1. Introduction

Globally, a strong urbanization trend is apparent. In 2007, the total urban population exceeded the total rural population [

1]. It is expected that by 2050, cities or other urban centres would house 68% of the world population [

2]. Given this trend, local and regional authorities center their attention on developing their built environment, which stimulates construction and renovation works [

1]. The construction of new buildings and the renovation of older ones follows a natural evolution pattern for a city [

3], and the sector often brings along more attractive, more sustainable and more economically viable cities in the long run, i.e., when the construction works are finished.

However, often little attention is paid to the logistical costs and nuisances caused during the construction activities, which sometimes expand over several years or decades in the case of refurbishing entire neighborhoods. Urban construction is intrinsically heavily reliant on logistics [

4], as the building is always produced at the final site of use, causing a vast number of resources to be transported to and from the site at the right time [

5]. Construction logistics is said to represent 20–35% of all urban traffic in the EU, and responsible for the lion’s share of environmental costs such as air pollution and traffic accidents [

6,

7,

8]. However, these figures need to be solidified in future studies, as current studies do not use robust transport performance indicators to measure the impact of the sector, mainly due to the data availability issue [

8]. Nonetheless, there is a general consensus that scheduling construction logistics aids to enable smooth construction works efficiently and sustainably [

3,

9].

Logistics optimization can be based on planning, consolidation and cooperation, as to use resources optimally, reduce traffic and emissions, avoid congestions and avoid unproductive times [

3,

10,

11]. The construction logistics and city development industry naturally affects a vast amount of stakeholders, such as (sub)contractors, logistics providers, municipalities, etc. [

12,

13]. It is thus of importance to develop and implement the right Construction Logistics Scenarios (CLS) in order to meet the demands and opinions of various stakeholders. Stakeholder consultation and taking into account their various perspectives and needs from the beginning of the project thus play a vital role in developing freight transport strategies and policy implementations with a higher acceptance rate amongst stakeholders and decreased chances of project failure [

14,

15,

16,

17].

Frequently, each of these stakeholder groups has their own opinion and benefits associated to construction projects, which adds to the complexity of managing the interrelationships amongst the different parties [

12,

13]. Moreover, many stakeholders are directly or indirectly affected by city logistics measures given its urban environment [

18,

19]. Although cities pay more and more attention to create awareness and value for stakeholders in city logistics [

20,

21], the focus has mainly been on the technical aspects (e.g., the reduction of amounts of vehicles) [

22,

23], and not on the management of stakeholder interrelationships.

Additionally, many policies and regulatory bodies are at heart of urban transport systems [

24,

25]. These are required to enable the smooth use of the available infrastructure [

26], but private and public urban freight transport actors often fail to consolidate their points of view on the management or the regulation of such a system. The cause is mainly due to the limited efforts put in the coordination between the involved stakeholders [

20]. Furthermore, no guidelines are set when implementing novel Construction Logistics Scenarios [

3]. Thus, the inclusion and coordination of stakeholders is a pain point in the urban freight transport industry [

25].

A new, innovative way to reduce the negative impact of construction works on different stakeholders in the city is to address the issue of construction logistics from a systems and city perspective [

27]. Cities have the largest potential to reduce negative impacts through requirements on construction logistics. However, today there is a lack of knowledge within cities of how to set such demands and how to involve and manage stakeholders in these processes [

9]. The issue is especially relevant as the sector is inherently characterized by numerous and varying stakeholders.

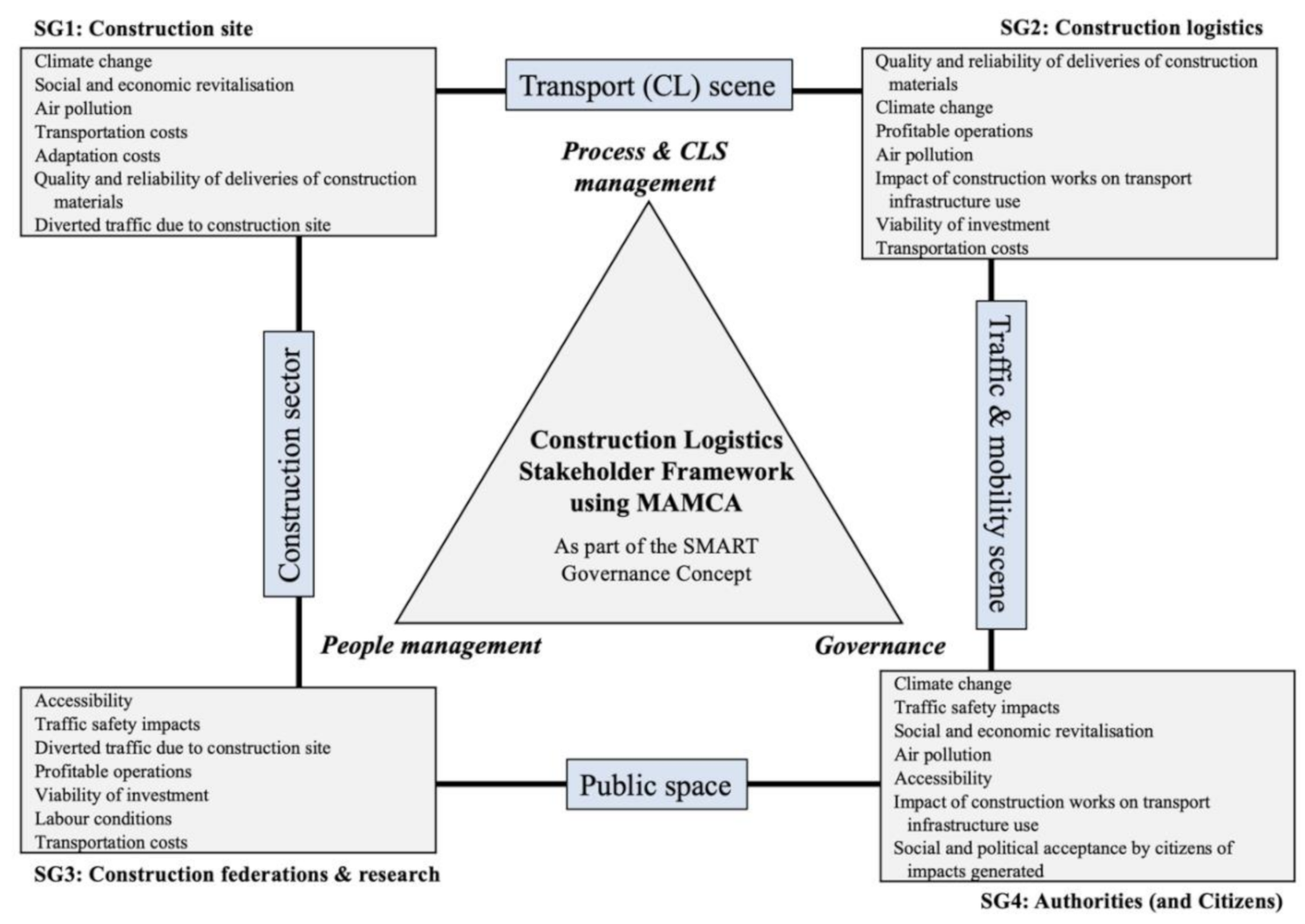

This research addresses the main pain points in the sector and contributes by offering solutions on how to set construction logistics demands and manage stakeholders in the processes. It explores how cities and stakeholders can act towards the reduction of multi-dimensional impacts and towards a more sustainable construction logistics supply chain. This is achieved by the development of a Construction Logistics Stakeholder Framework within the governance of urban construction works, adapted from the Multi-Actor Multi-Criteria Analysis (MAMCA) [

28] by mathematically underpinning stakeholders’ preferences and improve the decision-making process in a multi-governance setting [

29,

30,

31]. The framework was then tested and implemented in the context of a use case in the Brussels-Capital Region (BCR), Belgium. Special attention was paid on the identification of implementation barriers and the role of (local) government to facilitate introduction and city-wide roll-out of novel construction logistics concepts. Because of the numerous and varying nature of stakeholders in construction logistics, this paper presents a flexible, replicable and upscalable framework both from an inter- and intracity perspective.

To our knowledge, this study is a pioneering collaborative exercise in the field construction logistics. First, the developed framework mathematically underpins stakeholders’ preferences and improve the group decision-making process in a multi-actor, multi-criteria governance setting. Hence, it increases the chances of implementing scenarios and guidelines from the start of a construction logistics project, which, in turn, enable the reduction of financial, policy and organizational barriers that often prevent the uptake of these solutions. Second, a large city-wide panel of direct and indirect stakeholders and experts in the domain was involved to appraise their points of view and in the decision-making process of future construction logistics scenarios in the BCR, hence testing and validating the presented framework in a dense urban area with relevancy to other cities or urban centres in Europe. Third, given the flexible, replicable and upscalable nature of the framework, its results can serve to support (1) the management of processes and Construction Logistics Scenarios (CLS), (2) the management of people and the community, and (3) the project and city governance, in a multi-level governance context.

2. Literature Review

Macroeconomically, the construction sector accounts for 9.7% of the EU’s GDP, employing 12.7 million people [

32]. Similar figures exist for Belgium, where the sector represents 6% of the country’s GDP, which roughly corresponds to an annual turnover of 36 billion EUR. At the same time, the sector accounts for more than 275,000 FTEs, employing close to 7% of the working population in more than 127,000 companies (21.2% of all companies in Belgium) [

33,

34,

35,

36].

Although construction represents one of the largest economical industries, often little attention is paid to the logistical costs and nuisances caused during the construction activities. Urban construction is intrinsically heavily reliant on logistics [

4], and 60 to 80% of the materials and services required for the gross work are procured from suppliers and subcontractors [

37]. The construction sector distinguishes itself by its case-specific nature, its unique location of production and temporary multi-organization [

38]. In the case of construction works, the voluminous and immobile end product is always produced at the final site of use, which causes a numerous amount of resources to be transported to and from the site at the right time [

5,

9]. The macroeconomic figures therefore also cascade to the sector’s logistics activities and the costs incurred on microeconomic level. Construction logistics (CL) is said to represent 20–35% of all urban traffic in the EU [

6,

7,

8]. This large share of construction-related traffic is also heavily relying on the use of vans; 53% of vans would be linked to the construction and services industry [

39].

Construction-related logistics movements are the source of important environmental nuisances if these are not handled appropriately [

8,

9,

40]. Introduced by Hardin [

41] as commons, natural resources are shared amongst many, but can, in the lack of regulation, be exploited limitlessly to one’s own benefit, as the nuisances caused to society are not borne by the polluters. In the case of transport, these nuisances are commonly housed under the denominator of external costs [

42,

43,

44]. The main transport externalities include air pollution, greenhouse gas emissions, noise pollution, congestion, accidents, infrastructure costs and well-to-tank costs. Estimates show that the size of external costs engendered by the transport sector would reach 1000 billion euro per annum [

45]. Studies so far approximate the share of construction logistics to represent 20–35% of urban freight traffic [

6,

7,

8,

21]. However, these figures need to be solidified in future studies, as current studies do not use robust transport performance indicators to measure the impact of the sector [

8]. Nonetheless, there is a general consensus that scheduling construction logistics aids to enable smooth construction works efficiently and sustainably [

3,

9]. Logistics optimization can be based on planning, consolidation and cooperation, as to use resources optimally, reduce traffic and emissions, avoid congestions and avoid unproductive times [

3,

10,

11]. It is thus of importance to develop and implement the right Construction Logistics Scenarios (CLS) in order to meet the demands and opinions of various stakeholders.

Additionally, in light of making Europe climate-neutral by 2050, the ecological aspect of urban construction and renovation is particularly high on the political agenda, given 40% of Europe’s energy consumption and 36% of GHG emissions are responsible from buildings. The Renovation Wave Strategy therefore ambitions to enhance the building’s energy performance by doubling renovation rates in the upcoming decade [

46]. Thus, important attention also needs to be paid on the vast impact of the associated construction logistics activities and the decarbonization strategy of transport, which are inherent to the construction and renovation works in the upcoming decades.

In the total construction budget, the logistics activities represent 8–15% of the incurred costs [

47]. Often, additional logistics costs are incurred worth up to 10% of the total construction budget [

47]. The costs are referred to as failure costs and are the consequence of poor communication or coordination, quality problems, repair or rework etc. Currently, the sector still does not stack up against others when it comes to productivity performance [

48]. Studies estimate that transport and logistics could cut the total construction budget up to 20% by implementing a rigorous planning of logistics activities [

5,

49,

50]. There is thus also ample room to reduce the substantial financial logistics costs inherent to construction.

The construction logistics and city development industry naturally affects a vast amount of stakeholders, such as (sub)contractors, logistics providers, municipalities etc. Frequently, each of these stakeholder groups has their own opinion and benefits associated to construction projects, which adds to the complexity of managing the interrelationships amongst the different parties [

12,

13]. Moreover, many stakeholders are directly or indirectly affected by city logistics measures given its urban environment [

18,

19]. Although cities pay more and more attention to create awareness and value for stakeholders in city logistics [

20,

21], the focus has mainly been on the technical aspects (e.g., the reduction of amounts of vehicles) [

22,

23], and not on the management of stakeholder interrelationships.

Additionally, to better monitor and manage construction logistics flows, cities and municipalities need to adjust tendering and procurement procedures [

9], for example by placing procurement demands regarding type of transports and vehicles used, and how to organize construction logistics from a city-level perspective. Therefore, a significant number of policies and regulatory bodies are at heart of urban transport systems [

24,

25]. These are required to enable the smooth use of the available infrastructure [

26], but private and public urban freight transport actors often fail to consolidate their points of view on the management or the regulation of such a system. This is mainly caused by the fact cities and/or authorities often do not put efforts in the coordination between the involved stakeholders [

20]. Often, however, no guidelines are set when implementing novel Construction Logistics Scenarios [

3]. Thus, the inclusion and coordination of stakeholders is a pain point in the urban freight transport industry [

25].

A new innovative way to reduce the negative impact of construction works on different stakeholders in the city is to address the issue of construction logistics from a systems and city perspective [

27]. Indeed, the earlier the issue of construction logistics is brought up in the construction/city planning process, the better possibilities of stakeholder involvement [

51]. The main issue is that, today, there is a lack of knowledge within cities of how to set sustainable construction logistics demands and how to involve and manage stakeholders in these processes. To better monitor and manage construction logistics flows, cities and municipalities need to adjust tendering and procurement procedures in order to reduce the impact of urban mobility [

9], for example by placing procurement demands regarding type of transports and vehicles used, and how to organize construction logistics from a city-level perspective. The goal for the cities is to keep the community surrounding the construction sites livable and acceptable places of work and visit during the construction period, whilst at the same time ensuring productivity at the construction sites. The question for the authorities becomes how much control they should and can exhort to accomplish this. As such, authorities need to consider solutions from several stakeholders’ perspectives.

Furthermore, there is a need to identify the relevant case-specific stakeholders, in which phases of the construction projects to involve them and how these are to be communicated with. Contractors running several projects in a city or active within the same construction area need to coordinate deliveries and waste removals between multiple projects to decrease the number of transports in a city. They also need to increase their understanding of the social, environmental and economic impacts of novel logistics scenarios on the different parts in the construction supply chain as well as other stakeholders. Property developers and clients need to reduce the impact from construction deliveries on their customers by setting demands on what machinery to use and the importance of transport consolidation. Construction material suppliers need to plan and coordinate material flows within and across individual supply chains to enable the reduction of transport need (e.g., consolidation) and a smooth construction process. However, little to no research has been conducted to measure these effects and interrelations in construction logistics.

With the concept of stakeholders [

52], the idea and need to include stakeholders in firms’ decision-making processes became more and more evident with the emergence of Corporate Social Responsibility [

53]. A stakeholder can be a person or group of individuals, able to either directly or indirectly influence or be influenced by the objectives of a firm, thus who can affect or will be affected by the problem at hand [

54]. It is necessary to involve stakeholders in order to evaluate particular decision issues, such as the assessment of urban logistics solutions. By doing so, each stakeholder’s objectives are taken into consideration. This is especially useful as often a large variety of stakeholders are involved in public decision-making. Particularly in complex processes such as the assessment of urban or inter-urban construction logistics, the importance of involving the large number of scattered stakeholders must be stressed, as taking all these different points of view into account is proven to increase a project’s rate of acceptance [

55]. In order to implement this dimension in the traditional Multi-Criteria Analysis (MCA) or Multi-Criteria Decision Analysis (MCDA) [

56,

57], improved socio-political aspects should be integrated in the process of decision-making [

58]. Although traditional MCA/MCDA evaluates multiple conflicting criteria in decision-making, they do not contain the multi-stakeholder dimension. This implementation is made possible using Group Decision Support Methods (GDSM), such as the Multi-Actor Multi-Criteria Analysis (MAMCA) developed by Macharis [

28,

59,

60].

Developing urban freight solutions without any disadvantages to any of the stakeholders is not only impossible but also unnecessary; common ground can be reached when the perceived advantages of a particular measure are greater than its disadvantages, requiring reflective collaboration between the actors [

61]. Improved freight partnerships, mainly characterized by a core set of interested and engaged parties, increased involvement and seeking cooperation between stakeholders from the start, often leads to greater chances of success of a project. Stakeholder consultation and taking into account their various perspectives and needs from the beginning of the project thus play a vital role in developing freight transport strategies and policy implementations with a higher acceptance rate amongst stakeholders and decreased chances of project failure [

14,

15,

16,

17]. So far, only one other study was found of the kind in the sector. However, this construction logistics-themed analysis was solely conducted as a demonstration of the MAMCA methodology in a role-playing setting with 20 students at the University of Applied Sciences in Amsterdam [

62]. The participants (i.e., students acting as a certain stakeholder group, such as LSP, supplier, building contractor and municipality) are not included in various important steps of the MAMCA, including the scenario definition and the stakeholder group’s own criteria selection. The aim of the demonstration was thus mainly to show the difficulty of taking decisions in fields such as transport with many diverging interests and opinions, by letting students discover the criteria weighting (AHP) and scenario evaluation (AHP) exercise. The study also highlights the need for further development in this regard, as well as the involvement of real stakeholders. Despite its limitations, some structural elements (i.e., MAMCA methodology) was used to build the presented framework. Indeed, the current study is a pioneering collaborative exercise in the field construction logistics, as it (1) involves a large city-wide panel of direct and indirect stakeholders and experts in the sector to appraise their points of view and in the decision-making process of future construction logistics scenarios in the BCR, and (2) presents a flexible construction logistics stakeholder framework which can be replicated, upscaled and further validated in other urban centres in Europe.

This research first and foremost contributes by offering solutions on how to set construction logistics demands and manage stakeholders in the processes, and explores how cities and stakeholders can act towards the reduction of multi-dimensional impacts, ultimately contributing to a more sustainable construction logistics supply chain. This is needed as (1) there is currently a lack of knowledge on stakeholder involvement or group decision-making in construction logistics; (2) the magnitude of the environmental and financial costs generated by the sector and; (3) the numerous and varying direct and indirect stakeholders inherent to the sector which further reinforces the issue. This is achieved by the development of a Construction Logistics Stakeholder Framework within the governance of urban construction works, adapted from the Multi-Actor Multi-Criteria Analysis (MAMCA) [

28] by mathematically underpinning stakeholders’ preferences and improve the decision-making process in a multi-actor, multi-criteria construction logistics governance setting. The presented framework is flexible, replicable and upscalable, and can be deployed from an inter- and intracity perspective. The framework has been implemented in a city-wide construction logistics environment in Brussels, the capital of Belgium and Europe. Consequently, the framework aims to be deployed on a larger geographic scale in future research, in particular in other European cities and urban centres, and serves to support (1) the management of processes and CLS, (2) the management of people and the community, and (3) the project and city, in a multi-level governance context.

3. Methodology

This study builds further on the Multi-Actor Multi-Criteria Analysis (MAMCA). The MAMCA allows the evaluation of different alternatives (e.g., policy measures, scenarios, technologies) with regards to the objectives of the different stakeholders that are involved in the group decision-making process. This allows the MAMCA to explicitly include the stakeholders in the analysis. Their preferences are then integrated at the core of the evaluation. As an extension of traditional MCA/MCDA, the MAMCA has proved its use in complex problem scenarios with scattered stakeholders and conflicting objectives, mainly in transport-related group decision-making problems [

63,

64,

65,

66].

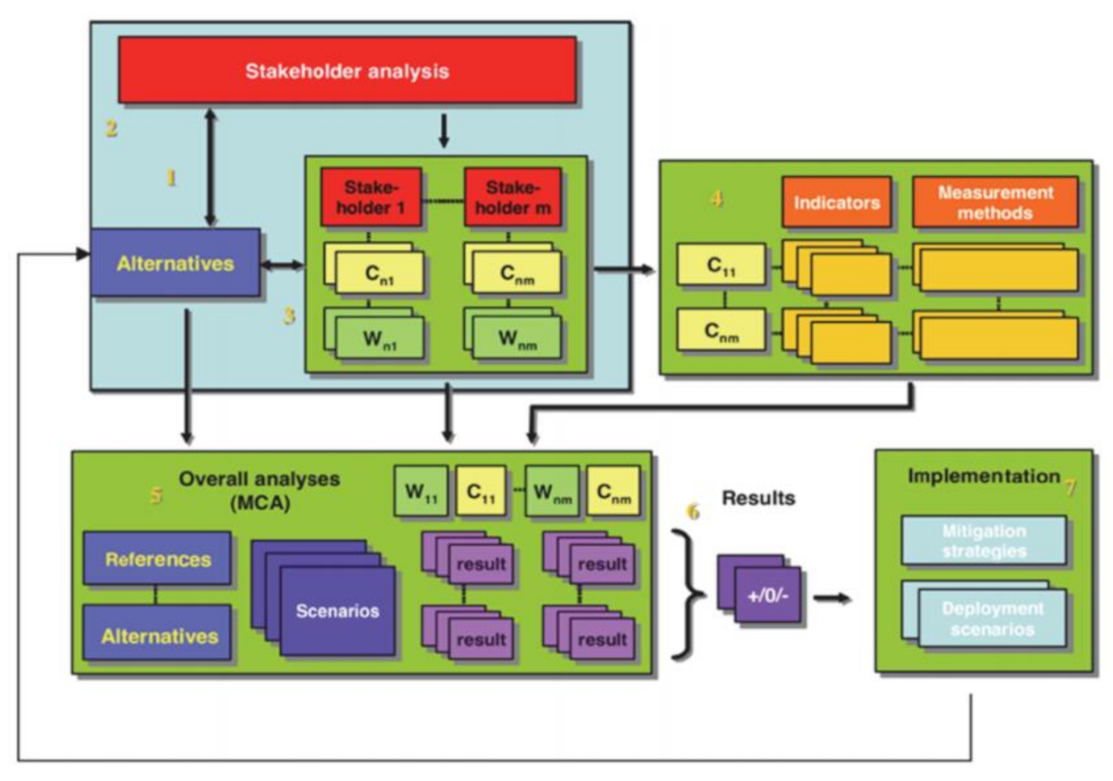

The MAMCA methodology can be divided into two main phases [

59,

60]; the first one being mainly analytical and trying to gather all the necessary information in order to conduct the analysis. The second phase is the synthetic or exploitation phase and entails the actual analysis, during which the extent to which the different alternatives contribute towards the stakeholders’ objectives is evaluated. These two phases are then respectively subdivided in four and three steps [

60], as presented in

Figure 1.

Step 1 highlights a clear problem definition and formulates the alternatives to take into account. The current situation (‘business-as-usual’ or ‘As-Is’ situation) is included as a benchmark and is compared to ‘Should-Be’ situations, later referred to as Construction Logistics Scenarios (CLS). In many cases, the possibilities will include combinations of complementary measures. Potential CLS are sourced from state-of-the-art literature and were evaluated for implementation on three aspects: (1) The availability of resources and services allowing for a potential (current or future) successful implementation given the local context and specificities; (2) The measurability of potential logistics solutions, in order to allow comparability across cases, and; (3) The relevancy of implementing certain scenarios over others given characteristics inherent to the construction (logistics) sector. The preferential CLSs are then utilized as input for the analysis in the MAMCA and encompass both potential feasible scenarios to implement in real-life, as well as hypothetical scenarios for a simulation of impacts. Step 2 provides a listing of all relevant stakeholders, including their objectives, which will later be translated into criteria during step 3. The objectives or criteria can be identified through a literature study and stakeholder consultation. If the stakeholders are involved in (co-)creating the alternatives, there is clearly a link between Step 1 and Step 2, as first the relevant stakeholders to be involved in alternative creation/identification should be assessed, hence the double arrow connecting both steps in

Figure 1. If alternatives are identified top-down, the chronology between Step 1 and Step 2 is considered stricter. Once the criteria have been determined, a crucial step is to identify how important every criterion is for each of the actors, covered in Step 3. This is achieved by assigning weights to the different criteria and is done by the stakeholders themselves. For example, the Logistics Service Provider will likely be focussed on timely deliveries and/or meeting customer demands, whereas public authorities might be more interested in traffic safety or reducing congestion levels. In order to weight the different criteria against one another, the Analytical Hierarchy Process (AHP) developed by Saaty [

67] is used, because it provides a systematic way to allocate the weights [

68]. The criteria are pairwise compared, matching each criterion one-on-one with the other ones using a 9-point scale, as such expressing the stakeholders’ preferences. The relative preferences which are obtained as part of the pairwise comparison using AHP are organized into a matrix and normalized, which produces a priority vector, aggregated based on the geometric mean [

69]. The weighted methodology score can also show certain limitations. A first limitation is that AHP requires significant effort from the involved stakeholders to achieve a consensus within a group [

70]. The current study solves this by keeping the weighting process manageable. Indeed, it is advisable to keep the number of criteria limited, complying with the methodological requirements for criteria definition being non-redundancy, minimality, homogeneity and operationality [

69]. Therefore, the current study opted to limit the number of ‘most important criteria’ to a maximum of seven, in order to keep the pairwise comparison manageable for the participants. A second limitation which is often associated with AHP, is the failure to consider interrelationships between criteria due to the assumption of their scores’ independence [

70]. Indeed, studies show that there frequently is a certain degree of dependence between criteria [

71]. The MAMCA methodology answers this concern by letting the stakeholder determine the weights of the criteria themselves [

60,

72,

73,

74]. Furthermore, AHP is considered the most appropriate method in a workshop and/or multi-actor multi-criteria evaluation context which includes subjective criteria, thanks to its ease of use, particularly in a decision-making context on sustainability or energy problems [

75,

76,

77,

78]. Step 4 attempts to couple one or more measurable indicators to each criterion, hence allowing to evaluate each alternative with regards to each criterion. These indicators can either be quantitative or qualitative in nature, depending on its respective criterion. Step 5 presents the aggregation of the information from the previous steps, resulting in an evaluation matrix. A multitude of different multi-criteria analysis (MCA) methods are available to evaluate different alternatives, making the MCA methods of the Group Decision Support Methods (GDSM) especially useful to apply in the MAMCA methodology. These include PROMETHEE [

79,

80], ELECTRE [

81] and the Analytical Hierarchy Process (AHP) [

67]. Most often, AHP is preferred when conducting a MAMCA, to pairwise compare and evaluate the performance of different CLS. The actual results are part of Step 6 and are generated using a Multi Criteria Analysis (MCA), allowing the researcher to analyze the (dis)advantages associated to every alternative. The output provides a clear overview of the (dis)advantages of the different scenarios for the involved stakeholders. This allows the search for win–win scenarios, and ultimately to gain support or consensus for preferential solutions. The 7th and last step seeks to actually implement the results, revealing the alternatives that receive overall stakeholder support. This last step is primarily aimed at the policy maker. The methodology will be further explained in detail in the next section, implementing the developed framework on a use case in Belgium.

4. Framework Development and Use Case Implementation

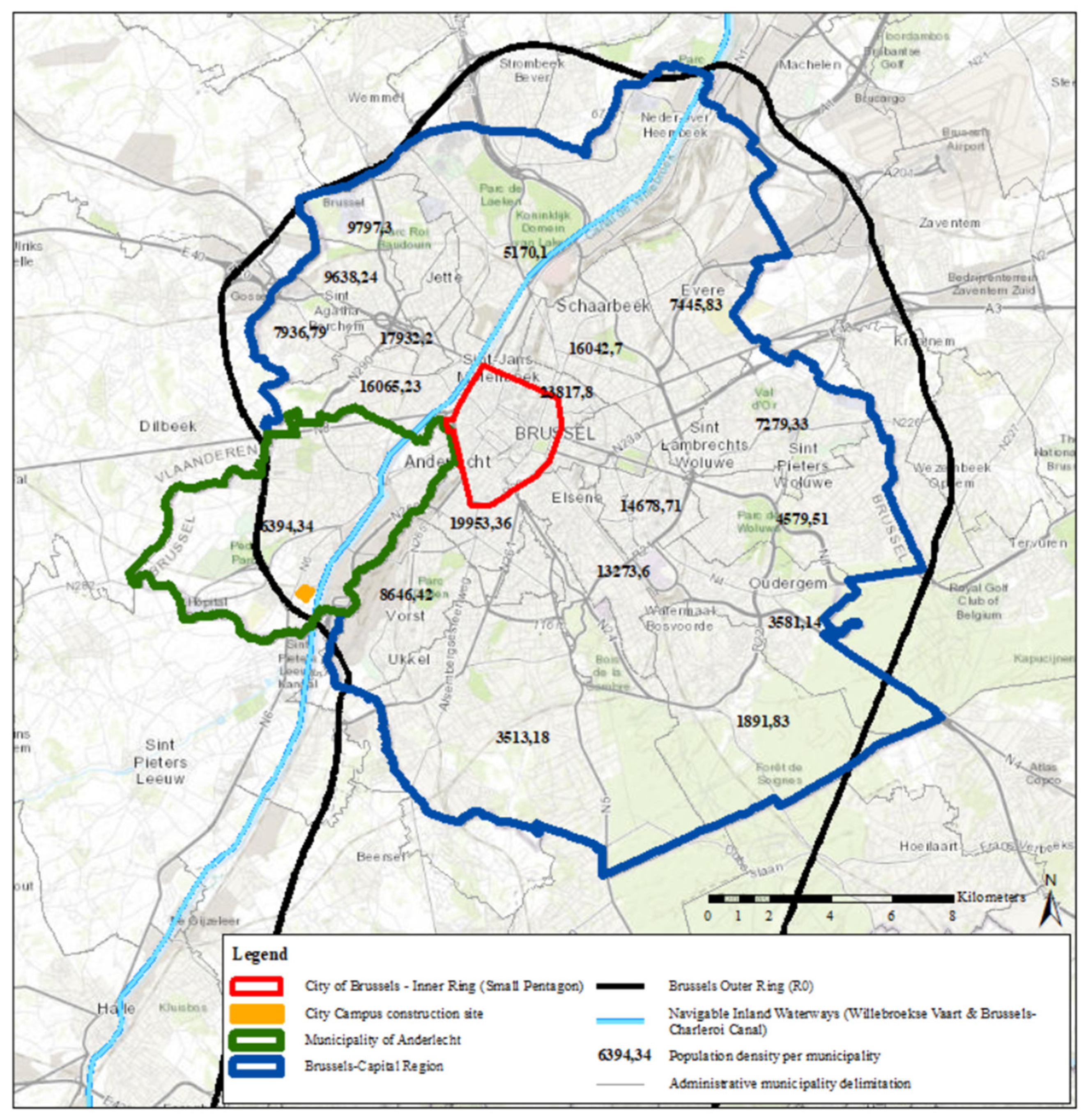

The framework was tested and implemented on a use case in the Brussels-Capital Region (BCR), as visualized in

Figure 2. The BCR (Dark Blue) comprises the inner City (municipality) of Brussels (Red Pentagon), along with its 19 surrounding municipalities, of which one is Anderlecht (Green). The pilot site is the mixed ‘City Campus’ project (Orange) in Anderlecht, which will ultimately result in a 17,600 m

2 site for an SME park for agri-food companies and social and student residences. ‘City Campus’ is organized in association with the public–private partnership between owner and city development agency CityDev and main building contractor Van Roey Vastgoed.

The site offers high relevancy for the construction logistics sector and for a metropolitan area—such as the BCR—for several reasons. First, the site is located within the Brussels Outer Ring (R0) and the BCR. The Capital of Europe is categorized as a dense Urban Centre with a total population of 1.2 million inhabitants [

84]. Anderlecht, the municipality in which the site is located, has a population density of 6394.34 inhabitants/km

2 [

82] and a total population of 108,940 inhabitants [

84]. Both the construction area, as well as the greater transport area to and from the site, thus offer a solid playground to test and implement CLS in a European urban area. Second, the construction site is considered as a typical ‘large’ construction project in Brussels, with a strong output value upon completion. Third, the location offers a variety of relevant and potential transport accessibility entries and exits: the area is in close proximity of major road axes such as the R0 ring of Brussels and the E19 highway (Black) as well as the main navigable inland waterway axes of the Brussels-Charleroi Canal and the Willebroekse Vaart (Light Blue). Finally, the BCR is a complex web of actors, reinforced by the fact each of the 19 municipalities has its own and unique administration and legislation. Furthermore, the neighborhood offers a rich diversity in vicinal stakeholders, including a shopping centre, a higher-education college and various local businesses. With many stakeholders involved and many potential conflicts, the area thus provides a thorough testing ground for the MAMCA-based stakeholder framework for urban construction logistics.

4.1. Construction Logistics Scenarios (CLS)

The first step encompasses the definition of CLS. The alternatives can be policy measures, logistics scenarios, strategies or other actions that are able to solve or affect the problem at hand. When defining CLS, an important aspect is who is deciding on the different scenarios. If the stakeholders are involved in (co-)creating the alternatives, there is clearly a link between Step 1 and Step 2, as first the relevant stakeholders to be involved in alternative creation/identification should be assessed. This is represented as the double arrow connecting both these steps in

Figure 1. If alternatives are identified top-down, the chronology between Step 1 and Step 2 is considered stricter. For this implementation case, the scenario definition was completed using a top-down approach using a Brussels construction logistics expert panel. This panel consisted of (1) the construction company (i.e., Van Roey Vastgoed and partners), (2) the owner and city development agency (i.e., citydev.brussels), and (3) urban mobility authorities (i.e., Brussels Mobility, Strategic Department Urban Freight Transport), as these were the most relevant actors within the sector to judge the evaluation of potential scenarios on 3 main implementation aspects in the BCR (i.e., availability, measurability and relevancy; cf. below). First, an exhaustive list of construction logistics scenarios was compiled, which was based on the state-of-the-art academic literature ranging from small modifications in working practices [

85,

86,

87,

88], to larger scale infrastructures including material consolidation and joint delivery systems (e.g., UCC, CCC, Hubs, mobile depots, transshipments locations), land use management, traffic management (e.g., modal shifts, dynamic routing, off-hour delivery tours, eco-driving), regulatory measures (e.g., Construction Logistics Plan, Sustainable Urban Logistics Plan, dynamic road pricing, access management) and technological advancements (e.g., vehicle fleets and technologies, information, communication, traffic and routings services, modular building) [

89,

90,

91,

92,

93]. A recent and complete overview and categorization can be retrieved in Janné, 2020 [

3]. This list was further enriched with solutions from the broader urban freight transport sector, which could serve as inspiration for the construction industry (such as mobile depots, off-hour deliveries and joint delivery systems). Next, the potential solutions were evaluated by the construction logistics panel on three main aspects: (1) The availability of resources and services allowing for a potential (current or future) successful (actual or theoretical) implementation given the local (Brussels) context and specificities; (2) The measurability of potential logistics solutions, in order to allow comparability across cases & the replicability/measurability of the framework, and; (3) The relevancy of implementing certain scenarios over others given characteristics inherent to the construction (logistics) sector.

This analysis resulted in four preferential construction logistics scenarios (CLS), in addition with the baseline ‘business-as-usual’ or ‘As-Is’ scenario. The baseline scenario implies that operations are continued the way they are being dealt with currently, while the four preferential ‘Should-Be’ CLSs each have their own specific characteristics and sometimes include combinations of measures, which are shown in

Table 1. These defined preferential CLSs will be utilized as input for the analysis in the MAMCA and encompass both potential feasible scenarios to implement in real-life, as well as hypothetical scenarios for a simulation of impacts.

4.2. Stakeholder and Criteria Identification

Step 2 envelops the identification of stakeholders that are involved. Stakeholders in the sector are very diverse. This often renders it complex to include everyone in the analysis. In the implementation case, first an exhaustive list of actors linked to the construction logistics sector within the Brussels-Capital Region (BCR) was compiled. In total, 44 expert actors either directly or indirectly linked to the City Campus pilot case and/or construction logistics in the BCR were invited for the MAMCA workshop and were sent a pre-workshop questionnaire (by means of Qualtrics). In this survey, the respondents were first asked to identify themselves with a detailed series of predefined potential stakeholder categories by means of single answer drill-down multiple-choice questions (or other if not applicable). The respondents were then presented with 23 criteria which are important in the sector. These criteria were based on the findings of the CIVIC project [

62,

94], and encompass the most relevant economic, environmental and societal criteria in the construction logistics sector, which can be found in

Table 2 along with their description.

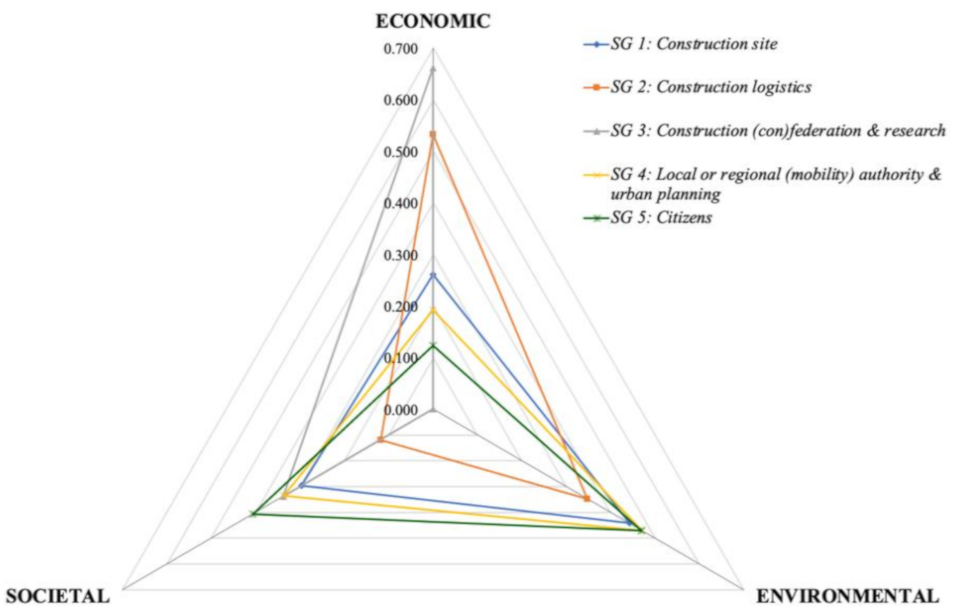

The same 23 criteria were presented to every respondent, regardless of their stakeholder group choice. The respondents were then asked to choose the most important criteria for them amongst the list. This was done in a two-step approach, first selecting the criteria (minimum 6) that affect the respondent from the entire list in a binary way by means of a multiple answer multiple-question, then comparatively ranking the selected criteria (carry forward statements) on a five-point Likert scale. In total, 20 survey responses (out of 44) were received. Based on the survey results, the researchers conducted a profiling exercise to (1) define similar group profiles and (2) identify the most impactful criteria for each group. First, a profile was drawn per respondent based on the relative share per criteria group between economic, environmental and societal scores, which defined four distinct stakeholder groups. These clusters of similar profiles are represented in

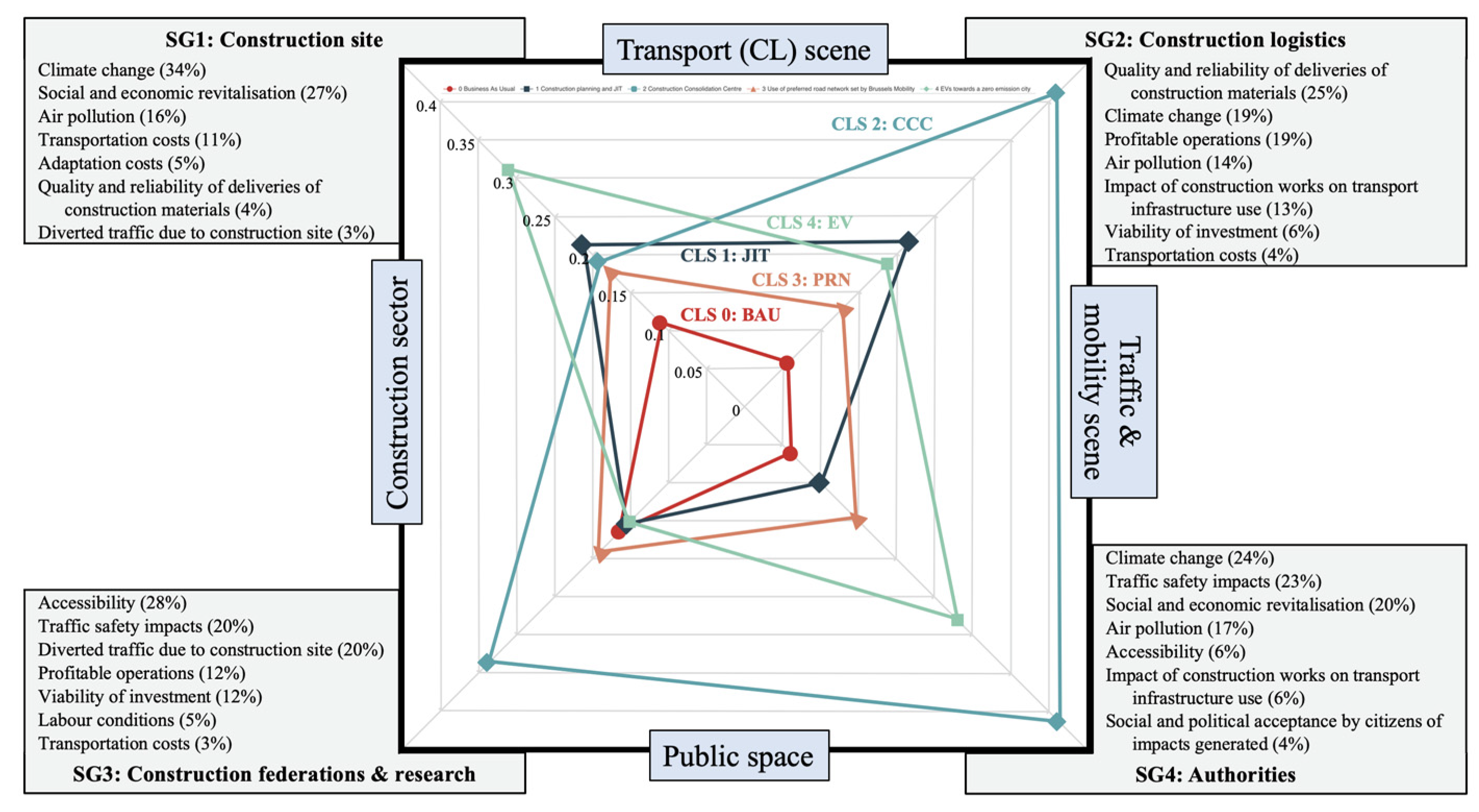

Figure 3. To our knowledge, the notion of profiling to match groups with a similar criteria selection and scoring has not yet been conducted in multi-actor multi-criteria analyses. Although this approach could potentially enrich these types of analyses, the current profile matching currently presented in this study served to mathematically aid in clustering respondents into groups with similar profiles and could thus be further refined in future research.

Given the public–private partnership (PPP) between the public owner (and city development agency) and the private construction company, both these actors have aligned goals consisting of mixed economic, environmental and societal goals, as reflected in a well-distributed share among criteria for

Group 1. The second group, encompassing construction logistics-related actors, mainly puts forward economic criteria, along with environmental ones. The third group, which consist of construction federations and research institutes show a strong preference for economic, and to a lesser extent societal criteria, reflected in the grey triangle. Noticeable here is that none of the respondents within this profile have attributed a score to any of the environmental criteria.

Group 4 (local authorities and urban planners) forms the last actor group, consisting of local and regional (urban) mobility authorities and urban planners.

Table 3 presents the different actors with similar profiles which were clustered in the four final stakeholder groups (SG). The subgroups indicate the professional profiles which were included in the SG, which more often than not overlap, as many individuals fulfill one or more positions. The overlap does, however, solely exist within the same SG. Therefore, an alphabetic code has been assigned to distinguish the number of participants and profiles present in the workshop.

Due to the SARS-CoV-2 pandemic, the researchers were unable to include Citizens (i.e., resident or landowners, visitors or customers, students (CERIA), local businesses, employers or employees, and members of local neighborhood committees) as an additional actor group because of practical workshop reasons. Gathering a representative number of participants joining an online call where each person has an equal voice, would have been extremely difficult, as each participant within each group has an equal vote in order to reach a consensus within the group. This quantified consensus is captured though a constructive group discussion. The online format, which was imposed by the current situation, did not allow for a natural discussion in larger group due to time and technological constraints. The inclusion of this stakeholder group can however be subject to future development to this analysis. Furthermore, the number of respondents also leaves room for further improvement in the context of mass participation of multi-actor multi-criteria analyses, which is currently under development (Huang et al., 2020). The authors did however incorporate Citizens as a potential group in the final Construction Logistics Stakeholder Framework (presented in Figure 10).

Next, the attributed criteria scores where standardized and normalized within the same actor group (rounded up to three decimal spaces), in order to highlight the seven most important criteria for each actor group. It was opted by the researchers to limit the number of ‘most important criteria’ to a maximum of seven in order to keep the pairwise comparison manageable for the participants, following the methodological requirements for criteria definition being non-redundancy, minimality, homogeneity and operationality [

69]. Empty cells indicate that none of the respondents belonging to their respective group have indicated the according criterion to be important in the first place. Each stakeholder group shows a diverse (and sometimes partially overlapping) list of 7 most important criteria per group, which are presented in bold in

Table 4.

5. Analysis and Results

5.1. Criteria Weighting

Once criteria are determined for each stakeholder group, the next step is to allocate weights to these criteria [

59,

60], as not every criterion is equally important for a given stakeholder. This is thus useful in order to show the relative importance of each criterion within the stakeholder group [

67,

95]. Multiple methods exist in order to determine the weights, as is presented in Nijkamp et al., 1990 [

96]. Generally, however, the Analytical Hierarchy Process (AHP) developed by Saaty [

67] is used, as it provides a systematic way to allocate the weights [

68]. Applying the AHP method, the criteria are pairwise compared, matching each criterion one-on-one with the other ones using a nine-point scale, expressing the stakeholders’ preferences. As (sub)groups of stakeholders consisted of different members, common weights for a given stakeholder group were determined through consensus. The relative preferences which are obtained as part of the weight allocation (pairwise comparison using AHP) are organized into a matrix and normalized, which produces a priority vector representing the relative weights on a ratio scale. Although some of the criteria are sometimes considered difficult to evaluate on a 9-point scale, the method of pairwise comparison is better suited in a workshop environment, as this method allows to use theoretically valid weights and is praised by users for its reliability and ease of use [

78]. However, it’s also worth pointing out other methodologies exist and might be more appropriate, depending on the circumstances (number of stakeholder groups and criteria, time and budget constraints, etc.). Determining the criteria from a stakeholder–based perspective has one main advantage. When performing an MCA, the criteria are assumed to be independent or non–redundant.

However, studies show that there often is a certain degree of dependence amongst criteria [

71]. The MAMCA solves this issue by letting the stakeholder determine the weights of the criteria themselves [

60,

72,

73,

74]. In order to keep the process of weighting manageable, also here it is advisable to keep the number of criteria limited, hence complying with the methodological requirements for criteria definition being non-redundancy, minimality, homogeneity and operationality [

69]. It was opted to limit the number of ‘most important criteria’ to a maximum of seven to keep the pairwise comparison manageable for the participants. Future research could explore possibilities to take into consideration larger amounts of criteria, which could presumably render even more detailed results. Furthermore, future research can investigate whether a statistical link or correlation exists between the scores attributed by the individual respondents in the pre-workshop survey compared with the weight allocation of the criteria in each actor group.

Despite the drawbacks, AHP is considered the most appropriate method in a workshop and/or multi-criteria evaluation context which includes subjective criteria, thanks to its ease of use, particularly in a decision-making context on sustainability or energy problems [

75,

76,

77,

78].

Along with steps 5 (evaluation) and 6 (results), steps 3 and 4 (the weighting of different criteria by each stakeholder group and their indicators) has been carried out by means of a half-day workshop in November 2020. During the workshop, the stakeholders allocated the weights to the criteria themselves in their respective stakeholder group using the latest release of the MAMCA software [

97]. The relative preferences were then organized into a matrix and normalized, producing a priority vector representing the relative weights on a ratio scale. The results of the criteria weighting are represented in

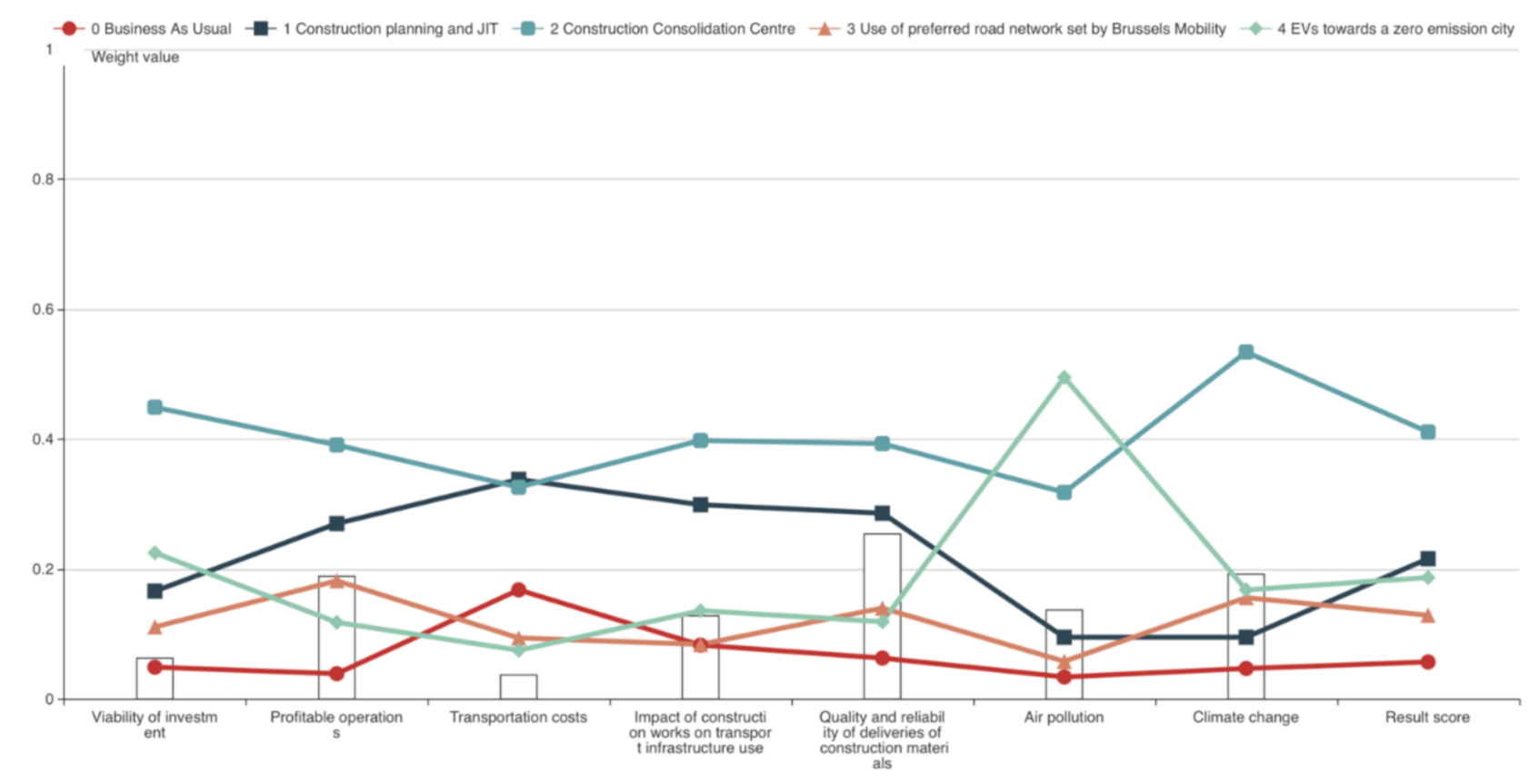

Table 5, and are visually represented in the uni-actor result views in

Figure 4,

Figure 5,

Figure 6 and

Figure 7.

The four highest ranked criteria given in

Group 1 are climate change (0.344), social and economic revitalisation (0.275), air pollution (0.160) and transportation costs (0.107). Especially these ones were consistently ranked higher compared to the other criteria by construction site actors. While air pollution is currently high on the political agenda and is said to play an even more important role in the coming years and decades [

98], the required technology and infrastructure beyond the EURO-6 norm is currently insufficiently ubiquitous, driving up the costs dramatically. These could become more accessible when more CCCs are opened, or electric concrete trucks are imposed (and financially supported). By enforcing its implementation (e.g., by means of taxes on more polluting vehicles), the city could also create a level playing field with more sustainable solutions in terms of incurred costs. A duality presented itself where the city development agency will tighten the environmental requirements in the tendering process for future building projects, while private companies can currently not justify the (too) high price point to make the transport shift to more sustainable solutions like inland waterway and rail transport. Moreover, road freight transport currently remains more flexible compared to alternative transport modes.

Assuming tighter environmental regulations in the (near) future, climate change and air pollution were consistently ranked higher than economic choices (such as quality and reliability of deliveries). Both the public city development agency and the construction firm have the ultimate goal to aim for social and economic revitalisation in the long term, which is measured by economic indicators, hence ranked higher than air pollution, the latter being considered as a short-term objective. Overall, transport costs (0.107) were given a higher score than both adaptation costs (0.049) and quality and reliability of deliveries (0.035). The logic here is that currently multiple workarounds are put in place to limit transport delays: construction firms can either deliver very early or very late to avoid congestion peaks; however, unforeseen circumstances can lead to a drastic increase in transport cost. The same logic goes up when comparing transport costs (0.107) with the quality and reliability of deliveries (0.035), where most often the risk of transport is assessed by the number of flows needed to transport the necessary materials to site, which has a direct impact in transportation costs (one larger truck vs. two smaller trucks for the same quantity of materials). The social and economic revitalisation (0.275) lies at core of the project, and forms an sich a higher importance than the transportation costs alone.

Finally, the transportation costs (0.107) have been assigned a significantly higher score than the diverted traffic due to the construction site (0.029), as this first criterion also often tries to minimize the impact on the surrounding community. The adaptation costs (0.049) follow the same pattern than transport costs when compared to air pollution (0.160), climate change (0.344) and social and economic revitalization (0.275). The private construction firm and the public owner and city developer clearly show a common goal, reflected in the high score attributed to economic and social revitalisation (0.275). The results from the pre-workshop survey also indicate a slight preference from the construction firm to economic criteria, and the city development agency for environmental ones. Interestingly, although the public–private partnership (PPP) has similar ambitions, it seems both parties push each other forward towards both environmental and economic benefits, respectively.

The highest ranked criteria within the group of the logistics service providers and transport companies (Group 2) are the quality and reliability of deliveries of construction materials (0.254), followed by climate change (0.192), profitable operations (0.189), air pollution (0.137) and the impact of construction works on transport infrastructure use (0.128). Quality and reliable deliveries (0.254), along with running profitable operations (0.189) were consistently ranked higher than other economic criteria such as viability of investment (0.063). The large discrepancy between the two criteria is explained by the fact most innovative solutions are or should be initially driven by subsidies. Overall, the quality and reliability of the deliveries (0.254) and running profitable operations (0.189) is key in operating in the business. Next, climate change (0.192) and air pollution (0.137) are top of mind.

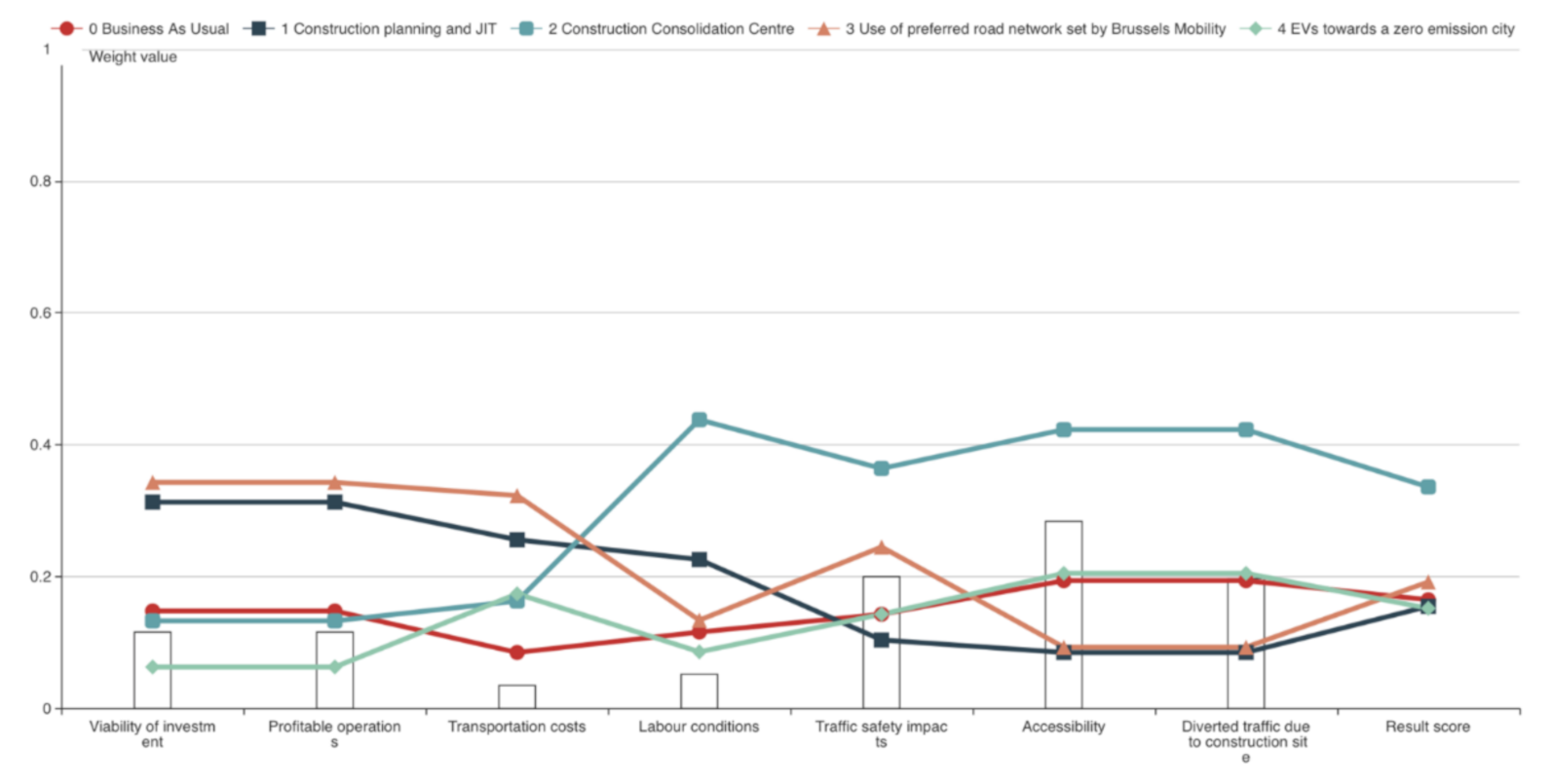

The highest weights in Group 3 (construction (con)federation and research institutes) were allocated to accessibility (0.284), traffic safety impacts (0.200) and diverted traffic due to the construction site (0.197). The economic criteria such as viability of investment (0.116) and profitable operations (0.116) were both similarly compared to the other criteria as they are dependent on societal parameters such as labour conditions (0.052) and the accessibility (0.284) of the site’s surroundings. The general consensus is that all the criteria put forward in this group are often in function of the viability of investment (0.116), even if accessibility was allocated a higher weight due to its overall higher importance (0.284).

While actors in Group 4 (local or regional (mobility) authority and urban planning) show similar goals and ambitions, a noticeable duality existed between the local authorities and more environmental-oriented actors. This discrepancy can mainly be explained by the local authorities aiming to give the criterion climate change (0.237) the highest score in every comparison, while environmental groups nuance this idea by favoring more short-term criteria. This led to a fruitful discussion between actors in the group, and consensus weights with the support of the entire group was found. Overall, criteria representing a long-term impact, such as climate change (0.237), social and economic revitalization (0.200) and air pollution (0.173), were typically given a higher weight compared to criteria that are solely relevant during the construction phase, as reflected in the criteria accessibility (0.064) and the impact on transport infrastructure use (0.055) during the construction activities. Local authorities also placed their long-term policy goals, including healthier and safer environments, higher than the direct ‘popularity’ criteria, such as citizen acceptance (0.044).

5.2. Evaluation

The weighted criteria and the Construction Logistics Scenarios (CLS) were then combined, thereby constructing an evaluation matrix. A multitude of different multi-criteria analysis (MCA) methods are available to evaluate different alternatives, making the MCA methods of the Group Decision Support Methods (GDSM) especially useful to apply in the MAMCA methodology. The main advantage of these GDSM is that they offer a certain freedom to the stakeholders in terms of defining their own criteria, weights and preference structure and only at the end of the analysis the different points of view are being confronted [

60]. These methods entail the PROMETHEE methods [

79,

80], ELECTRE [

81] and AHP [

67]. Most often, the Analytical Hierarchy Process (AHP) is preferred when conducting a MAMCA, which was also opted for in this study. AHP was used to pairwise compare and evaluate the performance of different CLS (presented in

Table 1) on a nine-point scale for each of the seven most important group criteria.

| SG 1: Construction Site |

| Criteria Group | Criterion (Weight) | CLS 0—BAU | CLS 1 | CLS 2 | CLS 3 | CLS 4 |

| Economic | Transportation costs (11%) | 0.188 | 0.421 | 0.030 | 0.182 | 0.179 |

| | Adaptation costs (5%) | 0.146 | 0.491 | 0.040 | 0.190 | 0.132 |

| | Quality and reliability of deliveries of construction materials (4%) | 0.146 | 0.563 | 0.050 | 0.120 | 0.120 |

| Environmental | Air pollution (16%) | 0.035 | 0.098 | 0.151 | 0.116 | 0.601 |

| | Climate change (34%) | 0.044 | 0.109 | 0.292 | 0.182 | 0.373 |

| Societal | Social and economic revitalisation (28%) | 0.200 | 0.200 | 0.200 | 0.200 | 0.200 |

| | Diverted traffic due to construction site (3%) | 0.064 | 0.514 | 0.124 | 0.256 | 0.042 |

| Evaluation score | 0.110 | 0.212 | 0.190 | 0.177 | 0.311 |

The CLS evaluation with criteria weights (represented as white rectangles) for Group 1 is represented in

Figure 4. The implementation of a rigorous planning and Just-In-Time deliveries (CLS 1, 0.212) bears a strong favor compared to BAU (0.110) and other scenarios when it comes to transport costs (0.421), adaptation costs (0.491) and quality and reliability of deliveries (0.563), as this is currently considered to be the most cost-efficient road transport flows. The use of a CCC (CLS 2, 0.190), even combined with a rigorous planning, demands a stronger mental and operational shift as both the incoming and outgoing material flows have various origin and destination points in all directions away from the Brussels-Capital Region (BCR). This would increase overall costs unless the water-bound consolidation centre is located in very close proximity to the construction site, and enough volume can be bundled for other (neighboring) construction sites. Although the construction firm in the pilot case partners with local companies (such as concrete, prefab and reinforced steel suppliers at <0.5 km from the site), other (often rooted) agreements with scattered material manufacturers and regulations pose complications in consolidating goods efficiently. This is especially true for soil and waste flows, where different regulations and prices are in place in the three regions of Belgium: a logistics plan needs to be drawn specifically for these flows, as Flanders, Wallonia and Brussels each have different prices and regulations for the (re)collection of certain compounds. The company thus needs to remove and transport soil and rubble to different locations based on the rules and prices in order. A unified regulatory body and equal pricing would simplify this exercise and potentially optimize the logistics planning. Furthermore, the on-site storage capacity of construction sites outside of the inner Pentagon (Brussels-Capital) is greater than in the city centre.

Although the implementation of an extra party (such as a CCC) gives rise to efficiency gains, often mainly the direct extra incurred costs are associated, rendering BAU more appealing than the CCC scenario. CLS 3 (0.175) is supported, but the participants believe that this should be imposed by the government in order to avoid inner-city traffic and congestion. However, the measure only has an impact on transport costs for construction sites on inner-city roads, and has no to little impact in the rest of the BCR. Analogically with the criteria weighting, the current costs associated with electric (concrete) trucks in CLS 4 (0.315) are currently too high to render the project feasible from a financial point of view. Noticeable however is that the use of EVs on the long-term is considered to be less cost-intensive than the implementation of a CCC. The quality and reliability of deliveries is reliant on the number of transshipments, hence making CLS 1 (JIT) a preferred choice over CLS 2 (CCC).

Regarding environmental criteria (air pollution and climate change), the four alternative scenarios systematically scored better than BAU, with the use of a CCC (CLS 2) and the implementation of electric concrete trucks (CLS 4) showing the greatest discrepancies.

Although social and economic revitalisation has been assigned the second-highest weight, this criterion has been evaluated to have no impact across the different logistics scenarios, as it takes into account the changes after finishing the construction activities. More discrepancies could be visible if the revitalization would also be considered during the construction site activities (e.g., use of silent, zero-exhaust emission electric concrete truck for surrounding community). CLS 1 (0.514) followed by CLS 3 (0.256) offer the best results in terms of limiting the diverted traffic due to the construction site, mainly due to the optimized coordination of transports and traffic situations. Noticeable is that CLS 4 (electric concrete trucks) scores below the BAU.

Overall, the first three criteria, which are economic in nature, score the highest on CLS 1, as these were evaluated based on short-term feasible objectives, albeit with sacrifices in terms of environmental and societal criteria. The consensus within the group highlights the fact that environmental criteria will become more important in the future, and further simulations and incentives need to be implemented as to render mitigating solutions more financially appealing and feasible for private companies.

Also remarkable are the scores of the economic criteria, which are well-below the BAU scenario when compared to CLS 2, 3 and 4. Here, the notion of a centralized bundling hub is still too premature, as subcontractors currently have no contractual obligation whatsoever on how they need to organize and handle their own transport activities.

| SG 2: Construction Logistics |

| Criteria Group | Criterion (Weight) | CLS 0—BAU | CLS 1 | CLS 2 | CLS 3 | CLS 4 |

| Economic | Viability of investment (6%) | 0.049 | 0.166 | 0.449 | 0.111 | 0.225 |

| | Profitable operations (19%) | 0.039 | 0.27 | 0.391 | 0.182 | 0.118 |

| | Transportation costs (4%) | 0.168 | 0.338 | 0.326 | 0.094 | 0.075 |

| | Impact of construction works on transport infrastructure use (13%) | 0.083 | 0.299 | 0.398 | 0.084 | 0.136 |

| | Quality and reliability of deliveries of construction materials (25%) | 0.063 | 0.286 | 0.393 | 0.14 | 0.119 |

| Environmental | Air pollution (14%) | 0.034 | 0.095 | 0.318 | 0.058 | 0.495 |

| | Climate change (19%) | 0.047 | 0.095 | 0.534 | 0.156 | 0.168 |

| Evaluation score | 0.057 | 0.216 | 0.411 | 0.129 | 0.187 |

Figure 5 presents the CLS evaluation for

SG 2 (construction logistics). Both CLS 1 (0.216) and 2 (0.411) consistently score better than BAU (0.057), with a noticeable lead on economic criteria. The logic behind this evaluation is that the JIT scenario (CLS 1) was considered part of CCC (CLS 2): in order to consolidate, a tight and rigorous schedule is needed. The high importance of profitable operations is explained by the fact there first need to be initial investment opportunities in order to tackle greater societal or environmental goals. Even when subsidized, initial partners need to be found to take the risk and keep the business model viable in the first years of the initiative. Transportation costs are managed more efficiently in scenarios where a rigorous planning is present (CLS 1; 0.0.338, CLS 2; 0.326). Noticeable here is that the BAU scenario (CLS 0; 0.168) is preferred over CLS 3 (0.094) and CLS 4 (0.075). The rationale behind these figures is that the use of a preferred road network will engender more detours and more costs related to the transport movement compared to BAU. This is even further pronounced in CLS 4 when electric concrete trucks are deployed.

The same logic can be applied to the remaining economic criteria where especially CLS 1 and CLS 2 are preferred when it comes to the impact of construction works on transport infrastructure use (CLS 1, 0.299; CLS 2, 0.398) and the quality and reliability of deliveries of construction materials (CLS 1, 0.286; CLS 2, 0.393) are scored higher. The use of a CCC here reduces the number of vehicle-kilometres and is thus a more favorable choice.

The environmental criteria indicate a preference for the implementation of electric concrete trucks (especially for air pollution) and the use of a CCC (especially for climate change).

Overall, the most popular solution across the board is the use of a Construction Consolidation Centre (CLS 2), followed by a rigorous planning and JIT deliveries (CLS 1). Both solutions are similar and CLS 2 comprises CLS 1 in the sense that a rigorous planning is inherent to the consolidation of materials.

| SG 3: Construction (Con)Federation & Research Institutes |

| Criteria Group | Criterion (Weight) | CLS 0—BAU | CLS 1 | CLS 2 | CLS 3 | CLS 4 |

| Economic | Viability of investment (12%) | 0.148 | 0.313 | 0.133 | 0.343 | 0.063 |

| | Profitable operations (12%) | 0.148 | 0.313 | 0.133 | 0.343 | 0.063 |

| | Transportation costs (4%) | 0.085 | 0.256 | 0.163 | 0.323 | 0.174 |

| Societal | Labour conditions (5%) | 0.116 | 0.226 | 0.438 | 0.134 | 0.086 |

| | Traffic safety impacts (20%) | 0.143 | 0.104 | 0.364 | 0.245 | 0.143 |

| | Accessibility (28%) | 0.194 | 0.085 | 0.423 | 0.093 | 0.205 |

| | Diverted traffic due to construction site (20%) | 0.194 | 0.085 | 0.423 | 0.093 | 0.205 |

| Evaluation score | 0.165 | 0.155 | 0.336 | 0.192 | 0.152 |

Analogically with the criteria weight allocation, the participants of

SG 3 (construction federations and research institutes) did not express much of a preference across the evaluation of CLS, such that the highest preference noted is 4 (moderately important) out of a nine-point scale. Its results can be found in

Figure 6. Mutual consensus is found on the implementation of a CCC as is described in CLS 2. Noticeable is that the (gradual) implementation of electric vehicles (starting with concrete trucks) (CLS 4) closely follows the BAU evaluation, caused by the higher investment requirements and little difference it makes on some of the criteria within this group.

Transportation costs are argued to be higher in CLS 1 due to the JIT deliveries, which typically cause less optimized loading rates and more transport movements, making it less cost-efficient compared to other solutions where the elements of bundling and consolidating are present.

Overall, CLS 2 (CCC) is strongly favored over other solutions on the most impactful criteria put forward by the SG. In theory, the use of a CCC would benefit labour conditions (0.438), traffic safety (0.364), accessibility (0.423) and decrease diverted traffic (0.423) the most. However, it is noted is all comes down to the practical implementation of such a centre. These same criteria also score lower in CLS 1 and CLS 3 compared to BAU. Here again, it is argued that the current road network implementations are far from being optimized, often leading to inefficiencies in terms of road safety and accessibility on the current BCR road network.

| SG 4: Local or Regional (Urban Mobility) Authority & Urban Planning |

| Criteria Group | Criterion (Weight) | CLS 0—BAU | CLS 1 | CLS 2 | CLS 3 | CLS 4 |

| Economic | Impact of construction works on transport infrastructure use (5%) | 0.039 | 0.137 | 0.516 | 0.089 | 0.218 |

| Environmental | Air pollution (17%) | 0.048 | 0.100 | 0.504 | 0.071 | 0.278 |

| | Climate change (24%) | 0.068 | 0.090 | 0.378 | 0.073 | 0.392 |

| Societal | Social and political acceptance by citizens of impacts generated (4%) | 0.058 | 0.095 | 0.436 | 0.138 | 0.272 |

| | Social and economic revitalisation (20%) | 0.070 | 0.113 | 0.317 | 0.219 | 0.281 |

| | Traffic safety impacts (23%) | 0.062 | 0.091 | 0.444 | 0.208 | 0.195 |

| | Accessibility (6%) | 0.056 | 0.097 | 0.398 | 0.225 | 0.225 |

| Evaluation score | 0.061 | 0.100 | 0.414 | 0.146 | 0.280 |

The results of SG 4 (Local or regional authority and urban planning) are represented in

Figure 7. Overall, the implementation of a Construction Consolidation Centre (CCC) (0.414) is considered as the most efficient use of existing transport infrastructure (0.516), as it offers better distribution across modes and the use of otherwise underutilized transport infrastructure. By pushing transport flows off the road towards inland waterways causes less impact of the road infrastructure, the CCC scenario offers greater efficiency, also when compared to the implementation of electric concrete trucks (CLS 4; 0.218). CLS 1 (0.137) and CLS 4 (0.218) are runners-up for this criterion, mainly because it was argued that JIT deliveries and the bundling aspect are also elements that are present in CLS 2. A distinction is made when comparing the individual use case vs. a city-wide implementation of scenarios: for this specific pilot case, it is argued that the most optimal solution would be JIT delivery (especially when compared to CLS 3; 0.089).

However, for city-wide rollout of measures, the preferred road network could be favored, as it would restrict more inner-city transport movements in time and space. Hence, the preferred road network (CLS 3) inspired by the mobility and logistics plans of the Brussels-Capital Region aims to reduce traffic accidents and aims for a more intelligent distribution of space for all road users (trucks, bicycles etc.). Thus, the emphasis of this plan is not on the impact of transport infrastructure use. From a public authority point of view, more significance was given to CLS 4 (0.280) compared to CLS 1 (0.100), mainly to reach long-term ambitions. The criterion traffic safety impacts was evaluated accordingly, with the most preferential scenario being the implementation of a CCC (CLS 2; 0.444) because of the reduction in vehicles movements on the road. The preferred road network ranks second (CLS 3; 0.208), as it is noted that, although of major importance within the rollout of the plan, the plan can only be truly effective if every street in the Brussels-Capital Region undergoes refurbishments. CLS 4 (0.195) scores almost identically to the previous one on this criterion, as it is assumed electric vehicles will entail technological advancements (such as bigger windows, reduced blind angles and improved sensors).

Environmental criteria (air pollution and climate change) were similarly evaluated. Air pollution and climate change are high on the political agenda, and it was noted that measures to improve these criteria should be a mitigating element in whichever scenario was implemented. However, it was found difficult to evaluate these elements, because of a general lack of data and figures in the sector and missing rigorous impact assessments on innovative construction logistics solutions.

The social and political acceptance is weighted less high than all the other criteria across the board (4%), and this low importance attribution is also translated throughout the scenario evaluation. The acceptance of citizens on certain scenarios can potentially be perceived by the population, although they typically do not have an overview of the entire process. Here again, the greatest difference is found with the implementation of a CCC (0.436), taking trucks of the road. The social and economic revitalisation was found to be a hard criterion to measure on the long-term. The assumption of alternative scenarios, such as the preferred road network of the government could entice individuals and companies to use alternative modes of road transport, such as cargo bikes, in the assumption it becomes safer for their employees. Therefore, CLS 2, 3 and 4 are scored similarly in this regard.

Overall, CLS 2 (CCC) scores higher than other solutions across almost any criterion. In this group, the use case was taken as an example, but the idea of using a CCC for the delivery of construction materials was perceived for the entire city. Because of the reduction of both environmental and societal impact through this solution, it is a preferred choice within this actor group.

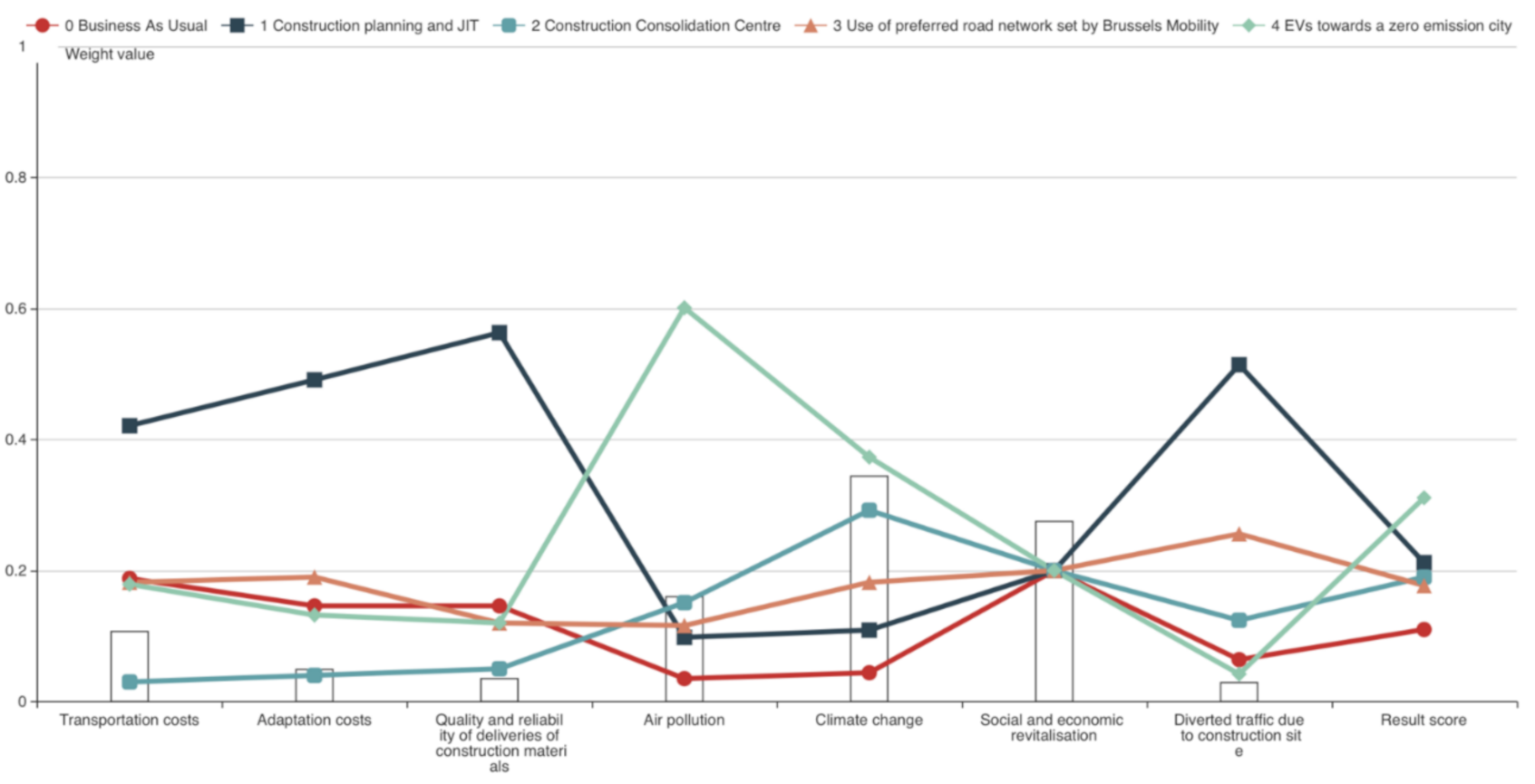

5.3. Results

The final step proposes the output, which consists of an overview of the advantages and disadvantages of the different scenarios for the stakeholders that are involved. By evaluating all points of view, the framework enables the decision-making process to be enhanced and ultimately to deploy scenarios that are carried by the majority of stakeholders.

| Scenario | SG 1 | SG 2 | SG 3 | SG 4 |

| CLS 0: Business As Usual | 0.110 | 0.057 | 0.165 | 0.061 |

| CLS 1: Construction planning and JIT | 0.212 | 0.216 | 0.155 | 0.100 |

| CLS 2: Construction Consolidation Centre | 0.190 | 0.411 | 0.336 | 0.414 |

| CLS 3: Use of preferred road network set by Brussels Mobility | 0.177 | 0.129 | 0.192 | 0.146 |

| CLS 4: EVs towards a zero-emission city | 0.311 | 0.187 | 0.152 | 0.280 |

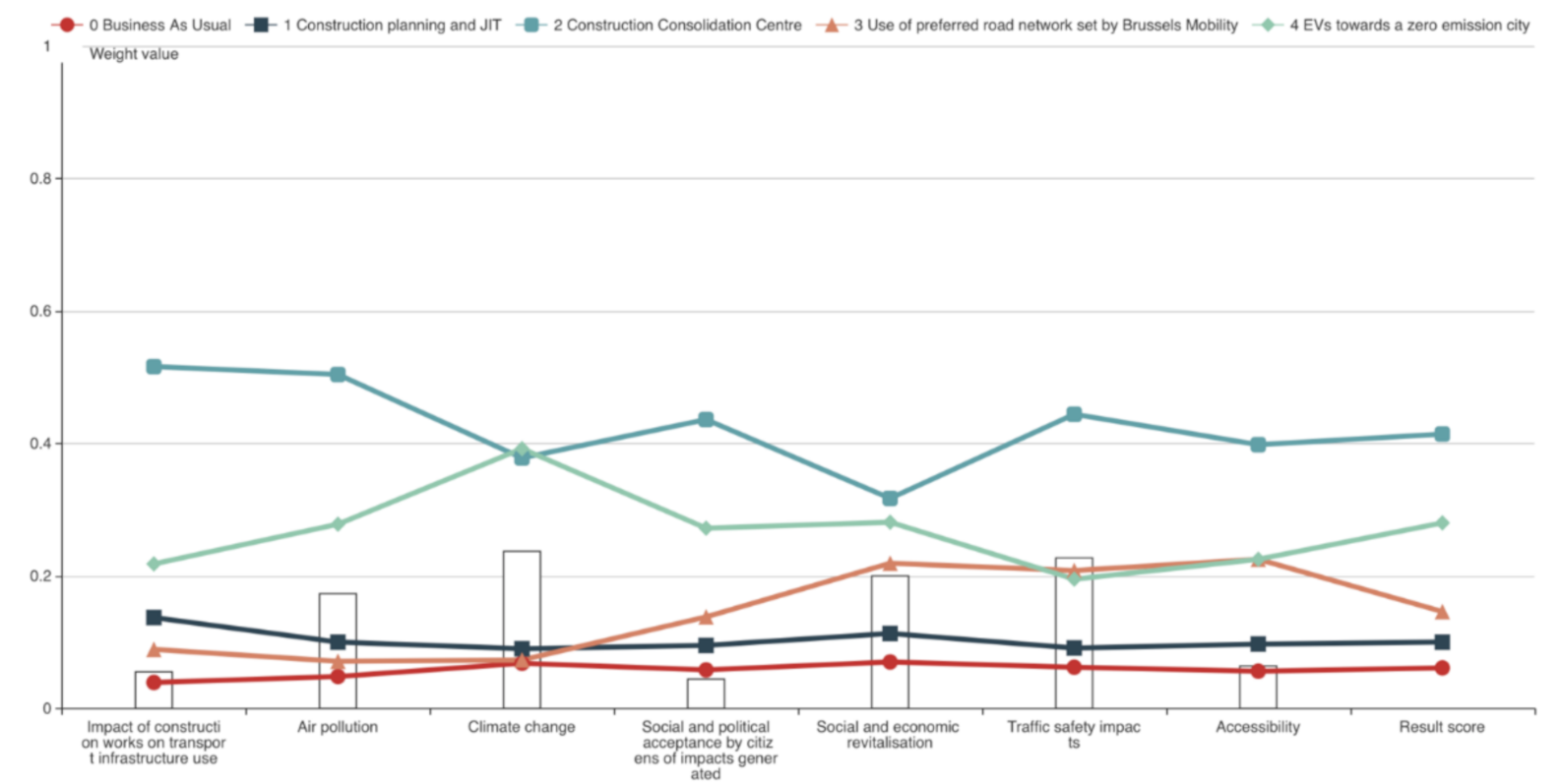

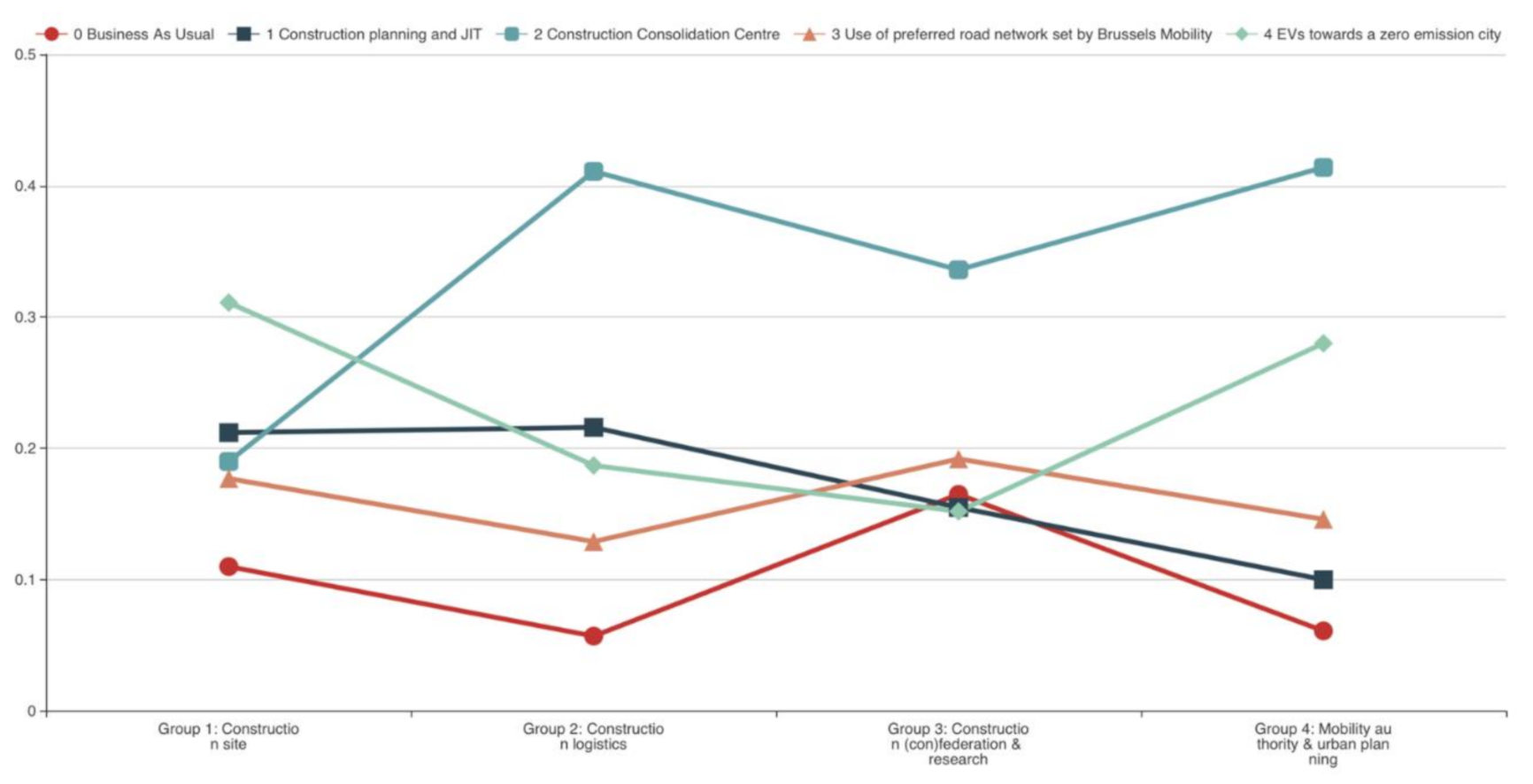

As presented in

Figure 8, the use case of the City Campus construction site in the Brussels-Capital Region (BCR) first and foremost highlights an overall favor for the Construction Consolidation Centre (CCC) solution, in particular for the construction logistics (SG 2, 0.411), (con)federation and research’s (SG 3, 0.336) and authorities’ groups (SG 4, 0.414). The site owner, developer and construction company (SG 1, 0.190) are ranking the CCC solution, as it exists now, lower than most of its alternatives. This is mainly due to the additional handling costs and increased damage risk due to additional transshipment in the CCC scenario.

First, inland waterway and rail transport are still not the main way of operating for (sub)contractors nowadays. Although the implementation of an extra party (such as a water-bound CCC and transshipment area) gives rise to efficiency gains, often a rise in direct extra incurred costs are associated, rendering BAU more appealing on economic criteria than the CCC scenario on the short-term. Nevertheless, the costs engendered are typically not much higher compared to the traditional full-road supply chain on the long-term: as argued by the logistics service providers, although there is a break-even distance to be filled in order to meet a level playing field amongst different transport modes, often a great hurdle of the modal shift is its mental shift. However, the environmental and societal scores attributed by Group 1 conclude that this group evaluates the CCC as a good environmental solution, hence scoring higher than BAU in the overall evaluation. This uncovers more about the relationship between the different business models. Today, there is a lack of knowledge on how to adjust operations to the structure of such a CCC or construction hub setup. Often, there is no contractual obligation as to how subcontractors handle their transport activities and operations, allowing the truck to maintain its leading position because of is accessibility and flexibility.

Since 2020, a CCC was set up in Brussels at the Northern Quarter of the city. The Brussels Construction Consolidation Centre is said to be especially useful to bring in materials by barge into the heart of the BCR and City of Brussels, and to then consolidate and distribute these efficiently in the dense City of Brussels (Inner Pentagon). In contrast, this current location has little advantages if the construction site is located inside the densely populated Brussels-Capital Region (outer ring), but outside the very dense city limits of the City of Brussels (inner ring), as these sites often come with more (although still limited) on-site storage capacity, and are located closer to major road axes. Future research could therefore investigate the feasibility of supplying larger geographical areas by implementing further bundling options on the main entry points of the city. Also, further marketing efforts are needed to convince the construction site, subcontractors on the CCC solution, on which the authorities already seem to be aligned.

Overall, the Business-As-Usual is considered suboptimal across all actor groups. Noticeable is how close CLS 1 (0.155), 3 (0.192) and 4 (0.152) are to BAU (0.165) for SG 3. This is due to (1) the high valuation of economic and societal criteria of this group, and the nature of the heavy initial investments that go along with the acquisition of electric vehicles, and (2) the basic bottlenecks in the current basic road network in the BCR which have an immediate impact on congestion and accessibility, and which should first be addressed before adding extra implementation layers or taxes. IWT strongly reduces the use of the heavily congested road network [

99,

100], making the water-bound CCC the most favorable solution for material distribution in the BCR (0.336).

The presented scenarios in this workshop contained overlapping measures, but both a single action and a combination of measures could have side effects. Examples include that if authorities would impose the use of electric vehicles, the assumption is that traffic safety would be improved due to technological advancements of a new and enhanced vehicle fleets (larger windows and less blind angles). Combined with governmental measures aiming for more traffic safety and enticing other means of road transport, this increased safety for workers could be a convincing factor for companies to invest in cargo bikes for smaller deliveries in proximity to the site. Further environmental benefits could be achieved when the element of bundling or consolidation is coupled with the gradual phase-out out of combustion engines. At the same time however, it is expected that the use of EVs will engender more individual transport movements due to their limited driving radius. These results thus suggest that solutions should be analyzed and simulated before implementation, as to have an integrated overview of the environmental and societal impact of different hybrid solutions. Mostly a combination of measures or hybrid scenarios will be optimal for implementation and taking into consideration all stakeholder views, as every evaluated scenario has its own advantages and disadvantages.

An overview of the results of the implementation case are presented in

Figure 9, and encompass the scenario evaluation for the four main stakeholder groups, as well are their respective most important weighted criteria.

6. Discussion

The developed framework provided insights on how cities and stakeholders can act towards the reduction of multi-dimensional impacts, contributing to a more sustainable construction logistics supply chain. Adapted from the Multi-Actor Multi-Criteria Analysis (MAMCA) developed by Macharis [

28], the framework mathematically underpins stakeholders’ preferences and improves the group decision-making process in a multi-actor, multi-criteria construction logistics governance setting. The use case in the BCR evidences how different processes are site-, actor- and condition-specific, thereby delivering a common built object. Often however, although facing the same result, different motivations and concerns are at play.

Studies so far have failed to accurately evaluate (1) the true share of construction logistics in total urban traffic and (2) the magnitude of the sector’s external costs, because of a general lack of figures in the sector and construction logistics solutions [

8]. The highest transport external costs on the political agenda are air pollution, climate change, traffic safety and congestion, as also highlighted in the Brussels mobility and logistics plan [

101]. Omnipresent in this workshop is the notion that these external effects should be a mitigating element across all future logistics scenarios implemented in the sector and are planned to be enforced in future tendering and policy regulations. The city development agency already stated that it will adjust future tendering procedures to be stricter in the construction logistics handling. This could come in the form of an environmental score for air pollution, climate change, congestion, traffic safety etc. While such enforcements will initially go along with a price increase, it is also expected to reduce overall construction-related costs upon and after completion of the construction site (Cfr.

economic and social revitalisation). There is however an overall consensus across the stakeholder groups that environmental criteria will become more important in the future, and further simulations and incentives need to be implemented as to render mitigating solutions more financially appealing and feasible for private companies.

Currently two separate measures are in place to reduce or contain negative externalities, in particular for air pollution levels, in the Brussels-Capital Region (BCR). A first one is the kilometre charge, which is mandatory for road vehicles with a maximal authorized mass higher than 3.5t [