Numerical Analysis of the Effect of Ground Dampness on Heat Transfer between Greenhouse and Ground

Abstract

1. Introduction

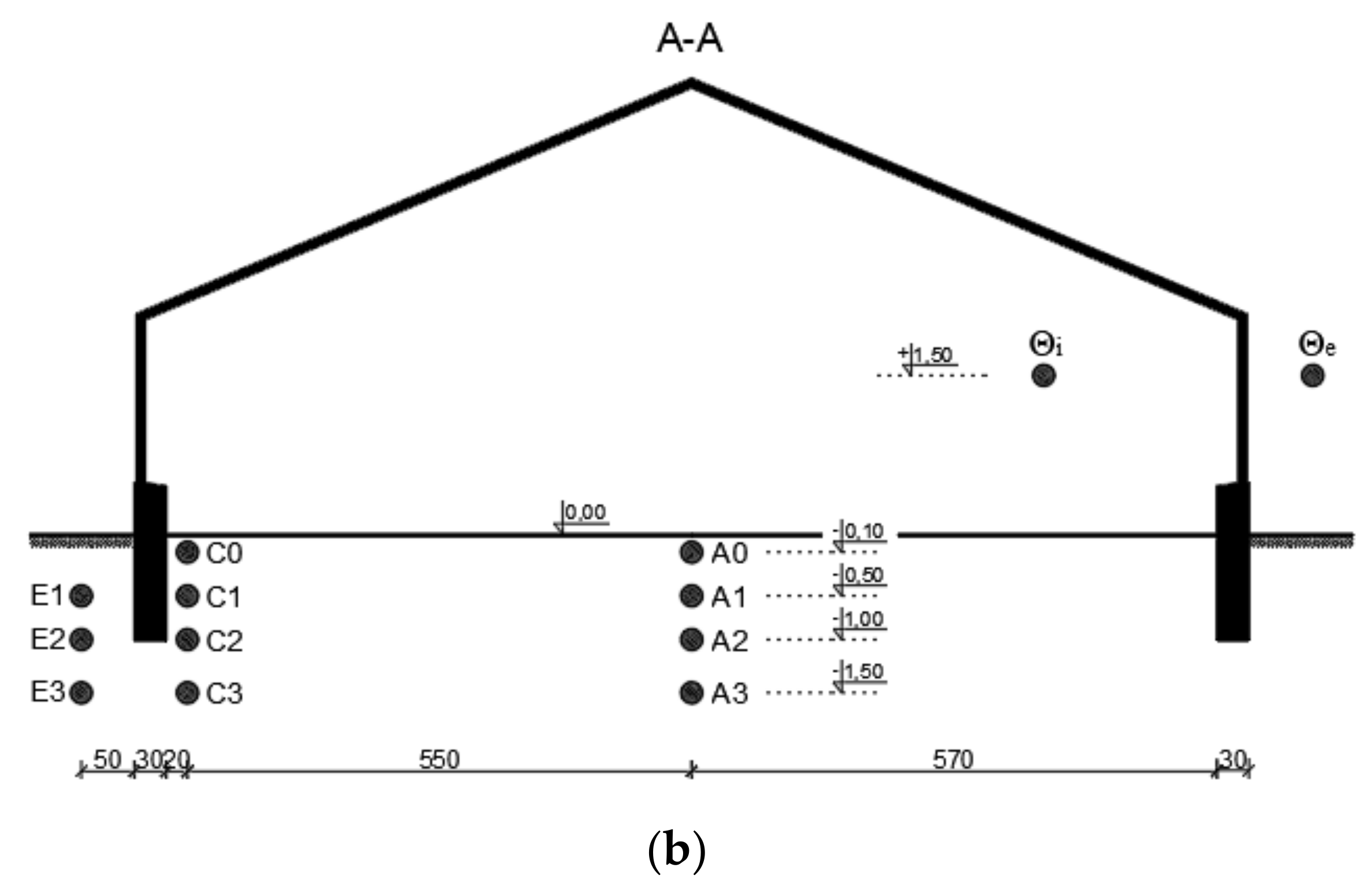

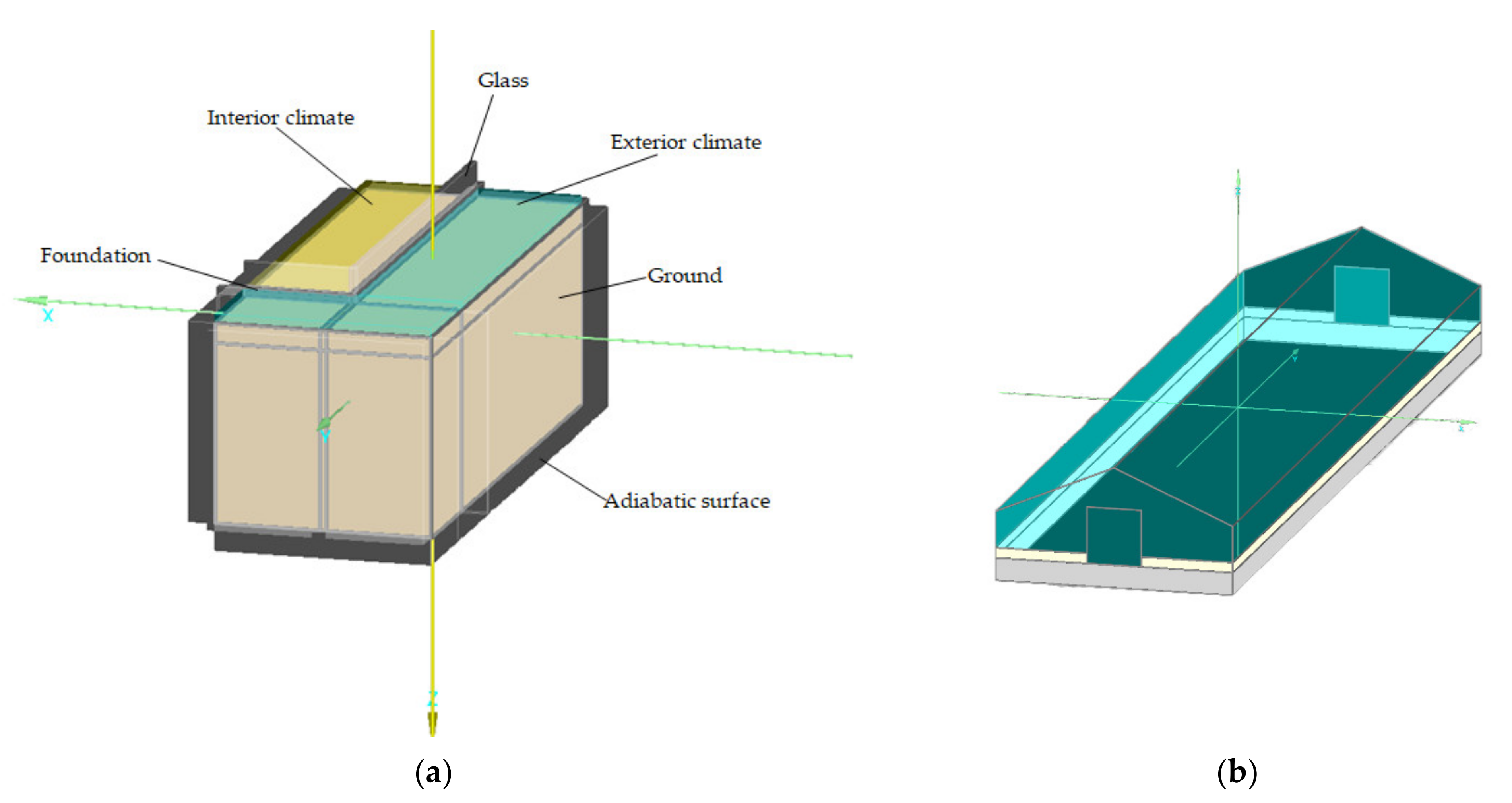

2. Materials and Methods

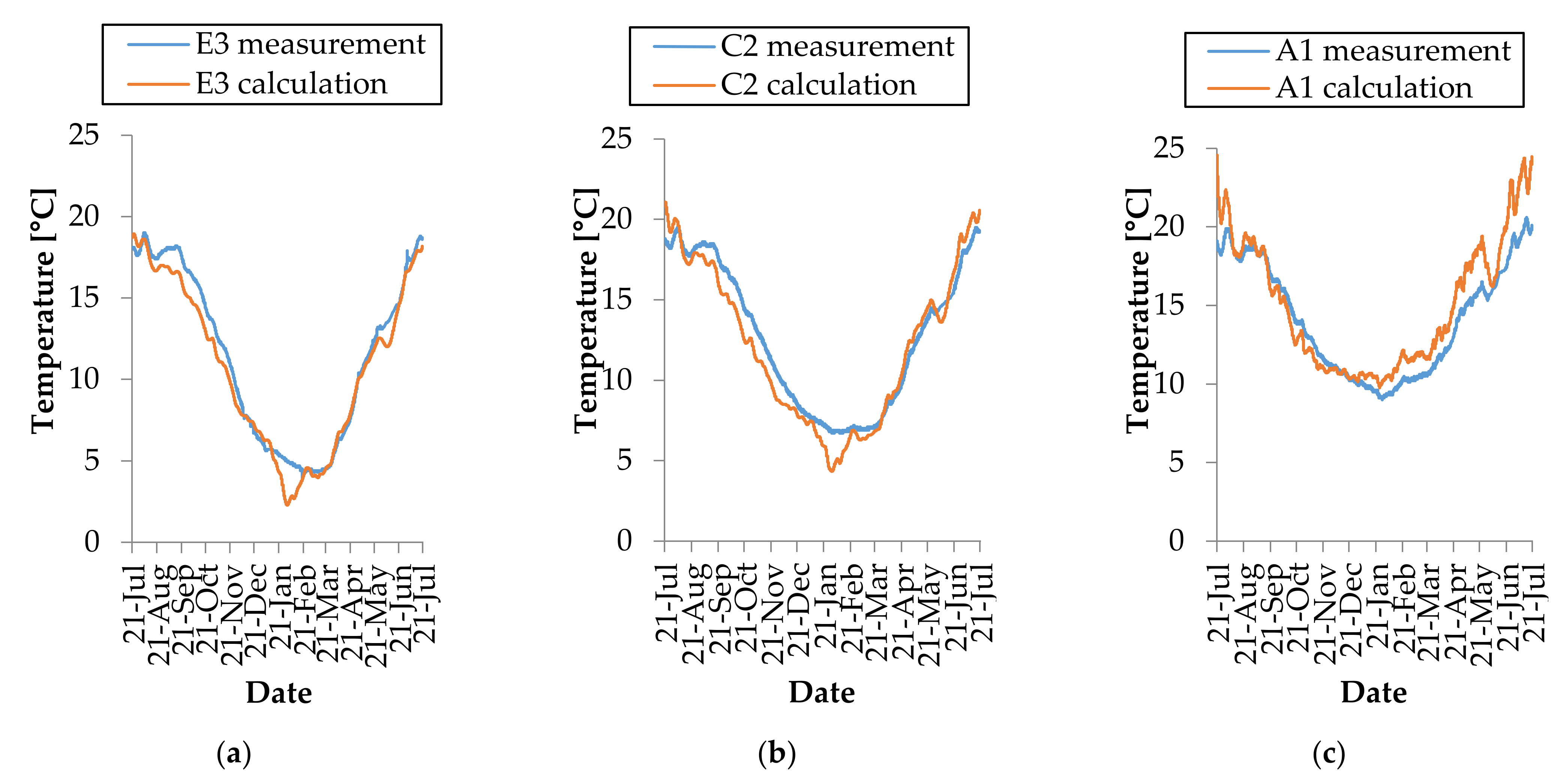

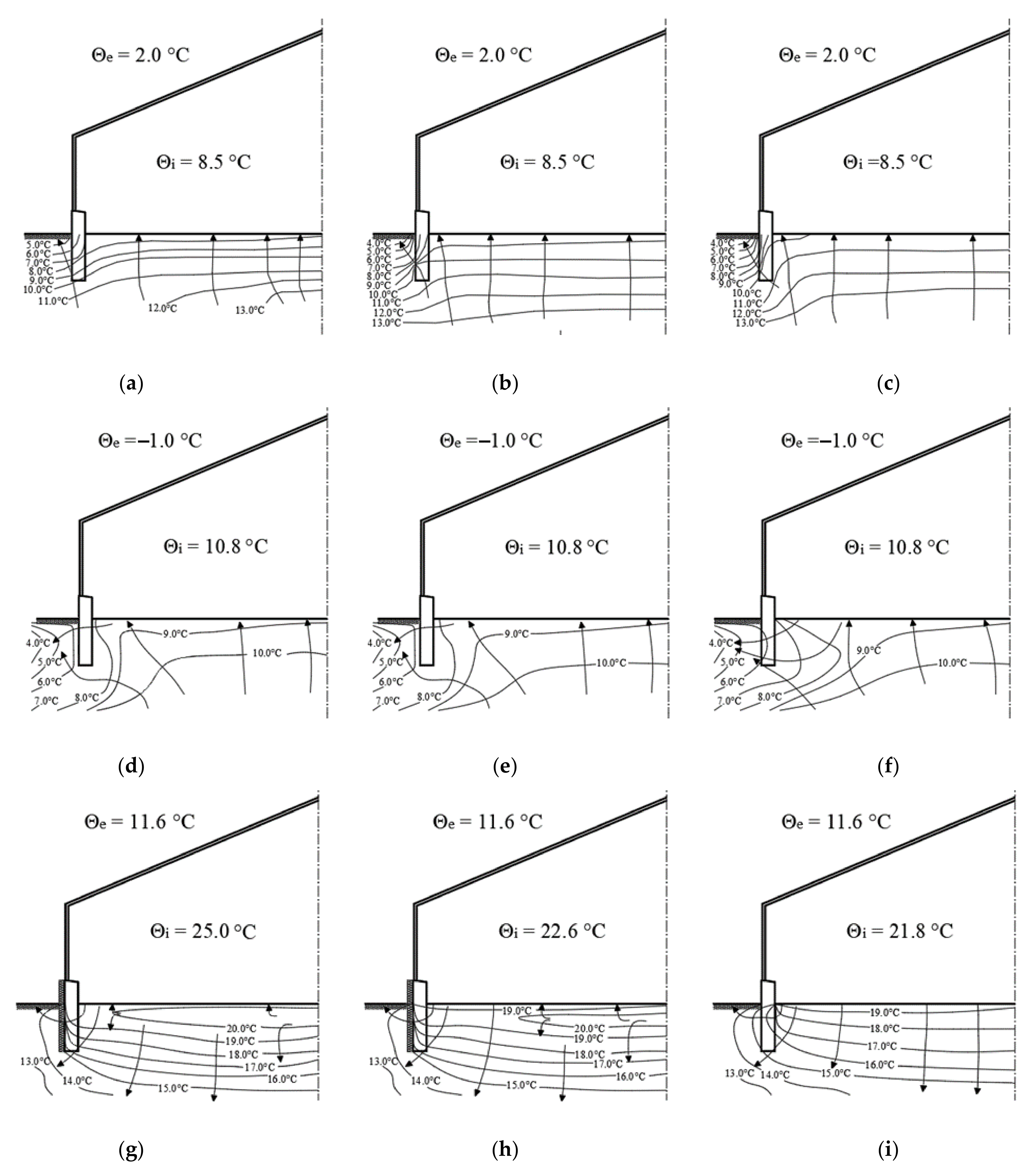

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vadiee, A.; Martin, V. Energy management in horticultural applications through the closed greenhouse concept, state of the art. Renew. Sustain. Energy Rev. 2012, 16, 87–100. [Google Scholar] [CrossRef]

- Mohammadi, B.; Ranjbar, S.F.; Ajabshirchi, Y. Application of dynamic model to predict some inside environment variables in a semi-solar greenhouse. Inf. Process. Agric. 2018, 5, 279–288. [Google Scholar] [CrossRef]

- Taki, M.; Ajabshirchi, Y.; Ranjbar, S.F.; Rohani, A.; Matloobi, M. Modeling and experimental validation of heat transfer and energy consumption in an innovative greenhouse structure. Inf. Process. Agric. 2016, 3, 57–74. [Google Scholar] [CrossRef]

- Yang, L.-H.; Huang, B.-H.; Hsu, C.-Y.; Chen, S.-L. Performance analysis of an earth–air heat exchanger integrated into an agricultural irrigation system for a greenhouse environmental temperature-control system. Energy Build. 2019, 202. [Google Scholar] [CrossRef]

- Ghani, S.; Bakochristou, F.; ElBialy, E.M.A.A.; Gamaledin, S.M.A.; Rashwan, M.M.; Abdelhalim, A.M. Design challenges of agricultural greenhouses in hot and arid environments—A review. Eng. Agric. Environ. Food 2019, 12, 48–70. [Google Scholar] [CrossRef]

- Taki, M.; Rohani, A.; Rahmati-Joneidabad, M. Solar thermal simulation and applications in greenhouse. Inf. Process. Agric. 2018, 5, 83–113. [Google Scholar] [CrossRef]

- Menhoudj, S.; Mokhtari, A.M.; Benzaama, M.-H.; Maalouf, C.; Lachi, M.; Makhlouf, M. Study of the energy performance of an earth—Air heat exchanger for refreshing buildings in Algeria. Energy Build. 2018, 158, 2–12. [Google Scholar] [CrossRef]

- Choab, N.; Allouhi, A.; El Maakoul, A.; Kousksou, T.; Saadeddine, S.; Jamil, A. Review on greenhouse microclimate and application: Design parameters, thermal modeling and simulation, climate controlling technologies. Sol. Energy 2019, 191, 109–137. [Google Scholar] [CrossRef]

- Barbaresi, A.; Maioli, V.; Bovo, M.; Tinti, F.; Torreggiani, D.; Tassinari, P. Application of basket geothermal heat exchangers for sustainable greenhouse cultivation. Renew. Sustain. Energy Rev. 2020, 129. [Google Scholar] [CrossRef]

- Nawalany, G.; Radoń, J.; Bieda, W.; Sokołowski, P. Influence of selected factors on heat exchange with the ground in a greenhouse. Trans. Asabe 2017, 60, 479–487. [Google Scholar]

- Nawalany, G.; Bieda, W.; Radoń, J.; Herbut, P. Experimental study on development of thermal conditions In ground beneath a greenhouse. Energy Build. 2014, 69, 103–111. [Google Scholar] [CrossRef]

- Kittas, C.; Karamanis, M.; Katsoulas, N. Air temperature regime in a forced-ventilated greenhouse with rose crop. Energy Build. 2005, 37, 807–812. [Google Scholar] [CrossRef]

- Al-Kayssi, A.W. Spatial variability of soil temperature under greenhouse conditions. Renew. Energy 2002, 27, 453–462. [Google Scholar] [CrossRef]

- Nawalany, G.; Sokołowski, P.; Herbut, P.; Angrecka, S. Development of selected parameters of microclimate in a stand alone cellar plunged into soil. J. Ecol. Eng. 2017, 18, 156–161. [Google Scholar] [CrossRef]

- Nawalany, G.; Sokołowski, P. Analysis of hygrothermal conditions of external partitions in an underground fruit store. J. Ecol. Eng. 2016, 17, 75–82. [Google Scholar] [CrossRef]

- Sethi, V.P.; Sumathy, K.; Chiwon, L.; Pal, D.S. Thermal modelling aspects of solar greenhouse microclimate control: A review on heating technologies. Sol. Energy 2013, 96, 56–82. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Solar greenhouse an option for renewable and sustainable farming. Renew. Sustain. Energy Rev. 2011, 15, 34–45. [Google Scholar] [CrossRef]

- Liying, C.; Sanpeng, H.; Minghan, C.; Danfeng, H. Temperature-driven growth shape simulation and model of greenhouse melon leaves. Math. Comput. Model. 2011, 54, 1175–1180. [Google Scholar]

- Ghosal, M.K.; Tiwari, G.N.; Srivastava, N.S. Thermal modelling of a greenhouse with an integrated earth to air heat exchanger: An experimental validation. Energy Build. 2004, 36, 219–227. [Google Scholar] [CrossRef]

- Kurpaska, S.; Latała, H. Energy analysis of heat sur plus storage systems in plastic tunnels. Renew. Energy 2010, 35, 2656–2665. [Google Scholar] [CrossRef]

- Larwa, B. Heat transfer model to predict temperature distribution in the ground. Energies 2019, 12, 25. [Google Scholar] [CrossRef]

- Mihalakakou, G.; Santamouris, M.; Lewis, J.O.; Asimakopoulos, D.N. On the application of the energy balance equation to predict ground temperature profiles. Sol. Energy 1997, 60, 181–190. [Google Scholar] [CrossRef]

- Yilmaz, T.; Oezbek, A.; Yilmaz, A.; Bueyuekalaca, O. Influence of upper layer properties on the ground temperature distribution. J. Therm. Sci. Technol. 2009, 29, 43–51. [Google Scholar]

- Cosenza, P.; Guérin, R.; Tabbagh, A. Relationship Between Thermal Conductivity and Water Content of Soils Using Numerical Modeling. Eur. J. Soil Sci. 2003, 54, 581–588. [Google Scholar] [CrossRef]

- Usowicz, B.; Marczewski, W. Rozkładwłaściwościcieplnychglebynaczarnymugorze i pod murawą. Acta Agrophisica 2005, 5, 745–757. [Google Scholar]

- Staniec, M.; Nowak, H. The influence of different soil moisture content on its vertical temperature distribution. Build. Phys. Theory Pract. 2007, 2, 255–260. [Google Scholar]

- Künzel, H.M.; Holm, A.; Zirkelbach, D.; Karagiozis, A.N. Simulation of interior temperature and humidity conditions including hygrothermal interactions with the building envelope. Sol. Energy 2005, 78, 554–561. [Google Scholar] [CrossRef]

- Antretter, F.; Pazold, M.; Radoń, J.; Künzel, H.M. Kopplung von dynamischer Wärmebrückenberechnung mit hygrothermischer Gebäudesimulation. Bauphysik 2013, 35, 181–192. [Google Scholar] [CrossRef]

- Antretter, F.; Radon, J.; Pazold, M. Coupling of dynamic thermal bridge and whole-building simulation. In Proceedings of the 12th International Conference Thermal Performance of the Exterior Envelopes of Whole Buildings, Clearwater, FL, USA, 1–15 December 2013. [Google Scholar]

- Staszczuk, A.; Kuczyński, T.; Radoń, J. Effect of hot weather periods in moderate climate regions on approach to slab thermal design in residential buildings. Build. Phys. (Nsb) 2011, 2, 825–832. [Google Scholar]

- Staszczuk, A.; Radoń, J.; Holm, A. Evaluation of simplified calculation method of heat exchange between building and ground. In Proceedings of the 1st Central European Symposium on Building Physics, Cracow, Poland, 13–15 September 2010; pp. 371–376. [Google Scholar]

- Sokołowski, P.; Nawalany, G. Analysis of Energy Exchange with the Ground in a Two-Chamber Vegetable Cold Store, Assuming Different Lengths of Technological Break, with the Use of a Numerical Calculation Method—A Case Study. Energies 2020, 13, 4970. [Google Scholar] [CrossRef]

- Nawalany, G.; Sokołowski, P. Improved Energy Management in an Intermittently Heated Building Using a Large Broiler House in Central Europe as an Example. Energies 2020, 13, 1371. [Google Scholar] [CrossRef]

- Nawalany, G.; Sokołowski, P. Building–Soil Thermal Interaction: A Case Study. Energies 2019, 12, 2922. [Google Scholar] [CrossRef]

| Specification | Value | Unit |

|---|---|---|

| Concrete | ||

| Volumetric density | 2322 | kg·m−3 |

| Specific heat | 850 | J·kg−1·K−1 |

| Heat transfer coefficient | 1.70 | W·m−1·K−1 |

| Single glazing | ||

| Sash section coefficient | 0.80 | - |

| Average permeability coefficient | 0.60 | - |

| Emissivity coefficient | 0.80 | - |

| Mean heat transfer coefficient U | 3.50 | W·m−2·K−1 |

| Sandy clay | ||

| Volumetric density | 1800 | kg·m−3 |

| Specific heat | 1000 | J·kg−1·K−1 |

| Thermal conductivity coefficient | 1.70 | W·m−1·K−1 |

| Physical Parameters | Unit | Variant 1 | Variant 2 | Variant 3 |

|---|---|---|---|---|

| Moisture status | - | dry | moist | wet |

| Relative humidity of the ground | % | 4 | 7 | 15 |

| Volumetric density | kg·m−3 | 1750 | 1468 | 1442 |

| Specific heat | J·kg−1·K−1 | 830 | 980 | 1250 |

| Thermal conductivity coefficient | W·m−1·K−1 | 0.25 | 0.69 | 1.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nawalany, G.; Sokołowski, P. Numerical Analysis of the Effect of Ground Dampness on Heat Transfer between Greenhouse and Ground. Sustainability 2021, 13, 3084. https://doi.org/10.3390/su13063084

Nawalany G, Sokołowski P. Numerical Analysis of the Effect of Ground Dampness on Heat Transfer between Greenhouse and Ground. Sustainability. 2021; 13(6):3084. https://doi.org/10.3390/su13063084

Chicago/Turabian StyleNawalany, Grzegorz, and Paweł Sokołowski. 2021. "Numerical Analysis of the Effect of Ground Dampness on Heat Transfer between Greenhouse and Ground" Sustainability 13, no. 6: 3084. https://doi.org/10.3390/su13063084

APA StyleNawalany, G., & Sokołowski, P. (2021). Numerical Analysis of the Effect of Ground Dampness on Heat Transfer between Greenhouse and Ground. Sustainability, 13(6), 3084. https://doi.org/10.3390/su13063084