Towards More Sustainable Materials for Geo-Environmental Engineering: The Case of Geogrids

Abstract

1. Introduction

- -

- to explore the market of PLA-based materials and to analyze the recent scientific research aiming at developing innovative bioplastics. The state-of-the-art will provide a complete spectrum of the availability/progress of technology on this kind of materials and the most common applications;

- -

- to produce prototype samples with standard geometry using biopolymers already available on the market and to repeat the chemical and mechanical characterization of these samples;

- -

- to compare the prototype samples produced with different materials analyzing advantages and disadvantage.

2. Materials and Methods

2.1. State-of-the-Art: Neat-PLA and PLA-Based Materials

2.2. Tested Biomaterials

- neat-PLA filament (n-PLA; PLA, Orbi-Tech© company, Leichlingen, Germany);

- neat-PLA filament containing co-polyesters and non-toxic additives to enhance 3D printing performance (ad-PLA; PLA NX2, Extrudr© company, Lauterach, Austria);

- neat-PLA filament containing polymeric additives and titanium dioxide for improving the strength performance under thermal treatment (ht-PLA; HTPLA V3, Proto-Pasta©, Protoplant, Vancouver, WA, USA);

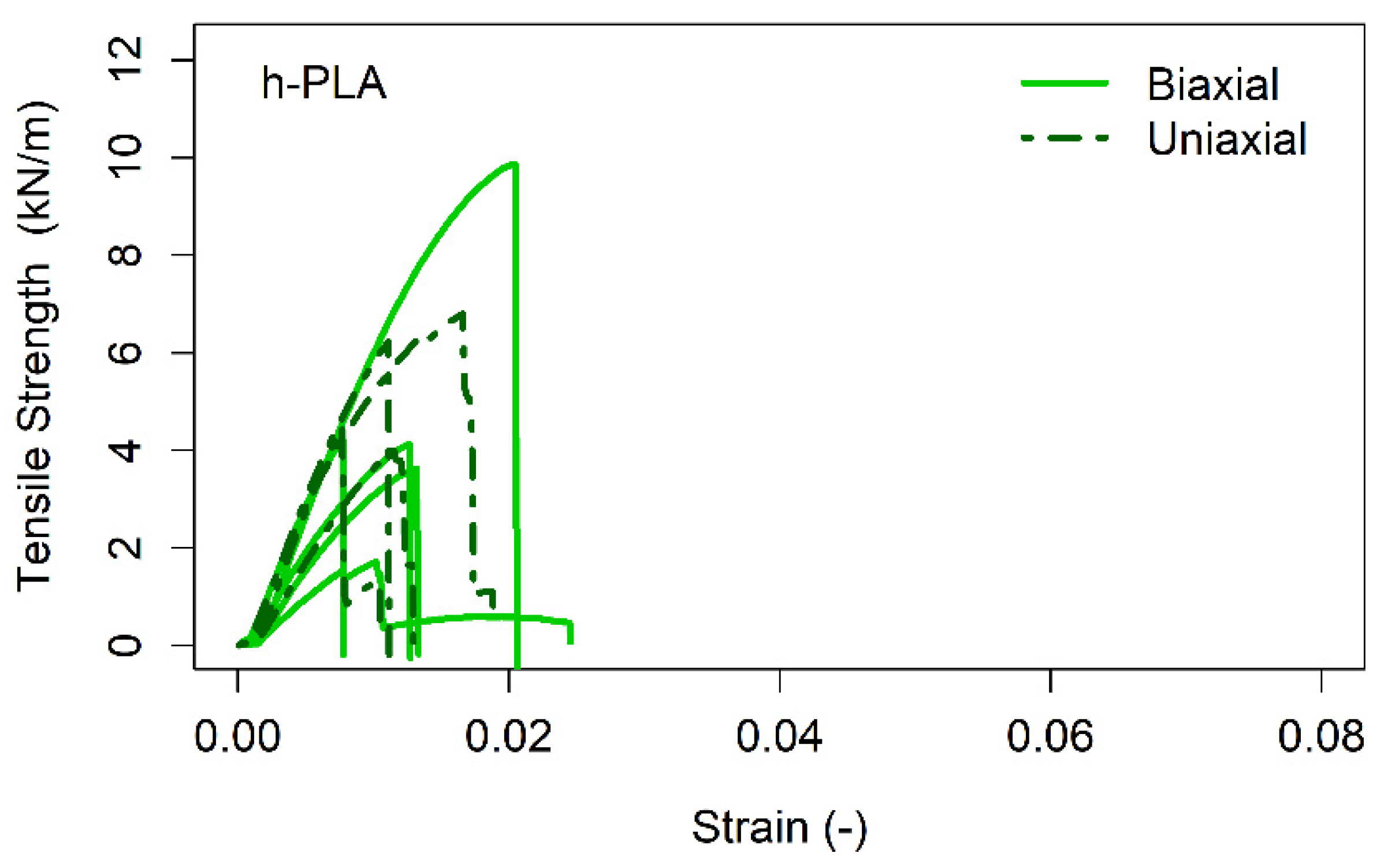

- hemp fibers reinforced-PLA filament containing approximately 20% of raw fibers (h-PLA; HempBioPlastic, Kànesis©, MICA company, Catania, Italy);

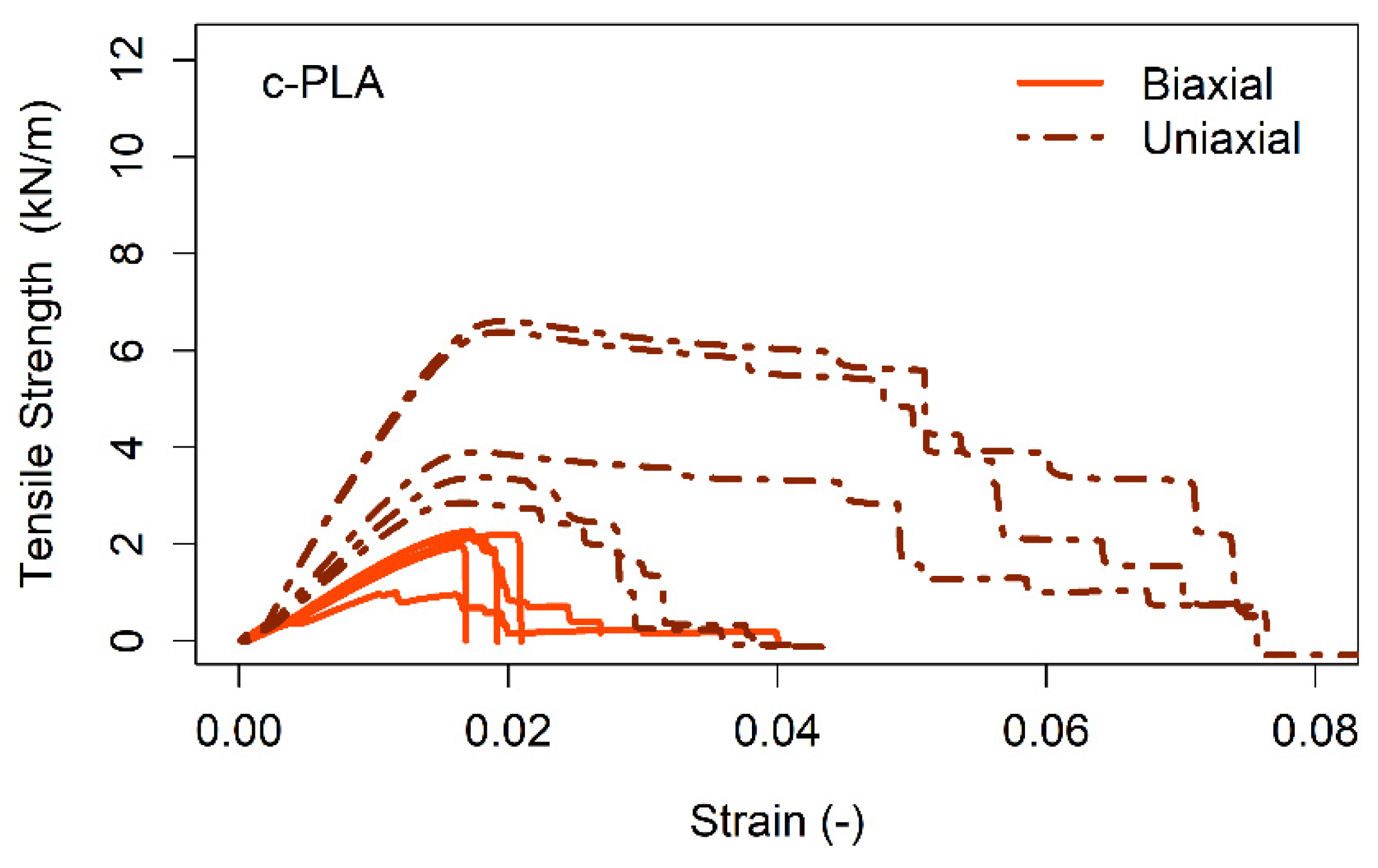

- cork fibers reinforced-PLA filament containing approximately 20% of raw fibers (c-PLA; Corkfill, ColorFabb© company, Belfeld, The Netherlands);

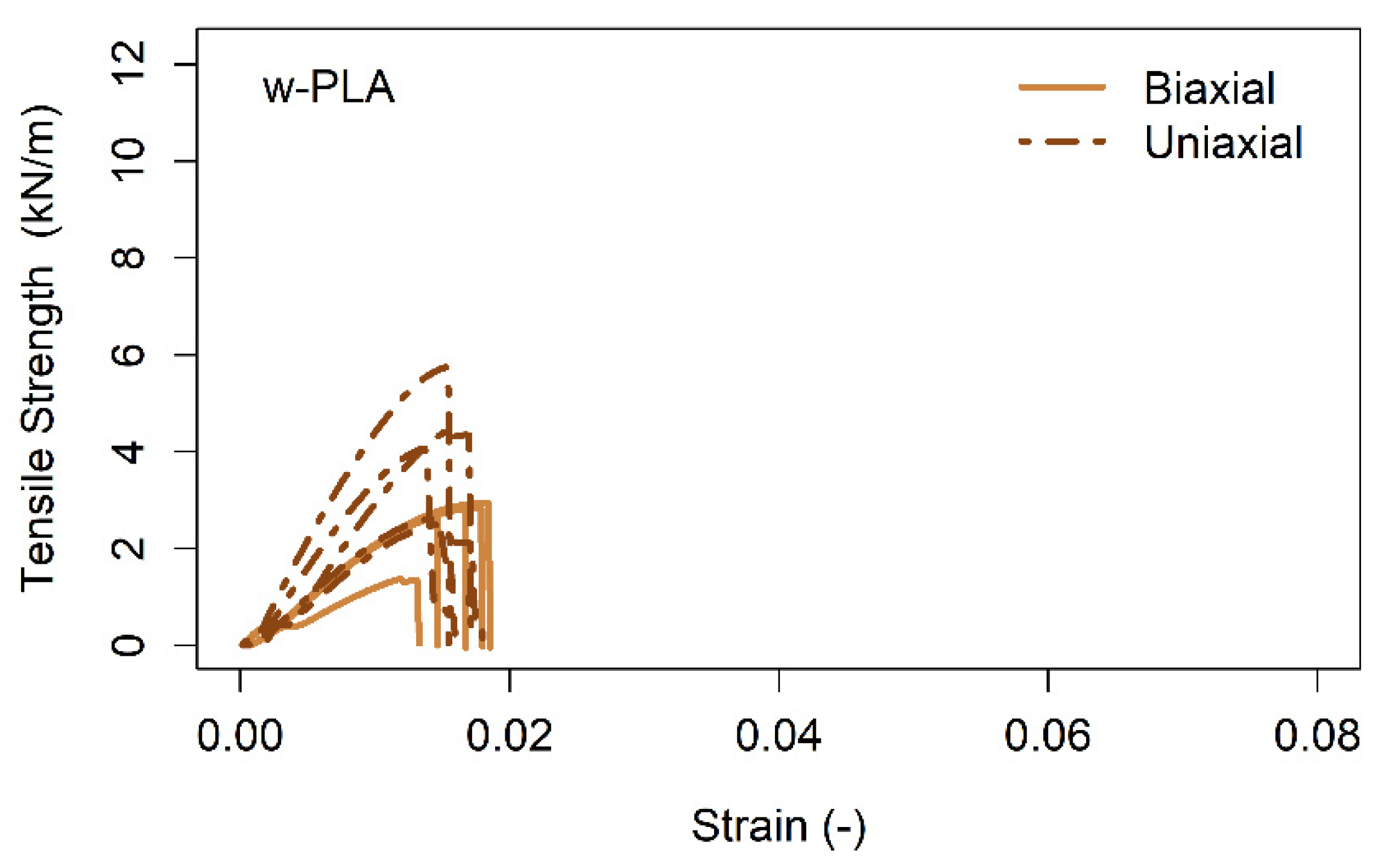

- wood fibers reinforced-PLA filament containing approximately 20% of raw fibers (w-PLA; Woodfill, ColorFabb© company, Belfeld, The Netherlands).

2.3. Chemical and Mechanical Characterization of Biomaterials

2.4. Prototypes Building and Testing

3. Results

3.1. Chemical and Mechanical Characterization of Biomaterials

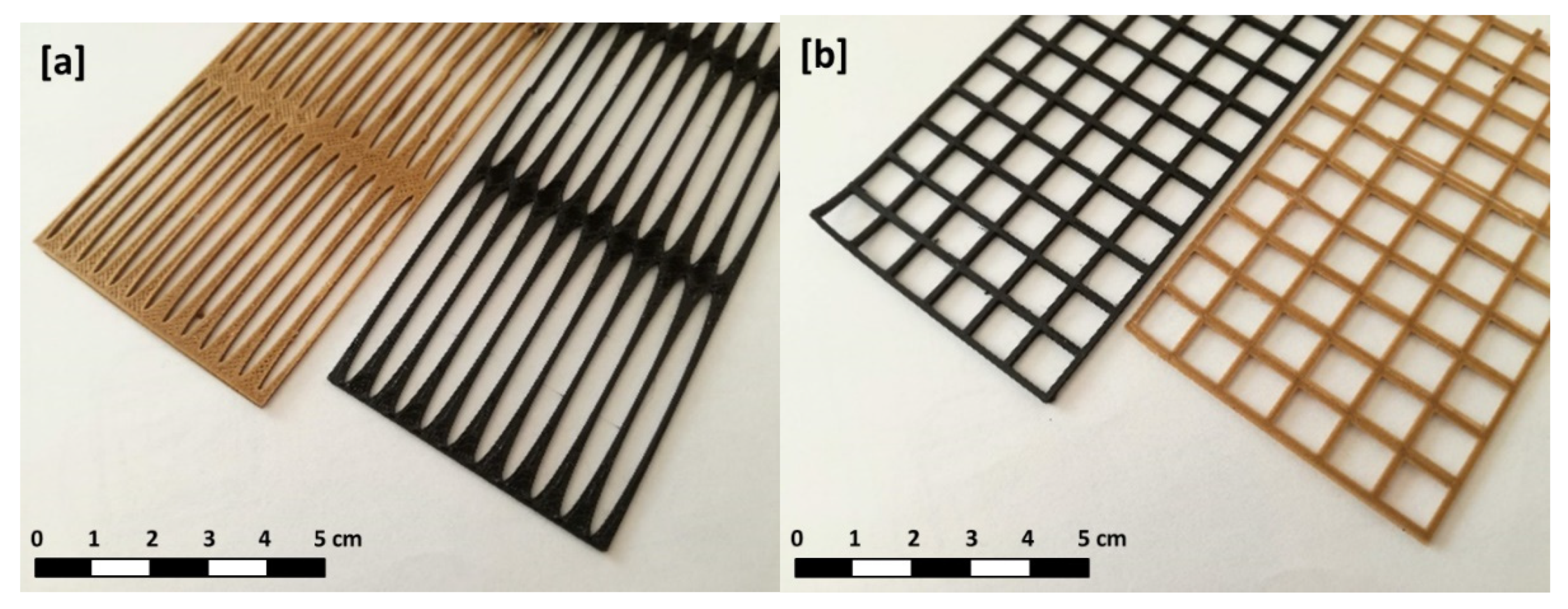

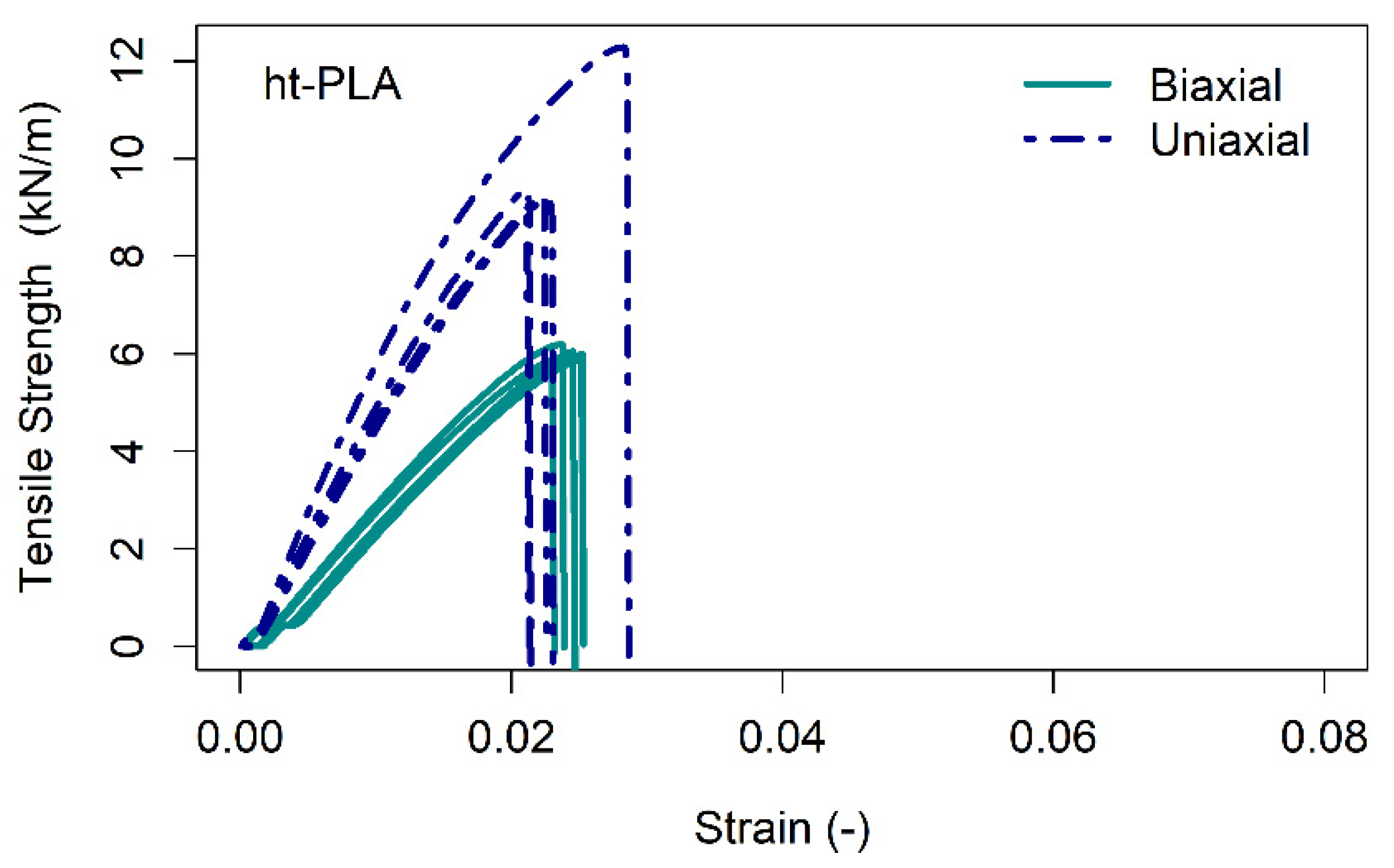

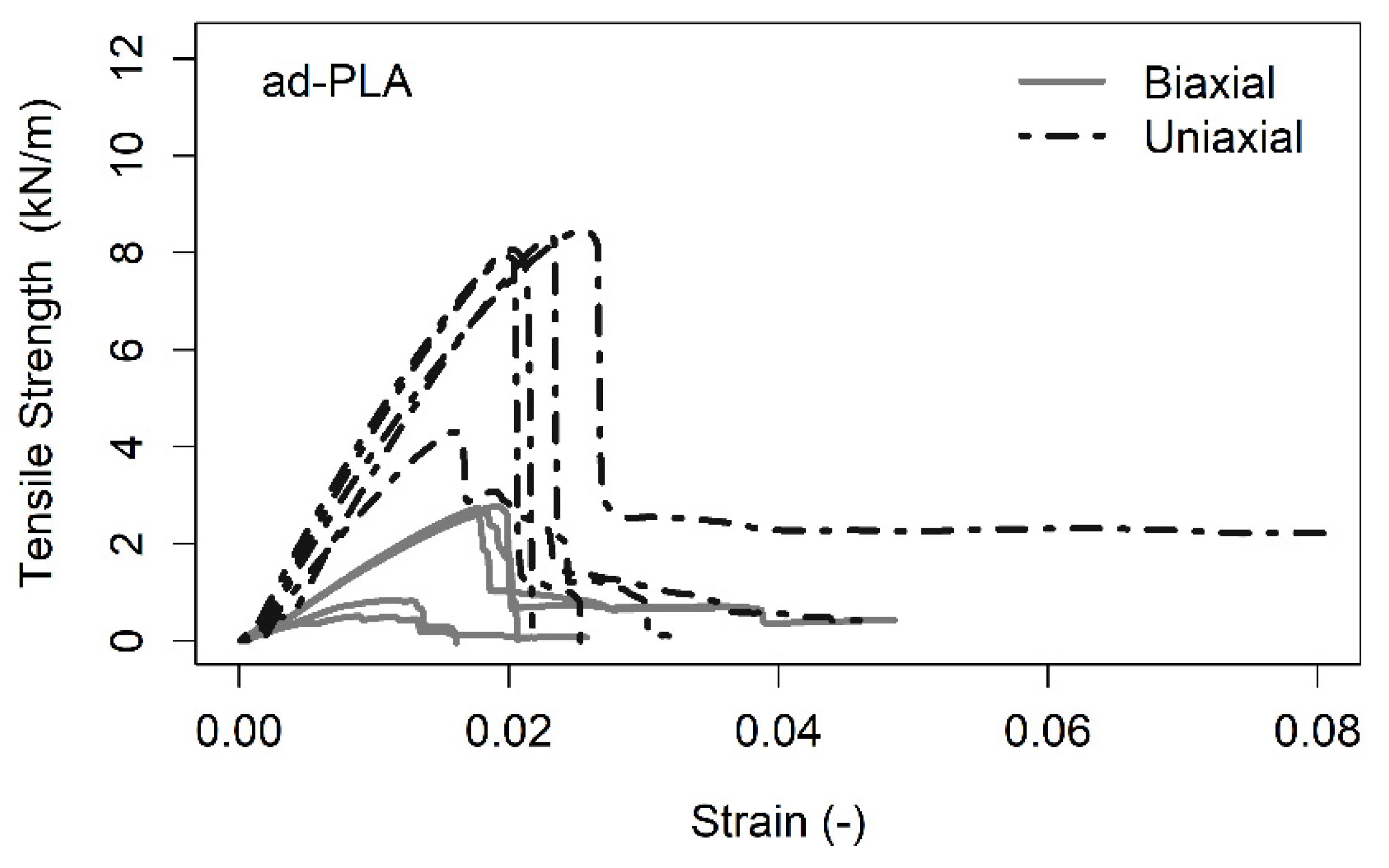

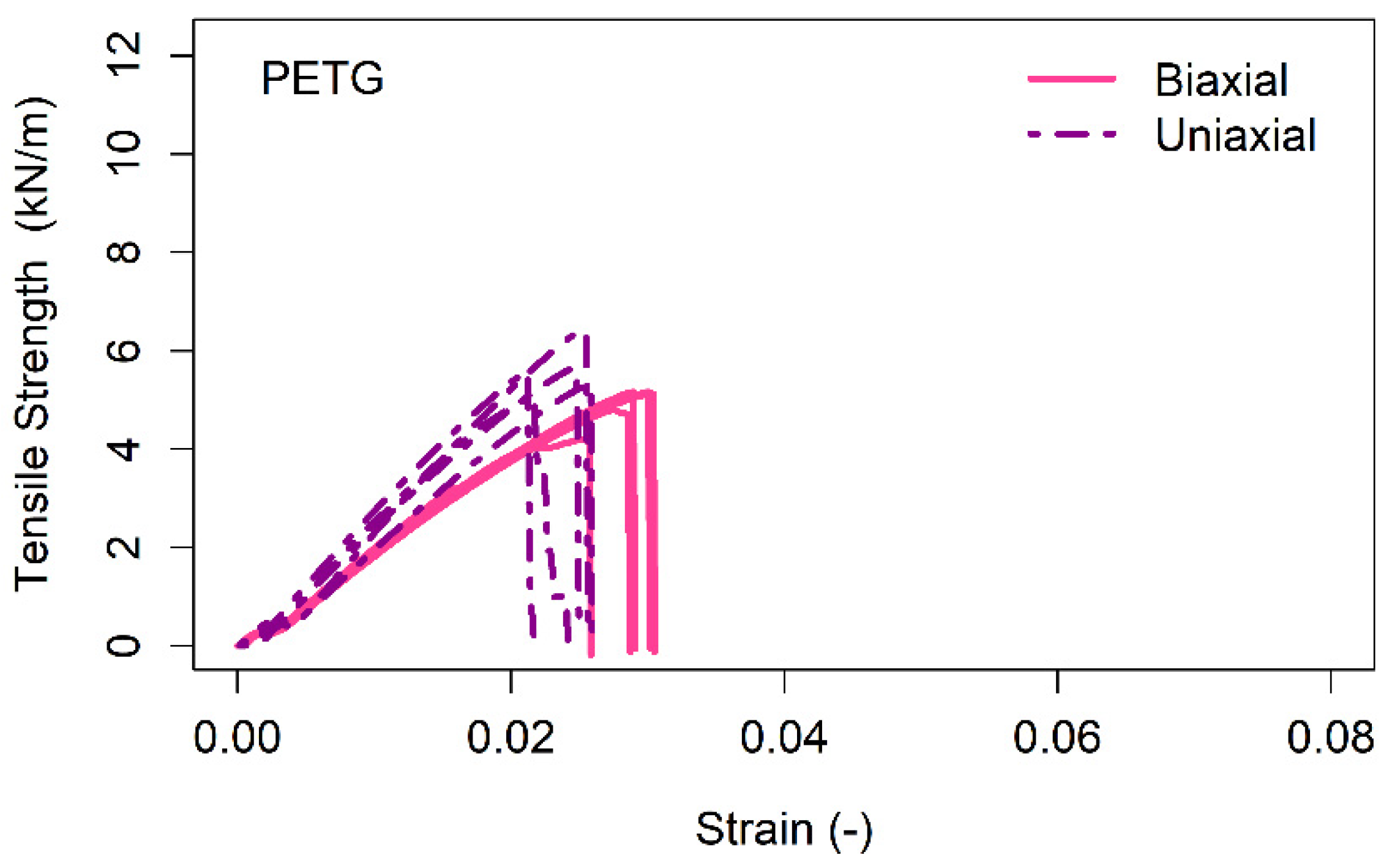

3.2. Prototypes Samples Building and Testing

4. Discussion

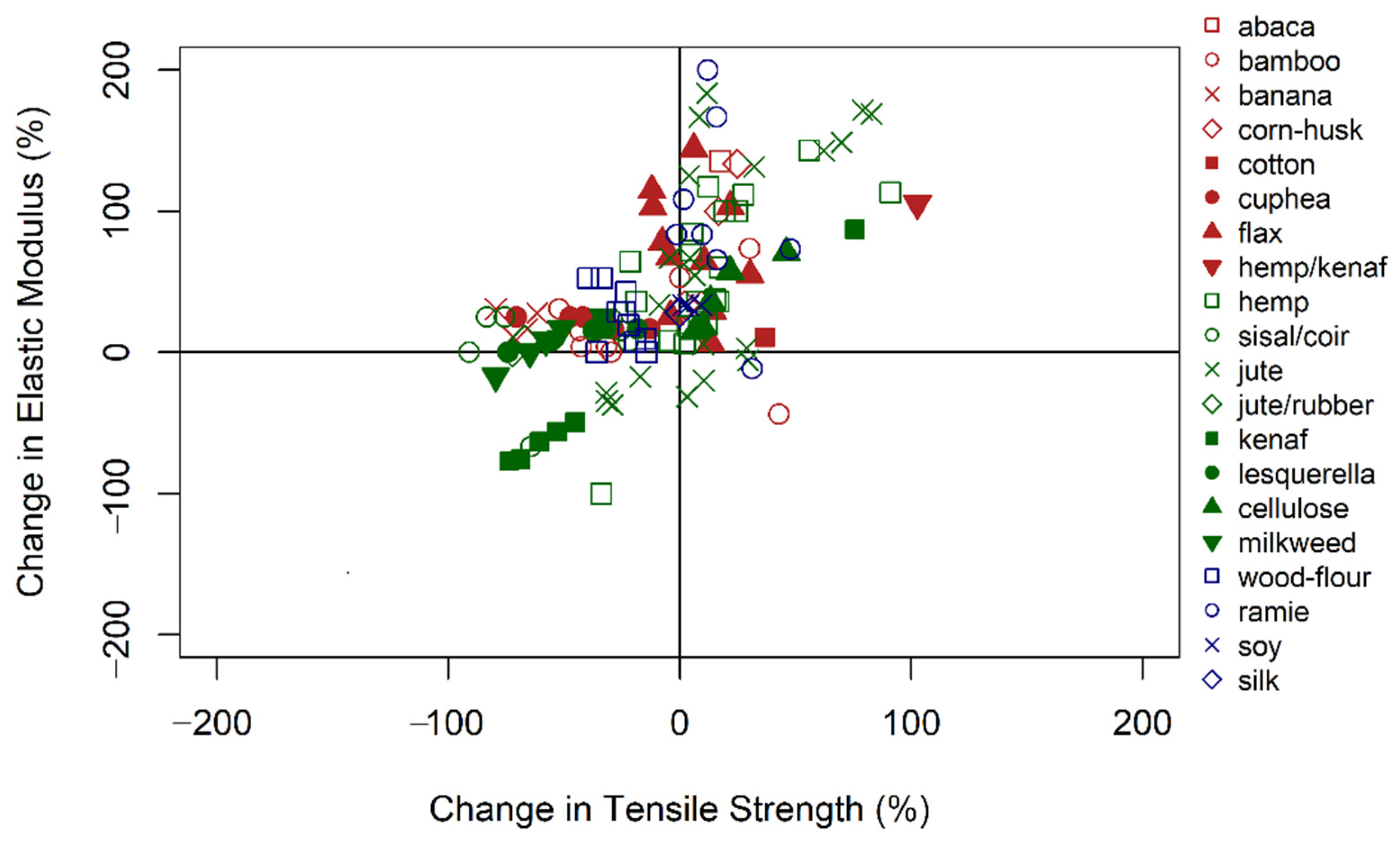

4.1. An Overview of Biomaterials: From the Mechanical Properties to the Biodegradation

4.2. Applications in Geo-Environmental Engineering

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. COM(2014) 398 Final; Towards a Circular Economy: A ZeroWaste Programme for Europe; European Commission: Brussels, Belgium, 2014; p. 14. [Google Scholar]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and Demolition Waste Management in China through the 3R Principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H. A Framework for Understanding Waste Management Studies in Construction. Waste Manag. 2011, 31, 1252–1260. [Google Scholar] [CrossRef]

- European Commission. COM(2018) 35 Final; On the Impact of the Use of Oxo-Degradable Plastic, Including Oxo-Degradable Plastic Carrier Bags, On the Environment; European Commission: Brussels, Belgium, 2018; p. 9. [Google Scholar]

- Wiewel, B.V.; Lamoree, M. Geotextile Composition, Application and Ecotoxicology: A Review. J. Hazard. Mater. 2016, 317, 640–655. [Google Scholar] [CrossRef] [PubMed]

- Müller, W.W.; Saathoff, F. Geosynthetics in Geoenvironmental Engineering. Sci. Technol. Adv. Mater. 2015, 16, 034605. [Google Scholar] [CrossRef]

- Browne, M.A.; Galloway, T.; Thompson, R. Microplastic-an Emerging Contaminant of Potential Concern?: Learned Discourses. Integr. Environ. Assess. Manag. 2007, 3, 559–561. [Google Scholar] [CrossRef]

- Beißmann, S.; Stiftinger, M.; Grabmayer, K.; Wallner, G.; Nitsche, D.; Buchberger, W. Monitoring the Degradation of Stabilization Systems in Polypropylene during Accelerated Aging Tests by Liquid Chromatography Combined with Atmospheric Pressure Chemical Ionization Mass Spectrometry. Polym. Degrad. Stab. 2013, 98, 1655–1661. [Google Scholar] [CrossRef]

- Avella, M.; Buzarovska, A.; Errico, M.; Gentile, G.; Grozdanov, A. Eco-Challenges of Bio-Based Polymer Composites. Materials 2009, 2, 911–925. [Google Scholar] [CrossRef]

- Pozo Morales, A.; Güemes, A.; Fernandez-Lopez, A.; Carcelen Valero, V.; De La Rosa Llano, S. Bamboo–Polylactic Acid (PLA) Composite Material for Structural Applications. Materials 2017, 10, 1286. [Google Scholar] [CrossRef] [PubMed]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications: A Comprehensive Review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. A State-of-the-Art Review on Soil Reinforcement Technology Using Natural Plant Fiber Materials: Past Findings, Present Trends and Future Directions. Materials 2018, 11, 553. [Google Scholar] [CrossRef] [PubMed]

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-Lactic Acid: Production, Applications, Nanocomposites, and Release Studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef] [PubMed]

- Tuominen, J.; Kylmä, J.; Kapanen, A.; Venelampi, O.; Itävaara, M.; Seppälä, J. Biodegradation of Lactic Acid Based Polymers under Controlled Composting Conditions and Evaluation of the Ecotoxicological Impact. Biomacromolecules 2002, 3, 445–455. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(Lactic Acid) Modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Drumright, R.E.; Gruber, P.R.; Henton, D.E. Polylactic Acid Technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Farrington, D.W.; Davies, J.L.S.; Blackburn, R.S. Poly(lactic acid) fibers. In Biodegradable and Sustainable Fibres; Elsevier: Amsterdam, The Netherlands, 2005; pp. 191–220. ISBN 978-1-85573-916-1. [Google Scholar]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Ho, M.; Lau, K.; Wang, H.; Bhattacharyya, D. Characteristics of a Silk Fibre Reinforced Biodegradable Plastic. Compos. Part B Eng. 2011, 42, 117–122. [Google Scholar] [CrossRef]

- Uddin, N.; Kalyankar, R.R. Manufacturing and Structural Feasibility of Natural Fiber Reinforced Polymeric Structural Insulated Panels for Panelized Construction. Int. J. Polym. Sci. 2011, 2011, 1–7. [Google Scholar] [CrossRef]

- Bhatraju, N.S.; Kumar, K.K. To Learn on Construction of Pavement by Using Geotextile. Int. J. Innov. Technol. Res. 2018, 6, 7867–7869. [Google Scholar]

- Jeon, H.-Y. Environmental Adaptability of Green Geosynthetics as Sustainable Materials for Civil Engineering Applications. In Proceedings of the Geosynthetics, Forging a Path to Bona Fide Engineering Materials; American Society of Civil Engineers: Chicago, IL, USA, 2016; pp. 318–325. [Google Scholar]

- Murariu, M.; Dubois, P. PLA Composites: From Production to Properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef] [PubMed]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and Biotic Environmental Degradation of the Bioplastic Polymer Poly(Lactic Acid): A Review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef]

- Lasprilla, A.J.R.; Martinez, G.A.R.; Lunelli, B.H.; Jardini, A.L.; Filho, R.M. Poly-Lactic Acid Synthesis for Application in Biomedical Devices: A Review. Biotechnol. Adv. 2012, 30, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Gunti, R.; Ratna Prasad, A.V.; Gupta, A.V.S.S.K.S. Mechanical and Degradation Properties of Natural Fiber-Reinforced PLA Composites: Jute, Sisal, and Elephant Grass. Polym. Compos. 2018, 39, 1125–1136. [Google Scholar] [CrossRef]

- Mochane, M.J.; Mokhena, T.C.; Sadiku, E.R.; Ray, S.S.; Mofokeng, T.G. Green polymer composites based on polylactic acid (PLA) and fibers. In Green Biopolymers and Their Nanocomposites; Gnanasekaran, D., Ed.; Springer: Singapore, 2019; pp. 29–54. ISBN 9789811380624. [Google Scholar]

- Ochi, S. Mechanical Properties of Kenaf Fibers and Kenaf/PLA Composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, L.; Liang, D.; Xiao, W.; Lin, J. Mechanical and Thermal Properties of PLA Biocomposites Reinforced by Coir Fibers. Int. J. Polym. Sci. 2017, 2017, 1–8. [Google Scholar] [CrossRef]

- Wang, Y.; Weng, Y.; Wang, L. Characterization of Interfacial Compatibility of Polylactic Acid and Bamboo Flour (PLA/BF) in Biocomposites. Polym. Test. 2014, 36, 119–125. [Google Scholar] [CrossRef]

- Yu, T.; Ding, D.; Sheng, C.; Tuerhongjiang, T.; Li, Y. Enhanced Mechanical Properties and Flame Retardancy of Short Jute Fiber/Poly(Lactic Acid) Composites with Phosphorus-Based Compound. Sci. China Technol. Sci. 2017, 60, 1716–1723. [Google Scholar] [CrossRef]

- Plackett, D.; Løgstrup Andersen, T.; Batsberg Pedersen, W.; Nielsen, L. Biodegradable Composites Based on L-Polylactide and Jute Fibres. Compos. Sci. Technol. 2003, 63, 1287–1296. [Google Scholar] [CrossRef]

- Ben, G.; Kihara, Y. Development and Evaluation of Mechanical Properties for Kenaf Fibers/PLA Composites. Key Eng. Mater. 2007, 334–335, 489–492. [Google Scholar] [CrossRef]

- Saenghirunwattana, P.; Noomhorm, A.; Rungsardthong, V. Mechanical Properties of Soy Protein Based “Green” Composites Reinforced with Surface Modified Cornhusk Fiber. Ind. Crop. Prod. 2014, 60, 144–150. [Google Scholar] [CrossRef]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and Man-Made Cellulose Fibre-Reinforced Poly(Lactic Acid) (PLA) Composites: An Overview about Mechanical Characteristics and Application Areas. Compos. Part A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Bax, B.; Müssig, J. Impact and Tensile Properties of PLA/Cordenka and PLA/Flax Composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar] [CrossRef]

- Yu, T.; Ren, J.; Li, S.; Yuan, H.; Li, Y. Effect of Fiber Surface-Treatments on the Properties of Poly(Lactic Acid)/Ramie Composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 499–505. [Google Scholar] [CrossRef]

- Febrianto, F.; Yoshioka, M.; Nagai, Y.; Syafii, W.; Shiraishi, N. Characterization and Properties of Composites of Wood Flour and Poly Lactic Acid. Mokchae Konghak 2006, 34, 67–78. [Google Scholar]

- Muller, J.; González-Martínez, C.; Chiralt, A. Combination of Poly(Lactic) Acid and Starch for Biodegradable Food Packaging. Materials 2017, 10, 952. [Google Scholar] [CrossRef] [PubMed]

- Finkenstadt, V.L.; Liu, C.-K.; Evangelista, R.; Liu, L.; Cermak, S.C.; Hojilla-Evangelista, M.; Willett, J.L. Poly(Lactic Acid) Green Composites Using Oilseed Coproducts as Fillers. Ind. Crop. Prod. 2007, 26, 36–43. [Google Scholar] [CrossRef]

- Rawi, N.F.M.; Jayaraman, K.; Bhattacharyya, D. A Performance Study on Composites Made from Bamboo Fabric and Poly(Lactic Acid). J. Reinf. Plast. Compos. 2013, 32, 1513–1525. [Google Scholar] [CrossRef]

- Hu, R.; Lim, J.-K. Fabrication and Mechanical Properties of Completely Biodegradable Hemp Fiber Reinforced Polylactic Acid Composites. J. Compos. Mater. 2007, 41, 1655–1669. [Google Scholar] [CrossRef]

- Ma, H.; Joo, C.W. Structure and Mechanical Properties of Jute-Polylactic Acid Biodegradable Composites. J. Compos. Mater. 2011, 45, 1451–1460. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A.; Scherzer, D. Mechanical Properties of PLA Composites with Man-Made Cellulose and Abaca Fibres. Compos. Part A Appl. Sci. Manuf. 2009, 40, 404–412. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural Fibres as Reinforcement in Polylactic Acid (PLA) Composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Jandas, P.J.; Mohanty, A.K.; Nayak, S.K.; Srivastava, H. Effect of Surface Treatments of Banana Fiber on Mechanical, Thermal, and Biodegradability Properties of PLA/Banana Fiber Biocomposites. Polym Compos 2011, 32, 1689–1700. [Google Scholar] [CrossRef]

- Shih, Y.-F.; Huang, C.-C. Polylactic Acid (PLA)/Banana Fiber (BF) Biodegradable Green Composites. J. Polym. Res. 2011, 18, 2335–2340. [Google Scholar] [CrossRef]

- Song, Y.S.; Lee, J.T.; Ji, D.S.; Kim, M.W.; Lee, S.H.; Youn, J.R. Viscoelastic and Thermal Behavior of Woven Hemp Fiber Reinforced Poly(Lactic Acid) Composites. Compos. Part B Eng. 2012, 43, 856–860. [Google Scholar] [CrossRef]

- Porras, A.; Maranon, A. Development and Characterization of a Laminate Composite Material from Polylactic Acid (PLA) and Woven Bamboo Fabric. Compos. Part B Eng. 2012, 43, 2782–2788. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Yunus, W.M.Z.W.; Othman, M.; Abdan, K.; Hadithon, K.A. Poly(Lactic Acid) (PLA)-Reinforced Kenaf Bast Fiber Composites: The Effect of Triacetin. J. Reinf. Plast. Compos. 2010, 29, 1099–1111. [Google Scholar] [CrossRef]

- Lee, S.-H.; Wang, S. Biodegradable Polymers/Bamboo Fiber Biocomposite with Bio-Based Coupling Agent. Compos. Part A: Appl. Sci. Manuf. 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Ruksakulpiwat, Y.; Tonimit, P.; Kluengsamrong, J. Mechanical Properties of PLA-Jute Composites by Using Natural Rubber and Epoxidized Natural Rubber as Impact Modifiers: Effect of Molding Technique. Clean Technol. 2010, 4, 310–313. [Google Scholar]

- Taha, I.; Ziegmann, G. A Comparison of Mechanical Properties of Natural Fiber Filled Biodegradable and Polyolefin Polymers. J. Compos. Mater. 2006, 40, 1933–1946. [Google Scholar] [CrossRef]

- Stoof, D.; Pickering, K.; Zhang, Y. Fused Deposition Modelling of Natural Fibre/Polylactic Acid Composites. J. Compos. Sci. 2017, 1, 8. [Google Scholar] [CrossRef]

- Le Duigou, A.; Pillin, I.; Bourmaud, A.; Davies, P.; Baley, C. Effect of Recycling on Mechanical Behaviour of Biocompostable Flax/Poly(l-Lactide) Composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1471–1478. [Google Scholar] [CrossRef]

- Yu, T.; Li, Y.; Ren, J. Preparation and Properties of Short Natural Fiber Reinforced Poly(Lactic Acid) Composites. Trans. Nonferrous Met. Soc. China 2009, 19, s651–s655. [Google Scholar] [CrossRef]

- Kuciel, S.; Mazur, K.; Hebda, M. The Influence of Wood and Basalt Fibres on Mechanical, Thermal and Hydrothermal Properties of PLA Composites. J Polym Environ. 2020, 28, 1204–1215. [Google Scholar] [CrossRef]

- Mazzanti, V.; Pariante, R.; Bonanno, A.; Ruiz de Ballesteros, O.; Mollica, F.; Filippone, G. Reinforcing Mechanisms of Natural Fibers in Green Composites: Role of Fibers Morphology in a PLA/Hemp Model System. Compos. Sci. Technol. 2019, 180, 51–59. [Google Scholar] [CrossRef]

- Suryanegara, L.; Nakagaito, A.N.; Yano, H. The Effect of Crystallization of PLA on the Thermal and Mechanical Properties of Microfibrillated Cellulose-Reinforced PLA Composites. Compos. Sci. Technol. 2009, 69, 1187–1192. [Google Scholar] [CrossRef]

- Graupner, N.; Narkpiban, K.; Poonsawat, T.; Tooptompong, P.; Müssig, J. Toddy Palm (Borassus Flabellifer) Fruit Fibre Bundles as Reinforcement in Polylactide (PLA) Composites: An Overview about Fibre and Composite Characteristics. J. Renew. Mater. 2019, 7, 693–711. [Google Scholar] [CrossRef]

- Duan, J.; Wu, H.; Fu, W.; Hao, M. Mechanical Properties of Hybrid Sisal/Coir Fibers Reinforced Polylactide Biocomposites. Polym. Compos. 2018, 39, E188–E199. [Google Scholar] [CrossRef]

- Dong, Y.; Ghataura, A.; Takagi, H.; Haroosh, H.J.; Nakagaito, A.N.; Lau, K.-T. Polylactic Acid (PLA) Biocomposites Reinforced with Coir Fibres: Evaluation of Mechanical Performance and Multifunctional Properties. Compos. Part A Appl. Sci. Manuf. 2014, 63, 76–84. [Google Scholar] [CrossRef]

- Marques, D.S.; Gil, M.H.; Baptista, C.M.S.G. Bulk Polytransesterification of L-Lactic Acid Esters: An Alternative Route to Synthesize Poly(Lactic Acid). J. Appl. Polym. Sci. 2012, 125, E283–E289. [Google Scholar] [CrossRef]

- Hufenus, R.; Rueegger, R.; Banjac, R.; Mayor, P.; Springman, S.M.; Bronnimann, R. Full-Scale Field Tests on Geosynthetic Reinforced Unpaved Roads on Soft Subgrade. Geotext. Geomembr. 2006, 24, 21–37. [Google Scholar] [CrossRef]

- Yoo, C.; Lee, D. Performance of Geogrid-Encased Stone Columns in Soft Ground: Full-Scale Load Tests. Geosynth. Int. 2012, 19, 480–490. [Google Scholar] [CrossRef]

- Bathurst, R.J.; Vlachopoulos, N.; Walters, D.L.; Burgess, P.G.; Allen, T.M. The Influence of Facing Stiffness on the Performance of Two Geosynthetic Reinforced Soil Retaining Walls. Can. Geotech. J. 2006, 43, 1225–1237. [Google Scholar] [CrossRef]

- Garnier, J.; Gaudin, C.; Springman, S.M.; Culligan, P.J.; Goodings, D.; Konig, D.; Kutter, B.; Phillips, R.; Randolph, M.F.; Thorel, L. Catalogue of Scaling Laws and Similitude Questions in Geotechnical Centrifuge Modelling. Int. J. Phys. Model. Geotech. 2007, 7, 01–23. [Google Scholar] [CrossRef]

- Springman, S.M.; Bolton, M.D.; Sharma, J.; Balachandran, S. Modelling and instrumentation of a geotextile in the geotechnical centrifuge. In Proceedings of the International Symposyum on Earth Reinforcement Practice, Kyushu, Japan, 11–13 November 1992; 167, pp. 172–178. [Google Scholar]

- Amurane, I.; Zhang, M.; Li, T.; Jiang, H. Optimization of 3D Printed Geocells Based on Numerical Simulation and Experimental Investigation. IOP Conf. Ser. Earth Environ. Sci. 2019, 233, 032043. [Google Scholar] [CrossRef]

- Arab, M.G.; Omar, M.; Alotaibi, E.; Mostafa, O.; Naeem, M.; Badr, O. Bio-Inspired 3D-Printed Honeycomb for Soil Reinforcement. In Proceedings of the Geo-Congress 2020; American Society of Civil Engineers: Minneapolis, Minnesota, 2020; pp. 262–271. [Google Scholar]

- Mallett, S.D.; Matsumura, S.; David Frost, J. Additive Manufacturing and Computed Tomography of Bio-Inspired Anchorage Systems. Géotechnique Lett. 2018, 8, 219–225. [Google Scholar] [CrossRef]

- Stathas, D.; Wang, J.P.; Ling, H.I. Model Geogrids and 3D Printing. Geotext. Geomembr. 2017, 45, 688–696. [Google Scholar] [CrossRef]

- Viswanadham, B.V.S.; Jessberger, H.L. Centrifuge Modeling of Geosynthetic Reinforced Clay Liners of Landfills. J. Geotech. Geoenviron. Eng. 2005, 131, 564–574. [Google Scholar] [CrossRef]

- Viswanadham, B.V.S.; König, D. Studies on Scaling and Instrumentation of a Geogrid. Geotext. Geomembr. 2004, 22, 307–328. [Google Scholar] [CrossRef]

- Cislaghi, A.; Sala, P.; Borgonovo, G.; Gandolfi, C.; Bischetti, G.B. Biodegradable geosynthetics for geotechnical and geo-environmental engineering. In Innovative Biosystems Engineering for Sustainable Agriculture, Forestry and Food Production; Coppola, A., Di Renzo, G.C., Altieri, G., D’Antonio, P., Eds.; Lecture Notes in Civil Engineering; Springer International Publishing: Cham, Switerland, 2020; Volume 67, pp. 49–57. ISBN 978-3-030-39298-7. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive Manufacturing of Multi-Material Structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Bose, S.; Ke, D.; Sahasrabudhe, H.; Bandyopadhyay, A. Additive Manufacturing of Biomaterials. Prog. Mater. Sci. 2018, 93, 45–111. [Google Scholar] [CrossRef] [PubMed]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused Filament Fabrication of Fiber-Reinforced Polymers: A Review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of Porosity and Crystallinity on 3D Printed PLA Properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef]

- Ghorpade, V.M.; Gennadios, A.; Hanna, M.A. Laboratory Composting of Extruded Poly(Lactic Acid) Sheets q. Bioresour. Technol. 2001, 76, 57–61. [Google Scholar] [CrossRef]

- Weng, Y.-X.; Jin, Y.-J.; Meng, Q.-Y.; Wang, L.; Zhang, M.; Wang, Y.-Z. Biodegradation Behavior of Poly(Butylene Adipate-Co-Terephthalate) (PBAT), Poly(Lactic Acid) (PLA), and Their Blend under Soil Conditions. Polym. Test. 2013, 32, 918–926. [Google Scholar] [CrossRef]

- Karamanlioglu, M.; Houlden, A.; Robson, G.D. Isolation and Characterisation of Fungal Communities Associated with Degradation and Growth on the Surface of Poly(Lactic) Acid (PLA) in Soil and Compost. Int. Biodeterior. Biodegrad. 2014, 95, 301–310. [Google Scholar] [CrossRef]

- Rudnik, E.; Briassoulis, D. Degradation Behaviour of Poly(Lactic Acid) Films and Fibres in Soil under Mediterranean Field Conditions and Laboratory Simulations Testing. Ind. Crop. Prod. 2011, 33, 648–658. [Google Scholar] [CrossRef]

- Shogren, R.L.; Doane, W.M.; Garlotta, D.; Lawton, J.W.; Willett, J.L. Biodegradation of Starch/Polylactic Acid/Poly(Hydroxyester-Ether) Composite Bars in Soil. Polym. Degrad. Stab. 2003, 79, 405–411. [Google Scholar] [CrossRef]

- Itävaara, M.; Karjomaa, S.; Selin, J.-F. Biodegradation of Polylactide in Aerobic and Anaerobic Thermophilic Conditions. Chemosphere 2002, 46, 879–885. [Google Scholar] [CrossRef]

- Calmon, A.; Guillaume, S.; Bellon-Maurel, V.; Feuilloley, P.; Silvestre, F. Evaluation of Material Biodegradability in Real Conditions-Development of a Burial Test and an Analysis Methodology Based on Numerical Vision. J. Environ. Polym. Degrad. 1999, 7, 157–166. [Google Scholar] [CrossRef]

- Kinnersley, A.M.; Scott, T.C.; Yopp, J.H.; Whitten, G.H. Promotion of Plant Growth by Polymers of Lactic Acid. Plant Growth Regul. 1990, 9, 137–146. [Google Scholar] [CrossRef]

- Bischetti, G.B.; Di Fidio, M.; Florineth, F. On the Origin of Soil Bioengineering. Landsc. Res. 2014, 39, 583–595. [Google Scholar] [CrossRef]

- Cazzuffi, D.; Cardile, G.; Gioffrè, D. Geosynthetic Engineering and Vegetation Growth in Soil Reinforcement Applications. Transp. Infrastruct. Geotechnol. 2014, 1, 262–300. [Google Scholar] [CrossRef]

- Gray, D.H.; Sotir, R.B. Biotechnical and Soil Bioengineering Slope Stabilization: A Practical Guide for Erosion Control; John Wiley & Sons: Hoboken, NJ, USA, 1996; ISBN 978-0-471-04978-4. [Google Scholar]

- Fox, J.L.; Bhattarai, S.P.; Gyasi-Agyei, Y. Evaluation of Different Seed Mixtures for Grass Establishment to Mitigate Soil Erosion on Steep Slopes of Railway Batters. J. Irrig. Drain Eng. 2011, 137, 624–631. [Google Scholar] [CrossRef]

- Bischetti, G.B.; Chiaradia, E.A.; D’Agostino, V.; Simonato, T. Quantifying the Effect of Brush Layering on Slope Stability. Ecol. Eng. 2010, 36, 258–264. [Google Scholar] [CrossRef]

- Cislaghi, A.; Giupponi, L.; Tamburini, A.; Giorgi, A.; Bischetti, G.B. The Effects of Mountain Grazing Abandonment on Plant Community, Forage Value and Soil Properties: Observations and Field Measurements in an Alpine Area. CATENA 2019, 181, 104086. [Google Scholar] [CrossRef]

- De Baets, S.; Poesen, J.; Gyssels, G.; Knapen, A. Effects of Grass Roots on the Erodibility of Topsoils during Concentrated Flow. Geomorphology 2006, 76, 54–67. [Google Scholar] [CrossRef]

- Gyssels, G.; Poesen, J.; Bochet, E.; Li, Y. Impact of Plant Roots on the Resistance of Soils to Erosion by Water: A Review. Prog. Phys. Geogr. 2005, 29, 189–217. [Google Scholar] [CrossRef]

- Lian, B.; Peng, J.; Zhan, H.; Wang, X. Mechanical Response of Root-Reinforced Loess with Various Water Contents. Soil Tillage Res. 2019, 193, 85–94. [Google Scholar] [CrossRef]

- Bastola, S.; Ishidaira, H.; Takeuchi, K. Regionalisation of Hydrological Model Parameters under Parameter Uncertainty: A Case Study Involving TOPMODEL and Basins across the Globe. J. Hydrol. 2008, 357, 188–206. [Google Scholar] [CrossRef]

- Gray, D.H.; Leiser, A.T. Biotechnical Slope Protection and Erosion Control; Van Nostrand Reinhold Company Inc.: New York, NY, USA, 1982; ISBN 0-442-21222-4. [Google Scholar]

- Zhang, X.; Zhao, W.; Wang, L.; Liu, Y.; Feng, Q.; Fang, X.; Liu, Y. Distribution of Shrubland and Grassland Soil Erodibility on the Loess Plateau. Int. J. Environ. Res. Public Health 2018, 15, 1193. [Google Scholar] [CrossRef]

- Gonzalez-Ollauri, A.; Mickovski, S.B. Plant-Best: A Novel Plant Selection Tool for Slope Protection. Ecol. Eng. 2017, 106, 154–173. [Google Scholar] [CrossRef]

- Gonzalez-Ollauri, A.; Mickovski, S.B. Using the Root Spread Information of Pioneer Plants to Quantify Their Mitigation Potential against Shallow Landslides and Erosion in Temperate Humid Climates. Ecol. Eng. 2016, 95, 302–315. [Google Scholar] [CrossRef]

| Supplier and Product | Form | Process | SG (g/cc) | EL (%) | TS (MPa) | YM (GPa) |

|---|---|---|---|---|---|---|

| NatureWorks Biopolymer 3D850 | Filament | Extrusion-Injection molding | 1.24 | 3.3 | 50.0 | 2.3 |

| NatureWorks Biopolymer 3D870 | Filament | Extrusion-Injection molding | 1.22 | 4.0 | 40.0 | 2.9 |

| NatureWorks Biopolymer 4043D | Filament | Extrusion-Injection molding | 1.24 | 6.0 | 53.0 | 3.6 |

| NatureWorks Biopolymer 4032D | Resin | Extrusion-Injection molding | 1.24 | 6.0 | 53.0 | 3.5 |

| NatureWorks Biopolymer 4042D | Film | Melt blending-Compression molding | 1.25 | 3.6 | 56.3 | 3.3–3.8 |

| colorFabb PLA Economy | Filament | Extrusion-Injection molding | 1.20–1.30 | 6.0 | 45.0 | 3.4 |

| colorFabb SteelFill | Filament | Extrusion-Injection molding | 1.13 | 1.0–3.0 | 23.0 | - |

| NatureWorks Biopolymer 2000D | Film | Extrusion-Thermoforming | 1.25 | 6.0 | 53.0 | 3.5 |

| NatureWorks Biopolymer 3010D | Film | Extrusion-Injection molding | 1.21 | 2.5 | 48.0 | - |

| NatureWorks Biopolymer 2002D | Resin | Extrusion-Injection molding | 1.24 | 2.0 | 60.0 | 3.5 |

| NatureWorks Biopolymer 2002D | Resin | Extrusion-Blown molding | 1.24 | 2.1 | 34.6 | 3.5 |

| NatureWorks Biopolymer 4042D | Film | Melt blending-Compression molding | 1.25 | 7.4 | 70.2 | 3.3 |

| NatureWorks Biopolymer 4042D | Film | Extrusion-Injection molding | 1.25 | 1.0 | 38.0 | 3.8 |

| NatureWorks Biopolymer 2002D | Resin | Melt blending-Compression molding | 1.24 | 4.5 | 55.0 | 3.5 |

| NatureWorks Biopolymer 4032D | Resin | Extrusion-Injection molding | 1.24 | 5.0 | 65.0 | 3.5 |

| NatureWorks Biopolymer 2000D | Film | Casting (chloroform) | 1.25 | 7.9 | 24.8 | 3.5 |

| Reinforced-PLA | Processing | C (%) | PT (°C) | TS (MPa) | YM (GPa) | EL (%) |

|---|---|---|---|---|---|---|

| neat-PLA blended with jute fibers (Corchorus capsularis) [34] | film-stacking | 0 | 190 | 55.0 | 3.5 | 2.1 |

| 40 | 180 | 72.7 | 8.1 | 1.5 | ||

| 40 | 190 | 89.3 | 8.5 | 1.8 | ||

| 40 | 200 | 93.5 | 8.7 | 1.6 | ||

| 40 | 210 | 100.5 | 9.4 | 1.6 | ||

| 40 | 220 | 98.5 | 9.5 | 1.5 | ||

| neat-PLA blended with cuphea oil-seeds (Cuphea viscosissima × C. lanceolata) [42] | twin-screw extrusion | 0 | 160 | 72.0 | 1.2 | 14.5 |

| 8 | 156 | 62.6 | 1.4 | 7.8 | ||

| 15 | 153 | 51.4 | 1.4 | 6.1 | ||

| 22 | 155 | 41.9 | 1.5 | 5.4 | ||

| 30 | 150 | 37.9 | 1.5 | 7.9 | ||

| 45 | 148 | 21.2 | 1.5 | 4.6 | ||

| neat-PLA blended with lesquerella oil-seeds (Lesquerella fenderli) [42] | twin-screw extrusion | 0 | 160 | 72.0 | 1.2 | 14.5 |

| 8 | 156 | 58.9 | 1.4 | 8.8 | ||

| 15 | 156 | 48.9 | 1.4 | 7.6 | ||

| 22 | 155 | 45.6 | 1.4 | 5.4 | ||

| 30 | 154 | 32.2 | 1.3 | 7.9 | ||

| 45 | 149 | 18.5 | 1.2 | 4.6 | ||

| neat-PLA blended with milkweed oil-seeds (Asclepias syriaca and Asclepias speciose) [42] | twin-screw extrusion | 0 | 160 | 72.0 | 1.2 | 14.5 |

| 8 | 154 | 48.1 | 1.5 | 20.1 | ||

| 15 | 155 | 35.2 | 1.4 | 34.6 | ||

| 22 | 155 | 30.3 | 1.3 | 30.4 | ||

| 30 | 155 | 25.3 | 1.2 | 23.1 | ||

| 45 | 155 | 14.7 | 1.0 | 14.3 | ||

| neat-PLA [37] | compression molding | 0 | 160–170 | 30.1 | 3.8 | 0.8 |

| neat-PLA blended with cotton fibers (Gossypium sp.) [37] | 40 | 160–170 | 41.2 | 4.2 | 3.1 | |

| neat-PLA blended with kenaf fibers (Hibiscus cannabinus) [37] | 40 | 160–170 | 52.9 | 7.1 | 1.1 | |

| neat-PLA blended with hemp fibers (Cannabis sativa) [37] | 40 | 160–170 | 57.5 | 8.1 | 1.2 | |

| neat-PLA blended with hemp fibers (Cannabis sativa) and kenaf fibers (Hibiscus cannabinus) [37] | 20/20 | 160–170 | 61.0 | 7.8 | 1.2 | |

| neat-PLA blended with ramie fibers (Boehmeria nivea) [32,39] | - | 0 | 170 | 45.2 | 2.6 | 1.2 |

| compression molding | 30 | 170 | 52.5 | 4.3 | 3.2 | |

| 30 ** | 170 | 66.8 | 4.5 | 4.8 | ||

| twin-screw extrusion | 30 | 170 | 59.3 | 2.3 | 4.1 | |

| neat-PLA blended with bamboo fibers [43] | - | 0 | 170 | 61.9 | 3.4 | |

| 35 | 170 | 80.6 | 5.9 | |||

| 35 | 170 | 61.9 | 5.2 | |||

| neat-PLA blended with hemp fibers (Cannabis sativa) [44] | compression molding | 0 | 170 | 35.0 | 3.5 | 6.0 |

| 30 ** | 170 | 39.3 | 7.6 | |||

| 30 | 170 | 41.1 | 5.6 | |||

| 40 ** | 170 | 54.6 | 8.5 | |||

| 40 | 170 | 44.6 | 7.4 | |||

| 50 ** | 170 | 41.8 | 7.0 | |||

| 50 | 170 | 43.7 | 7.0 | |||

| neat-PLA blended with jute fibers (Corchorus capsularis) [45] | compression molding | 0 | 180 | 34.6 | 3.5 | 2.1 |

| 5 | 200 | 23.6 | 2.5 | 6.4 | ||

| 10 | 200 | 38.2 | 2.8 | 5.7 | ||

| 15 | 200 | 44.8 | 3.3 | 5.8 | ||

| 5 | 210 | 24.6 | 2.2 | 5.6 | ||

| 10 | 210 | 35.7 | 2.4 | 5.6 | ||

| 15 | 210 | 44.6 | 3.6 | 5.2 | ||

| 5 | 220 | 23.7 | 2.3 | 5.6 | ||

| 10 | 220 | 28.7 | 2.9 | 5.2 | ||

| 15 | 220 | 38.1 | 3.7 | 5.4 | ||

| neat-PLA blended with flax fibers (Linum usitastissimum L. and Linum Linacea) [38] | compression and injection | 0 | 180 | 44.5 | 3.1 | |

| 10 | 180 | 42.7 | 3.9 | |||

| 20 | 180 | 49.2 | 5.1 | |||

| 30 | 180 | 54.2 | 6.3 | |||

| neat-PLA blended with rayon fibers [38] | 10 | 180 | 50.4 | 3.3 | ||

| 20 | 180 | 50.8 | 4.0 | |||

| 30 | 180 | 58.0 | 4.8 | |||

| neat-PLA [46] | single-screw extrusion and injection | 0 | 63.0 | 3.4 | ||

| neat-PLA blended with abaca fibers (Musa textilis) [46] | 30 | 180 | 74.0 | 8.0 | ||

| neat-PLA blended with man-made cellulose fibers [46] | 30 | 180 | 92.0 | 5.8 | ||

| neat-PLA blended with flax fibers (Linum usitatissimum) [47] | twin-screw extrusion and compression molding | 0 | 190 | 50.0 | 3.4 | 2.0 |

| 30 | 190 | 53.0 | 8.3 | 1.0 | ||

| 40 | 190 | 44.0 | 7.3 | 0.9 | ||

| neat-PLA blended with banana fibers (Musa indica) [48] | compression molding | 0 | 190 | 38 | 3.6 | 2.9 |

| 10 ** | 190 | 10.6 | 4.0 | 1.5 | ||

| 20 ** | 190 | 13.0 | 4.2 | 1.1 | ||

| 30 ** | 190 | 14.6 | 4.6 | 1.1 | ||

| 40 ** | 190 | 7.8 | 4.7 | 0.9 | ||

| neat-PLA blended with banana fibers (Musa indica) [49] | compression molding | 0 | 39.3 | 1.2 | 2.5 | |

| 20 | 185 | 46.3 | 6.6 | 0.2 | ||

| neat-PLA blended with hemp fibers (Cannabis sativa) [50] | hot pressing | 0 | 58.8 | 2.5 | ||

| 6 | 170 | 65.7 | 3.0 | |||

| 20 | 170 | 68.7 | 3.4 | |||

| neat-PLA blended with kenaf fibers (Hibiscus cannabinus) [35] | hot pressing | 0 | 55.4 | 1.4 | 4.8 | |

| 38 | 185 | 111.6 | 5.9 | 2.7 | ||

| neat-PLA blended with bamboo fibers [51] | film-stacking | 0 | 54.3 | 3.2 | 5.3 | |

| 50 | 160 | 77.58 | 1.8 | 14.6 | ||

| neat-PLA blended with wood-flour [40] | hot pressing | 0 | 67.4 | 2.1 | 5.1 | |

| 10 | 200 | 57.5 | 2.3 | 3.4 | ||

| 20 | 200 | 52.5 | 2.5 | 2.9 | ||

| 30 | 200 | 51.4 | 2.7 | 2.4 | ||

| 40 | 200 | 49.3 | 2.7 | 2.5 | ||

| 50 | 200 | 44.8 | 3.2 | 1.9 | ||

| 60 | 200 | 40.7 | 3.2 | 1.8 | ||

| neat-PLA blended with silk fibers [21] | twin-screw extrusion | 0 | 180 | 70.73 | 3.2 | 5.5 |

| 5 | 180 | 70.6 | 4.1 | 3.8 | ||

| neat-PLA blended with kenaf fibers (Hibiscus cannabinus) [52] | hot pressing | 0 | 180 | 58.2 | 8.7 | 1.9 |

| 10 | 180 | 23.0 | 3.2 | |||

| 20 | 180 | 27.3 | 3.8 | |||

| 30 | 180 | 31.9 | 4.4 | 0.7 | ||

| 40 | 180 | 18.2 | 2.1 | |||

| 50 | 180 | 15.3 | 2.0 | |||

| neat-PLA blended with bamboo fibers [53] | compression molding | 0 | 49.8 | 2.6 | 3.1 | |

| 10 | 180 | 35.1 | 2.6 | 2.3 | ||

| 20 | 180 | 34.1 | 2.7 | 2.4 | ||

| 30 | 180 | 28.6 | 2.7 | 2.6 | ||

| 40 | 180 | 28.2 | 3.0 | 1.8 | ||

| 50 | 180 | 23.8 | 3.4 | 1.6 | ||

| neat-PLA [54] | injection | 0 | 160 | 51.9 | 1.1 | 8.8 |

| compression molding | 0 | 160 | 55.7 | 0.6 | 15.5 | |

| neat-PLA blended with jute fibers (Corchorus capsularis) [54] | injection | 20 | 160 | 55.3 | 1.7 | 4.7 |

| compression molding | 20 | 160 | 50.8 | 0.8 | 8.2 | |

| neat-PLA blended with jute fibers (Corchorus capsularis) and natural rubber [54] | injection | 20/10 | 160 | 17.2 | 1.2 | 2.3 |

| compression molding | 20/10 | 160 | 15.4 | 0.6 | 9.4 | |

| neat-PLA [36] | single-screw extrusion | 0 | 7.2 | 0.5 | ||

| 0 ** | 160 | 13.7 | 0.3 | |||

| neat-PLA blended with corn husk [36] | 1.5 ** | 160 | 15.0 | 0.4 | ||

| 2.5 ** | 160 | 14.2 | 0.4 | |||

| 3.5 ** | 160 | 13.9 | 0.4 | |||

| neat-PLA blended with corn husk and treated with silane [36] | 3/1.5 | 160 | 15.0 | 0.4 | ||

| 5/1.5 | 160 | 17.1 | 0.7 | |||

| 7/1.5 | 160 | 16.0 | 0.6 | |||

| 10/1.5 | 160 | 14.0 | 0.4 | |||

| neat-PLA [55] | - | 0 | 67.3 | 3.7 | 6.6 | |

| neat-PLA blended with flax fibers (Linum usitatissimum) [55] | 20 | 190–230 | 64.4 | 6.2 | 6.2 | |

| neat-PLA blended with hemp fibers (Cannabis sativa) [55] | 20 | 190–230 | 71.0 | 6.8 | 5.8 | |

| neat-PLA [56] | twin-screw extrusion | 0 | 35.1 | 2.5 | ||

| neat-PLA blended with hemp fibers (Cannabis sativa) [56] | 10 ** | 160 | 37.7 | 3.4 | ||

| 20 ** | 160 | 28.5 | 3.4 | |||

| 30 ** | 160 | 23.2 | ||||

| neat-PLA blended with harakeke fibers (Phormium tenax) [56] | 10 ** | 170 | 33.5 | 2.7 | ||

| 20 ** | 170 | 36.8 | 4.3 | |||

| 30 ** | 170 | 27.6 | 4.1 | |||

| neat-PLA blended with Osage orange fibers (Maclura pomifera) [42] | single-screw extrusion | 0 | 57.5 | 0.6 | 18.6 | |

| 10 | 150–170 | 49.2 | 0.6 | 11.4 | ||

| 25 | 150–170 | 36.9 | 0.6 | 8.0 | ||

| neat-PLA blended with flax fibers (Linum usitatissimum) [57] | injection | 0 | 60.1 | 3.6 | 2.4 | |

| 20 | 220 | 55.5 | 6.4 | 1.4 | ||

| 30 | 220 | 53.1 | 7.3 | 1.1 | ||

| neat-PLA [58] | hot pressing | 0 | 45.3 | 1.2 | ||

| neat-PLA blended with jute fibers (Corchorus capsularis) [58] | 10 | 170 | 47.3 | 2.0 | ||

| 20 | 170 | 49.1 | 3.2 | |||

| 30 | 170 | 50.6 | 3.4 | |||

| 40 | 170 | 47.1 | 2.7 | |||

| 50 | 170 | 43.3 | 2.0 | |||

| neat-PLA blended with ramie fibers (Boehmeria nivea) [58] | 10 | 170 | 49.7 | 2.2 | ||

| 20 | 170 | 50.8 | 3.6 | |||

| 30 | 170 | 52.5 | 3.2 | |||

| 40 | 170 | 46.1 | 2.5 | |||

| 50 | 170 | 44.7 | 2.2 | |||

| neat-PLA blended with wood-flour [59] | injection | 0 | 67.9 | 4.2 | 4.4 | |

| 7.5 | 160–170 | 54.8 | 4.5 | 2.8 | ||

| 15 | 160–170 | 52.0 | 6.0 | 2.0 | ||

| neat-PLA blended with hemp fibers (Cannabis sativa) [60] | twin-screw extrusion | 0 | 51.4 | 3.2 | 4.5 | |

| 3 | 170–180 | 52.5 | 3.4 | 4.1 | ||

| 3 ** | 170–180 | 55.7 | 3.8 | 3.1 | ||

| 6 | 170–180 | 53.2 | 3.8 | 2.9 | ||

| 6 ** | 170–180 | 59.3 | 4.4 | 1.8 | ||

| neat-PLA blended with microfibrillated cellulose [61] | hot pressing | 0 | 164 | 57.7 | 3.3 | 6.8 |

| 3 | 164 | 61.4 | 3.8 | 2.7 | ||

| 5 | 164 | 63.4 | 3.9 | 2.5 | ||

| 10 | 164 | 65.4 | 4.5 | 2.2 | ||

| 20 | 164 | 70.2 | 5.2 | 1.9 | ||

| neat-PLA blended with toddy palm fibers (Borassus Flabellifer) [62] | compression molding | 0 | 52.7 | 2.0 | ||

| 30 | 180 | 25.0 | 2.0 | 9.1 | ||

| neat-PLA blended with hybrid sisal and coir fibers [63] | hot compression molding | 0 | 53.6 | 1.3 | ||

| 10 | 180 | 41.7 | 1.4 | |||

| 20 | 180 | 39.9 | 1.5 | |||

| 30 | 180 | 38.0 | 1.6 | |||

| 40 | 180 | 33.6 | 1.5 | |||

| neat-PLA blended with hybrid sisal and coir fibers [64] | hot pressing | 0 | 23.5 | 1.2 | 2.3 | |

| 5 | 180 | 3.9 | 1.5 | 0.4 | ||

| 10 | 180 | 2.1 | 1.2 | 0.5 | ||

| 20 | 180 | 5.7 | 1.5 | 0.8 | ||

| 30 | 180 | 8.4 | 0.4 | 3.3 |

| Biomaterial | [α]D (°) | OP (%) |

|---|---|---|

| n-PLA | −128.70 ± 1.40 | 81.96 ± 0.52 |

| ad-PLA | −35.50 ± 0.14 | 23.50 ± 0.05 |

| ht-PLA | −70.75 ± 1.01 | 45.73 ± 0.18 |

| h-PLA | −110.05 ± 1.56 | 70.54 ± 1.30 |

| c-PLA | −107.62 ± 0.16 | 68.63 ± 0.09 |

| w-PLA | −102.17 ± 0.14 | 67.47 ± 0.07 |

| Biomaterial | TS (MPa) | YM (GPa) | EL (%) |

|---|---|---|---|

| n-PLA | 51.93 ± 2.28 | 2.70 ± 1.82 | 5.87 ± 2.53 |

| ad-PLA | 34.60 ± 1.00 | 2.89 ± 0.72 | 4.53 ± 0.62 |

| ht-PLA | 47.28 ± 1.72 | 3.44 ± 0.52 | 6.89 ± 1.73 |

| h-PLA | 23.00 ± 4.56 | 3.73 ± 1.01 | 3.08 ± 1.06 |

| c-PLA | 27.58 ± 0.34 | 2.74 ± 0.67 | 3.83 ± 0.15 |

| w-PLA | 28.74 ± 0.58 | 3.37 ± 1.63 | 3.80 ± 0.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cislaghi, A.; Sala, P.; Borgonovo, G.; Gandolfi, C.; Bischetti, G.B. Towards More Sustainable Materials for Geo-Environmental Engineering: The Case of Geogrids. Sustainability 2021, 13, 2585. https://doi.org/10.3390/su13052585

Cislaghi A, Sala P, Borgonovo G, Gandolfi C, Bischetti GB. Towards More Sustainable Materials for Geo-Environmental Engineering: The Case of Geogrids. Sustainability. 2021; 13(5):2585. https://doi.org/10.3390/su13052585

Chicago/Turabian StyleCislaghi, Alessio, Paolo Sala, Gigliola Borgonovo, Claudio Gandolfi, and Gian Battista Bischetti. 2021. "Towards More Sustainable Materials for Geo-Environmental Engineering: The Case of Geogrids" Sustainability 13, no. 5: 2585. https://doi.org/10.3390/su13052585

APA StyleCislaghi, A., Sala, P., Borgonovo, G., Gandolfi, C., & Bischetti, G. B. (2021). Towards More Sustainable Materials for Geo-Environmental Engineering: The Case of Geogrids. Sustainability, 13(5), 2585. https://doi.org/10.3390/su13052585