Optimization of the Opening Shape in Slot Spray Nozzles in a Field Boom Sprayer

Abstract

1. Introduction

1.1. Sustainable Development and Modern Agricultural Production

- -

- Improved uniformity and accuracy of chemical agricultural treatments;

- -

- Reduced consumption of agrochemicals;

- -

- Reduced agricultural treatment costs;

- -

- Improved agricultural and food product quality;

- -

- Maintenance of a better agricultural culture in agricultural areas;

- -

- Reduced pollution of soil, groundwater, reservoirs, water courses, and air.

1.2. Spray Accuracy and Uniformity

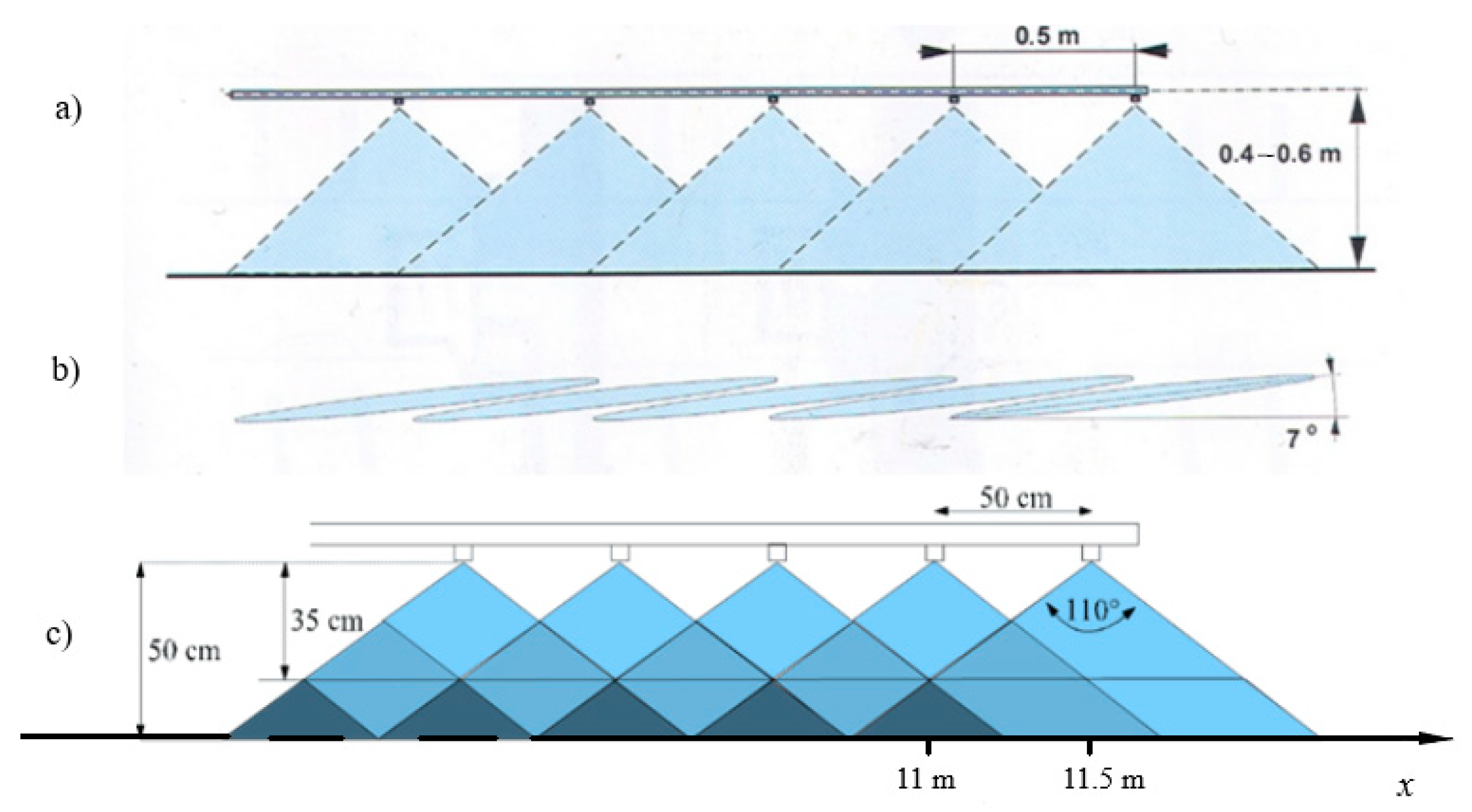

2. Materials and Methods

2.1. Methodology of Designing the Shape of a Slotted Sprayer Nozzle Opening

2.2. Previous Models of Liquid Flow from a Single Nozzle

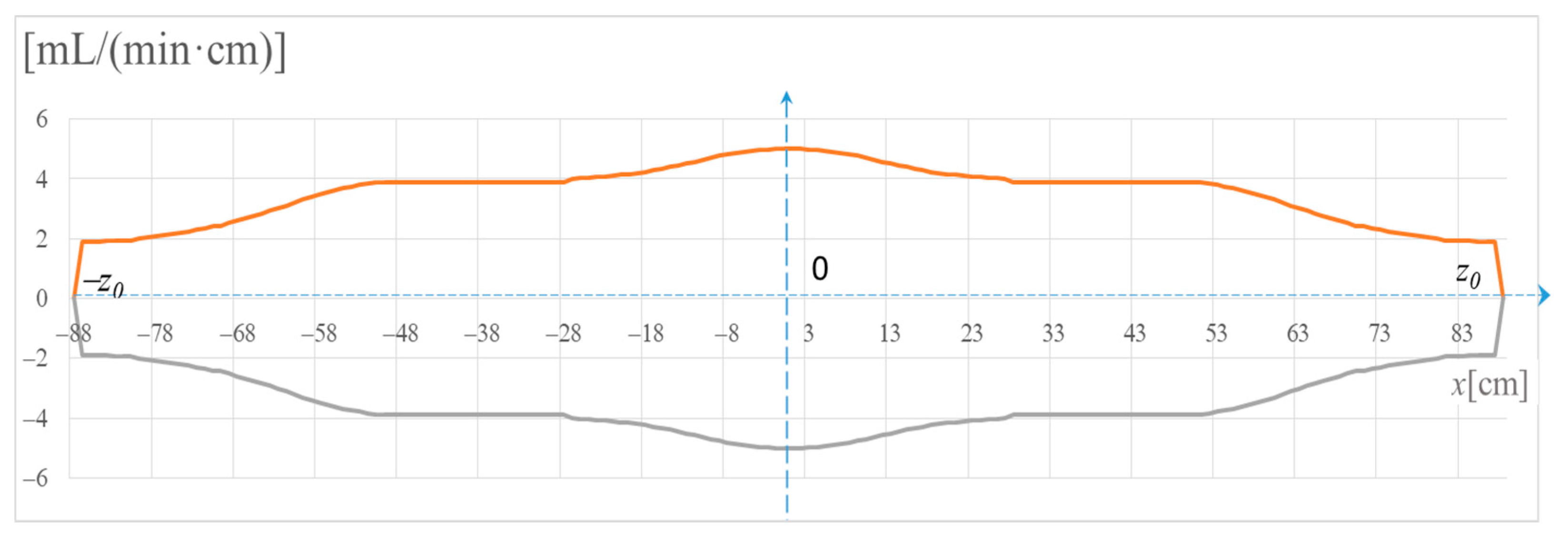

2.3. The Proposed Method of Modelling the Output from the Single Nozzle

2.4. Procedures and Functions Used

3. Results

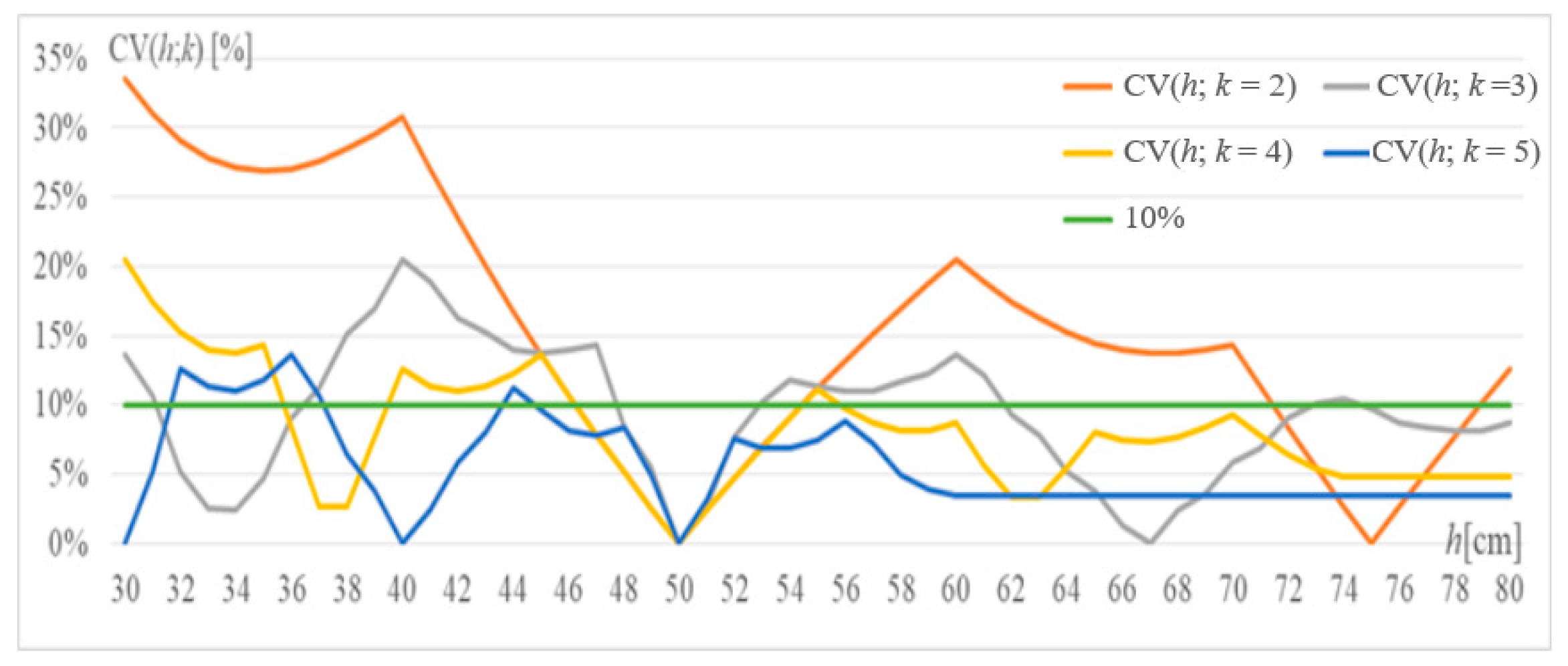

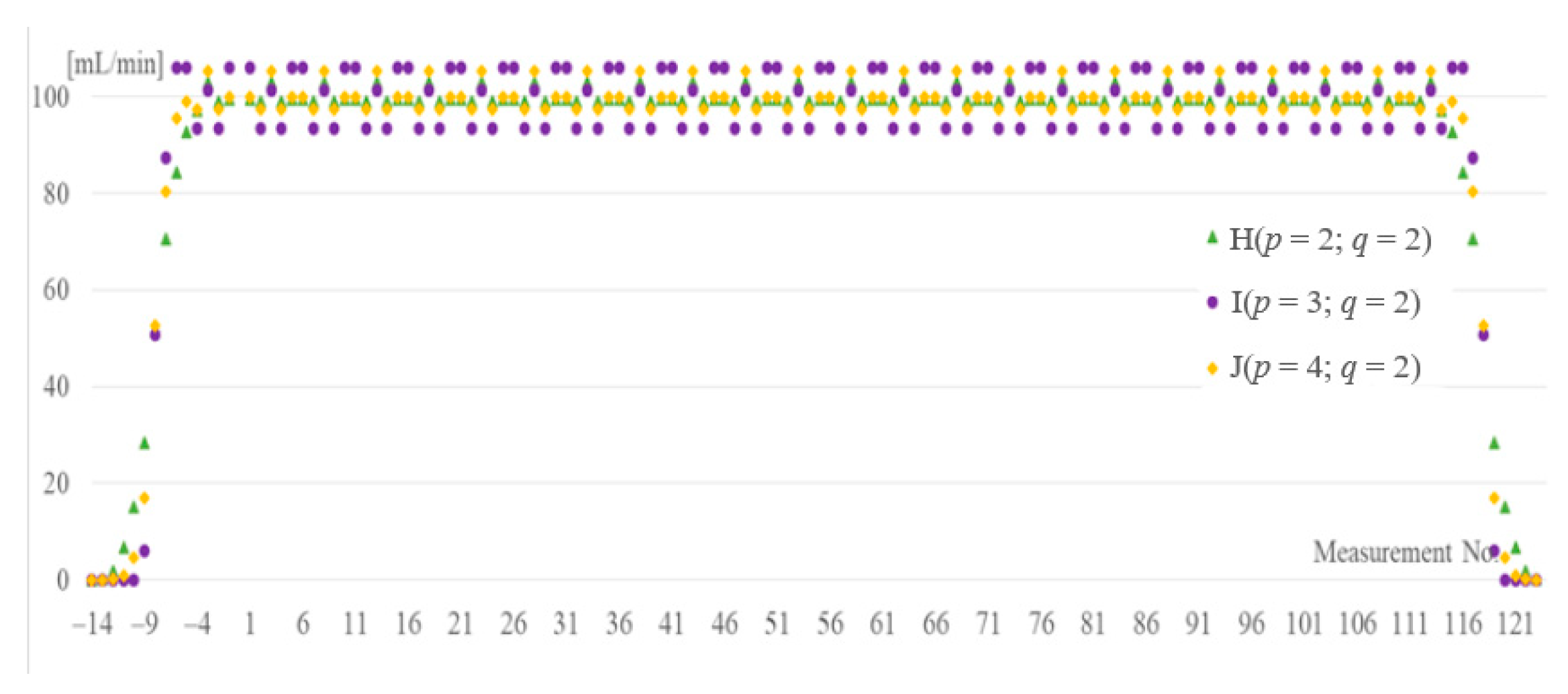

3.1. The Optimal Shape of the Nozzle Outlet for and

3.2. Accuracy and Uniformity of Spraying with Designed Nozzles

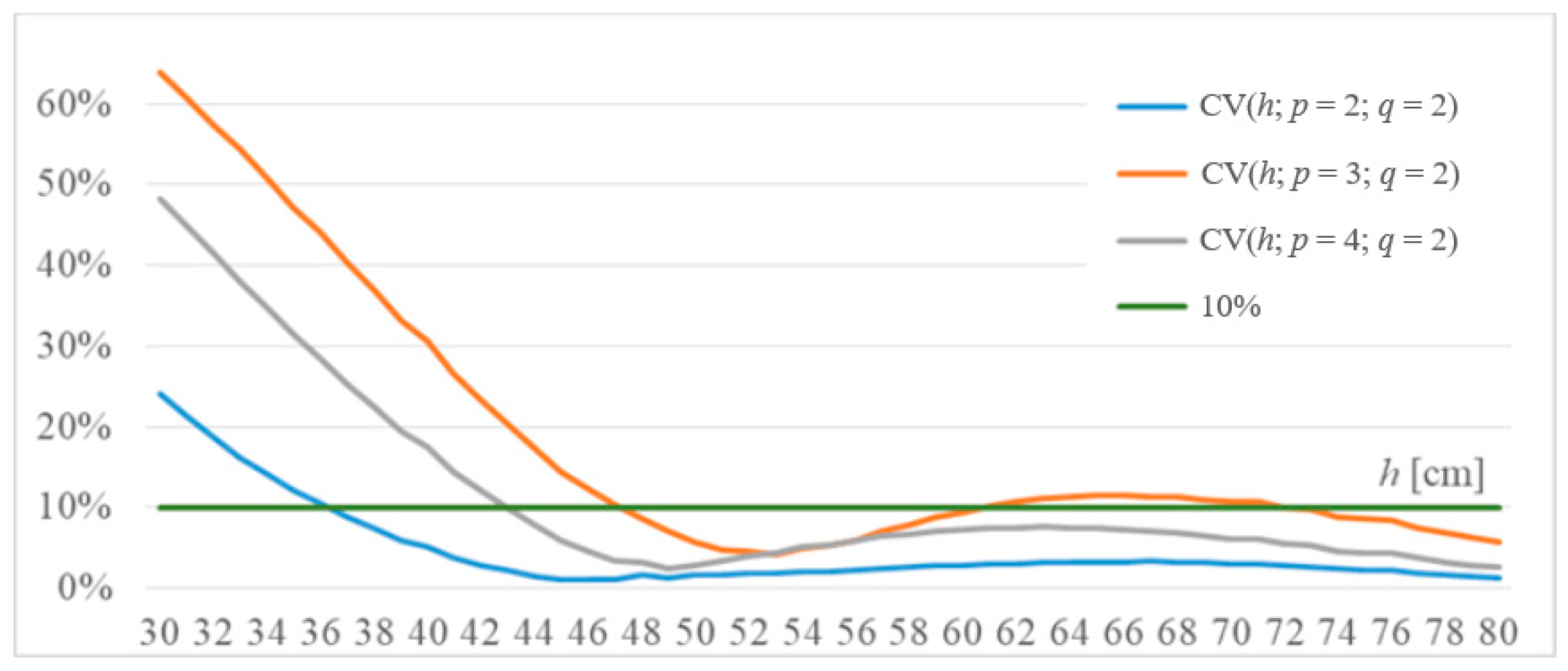

3.3. Alternative Suboptimal Shape of the Nozzle Opening

3.4. Results for a Measuring Table with 0.1 m Wide Grooves

- For the optimal shape of the cross-section of a single nozzle stream from Figure 3 and for a measuring table equipped with 0.1 m wide grooves, it was possible to obtain a coefficient of variation for the entire boom amounting to 1.27 × 10−4%.

- For the suboptimal shape of the cross-section of a single nozzle stream from Figure 7 (i.e., for a much simpler implementation, a coefficient of variation amounting to 0.388% was obtained.

3.5. Optimum Spray Angles from Nozzles with a Parallelogram-Shaped Slot

3.6. Nozzle Slot Shapes Created by Gluing Polynomials

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pruszyński, S.; Skrzypczak, G. Plant protection in sustainable agriculture. Fragm. Agron. 2007, 4, 127–139. [Google Scholar]

- Pruszyński, S.; Pruszyński, G. Sustainable use of pesticides. In Zagadnienia Doradztwa Rolniczego; 2013; pp. 23–39. Available online: https://www.cdr.gov.pl/pol/zdr/ZDR_2_2013.pdf (accessed on 16 March 2021).

- Lodwik, D.; Pietrzyk, J. Automated test station for transverse spray non-uniformity. J. Res. Appl. Agric. Eng. 2013, 59, 103–106. [Google Scholar]

- Orzechowski, Z.; Prywer, J. Wytwarzanie i Zastosowanie Rozpylonej Cieczy; PWN: Warsaw, Poland, 2018. [Google Scholar]

- Nowakowski, T.; Chlebowski, J. The impact of liquid pressure and design of fan atomizers on spraying angle. Agric. Eng. 2008, 1, 319–323. [Google Scholar]

- Butler Ellis, M.C.; Swan, T.; Miller, P.C.H.; Waddelow, S.; Bradley, A.; Tuck, C.R. PM—Power and Machinery: Design factors affecting spray characteristics and drift performance of air induction nozzles. Biosyst. Eng. 2002, 82, 289–296. [Google Scholar] [CrossRef]

- Mawer, C.J.; Miller, P.C.H. Effect of roll angle and nozzle spray pattern on the uniformity of spray volume distribution below a boom. Crop Prot. 1989, 8, 217–222. [Google Scholar] [CrossRef]

- Declercq, J.; Huyghebaert, B.; Nuyttens, D. An overview of the defects on test field sprayers in Belgium. In Proceedings of the 3rd European Workshop on Standardised Procedure for the Inspection of Sprayers in Europe—SPISE 3, Brno, Czech Republic, 22–24 September 2009; Volume 3, pp. 157–163, ISBN 978-3-930037-66-7. [Google Scholar]

- Nuyttens, D.; Baetens, K.; De Schampheleire, M.; Sonck, B. Effect of nozzle type, size and pressure on spray droplet characteristic. Biosyst. Eng. 2007, 97, 333–345. [Google Scholar] [CrossRef]

- Ozkan, H.E. Reducing Spray Drift; Ohio State University Extension Service, Publication AEX: Columbus, OH, USA, 2000; pp. 816–900. [Google Scholar]

- Ozkan, H.E.; Derksen, R.C. Effectiveness of TurboDrop and Turbo TeeJet Nozzles in Drift Reduction; Ohio State University Extension Service, Publication AEX: Columbus, OH, USA, 1998; pp. 524–598. [Google Scholar]

- Lodwik, D.; Pietrzyk, J. Evaluation of resistance to spray drift of selected sprayer nozzles in the aspect of non-uniformity in transverse distribution of liquid. Teka. Comm. Mot. Power Ind. Agric. 2017, 17, 65–70. [Google Scholar]

- Kluza, P.A.; Kuna-Broniowska, I.; Parafiniuk, S. Modeling and Prediction of the Uniformity of Spray Liquid Coverage from Flat Fan Spray Nozzles. Sustainability 2019, 11, 6716. [Google Scholar] [CrossRef]

- Mawer, C.J. The Effect of Nozzle Characteristics and Boom Attitude on the Volume Distribution below a Boom; Div. Note DN 1462; AFRC Institute of Engineering Research: Bedford, UK, 1988. [Google Scholar]

- Leunda, P.; Debouche, C.; Caussin, R. Predicting the transverse volume distribution under an agricultural spray boom. Crop Prot. 1990, 9, 111–114. [Google Scholar]

- Enfält, P. A method for measuring single-nozzle distributions influenced by other nozzles; Report 173 Dept. of Agric. Engineering; Swedish University of Agricultural Sciences: Uppsala, Sweden, 1993. [Google Scholar]

- Parafiniuk, S.; Tarasińska, J. Work simulation of the sprayer field boom with the use of R program. J. Cent. Eur. Agric. 2013, 14, 166–175. [Google Scholar] [CrossRef][Green Version]

- Wawrzosek, J.; Parafiniuk, S. The use of the permutation algorithm for suboptimizing the position of used nozzles on the field sprayer boom. Sci. Rep. 2021. in review. [Google Scholar]

- Nation, H.J. Spray Nozzle Performance and Effects of Boom Height on Distribution; NIAE Departmental Note DN/S/777/1925, National Institute of Agricultural Engineering Silsoe; Wrest Park: Silsoe, Bedford, UK, 1976; unpublished. [Google Scholar]

- Sinfort, N.; Bellon, V.; Sevila, F. Image analysis for in-flow measurement of particle size. Food Control 1992, 3, 84–90. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 16122. Agricultural and Forestry Machinery—Inspection of Sprayers in Use—Part 2: Horizontal Boom Sprayers; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Excel Solver Online Help. Available online: https://www.solver.com/excel-solver-online-help (accessed on 16 March 2021).

- Field, R. Geometric Patterns from Tiles and Brickwork; Tarquin Group: St Albans, UK, 1999. [Google Scholar]

- Verner, I.M.; Maor, S. Mathematical aspects of educating architecture designers: A college study, International. J. Math. Educ. Sci. Technol. 2005, 36, 655–671. [Google Scholar] [CrossRef]

- Stephenson, P. The Mathematical History of a Paving Stone. Math. Sch. 2007, 36, 23–27. [Google Scholar]

- Fathauer, R.W. Real-World Tessellations. In Proceedings of the Bridges 2015: Mathematics, Music, Art, Architecture, Culture, Baltimore, MD, USA, 29 July–1 August 2015; pp. 107–112. [Google Scholar]

- Van de Zande, J.C.; Huijsmans, J.F.M.; Porskamp, H.A.J.; Michielsen, J.M.G.P.; Stallinga, H.; Holterman, H.J.; De Jong, A. Spray technics: How to optimise deposition and minimize spray drift. Environmentalist 2008, 28, 9–17. [Google Scholar] [CrossRef]

- Dongoski, R.; Selck, A. How digital agriculture and big data will help to feed a growing world Agribusinesses are working to solidify their place in Ag 3.0. EY Glob. Perform. 2017, 9, 82–89. [Google Scholar]

- International Organization for Standardization. ISO 5682-1. Equipment for Crop Protection—Spraying Equipment—Part 1: Test Methods for Sprayer Nozzles; ISO: Geneva, Switzerland, 1996. [Google Scholar]

- He, Y.J.; Hua, H.M.; Li, X.F.; Shi, J.Z. Experimental Study on Spray Uniformity of Spraying Machinery. Adv. Mater. Res. 2013, 671–674, 1993–1997. [Google Scholar] [CrossRef]

- Lodwik, D.; Pietrzyk, J.; Malesa, W. Analysis of Volume Distribution and Evaluation of the Spraying Spectrum in Terms of Spraying Quality. Appl. Sci. 2020, 10, 2395. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wawrzosek, J.; Parafiniuk, S. Optimization of the Opening Shape in Slot Spray Nozzles in a Field Boom Sprayer. Sustainability 2021, 13, 3291. https://doi.org/10.3390/su13063291

Wawrzosek J, Parafiniuk S. Optimization of the Opening Shape in Slot Spray Nozzles in a Field Boom Sprayer. Sustainability. 2021; 13(6):3291. https://doi.org/10.3390/su13063291

Chicago/Turabian StyleWawrzosek, Jacek, and Stanisław Parafiniuk. 2021. "Optimization of the Opening Shape in Slot Spray Nozzles in a Field Boom Sprayer" Sustainability 13, no. 6: 3291. https://doi.org/10.3390/su13063291

APA StyleWawrzosek, J., & Parafiniuk, S. (2021). Optimization of the Opening Shape in Slot Spray Nozzles in a Field Boom Sprayer. Sustainability, 13(6), 3291. https://doi.org/10.3390/su13063291