Future Power Train Solutions for Long-Haul Trucks

Abstract

1. Introduction

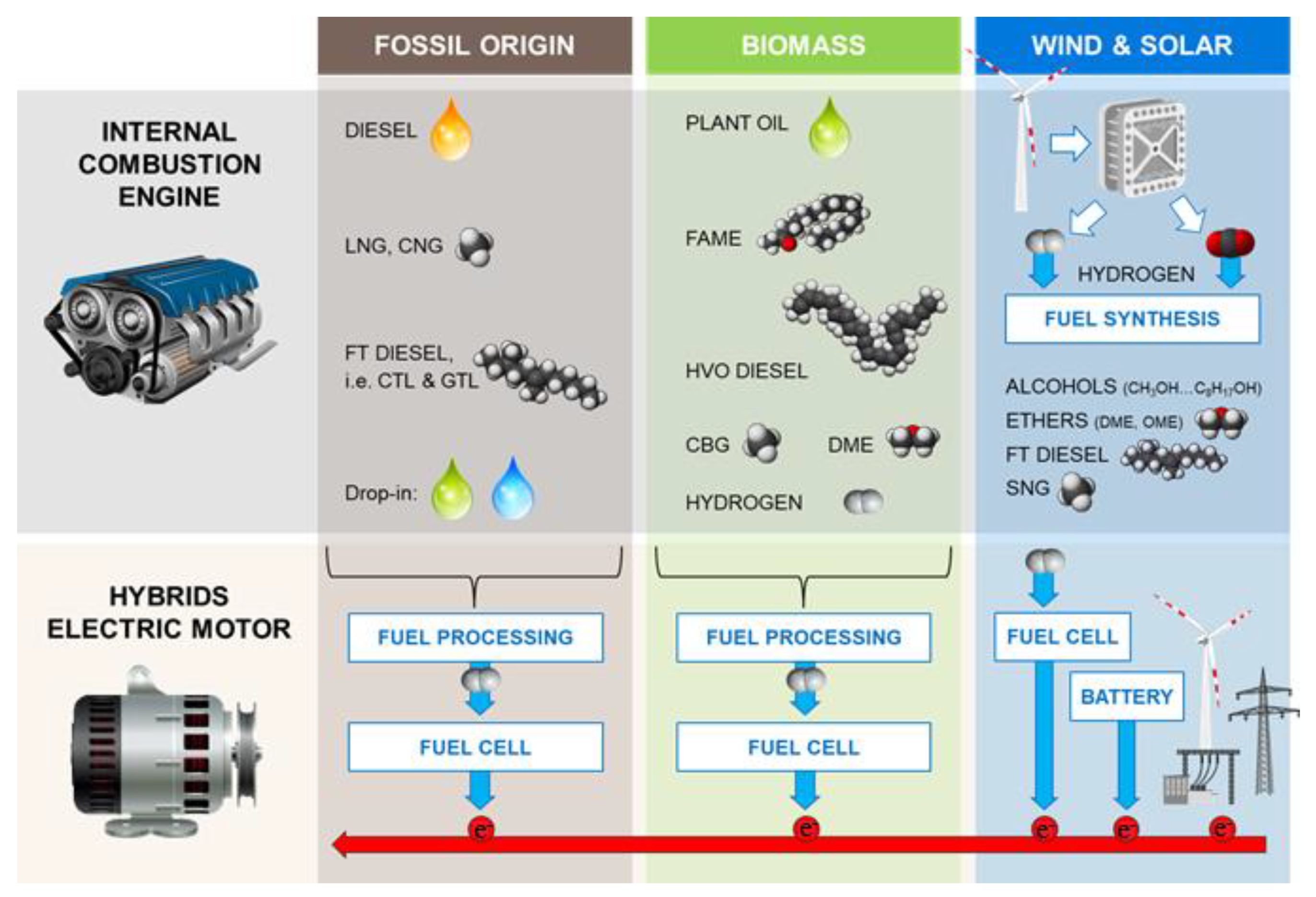

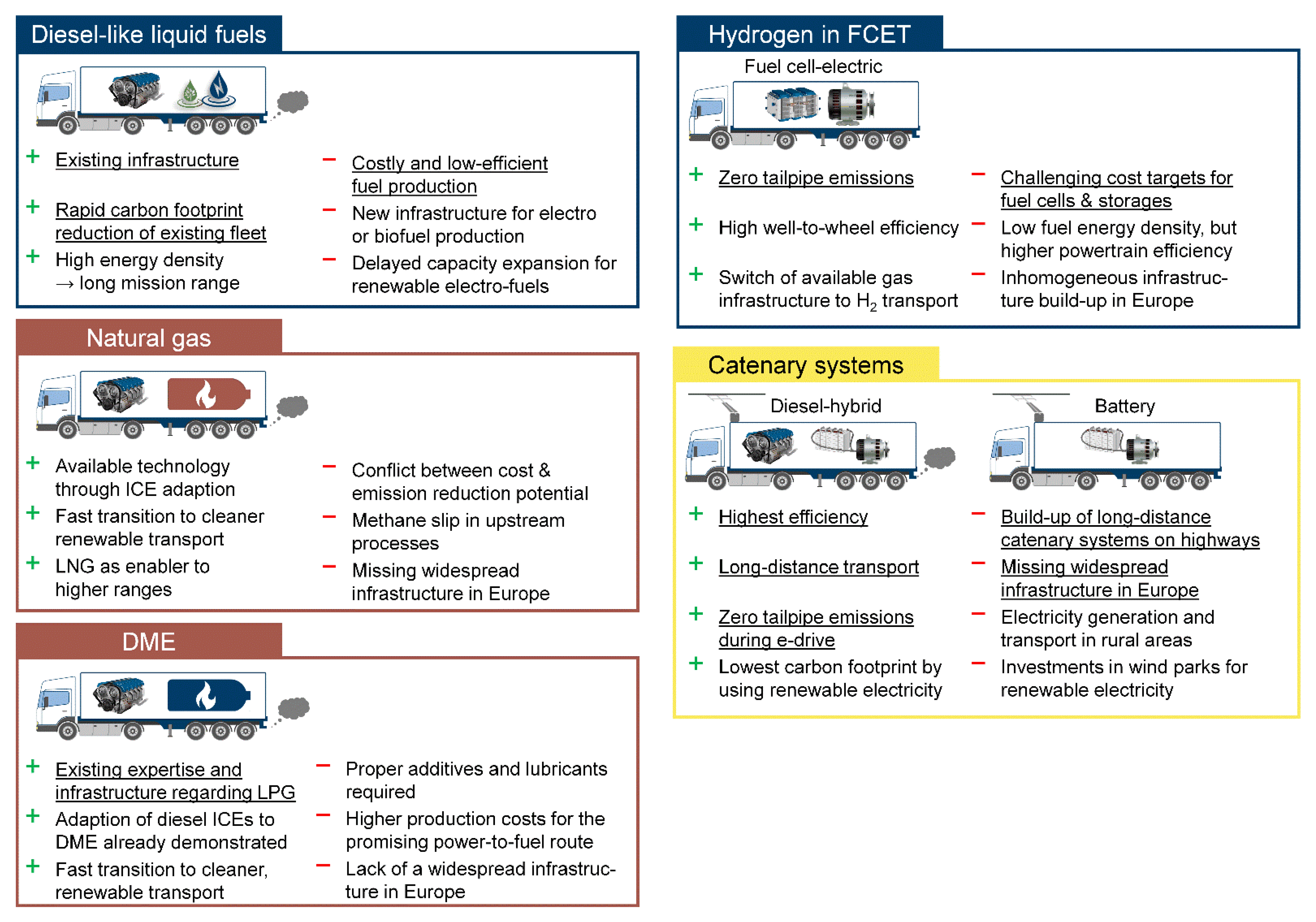

1.1. General Overview of Future Power Train Options

1.2. Scope of the Review

- Internal combustion engines driven by CBG, SNG or LNG;

- Internal combustion engines driven by DME;

- Internal combustion engines driven by biofuels or power-to-fuel;

- Electric drivetrains utilizing hydrogen and fuel cells;

- Electric drive trains with a catenary system.

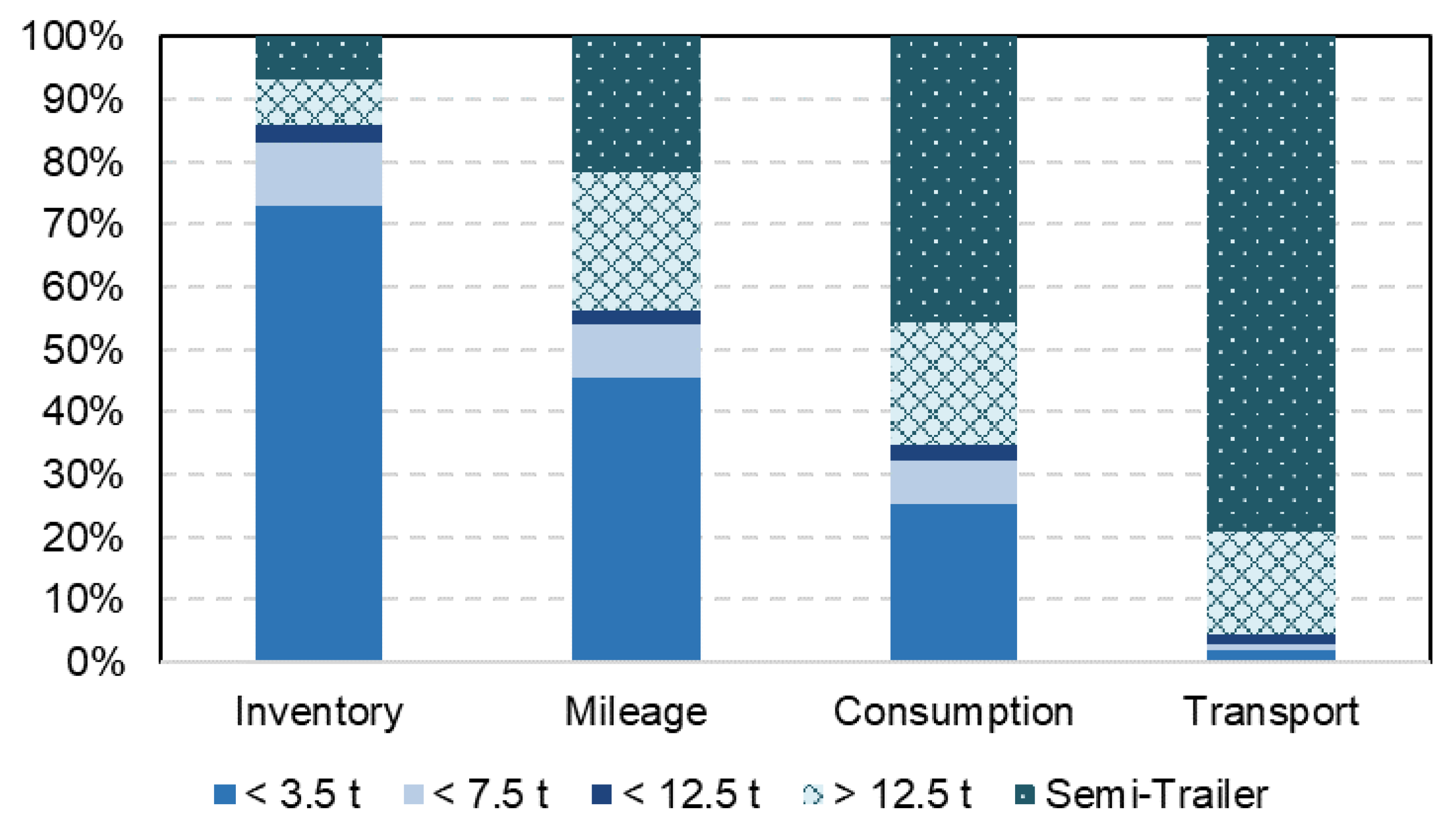

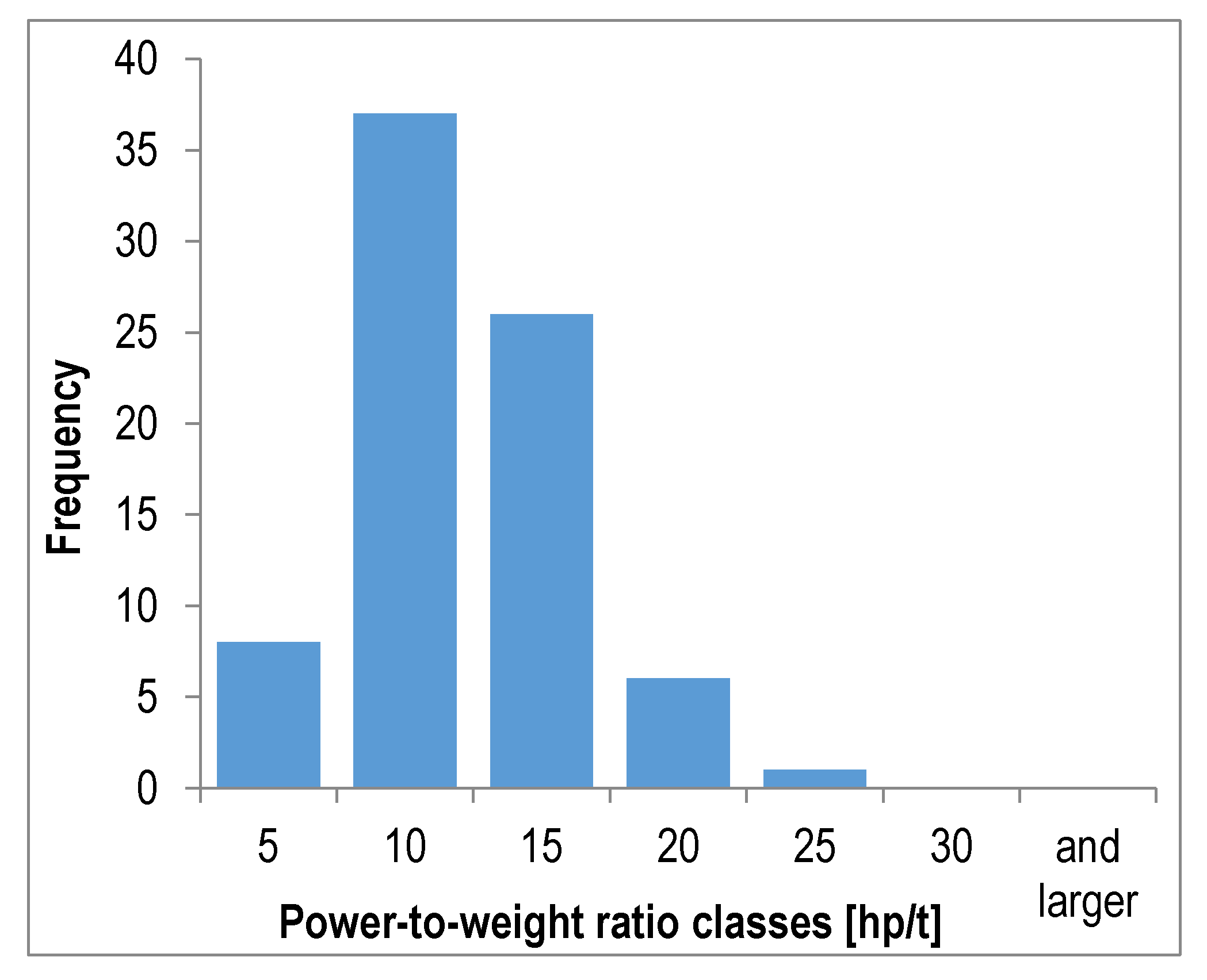

2. Vehicle Fleet for Freight Transport in Germany: Current and Future Capacity

- A change in drive system technology in freight disposal by LDVs affects a large number of vehicles

- More than 95% of freight transport is performed by 15% of the total vehicle inventory, that is, semi-trailers and HDVs in the >12.5 t class.

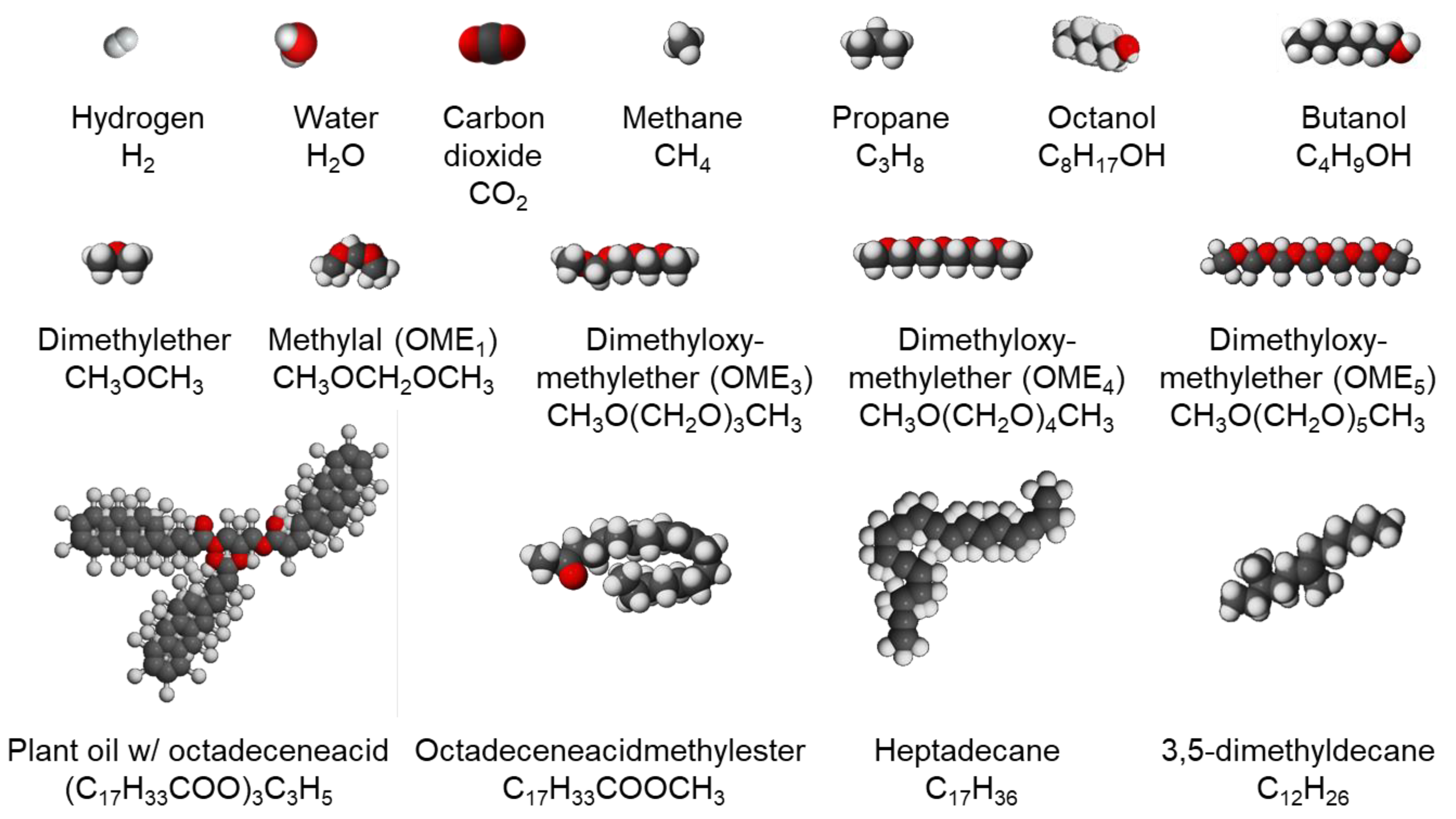

3. Fuels for Light- and Heavy-Duty Transport

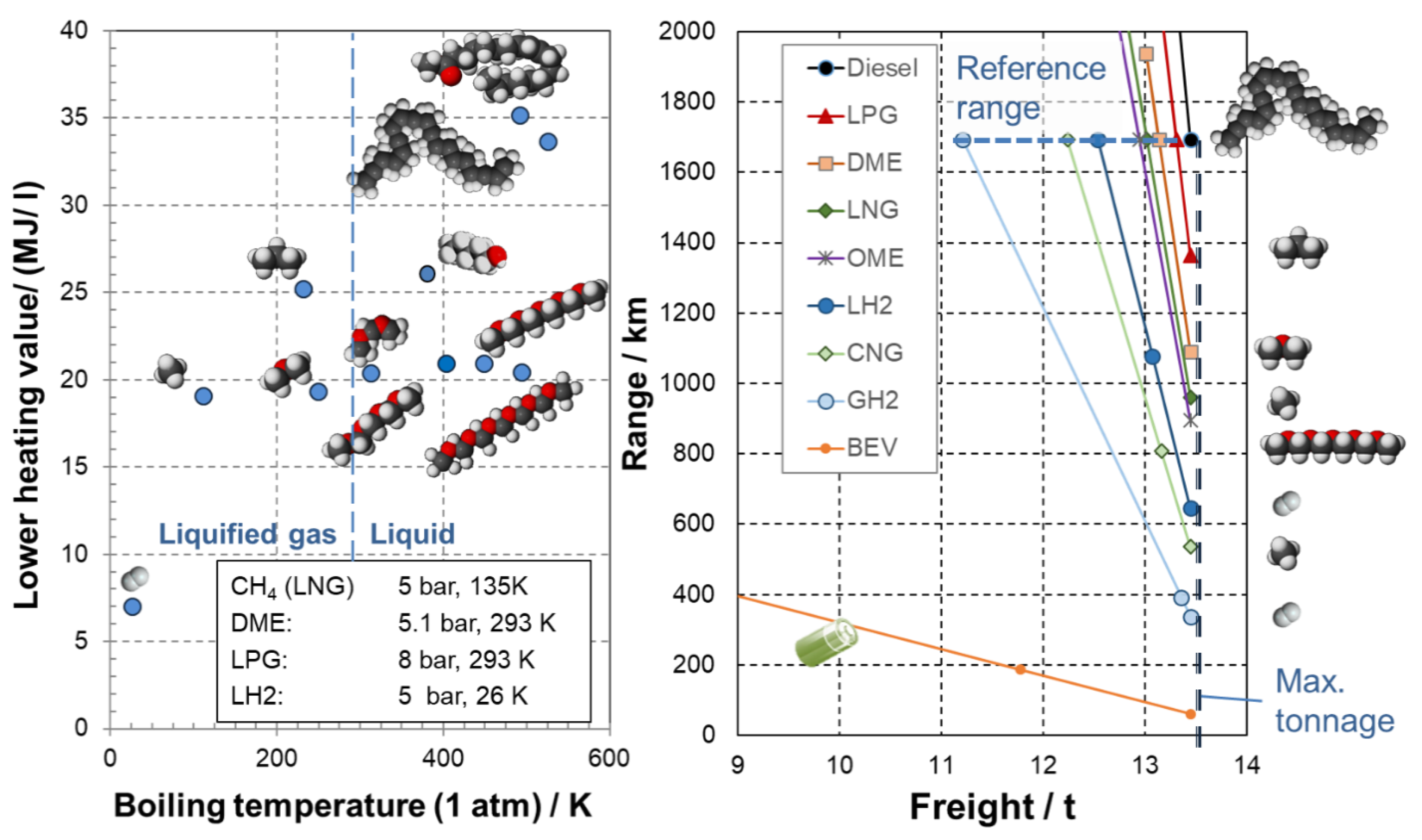

3.1. Fuel Properties and Storage

3.1.1. Natural Gas

3.1.2. Hydrogen

3.1.3. DME

3.1.4. A Comparative Analysis of Fuel Properties and Storage

3.2. Production of Renewable Fuels

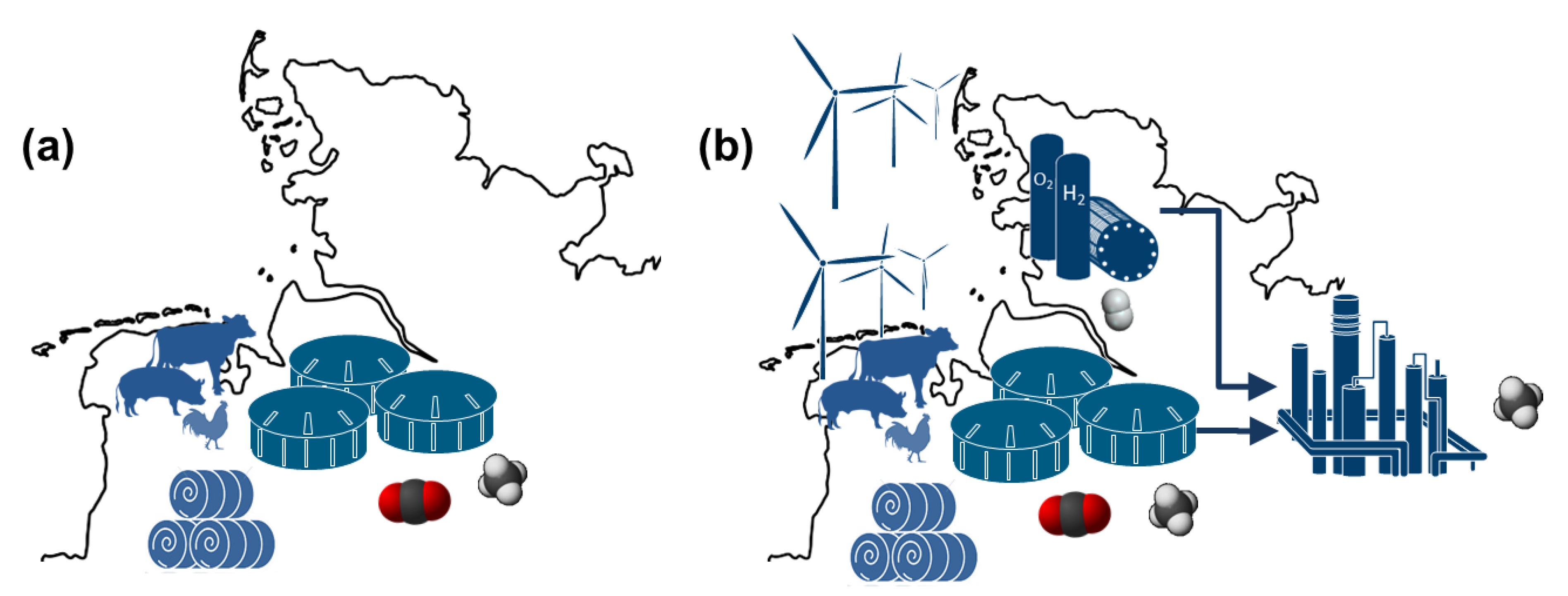

3.2.1. Biogas

3.2.2. Biofuels

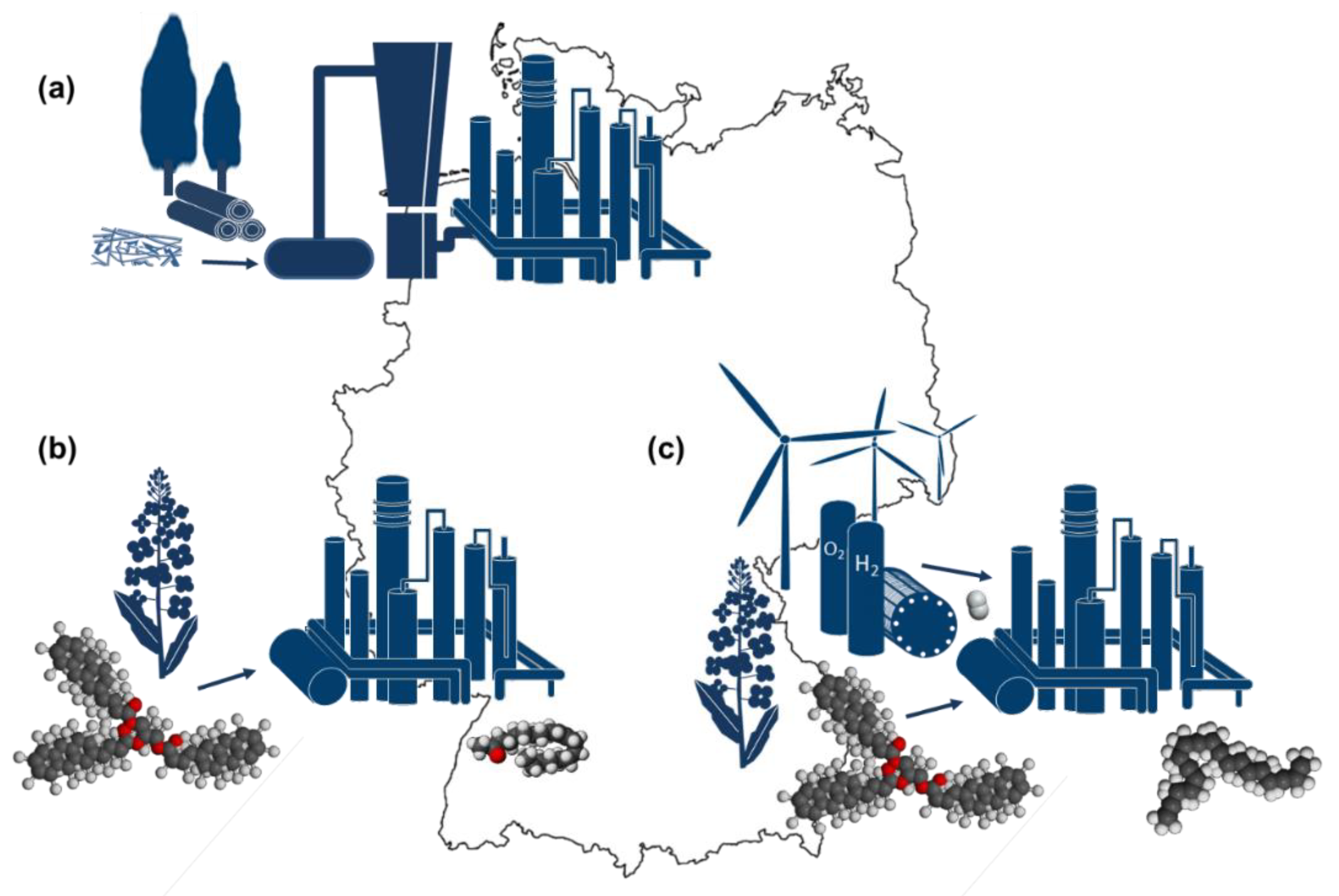

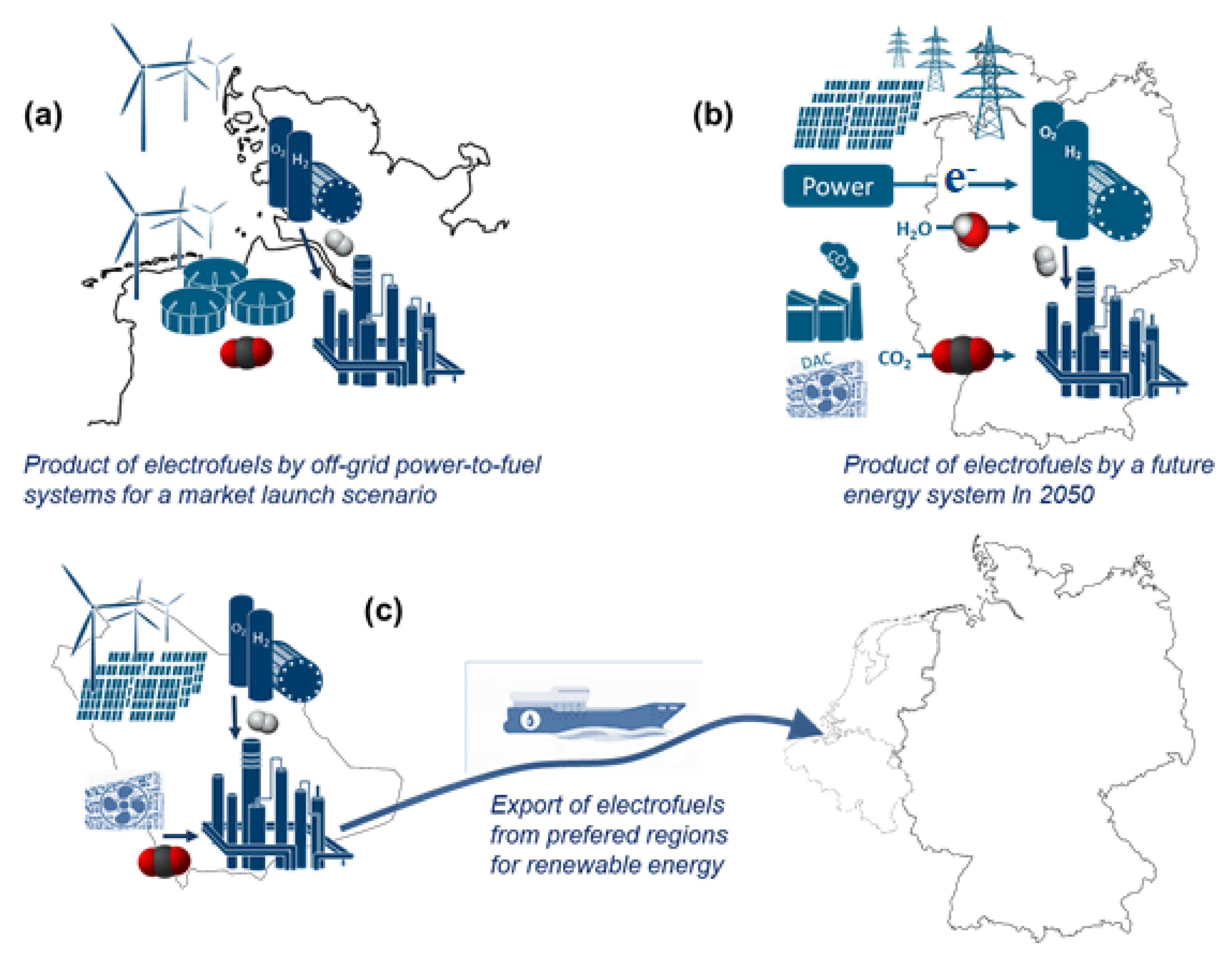

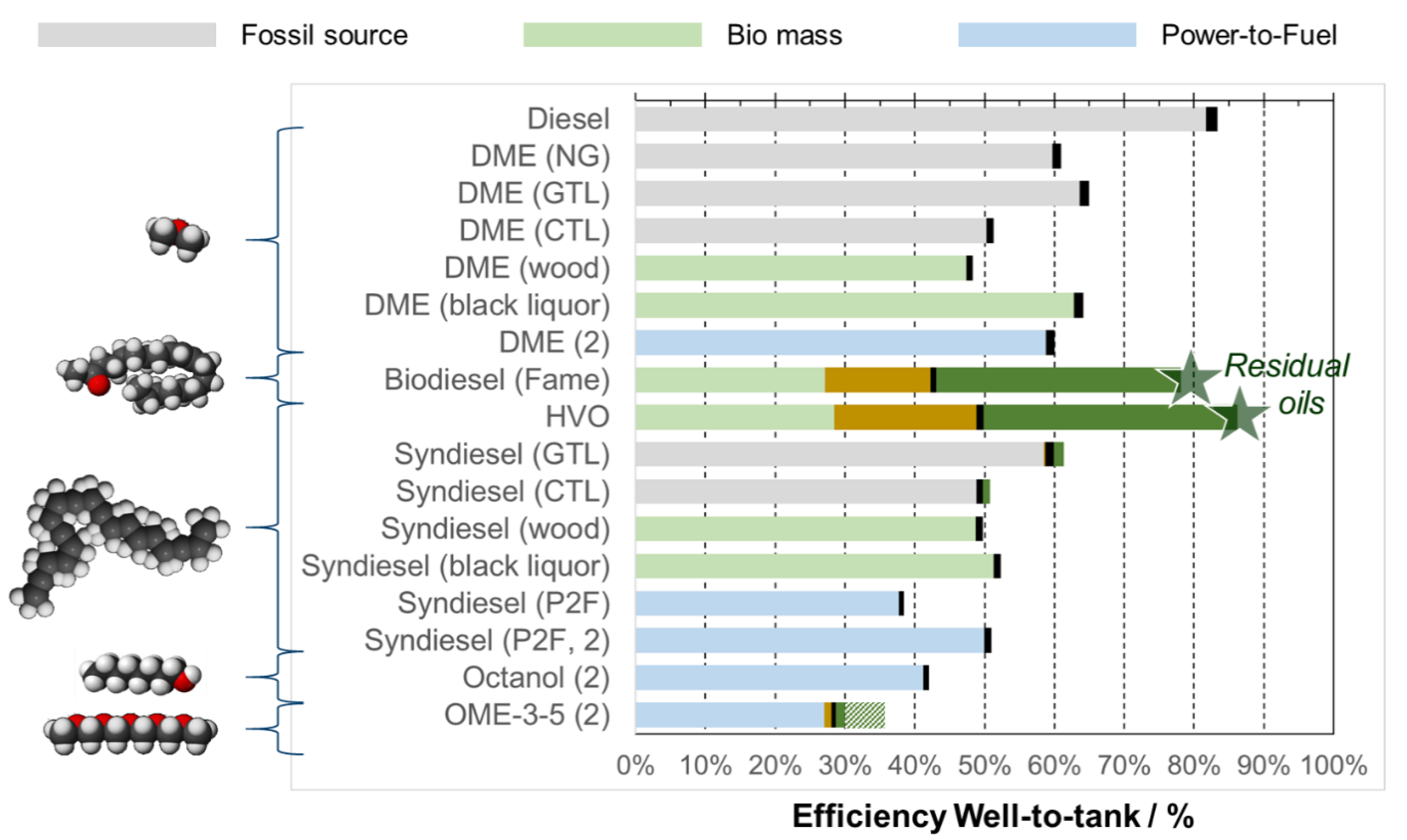

3.2.3. Power-to-Fuel

3.2.4. Comparison of Liquid Bio- and Electrofuels

4. Options for Future Heavy-Duty Transportation

- ICEs driven by renewable diesel-like liquid fuels or DME or natural gas (including bio methane),

- Electric drive trains using catenary systems or hydrogen-based fuel cells.

4.1. Renewable Diesel-Like Liquid Fuels in Heavy-Duty Transportation

4.1.1. Motivation for Using Biofuels and Electro-Fuels in Heavy Duty Transport

4.1.2. Power Train Technology and Vehicle Availability

4.1.3. Greenhouse Gas Reduction Potential

4.1.4. Emission Behavior

4.1.5. Infrastructure

4.1.6. Economic Considerations

4.1.7. SWOT Analysis

4.2. Catenary Systems

4.2.1. Motivation for Using Catenary Systems in Heavy-Duty Transport

4.2.2. Power Train Technology and Vehicle Availability

4.2.3. Greenhouse Gas Reduction Potential

4.2.4. Emission Behavior

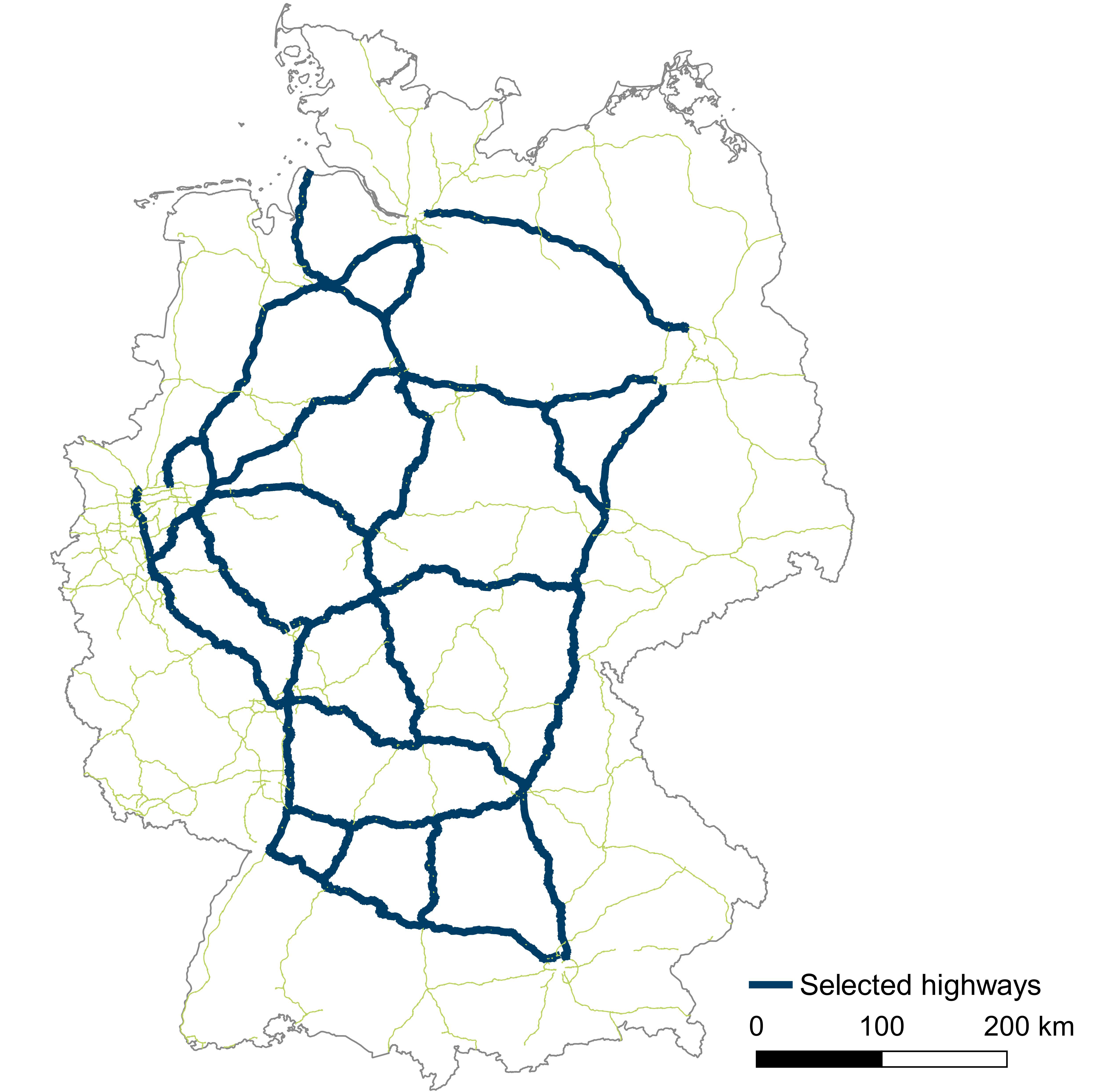

4.2.5. Infrastructure

4.2.6. Economic Considerations

4.2.7. SWOT Analysis

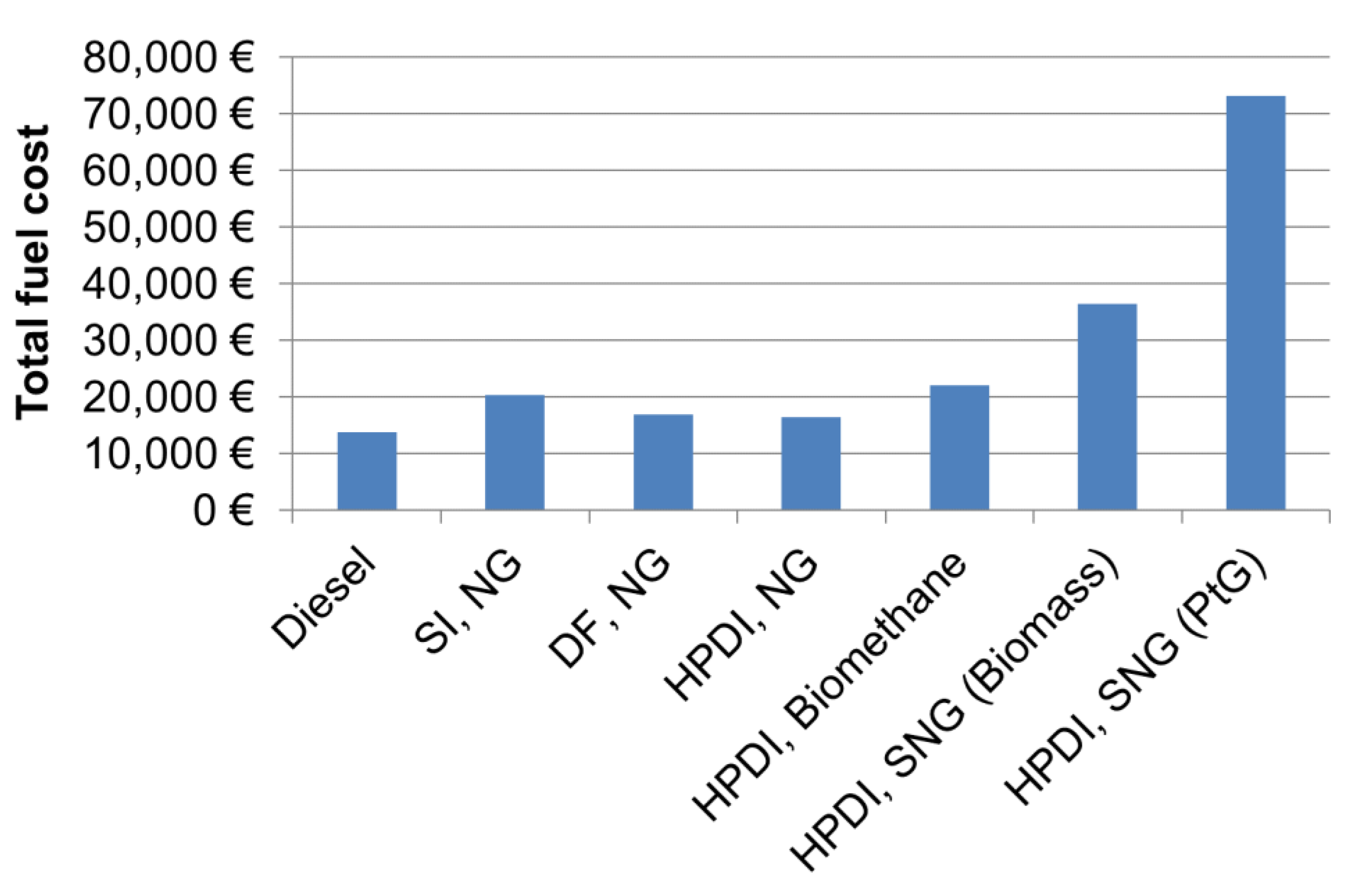

4.3. Natural Gas as an Alternative Fuel in Heavy-Duty Transportation

4.3.1. Motivation for Using Natural Gas in Heavy-Duty Transport

4.3.2. Power Train Technology and Vehicle Availability

4.3.3. Greenhouse Gas Reduction Potential

4.3.4. Emission Behavior

4.3.5. Infrastructure

4.3.6. Economic Considerations

4.3.7. SWOT Analysis

4.4. DME as an Alternative Fuel for Heavy-Duty Transportation

4.4.1. Motivation for DME Use in Heavy-Duty Transport

4.4.2. Power Train Technology and Vehicle Availability

4.4.3. Greenhouse Gas Reduction Potential

4.4.4. Emission Behavior

4.4.5. Infrastructure

4.4.6. Economic Considerations

4.4.7. SWOT Analysis

4.5. Hydrogen-Fueled Heavy-Duty Vehicles

4.5.1. Motivation for Using Hydrogen in Heavy-Duty Transport

4.5.2. Fuel Cell Technology and Vehicle Availability

4.5.3. Greenhouse Gas Reduction Potential

4.5.4. Emission Behavior

4.5.5. Infrastructure

4.5.6. Economic Considerations

4.5.7. SWOT Analysis

5. Conclusions

6. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Further Options for Future Heavy-Duty Transportation

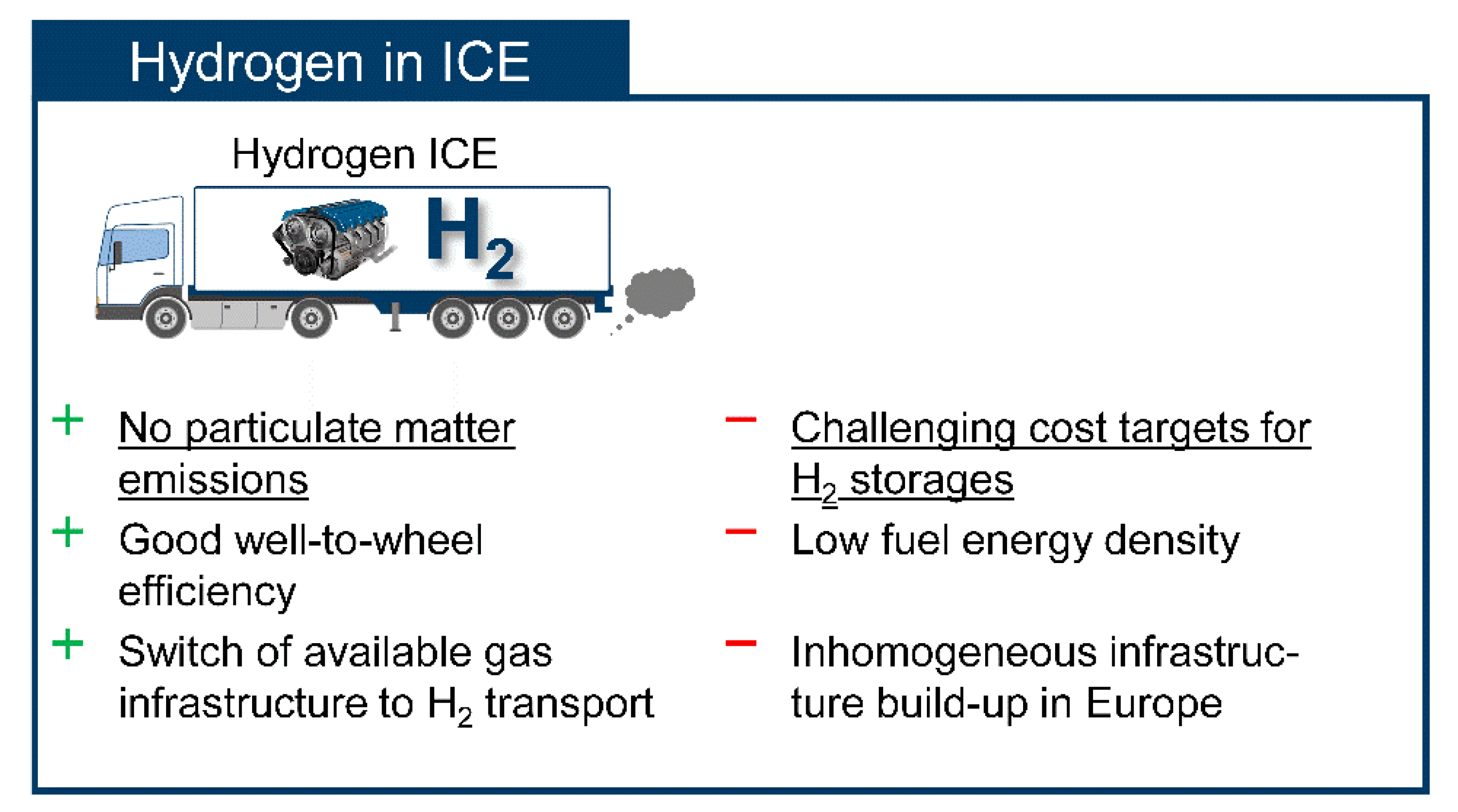

Appendix A.1. Hydrogen-Fueled ICEs for Heavy-Duty Vehicles

Appendix A.1.1. Motivation for Using Hydrogen in ICEs for Heavy-Duty Transport

Appendix A.1.2. Engine Technology and Vehicle Availability

Appendix A.1.3. Greenhouse Gas Reduction Potential

Appendix A.1.4. Emission Behavior

Appendix A.1.5. Infrastructure

Appendix A.1.6. Economic Considerations

Appendix A.1.7. SWOT Analysis

| Strengths | Weaknesses |

|---|---|

| High well-to-tank efficiency | Efficiency losses from hydrogen production and processing Moderate fuel energy density |

| No particle matter emissions | Low tank-to-wheel efficiency |

| Low developing effort | High cost of fuel storage |

| Opportunities | Threats |

| Allows for very low greenhouse gas emission levels in transport | Delayed or constrained capacity build-up of renewable power and electrolysis |

| Hydrogen provision may benefit from hydrogen demand in other markets | Technology lock-in for BEVs due to the advanced state of battery technology |

| Improved operating range compared to battery-electric trucks | The development of other markets might not significantly increase hydrogen demand |

| Available gas infrastructure could be switched to hydrogen transport | Inhomogeneous infrastructure build-up in Europe |

Appendix A.2. Additional Information on Fuel Chemistry

References

- Ribeiro, S.K.; Figueroa, M.J.N.; Creutzig, F.; Dubeux, C.; Hupe, J.; Kobayashi, S.; Brettas, L.A.D.M.; Thrasher, T.; Webb, S. Energy End-Use: Transport; International Institute for Applied System Analysis: Laxenburg, Austria, 2012. [Google Scholar]

- Mineralölwirtschaftsverband. MWV-Prognose 2025 für die Bundesrepublik Deutschland; Mineralölwirtschaftsverband e. V.: Berlin, Germany, 2011; p. 13. [Google Scholar]

- Victor, D.G.; Zhou, D.; Ahmed, E.H.M.; Dadhich, P.K.; Olivier, J.G.J.; Rogner, H.-H.; Sheikho, K.; Yamaguchi, M. Introductory Chapter. In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Umweltbundesamt. Klimagase in Deutschland 2014 Deutlich Gesunken. Available online: https://www.umweltbundesamt.de/presse/pressemitteilungen/klimagase-in-deutschland-2014-deutlich-gesunken (accessed on 15 April 2020).

- Eurostat. Greenhouse Gas Emissions, Analysis by Source Sector, EU-28, 1990 and 2015. Available online: Eurostat// http://ec.europa.eu/eurostat/statistics-explained/index.php/File:Greenhouse_gas_emissions,_analysis_by_source_sector,_EU-28,_1990_and_2015_(percentage_of_total)_new.png (accessed on 15 April 2020).

- Akermann, P. eHighway. In The Future Role of Trucks for Energy and Environment; Workshop: Brussels, Belgium, 2016. [Google Scholar]

- Cebon, D. Technology options for decarbonizing road freight. In The Future Role of Trucks for Energy and Environment; Joint Research Centre of the European Commission & International Energy Agency: Brussels, Belgium, 2016. [Google Scholar]

- Delgado, O.; Sharpe, B.; Miller, J.; Muncrief, R. Assessing near-term efficiency potential of engine and vehicle technologies. In The Future Role of Trucks for Energy and Environment; Joint Research Centre of the European Commission & International Energy Agency: Brussels, Belgium, 2016. [Google Scholar]

- Greening, P. Proven strategies to enable more efficient and low-carbon logistics. In The Future Role of Trucks for Energy and Environment; Joint Research Centre of the European Commission & International Energy Agency: Brussels, Belgium, 2016. [Google Scholar]

- Schuckert, M. Daimler‘s advances in fuel efficiency and zero emission activities. In The Future Role of Trucks for Energy and Environment; Joint Research Centre of the European Commission & International Energy Agency: Brussels, Belgium, 2016. [Google Scholar]

- Teter, J.; Cazzola, P.; Gül, T.; Mulland, E. The Future of Trucks; International Energy Agency: Paris, France, 2017; pp. 3–161. [Google Scholar]

- Peters, R.; Decker, M.; Eggemann, L.; Schemme, S.; Schorn, F.; Breuer, J.L.; Weiske, S.; Pasel, J.; Samsun, R.C.; Stolten, D. Thermodynamic and ecological preselection of synthetic fuel intermediates from biogas at farm sites. Energy Sustain. Soc. 2020, 10, 4. [Google Scholar] [CrossRef]

- Energy, D.O. On-Board Fuel Processing Go/No-Go Decision. Available online: www.eere.energy.gov/hydrogenandfuelcells/news_fuel_processor.html (accessed on 16 November 2009).

- Peters, R. Auxiliary Power Units for Light-Duty Vehicles, Trucks, Ships and Airplanes. In Hydrogen and Fuel Cells; Stolten, D., Ed.; Wiley: Weinheim, Germany, 2010; pp. 681–714. [Google Scholar]

- Peters, R.; Westenberger, A. Large auxiliary power units for vessels and airplanes. In Innovations in Fuel Cell Technologies; Steinberger-Wilckens, R., Lehnert, W., Eds.; The Royal Society of Chemistry: Cambridge, UK, 2010; pp. 76–148. [Google Scholar]

- Samsun, R.C.; Krekel, D.; Pasel, J.; Prawitz, M.; Peters, R.; Stolten, D. A diesel fuel processor for fuel-cell-based auxiliary power unit applications. J. Power Sources 2017, 355, 44–52. [Google Scholar] [CrossRef]

- Samsun, R.C.; Krupp, C.; Baltzer, S.; Gnörich, B.; Peters, R.; Stolten, D. A battery-fuel cell hybrid auxiliary power unit for trucks: Analysis of direct and indirect hybrid configurations. Energy Convers. Manag. 2016, 127, 312–323. [Google Scholar] [CrossRef]

- Samsun, R.C.; Krupp, C.; Tschauder, A.; Peters, R.; Stolten, D. Electrical start-up for diesel fuel processing in a fuel-cell-based auxiliary power unit. J. Power Sources 2016, 302, 315–323. [Google Scholar] [CrossRef]

- Samsun, R.C.; Prawitz, M.; Tschauder, A.; Pasel, J.; Peters, R.; Stolten, D. An autothermal reforming system for diesel and jet fuel with quick start-up capability. Int. J. Hydrog. Energy 2019, 44, 27749–27764. [Google Scholar] [CrossRef]

- Samsun, R.C.; Prawitz, M.; Tschauder, A.; Pasel, J.; Pfeifer, P.; Peters, R.; Stolten, D. An integrated diesel fuel processing system with thermal start-up for fuel cells. Appl. Energy 2018, 226, 145–159. [Google Scholar] [CrossRef]

- Pavlo. Spare part–Vektor Illustration; spare-part-gm164474197-20458528; Istock: Calgary, AB, Canada, 2012. [Google Scholar]

- Dashadima. Vektor Elektrisches Auto Parts Symbole; Ektor-Elektrisches-Auto-Parts-Symbole-gm530411287-54508076; Istock: Calgary, AB, Canada, 2015. [Google Scholar]

- Eskiner, M.; Bär, F.; Rossner, M.; Munack, A.; Krahl, J. Determining the aging degree of domestic heating oil blended with biodiesel by means of dielectric spectroscopy. Fuel 2015, 143, 327–333. [Google Scholar] [CrossRef]

- Unglert, M.; Bockey, D.; Bofinger, C.; Buchholz, B.; Fisch, G.; Luther, R.; Müller, M.; Schaper, K.; Schmitt, J.; Schröder, O.; et al. Action areas and the need for research in biofuels. Fuel 2020, 268, 117727. [Google Scholar] [CrossRef]

- Agarwal, A.K. Alternative fuels for internal combustion engines. Proc. Combust. Inst. 2017, 36, 3389–3413. [Google Scholar] [CrossRef]

- Bae, C.; Kim, J. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Schemme, S.; Samsun, R.C.; Peters, R.; Stolten, D. Power-to-fuel as a key to sustainable transport systems–An analysis of diesel fuels produced from CO2 and renewable electricity. Fuel 2017, 205, 198–221. [Google Scholar] [CrossRef]

- Kroom, R. Electrifying freight & distribution in Europe. In Green Energy Hubs; EnergieAgentur NRW: Düsseldorf, Germany, 2020; p. 22. [Google Scholar]

- Wken, H. Electrifying freight & distribution in Europe. In Jahrestagung Mobilität; EnergieAgentur NRW: Düsseldorf, Germany, 2020. [Google Scholar]

- Mineaud, F. HyTrucks. In Green Energy Hubs; EnergieAgentur NRW: Düsseldorf, Germany, 2020; p. 16. [Google Scholar]

- Schwaderlapp, M. Sustainable Powertrains for Off Highway Mobile Machinery; ZERO CO2 MOBILITY: Aachen, Germany, 2020. [Google Scholar]

- Nour, M.; Kosaka, H.; Bady, M.; Sato, S.; Abdel-Rahman, A.K. Combustion and emission characteristics of DI diesel engine fuelled by ethanol injected into the exhaust manifold. Fuel Process. Technol. 2017, 164, 33–50. [Google Scholar] [CrossRef]

- Kramer, U.; Ortloff, F.; Stollenwerk, S.; Thee, R. Defossilisierung des Transportsektors; FVV-Forschungsvereinigung Verbrennungskraftmaschinen e.V.: Frankfurt am Main, Germany, 2018. [Google Scholar]

- Hacker, F.; Blanck, R.; Hülsmann, F.; Kasten, P.; Loreck, C.; Ludig, S.; Mottschall, M.; Zimmer, W. eMobil 2050-Szenarien zum Möglichen Beitrag Des Elektrischen Verkehrs Zum Langfristigen Klimaschutz; Öko-Institut e.V.: Breisgau, Germany, 2014. [Google Scholar]

- Zimmer, W.; Blanck, R.; Bergmann, T.; Mottschall, M.; von Waldenfels, R.; Förster, H. Endbericht Renewbility III-Optionen Einer Dekarbonisierung des Verkehrssektors; Öko-Institut e.V.: Breisgau, Germany, 2017. [Google Scholar]

- Schlesinger, D.M.; Hofer, P.; Kemmler, D.A.; Kirchner, D.A.; Strassburg, S. Energieszenarien für ein Energiekonzept der Bundesregierung; Prognos AG, EWI-Energiewirtschaftliches Institut an der Universität zu Köln, Gesellschaft für Wirtschaftliche Strukturforschung mbH (GWS): Osnabrück, Germany, 2010. [Google Scholar]

- Kasten, P.; Mottschall, M.; Köppel, W.; Degünther, C.; Schmied, M.; Wüthrich, P. Erarbeitung einer Fachlichen Strategie zur Energieversorgung des Verkehrs bis zum Jahr 2050. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/377/publikationen/2016-11-10_endbericht_energieversorgung_des_verkehrs_2050_final.pdf (accessed on 2 July 2016).

- Adolf, J.; Balzer, C.; Haase, F.; Lenz, B.; Lischke, A.; Knitschky, G. Shell Nutzfahrzeug-Studie-Diesel oder Alternative Antriebe-Womit Fahren Lkw und Bus Morgen? Shell Deutschland, Deutsches Zentrum für Luft- und Raumfahrt (DLR): Bonn, Germany, 2016. [Google Scholar]

- Die Mobilitäts- und Kraftstoffstrategie der Bundesregierung (MKS); Bundesministerium für Verkehr, Bau und Stadtentwicklung: Berlin, Germany, 2013; p. 92.

- Smajla, I.; Karasalihović Sedlar, D.; Drljača, B.; Jukić, L. Fuel Switch to LNG in Heavy Truck Traffic. Energies 2019, 12, 515. [Google Scholar] [CrossRef]

- Rosenstiel, D.P.; Siegemund, S.; Bünger, U.; Schmidt, P.R.; Weindorf, W.; Wurster, R.; Zerhusen, J.; Usmani, O.A.; de Wilde, H.P.J. LNG in Germany: Liquefied Natural Gas and Renewable Methane in Heavy-Duty Road Freight Transport; Dena: Berlin, Germany, 2014. [Google Scholar]

- The Future of Natural Gas Engines in Heavy Duty Trucks: The Diesel of Tomorrow? Americas Commercial Transportation Research: Columbus, IN, USA, 2012.

- Westport™ iCE PACK LNG Tank System. Available online: https://www.westport.com/about/fuel-storage-and-delivery/ice-pack-lng-tank-system/brochures/westport-ice-pack-lng-tank-system-brochure.pdf (accessed on 16 April 2020).

- Multi-Year Research, Development and Demonstration Plan, Hydrogen, Fuel Cells & Infrastructure Technologies Program-Hydrogen Storage; Department of Energy, USA: Beaver, WA, USA, 2015.

- Gangloff, J.J., Jr.; Kast, J.; Morrison, G.; Marcinkoski, J. Design Space Assessment of Hydrogen Storage Onboard Medium and Heavy Duty Fuel Cell Electric Trucks. J. Electrochem. Energy Convers. Storage 2017, 14, 021001. [Google Scholar] [CrossRef]

- Ahluwalia, R.K.; Peng, J.K.; Roh, H.S.; Hua, T.Q.; Houchins, C.; James, B.D. Supercritical cryo-compressed hydrogen storage for fuel cell electric buses. Int. J. Hydrog. Energy 2018, 43, 10215–10231. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, C.S. Combustion performance and emission reduction characteristics of automotive DME engine system. Prog. Energy Combust. Sci. 2013, 39, 147–168. [Google Scholar] [CrossRef]

- Arcoumanis, C.; Bae, C.; Crookes, R.; Kinoshita, E. The potential of di-methyl ether (DME) as an alternative fuel for compression-ignition engines: A review. Fuel 2008, 87, 1014–1030. [Google Scholar] [CrossRef]

- Semelsberger, T.A.; Borup, R.L.; Greene, H.L. Dimethyl ether (DME) as an alternative fuel. J. Power Sources 2006, 156, 497–511. [Google Scholar] [CrossRef]

- Zubel, M.; Ottenwälder, T.; Heuser, B.; Herudek, C.; Maas, H.; Willems, W. DME–A Sustainable Fuel Solution for Clean and Closed CO2-Cycle-Mobility for CI Powertrain. In Zukünftige Kraftstoffe; ATZ/MTZ-Fachbuch, Springer-GmbH: Wiesbaden, Deutschland, 2019; pp. 783–798. [Google Scholar]

- Park, S.H.; Lee, C.S. Applicability of dimethyl ether (DME) in a compression ignition engine as an alternative fuel. Energy Convers. Manag. 2014, 86, 848–863. [Google Scholar] [CrossRef]

- Thomas, G.; Feng, B.; Veeraragavan, A.; Cleary, M.J.; Drinnan, N. Emissions from DME combustion in diesel engines and their implications on meeting future emission norms: A review. Fuel Process. Technol. 2014, 119, 286–304. [Google Scholar] [CrossRef]

- Fuel information: Dimethyl Ether (DME). Available online: https://www.iea-amf.org/content/fuel_information/dme (accessed on 28 April 2020).

- Meinert, M. Wasserstoff Speichertechnologien für Fahrzeuge. Wasserstoff und Brennstoffzellen im Automobil; Haus der Technik: Essen, Germany, 2007; Volume 15, p. 402. [Google Scholar]

- Der Neue Actros; Mercedes Benz: Stuttgart, Germany, 2013; p. 78.

- Mareev, I.; Becker, J.; Sauer, D. Battery Dimensioning and Life Cycle Costs Analysis for a Heavy-Duty Truck Considering the Requirements of Long-Haul Transportation. Energies 2017, 11, 55. [Google Scholar] [CrossRef]

- Füßel, A. Entwicklungspotenzial technischer Kriterien der BEV-Technologie. In Technische Potenzialanalyse der Elektromobilität: Stand der Technik, Forschungsausblick und Projektion auf das Jahr 2025; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2017; pp. 35–82. [Google Scholar] [CrossRef]

- Schaffelhofer, F. MAN Engines Präsentiert 16,2-Liter-Motor D4276 für Spitzenleistungen in der Landtechnik; MAN Engines: Nürnber, Germany, 2019. [Google Scholar]

- Zeitzen, F.; Wolf, A. Neuer Mercedes Actros Kraftvoller Motor. Available online: https://www.eurotransport.de/artikel/neuer-mercedes-actros-kraftvoller-motor-445142.html (accessed on 21 June 2011).

- Elfasakhany, A. Engine performance evaluation and pollutant emissions analysis using ternary bio-ethanol–iso-butanol–gasoline blends in gasoline engines. J. Clean. Prod. 2016, 139, 1057–1067. [Google Scholar] [CrossRef]

- Biogas, F. Branchenzahlen. Available online: https://www.biogas.org/edcom/webfvb.nsf/id/de_branchenzahlen (accessed on 29 June 2018).

- Billig, E.; Decker, M.; Benzinger, W.; Ketelsen, F.; Pfeifer, P.; Peters, R.; Stolten, D.; Thrän, D. Non-fossil CO2 recycling—The technical potential for the present and future utilization for fuels in Germany. J. Co2 Util. 2019, 30, 130–141. [Google Scholar] [CrossRef]

- Baumgarten, C.; Bilharz, M.; Döring, U.; Eisold, A.; Friedrich, B.; Frische, T.; Gather, C.; Günther, D.; Große Wichtrup, W.; Hofmeier, K.; et al. Umwelt und Landwirtschaft; Umweltbundesamt: Dessau-Roßlau, Germany, 2018; p. 158. [Google Scholar]

- Umweltbundesamt. Biogasproduktion aus Gülle und Bioabfall ausbauen. Available online: https://www.umweltbundesamt.de/themen/biogasproduktion-aus-guelle-bioabfall-ausbauen (accessed on 6 December 2019).

- Peters, R.; Baltruweit, M.; Grube, T.; Samsun, R.C.; Stolten, D. Techno Economic Analysis of Power to Gas Route; Forschungszentrum Jülich GmbH, Insitute for Energy and Climate Research, Electrochemical Process Engineering: Jülich, Germany, 2019. [Google Scholar]

- Leible, L.; Kälber, S.; Kappler, G.; Eltrop, L.; Stenull, M.; Lansche, J.; Poboss, N.; Stürmer, B.; Kelm, T.; Köppel, W. Perspektiven für Bio-Erdgas. Teil I: Bereitstellung aus nasser und trockener Biomasse. BWK 2012, 5, 21–27. [Google Scholar]

- Kappler, G.; Hurtig, O.; Kälber, S.; Leible, L. Perspektiven für Bio-Erdgas. Teil II: Perspektiven für Erdgas. BWK 2012, 5, 28–34. [Google Scholar]

- Peters, R. Heutige und zukünftige Kraftstoffe in der Luftfahrt. In Brennstoffzellensysteme in der Luftfahrt; Peters, R., Ed.; Springer: Berlin, Germany, 2015; pp. 7–100. [Google Scholar]

- Berndes, G.; Hoogwijk, M.; van den Broek, R. The contribution of biomass in the future global energy supply: A review of 17 studies. Biomass Bioenergy 2003, 25, 1–28. [Google Scholar] [CrossRef]

- Offermann, R.; Seidenberger, T.; Thrän, D.; Kaltschmitt, M.; Zinoviev, S.; Miertus, S. Assessment of global bioenergy potentials. Mitig. Adapt. Strateg. Glob. Chang. 2010, 16, 103–115. [Google Scholar] [CrossRef]

- Parikka, M. Global biomass fuel resources. Biomass Bioenergy 2004, 27, 613–620. [Google Scholar] [CrossRef]

- Kaltschmitt, M.; Lenz, V.; Thrän, D. Zur Energetischen Nutzung von Biomasse in Deutschland-Potenziale, Stand und Perspektiven; Leibnitz Institut für interdisiplinäre Studien: Berlin, Germany, 2008; p. 12. [Google Scholar]

- Peters, R. Brennstoffzellen in der Luftfahrt; Springer: Berlin, Germany, 2015. [Google Scholar]

- Dahmen, N.; Dinjus, E. Synthetische Chemieprodukte und Kraftstoffe aus Biomasse. Chem. Ing. Tech. 2010, 82, 1147–1152. [Google Scholar] [CrossRef]

- Dahmen, N.; Sauer, J. Das Bioliq -Konzept-Hintergrund und Aktueller Stand. Available online: http://www.fornebik.bayern.de/allgemein/a_veranstaltungen/box_rechts_auf_VAseite/130604_05/Vortraege/Dahmen.pdf (accessed on 3 December 2015).

- Dinjus, E.; Dahmen, N. Das BIOLIQ-Verfahren-Konzept, Technologie und Stand der Entwicklung. Mot. Z. 2010, 12, 7. [Google Scholar] [CrossRef]

- Dahmen, N.; Dinjus, E.; Kolb, T.; Arnold, U.; Leibold, H.; Stahl, R. State of the art of the bioliq® process for synthetic biofuels production. Environ. Prog. Sustain. Energy 2012, 31, 176–181. [Google Scholar] [CrossRef]

- Presse-Agentur, D. Linde Engineering Dresden kauft Choren-Technologie für Synthesegas. In Der Insolvenzverwalter der Choren Industries GmbH (Freiberg) hat Eine Technologie zur Herstellung von Synthesegas an das Unternehmen Linde Engineering Dresden GmbH Verkauft; Redaktionsnetzwerk Deutschland: Berlin, Germany, 2015. [Google Scholar]

- Vollhardt, K.P.C.; Schore, N.E. Organische Chemie, 5th ed.; Wiley-VCH: Weinheim, Germany, 2011. [Google Scholar]

- Brennan, L.; Owende, P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 2010, 14, 557–577. [Google Scholar] [CrossRef]

- Chisti, Y.; Yan, J. Energy from algae: Current status and future trends. Algal biofuels–A status report. Appl. Energy 2011, 88, 3277–3279. [Google Scholar] [CrossRef]

- Hu, Q.; Sommerfeld, M.; Jarvis, E.; Ghirardi, M.; Posewitz, M.; Seibert, M.; Darzins, A. Microalgal triacylglycerols as feedstocks for biofuel production: Perspectives and advances. Plant J. 2008, 54, 621–639. [Google Scholar] [CrossRef] [PubMed]

- Roncarati, A.; Meluzzi, A.; Acciarri, S.; Tallarico, N.; Eloti, P. Fatty acid composition of different microalgae strains (Nannochloropsis sp., Nannochloropsis oculata (Droop) Hibberd, Nannochloris atomus Butcher and Isochrysis sp.) according to the culture phase and the carbon dioxide concentration. J. World Aquac. Soc. 2004, 35, 401–411. [Google Scholar] [CrossRef]

- Weyer, K.M.; Bush, D.R.; Darzins, A.; Willson, B.D. Theoretical maximum algal oil production. Bioenergy Res. 2009, 3, 204–213. [Google Scholar] [CrossRef]

- Willson, B. Large scale production of microalgae for biofuels. In Automotive Biofuels; IQPC: Berlin, Germany, 2009; p. 68. [Google Scholar]

- Berchmans, H.J.; Hirata, S. Biodiesel production from crude Jatropha curcas L. seed oil with a high content of free fatty acids. Bioresour. Technol. 2008, 99, 1716–1721. [Google Scholar] [CrossRef] [PubMed]

- Banerji, R.; Chowdhury, A.R.; Misra, G.; Sudarsanan, G.; Verma, S.C.; Srivastava, G.S. Jatropha seed oils for energy. Biomass 1985, 8, 277–282. [Google Scholar] [CrossRef]

- Aatola, H.; Larmi, M.; Sarjovaara, T.; Mikkonen, S. Hydrotreated Vegetable oil (HVO) as a Renewable Diesel Fuel: Trade-off between NOx, Particulate Emission, and Fuel Consumption of a Heavy Duty Engine. SAE Int. J. Engines 2008, 1, 1251–1262. [Google Scholar] [CrossRef]

- Dörr, S. NExBTL General Presentation; Neste Oil: Espoo, Finland, 2012. [Google Scholar]

- van Eijck, J.; Batidzirai, B.; Faaij, A. Current and future economic performance of first and second generation biofuels in developing countries. Appl. Energy 2014, 135, 115–141. [Google Scholar] [CrossRef]

- Grube, T.; Menzer, R.; Peters, R.; Arnold, K.; Ramesohl, S. Verfahrensanalyse der Herstellung Flüssiger Synthetischer Kraftstoffe auf Biomassebasis; VDI: Düsseldorf, Germany, 2006; pp. 379–403. [Google Scholar]

- Althapp, A. Kraftstoffe aus Biomasse mit dem Carbo-V®- Vergasungsverfahren. Forschungsverbund Sonnenenergie. In FVEE Jahrestagung; University of Stuttgart: Stuttgart, Germany, 2003. [Google Scholar]

- König, D.H.; Freiberg, M.; Dietrich, R.-U.; Wörner, A. Techno-economic study of the storage of fluctuating renewable energy in liquid hydrocarbons. Fuel 2015, 159, 289–297. [Google Scholar] [CrossRef]

- Decker, M.; Schorn, F.; Samsun, R.C.; Peters, R.; Stolten, D. Off-grid power-to-fuel systems for a market launch scenario–A techno-economic assessment. Appl. Energy 2019, 250, 1099–1109. [Google Scholar] [CrossRef]

- Stolten, D. Status and Potential of PEM Technology for Transportation and the Related Hydrogen Infrastructure. In Proceedings of the mESC-IS 2015, International Symposium on Materials for Energy Storage and Conversion, Ankara, Turkey, 7–9 September 2015; p. 40. [Google Scholar]

- Robinius, M.; Otto, A.; Heuser, P.; Welder, L.; Syranidis, K.; Ryberg, D.; Grube, T.; Markewitz, P.; Peters, R.; Stolten, D. Linking the Power and Transport Sectors—Part 1: The Principle of Sector Coupling. Energies 2017, 10, 956. [Google Scholar] [CrossRef]

- Bongartz, D.; Doré, L.; Eichler, K.; Grube, T.; Heuser, B.; Hombach, L.E.; Robinius, M.; Pischinger, S.; Stolten, D.; Walther, G.; et al. Comparison of light-duty transportation fuels produced from renewable hydrogen and green carbon dioxide. Appl. Energy 2018, 231, 757–767. [Google Scholar] [CrossRef]

- Maurer, G. Vapor-Liquid Equilibrium of Formaldehyde- and Water-Containing Multicomponent Mixtures. Aiche J. 1986, 32, 932–948. [Google Scholar] [CrossRef]

- Burger, J. A Novel Process for The Production of Diesel Fuel Additives by Hierarchical Design. Ph.D. Thesis, TechnicalUniversity Kaiserslautern, Kaiserslautern, Germany, 2012. [Google Scholar]

- Burger, J.; Siegert, M.; Ströfer, E.; Hasse, H. Poly(oxymethylene) dimethyl ethers as components of tailored diesel fuel: Properties, synthesis and purification concepts. Fuel 2010, 89, 3315–3319. [Google Scholar] [CrossRef]

- Baranowski, C.J.; Bahmanpour, A.M.; Kröcher, O. Catalytic synthesis of polyoxymethylene dimethyl ethers (OME): A review. Appl. Catal. B Environ. 2017, 217, 407–420. [Google Scholar] [CrossRef]

- Hackbarth, K.; Haltenort, P.; Arnold, U.; Sauer, J. Recent Progress in the Production, Application and Evaluation of Oxymethylene Ethers. Chem. Ing. Tech. 2018, 90, 1520–1528. [Google Scholar] [CrossRef]

- Bhatelia, T.; Lee, W.J.; Samanta, C.; Patel, J.; Bordoloi, A. Processes for the production of oxymethylene ethers: Promising synthetic diesel additives. Asia-Pac. J. Chem. Eng. 2017, 12, 827–837. [Google Scholar] [CrossRef]

- Oestreich, D. Prozessentwicklung zur Gewinnung von Oxymethylenethern (OME) aus Methanol und Formaldehyd; Karlsruher Institut für Technology: Karlsruhe, Germany, 2017. [Google Scholar]

- Ouda, M.; Mantei, F.; Hesterwerth, K.; Bargiacchi, E.; Klein, H.; White, R.J. A hybrid description and evaluation of oxymethylene dimethyl ethers synthesis based on the endothermic dehydrogenation of methanol. React. Chem. Eng. 2018, 3, 676–695. [Google Scholar] [CrossRef]

- Ouda, M.; Yarce, G.; White, R.J.; Hadrich, M.; Himmel, D.; Schaadt, A.; Klein, H.; Jacob, E.; Krossing, I. Poly(oxymethylene) dimethyl ether synthesis–a combined chemical equilibrium investigation towards an increasingly efficient and potentially sustainable synthetic route. React. Chem. Eng. 2017, 2, 50–59. [Google Scholar] [CrossRef]

- Bongartz, D.; Burre, J.; Mitsos, A. Production of Oxymethylene Dimethyl Ethers from Hydrogen and Carbon Dioxide—Part I: Modeling and Analysis for OME1. Ind. Eng. Chem. Res. 2019, 58, 4881–4889. [Google Scholar] [CrossRef]

- Breitkreuz, C.F.; Schmitz, N.; Ströfer, E.; Burger, J.; Hasse, H. Design of a Production Process for Poly(oxymethylene) Dimethyl Ethers from Dimethyl Ether and Trioxane. Chem. Ing. Tech. 2018, 90, 1489–1496. [Google Scholar] [CrossRef]

- Burre, J.; Bongartz, D.; Mitsos, A. Production of Oxymethylene Dimethyl Ethers from Hydrogen and Carbon Dioxide—Part II: Modeling and Analysis for OME3–5. Ind. Eng. Chem. Res. 2019, 58, 5567–5578. [Google Scholar] [CrossRef]

- Held, M.; Tönges, Y.; Pélerin, D.; Härtl, M.; Wachtmeister, G.; Burger, J. On the energetic efficiency of producing polyoxymethylene dimethyl ethers from CO2 using electrical energy. Energy Environ. Sci. 2019, 12, 1019–1034. [Google Scholar] [CrossRef]

- Schemme, S.; Breuer, J.L.; Köller, M.; Meschede, S.; Walman, F.; Samsun, R.C.; Peters, R.; Stolten, D. H2-based synthetic fuels: A techno-economic comparison of alcohol, ether and hydrocarbon production. Int. J. Hydrog. Energy 2020, 45, 5395–5414. [Google Scholar] [CrossRef]

- Schmitz, N.; Burger, J.; Ströfer, E.; Hasse, H. From methanol to the oxygenated diesel fuel poly(oxymethylene) dimethyl ether: An assessment of the production costs. Fuel 2016, 185, 67–72. [Google Scholar] [CrossRef]

- König, D.H.; Baucks, N.; Dietrich, R.-U.; Wörner, A. Simulation and evaluation of a process concept for the generation of synthetic fuel from CO2 and H2. Energy 2015, 91, 833–841. [Google Scholar] [CrossRef]

- Weidert, J.-O.; Burger, J.; Renner, M.; Blagov, S.; Hasse, H. Development of an Integrated Reaction–Distillation Process for the Production of Methylal. Ind. Eng. Chem. Res. 2017, 56, 575–582. [Google Scholar] [CrossRef]

- Schmitz, N.; Strofer, E.; Burger, J.; Hasse, H. Conceptual Design of a Novel Process for the Production of Poly(oxymethylene) Dimethyl Ethers from Formaldehyde and Methanol. Ind. Eng. Chem. Res. 2017, 56, 11519–11530. [Google Scholar] [CrossRef]

- Schmitz, N.; Breitkreuz, C.F.; Ströfer, E.; Burger, J.; Hasse, H. Vapor–liquid equilibrium and distillation of mixtures containing formaldehdye and poly(oxymethylene) dimethyl ethers. Chem. Eng. Process.-Process Intensif. 2018, 131, 116–124. [Google Scholar] [CrossRef]

- Haarlemmer, G.; Boissonnet, G.; Peduzzi, E.; Setier, P.-A. Investment and production costs of synthetic fuels–A literature survey. Energy 2014, 66, 667–676. [Google Scholar] [CrossRef]

- Brynolf, S.; Taljegard, M.; Grahn, M.; Hansson, J. Electrofuels for the transport sector: A review of production costs. Renew. Sustain. Energy Rev. 2018, 81, 1887–1905. [Google Scholar] [CrossRef]

- Schemme, S. Techno-Economic Assessment of Processes for the Production of Fuels from H2 and CO2. Ph.D. Thesis, RWTH Aachen University, Jülich, Germany, 2020. [Google Scholar]

- Pasel, J.; Samsun, R.C.; Meißner, J.; Tschauder, A.; Peters, R. Recent advances in diesel autothermal reformer design. Int. J. Hydrog. Energy 2020, 45, 2279–2288. [Google Scholar] [CrossRef]

- Linnhoff, B. Pinch Technology for Synthesis of Optimal Heat and Power Systems. J. Energy Ressour. Technol. 1989, 113, 137–147. [Google Scholar] [CrossRef]

- Thenert, K.; Beydoun, K.; Wiesenthal, J.; Leitner, W.; Klankermayer, J. Ruthenium-Catalyzed Synthesis of Dialkoxymethane Ethers Utilizing Carbon Dioxide and Molecular Hydrogen. Angew. Chem. Int. Ed. Engl. 2016, 55, 12266–12269. [Google Scholar] [CrossRef]

- Peter, A.; Fehr, S.M.; Dybbert, V.; Himmel, D.; Lindner, I.; Jacob, E.; Ouda, M.; Schaadt, A.; White, R.J.; Scherer, H.; et al. Towards a Sustainable Synthesis of Oxymethylene Dimethyl Ether by Homogeneous Catalysis and Uptake of Molecular Formaldehyde. Angew. Chem. Int. Ed. Engl. 2018, 57, 9461–9464. [Google Scholar] [CrossRef]

- Moser, P.; Schmidt, S.; Stahl, K.; Wiechers, G.; Heberle, A.; Kuhr, C.; Schroer, K.; Kakihara, H.; Peters, R.; Weiske, S.; et al. Das Projekt ALIGN-CCUS-Ein Beitrag zum evolutiven Transformationsprozess der Energie- und Rohstoffversorgung durch Rycycling von Kohlenstofff. Vgb Power Tech. 2020, 1, 43–49. [Google Scholar]

- Moser, P.; Wiechers, G.; Schmidt, S.; Stahl, K.; Maijd, M.; Bosser, S.; Heberle, A.; Kakihara, H.; Maruyama, M.; Peters, R.; et al. Demonstrating the CCU-chain and sector coupling as part of ALIGN-CCUS–Dimethyl ether from CO2 as chemical energy storage, fuel and feedstock for industries. In Proceedings of the 14th International Conference on Greenhouse Gas Control Technologies, GHGT-14, Melbourne, Australia, 21–25 October 2018; p. 14. [Google Scholar]

- Boeltken, T.; Selinsek, M.; Pfeifer, P. Chemische Energiekonversion: Aus Wasser und Wind. Nachr. Aus Der Chem. 2017, 65, 1112–1114. [Google Scholar] [CrossRef]

- Dittmeyer, R.; Boeltken, T.; Piermartini, P.; Selinsek, M.; Loewert, M.; Dallmann, F.; Kreuder, H.; Cholewa, M.; Wunsch, A.; Belimov, M.; et al. Micro and micro membrane reactors for advanced applications in chemical energy conversion. Curr. Opin. Chem. Eng. 2017, 17, 108–125. [Google Scholar] [CrossRef]

- Edwards, R.; Larivé, J.-F.; Rickeard, D.; Weindorf, W. Well-to-tank Appendix 2-Version 4 a; Joint Research Centre, Institute for Energy and Transport: Ispra, Italy, 2014; p. 32. [Google Scholar]

- Entwicklung des Tankstellenbestandes ab 1950 in Deutschland Jeweils zu Jahresbeginn. Available online: https://www.mwv.de/statistiken/tankstellenbestand/ (accessed on 1 July 2020).

- Fahrzeugzulassungen (FZ) Bestand an Nutzfahrzeugen, Kraftfahrzeugen Insgesamt und Kraftfahrzeuganhängern Nach Technischen Daten (Größenklassen, Motorisierung, Fahrzeugklassen und Aufbauarten); Kraftfahrt-Bundesamt: Flensburg, Germany, 2020; p. 112.

- Fahrzeugbestand. Available online: https://www.bmvi.de/SharedDocs/DE/Artikel/G/fahrzeugbestand.html (accessed on 27 December 2020).

- Nutzfahrzeug-Bestand in Deutschland Nach Gewichtsklassen im Jahr 2019. Available online: https://de.statista.com/statistik/daten/studie/687713/umfrage/bestand-an-nutzfahrzeugen-in-deutschland-nach-gewichtsklassen/ (accessed on 27 December 2020).

- Verbeek, R.; van Zyl, S.; van Grinsven, A.; van Essen, H. Brandstoffen Voor Het Wegverkeer: Kenmerken en Perspectief; TNO & CE Delft: Delft, The Netherlands, 2014. [Google Scholar]

- Deutz, S.; Bongartz, D.; Heuser, B.; Kätelhön, A.; Schulze Langenhorst, L.; Omari, A.; Walters, M.; Klankermayer, J.; Leitner, W.; Mitsos, A.; et al. Cleaner production of cleaner fuels: Wind-to-wheel–environmental assessment of CO2-based oxymethylene ether as a drop-in fuel. Energy Environ. Sci. 2018, 11, 331–343. [Google Scholar] [CrossRef]

- Härtl, M.; Seidenspinner, P.; Jacob, E.; Wachtmeister, G. Oxygenate screening on a heavy-duty diesel engine and emission characteristics of highly oxygenated oxymethylene ether fuel OME1. Fuel 2015, 153, 328–335. [Google Scholar] [CrossRef]

- Lumpp, B.; Rothe, D.; Pastötter, C.; Lämmermann, R.; Jacob, E. Oxymethylene Ethers as Diesel Fuel Additives of the Future. Mtz Worldw. Emag. 2011, 72, 34–38. [Google Scholar] [CrossRef]

- Iannuzzi, S.E.; Barro, C.; Boulouchos, K.; Burger, J. POMDME-diesel blends: Evaluation of performance and exhaust emissions in a single cylinder heavy-duty diesel engine. Fuel 2017, 203, 57–67. [Google Scholar] [CrossRef]

- Barro, C.; Parravicini, M.; Boulouchos, K. Neat polyoxymethylene dimethyl ether in a diesel engine; part 1: Detailed combustion analysis. Fuel 2019, 256, 115892. [Google Scholar] [CrossRef]

- Parravicini, M.; Barro, C.; Boulouchos, K. Compensation for the differences in LHV of diesel-OME blends by using injector nozzles with different number of holes: Emissions and combustion. Fuel 2020, 259, 116166. [Google Scholar] [CrossRef]

- Zhang, T.; Munch, K.; Denbratt, I. An Experimental Study on the Use of Butanol or Octanol Blends in a Heavy Duty Diesel Engine. Sae Int. J. Fuels Lubr. 2015, 8, 610–621. [Google Scholar] [CrossRef]

- Kerschgens, B.; Cai, L.; Pitsch, H.; Heuser, B.; Pischinger, S. Di-n-buthlyether, n-octanol, and n-octane as fuel candidates for diesel engine combustion. Combust. Flame 2016, 613, 166–178. [Google Scholar]

- Gill, S.S.; Tsolakis, A.; Dearn, K.D.; Rodríguez-Fernández, J. Combustion characteristics and emissions of Fischer–Tropsch diesel fuels in IC engines. Prog. Energy Combust. Sci. 2011, 37, 503–523. [Google Scholar] [CrossRef]

- Bestand an Tankstellen in europäischen Ländern im Jahr 2019. Available online: https://de.statista.com/statistik/daten/studie/388155/umfrage/anzahl-der-tankstellen-in-europa/ (accessed on 27 December 2020).

- DIN EN 590, Automotive Fuels-Diesel-Requirements and Test Methods; German Version (EN 590:2013+AC:2014). Deutsches Institut für Normung e.V.: Berlin, Germany, 2014.

- Kramer, U.; Stollenwerk, S.; Ortloff, F.; Sava, X.; Janssen, A.; Eppler, S.; Schule, H.; Dohler, A.; Otten, R.; Lohrmann, M.; et al. Klimaneutrales Fahren in 2050: Optionen zur vollständigen Defossilisierung des Transportsektors. Betrachtungen auf Basis der “FW-Kraftstoffstudie 2018”/Climate-Neutral Driving in 2050: Options for th. In 40. Internationales Wiener Motorensymposium 15.–17. Mai 2019: Band 1: Erster Tag; Band 2: Zweiter Tag/40th International Vienna Motor Symposium 15–17 May 2019 in Two Volumes. Volume 1: First, Day; Volume 2: Second Day, 1st ed.; Geringer, B., Lenz, H.-P., Eds.; VDI Verlag: Düsseldorf, Germany, 2019; pp. II-143–II-175. [Google Scholar]

- ASTM D975-20c. Standard Specification for Diesel Fuel; International, A., Ed.; ASTM: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- Bohl, T.; Smallbone, A.; Tian, G.; Roskilly, A.P. Particulate number and NO trade-off comparisons between HVO and mineral diesel in HD applications. Fuel 2018, 215, 90–101. [Google Scholar] [CrossRef]

- Kuronen, M.; Mikkonen, S.; Aakko, P.; Murtonen, T. Hydrotreated Vegetable Oil as Fuel for Heavy Duty Diesel Engines; SAE Technical Paper; SAE: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- DIN EN 16734. Automotive Fuels-Automotive B10 Diesel fuel-Requirements and Test Methods; German Version EN 16734:2016. Deutsches Institut für Normung e.V.; DIN: Berlin, Germany, 2016. [Google Scholar]

- DIN EN 16709. Automotive Fuels-High FAME Diesel Fuel (B20 and B30)-Requirements and Test Methods; German Version EN 16709:2015+A1:2018. Deutsches Institut für Normung e.V.; DIN: Berlin, Germany, 2019. [Google Scholar]

- DIN EN 14214. Liquid Petroleum Products-Fatty acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications-Requirements and Test Methods; German Version EN 14214:2012+A2:2019. Deutsches Institut für Normung e.V.; DIN: Berlin, Germany, 2019. [Google Scholar]

- Beidl, C.; Münz, M.; Mokros, A. Anwendung von Oxymethylenether (OME) am Dieselmotor. In Zukünftige Kraftstoffe; Springer: Berlin/Heidelberg, Germany, 2019; pp. 814–849. [Google Scholar] [CrossRef]

- Damyanov, A. Alcoholic Fuels in Diesel Engines. Methanol, Ethanol and Butanol. In Zukünftige Kraftstoffe; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Sayin, C. Engine performance and exhaust gas emissions of methanol and ethanol–diesel blends. Fuel 2010, 89, 3410–3415. [Google Scholar] [CrossRef]

- Rajesh Kumar, B.; Saravanan, S.; Rana, D.; Anish, V.; Nagendran, A. Effect of a sustainable biofuel–n-octanol–on the combustion, performance and emissions of a DI diesel engine under naturally aspirated and exhaust gas recirculation (EGR) modes. Energy Convers. Manag. 2016, 118, 275–286. [Google Scholar] [CrossRef]

- SIEMENS AG. Mit eHighway in die Zukunft. In Innovative Lösungen für den Straßengüterverkehr; SIEMENS AG: München, Germany, 2012. [Google Scholar]

- SIEMENS AG. ENUBA-Elektromobilität bei Schweren Nutzfahrzeugen zur Umweltentlastung von Ballungsräumen; f-Cell; SIEMENS AG: München, Germany, 2012; p. 64. [Google Scholar]

- Von Helmolt, R. Fuel Cell or Battery Vehicles? Similar Technology, Different Infrastructure; Holtzbrinck Publishing: Stuttgart, Germany, 2009. [Google Scholar]

- Daniels, A. LKW Mit Oberleitung Auf Dem eHighway-so Funktioniert es. Available online: https://nextdrive.de/lkw-mit-oberleitung-auf-dem-ehighway-so-funktioniert-es (accessed on 4 September 2020).

- Ziegert, S. Scania Deutschland Nachhaltiger Transport. In Jahrestagung Mobilität; Energieagentur NRW: Düsseldorf, Germany, 2020; p. 20. [Google Scholar]

- Mareev, I.; Sauer, D. Energy Consumption and Life Cycle Costs of Overhead Catenary Heavy-Duty Trucks for Long-Haul Transportation. Energies 2018, 11, 2446. [Google Scholar] [CrossRef]

- Wietschel, M.; Gnann, T.; Kühn, A.; Plötz, P.; Moll, C.; Speth, D.; Buch, J.; Boßmann, T.; Stütz, S.; Schellert, M.; et al. Machbarkeitsstudie zur Ermittlung der Potentiale des Hybrid-Oberleitungs-Lkw; Fraunhofer Institut für System und Innovationsforschung (ISI): Karlsruhe, Germany, 2017. [Google Scholar]

- Gnann, T.; Wietschel, M.; Plötz, P.; Kühn, A. Potenziale und Finanzierungsbedarf von Hybrid-Oberleitungs−LKW; Fraunhofer: Berlin, Germany, 2017. [Google Scholar]

- Kühnel, S.; Hacker, F.; Görz, W. Oberleitungs-Lkw im Kontext Weiterer Antriebs- und Energieversorgungsoptionen für den Straßengüterfernverkehr; Öko-Institut e.V.: Berlin, Germany, 2018; p. 151. [Google Scholar]

- Advancing Technology for America’s Transportation Future, Chapter 14–Natural Gas; National Petroleum Council: Washington, DC, USA, 2012.

- Wei, L.; Geng, P. A review on natural gas/diesel dual fuel combustion, emissions and performance. Fuel Process. Technol. 2016, 142, 264–278. [Google Scholar] [CrossRef]

- Boretti, A. Advances in diesel-LNG internal combustion engines. Appl. Sci. 2020, 10, 1296. [Google Scholar] [CrossRef]

- Fasching, P.; Sprenger, F.; Granitz, C. A holistic investigation of natural gas–diesel dual fuel combustion with dual direct injection for passenger car applications. Automot. Engine Technol. 2017, 2, 79–95. [Google Scholar] [CrossRef]

- Dunn, M.E.; McTaggart-Cowan, G.P.; Saunders, J. High efficiency and low emission natural gas engines for heavy duty vehicles. In Internal Combustion Engines: Performance, Fuel Economy and Emissions: IMechE, London, 27–28 November 2013; Elsevier: Amsterdam, The Netherlands, 2013; pp. 123–136. [Google Scholar] [CrossRef]

- Anderhofstadt, B.; Spinler, S. Factors affecting the purchasing decision and operation of alternative fuel-powered heavy-duty trucks in Germany–A Delphi study. Transp. Res. Part D Transp. Environ. 2019, 73, 87–107. [Google Scholar] [CrossRef]

- Der neue Stralis NP Pure Power. Available online: https://www.iveco.com/austria/Neufahrzeuge/Documents/stralis/StralisNP_brochure_AT.pdf (accessed on 16 April 2020).

- New Stralis NP 460: A Complete Range of Natural Gas Trucks for All Missions That Hits the Sweet Spot of the Market with its 460 hp of Pure Power. 2017. Available online: https://www.iveco.com/en-us/press-room/release/Documents/2017/NewStralisNP460.pdf (accessed on 17 February 2021).

- Volvo FM LNG. Available online: https://www.volvotrucks.com/en-en/trucks/trucks/volvo-fm/volvo-fm-lng.html (accessed on 16 April 2020).

- Cummins Wesport Engines: ISX12N. Available online: https://www.cumminswestport.com/models/isx12n (accessed on 16 April 2020).

- Westport™ HPDI 2.0. A New Generation Natural Gas Fuel System Optimal for Heavy-Duty Vehicles. Available online: https://www.westport.com/is/core-technologies/hpdi-2 (accessed on 16 April 2020).

- Alamia, A.; Magnusson, I.; Johnsson, F.; Thunman, H. Well-to-wheel analysis of bio-methane via gasification, in heavy duty engines within the transport sector of the European Union. Appl. Energy 2016, 170, 445–454. [Google Scholar] [CrossRef]

- Vermeulen, R.J. TNO Report: TNO 2019 R10193. Emissions Testing of a Euro VI LNG-Diesel Dual Fuel Truck in the Netherlands; TNO 2019 R10193; TNO: The Hague, The Netherlands, 2019; p. 36. [Google Scholar]

- Camuzeaux, J.R.; Alvarez, R.A.; Brooks, S.A.; Browne, J.B.; Sterner, T. Influence of methane emissions and vehicle efficiency on the climate implications of heavy-duty natural gas trucks. Environ. Sci. Technol. 2015, 49, 6402–6410. [Google Scholar] [CrossRef]

- Otten, M.; Hoen, M.; den Boer, E. STREAM Freight Transport 2016: Emissions of Freight Transport Modes; CE Delft: Delft, The Netherlands, 2017. [Google Scholar]

- Matzer, C.; Weller, K.; Dippold, M.; Lipp, S.; Röck, M.; Rexeis, M.; Hausberger, S. Update of Emission Factors for HBEFA Version 4.1; Final Report, I-05/19/CM EM-I-16/26/679; TU Graz: Graz, Austria, 2019. [Google Scholar]

- Röck, M.; Rexeis, M.; Hausberger, S. JEC Well -to-Wheels Analyses of Future Automotive Fuels and Powertrains in the European Context; Graz University of Technology: Graz, Austria, 2018. [Google Scholar]

- Erdgas-Tankstellen in Ihrer Nähe oder auf Ihrer Route, Zukunft Gas e.V., Berlin, Germany. Available online: https://www.erdgas.info/erdgas-mobil/erdgas-tankstellen/tankstellenfinder/ (accessed on 29 April 2020).

- U.S. Department of Energy-Energy Efficiency and Renewable Energy, Alternative Fuels Data Center, Natural Gas Fueling Station Locations. Available online: https://afdc.energy.gov/fuels/natural_gas_locations.html#/analyze?country=US&fuel&access=public&access=private&cng_vehicle_class=HD&lng_vehicle_class=HD (accessed on 16 April 2020).

- NGVA Europe, Stations Map. Available online: https://www.ngva.eu/stations-map/ (accessed on 16 April 2020).

- Heckler, D. LNG-Tankstellen Infrastruktur. In Green Energy Hubs; EnergieAgentur.NRW: Nordrhein-Westfalen, Germany, 2020. [Google Scholar]

- Thys, M. Grünes CNG/LNG: Erneuerbares Gas für Nutzfahrzeuge. In Jahrestagung Mobilität; EnergieAgentur: Nordrhein-Westfalen, Germany, 2020. [Google Scholar]

- Westport Fuel Systems, Corporate Overview, November 2019. Available online: https://wfsinc.com/investors/corporate-overview (accessed on 22 April 2020).

- Lischke, A.; Windmüller, D.; Wurster, R.; Weindorf, W.; Heidt, C.; Naumann, K. Identifizierung von Hemmnissen der Nutzung von LNG und CNG im Schweren Lkw-Verkehr Sowie Möglichkeiten zu Deren Überwindung; Deutsches Zentrum für Luft- und Raumfahrt e.V.: Köln, Germany, 2015. [Google Scholar]

- Bundesministerium für Verkehr und Digitale Infrastruktur. Richtlinie über die Förderung von energieeffizienten und/oder CO2-armen schweren Nutzfahrzeugen in Unternehmen des Güterkraftverkehrs; Bundesministerium für Verkehr und Digitale Infrastruktur: Berlin, Germany, 2018. [Google Scholar]

- Burnham, A. Case Study-Liquefied Natural Gas; eere_es_cleancities-082813lb; Argonne National Laboratory: Argonne, IL, USA, 2013; p. 6. [Google Scholar]

- Langshaw, L.; Ainalis, D.; Acha, S.; Shah, N.; Stettler, M.E.J. Environmental and economic analysis of liquefied natural gas (LNG) for heavy goods vehicles in the UK: A Well-to-Wheel and total cost of ownership evaluation. Energy Policy 2020, 137, 111161. [Google Scholar] [CrossRef]

- Mojtaba Lajevardi, S.; Axsen, J.; Crawford, C. Comparing alternative heavy-duty drivetrains based on GHG emissions, ownership and abatement costs: Simulations of freight routes in British Columbia. Transp. Res. Part D Transp. Environ. 2019, 76, 19–55. [Google Scholar] [CrossRef]

- Aral. FAQ AdBlue®. Available online: https://www.aral.de/de/global/forschung/faq/faq-adblue.html#accordion_5 (accessed on 22 April 2020).

- dena-Analyse: Branchenbarometer Biomethan 2019; Deutsche Energie-Agentur GmbH (dena): Berlin, Germany, 2019; p. 14.

- Peters, R.; Baltruweit, M.; Grube, T.; Samsun, R.C.; Stolten, D. A techno economic analysis of the power to gas route. J. Co2 Util. 2019, 34, 616–634. [Google Scholar] [CrossRef]

- Fleisch, T.H.; Basu, A.; Sills, R.A. Introduction and advancement of a new clean global fuel: The status of DME developments in China and beyond. J. Nat. Gas Sci. Eng. 2012, 9, 94–107. [Google Scholar] [CrossRef]

- Arnold, U.; Haltenort, P.; Herrera Delgado, K.; Niethammer, B.; Sauer, J. Die Rolle von Dimethylether (DME) als Schlüsselbaustein synthetischer Kraftstoffe aus erneuerbaren Rohstoffen. In Zukünftige Kraftstoffe; ATZ/MTZ-Fachbuch, Springer-GmbH: Wiesbaden, Deutschland, 2019. [Google Scholar] [CrossRef]

- Geng, P.; Cao, E.; Tan, Q.; Wei, L. Effects of alternative fuels on the combustion characteristics and emission products from diesel engines: A review. Renew. Sustain. Energy Rev. 2017, 71, 523–534. [Google Scholar] [CrossRef]

- Salomonsson, P. Final Report of the European BioDME Project. In Proceedings of the 5th International DME Conference, Ann Arbor, MI, USA, 18 April 2013. [Google Scholar]

- Szybist, J.P.; McLaughlin, S.; Iyer, S. Emissions and Performance Benchmarking of a Prototype Dimethyl Ether-Fueled Heavy-Duty Truck; ORNL/TM-2014/59; Oak Ridge National Laboratory: Springfield, VA, USA, 2014; p. 56. [Google Scholar]

- Ying, W.; Li, H.; Jie, Z.; Longbao, Z. Study of HCCI-DI combustion and emissions in a DME engine. Fuel 2009, 88, 2255–2261. [Google Scholar] [CrossRef]

- Ying, W.; Longbao, Z. Experimental study on exhaust emissions from a multi-cylinder DME engine operating with EGR and oxidation catalyst. Appl. Therm. Eng. 2008, 28, 1589–1595. [Google Scholar] [CrossRef]

- Benajes, J.; Novella, R.; Pastor, J.M.; Hernández-López, A.; Kokjohn, S. Computational optimization of a combustion system for a stoichiometric DME fueled compression ignition engine. Fuel 2018, 223, 20–31. [Google Scholar] [CrossRef]

- Benajes, J.; Novella, R.; Pastor, J.M.; Hernández-López, A.; Kokjohn, S.L. Computational optimization of the combustion system of a heavy duty direct injection diesel engine operating with dimethyl-ether. Fuel 2018, 218, 127–139. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, S.H. Optimization study on exhaust emissions and fuel consumption in a dimethyl ether (DME) fueled diesel engine. Fuel 2016, 182, 541–549. [Google Scholar] [CrossRef]

- Michailos, S.; McCord, S.; Sick, V.; Stokes, G.; Styring, P. Dimethyl ether synthesis via captured CO2 hydrogenation within the power to liquids concept: A techno-economic assessment. Energy Convers. Manag. 2019, 184, 262–276. [Google Scholar] [CrossRef]

- MAN Presents Zero-Emission Roadmap. Available online: https://press.mantruckandbus.com/man-presents-zero-emission-roadmap (accessed on 24 November 2020).

- Toyota and Hino to Jointly Develop Heavy-Duty Fuel Cell Truck. Available online: https://global.toyota/en/newsroom/corporate/32024083.html (accessed on 23 March 2020).

- The Volvo Group and Daimler Truck AG to Lead the Development of Sustainable Transportation by Forming Joint Venture for Large-Scale Production of Fuel Cells; AB Volvo: Gothenburg, Sweden, 2020.

- IVECO. FPT Industrial and Nikola Corporation Launch Their Partnership to Achieve Zero-Emissions Transport; Nikola Motor Corporation: Salt Lake City, UT, USA, 2020. [Google Scholar]

- Blanco, S. Toyota, Kenworth Expand Hydrogen Semi-Truck Push At Los Angeles Ports. Available online: https://www.forbes.com/sites/sebastianblanco/2019/04/23/toyota-kenworth-expand-hydrogen-semi-truck-push-at-los-angeles-ports/?sh=1cbc0519d762 (accessed on 10 May 2020).

- The Future of Emission Free Logistics Starts Here. Available online: http://trucknbus.hyundai.com/global/en/eco/hyundai-hydrogen-mobility (accessed on 5 May 2020).

- Multi-Year Research, Development and Demonstration Plan, Hydrogen, Fuel Cells & Infrastructure Technologies Program-Fuel Cells; Department of Energy: Washington, DC, USA, 2017.

- Edwards, R.; Hass, H.; Larivé, J.-F.; Lonza, L.; Maas, H.; Rickeard, D. WELL-TO-WHEELS Report Version 4.a; Report EUR 26236 EN; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar]

- Robinius, M.; Linßen, J.; Grube, T.; Reuß, M.; Stenzel, P.; Syranidis, K.; Kuckertz, P.; Stolten, D. Comparative Analysis of Infrastructures: Hydrogen Fueling and Electric Charging of Vehicles; Forschungszentrum Jülich GmbH: Jülich, Germany, 2018; Volume 408. [Google Scholar]

- Rose, P.K.; Neumann, F. Hydrogen refueling station networks for heavy-duty vehicles in future power systems. Transp. Res. Part D Transp. Environ. 2020, 83, 102358. [Google Scholar] [CrossRef]

- Coiffier, B. Technische Herausforderungen bei der H2-Betankung von Heavy Duty-Anwendungen. In Jahrestagung Mobilität; EnergieAgentur: Nordrhein-Westfalen, Germany, 2020. [Google Scholar]

- Marcinkoski, J. DOE Advanced Truck Technologies. In 19006; Department of Energy, U.S.A., Ed.; Department of Energy: Washington, DC, USA, 2019. [Google Scholar]

- Cerniauskas, S.; Grube, T.; Praktiknjo, A.; Stolten, D.; Robinius, M. Future Hydrogen Markets for Transportation and Industry: The Impact of CO2 Taxes. Energies 2019, 12, 4707. [Google Scholar] [CrossRef]

- Daum, J. Nutzfahrzeuge mit alternativen Antrieben und dafür nötige Tank- und Ladeinfrastrukur. In Green Energy Hubs; EnergieAgentur: Nordrhein-Westfalen, Germany, 2020. [Google Scholar]

- Boretti, A. Hydrogen internal combustion engines to 2030. Int. J. Hydrog. Energy 2020, 45, 23692–23703. [Google Scholar] [CrossRef]

- BMW Hydrogen 7. Available online: https://www.wired.com/images_blogs/autopia/files/bmw_hydrogen_7.pdf (accessed on 23 January 2021).

- Akal, D.; Öztuna, S.; Büyükakın, M.K. A review of hydrogen usage in internal combustion engines (gasoline-Lpg-diesel) from combustion performance aspect. Int. J. Hydrog. Energy 2020, 45, 35257–35268. [Google Scholar] [CrossRef]

- Mehra, R.K.; Duan, H.; Juknelevičius, R.; Ma, F.; Li, J. Progress in hydrogen enriched compressed natural gas (HCNG) internal combustion engines-A comprehensive review. Renew. Sustain. Energy Rev. 2017, 80, 1458–1498. [Google Scholar] [CrossRef]

- Wind, J. Hydrogen-fueled road automobiles–Passenger cars and buses. In Compendium of Hydrogen Energy; Elsevier: Frankfurt, Germany, 2016; pp. 3–21. [Google Scholar] [CrossRef]

- Chintala, V.; Subramanian, K.A. A comprehensive review on utilization of hydrogen in a compression ignition engine under dual fuel mode. Renew. Sustain. Energy Rev. 2017, 70, 472–491. [Google Scholar] [CrossRef]

- KEYOU-inside for Hydrogen Engines and Vehicle. Available online: https://www.keyou.de/wp-content/uploads/2018/10/181025_IAA_Broschu%CC%88re_2018_Lkw_EN_210x297.pdf (accessed on 27 December 2020).

- Heffel, J. NOx emission and performance data for a hydrogen fueled internal combustion engine at 1500 rpm using exhaust gas recirculation. Int. J. Hydrog. Energy 2003, 28, 901–908. [Google Scholar] [CrossRef]

- Mathai, R.; Malhotra, R.K.; Subramanian, K.A.; Das, L.M. Comparative evaluation of performance, emission, lubricant and deposit characteristics of spark ignition engine fueled with CNG and 18% hydrogen-CNG. Int. J. Hydrog. Energy 2012, 37, 6893–6900. [Google Scholar] [CrossRef]

- Dimitriou, P.; Tsujimura, T. A review of hydrogen as a compression ignition engine fuel. Int. J. Hydrog. Energy 2017, 42, 24470–24486. [Google Scholar] [CrossRef]

| Energy Carrier | Drive System | Conversion Technology | Infra-Structure | TRL | Remark |

|---|---|---|---|---|---|

| NG (SNG, BNG, LNG) | ICE | none | To be extended | TRL 8–9 | Focus on methane slip |

| DME | ICE | none | To be built-up | TRL 7–8 | Focus on production chain |

| Hydrogen | ICE | none | To be extended | TRL 5–6 | Focus on renewable electricity and H2 infrastructure |

| PTF | ICE | none | Existing | TRL 7–9 | Focus on renewable production chain |

| Electricity (catenary) | Hybrid (1) | none | To be built-up | TRL 7–8 | Focus on renewable electricity |

| Battery | E-motor | none | To be extended | TRL 9 | Focus on renewable electricity and infra-structure for charging |

| Hydrogen | E-motor | fuel cell | To be extended | TRL 7–8 | Focus on renewable electricity and H2 infrastructure |

| NG (SNG, BNG, LNG) | E-motor | fuel cell and fuel processing | To be extended | TRL 5–6 | Complex system technology |

| PTF | E-motor | fuel cell and fuel processing | Existing | TRL 4–5 | Complex system technology |

| Strengths | Weaknesses |

|---|---|

| Existing infrastructure | Investments in wind parks and electrolyzers required |

| High energy density ⇒ long mission range | New infrastructure for electro or biofuel production |

| Improved local emissions with clean fuels—especially for particle matter (PM) | Costly and low-efficient fuel production |

| Opportunities | Threats |

| Rapid carbon footprint reduction of existing fleet | Delayed capacity expansion for renewable electro-fuels |

| Build-up of a renewable PTX economy | Labeled as a bridging technology with limited meaning in 2050 |

| Storage possibility for renewable electricity | Other applications compete with electro or biofuels for renewable energy |

| Different sector coupling chains |

| Strengths | Weakness |

|---|---|

| High efficiency | Build-up of long-distance catenary systems on highways |

| Zero-emission, long-distance transport | Investments in wind parks for renewable electricity |

| Electricity generation and transport in rural areas | |

| Opportunities | Threats |

| High-efficient, zero-emission heavy duty transport | Missing widespread infrastructure in Europe |

| Lowest carbon footprint by using renewable electricity | Low acceptance for heavy-duty vehicles in Europe |

| Competition with railway container transport |

| Strengths | Weaknesses |

|---|---|

| Available technology through the adaption of combustion engines to NG | Conflict between cost and emission reduction potential |

| Lower fuel costs than diesel today | Incremental costs for purchasing vehicles |

| Reduced dependency on crude oil for heavy-duty transport | Increased emissions for certain drive cycles in practice |

| Opportunities | Threats |

| High greenhouse gas reduction potential using renewable methane | Risk of changes in natural gas taxation policy |

| Fast transition to cleaner renewable transport | Methane slips in upstream processes |

| The use of LNG enables higher ranges | Missing widespread infrastructure in Europe |

| Strengths | Weaknesses |

|---|---|

| Existing expertise and infrastructure regarding LPG, and similar physical properties | Proper additives and lubricants required |

| Adaption of diesel engines to DME already demonstrated | Larger and more complex tanks than for diesel |

| Improved local emissions with cleaner fuel | Dedicated engine development is required |

| Opportunities | Threats |

| High greenhouse gas reduction potential using renewable routes | Higher production costs for the promising power-to-fuel route |

| Fast transition to cleaner, renewable transport | Limited capacities for renewable DME |

| Smoke-free operation eliminates NOX/soot trade-off | Lack of a widespread infrastructure in Europe |

| Strengths | Weaknesses |

|---|---|

| High well-to-wheel efficiency (second-best to battery-electric) | Efficiency losses from hydrogen production and processing Moderate fuel energy density, partly compensated by higher powertrain efficiency |

| Zero local emissions level | More significant environmental impact based on present LCA Total environmental performance is a function of fuel cycle performance |

| Compact powertrain and storage compared to battery-electric alternatives | High cost of fuel storage |

| Opportunities | Threats |

| Allows for very low greenhouse gas emission levels in transport | Delayed or constrained capacity build-up of renewable power and electrolysis |

| Hydrogen provision may benefit from hydrogen demand in other markets | Technology lock-in for BEVs due to the advanced state of battery technology |

| Improved operating range compared to battery-electric trucks | The development of other markets might not significantly increase hydrogen demand |

| Available gas infrastructure could be switched to hydrogen transport | Cost targets for fuel cells and storages may not be achieved |

| Inhomogeneous infrastructure build-up in Europe |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peters, R.; Breuer, J.L.; Decker, M.; Grube, T.; Robinius, M.; Samsun, R.C.; Stolten, D. Future Power Train Solutions for Long-Haul Trucks. Sustainability 2021, 13, 2225. https://doi.org/10.3390/su13042225

Peters R, Breuer JL, Decker M, Grube T, Robinius M, Samsun RC, Stolten D. Future Power Train Solutions for Long-Haul Trucks. Sustainability. 2021; 13(4):2225. https://doi.org/10.3390/su13042225

Chicago/Turabian StylePeters, Ralf, Janos Lucian Breuer, Maximilian Decker, Thomas Grube, Martin Robinius, Remzi Can Samsun, and Detlef Stolten. 2021. "Future Power Train Solutions for Long-Haul Trucks" Sustainability 13, no. 4: 2225. https://doi.org/10.3390/su13042225

APA StylePeters, R., Breuer, J. L., Decker, M., Grube, T., Robinius, M., Samsun, R. C., & Stolten, D. (2021). Future Power Train Solutions for Long-Haul Trucks. Sustainability, 13(4), 2225. https://doi.org/10.3390/su13042225