Innovative Circular Business Models in the Olive Oil Sector for Sustainable Mediterranean Agrifood Systems

Abstract

1. Introduction

2. Background

2.1. Olive Waste and by-Products

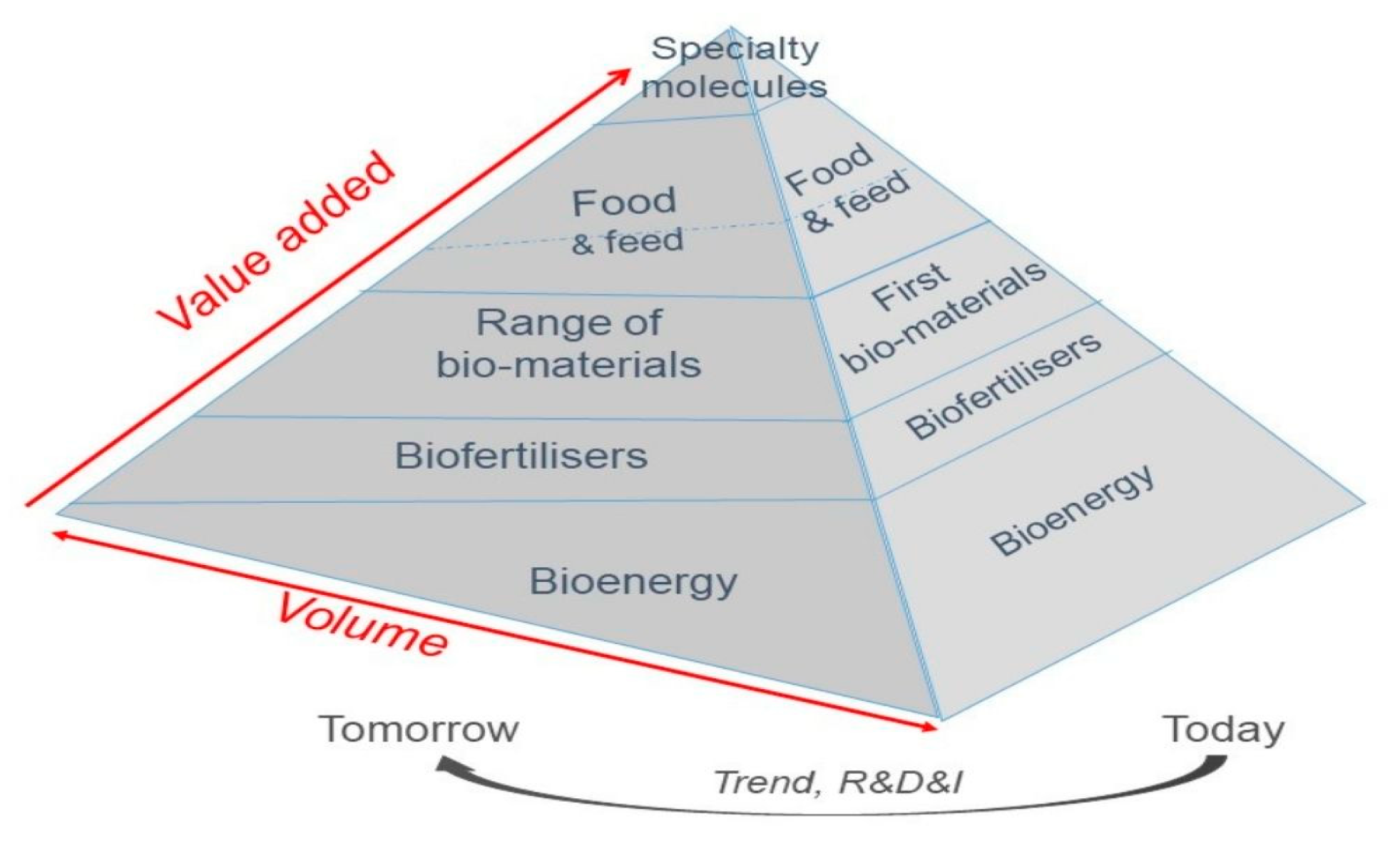

2.2. Circular Business Models

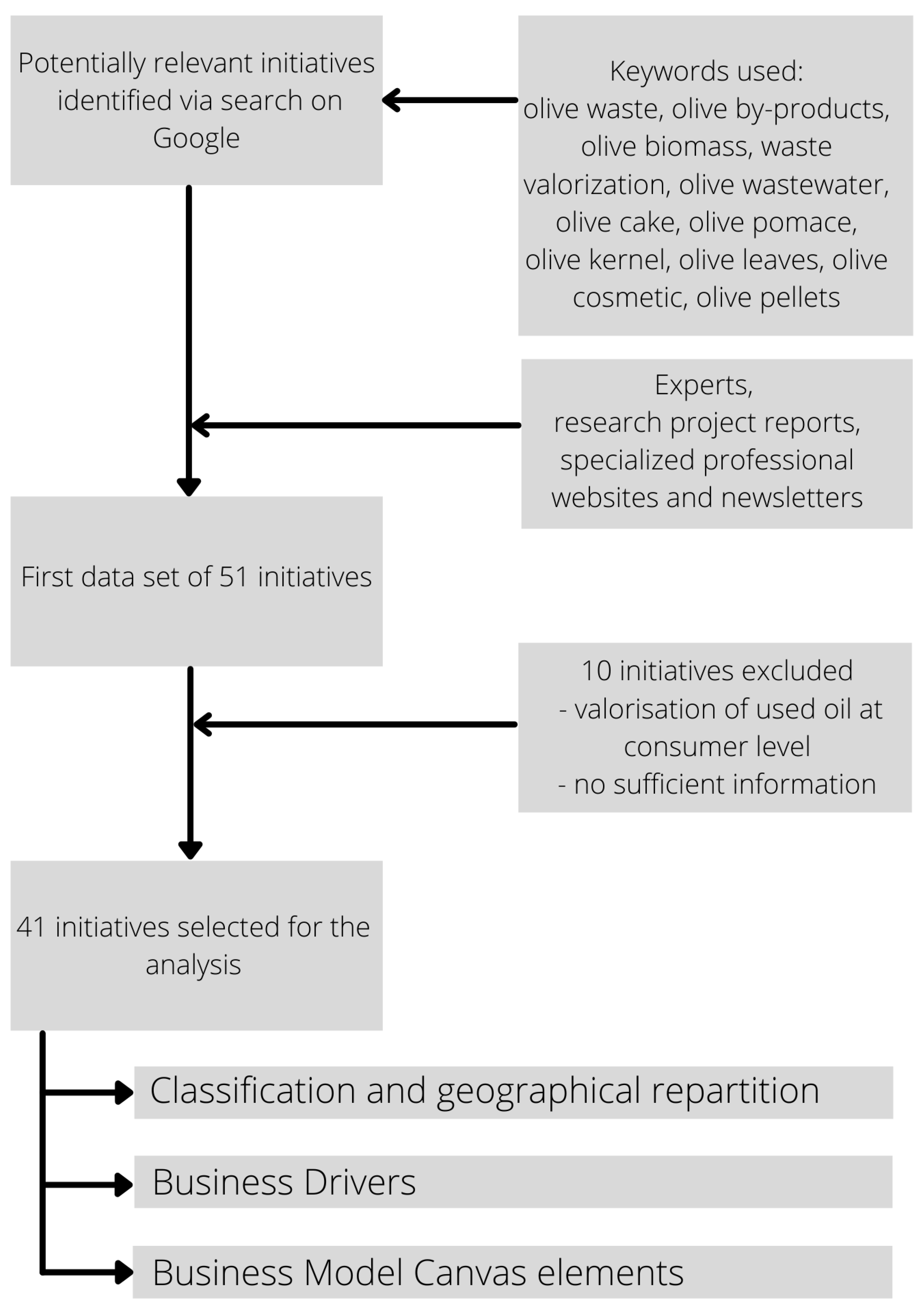

3. Methodology

4. Results

4.1. General Classification and Geographical Repartition of the Businesses

4.2. Business Drivers

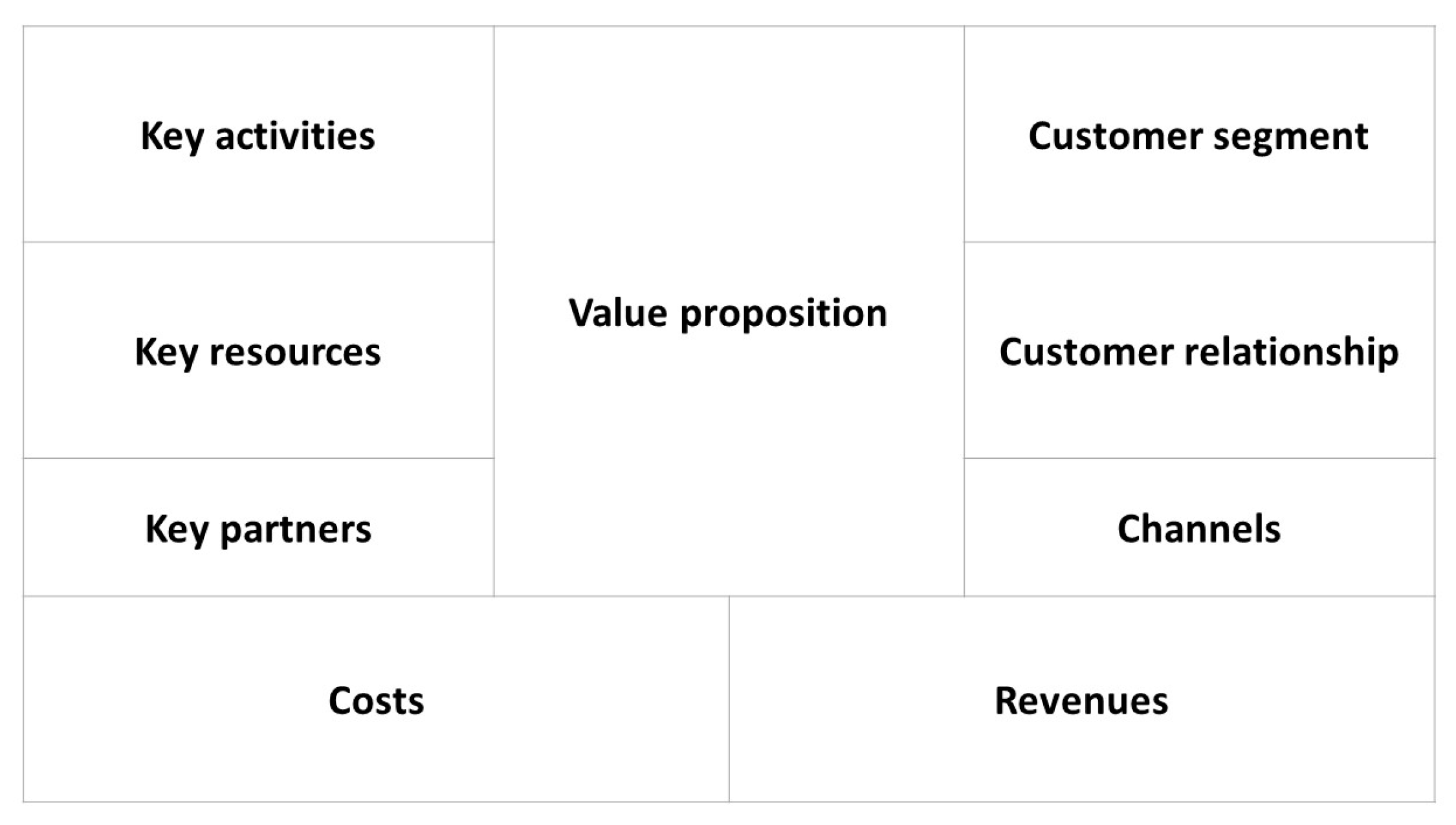

4.3. Characterisation According to the Business Canvas Model

5. Discussion

- i.

- The main driver for starting olive waste valorization activities is a general commitment to the environment given the unused and partly environmentally harmful residues. With high amounts of olive oil, olive waste and by-products produced, Spain is the leader in this domain.

- ii.

- Very often, businesses make olive waste and by-product valorization their main activity by specializing in this domain. However, the valorization can also perfectly be a side activity for olive oil producers.

- iii.

- The majority of cases are individual businesses, i.e., olive oil producers, start-ups, or highly specialized multinationals, but several initiatives are collective such as cooperatives, associations, or public-private partnerships.

- iv.

- While all resources of the olive tree and olive oil production process have the potential to be valorized, value-adding activities are currently often still limited to one or several resources.

- v.

- Olive waste and by-products are currently rather converted into low added-value products (bioenergy or fertilizers), but also several initiatives exist that successfully market high added value products (e.g., extracts for cosmetics, artisanal products based on olive wood).

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No | Name/Type of Initiative | Country/Region | Principal/ Side Activity | Context/ Business Drivers | Type of Agro-Waste Valorized | Valorisation Pathway & Outputs | Source/Homepage |

|---|---|---|---|---|---|---|---|

| 1 | Trainalba SL, olive oil extraction company & Fundación Cartif, R&D project | Spain, Andalucía | Principal activity | Large amounts of by-products in Andalucía, olive waste thrown away before | Olive cake, olive mill wastewater | By-product treatment plant, organic fertilizers, cleaned irrigation water | http://www.cprac.org/docs/med111fran.pdf (accessed on 10 January 2021) |

| 2 | CAD Environnement, start-up company | France, Provence | Principal activity | Lots of unused olive waste in the Provence | Olive cake, olive mill wastewater | Soaps, (vermi)composting | https://www.imbe.fr/IMG/pdf/re-40_amic-dalmasso.pdf (accessed on 10 January 2021) |

| 3 | Grap’Sud, union of cooperatives | France, Occitanie | Principal activity | Specialized in valorizing grape by-products, diversification with other agricultural by-products | Olive mill wastewater | Polyphenols from wastewater, cosmetic and functional food industry | http://www.grapsud.com/en/our-products/nutraceuticals/olive-polyphenols (accessed on 10 January 2021) |

| 4 | Cho Company, multinational industrial olive oil group | Tunisia, Sfax | Side activity | Commitment to sustainable development, quality products, environmental protection and human health, diversification of activities | Olive cake, pomace | Production of refined olive pomace oil, soap, and eco-charcoal | http://groupe-cho.netissedev.com/index.php/nos-metiers/valorisation-des-sous-produits/extraction-des-huiles-de-grignons-dolives/ (accessed on 10 January 2021) |

| 5 | Abu Walid Group, large international olive oil producing company | Tunisia, Tunis | Side activity | One of the first organic olive oil producers, commitment to quality and the environment | Olive stones and pomace | Biomass for energy use: heat and electricity | http://www.abouwalid-group.com/biomas_en.php?br=1 (accessed on 10 January 2021) |

| 6 | Ons Art, wood manufacturer | Tunisia, Sfax | Principal activity | Business opportunity, as located in a dense olive growing region | Olive wood | Various articles handmade from olive wood | http://olivewoodons-art.com/Catalog-2018/#p=1 (accessed on 10 January 2021) |

| 7 | Elayo, large company | Spain, Andalucía | Principal activity | Highly specialized in the development of innovative products derived from olive by-products | Olives and all by- products | Extraction, dehydration, large innovative product portfolio | https://www.elayo.es/ (accessed on 10 January 2021) |

| 8 | Aveo, start-up energy company | Morocco, Casablanca | Principal activity | Originally an olive oil-producing enterprise, since 2014 Aveo-Energie; need to valorize by-products | Olive stones, pomace | Bio-energy production (heat) | http://www.aveo.ma (accessed on 10 January 2021) |

| 9 | Oliobric, commercial enterprise | Germany | Principal activity | ‘100% ecologic and sustainable’ | Olive cake | Barbecue pellets for household use | http://www.oliobric.com/ (accessed on 10 January 2021) |

| 10 | Edilteco Group, multinational group | Italy, Emilia Romagna | Side activity | Energy saving | Olive stones | Lightweight insulating mortar ‘Mixxol’ à eco-material construction sector | http://www.edilteco.fr/fr/; https://www.batiactu.com/edito/un-mortier-leger-a-base-de-noyaux-d-olives-35405.php (accessed on 10 January 2021) |

| 11 | Sabra Olive Oil, olive oil producer, Switchmed pilot project | Tunisia, Kairouan | Side activity | ‘Why throw away resources that can increase the firm’s profitability?’ | Olive stones, pomace, wastewater | Combustion material, fertilizers, animal feed, water reuse, and efficiency | https://2014-2019.switchmed.eu/fr/country-hubs/tunisia/actions/Sabra-oliv-oil.html?c=policy&q=tunisia (accessed on 10 January 2021) |

| 12 | Agraria Riva del Gardo, large agricultural cooperative | Italy, Lago del Garda | Side activity | All waste and by-products are reprocessed for reusable materials | Olive pomace, pits, wastewater | Cattle nutrition (pomace), pellets for heating (from pits) | http://www.agririva.it/DE/wiederverwendung-von-prozessabfaellen.php (accessed on 10 January 2021) |

| 13 | BioLive, biotechnology enterprise | Turkey | Principal activity | Overcome the environmental problem of petrol-based plastics by producing biodegradable plastics | Olive seeds | Production of bio-based granules as raw material by using olive seeds | http://www.biolivearge.com/indexen.html (accessed on 10 January 2021) |

| 14 | Cooperative oléicole de Levens, with the municipality of Broc | France, Côte d’Azur | Side activity | Valuable use instead of throwing away, diversification of activities | Olive pits | Drying of olive pits that are put in bags as pellets for heating of public buildings | https://www.nicematin.com/economie/cette-commune-des-alpes-maritimes-chauffe-des-batiments-publics-aux-noyaux-dolives-16295 (accessed on 10 January 2021) |

| 15 | Oleafood, branch of the groupe «Les Conserves de Meknès-Aïcha» | Morocco, Meknès | Principal activity | Circular economy project | Olive pomace, kernel, branches | Biomass; olive kernel bio-fuel | http://www.aicha.com; https://leseco.ma/business/les-solutions-ecologiques-d-olea-food-meknes.html (accessed on 10 January 2021) |

| 16 | Bioland Energy, filial del Grupo Oleícola Jaén | Spain, Andalucía | Side activity | Zero waste and respect for the environment | Olive kernels, pomace | Biomass/fuel, olive pomace oil | https://www.grupooleicolajaen.com (accessed on 10 January 2021) |

| 17 | Fiusis SRL, company | Italy, Camimera | Principal activity | We produce energy from renewable sources, so the environment is a priority for us | Olive tree pruning | First power plant in the world fuelled exclusively by olive tree pruning; 8000 tons/year valorized | http://fiusis.com/ (accessed on 10 January 2021) |

| 18 | As Pontis Almazara, olive oil factory | Spain, Extrema-dura | Side activity. | Become an ecological olive mill without any waste; all wastes should be recycled and valorized | Leaves, wastewater kernels, branches, pomace | Resources reused in the proper farm: wastewater purified, leaves for animal feed and compost, kernels for energy, olive pomace oil | http://aspontis.com/ (accessed on 10 January 2021) |

| 19 | Cooperativa Oleicola El Tejar | Spain, Andalucía | Principal activity | ‘Las energías renovables contribuyen además al equilibrio territorial y a la disminución de la dependencia de suministros externos’ | Olive cake, kernels, wastewater | Biomass for energy | http://eltejar.sbsoftware.es/ (accessed on 10 January 2021) |

| 20 | ABEA, olive oil processing enterprise | Greece, Chania | Side activity | ‘Our goal: a production aligned with sound agricultural practices, which respect the environment and ensure sustainable development’ | Olive cake, olive seeds | Olive pomace oil and Cosmetics: olive soap with olive seed and honey | https://www.abea.gr/en/ (accessed on 10 January 2021) |

| 21 | Renergy UK, trading company for biomass | UK | Principal activity | ‘We strongly trust in the importance of sustainability of energy and this is why we are focused on trading biomass.’ | Olive cake, stones | Biofuel Pellets | http://www.renergyuk.com/home/ (accessed on 10 January 2021) |

| 22 | Express Commerce International (E.C.I) | Tunisia | One of many activities | Diversification of activities. | Olive kernels, olive wood | Biomass/fuel from olive kernels. Artisanal figurines from wood | https://www.ste-eci.com/product-biomass (accessed on 10 January 2021) |

| 23 | The Olive tree, cosmetic producer with online shop | Greece, Athens | Side activity | Originally cosmetics based on olive oil. Diversification of substances used, for better quality. | Leaf extracts | Various cosmetics (with olive leaf extract): body lotion, body cream, shampoo | https://theolivetree-organic.com/ (accessed on 10 January 2021) |

| 24 | Une Olive en Provence, cosmetic producer, online shop | France | Principal activity | Each element of the olive tree has its value. Natural products. | Olive flower, leaves | Cosmetics: soap, creams, shower gel | www.uneoliveenprovence.com (accessed on 10 January 2021) |

| 25 | Pure Olive, cosmetic producer, online shop | France | Principal activity | Cosmetics with high-quality ingredients and known local origin. | Pomace oil for soap | Cosmetics: soap, liquid soap, shampoo. | https://www.pureolive.fr/ (accessed on 10 January 2021) |

| 26 | Olivketts, biomass, bioenergy supplier | Global | Principal activity | Opportunity is using biomass for energy. ‘Why waste it?’ | Olive kernels, cake | Biomass for energy | http://www.olivketts.com/ (accessed on 10 January 2021) |

| 27 | Gestamp Biomass, power stations for the olive industry | Spain, Andalucía) | One of the activities | Energy efficiency, energy-saving, maximum use of available resources. | Olive cake, kernels | Biomass for production of electricity | http://newsletter.avebiom.com/AVEBIOM/ponenciasExpoFrioCalor/01_P05_Gestamp.pdf (accessed on 10 January 2021) |

| 28 | Rossano Calabro, power station for the olive industry | Italy | Principal activity | Plant located in olive producing zone with large quantities: Puglia, Calabria. | Olive cake, pomace, husk | Pomace gasifier for electricity | http://ieabioenergytask33.org/content/info/567 (accessed on 10 January 2021) |

| 29 | Kapoudia, olive oil processor | Tunisia | Side activity | Environmental responsibility and circular economy. ‘All is used, nothing is lost’ | Olive cake, kernels, wastewater | Biomass | http://www.kapoudia.com/ (accessed on 10 January 2021) |

| 30 | Jean Dubost, artisanal cutlery | France | Principal activity | High quality olive wood. | Olive wood | Artisanal knives | https://www.shop.couteaujeandubost.com/bois-olivier (accessed on 10 January 2021) |

| 31 | Lucchi & Guastalli, ecological olive mill | Italy | Side activity | Quality olive oil with respect for the environment and of the territory. | Olive cake, pomace, kernels | Biogas for electricity | https://frantoiolg.com/en/ (accessed on 10 January 2021) |

| 32 | Aceites Sierra Sur, olive oil processor | Spain | Side activity | Engagement for environment | Olive pomace | Biofuels, pellets | https://aceitessierrasur.es/granelesaceites/biomasa/ (accessed on 10 January 2021) |

| 33 | Daniel Espuny, enterprise specialized in biomass from olive | Spain | Principal activity | Historically production of olive oil. Environmental reasons for the valorization of by-products. | Olive pomace | Biofuels, pellets | http://danielespuny.es/productos/pellet-de-orujillo/ (accessed on 10 January 2021) |

| 34 | Extractadora de Mora, company producing pomace oil and biomass for energy | Spain | Principal activity | Environmental responsibility. | Olive kernels, pomace | Olive pomace oil, biomass | http://www.extractorademora.es/ (accessed on 10 January 2021) |

| 35 | Olivette, start-up | Morocco, Casablanca | Principal activity | Environmental responsibility. Human health. | Olive branches, stones | Barbecue pellets (eco-charcoal) for household use | https://www.olivette.ma/fr/ (accessed on 10 January 2021) |

| 36 | Hotel SPA Sierra de Cazorla | Spain | Side activity | Thermal water heated with olive biomass, for environment & quality. | Biomass | Two heaters | https://www.hotelspasierradecazorla.com/ (accessed on 10 January 2021) |

| 37 | Oleo Dorato, olive oil producing company | Croatia | Side activity | Environmental commitment and consumer awareness | Olive cake | Biofuel. Also produces furnaces for biofuel use | http://oleodorato.com/index.php (accessed on 10 January 2021) |

| 38 | Otok Krk, public community | Croatia | Side activity | Public initiative, environmental commitment | Olive cake | Soil fertilizer (from olive cake with algae) | https://www.novilist.hr/dom-i-vrt/majstori-reciklaze-krcka-firma-pretvorila-opasan-otpad-u-supergnojivo/ (accessed on 10 January 2021) |

| 39 | Association Tazmourth, Switchmed initiative | Algeria | Side activity | Reduce pollution, as the waste is normally thrown away in nature. | Olive pomace, wastewater | Compost | https://slideplayer.fr/slide/11900455/ (accessed on 10 January 2021) |

| 40 | Wet Green GmbH, International company | Germany | Principal activity | Leaves are often burned, but their extracts can serve as a sustainable alternative for premium leather | Olive leaves | Tanning agents for ecological leather for e.g., automobile industry, sofas | http://www.wet-green.com/index_engl.php (accessed on 10 January 2021) |

| 41 | Olive Feed Corporation | Ireland | Principal activity | Solve a major global environmental issue, human and animal health | Olive cake, pomace | Animal feed for Wagyu cattle, ducks, and pigs | https://www.olivefeed.com (accessed on 10 January 2021) |

References

- Antonelli, M.; Basile, L.; Gagliardi, F.; Riccaboni, A.; Isernia, P. The AGRIFOODMED Delphi Final Report. Trends, Challenges and Policy Options for Water Management, Farming Systems and Agri-Food Value Chains in 2020–2030. PRIMA Document. 2019. Available online: http://www.primaitaly.it/wp-content/uploads/2019/06/AGRIFOODMED-Delphi-Final-Report.pdf (accessed on 11 January 2021).

- Brundtland, G.; Khalid, M.; Agnelli, S.; Al-Athel, S.A.; Chidzero, B.; Fadika, L.M.; Hauff, V.; Lang, I.; Shijun, M.; de Botero, M.M.; et al. Our Common Future: Report of the 1987 World Commission on Environment and Development; United Nations: Oslo, Norway, 1987. [Google Scholar]

- Capone, R.; Bennett, A.; Debs, P.; El Bilali, H. Food losses and waste: Global overview from a Mediterranean perspective. In Zero Waste in the Mediterranean: Natural Resources, Food and Knowledge; Lacirignola, C., Graziano da Silva, J., Eds.; Presses de Sciences Po: Paris, France, 2016; pp. 197–254. [Google Scholar]

- International Centre for Advanced Mediterranean Agronomic Studies (CIHEAM). CIHEAM Strategic Agenda 2025. Available online: https://www.ciheam.org/uploads/attachments/233/CSA2025_DetailedDocument_CIHEAM_2016.pdf (accessed on 18 January 2021).

- Di Terlizzi, B.; Van Otterdijk, R.; Dragotta, A.; Pink, P.; El Bilali, H. Innovation for the reduction of food losses and waste. In Zero Waste in the Mediterranean: Natural Resources, Food and Knowledge; Lacirignola, C., Graziano da Silva, J., Eds.; Presses de Sciences Po: Paris, France, 2016; pp. 281–301. [Google Scholar]

- Souilem, S.; El-Abbassi, A.; Kiai, H.; Hafidi, A.; Sayadi, S.; Galanakis, C.M. Olive oil production sector: Environmental effects and sustainability challenges. In Olive Mill Waste: Recent Advances for Sustainable Management; Galanakis, C.M., Ed.; Academic Press: London, UK; Elsevier: London, UK, 2017; Chapter 1; pp. 1–28. [Google Scholar]

- Kashiwagi, K.; Yamna, E.; Arfa, L.; Zaibet, L. Growing Olive Oil Export and Intra-Industry Trade in Mediterranean Countries: Application of Gravity Model. Sustainability 2020, 12, 7027. [Google Scholar] [CrossRef]

- Vilar, J.; Pereira, J.E. International Olive Growing. In Historical Dissemination, Strategic Analysis and Descriptive Vision; Fundación Caja Rural: Jaen, Spain, 2018. [Google Scholar]

- Galanakis, C.M. Olive Mill Waste: Recent Advances for Sustainable Management; Academic Press: London, UK; Elsevier: London, UK, 2017; Preface. [Google Scholar]

- Jurgilevich, A.; Birge, T.; Kentala-Lehtonen, J.; Korhonen-Kurki, K.; Pietikäinen, J.; Saikku, L.; Schösler, H. Transition towards circular economy in the food system. Sustainability 2016, 8, 69. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation (EMF). Towards the Circular Economy. Economic and Business Rationale for an Accelerated Transition. 2013. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf (accessed on 11 January 2021).

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation (EMF). Growth within: A Circular Economy Vision for a Competitive Europe. 2015. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/EllenMacArthurFoundation_Growth-Within_July15.pdf (accessed on 11 January 2021).

- FoodDrinkEurope. FoodDrinkEurope Statement on the Circular Economy Action Plan. 2020. Available online: https://www.fooddrinkeurope.eu/news/statement/fooddrinkeurope-statement-circular-economy-action-plan/ (accessed on 16 July 2020).

- Esposito, B.; Sessa, M.R.; Sica, D.; Malandrino, O. Towards Circular Economy in the Agri-Food Sector: A Systematic Literature Review. Sustainability 2020, 12, 7401. [Google Scholar] [CrossRef]

- Rodias, E.; Aivazidou, E.; Achillas, C.; Aidonis, D.; Bochtis, D. Water-Energy-Nutrients Synergies in the Agrifood Sector: A Circular Economy Framework. Energies 2021, 14, 159. [Google Scholar] [CrossRef]

- Barros, M.V.; Salvador, R.; de Francisco, A.C.; Piekarski, C.M. Mapping of research lines on circular economy practices in agriculture: From waste to energy. Renew. Sustain. Energy Rev. 2020, 131, 109958. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Scarpellini, S.; Valero-Gil, J.; Moneva, J.M.; Andreaus, M. Environmental management capabilities for a “circular eco-innovation”. Bus. Strategy Environ. 2020, 29, 1850–1864. [Google Scholar] [CrossRef]

- Donner, M.; De Vries, H. How to innovate business models for a circular bio-economy? Bus. Strategy Environ. 2021, 1–16. [Google Scholar] [CrossRef]

- Nußholz, J.L. Circular business models: Defining a concept and framing an emerging research field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef]

- Whalen, K.A. Three circular business models that extend product value and their contribution to resource efficiency. J. Clean. Prod. 2019, 226, 1128–1137. [Google Scholar] [CrossRef]

- Bocken, N.; Strupeit, L.; Whalen, K.; Nußholz, J. A review and evaluation of circular business model innovation tools. Sustainability 2019, 11, 2210. [Google Scholar] [CrossRef]

- Ronzon, T.; Santini, F.; M’Barek, R. The Bioeconomy in the European Union in Numbers. Facts and Figures on Biomass, Turnover and Employment; European Commission, Joint Research Centre, Institute for Prospective Technological Studies: Seville, Spain, 2015; 4p. [Google Scholar]

- Eurostat Statistical Books—Agriculture, Forestry and Fishery Statistics. 2019. Available online: https://ec.europa.eu/eurostat/documents/3217494/10317767/KS-FK-19-001-EN-N.pdf (accessed on 22 January 2021).

- Roselló-Soto, E.; Koubaa, M.; Moubarik, A.; Lopes, R.P.; Saraiva, J.A.; Boussetta, N.; Grimi, N.; Barba, F.J. Emerging opportunities for the effective valorisation of wastes and by-products generated during olive oil production process: Non-conventional methods for the recovery of high-added value compounds. Trends Food Sci. Technol. 2015, 45, 296–310. [Google Scholar] [CrossRef]

- Berbel, J.; Posadillo, A. Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 2018, 10, 237. [Google Scholar] [CrossRef]

- Azbar, N.; Bayram, A.; Filibeli, A.; Muezzinoglu, A.; Sengul, F.; Ozer, A. A review of waste management options in olive oil production. Crit. Rev. Environ. Sci. Technol. 2004, 34, 209–247. [Google Scholar] [CrossRef]

- Roig, A.; Cayuela, M.L.; Sánchez-Monedero, M.A. An overview on olive mill wastes and their valorisation methods. Waste Manag. 2006, 26, 960–969. [Google Scholar] [CrossRef]

- Doula, M.K.; Moreno-Ortego, J.L.; Tinivella, F.; Inglezakis, V.J.; Sarris, A.; Komnitsas, K. Olive mill waste: Recent advances for the sustainable development of olive oil industry. In Olive Mill Waste: Recent Advances for Sustainable Management; Galanakis, C.M., Ed.; Academic Press: London, UK; Elsevier: London, UK, 2017; Chapter 2; pp. 29–56. [Google Scholar]

- Komnitsas, K.; Modis, K.; Doula, M.; Kavvadias, V.; Sideri, D.; Zaharaki, D. Geostatistical estimation of risk for soil and water in the vicinity of olive mill wastewater disposal sites. Desalination Water Treat. 2016, 57, 2982–2995. [Google Scholar] [CrossRef]

- Ergüder, T.H.; Güven, E.; Demirer, G.N. Anaerobic treatment of olive mill wastes in batch reactors. Process Biochem. 2000, 36, 243–248. [Google Scholar] [CrossRef]

- Vlyssides, A.G.; Lamprou, G.K.; Vlysidis, A. Industrial case studies on the detoxificaton of OMWW using Fenton oxidation process followed by biological processes for energy and compost production. In Olive Mill Waste: Recent Advances for Sustainable Management; Galanakis, C.M., Ed.; Academic Press: London, UK; Elsevier: London, UK, 2017; Chapter 6; pp. 119–138. [Google Scholar]

- Negro, M.J.; Manzanares, P.; Ruiz, E.; Castro, E.; Ballesteros, M. The biorefinery concept for the industrial valorization of residues from olive oil industry. In Olive Mill Waste: Recent Advances for Sustainable Management; Galanakis, C.M., Ed.; Academic Press: London, UK; Elsevier: London, UK, 2017; Chapter 3; pp. 57–78. [Google Scholar]

- Barbulova, A.; Colucci, G.; Apone, F. New trends in cosmetics: By-products of plant origin and their potential use as cosmetic active ingredients. Cosmetics 2015, 2, 82–92. [Google Scholar] [CrossRef]

- Sansoucy, R. Olive by-Products for Animal Feed; Food and Agricultural Organisation: Rome, Italy, 1985. [Google Scholar]

- Niaounakis, M.; Halvadakis, C.P. Olive Processing Waste Management: Literature Review and Patent Survey; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Lewandowski, M. Designing the business models for circular economy—Towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Pieroni, M.P.; McAloone, T.; Pigosso, D.A. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 241, 118271. [Google Scholar] [CrossRef]

- Lopez, F.J.D.; Bastein, T.; Tukker, A. Business model innovation for resource-efficiency, circularity and cleaner production: What 143 cases tell us. Ecol. Econ. 2019, 155, 20–35. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M. A review and typology of circular economy business model patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef]

- Ferasso, M.; Beliaeva, T.; Kraus, S.; Clauss, T.; Ribeiro-Soriano, D. Circular economy business models: The state of research and avenues ahead. Bus. Strategy Environ. 2020, 29, 3006–3024. [Google Scholar] [CrossRef]

- Magretta, J. Why business models matter. Harv. Bus. Rev. 2002, 80, 3–8. [Google Scholar]

- Casadesus-Masanell, R.; Ricart, J.E. From strategy to business models and onto tactics. Long Range Plan. 2010, 43, 195–215. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Jonker, J. New Business Models: An Explorative Study of Changing Transactions Creating Multiple Values; Jab Management Consultants BV: Doetinchem, The Netherlands, 2012. [Google Scholar]

- Antikainen, M.; Valkokari, K. A framework for sustainable circular business model innovation. Technol. Innov. Manag. Rev. 2016, 6, 5–12. Available online: http://timreview.ca/article/1000 (accessed on 26 December 2020). [CrossRef]

- Bocken, N.M.; De Pauw, I.; Bakker, C.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Ünal, E.; Urbinati, A.; Chiaroni, D. Managerial practices for designing circular economy business models. J. Manuf. Technol. Manag. 2019, 30, 561–589. [Google Scholar] [CrossRef]

- Mentink, B. Circular Business Model Innovation: A Process Framework and a Tool for Business Model Innovation in a Circular Economy. Master’s Thesis, University of Leiden, Leiden, The Netherlands, 2014. Available online: https://repository.tudelft.nl/islandora/object/uuid%3Ac2554c91-8aaf-4fdd-91b7-4ca08e8ea621 (accessed on 18 January 2021).

- Micheaux, H.; Aggeri, F. Innovation Environnementale et Création de Valeur: Emergence et Conditions de Développement de BM Circulaires Dans la Filière DEEE. In Proceedings of the AIMS Conference, Lyon, France, 15–16 September 2016; Available online: https://hal-mines-paristech.archives-ouvertes.fr/hal-01368036/document (accessed on 18 January 2021).

- Stål, H.I.; Corvellec, H. A decoupling perspective on circular business model implementation: Illustrations from Swedish apparel. J. Clean. Prod. 2018, 171, 630–643. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Sjödin, D.R. Circular business models for the bio-economy: A review and new directions for future research. Sustainability 2019, 11, 2558. [Google Scholar] [CrossRef]

- Donner, M.; Gohier, R.; De Vries, H. A new circular business model typology for creating value from agro-waste. Sci. Total Environ. 2020, 716, 137065. [Google Scholar] [CrossRef] [PubMed]

- Rizos, V.; Behrens, A.; Van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papdelis, S.; Hirschnitz-Gabers, M.; et al. Implementation of circular economy business models by small and medium-sized enterprises (SMEs): Barriers and enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Donner, M.; Verniquet, A.; Broeze, J.; Kayser, K.; De Vries, H. Critical success and risk factors for circular business models valorising agricultural waste and by-products. Resour. Conserv. Recycl. 2021, 165, 105236. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York, NY, USA, 1985. [Google Scholar]

- Ansoff, H.I. Strategic issue management. Strateg. Manag. J. 1980, 1, 131–148. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Strategy: Techniques for Analyzing Industries and Competitors; Free Press: New York, NY, USA, 1980. [Google Scholar]

- Aguilar, F. Scanning the Business Environment; Macmillan: New York, NY, USA, 1967. [Google Scholar]

- Joyce, A.; Paquin, R.L. The triple layered business model canvas: A tool to design more sustainable business models. J. Clean. Prod. 2016, 135, 1474–1486. [Google Scholar] [CrossRef]

- Boons, F.; Lüdeke-Freund, F. Business models for sustainable innovation: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2013, 45, 9–19. [Google Scholar] [CrossRef]

- Amic, A.; Dalmasso, C. Unité de Valorisation Complète de Déchets Oléicoles par Lombricompostage: Production de Produits à Haute Valeur Ajoutée: Lombricompost, Savon, Collagène et Lombrics. Master’s Thesis, University Aix-Marseille, Marseille, France, 2012. Available online: https://www.imbe.fr/IMG/pdf/re-40_amic-dalmasso.pdf (accessed on 12 January 2021).

- D’Adamo, I.; Falcone, P.M.; Gastaldi, M.; Morone, P. A Social Analysis of the Olive Oil Sector: The Role of Family Business. Resources 2019, 8, 151. [Google Scholar] [CrossRef]

- Bazeley, P.; Jackson, K. Qualitative Data Analysis with NVivo; SAGE Publications Limited: London, UK, 2013. [Google Scholar]

- Zamfir, A.M.; Mocanu, C.; Grigorescu, A. Circular economy and decision models among European SMEs. Sustainability 2017, 9, 1507. [Google Scholar] [CrossRef]

- Russo, C.; Cappelletti, G.M.; Nicoletti, G.M.; Di Noia, A.E.; Michalopoulos, G. Comparison of European olive production systems. Sustainability 2016, 8, 825. [Google Scholar] [CrossRef]

- Federici, F.; Fava, F.; Kalogerakis, N.; Mantzavinos, D. Valorisation of agro-industrial by-products, effluents and waste: Concept, opportunities and the case of olive mill wastewaters. J. Chem. Technol. Biotechnol. 2009, 84, 895–900. [Google Scholar] [CrossRef]

| Business Drivers | Reference to Cases | Illustration Example |

|---|---|---|

| Commitment to sustainable development, particularly to environmental protection | Indicated by half of the cases studied, e.g., cases 4, 5, 9, 13, 16, 36, 37, 38 | “Where technology and nature meet. Let’s protect the Earth together. We don’t have another one” (case 13) |

| Circular economy principles and closed-loop thinking | Cases 11, 14, 15, 18, 27, 29, 39 | Collective action for locally using olive pits for heating of public buildings (case 14) |

| Diversifying activities of traditional olive oil mills | Cases 4, 8, 14, 22, 23 | Olive oil production as the main activity, completed with a production of olive pomace oil, soap, and eco-charcoal (case 4) |

| Quality, combined with origin and environment | Cases 23, 24, 25, 31 | Evoke the resource origin (Provence, France), as well as particular methodology for extracting high-quality molecules from olive flowers and leaves (case 24) |

| Treating the high volumes of existing olive waste and by-products | Cases 1, 2, 8, 28 | “1MW installed = 600 tons of waste valorized” (case 8) |

| Specializing in agro-waste conversion | Cases 3, 7, 40 | Production of tanning agents used for premium eco-leather based on olive leaves (case 40) |

| Business opportunity | Cases 6, 11 | Business opportunity by utilizing olive wood for artistic creation and offer as souvenirs (case 6) |

| Key activities Collecting pruning residues Wastewater treatment Olive pomace oil extraction | Value proposition Cosmetics Specialty bio-molecules Artisanal products Animal feed Refined pomace oil Purified water Bio-fertilizers Bioenergy | Customer segment B2B B2C |

| Key resources Olive fruit Branches Leaves Flowers Seed Olive kernels Olive cake Olive pomace | Customer relationship - | |

| Key partners Private (partners from within and outside the olive chain) Research Public Associative | Channels Direct: (e-)shops (cosmetics, artisanal products) Indirect: specialized platforms for biomass trade Websites Social media Traditional media Participation at fairs | |

| Costs - | Revenues Certain types of products obtain higher market prices than other products from the same category | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Donner, M.; Radić, I. Innovative Circular Business Models in the Olive Oil Sector for Sustainable Mediterranean Agrifood Systems. Sustainability 2021, 13, 2588. https://doi.org/10.3390/su13052588

Donner M, Radić I. Innovative Circular Business Models in the Olive Oil Sector for Sustainable Mediterranean Agrifood Systems. Sustainability. 2021; 13(5):2588. https://doi.org/10.3390/su13052588

Chicago/Turabian StyleDonner, Mechthild, and Ivana Radić. 2021. "Innovative Circular Business Models in the Olive Oil Sector for Sustainable Mediterranean Agrifood Systems" Sustainability 13, no. 5: 2588. https://doi.org/10.3390/su13052588

APA StyleDonner, M., & Radić, I. (2021). Innovative Circular Business Models in the Olive Oil Sector for Sustainable Mediterranean Agrifood Systems. Sustainability, 13(5), 2588. https://doi.org/10.3390/su13052588