jiang, J. Economic analysis of lithium-ion batteries recycled from electric vehicles for secondary use in power load peak shaving in China. J. Clean. Prod. 2020, 276, 123327. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, M.; Yu, X.; Ren, H. What keeps chinese from recycling: Accessibility of recycling facilities and the behavior. Resour. Conserv. Recycl. 2016, 109, 176–186. [Google Scholar] [CrossRef]

- Chen, S.; Lian, Z.; Li, S.; Junbeum, K.; Li, Y.; Cao, L.; Liu, Z. The Environmental Burdens of Lead-Acid Batteries in China: Insights from an Integrated Material Flow Analysis and Life Cycle Assessment of Lead. Energies 2017, 10, 1969. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y. An overview of recycling and treatment of spent LiFePO4 batteries in China. Resour. Conserv. Recycl. 2017, 127, 233–243. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, Y.; Li, W.; Wu, C. Evolutionary Game Study between Government Subsidy and R&D Activities of New Energy Vehicle Enterprises. Oper. Res. Manag. Sci. 2020, 29, 22–28. (In Chinese) [Google Scholar]

- Notice on Issuing the Pilot Implementation Plan for the Recycling and Utilization of Power Batteries for New Energy Vehicles in the Beijing-Tianjin-Hebei Region and Soliciting Pilot Demonstration Projects. Available online: http://gxt.hebei.gov.cn/hbgyhxxht/xwzx32/tzgg83/617987bb/index.html (accessed on 12 January 2021).

- Friedman, D. On Economic Applications of Evolutionary Game Theory. J. Evol. Econ. 1998, 8, 15–43. [Google Scholar] [CrossRef]

| Category | Symbol | Definition |

|---|---|---|

| Market parameters | Battery purchase costs that GUEs pay to NEV manufacturers when choosing the “purchasing” strategy. | |

| Battery renting costs that GUEs pay to NEV manufacturers when choosing the “leasing” strategy. | ||

| Construction costs incurred by NEV manufacturers when they choose the “self-constructing” strategy. | ||

| Construction costs incurred by NEV manufacturers when they choose the “co-constructing” strategy. | ||

| Operating costs of battery recycling sites (including costs of recycling, storage, transportation of batteries from consumers, etc.) | ||

| Operation and transportation costs of the secondary recycle of batteries after GU when NEV manufacturers choose “self-construction” strategy. | ||

| Testing fee of batteries after GU in the mode of “leasing”. | ||

| Income that the GUEs can obtain from the gradient batteries when choosing the strategy of “purchasing”. | ||

| Income that the GUEs can obtain from the gradient batteries when choosing the strategy of “leasing”. | ||

| The proportion of costs borne by the NEV manufacturers in the mode of “co-constructing”. | ||

| The proportion of costs borne by the GUEs in the mode of “co-constructing”. | ||

| Preferential discounts that the GUEs can get in the mode of “co-constructing”. | ||

| Revenue generated when the NEV manufacturers resell the leased batteries regenerated utilization enterprises in the mode of “leasing”. | ||

| Revenue generated when the GUEs sell the batteries after GU to regenerated utilization enterprises in the mode of “purchasing”. | ||

| Government parameters | λ | Government supervision of battery recycling and GU, such as standardizing the recycling channels and improving the battery traceability management system. (Enhancing supervision is beneficial to GUEs to improve income.) |

| Discounts of construction cost of the recycling sites that caused by government subsidies. (Discounts decrease when subsidies increase.) | ||

| Discounts of operation cost of the recycling sites that caused by government subsidies. (Discounts decrease when subsidies increase.) |

| Gradient Utilization Enterprises (GUEs) | |||

|---|---|---|---|

| Leasing Batteries (y) | Purchasing Batteries (1 − y) | ||

| NEV Manufacturers | Co-constructing recycling sites (x) | ||

| Self-constructing recycling sites (1 − x) | |||

| Symbol | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| value | 5 | 3 | 9 | 7 | 10 | 14 | 2 | 1 | 0.5 | 0.7 | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, X.; Xu, Y.; Sun, D. An Evolutionary Game Research on Cooperation Mode of the NEV Power Battery Recycling and Gradient Utilization Alliance in the Context of China’s NEV Power Battery Retired Tide. Sustainability 2021, 13, 4165. https://doi.org/10.3390/su13084165

Lyu X, Xu Y, Sun D. An Evolutionary Game Research on Cooperation Mode of the NEV Power Battery Recycling and Gradient Utilization Alliance in the Context of China’s NEV Power Battery Retired Tide. Sustainability. 2021; 13(8):4165. https://doi.org/10.3390/su13084165

Chicago/Turabian StyleLyu, Xichen, Yingying Xu, and Dian Sun. 2021. "An Evolutionary Game Research on Cooperation Mode of the NEV Power Battery Recycling and Gradient Utilization Alliance in the Context of China’s NEV Power Battery Retired Tide" Sustainability 13, no. 8: 4165. https://doi.org/10.3390/su13084165

APA StyleLyu, X., Xu, Y., & Sun, D. (2021). An Evolutionary Game Research on Cooperation Mode of the NEV Power Battery Recycling and Gradient Utilization Alliance in the Context of China’s NEV Power Battery Retired Tide. Sustainability, 13(8), 4165. https://doi.org/10.3390/su13084165