Specific and Cumulative Exhaust Gas Emissions in Micro-Scale Generators Fueled by Syngas from Biomass Gasification

Abstract

1. Introduction

2. Materials and Methods

2.1. APL PP30

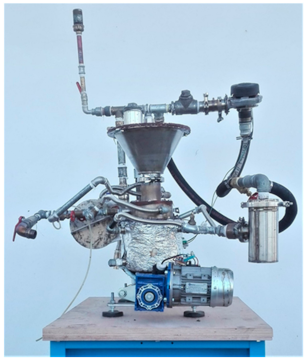

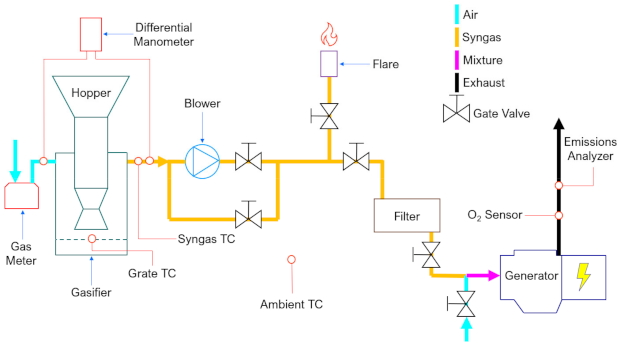

2.2. Portable Petrol Generator and Femto Gasifier

- Air was considered dry with 78.1% N2, 20.9% O2, and 1% Ar;

- Syngas was considered dry and without molecular oxygen.

3. Results and Discussion

- (Average result ± Standard deviation) if the result is a percentage.

- (Average result ± Relative standard deviation) for the others.

3.1. APL PP30

3.2. Portable Petrol Generator and Femto Gasifier

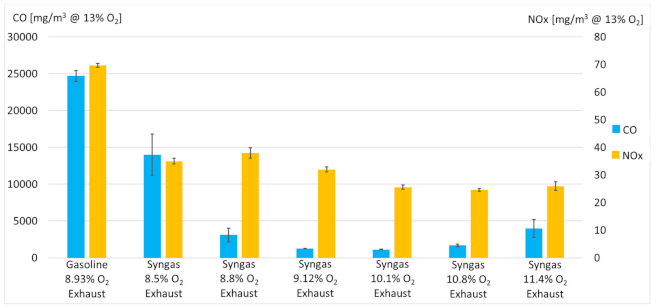

3.2.1. Gasoline and Syngas Analytical Comparison

3.2.2. Gasoline and Syngas Emissions Comparison

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| M | Molar mass |

| mf | Mass fraction |

| n | Moles number |

| Mass flow | |

| Volume flow | |

| ρ | Density |

| η | Efficiency |

| m | Mass |

| x | Percentage of gas by volume |

| CEC | Chemical energy consumption |

| GHG | Greenhouse gas |

| n.d. | Not detected |

| CHP | Combined heat and power |

Subscripts

| bio | Biomass |

| exh | Exhaust gas |

| gas | Gasoline |

| syn | Syngas |

References

- Gatto, F.; Re, I. Circular Bioeconomy Business Models to Overcome the Valley of Death. A Systematic Statistical Analysis of Studies and Projects in Emerging Bio-Based Technologies and Trends Linked to the SME Instrument Support. Sustain. J. Rec. 2021, 13, 1899. [Google Scholar] [CrossRef]

- Chaves, L.I.; Da Silva, M.J.; De Souza, S.N.M.; Secco, D.; Rosa, H.A.; Nogueira, C.E.C.; Frigo, E.P. Small-scale power generation analysis: Downdraft gasifier coupled to engine generator set. Renew. Sustain. Energy Rev. 2016, 58, 491–498. [Google Scholar] [CrossRef]

- Alsaleh, M.; Abdulwakil, M.; Abdul-Rahim, A. Does Social Businesses Development Affect Bioenergy Industry Growth under the Pathway of Sustainable Development? Sustain. J. Rec. 2021, 13, 1989. [Google Scholar] [CrossRef]

- Hoque, E.; Rashid, F.; Aziz, M. Gasification and Power Generation Characteristics of Rice Husk, Sawdust, and Coconut Shell Using a Fixed-Bed Downdraft Gasifier. Sustain. J. Rec. 2021, 13, 2027. [Google Scholar] [CrossRef]

- Shah, A.; Srinivasan, R.; To, S.D.F.; Columbus, E.P. Performance and emissions of a spark-ignited engine driven generator on biomass based syngas. Bioresour. Technol. 2010, 101, 4656–4661. [Google Scholar] [CrossRef] [PubMed]

- Puglia, M.; Morselli, N.; Tartarini, P. Design and First Tests of a Lab Scale (2KG/H) Gasifier. In Proceedings of the 27th European Biomass Conference and Exhibition, EUBCE 2019, Lisbon, Portugal, 27–30 May 2019; ETA-Florence Renewable Energies: Florence, Italy, 2019; pp. 797–801. [Google Scholar] [CrossRef]

- Rasmussen, N.B.; Aryal, N. Syngas production using straw pellet gasification in fluidized bed allothermal reactor under different temperature conditions. Fuel 2020, 263, 116706. [Google Scholar] [CrossRef]

- Kul, B.S.; Kahraman, A. Energy and Exergy Analyses of a Diesel Engine Fuelled with Biodiesel-Diesel Blends Containing 5% Bioethanol. Entropy 2016, 18, 387. [Google Scholar] [CrossRef]

- Blakemore, F.; Davies, C.; Isaac, J. Effects of changes in the UK energy-demand and environmental legislation on atmospheric pollution by oxides of nitrogen and black smoke. Appl. Energy 2001, 68, 83–117. [Google Scholar] [CrossRef]

- Baukal, C.E., Jr. The John Zink Hamworthy Combustion Handbook, Fundamentals, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; Volume 1, ISBN 978-1-4398-3962-1. [Google Scholar]

- Farid, M.A.A.; Hassan, M.A.; Roslan, A.M.; Samsudin, M.H.; Mohamad, Z.J.J.; Othman, M.R.; Shirai, Y. Carbon monoxide reduction in the flue gas during biochar production from oil palm empty fruit bunch. J. Clean. Prod. 2020, 258, 120580. [Google Scholar] [CrossRef]

- Kapitány, S.; Nagy, D.; Posta, J.; Béni, Á. Determination of atmospheric sulphur dioxide and sulphuric acid traces by indirect flame atomic absorption method. Microchem. J. 2020, 157, 104853. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; Hill Series in Mechanical Engineering; McGraw: New York, NY, USA, 1988; ISBN 0-07-028637-X. [Google Scholar]

- Renzi, M.; Patuzzi, F.; Baratieri, M. Syngas feed of micro gas turbines with steam injection: Effects on performance, combustion and pollutants formation. Appl. Energy 2017, 206, 697–707. [Google Scholar] [CrossRef]

- Elsner, W.; Wysocki, M.; Niegodajew, P.; Borecki, R. Experimental and economic study of small-scale CHP installation equipped with downdraft gasifier and internal combustion engine. Appl. Energy 2017, 202, 213–227. [Google Scholar] [CrossRef]

- Singh, S.; Chakraborty, J.P.; Mondal, M.K. Pyrolysis of torrefied biomass: Optimization of process parameters using response surface methodology, characterization, and comparison of properties of pyrolysis oil from raw biomass. J. Clean. Prod. 2020, 272, 122517. [Google Scholar] [CrossRef]

- Allesina, G.; Pedrazzi, S.; Allegretti, F.; Morselli, N.; Puglia, M.; Santunione, G.; Tartarini, P. Gasification of cotton crop residues for combined power and biochar production in Mozambique. Appl. Therm. Eng. 2018, 139, 387–394. [Google Scholar] [CrossRef]

- Li, L.; Yao, Z.; You, S.; Wang, C.-H.; Chong, C.; Wang, X. Optimal design of negative emission hybrid renewable energy systems with biochar production. Appl. Energy 2019, 243, 233–249. [Google Scholar] [CrossRef]

- Belgiorno, G.; Dimitrakopoulos, N.; Di Blasio, G.; Beatrice, C.; Tunestål, P.; Tunér, M. Effect of the engine calibration parameters on gasoline partially premixed combustion performance and emissions compared to conventional diesel combustion in a light-duty Euro 6 engine. Appl. Energy 2018, 228, 2221–2234. [Google Scholar] [CrossRef]

- Mueller, C.J.; Nilsen, C.W.; Ruth, D.J.; Gehmlich, R.K.; Pickett, L.M.; Skeen, S.A. Ducted fuel injection: A new approach for lowering soot emissions from direct-injection engines. Appl. Energy 2017, 204, 206–220. [Google Scholar] [CrossRef]

- Mason, J.; Kaufmann, B.; Tartarini, P.; Puglia, M.; Morselli, N.; Veratti, G.; Bigi, A. Compression Ratios Comparisons between Engines Operating with Producer Gas. Eur. Biomass Conf. Exhib. Proc. 2019, 2019, 1927–1931. [Google Scholar] [CrossRef]

- Puglia, M.; Morselli, N.; Ottani, F.; Tartarini, P. Implementation of a Portable Petrol—Powered Generator Fueled through a Tabletop Biomass Gasifier. In Proceedings of the 28th European Biomass Conference and Exhibition, e-EUBCE 2020, Marseille, France, 6–9 July 2020; ETA-Florence Renewable Energies: Florence, Italy, 2019; pp. 396–400. [Google Scholar]

- Bhattacharyya, S.; Das, R.K. Catalytic reduction of NOx in gasoline engine exhaust over copper- and nickel-exchanged X–zeolite catalysts. Energy Convers. Manag. 2001, 42, 2019–2027. [Google Scholar] [CrossRef]

- All Power Labs Inc. Available online: http://www.allpowerlabs.com/ (accessed on 12 November 2020).

- MRU Instruments, Inc. Available online: http://www.mru-instruments.com/wp-content/uploads/2015/04/VARIO-plus-industrial-Brochure-2015.pdf (accessed on 13 November 2020).

- Zhejiang Anlu Cleaning Machinery Co., Ltd. Available online: https://www.anlu.com/product/n-series/ (accessed on 12 November 2020).

- Focus Technology Co., Ltd. Available online: https://it.made-in-china.com/co_cn-generator/product_Gasoline-Engine-168F-1-_hrhyiyhng.html (accessed on 14 November 2020).

- Maneerung, T.; Li, X.; Li, C.; Dai, Y.; Wang, C.-H. Integrated downdraft gasification with power generation system and gasification bottom ash reutilization for clean waste-to-energy and resource recovery system. J. Clean. Prod. 2018, 188, 69–79. [Google Scholar] [CrossRef]

- Pedrazzi, S.; Allesina, G.; Puglia, M.; Guidetti, L.; Tartarini, P. ICOPE-15-1004 Increased maize power production through an integrated biogas-gasification-SOFC power system. In Proceedings of the International Conference on Power Engineering (ICOPE), Yokohama, Japan, 15 April 2015; Japan Society of Mechanical Engineers: Sapporo, Japan, 2015; Volume 2015.12. [Google Scholar]

- dos Santos, R.G.; Bordado, J.C.; Mateus, M.M. Estimation of HHV of lignocellulosic biomass towards hierarchical cluster analysis by Euclidean’s distance method. Fuel 2018, 221, 72–77. [Google Scholar] [CrossRef]

- Kul, B.S.; Ciniviz, M. Assessment of waste bread bioethanol-gasoline blends in respect to combustion analysis, engine performance and exhaust emissions of a SI engine. Fuel 2020, 277, 118237. [Google Scholar] [CrossRef]

- IUPAC. Available online: https://iupac.org/wp-content/uploads/2018/12/IUPAC_Periodic_Table-01Dec18.pdf (accessed on 10 November 2020).

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; Dewitt, D.P. Fundamentals of Heat and Mass Transfer, 7th ed.; Wiley: Hoboken, NJ, USA, 2011; ISBN 978-0470-50197-9. [Google Scholar]

- Naterer, G.F. Advanced Heat Transfer, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9781138579323. [Google Scholar]

- Rohsenow, W.M.; Hartnett, J.P.; Cho, Y.I. Handbook of Heat Transfer, 3rd ed.; McGraw-Hill: New York, NY, USA, 1998; ISBN 0-07-053555-8. [Google Scholar]

- Ngamsidhiphongsa, N.; Ponpesh, P.; Shotipruk, A.; Arpornwichanop, A. Analysis of the Imbert downdraft gasifier using a species-transport CFD model including tar-cracking reactions. Energy Convers. Manag. 2020, 213, 112808. [Google Scholar] [CrossRef]

- Din, Z.U.; Zainal, Z. Tar reduction mechanism via compression of producer gas. J. Clean. Prod. 2018, 184, 1–11. [Google Scholar] [CrossRef]

- Kamble, P.; Khan, Z.; Gillespie, M.; Farooq, M.; McCalmont, J.; Donnison, I.; Watson, I. Biomass gasification of hybrid seed Miscanthus in Glasgow’s downdraft gasifier testbed system. Energy Procedia 2019, 158, 1174–1181. [Google Scholar] [CrossRef]

- Ayub, H.M.U.; Park, S.J.; Binns, M. Biomass to Syngas: Modified Stoichiometric Thermodynamic Models for Downdraft Biomass Gasification. Energies 2020, 13, 5383. [Google Scholar] [CrossRef]

- Pedrazzi, S.; Allesina, G.; Morselli, N.; Puglia, M.; Rinaldini, C.A.; Savioli, T.; Mattarelli, E.; Leonardi, C.; Giorgini, L.; Tar-tarini, P. Modified Diesel engine fueled by syngas: Modeling and experimental validation. In Proceedings of the European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; ETA-Florence Renewable Energies: Florence, Italy, 2016; Volume 2016, pp. 880–883. [Google Scholar]

- Vakalis, S.; Patuzzi, F.; Baratieri, M. Thermodynamic modeling of small scale biomass gasifiers: Development and assessment of the ‘‘Multi-Box’’ approach. Bioresour. Technol. 2016, 206, 173–179. [Google Scholar] [CrossRef]

- Soares, J.; Oliveira, A.C. Experimental assessment of pine wood chips gasification at steady and part-load performance. Biomass Bioenergy 2020, 139, 105625. [Google Scholar] [CrossRef]

- Yan, W.-C.; Shen, Y.; You, S.; Sim, S.H.; Luo, Z.-H.; Tong, Y.W.; Wang, C.-H. Model-based downdraft biomass gasifier operation and design for synthetic gas production. J. Clean. Prod. 2018, 178, 476–493. [Google Scholar] [CrossRef]

- Sridhar, G.; Yarasu, R.B. Facts about Producer Gas Engine Paths to Sustainable Energy. Artie, N., Ed.; InTech: London, UK, 2010. Available online: http://www.intechopen.com/books/paths-to-sustainable-energy/facts-about-producer-gas-engine (accessed on 18 November 2020).

- Monsalve-Serrano, J.; Belgiorno, G.; Di Blasio, G.; Guzmán-Mendoza, M. 1D Simulation and Experimental Analysis on the Effects of the Injection Parameters in Methane–Diesel Dual-Fuel Combustion. Energies 2020, 13, 3734. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Voltage Adjustment | AVR |

| Rated AC | data |

| Power Factor | 1 |

| Frequency | 50 Hz |

| Max. AC Output | 2.8 kW |

| Rated AC Output | 2.5 kW |

| Displacement | 196 cc |

| Measurement | 43 × 59 × 44 cm |

| Compression Ratio | 8.5:1 |

| Density | Value |

|---|---|

| ρCO2@500K | 1.0594 kg/m3 |

| ρH2@500K | 0.4405 kg/m3 |

| ρN2@500K | 0.6739 kg/m3 |

| ρAr@500K | 0.974 kg/m3 |

| ρCO2@300K | 1.773 kg/m3 |

| ρN2@300K | 1.1233 kg/m3 |

| ρH2@300K | 0.08078 kg/m3 |

| ρCO@300K | 1.1233 kg/m3 |

| ρair@300K | 1.1614 kg/m3 |

| ρCH4@300K | 0.65171 kg/m3 1 |

| xH2,syn | xN2,syn | xCH4,syn | xCO,syn | xCO2,syn | HHVsyn |

|---|---|---|---|---|---|

| 15.7% | 51.4% | 1.4% | 18.9% | 12.6% | 4.9 MJ/m3 |

| N° | O2 in Exhaust [%] | CO [mg/m3 @ 13% O2] | NO [mg/m3 @ 13% O2] | NOx [mg/m3 @ 13% O2] | SO2 [mg/m3 @ 13% O2] |

|---|---|---|---|---|---|

| 1 | 0.6 ± / | 8400 ± 6% | 650 ± 3% | 1000 ± 3% | n.d. |

| 2 | 0.5 ± / | 10,400 ± 6% | 633 ± 1% | 980 ± 1% | n.d. |

| 3 | 1.09 ± 0.09 | 1427 ± 0.3% | 957 ± 0.7% | 1480 ± 0.7% | n.d. |

| 4 | 1.7 ± 0.1 | 1350 ± 1% | 968 ± 0.9% | 1500 ± 0.8% | n.d. |

| 5 | 2.67 ± 0.05 | 1350 ± 1% | 941 ± 0.4% | 1462 ± 0.4% | n.d. |

| 6 | 2.54 ± 0.05 | 1350 ± 2% | 910 ± 1% | 1410 ± 1% | n.d. |

| N° | El. Power Output [kW] | O2 in Exhaust [%] | CO [mg/m3 @ 13% O2] | NO [mg/m3 @ 13% O2] | NOx [mg/m3 @ 13% O2] | SO2 [mg/m3 @ 13% O2] |

|---|---|---|---|---|---|---|

| 7 | 6.7 | 1.7 ± 0.4 | 1660 ± 2% | 594 ± 1% | 920 ± 1% | n.d. |

| 8 | 8.7 | 1.8 ± 0.3 | 1610 ± 4% | 680 ± 2% | 1050 ± 2% | n.d. |

| 9 | 10.0 | 1.2 ± 0.3 | 1700 ± 8% | 640 ± 2% | 990 ± 2% | n.d. |

| Test | Catalyst | El. Power Output [kW] | CO [mg/m3 @ 13% O2] | NOx [mg/m3 @ 13% O2] |

|---|---|---|---|---|

| [21] | On | 13.3 | 3 | 19 |

| [21] | On | 18.3 | 3 | 19 |

| 6 | Off | 10.8 | 1350 ± 2% | 1410 ± 1% |

| 7 | Off | 6.7 | 1660 ± 2% | 920 ± 1% |

| Fuel | Gasoline | Syngas |

|---|---|---|

| Fuel consumption | 0.467 kg/h | 2.62 m3/h |

| 21.88 MJ | 12.97 MJ | |

| 7.39 kg/h | 5.64 kg/h | |

| 10.61 m3/h | 7.84 m3/h | |

| 1.46 kg/h | 1.47 kg/h | |

| 13.02% | 17.71% |

| Fuel | O2 in Exhaust [%] | CO [mg/m3 @ 13% O2] | NO [mg/m3 @ 13% O2] | NOx [mg/m3 @ 13% O2] | SO2 [mg/m3 @ 13% O2] |

|---|---|---|---|---|---|

| Gasoline | 8.93 ± 0.09 | 24,700 ± 3% | 45.4 ± 2% | 69.7 ± 1% | 50 ± 60% |

| Syngas | 8.5 ± 0.1 | 14,000 ± 20% | 22.8 ± 3% | 35 ± 3% | n.d. |

| Syngas | 8.8 ± 0.1 | 3100 ± 30% | 24 ± 5% | 38 ± 5% | n.d. |

| Syngas | 9.12 ± 0.09 | 1250 ± 3% | 21.0 ± 3% | 32 ± 3% | n.d. |

| Syngas | 10.1 ± 0.1 | 1120 ± 5% | 16.6 ± 5% | 25.6 ± 3% | n.d. |

| Syngas | 10.8 ± 0.2 | 1700 ± 11% | 15.9 ± 2% | 24.6 ± 2% | n.d. |

| Syngas | 11.4 ± 0.5 | 4000 ± 30% | 16.8 ± 5% | 26 ± 6% | n.d. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puglia, M.; Morselli, N.; Pedrazzi, S.; Tartarini, P.; Allesina, G.; Muscio, A. Specific and Cumulative Exhaust Gas Emissions in Micro-Scale Generators Fueled by Syngas from Biomass Gasification. Sustainability 2021, 13, 3312. https://doi.org/10.3390/su13063312

Puglia M, Morselli N, Pedrazzi S, Tartarini P, Allesina G, Muscio A. Specific and Cumulative Exhaust Gas Emissions in Micro-Scale Generators Fueled by Syngas from Biomass Gasification. Sustainability. 2021; 13(6):3312. https://doi.org/10.3390/su13063312

Chicago/Turabian StylePuglia, Marco, Nicolò Morselli, Simone Pedrazzi, Paolo Tartarini, Giulio Allesina, and Alberto Muscio. 2021. "Specific and Cumulative Exhaust Gas Emissions in Micro-Scale Generators Fueled by Syngas from Biomass Gasification" Sustainability 13, no. 6: 3312. https://doi.org/10.3390/su13063312

APA StylePuglia, M., Morselli, N., Pedrazzi, S., Tartarini, P., Allesina, G., & Muscio, A. (2021). Specific and Cumulative Exhaust Gas Emissions in Micro-Scale Generators Fueled by Syngas from Biomass Gasification. Sustainability, 13(6), 3312. https://doi.org/10.3390/su13063312