A Systematic Review on Social Sustainability of Artificial Intelligence in Product Design

Abstract

1. Introduction

2. Literature Review

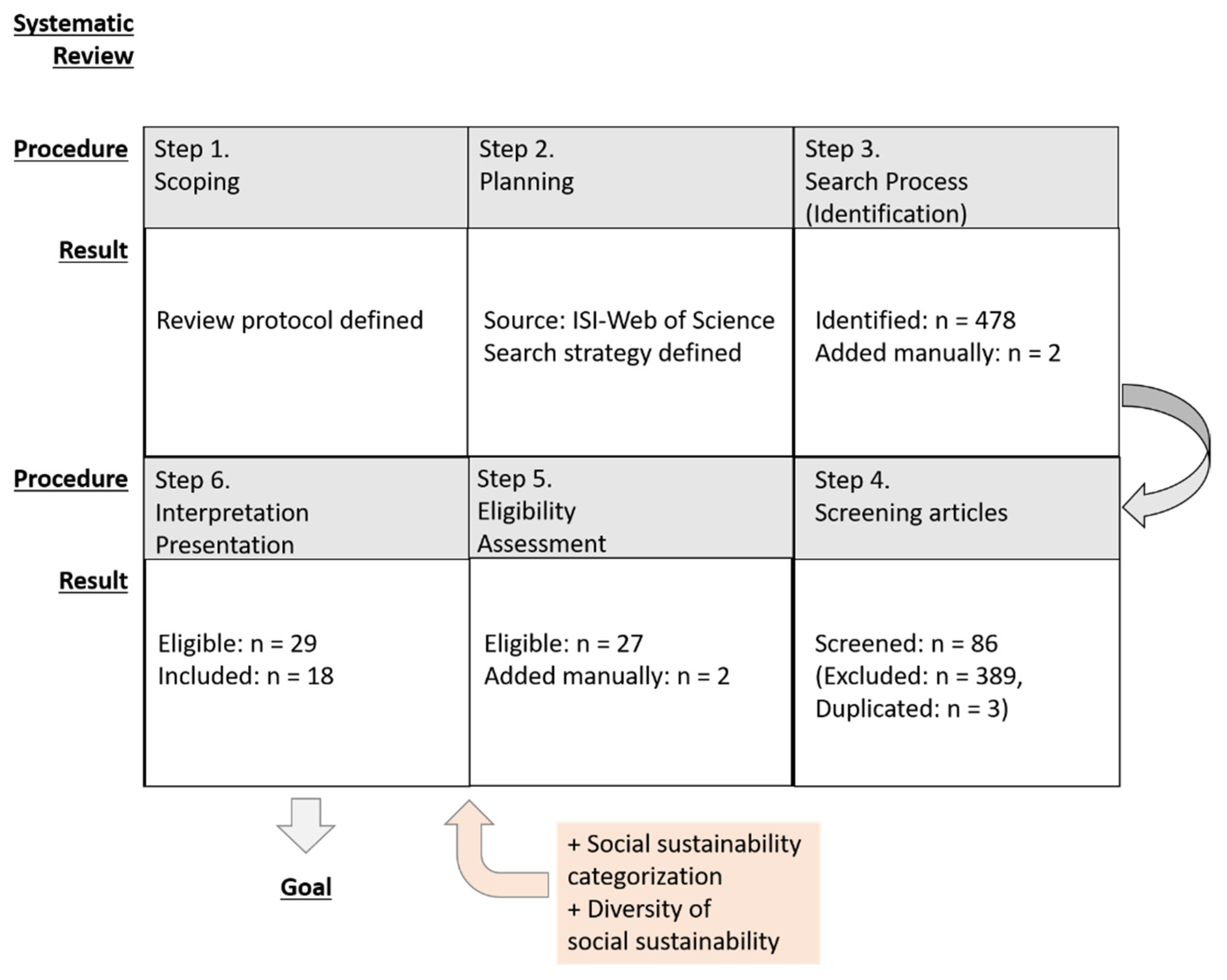

3. Methodology

4. Results

4.1. Contexts

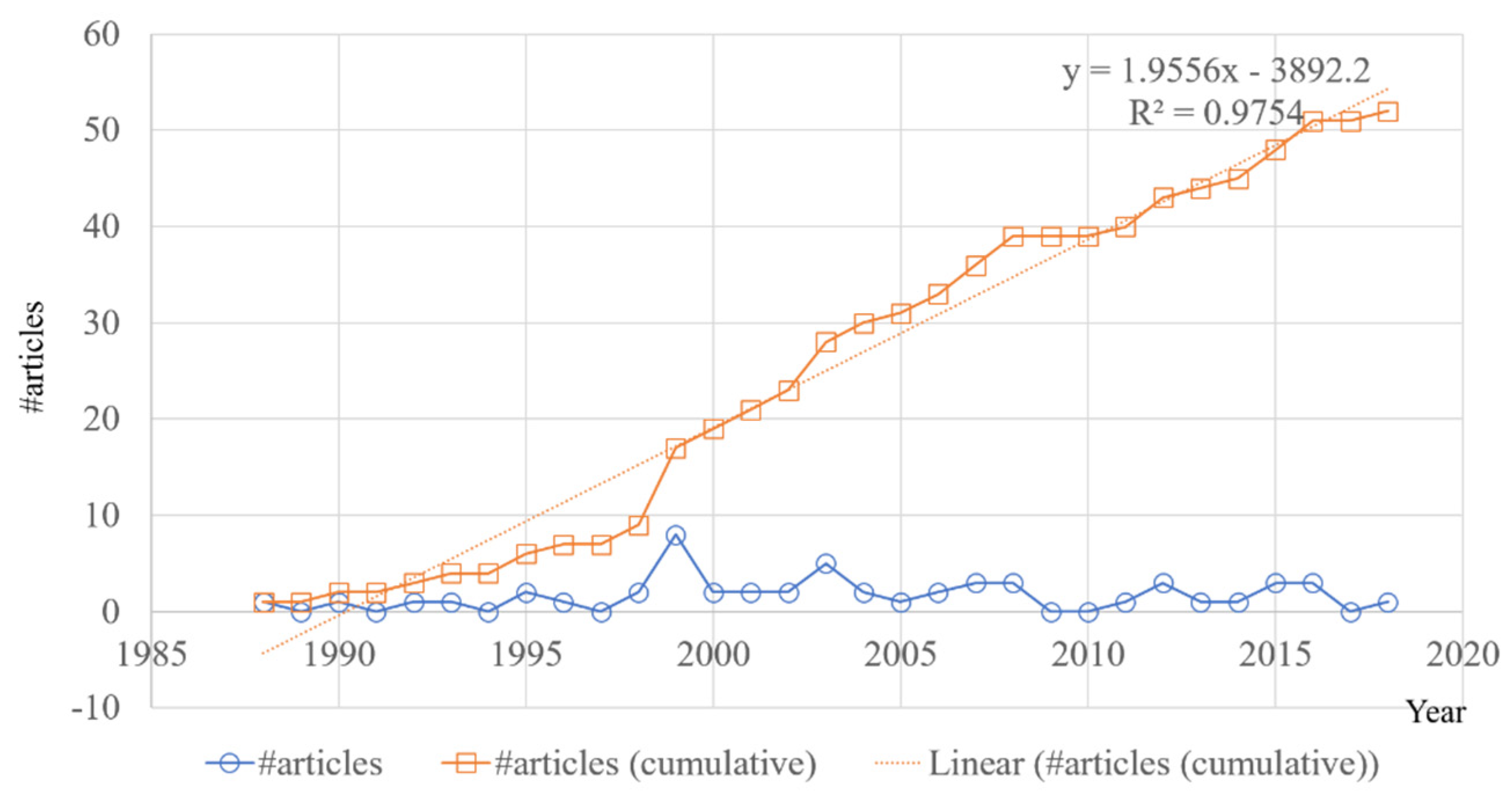

4.1.1. Thematic Context of Social Sustainability in Artificial Intelligence in Product Design

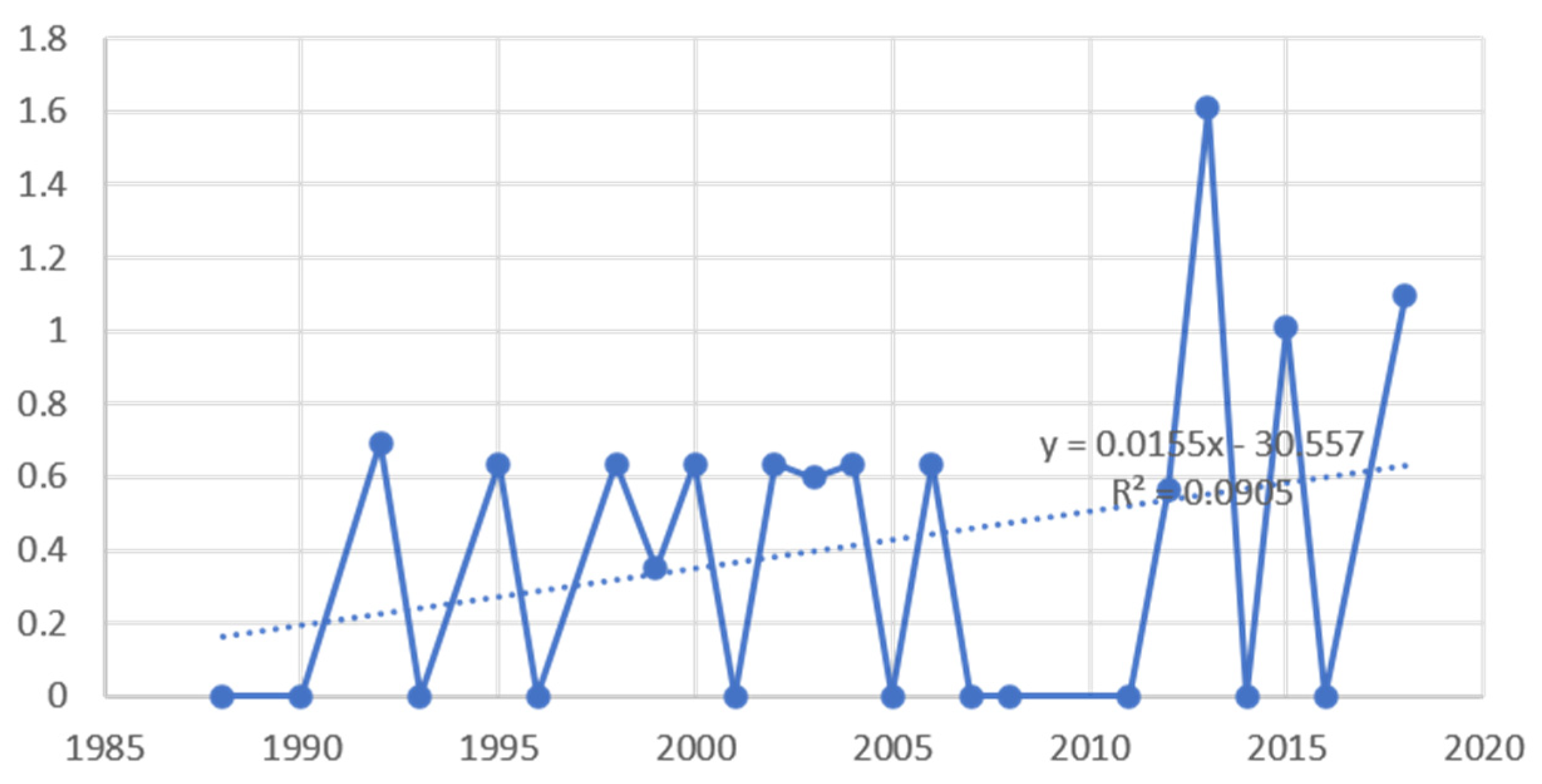

4.1.2. Scientific Contexts of Social Sustainability in Artificial Intelligence in Product Design

4.2. Social Sustainablity Categorization

4.2.1. Skewness to the Development Social Sustainability

4.2.2. The Small Rise of Social Sustainability

4.2.3. Necessary Social Sustainability Diversity

4.3. Content Analysis

4.3.1. Big Data and Artificial Intelligence

4.3.2. Bridge Social Sustainability by Considering Product Life Cycle

4.3.3. Maintenance Social Sustainability by Supporting Meeting Demand Preference

5. Discussion

5.1. More Than Economic and Environmental Sustainability

5.2. Diversity and Harmony

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of the 21st Century; New Society Publishers: Hamilton, ON, Canada, 1998. [Google Scholar]

- Kleindorfer, P.R.; Singhal, K.; Van Wassenhove, L.N. Sustainable Operations Management. Prod. Oper. Manag. 2009, 14, 482–492. [Google Scholar] [CrossRef]

- Cruz, J.M. Wakolbinger, Multiperiod effects of corporate social responsibility on supply chain networks, transaction costs, emissions, and risk. Int. J. Prod. Econ. 2008, 116, 61–74. [Google Scholar] [CrossRef]

- Bae, J.K.; Kim, J. Product development with data mining techniques: A case on design of digital camera. Exp. Syst. Appl. 2011, 38, 9274–9280. [Google Scholar] [CrossRef]

- Zhan, Y.; Tan, K.H.; Huo, B. Bridging customer knowledge to innovative product development: A data mining approach. Int. J. Prod. Res. 2019, 57, 6335–6350. [Google Scholar] [CrossRef]

- Chiner, M. Planning of expert systems for materials selection. Mater. Des. 1988, 9, 195–203. [Google Scholar] [CrossRef]

- Wang, X.; Chan, H.K.; White, L. A comprehensive decision support model for the evaluation of eco-designs. J. Oper. Res. Soc. 2014, 65, 917–934. [Google Scholar] [CrossRef]

- Zhu, J.; Deshmukh, A. Application of Bayesian decision networks to life cycle engineering in Green design and manufacturing. Eng. Appl. Artif. Intell. 2003, 16, 91–103. [Google Scholar] [CrossRef]

- Wang, X.; Chan, H.K.; Li, D. A case study of an integrated fuzzy methodology for green product development. Eur. J. Oper. Res. 2015, 241, 212–223. [Google Scholar] [CrossRef]

- Corsini, L.; Moultrie, J. Design for Social Sustainability: Using Digital Fabrication in the Humanitarian and Development Sector. Sustainability 2019, 11, 3562. [Google Scholar] [CrossRef]

- Er, Ö.; Kaya, Ç. Problems or Opportunities?: Overcoming the Mental Barrier for Socially Responsible Design in Turkey. Des. J. 2008, 11, 159–181. [Google Scholar] [CrossRef]

- Sklar, A.; Madsen, S. Global Ergonomics: Design for Social Impact. Ergon. Des. Q. Hum. Factors Appl. 2010, 18, 4–31. [Google Scholar] [CrossRef]

- Remmen, A. Life Cycle Management: A Business Guide to Sustainability; Technical Report; UNEP/Earthprint: Paris, France, 2007. [Google Scholar]

- Hutchins, M.J.; Sutherland, J.W. An exploration of measures of social sustainability and their application to supply chain decisions. J. Clean. Prod. 2008, 16, 1688–1698. [Google Scholar] [CrossRef]

- Zhou, Z.; Cheng, S.; Hua, B. Supply chain optimization of continuous process industries with sustainability consid-erations. Comput. Chem. Eng. 2000, 24, 1151–1158. [Google Scholar] [CrossRef]

- Koutsos, T.M.; Menexes, G.C.; Dordas, C.A.; Thomas, K.M.; Georgios, M.C. An efficient framework for conducting systematic literature reviews in agricultural sciences. Sci. Total. Environ. 2019, 682, 106–117. [Google Scholar] [CrossRef] [PubMed]

- Vallance, S.; Perkins, H.C.; Dixon, J.E. What is social sustainability? A clarification of concepts. Geoforum 2011, 42, 342–348. [Google Scholar] [CrossRef]

- Minsky, M. Steps toward Artificial Intelligence. Proc. IRE 1961, 49, 8–30. [Google Scholar] [CrossRef]

- Marr, D. Artificial intelligence—A personal view. Artificial Intell. 1977, 9, 37–48. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Hughes, L.; Ismagilova, E.; Aarts, G.; Coombs, C.; Crick, T.; Duan, Y.; Dwivedi, R.; Edwards, J.; Eirug, A.; et al. Artificial Intelligence (AI): Multidisciplinary perspectives on emerging challenges, opportunities, and agenda for research, practice and policy. Int. J. Inf. Manag. 2021, 57, 101994. [Google Scholar] [CrossRef]

- Rao, S.S.; Nahm, A.; Shi, Z.; Deng, X. Artificial intelligence and expert systems applications in new product development—A survey. J. Intell. Manuf. 1999, 10, 231–244. [Google Scholar] [CrossRef]

- Santillan-Gutierrez, S.D.; Wright, I.C. Solution Clustering with Genetic Algorithms and DFA: An Experimental Approach. In AI System Support for Conceptual Design; Springer: London, UK, 1996; pp. 37–53. [Google Scholar]

- Hewitt, C.; Planner, A. Language for proving theorems in robots. In Proceedings of the IJCAI, London, UK, 1–3 September 1971; Volume 2. [Google Scholar]

- Newell, A.; Simon, H.A. Computer science as empirical inquiry: Symbols and search. ACM Turing Award Lect. 2011, 19, 1975. [Google Scholar] [CrossRef]

- David, J.-M.; Krivine, J.-P.; Simmons, R. Second Generation Expert Systems: A Step Forward in Knowledge Engineering. In Second Generation Expert Systems; Springer International Publishing: Berlin, Germany, 1993; pp. 3–23. [Google Scholar]

- Hayes-Roth, F.; Lesser, V. Focus of Attention in the Hearsay-II Speech Understanding System; Defense Technical Information Center (DTIC): Fort Belvoir, VA, USA, 1977. [Google Scholar]

- Engelberger, J.F. Robotics in Practice; Kogan Page: London, UK, 1983. [Google Scholar]

- Minsky, M. A Framework for Representing Knowledge; Reprinted in The Psychology of Computer Vision; Winston, P., Ed.; McGraw Hill: New York, NY, USA, 1975. [Google Scholar]

- Smith, R.G.; Mitchell, T.M.; Chestek, R.A.; Buchanan, B.G. A Model for Learning Systems; Defense Technical Information Center (DTIC): Fort Belvoir, VI, USA, 1977. [Google Scholar]

- Holland, J. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Application to Biology, Control and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1975. [Google Scholar]

- Selfridge, O. Pandemonium: A Paradigm for Learning. In Proceedings of the Mechanization of Thought Processes, National Physics Laboratory, Teddington, UK, 24–27 November 1959. [Google Scholar]

- Hammond, K.J. CHEF: A model of case-based planning. In Proceedings of the AAAI, Philadelphia, PA, USA, 11–15 August 1986; pp. 267–271. [Google Scholar]

- Pawlak, Z.; Grzymala-Busse, J.; Slowinski, R.; Ziarko, W. Rough sets. Commun. ACM 1995, 38, 88–95. [Google Scholar] [CrossRef]

- Maes, P. Artificial life meets entertainment: Lifelike autonomous agents. Commun. ACM 1995, 38, 108–114. [Google Scholar] [CrossRef]

- Saridakis, K.M.; Dentsoras, A.J. Soft computing in engineering design–A review. Adv. Eng. Inf. 2008, 22, 202–221. [Google Scholar] [CrossRef]

- Nishant, R.; Kennedy, M.; Corbett, J. Artificial intelligence for sustainability: Challenges, opportunities, and a research agenda. Int. J. Inf. Manag. 2020, 53, 102104. [Google Scholar] [CrossRef]

- Sachs, J.D.; Schmidt-Traub, G.; Mazzucato, M.; Messner, D.; Nakicenovic, N.; Rockström, J. Six Transformations to achieve the Sustainable Development Goals. Nat. Sustain. 2019, 2, 805–814. [Google Scholar] [CrossRef]

- Vinuesa, R.; Azizpour, H.; Leite, I.; Balaam, M.; Dignum, V.; Domisch, S.; Nerini, F.F. The role of artificial intelligence in achieving the Sustainable Development Goals. Nat. Commun. 2020, 11, 1–10. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. Artificial Intelligence, Automation and Work; National Bureau of Economic Research: Cambridge, MA, USA, 2018. [Google Scholar] [CrossRef]

- Anthony, L.F.W.; Kanding, B.; Selvan, R. Carbontracker: Tracking and predicting the carbon footprint of training deep learning models. arXiv 2020, arXiv:2007.03051. [Google Scholar]

- Norouzzadeh, M.S.; Nguyen, A.; Kosmala, M.; Swanson, A.; Palmer, M.S.; Packer, C.; Clune, J. Automatically identifying, counting, and describing wild animals in camera-trap images with deep learning. Proc. Natl. Acad. Sci. USA 2018, 115, E5716–E5725. [Google Scholar] [CrossRef] [PubMed]

- Bolukbasi, T.; Chang, K.W.; Zou, J.Y.; Saligrama, V.; Kalai, A.T. Man is to computer programmer as woman is to homemaker? debiasing word embeddings. Adv. Neural Inf. Process. Syst. 2016, 29, 4349–4357. [Google Scholar]

- Nissim, M.; van Noord, R.; van der Goot, R. Fair is better than sensational: Man is to doctor as woman is to doctor. Comput. Linguist. 2020. [Google Scholar] [CrossRef]

- Khakurel, J.; Penzenstadler, B.; Porras, J.; Knutas, A.; Zhang, W. The Rise of Artificial Intelligence under the Lens of Sustainability. Technol. 2018, 6, 100. [Google Scholar] [CrossRef]

- Lahsen, M. Should AI be Designed to Save Us From Ourselves?: Artificial Intelligence for Sustainability. IEEE Technol. Soc. Mag. 2020, 39, 60–67. [Google Scholar] [CrossRef]

- Khakurel, J.; Melkas, H.; Porras, J. Tapping into the wearable device revolution in the work environment: A systematic review. Information Technol. People 2018. [Google Scholar] [CrossRef]

- Serholt, S.; Barendregt, W.; Vasalou, A.; Alves-Oliveira, P.; Jones, A.; Petisca, S.; Paiva, A. The case of classroom robots: Teachers’ deliberations on the ethical tensions. AI Soc. 2017, 32, 613–631. [Google Scholar] [CrossRef]

- Wisskirchen, G.; Biacabe, B.T.; Bormann, U.; Muntz, A.; Niehaus, G.; Soler, G.J.; von Brauchitsch, B. Artificial Intelligence and Robotics and Their Impact on the Workplace; IBA Global Employment Institute: London, UK, 2017; Volume 11, pp. 49–67. [Google Scholar]

- Zhao, R.; Liao, W.; Zou, B.; Chen, Z.; Li, S. Weakly-supervised simultaneous evidence identification and seg-mentation for automated glaucoma diagnosis. In Proceedings of the AAAI Conference on Artificial Intelligence, Honolulu, Hawaii, 27 January–1 February 2019; Volume 33, pp. 809–816. [Google Scholar]

- Wang, K.; Su, Z. Automated geometry theorem proving for human-readable proofs. In Proceedings of the Twenty-Fourth International Joint Conference on Artificial Intelligence, Buenos Aires, Argentina, 15–25 August 2015. [Google Scholar]

- Yano, K. How artificial intelligence will change HR. People Strategy 2017, 40, 42–47. [Google Scholar]

- Kirkpatrick, K. AI in contact centers. Commun. ACM 2017, 60, 18–19. [Google Scholar] [CrossRef]

- Lebeuf, C.; Storey, M.-A.; Zagalsky, A. Software Bots. IEEE Softw. 2018, 35, 18–23. [Google Scholar] [CrossRef]

- Borenstein, J.; Arkin, R.C. Nudging for good: Robots and the ethical appropriateness of nurturing empathy and charitable behavior. AI Soc. 2017, 32, 499–507. [Google Scholar] [CrossRef]

- Blei, D.M. Probabilistic topic models. Commun. ACM 2012, 55, 77–84. [Google Scholar] [CrossRef]

- Blei, D.M.; Ng, A.Y.; Jordan, M.I. Latent Dirichlet allocation. J. Mach. Learn. Res. 2003, 3, 993–1022. [Google Scholar]

- Amado, A.; Cortez, P.; Rita, P.; Moro, S. Research trends on Big Data in Marketing: A text mining and topic modeling based literature analysis. Eur. Res. Manag. Bus. Econ. 2018, 24, 1–7. [Google Scholar] [CrossRef]

- Moro, S.; Cortez, P.; Rita, P. Business intelligence in banking: A literature analysis from 2002 to 2013 using text mining and latent Dirichlet allocation. Expert Syst. Appl. 2015, 42, 1314–1324. [Google Scholar] [CrossRef]

- Lee, K.; Jung, H.; Song, M. Subject–method topic network analysis in communication studies. Science 2016, 109, 1761–1787. [Google Scholar] [CrossRef]

- Song, M.; Kim, S.; Lee, K. Ensemble analysis of topical journal ranking in bioinformatics. J. Assoc. Inf. Sci. Technol. 2017, 68, 1564–1583. [Google Scholar] [CrossRef]

- Fortunato, S.; Bergstrom, C.T.; Börner, K.; Evans, J.A.; Helbing, D.; Milojević, S.; Barabási, A.L. Science of science. Science 2018, 359. [Google Scholar] [CrossRef]

- Mingers, J.; Leydesdorff, L. A review of theory and practice in scientometrics. Eur. J. Oper. Res. 2015, 246, 1–19. [Google Scholar] [CrossRef]

- Nalimov, V.V.; Mulʹchenko, Z.M. Measurement of Science. Study of the Development of Science as an Information Process (No. FTD-MT-24-835-71); Foreign Technology Division Wright-Patterson AFB: Dayton, OH, USA, 1971. [Google Scholar]

- Doerfel, M.L.; Barnett, G.A. A Semantic Network Analysis of the International Communication Association. Hum. Commun. Res. 1999, 25, 589–603. [Google Scholar] [CrossRef]

- Leydesdorff, L.; Nerghes, A. Co-word maps and topic modeling: A comparison using small and medium-sized corpora (N < 1000). J. Assoc. Inf. Sci. Technol. 2016, 68, 1024–1035. [Google Scholar] [CrossRef]

- Lee, K.; Kim, S.; Kim, E.H.-J.; Song, M. Comparative evaluation of bibliometric content networks by tomographic content analysis: An application to Parkinson’s disease. J. Assoc. Inf. Sci. Technol. 2016, 68, 1295–1307. [Google Scholar] [CrossRef]

- Lee, K.; Jung, H. Dynamic semantic network analysis for identifying the concept and scope of social sustainability. J. Clean. Prod. 2019, 233, 1510–1524. [Google Scholar] [CrossRef]

- Levy, Y.; Ellis, T.J. A Systems Approach to Conduct an Effective Literature Review in Support of Information Systems Re-search. Inf. Sci. Int. J. Emerg. Transdiscipl. 2006, 9, 181–212. [Google Scholar] [CrossRef]

- Bloom, B.S. Taxonomy of Educational Objectives: The Classification of Educational Goals. Cognitive Domain; Longman: London, UK, 1956. [Google Scholar]

- Egger, M.; Smith, G.D. Meta-analysis: Potentials and promise. BMJ 1997, 315, 1371–1374. [Google Scholar] [CrossRef]

- Higgins, J.P.T.; Thompson, S.G.; Deeks, J.J.; Altman, D.G. Measuring inconsistency in meta-analyses. BMJ 2003, 327, 557–560. [Google Scholar] [CrossRef]

- Cook, D.J.; Mulrow, C.D.; Haynes, R.B. Systematic Reviews: Synthesis of Best Evidence for Clinical Decisions. Ann. Intern. Med. 1997, 126, 376–380. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.-J.; Choi, T.-M. A United Nations’ Sustainable Development Goals perspective for sustainable textile and apparel supply chain management. Transp. Res. Part E: Logist. Transp. Rev. 2020, 141, 102010. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

- Barron, L.; Gauntlet, E. WACOSS housing and sustainable communities indicators project. In Proceedings of the “Sustaining Our Communities” International Local Agenda 21 Conference, Adelaide, Australia, 3–6 March 2002; pp. 3–6. [Google Scholar]

- Ceres, R.; Pons, J.L.; Jiménez, A.R.; Martín, J.M.; Calderón, L. Design and implementation of an aided fruit–harvesting robot (Agribot). Ind. Robot. Int. J. 1998, 25, 337–346. [Google Scholar] [CrossRef]

- Onuh, S.O.; Yusuf, Y.Y. Rapid prototyping technology: Applications and benefits for rapid product development. J. Intell. Manuf. 1999, 10, 301–311. [Google Scholar] [CrossRef]

- Ohashi, H.; Tsujimoto, Y. Pump Research and Development: Past, Present, and Future—Japanese Perspective. J. Fluids Eng. 1999, 121, 254–258. [Google Scholar] [CrossRef]

- Murphy, R. “Competing” for a robotics education. IEEE Robot. Autom. Mag. 2001, 8, 44–55. [Google Scholar] [CrossRef]

- Cavallucci, D.; Weill, R.D. Integrating Altshuller’s development laws for technical systems into the design process. CIRP Ann. 2001, 50, 115–120. [Google Scholar] [CrossRef]

- Ahmed, S.; Wallace, K.M. Identifying and supporting the knowledge needs of novice designers within the aerospace industry. J. Eng. Des. 2004, 15, 475–492. [Google Scholar] [CrossRef]

- Mondada, F.; Pettinaro, G.C.; Guignard, A.; Kwee, I.W.; Floreano, D.; Deneubourg, J.-L.; Nolfi, S.; Gambardella, L.M.; Dorigo, M. Swarm-Bot: A New Distributed Robotic Concept. Auton. Robot. 2004, 17, 193–221. [Google Scholar] [CrossRef]

- Far, B.H.; Elamy, A.H. Functional reasoning theories: Problems and perspectives. Artif. Intell. Eng. Des. Anal. Manuf. 2005, 19, 75–88. [Google Scholar] [CrossRef]

- Whitby, B. Sometimes it’s hard to be a robot: A call for action on the ethics of abusing artificial agents. Interact. Comput. 2008, 20, 326–333. [Google Scholar] [CrossRef]

- Qiu, L.; Benbasat, I. Evaluating Anthropomorphic Product Recommendation Agents: A Social Relationship Perspective to Designing Information Systems. J. Manag. Inf. Syst. 2009, 25, 145–182. [Google Scholar] [CrossRef]

- Renzi, C.; Leali, F.; Cavazzuti, M.; Andrisano, A.O. A review on artificial intelligence applications to the optimal design of dedicated and reconfigurable manufacturing systems. Int. J. Adv. Manuf. Technol. 2014, 72, 403–418. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, C.K.M.; Wu, K.; Choy, K.L. Multi-objective optimization for sustainable supply chain network design considering multiple distribution channels. Expert Syst. Appl. 2016, 65, 87–99. [Google Scholar] [CrossRef]

- Nakandala, D.; Lau, H.; Zhang, J. Cost-optimization modelling for fresh food quality and transportation. Ind. Manag. Data Syst. 2016, 116, 564–583. [Google Scholar] [CrossRef]

- Zhang, X.; Chan, F.T.; Adamatzky, A.; Mahadevan, S.; Yang, H.; Zhang, Z.; Deng, Y. An intelligent physarum solver for supply chain network design under profit maximization and oligopolistic competition. Int. J. Prod. Res. 2017, 55, 244–263. [Google Scholar] [CrossRef]

- Sanderman, J.; Hengl, T.; Fiske, G.; Solvik, K.; Adame, M.F.; Benson, L.; Bukoski, J.J.; Carnell, P.; Cifuentes-Jara, M.; Donato, D.; et al. A global map of mangrove forest soil carbon at 30 m spatial resolution. Environ. Res. Lett. 2018, 13, 055002. [Google Scholar] [CrossRef]

- Liu, X.; Deng, R.H.; Yang, Y.; Tran, H.N.; Zhong, S. Hybrid privacy-preserving clinical decision support system in fog–cloud computing. Futur. Gener. Comput. Syst. 2018, 78, 825–837. [Google Scholar] [CrossRef]

- Chiu, M.-C.; Lin, Y.-H. Simulation based method considering design for additive manufacturing and supply chain. Ind. Manag. Data Syst. 2016, 116, 322–348. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2017, 56, 508–517. [Google Scholar] [CrossRef]

- Benardos, P.; Vosniakos, G.-C. Predicting surface roughness in machining: A review. Int. J. Mach. Tools Manuf. 2003, 43, 833–844. [Google Scholar] [CrossRef]

- Rosenman, M.; Wang, F. CADOM: A Component Agent-based Design-Oriented Model for Collaborative Design. Res. Eng. Des. 1999, 11, 193–205. [Google Scholar] [CrossRef]

- Huang, G.Q.; Mak, K.L. Web-based morphological charts for concept design in collaborative product development. J. Intell. Manuf. 1999, 10, 267–278. [Google Scholar] [CrossRef]

- Sim, S.K.; Duffy, A.H.B. Towards an ontology of generic engineering design activities. Res. Eng. Des. 2003, 14, 200–223. [Google Scholar] [CrossRef]

- Kwong, C.; Tam, S. Case-based reasoning approach to concurrent design of low power transformers. J. Mater. Process. Technol. 2002, 128, 136–141. [Google Scholar] [CrossRef]

- Deng, Y.-M. Function and behavior representation in conceptual mechanical design. Artif. Intell. Eng. Des. Anal. Manuf. 2002, 16, 343–362. [Google Scholar] [CrossRef]

- Balakrishnan, P.; Gupta, R.; Jacob, V.S. Development of Hybrid Genetic Algorithms for Product Line Designs. IEEE Trans. Syst. Man Cybern. Part B 2004, 34, 468–483. [Google Scholar] [CrossRef]

- Batory, D.; Benavides, D.; Ruiz-Cortes, A. Automated analysis of feature models: Challenges ahead. Commun. ACM 2006, 49, 45–47. [Google Scholar] [CrossRef]

- Rodgers, P.A.; Huxor, A.P.; Caldwell, N.H.M. Design Support Using Distributed Web-Based AI Tools. Res. Eng. Des. 1999, 11, 31–44. [Google Scholar] [CrossRef]

- Salvador, F.; Forza, C. Configuring products to address the customization-responsiveness squeeze: A survey of management issues and opportunities. Int. J. Prod. Econ. 2004, 91, 273–291. [Google Scholar] [CrossRef]

- Zha, X.F.; Lim, S.E. Assembly/disassembly task planning and simulation using expert Petri nets. Int. J. Prod. Res. 2000, 38, 3639–3676. [Google Scholar] [CrossRef]

- Closs, D.J.; Jacobs, M.A.; Swink, M.; Webb, G.S. Toward a theory of competencies for the management of product complexity: Six case studies. J. Oper. Manag. 2007, 26, 590–610. [Google Scholar] [CrossRef]

- Liu, T.I.; Yang, X.M.; Kalambur, G.J. Design for machining using expert system and fuzzy logic approach. J. Mater. Eng. Perform. 1995, 4, 599–609. [Google Scholar] [CrossRef]

- Wang, K. Applying data mining to manufacturing: The nature and implications. J. Intell. Manuf. 2007, 18, 487–495. [Google Scholar] [CrossRef]

- Kwong, C.K.; Jiang, H.; Luo, X.G. AI-based methodology of integrating affective design, engineering, and marketing for de-fining design specifications of new products. Eng. Appl. Artif. Intell. 2016, 47, 49–60. [Google Scholar] [CrossRef]

- Ishii, K. Life-cycle engineering design. J. Mech. Des. 1995, 117, 42–47. [Google Scholar] [CrossRef]

- Zhao, G.; Deng, J.; Shen, W. CLOVER: An agent-based approach to systems interoperability in cooperative design systems. Comput. Ind. 2001, 45, 261–276. [Google Scholar] [CrossRef]

- Sanderson, A.C.; de Mello, L.S.H.; Zhang, H. Assembly sequence planning. AI Mag. 1990, 11, 62. [Google Scholar]

- Lei, N.; Moon, S.K. A Decision Support System for market-driven product positioning and design. Decis. Support Syst. 2015, 69, 82–91. [Google Scholar] [CrossRef]

- Chan, S.L.; Ip, W.H. A dynamic decision support system to predict the value of customer for new product development. Decis. Support Syst. 2011, 52, 178–188. [Google Scholar] [CrossRef]

- Shih, L.-H.; Chang, Y.-S.; Lin, Y.-T. Intelligent evaluation approach for electronic product recycling via case-based reasoning. Adv. Eng. Inf. 2006, 20, 137–145. [Google Scholar] [CrossRef]

- Smith, S.; Smith, G.; Chen, W.-H. Disassembly sequence structure graphs: An optimal approach for multiple-target selective disassembly sequence planning. Adv. Eng. Inf. 2012, 26, 306–316. [Google Scholar] [CrossRef]

- Peien, F.; GuoRong, X.; Mingjun, Z. Feature modeling based on design catalogues for principle conceptual design. Artif. Intell. Eng. Des. Anal. Manuf. 1996, 10, 347–354. [Google Scholar] [CrossRef]

- Zha, X.; Du, H.; Qiu, J. Knowledge-based approach and system for assembly oriented design, Part I: The approach. Eng. Appl. Artif. Intell. 2001, 14, 61–75. [Google Scholar] [CrossRef]

- Stéphane, N.; Marc, L.L.J. Case-based reasoning for chemical engineering design. Chem. Eng. Res. Des. 2008, 86, 648–658. [Google Scholar] [CrossRef]

- Young, R.E.; Greef, A.; O’Grady, P. An artificial intelligence-based constraint network system for concurrent engineering. Int. J. Prod. Res. 1992, 30, 1715–1735. [Google Scholar] [CrossRef]

- Yu, B.; Skovgaard, H.J. A configuration tool to increase product competitiveness. IEEE Intell. Syst. 1998, 13, 34–41. [Google Scholar] [CrossRef]

- Wang, J.F.; Liu, J.H.; Li, S.Q.; Zhong, Y.F. Intelligent selective disassembly using the ant colony algorithm. Artif. Intell. Eng. Des. Anal. Manuf. 2003, 17, 325–333. [Google Scholar] [CrossRef]

- Sabbaghi, M.; Esmaeilian, B.; Mashhadi, A.R.; Behdad, S.; Cade, W. An investigation of used electronics return flows: A data-driven approach to capture and predict consumers storage and utilization behavior. Waste Manag. 2015, 36, 305–315. [Google Scholar] [CrossRef]

- Kristianto, Y.; Gunasekaran, A.; Helo, P.; Sandhu, M. A decision support system for integrating manufacturing and product design into the reconfiguration of the supply chain networks. Decis. Support Syst. 2012, 52, 790–801. [Google Scholar] [CrossRef]

- Agarwal, R. Computational fluid dynamics of whole-body aircraft. Annu. Rev. Fluid Mech. 1999, 31, 125–169. [Google Scholar] [CrossRef]

- Falco, J.; Van Wyk, K.; Liu, S.; Carpin, S. Grasping the Performance: Facilitating Replicable Performance Measures via Benchmarking and Standardized Methodologies. IEEE Robot. Autom. Mag. 2015, 22, 125–136. [Google Scholar] [CrossRef]

- He, Y.-H.; Wang, L.-B.; He, Z.-Z.; Xie, M. A fuzzy TOPSIS and Rough Set based approach for mechanism analysis of product infant failure. Eng. Appl. Artif. Intell. 2016, 47, 25–37. [Google Scholar] [CrossRef]

- Zha, X.F.; Lim, S.Y.E.; Fok, S.C. Integrated intelligent design and assembly planning: A survey. Int. J. Adv. Manuf. Technol. 1998, 14, 664–685. [Google Scholar] [CrossRef]

- Dutta, S. Fuzzy logic applications: Technological and strategic issues. IEEE Trans. Eng. Manag. 1993, 40, 237–254. [Google Scholar] [CrossRef]

- Chang, H.-H. A data mining approach to dynamic multiple responses in Taguchi experimental design. Expert Syst. Appl. 2008, 35, 1095–1103. [Google Scholar] [CrossRef]

- Catalano, C.E.; Giannini, F.; Monti, M.; Ucelli, G. A framework for the automatic annotation of car aesthetics. Artif. Intell. Eng. Des. Anal. Manuf. 2007, 21, 73–90. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, S.C.; Wang, X.; Tian, W.; Wu, R. Object oriented manufacturing resource modelling for adaptive process planning. Int. J. Prod. Res. 1999, 37, 4179–4195. [Google Scholar] [CrossRef]

- Zha, X.F.; Lim, S.Y.E.; Fok, S.C. Integrated knowledge-based approach and system for product design for assembly. Int. J. Comput. Integr. Manuf. 1999, 12, 211–237. [Google Scholar] [CrossRef]

- Yan, H.-S.; Xu, D. An Approach to Estimating Product Design Time Based on Fuzzy v-Support Vector Machine. IEEE Trans. Neural Netw. 2007, 18, 721–731. [Google Scholar] [CrossRef]

- Fromherz, M.P.; Bobrow, D.G.; De Kleer, J. Model-based computing for design and control of reconfigurable systems. AI Mag. 2003, 24, 120. [Google Scholar]

- Koh, S.L.; Genovese, A.; Acquaye, A.A.; Barratt, P.; Rana, N.; Kuylenstierna, J.; Gibbs, D. Decarbonising product supply chains: Design and development of an integrated evidence-based decision support system—The supply chain environmental analysis tool (SCEnAT). Int. J. Prod. Res. 2013, 51, 2092–2109. [Google Scholar] [CrossRef]

- Soroor, J.; Tarokh, M.J.; Khoshalhan, F.; Sajjadi, S. Intelligent evaluation of supplier bids using a hybrid technique in distributed supply chains. J. Manuf. Syst. 2012, 31, 240–252. [Google Scholar] [CrossRef]

- Ng, F.; Ritchie, J.; Simmons, J.; Dewar, R. Designing cable harness assemblies in virtual environments. J. Mater. Process. Technol. 2000, 107, 37–43. [Google Scholar] [CrossRef]

- Kathuria, R.; Anandarajan, M.; Igbaria, M. Linking IT Applications with Manufacturing Strategy: An Intelligent Decision Support System Approach. Decis. Sci. 1999, 30, 959–991. [Google Scholar] [CrossRef][Green Version]

- Zhang, W.; Tor, S.; Britton, G. A graph and matrix representation scheme for functional design of mechanical products. Int. J. Adv. Manuf. Technol. 2004, 25, 221–232. [Google Scholar] [CrossRef]

- Castilho, M.; De Ruijter, M.; Beirne, S.; Villette, C.C.; Ito, K.; Wallace, G.G.; Malda, J. Multitechnology Biofabrication: A New Approach for the Manufacturing of Functional Tissue Structures? Trends Biotechnol. 2020, 38, 1316–1328. [Google Scholar] [CrossRef] [PubMed]

- Woods, W.A. What’s in a Link: Foundations for Semantic Networks. In What’s in a Link: Foundations for Semantic Networks; Defense Technical Information Center (DTIC): Fort Belvoir, VI, USA, 1975; pp. 35–82. [Google Scholar]

- Battineni, G.; Chintalapudi, N.; Amenta, F. AI Chatbot Design during an Epidemic like the Novel Coronavirus. Healing 2020, 8, 154. [Google Scholar] [CrossRef] [PubMed]

| Social sustainability: “Social sustainability occurs when the formal and informal processes/systems/structures/relationships actively support the capacity of current and future generations to create healthy and liveable communities.” [76] | ||

| To meet the basic needs, ways to develop infrastructures that secure physical and non-physical requirements | Tangible: basic physical requirements |

| Intangible: basic nonphysical requirements | ||

| To support ecological sustainability, ways to promote eco-friendly behavior or stronger environmental ethics | Transformative: fundamental changes by socially constructed environment |

| Nontransformative: provision of information for changes | ||

| To sustain quality of life, ways of preferences, characteristics, and environments to be maintained over time. | |

| P ID | Development (Tangible) | Development (Intangible) | Bridge (Transformative) | Bridge (Non-Transformative) | Maintenance |

|---|---|---|---|---|---|

| 1 | 1 | 0 | 0 | 0 | 0 |

| … | |||||

| K | 1 | 1 | 1 | 1 | 1 |

| Paper ID | Year | Source Title | Title | Cited by | Paper ID | Year | Source Title | Title | Cited by |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2003 | International Journal of Machine Tools and Manufacture | Predicting surface roughness in machining: A review [95] | 622 | 33 | 1999 | Research in Engineering Design—Theory, Applications, and Concurrent Engineering | CADOM: A Component Agent-based Design-Oriented Model for collaborative design [96] | 51 |

| 2 | 2018 | International Journal of Production Research | Smart manufacturing [94] | 245 | 35 | 1999 | Journal of Intelligent Manufacturing | Web-based morphological charts for concept design in collaborative product development [97] | 50 |

| 5 | 2003 | Research in Engineering Design | Towards an ontology of generic engineering design activities [98] | 160 | 37 | 2002 | Journal of Materials Processing Technology | Case-based reasoning approach to concurrent design of low power transformers [99] | 47 |

| 6 | 2002 | Artificial Intelligence for Engineering Design, Analysis and Manufacturing: AIEDAM | Function and behavior representation in conceptual mechanical design [100] | 140 | 39 | 2004 | IEEE Transactions on Systems, Man, and Cybernetics, Part B: Cybernetics | Development of Hybrid Genetic Algorithms for Product Line Designs [101] | 46 |

| 7 | 2006 | Communications of the ACM | Automated analysis of feature models: Challenges ahead [102] | 128 | 40 | 1999 | Research in Engineering Design—Theory, Applications, and Concurrent Engineering | Design support using distributed web-based AI tools [103] | 45 |

| 8 | 2004 | International Journal of Production Economics | Configuring products to address the customization-responsiveness squeeze: A survey of management issues and opportunities [104] | 121 | 45 | 2000 | International Journal of Production Research | Assembly/disassembly task planning and simulation using expert Petri nets [105] | 39 |

| 9 | 2008 | Journal of Operations Management | Toward a theory of competencies for the management of product complexity: Six case studies [106] | 120 | 46 | 1995 | Journal of Materials Engineering and Performance | Design for machining using expert system and fuzzy logic approach [107] | 38 |

| 10 | 2007 | Journal of Intelligent Manufacturing | Applying data mining to manufacturing: The nature and implications [108] | 95 | 48 | 2016 | Engineering Applications of Artificial Intelligence | AI-based methodology of integrating affective design, engineering, and marketing for defining design specifications of new products [109] | 36 |

| 11 | 1995 | Journal of Vibration and Acoustics, Transactions of the ASME | Life-cycle engineering design [110] | 86 | 47 | 1999 | Journal of Intelligent Manufacturing | Artificial intelligence and expert systems applications in new product development—a survey [22] | 36 |

| 12 | 2003 | Engineering Applications of Artificial Intelligence | Application of Bayesian decision networks to life cycle engineering in Green design and manufacturing [9] | 80 | 49 | 2001 | Computers in Industry | CLOVER: An agent-based approach to systems interoperability in cooperative design systems [111] | 35 |

| 13 | 1990 | AI Magazine | Assembly sequence planning [112] | 78 | 50 | 2015 | Decision Support Systems | A Decision Support System for market-driven product positioning and design [113] | 35 |

| 17 | 2011 | Decision Support Systems | A dynamic decision support system to predict the value of customer for new product development [114] | 72 | 53 | 2006 | Advanced Engineering Informatics | Intelligent evaluation approach for electronic product recycling via case-based reasoning [115] | 34 |

| 18 | 2012 | Advanced Engineering Informatics | Disassembly sequence structure graphs: An optimal approach for multiple-target selective disassembly sequence planning [116] | 69 | 51 | 1996 | Artificial Intelligence for Engineering Design, Analysis and Manufacturing: AIEDAM | Feature modeling based on design catalogues for principle conceptual design [117] | 34 |

| 19 | 2001 | Engineering Applications of Artificial Intelligence | Knowledge-based approach and system for assembly oriented design, Part I: The approach [118] | 68 | 54 | 2008 | Chemical Engineering Research and Design | Case-based reasoning for chemical engineering design [119] | 34 |

| 21 | 1992 | International Journal of Production Research | An artificial intelligence-based constraint network system for concurrent engineering [120] | 65 | 52 | 1998 | IEEE Intelligent Systems and Their Applications | A configuration tool to increase product competitiveness [121] | 34 |

| 22 | 2003 | Artificial Intelligence for Engineering Design, Analysis and Manufacturing: AIEDAM | Intelligent selective disassembly using the ant colony algorithm [122] | 63 | 55 | 2015 | Waste Management | An investigation of used electronics return flows: A data-driven approach to capture and predict consumers storage and utilization behavior [123] | 34 |

| 23 | 2012 | Decision Support Systems | A decision support system for integrating manufacturing and product design into the reconfiguration of the supply chain networks [124] | 63 | 56 | 1999 | Annual Review of Fluid Mechanics | Computational fluid dynamics of whole-body aircraft [125] | 33 |

| 24 | 2014 | International Journal of Advanced Manufacturing Technology | A review on artificial intelligence applications to the optimal design of dedicated and reconfigurable manufacturing systems [87] | 63 | 59 | 2015 | IEEE Robotics and Automation Magazine | Grasping the performance [126] | 32 |

| 25 | 2016 | Engineering Applications of Artificial Intelligence | A fuzzy TOPSIS and Rough Set based approach for mechanism analysis of product infant failure [127] | 62 | 57 | 1988 | Materials and Design | Planning of expert systems for materials selection [7] | 32 |

| 27 | 1998 | International Journal of Advanced Manufacturing Technology | Integrated intelligent design and assembly planning: A survey [128] | 61 | 61 | 1993 | IEEE Transactions on Engineering Management | Fuzzy Logic Applications: Technological and Strategic Issues [129] | 30 |

| 29 | 2008 | Expert Systems with Applications | A data mining approach to dynamic multiple responses in Taguchi experimental design [130] | 59 | 62 | 2007 | Artificial Intelligence for Engineering Design, Analysis and Manufacturing: AIEDAM | A framework for the automatic annotation of car aesthetics [131] | 29 |

| 28 | 1999 | International Journal of Production Research | Object oriented manufacturing resource modelling for adaptive process planning [132] | 59 | 63 | 1999 | International Journal of Computer Integrated Manufacturing | Integrated knowledge-based approach and system for product design for assembly [133] | 28 |

| 30 | 2007 | IEEE Transactions on Neural Networks | An approach to estimating product design time based on fuzzy ν-support vector machine [134] | 57 | 64 | 2003 | AI Magazine | Model-Based Computing for Design and Control of Reconfigurable Systems [135] | 27 |

| 31 | 2013 | International Journal of Production Research | Decarbonising product supply chains: Design and development of an integrated evidence-based decision support system-the supply chain environmental analysis tool (SCEnAT) [136] | 54 | 65 | 2012 | Journal of Manufacturing Systems | Intelligent evaluation of supplier bids using a hybrid technique in distributed supply chains [137] | 27 |

| 32 | 2000 | Journal of Materials Processing Technology | Designing cable harness assemblies in virtual environments [138] | 53 | 68 | 2016 | Industrial Management and Data Systems | Simulation based method considering design for additive manufacturing and supply chain An empirical study of lamp industry [93] | 26 |

| 34 | 1999 | Decision Sciences | Linking IT applications with manufacturing strategy: An intelligent decision support system approach [139] | 51 | 67 | 2005 | International Journal of Advanced Manufacturing Technology | A graph and matrix representation scheme for functional design of mechanical products [140] | 26 |

| Journal Name | #Articles |

|---|---|

| International Journal of Production Research | 5 |

| Artificial Intelligence for Engineering Design, Analysis and Manufacturing: AIEDAM | 4 |

| Engineering Applications of Artificial Intelligence | 4 |

| International Journal of Advanced Manufacturing Technology | 3 |

| Journal of Intelligent Manufacturing | 3 |

| Decision Support Systems | 3 |

| Research in Engineering Design—Theory, Applications, and Concurrent Engineering | 3 |

| Advanced Engineering Informatics | 2 |

| AI Magazine | 2 |

| Journal of Materials Processing Technology | 2 |

| Annual Review of Fluid Mechanics | 1 |

| Chemical Engineering Research and Design | 1 |

| Communications of the ACM | 1 |

| Computers in Industry | 1 |

| Decision Sciences | 1 |

| Expert Systems with Applications | 1 |

| IEEE Intelligent Systems and Their Applications | 1 |

| IEEE Robotics and Automation Magazine | 1 |

| IEEE Transactions on Engineering Management | 1 |

| IEEE Transactions on Neural Networks | 1 |

| IEEE Transactions on Systems, Man, and Cybernetics, Part B: Cybernetics | 1 |

| Industrial Management and Data Systems | 1 |

| International Journal of Computer Integrated Manufacturing | 1 |

| International Journal of Machine Tools and Manufacture | 1 |

| International Journal of Production Economics | 1 |

| Journal of Manufacturing Systems | 1 |

| Journal of Materials Engineering and Performance | 1 |

| Journal of Operations Management | 1 |

| Journal of Vibration and Acoustics, Transactions of the ASME | 1 |

| Materials and Design | 1 |

| Waste Management | 1 |

| Total | 52 |

| Paper ID | Development-Tangible | Development-Intangible | Bridge-Transformative | Bridge-NonTransformative | Maintenance | Paper ID | Development-Tangible | Development-Intangible | Bridge-Transformative | Bridge-NonTransformative | Maintenance |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 0 | 0 | 0 | 33 | 1 | 0 | 0 | 0 | 0 |

| 2 | 1 | 0 | 1 | 0 | 1 | 35 | 1 | 0 | 0 | 0 | 0 |

| 5 | 1 | 0 | 0 | 0 | 0 | 37 | 1 | 0 | 1 | 0 | 0 |

| 6 | 1 | 0 | 0 | 0 | 0 | 39 | 1 | 0 | 0 | 0 | 1 |

| 7 | 1 | 0 | 0 | 0 | 0 | 40 | 1 | 0 | 0 | 0 | 0 |

| 8 | 1 | 0 | 0 | 0 | 0 | 45 | 1 | 0 | 0 | 0 | 0 |

| 9 | 1 | 0 | 0 | 0 | 0 | 46 | 1 | 0 | 0 | 0 | 0 |

| 10 | 1 | 0 | 0 | 0 | 0 | 48 | 1 | 0 | 0 | 0 | 0 |

| 11 | 1 | 0 | 1 | 0 | 0 | 47 | 1 | 0 | 0 | 0 | 1 |

| 12 | 1 | 0 | 1 | 0 | 0 | 49 | 1 | 0 | 0 | 0 | 0 |

| 13 | 1 | 0 | 0 | 0 | 0 | 50 | 1 | 0 | 0 | 0 | 1 |

| 17 | 1 | 0 | 0 | 0 | 0 | 53 | 1 | 0 | 1 | 0 | 0 |

| 18 | 1 | 0 | 1 | 0 | 0 | 51 | 1 | 0 | 0 | 0 | 0 |

| 19 | 1 | 0 | 0 | 0 | 0 | 54 | 1 | 0 | 0 | 0 | 0 |

| 21 | 1 | 0 | 1 | 0 | 0 | 52 | 1 | 0 | 0 | 0 | 1 |

| 22 | 1 | 0 | 1 | 0 | 0 | 55 | 1 | 0 | 1 | 0 | 1 |

| 23 | 1 | 0 | 0 | 0 | 0 | 56 | 1 | 0 | 0 | 0 | 0 |

| 24 | 1 | 0 | 0 | 0 | 0 | 59 | 1 | 0 | 0 | 0 | 0 |

| 25 | 1 | 0 | 0 | 0 | 0 | 57 | 1 | 0 | 0 | 0 | 0 |

| 27 | 1 | 0 | 0 | 0 | 0 | 61 | 1 | 0 | 0 | 0 | 0 |

| 29 | 1 | 0 | 0 | 0 | 0 | 62 | 1 | 0 | 0 | 0 | 0 |

| 28 | 1 | 0 | 0 | 0 | 0 | 63 | 1 | 0 | 0 | 0 | 0 |

| 30 | 1 | 0 | 0 | 0 | 0 | 64 | 1 | 0 | 0 | 0 | 0 |

| 31 | 1 | 1 | 1 | 1 | 1 | 65 | 1 | 0 | 0 | 0 | 0 |

| 32 | 1 | 0 | 0 | 0 | 1 | 68 | 1 | 0 | 1 | 0 | 0 |

| 34 | 1 | 0 | 0 | 0 | 0 | 67 | 1 | 0 | 0 | 0 | 0 |

| Total | 52 | 1 | 11 | 1 | 8 |

| Journal Name. | 1988 | 1990 | 1992 | 1993 | 1995 | 1996 | 1998 | 1999 | 2000 | 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2018 | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| International Journal of Production Research | 1,0,1,0,0 | 1,0,0,0,0 | 1,0,0,0,0 | 1,1,1,1,1 | 1,0,1,0,1 | 5,1,3,1,1 | |||||||||||||||||||

| Artificial Intelligence for Engineering Design, Analysis and Manufacturing: AIEDAM | 1,0,0,0,0 | 1,0,0,0,0 | 1,0,1,0,0 | 1,0,0,0,0 | 4,0,1,0,0 | ||||||||||||||||||||

| Engineering Applications of Artificial Intelligence | 1,0,0,0,0 | 1,0,1,0,0 | 2,0,0,0,0 | 4,0,1,0,0 | |||||||||||||||||||||

| International Journal of Advanced Manufacturing Technology | 1,0,0,0,0 | 1,0,0,0,0 | 1,0,0,0,0 | 3,0,0,0,0 | |||||||||||||||||||||

| Journal of Intelligent Manufacturing | 2,0,0,0,1 | 1,0,0,0,0 | 3,0,0,0,1 | ||||||||||||||||||||||

| Decision Support Systems | 1,0,0,0,0 | 1,0,0,0,0 | 1,0,0,0,1 | 3,0,0,0,1 | |||||||||||||||||||||

| Advanced Engineering Informatics | 1,0,1,0,0 | 1,0,1,0,0 | 2,0,2,0,0 | ||||||||||||||||||||||

| AI Magazine | 1,0,0,0,0 | 1,0,0,0,0 | 2,0,0,0,0 | ||||||||||||||||||||||

| Journal of Materials Processing Technology | 1,0,0,0,1 | 1,0,1,0,0 | 2,0,1,0,1 | ||||||||||||||||||||||

| Research in Engineering Design—Theory, Applications, and Concurrent Engineering | 2,0,0,0,0 | 1,0,0,0,0 | 3,0,0,0,0 | ||||||||||||||||||||||

| Annual Review of Fluid Mechanics | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Chemical Engineering Research and Design | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Communications of the ACM | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Computers in Industry | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Decision Sciences | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Expert Systems with Applications | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| IEEE Intelligent Systems and Their Applications | 1,0,0,0,1 | 1,0,0,0,1 | |||||||||||||||||||||||

| IEEE Robotics and Automation Magazine | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| IEEE Transactions on Engineering Management | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| IEEE Transactions on Neural Networks | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| IEEE Transactions on Systems, Man, and Cybernetics, Part B: Cybernetics | 1,0,0,0,1 | 1,0,0,0,1 | |||||||||||||||||||||||

| Industrial Management and Data Systems | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| International Journal of Computer Integrated Manufacturing | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| International Journal of Machine Tools and Manufacture | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| International Journal of Production Economics | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Journal of Manufacturing Systems | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Journal of Materials Engineering and Performance | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Journal of Operations Management | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Journal of Vibration and Acoustics, Transactions of the ASME | 1,0,1,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Materials and Design | 1,0,0,0,0 | 1,0,0,0,0 | |||||||||||||||||||||||

| Waste Management | 1,0,1,0,1 | 1,0,1,0,1 | |||||||||||||||||||||||

| Total | 1,0,0,0,0 | 1,0,0,0,0 | 1,0,1,0,0 | 1,0,0,0,0 | 2,0,1,0,0 | 1,0,0,0,0 | 2,0,0,0,1 | 8,0,0,0,1 | 2,0,0,0,1 | 2,0,0,0,0 | 2,0,1,0,0 | 5,0,2,0,0 | 2,0,0,0,1 | 1,0,0,0,0 | 2,0,1,0,0 | 3,0,0,0,0 | 3,0,0,0,0 | 1,0,0,0,0 | 3,0,1,0,0 | 1,1,1,1,1 | 1,0,0,0,0 | 3,0,1,0,2 | 3,0,0,0,0 | 1,0,1,0,1 | 52,1,11,1,8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, K. A Systematic Review on Social Sustainability of Artificial Intelligence in Product Design. Sustainability 2021, 13, 2668. https://doi.org/10.3390/su13052668

Lee K. A Systematic Review on Social Sustainability of Artificial Intelligence in Product Design. Sustainability. 2021; 13(5):2668. https://doi.org/10.3390/su13052668

Chicago/Turabian StyleLee, Keeheon. 2021. "A Systematic Review on Social Sustainability of Artificial Intelligence in Product Design" Sustainability 13, no. 5: 2668. https://doi.org/10.3390/su13052668

APA StyleLee, K. (2021). A Systematic Review on Social Sustainability of Artificial Intelligence in Product Design. Sustainability, 13(5), 2668. https://doi.org/10.3390/su13052668