An Internet of Things Approach for Water Efficiency: A Case Study of the Beverage Factory

Abstract

1. Introduction

2. Methodology

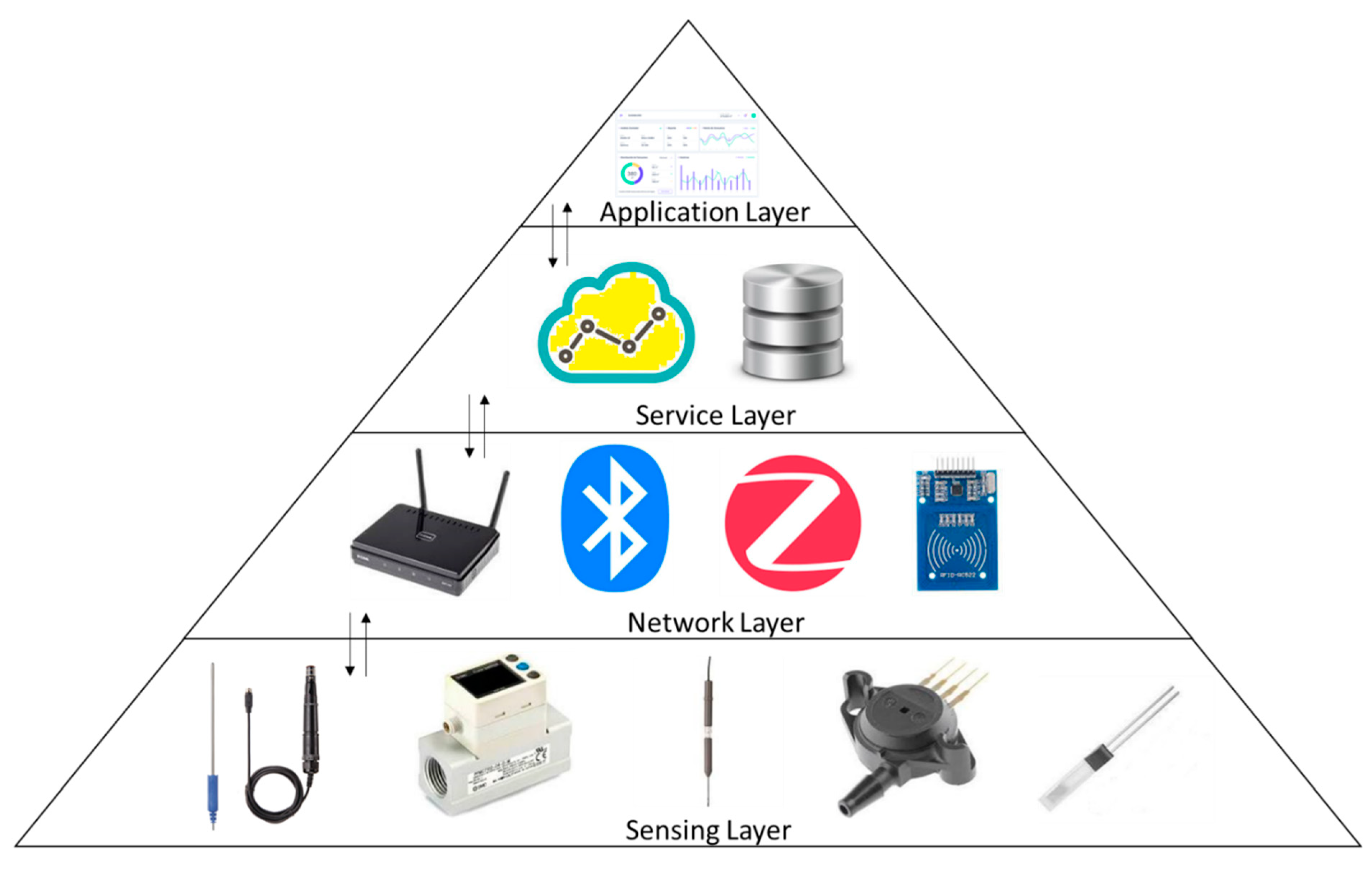

3. IoT-Based Water Monitoring Architecture

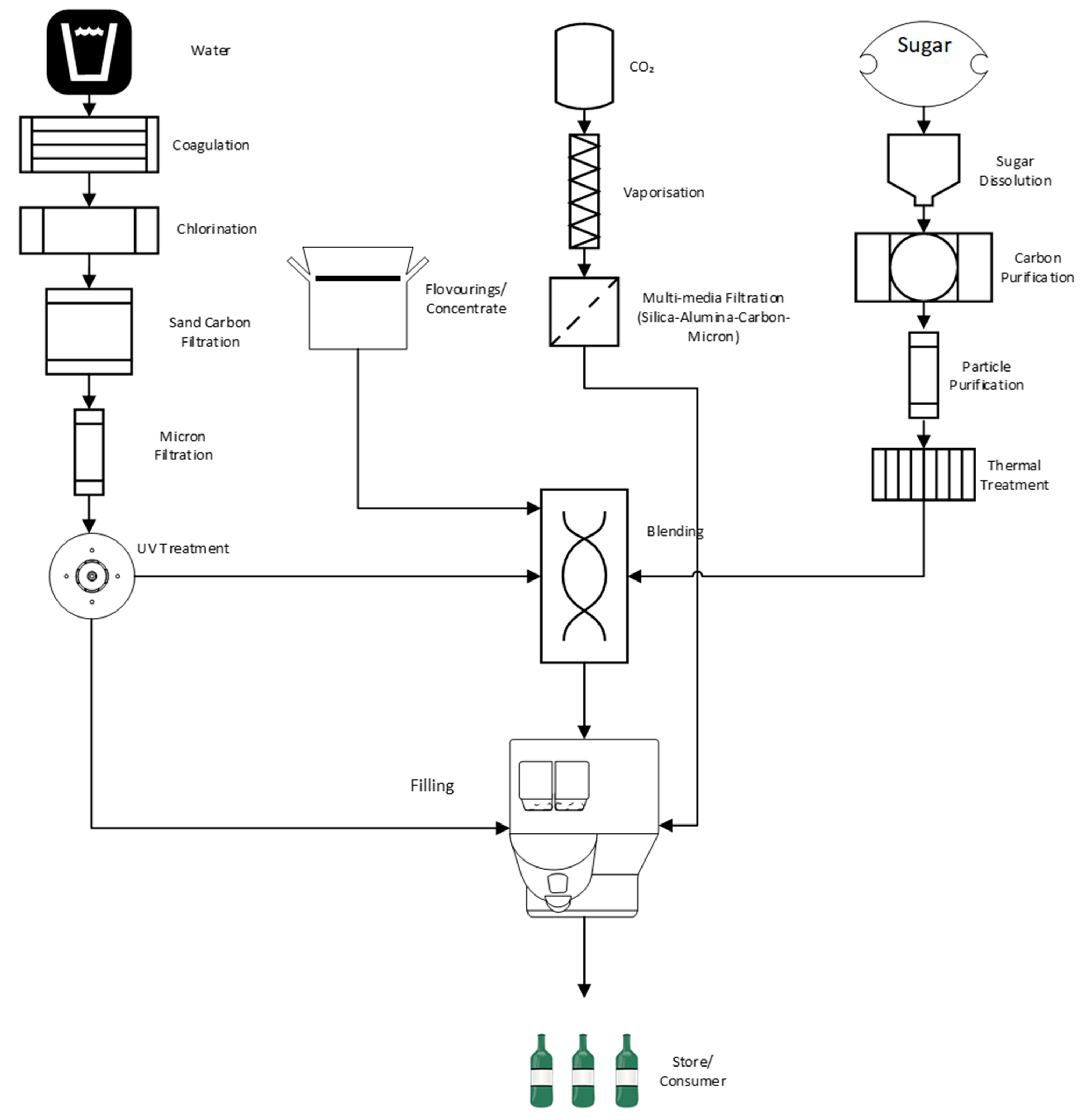

4. Case Study

4.1. Background

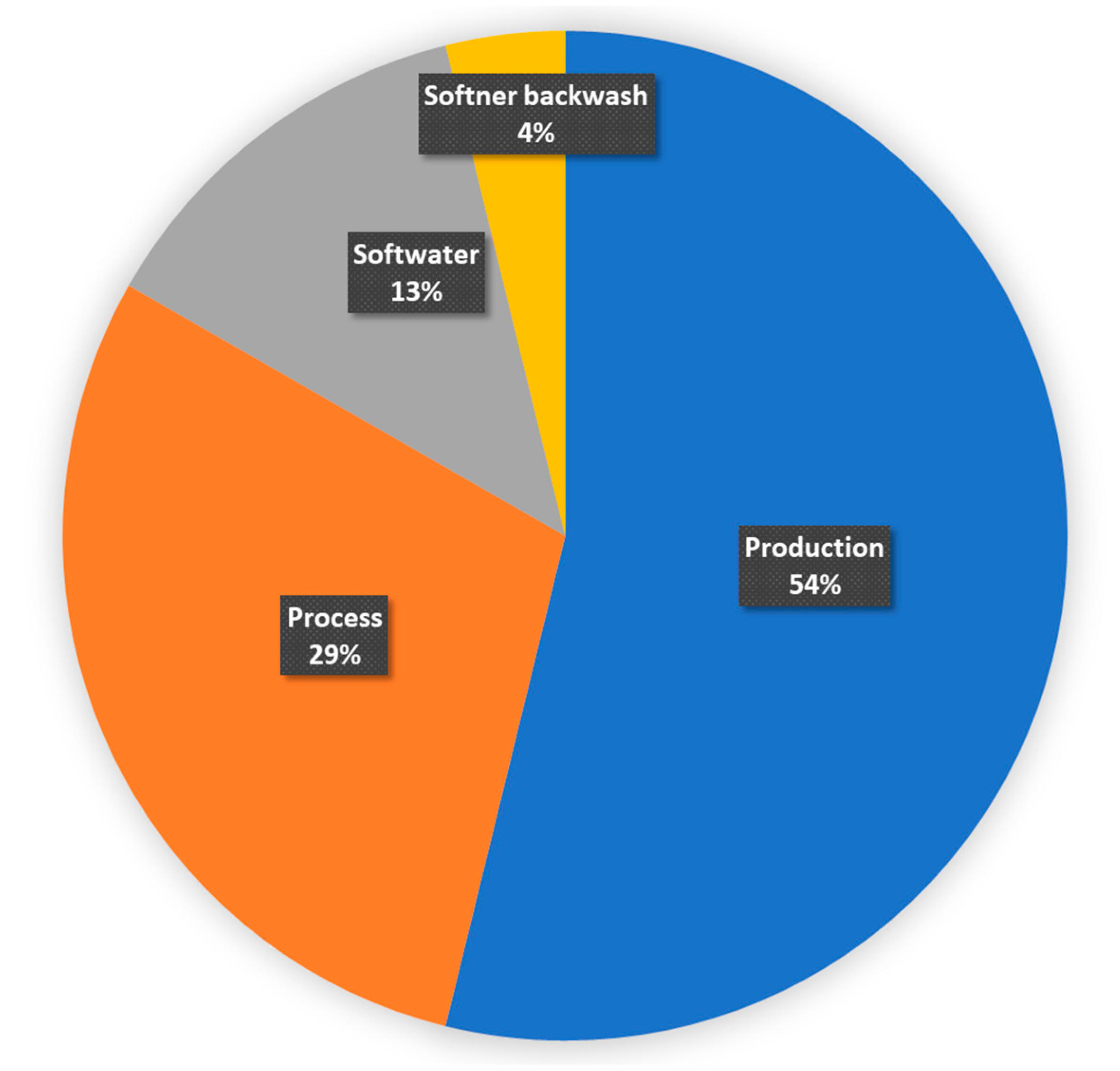

4.2. Water Consumption in the Beverage Factory

4.3. IoT System Implementation

4.3.1. Cooling Tower

4.3.2. Boiler

4.3.3. Other Water-Saving Initiatives

5. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Perumal, T.; Sulaiman, M.N.; Leong, C.Y. Internet of Things (IoT) enabled water monitoring system. In Proceedings of the 2015 IEEE 4th Global Conference on Consumer Electronics (GCCE), Osaka, Japan, 27–30 October 2015; pp. 86–87. [Google Scholar] [CrossRef]

- United Nations. World Population Prospects 2017. 2017. Available online: https://esa.un.org/unpd/wpp/DataQuery/ (accessed on 29 January 2020).

- Mullen, K. Information on Earth’s Water. 2012. Available online: http://www.ngwa.org/Fundamentals/teachers/Pages/information-on-earth-water.aspx (accessed on 11 January 2020).

- Luckmann, J.; Grethe, H.; McDonald, S.; Orlov, A.; Siddig, K. An integrated economic model of multiple types and uses of water. Water Resour. Res. 2014, 50, 3875–3892. [Google Scholar] [CrossRef]

- Bromley-Challenor, K.; Kowalski, M.; Barnard, R.; Lynn, S. Water Use in the UK Food and Drink Industry—A Review of Water Use in the Food and Drink Industry in 2007 and 2010, by Sub-Sector and UK Nations; WRAP: Banbury, UK, 2013. [Google Scholar]

- Casani, S.; Rouhany, M.; Knøchel, S. A discussion paper on challenges and limitations to water reuse and hygiene in the food industry. Water Res. 2005, 39, 1134–1146. [Google Scholar] [CrossRef] [PubMed]

- Jagtap, S.; Rahimifard, S. The digitisation of food manufacturing to reduce waste—Case study of a ready meal factory. Waste Manag. 2019, 87, 387–397. [Google Scholar] [CrossRef]

- Jagtap, S.; Rahimifard, S. Unlocking the Potential of the Internet of Things to Improve Resource Efficiency in Food Supply Chains. In Innovative Approaches and Applications for Sustainable Rural Development, Proceedings of the 8th International Conference (HAICTA 2017), Chania, Greece, 21–24 September 2017; Theodoridis, A., Ragkos, A., Salampasis, M., Eds.; Springer: Cham, Switzerland, 2019; pp. 287–301. [Google Scholar]

- Brame, J.; Li, Q.; Alvarez, P.J. Nanotechnology-enabled water treatment and reuse: Emerging opportunities and challenges for developing countries. Trends Food Sci. Technol. 2011, 22, 618–624. [Google Scholar] [CrossRef]

- Sodhi, M.S.; Yatskovskaya, E. Developing a sustainability index for companies’ efforts on responsible use of water. Int. J. Prod. Perform. Manag. 2014, 63, 800–821. [Google Scholar] [CrossRef]

- Manzocco, L.; Ignat, A.; Anese, M.; Bot, F.; Calligaris, S.; Valoppi, F.; Nicoli, M.C. Efficient management of the water resource in the fresh-cut industry: Current status and perspectives. Trends Food Sci. Technol. 2015, 46, 286–294. [Google Scholar] [CrossRef]

- Afzaal, H.; Farooque, A.A.; Abbas, F.; Acharya, B.; Esau, T. Precision irrigation strategies for sustainable water budgeting of potato crop in Prince Edward Island. Sustainability 2020, 12, 2419. [Google Scholar] [CrossRef]

- Jagtap, S.; Garcia-Garcia, G.; Rahimifard, S. Optimisation of the resource efficiency of food manufacturing via the Internet of Things. Comput. Ind. 2021, 127, 103397. [Google Scholar] [CrossRef]

- Jagtap, S.; Bader, F.; Garcia-Garcia, G.; Trollman, H.; Fadiji, T.; Salonitis, K. Food Logistics 4.0: Opportunities and Challenges. Logistics 2020, 5, 2. [Google Scholar] [CrossRef]

- Ebersold, K.; Glass, R. The impact of disruptive technology: The Internet of Things. Issues Inf. Syst. 2015, 16, 194–201. [Google Scholar]

- Meneses, Y.E.; Stratton, J.; Flores, R.A. Water reconditioning and reuse in the food processing industry: Current situation and challenges. Trends Food Sci. Technol. 2017, 61, 72–79. [Google Scholar] [CrossRef]

- Gourbesville, P.; Du, M.; Zavattero, E.; Ma, Q.; Gaëtano, M. Decision Support System Architecture for Real-Time Water Management. Manag. Water Resour. Pol. 2018, 259–272. [Google Scholar] [CrossRef]

- Lund, N.S.V.; Falk, A.K.V.; Borup, M.; Madsen, H.; Mikkelsen, P.S. Model predictive control of urban drainage systems: A review and perspective towards smart real-time water management. Crit. Rev. Environ. Sci. Technol. 2018, 48, 279–339. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horizons 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Jagtap, S.; Duong, L.N.K. Improving the new product development using big data: A case study of a food company. Br. Food J. 2019, 121, 2835–2848. [Google Scholar] [CrossRef]

- Jagtap, S.; Bhatt, C.; Thik, J.; Rahimifard, S. Monitoring Potato Waste in Food Manufacturing Using Image Processing and Internet of Things Approach. Sustainability 2019, 11, 3173. [Google Scholar] [CrossRef]

- Jagtap, S.; Rahimifard, S.; Duong, L.N.K. Real-time data collection to improve energy efficiency: A case study of food manufacturer. J. Food Process. Preserv. 2019. [Google Scholar] [CrossRef]

- Kassab, W.; Darabkh, K.A. A–Z survey of Internet of Things: Architectures, protocols, applications, recent advances, future directions and recommendations. J. Netw. Comput. Appl. 2020, 163, 102663. [Google Scholar] [CrossRef]

- Thomas, G. How To Do Your Case Study; Sage Publications Limited: London, UK, 2021. [Google Scholar]

- Robles, T.; Alcarria, R.; de Andrés, D.M.; de la Cruz, M.N.; Calero, R.; Iglesias, S.; Lopez, M. An IoT based reference architecture for smart water management processes. J. Wirel. Mob. Netw. Ubiquitous Comput. Dependable Appl. 2015, 6, 4–23. [Google Scholar]

- BIER. A Practical Perspective on Water Accounting in the Beverage Sector—Version 1.0. 2011. Available online: http://www.waterfootprint.org/media/downloads/BIER-2011-WaterAccountingSectorPerspective.pdf (accessed on 21 December 2019).

| Country | Manufacturing | Retail | Wholesale | Hospitality and Foodservice |

|---|---|---|---|---|

| Northern Ireland | 6.9 | 0.3 | 0 | 3.3 |

| Scotland | 51 | 0.8 | 0.1 | 11.5 |

| England | 125.5 | 7.1 | 1.2 | 135.6 |

| Wales | 7.2 | 0.4 | 0.1 | 5.8 |

| Total | 190.6 | 8.6 | 1.4 | 156.2 |

| Water-Saving Opportunities | Initiatives Undertaken |

|---|---|

| Cascade reuse | Washing of dirty bottles in a counter-current flow of water |

| Taps/pipes leakages | Fixing of identified leakages |

| Cooling tower | Recirculation of cooling waterExploring the reuse of cooling water as feedwater or make-up water for other processes |

| Cleaning in Place (CIP) | Exploring newer CIP technologies such as whirlwind/ozone/electrochemically active technology with better water-reducing opportunities |

| Year | Jan | Feb | Mar | Apr | May | June |

|---|---|---|---|---|---|---|

| Total water litre/litre of beverage (2017) | 1.74 | 2.11 | 2.19 | 1.99 | 2.14 | 2.49 |

| Total water litre/litre of beverage (2018) | 2.03 | 2.01 | 1.99 | 1.98 | 1.92 | 1.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jagtap, S.; Skouteris, G.; Choudhari, V.; Rahimifard, S.; Duong, L.N.K. An Internet of Things Approach for Water Efficiency: A Case Study of the Beverage Factory. Sustainability 2021, 13, 3343. https://doi.org/10.3390/su13063343

Jagtap S, Skouteris G, Choudhari V, Rahimifard S, Duong LNK. An Internet of Things Approach for Water Efficiency: A Case Study of the Beverage Factory. Sustainability. 2021; 13(6):3343. https://doi.org/10.3390/su13063343

Chicago/Turabian StyleJagtap, Sandeep, George Skouteris, Vilendra Choudhari, Shahin Rahimifard, and Linh Nguyen Khanh Duong. 2021. "An Internet of Things Approach for Water Efficiency: A Case Study of the Beverage Factory" Sustainability 13, no. 6: 3343. https://doi.org/10.3390/su13063343

APA StyleJagtap, S., Skouteris, G., Choudhari, V., Rahimifard, S., & Duong, L. N. K. (2021). An Internet of Things Approach for Water Efficiency: A Case Study of the Beverage Factory. Sustainability, 13(6), 3343. https://doi.org/10.3390/su13063343