Adding Technology Sustainability Evaluation to Product Development: A Proposed Methodology and an Assessment Model

Abstract

1. Introduction

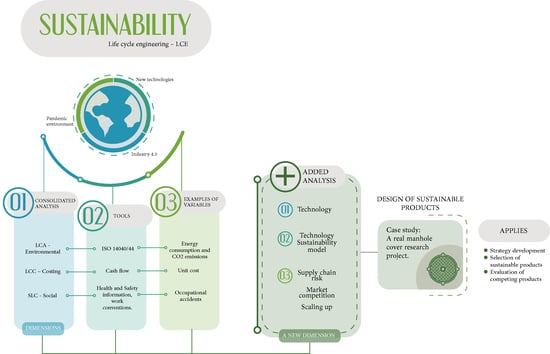

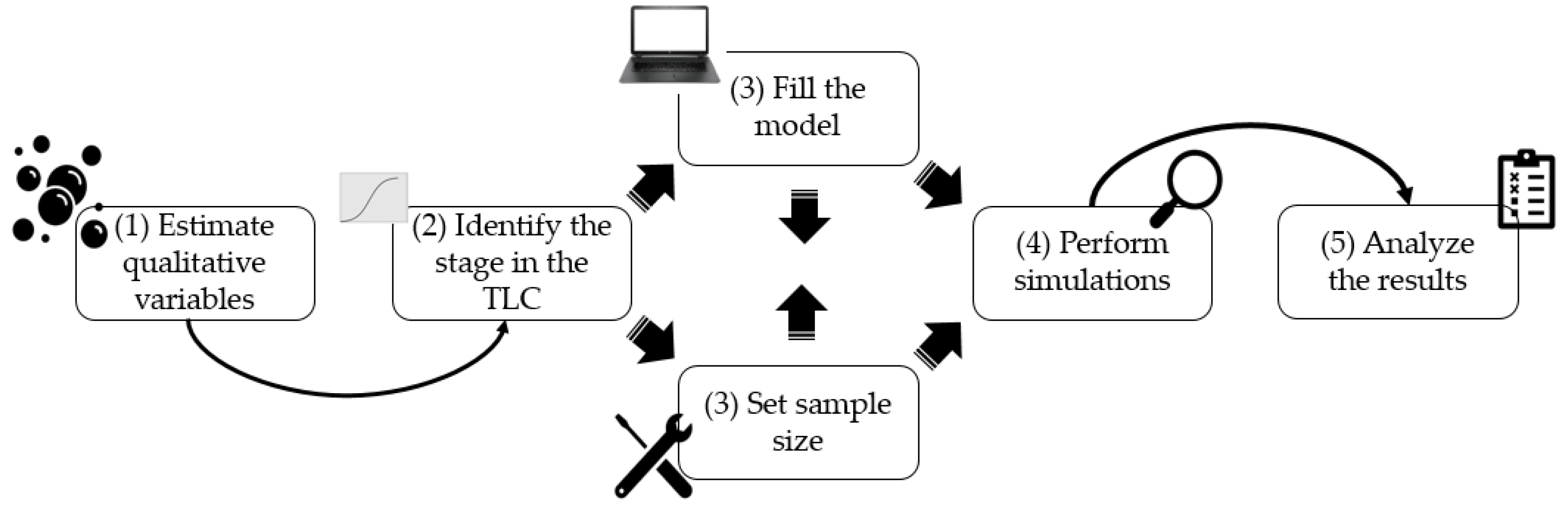

2. Current Methods for TM Assessment

3. The Proposed Approach

- Let f be a function derived up to the second order in the interval I, and suppose that . In this case, if , then the graph of f has a positive concavity in , and if , then it has a negative concavity in ; and

- Let f be a function derived up to the second order in the interval I, and suppose that ∈ I is the abscissa of an inflection point in the graph of f. Therefore, .

4. Case Study: Polymeric Concrete

Results and Discussion

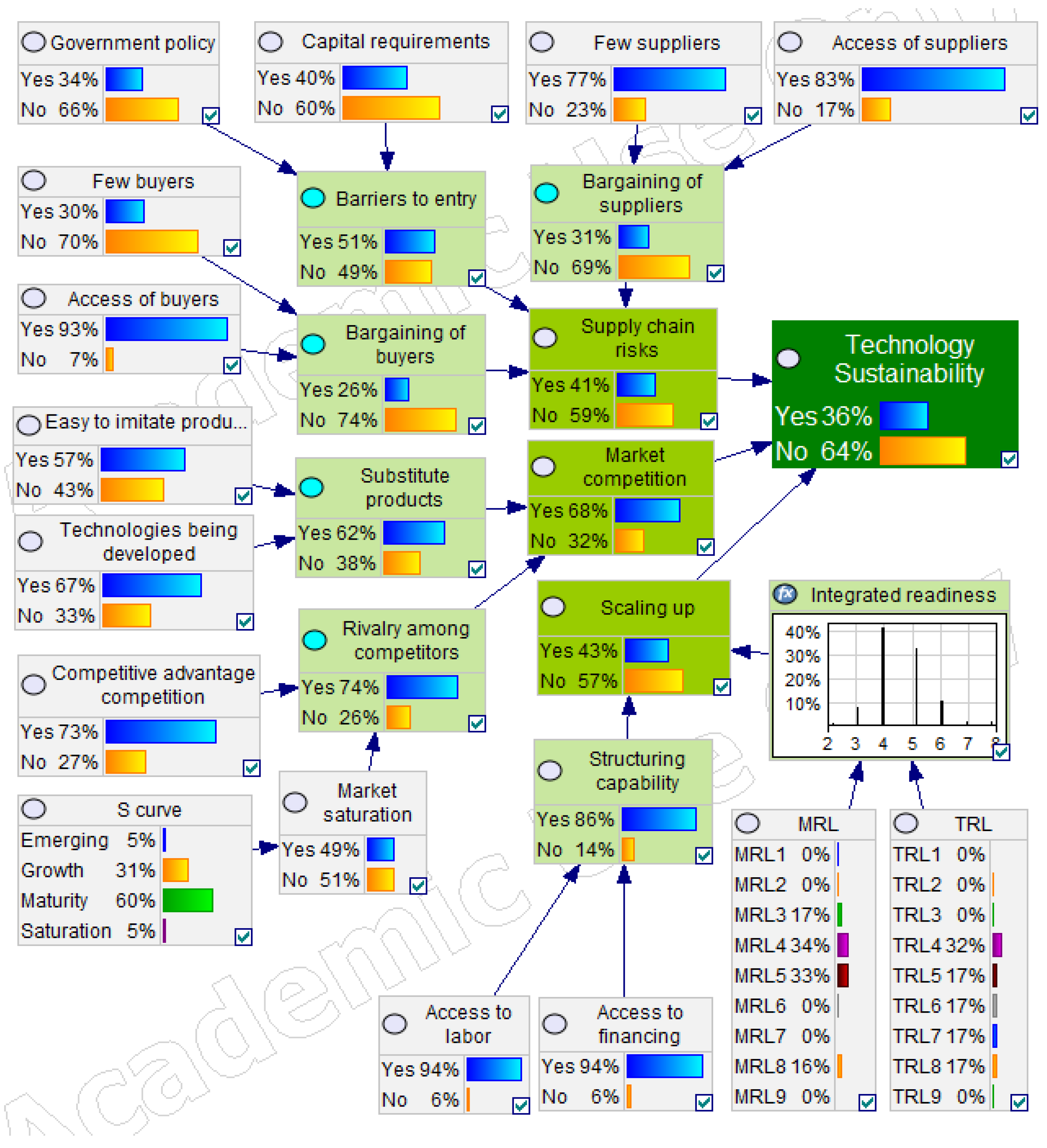

- Step 1. Estimate Qualitative Variables

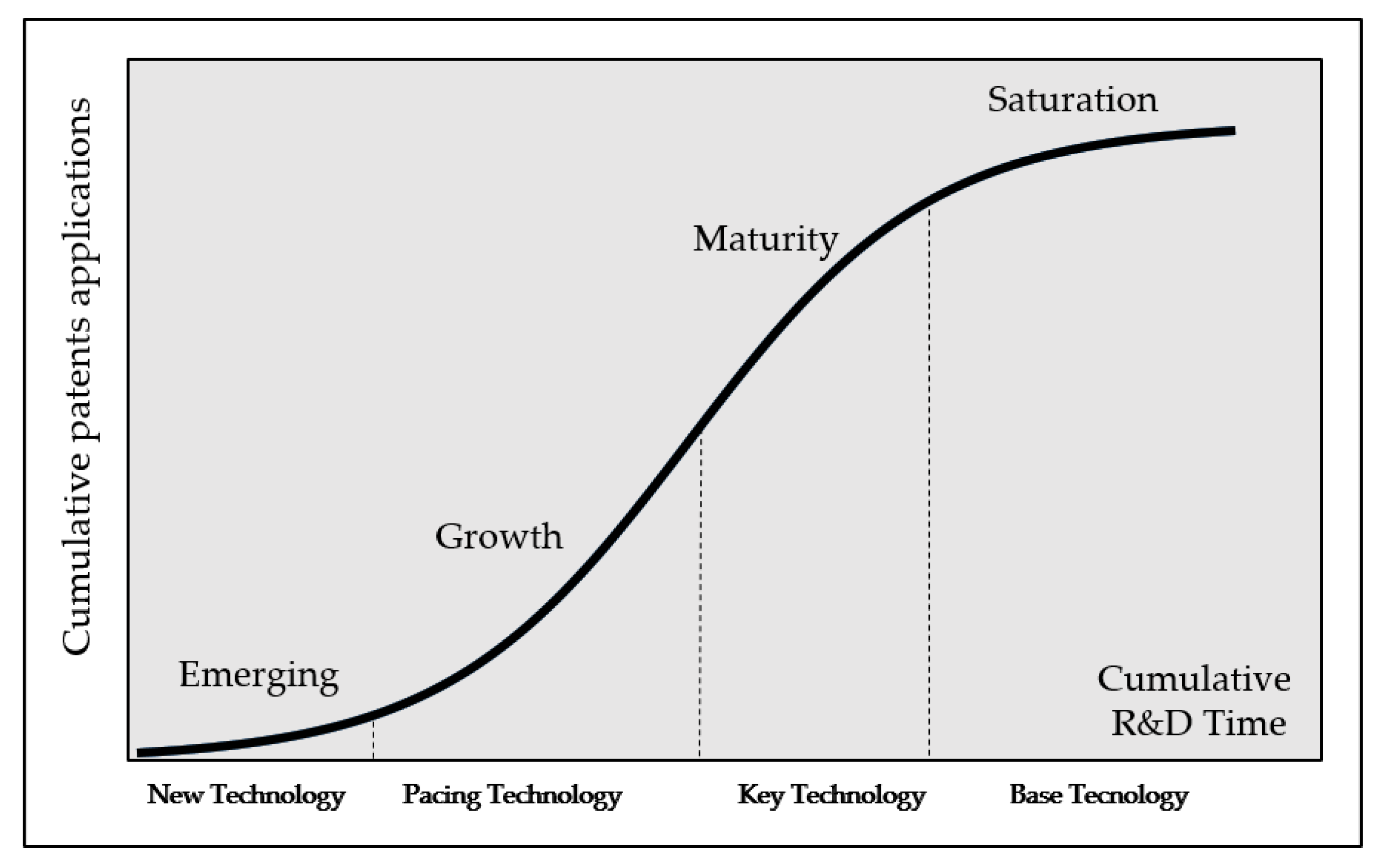

- Step 2. Identify the stage in the TLC

- Cast Iron: (AY >= (1900) AND AY <= (2020)) AND (AB = (grey adj cast adj iron) AND AB = ((sewer adj grate) or (drain adj cover) or manhole or (shaft adj cover*) or cover));

- Polymeric Concrete: (AY >= (1900) AND AY <= (2020)) AND AB = ("polymer resin" or “polymer” or epoxy or polyester) AND AB = (concrete) AND AB = ((sewer adj grate) or (drain adj cover) or manhole or (shaft adj cover*) or cover).

- Step 3. Enter Values in the Model and Define Sample Size

- Step 4. Perform Simulations

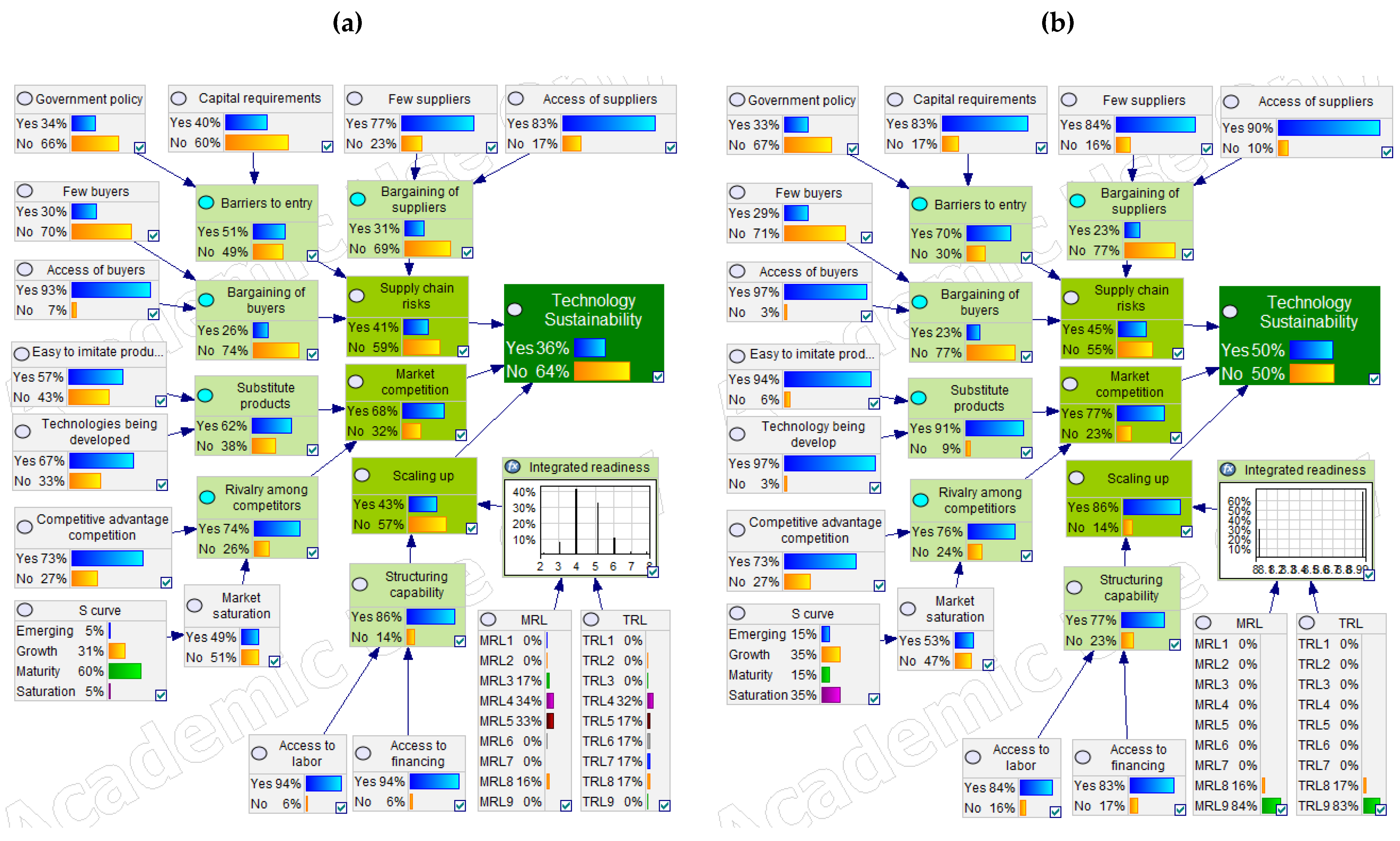

- Base scenario 1: Study of the data originally researched and calculated.

- Inference scenario 2: What if the TRL of PC were equal to 9?

- Inference scenario 3: What if the TRL and MRL of PC were equal to 9?

- Inference scenario 4: What if it were possible to develop new formulations for CI that would make imitations more difficult?

- Step 5. Analyze the Results

- Base scenario 1: Study of researched and originally calculated data.

- Inference scenario 2: What if the TRL of PC were equal to 9?

- Inference scenario 3: What if the TRL and MRL of PC were equal to 9?

- Inference scenario 4: What if it were possible to develop new formulations for CI that would make imitations more difficult?

5. Conclusions

- The use of a hybrid BN makes it possible to encompass quantitative and qualitative variables through the opinion of experts within the context of decision-making in a PDP. Other relevant characteristics of the model are linked to the incorporation of uncertainty related to the use of probabilistic theory. The application of the model in a real project demonstrates its capacity for practical use in both business and academic contexts. Simulations and inferences using the model emphasize its supportive role in the decision-making process.

- The results of the investigated case study suggest that PC is a potential technology for the production of manhole covers. If efforts are directed toward expanding the maturity of this technology, combined with a strategy to access new customers, the product may perform better than CI, assuming that the other variables remain constant. Even in the scenario involving the emergence of new formulations for CI, PC maintains an advantage over CI.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Keeble, B.R. The Brundtland Report: “Our Common Future”, 1st ed.; Oxford University Press: New York, NY, USA, 1988; Volume 4, ISBN 9780192820808. [Google Scholar]

- Peças, P.; Götze, U.; Henriques, E.; Ribeiro, I.; Schmidt, A.; Symmank, C. Life cycle engineering—Taxonomy and state-of-the-art. Procedia CIRP 2016, 48, 73–78. [Google Scholar] [CrossRef]

- Davis-Peccoud, J.; van den Branden, J.-C.; Brahm, C.; Mattios, G.; de Montgolfier, J. Sustainability Is the Next Digital; Bain & Company: Singapore, Singapore, 2020. [Google Scholar]

- Economist, T. Business and Climate Change—The Great Disrupter. Available online: https://www.economist.com/special-report/2020/09/17/the-great-disrupter (accessed on 21 September 2020).

- Fernandes, P.T.; Canciglieri Júnior, O.; Sant’Anna, Â.M.O. Method for integrated product development oriented to sustainability. Clean Technol. Environ. Policy 2017, 19, 775–793. [Google Scholar] [CrossRef]

- Wulf, C.; Werker, J.; Ball, C.; Zapp, P.; Kuckshinrichs, W. Review of sustainability assessment approaches based on life cycles. Sustainability 2019, 11, 5717. [Google Scholar] [CrossRef]

- Kuhlman, T.; Farrington, J. What is sustainability? Sustainability 2010, 2, 3436–3448. [Google Scholar] [CrossRef]

- Dong, S.; Li, C.; Xian, G. Environmental impacts of glass- and carbon-fiber-reinforced polymer bar-reinforced seawater and sea sand concrete beams used in marine environments: An LCA case study. Polymers 2021, 13, 154. [Google Scholar] [CrossRef] [PubMed]

- Dhillon, B.S.; Balbir, S. Life Cycle Costing for Engineers; Taylor & Francis: Oxfordshire, UK, 2010; ISBN 9781439816882. [Google Scholar]

- Jørgensen, A.; Le Bocq, A.; Nazarkina, L.; Hauschild, M. Methodologies for social life cycle assessment. Int. J. Life Cycle Assess. 2008, 13, 96–103. [Google Scholar] [CrossRef]

- NASA. NASA/SP-2106-6105 NASA Systems Engineering Handbook; NASA: Washington, DC, USA, 2007; ISBN 3016210134.

- Jesus, G.T.; Chagas, J.R.; Milton, F. Integration readiness levels evaluation and systems architecture: A literature review. Int. J. Adv. Eng. Res. Sci. 2018, 5, 73–84. [Google Scholar] [CrossRef]

- Sauser, B.; Verma, D.; Ramirez-Marquez, J.; Gove, R. From TRL to SRL: The concept of systems readiness levels. Conf. Syst. Eng. Res. Los Angeles CA 2006, 4, 1–10. [Google Scholar]

- Bergerson, J.A.; Brandt, A.; Cresko, J.; Carbajales-Dale, M.; MacLean, H.L.; Matthews, H.S.; McCoy, S.; McManus, M.; Miller, S.A.; Morrow, W.R.; et al. Life cycle assessment of emerging technologies: Evaluation techniques at different stages of market and technical maturity. J. Ind. Ecol. 2020, 24, 11–25. [Google Scholar] [CrossRef]

- Sinnwell, C.; Siedler, C.; Aurich, J.C. Maturity model for product development information. Procedia CIRP 2019, 79, 557–562. [Google Scholar] [CrossRef]

- Gao, L.; Porter, A.L.; Wang, J.; Fang, S.; Zhang, X.; Ma, T.; Wang, W.; Huang, L. Technology life cycle analysis method based on patent documents. Technol. Forecast. Soc. Chang. 2013, 80, 398–407. [Google Scholar] [CrossRef]

- Intepe, G.; Bozdag, E.; Koc, T. The selection of technology forecasting method using a multi-criteria interval-valued intuitionistic fuzzy group decision making approach. Comput. Ind. Eng. 2013, 65, 277–285. [Google Scholar] [CrossRef]

- Munthe, C.I.; Uppvall, L.; Engwall, M.; Dahlén, L. Dealing with the devil of deviation: Managing uncertainty during product development execution. R D Manag. 2014, 44, 203–216. [Google Scholar] [CrossRef]

- Thomé, A.M.T.; Scavarda, A.; Ceryno, P.S.; Remmen, A. Sustainable new product development: A longitudinal review. Clean Technol. Environ. Policy 2016, 18, 2195–2208. [Google Scholar] [CrossRef]

- Tegeltija, M.; Oehmen, J.; Kozin, I.; Kwakkel, J. Exploring deep uncertainty approaches for application in life cycle engineering. Procedia CIRP 2018, 69, 457–462. [Google Scholar] [CrossRef]

- Östlin, J.; Sundin, E.; Björkman, M. Linköping university post print product lifecycle implications for remanufacturing strategies. J. Clean. Prod. 2009, 11, 999–1009. [Google Scholar] [CrossRef]

- Valerdi, R.; Kohl, R.J. An approach to technology risk management. In Proceedings of the Engineering Systems Division Symposium, Cambridge, MA, USA, 29 March 2004; pp. 1–8. [Google Scholar]

- Andrade, H.; Chagas, M., Jr.; Silva, M.; Brito, M.A.; Rocha, D.; Ribeiro, J. Avaliação da Maturidade Tecnológica: Conceitos, 1st ed.; Fbra, E.B.E., Ed.; Edições Brasil and Editora Fibra: Jundiaí, São Paulo, Brazil, 2019; ISBN 9786551040009. [Google Scholar]

- Ward, M.; Halliday, S.; Uflewska, O.; Wong, T.C. Three dimensions of maturity required to achieve future state, technology-enabled manufacturing supply chains. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 605–620. [Google Scholar] [CrossRef]

- Marlyana, N.; Tontowi, A.E.; Yuniarto, H.A. A quantitative analysis of system readiness level plus (SRL+): Development of readiness level measurement. In Proceedings of the MATEC Web of Conferences, EDP Sciences. Bali, Indonesia, 24 August 2017; Volume 159, p. 02067. [Google Scholar]

- Darmani, A.; Jullien, C. Innovation Readiness Level Report—Energy Storage Technologies; REEEM: Stockholm, Sweden, 2017. [Google Scholar]

- Munir, M.T.; Mansouri, S.S.; Udugama, I.A.; Baroutian, S.; Gernaey, K.V.; Young, B.R. Resource recovery from organic solid waste using hydrothermal processing: Opportunities and challenges. Renew. Sustain. Energy Rev. 2018, 96, 64–75. [Google Scholar] [CrossRef]

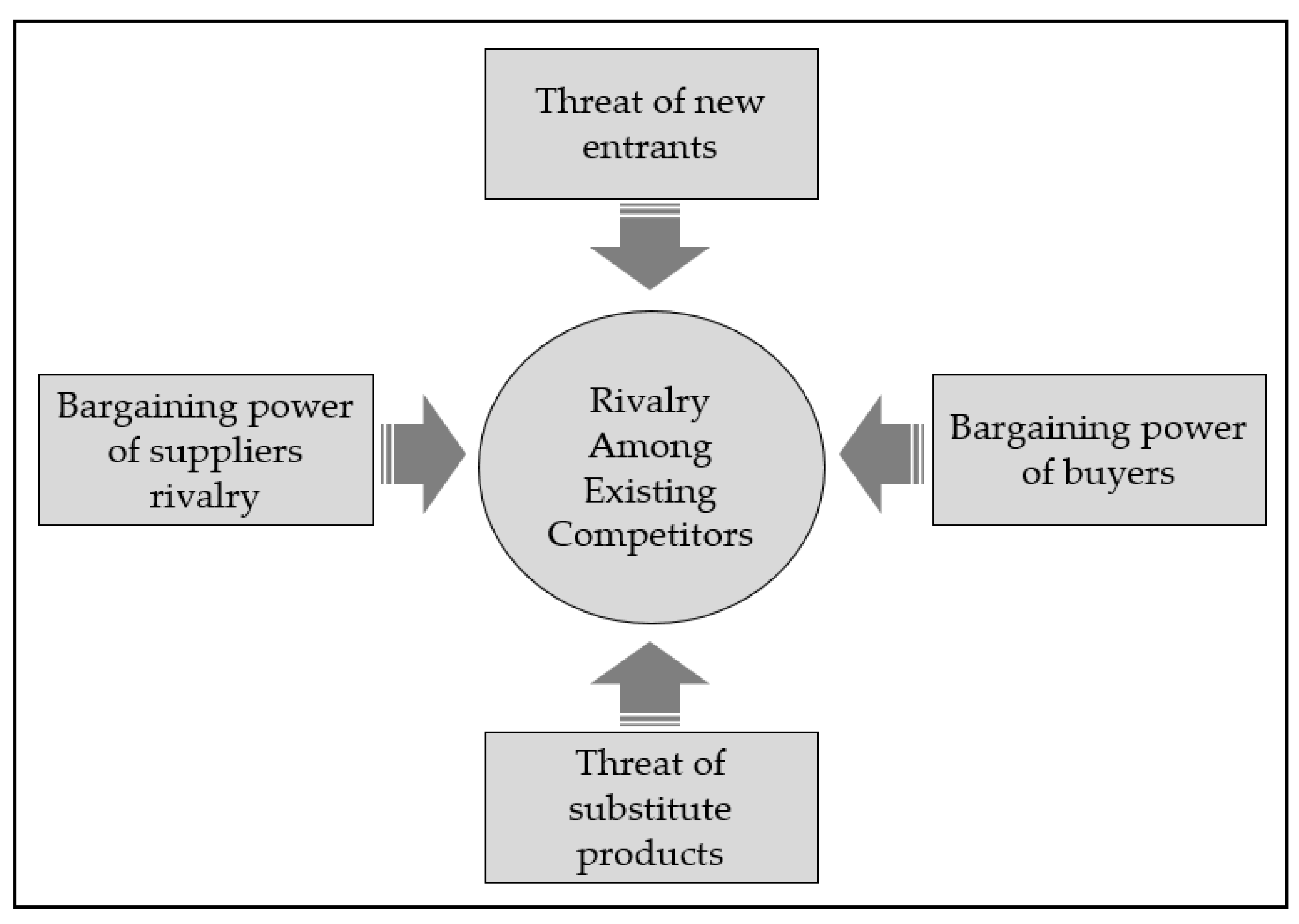

- Grundy, T. Rethinking and reinventing Michael Porter’s five forces model. Strateg. Chang. 2006, 15, 213–229. [Google Scholar] [CrossRef]

- Porter, M. The five competitive forces that shape strategy. Harv. Bus. Rev. 1996, 1, 23–41. [Google Scholar]

- Little, A.D. The strategic management of technology. Eur. Manag. Forum 1981, 1, 1–39. [Google Scholar]

- Yang, X.; Yu, X.; Liu, X. Obtaining a sustainable competitive advantage from patent information: A patent analysis of the graphene industry. Sustainability 2018, 10, 4800. [Google Scholar] [CrossRef]

- Fye, S.R.; Charbonneau, S.M.; Hay, J.W.; Mullins, C.A. An examination of factors affecting accuracy in technology forecasts. Technol. Forecast. Soc. Chang. 2013, 80, 1222–1231. [Google Scholar] [CrossRef]

- Wilder, J.; Sossa, Z.; Palop, F.; Alzate, B.A.; Mauricio, F.; Salazar, V.; Felipe, A.; Patiño, A. S-curve analysis and the technology life cycle: Application in series of data of articles and patents. Espacios 2016, 37, 19. [Google Scholar]

- Chang, S.H.; Fan, C.Y. Identification of the technology life cycle of telematics a patent-based analytical perspective. Technol. Forecast. Soc. Chang. 2016, 105. [Google Scholar] [CrossRef]

- Madvar, M.D.; Khosropour, H.; Khosravanian, A.; Mirafshar, M.; Azaribeni, A.; Rezapour, M.; Nouri, B. Patent-based technology life cycle analysis: The case of the petroleum industry. Foresight STI Gov. 2016, 10, 72–79. [Google Scholar] [CrossRef]

- Caglar, M.U.; Teufel, A.I.; Wilke, C.O. Sicegar: R package for sigmoidal and double-sigmoidal curve fitting. PeerJ 2018, 2018. [Google Scholar] [CrossRef] [PubMed]

- Pearl, J. Bayesian Networks; Press, M., Ed.; MIT Press: Cambridge, MA, USA, 2003. [Google Scholar]

- Hosseini, S.; Ivanov, D. Bayesian networks for supply chain risk, resilience and ripple effect analysis: A literature review. Expert Syst. Appl. 2020, 161. [Google Scholar] [CrossRef]

- Yang, Q.; Li, Z.; Jiao, H.; Zhang, Z.; Chang, W.; Wei, D. Bayesian network approach to customer requirements to customized product model. Discret. Dyn. Nat. Soc. 2019, 2019, 1–16. [Google Scholar] [CrossRef]

- Marquez, D.; Neil, M.; Fenton, N. Improved reliability modeling using Bayesian networks and dynamic discretization. Reliab. Eng. Syst. Saf. 2010, 95, 412–425. [Google Scholar] [CrossRef]

- BayesFusion GeNIe Academic Version. Available online: https://download.bayesfusion.com/files.html?category=Academia2020 (accessed on 16 September 2020).

- McNaught, K.R.; Zagorecki, A. Using dynamic Bayesian networks for prognostic modelling to inform maintenance decision making. In Proceedings of the IEEM 2009—IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009; pp. 1155–1159. [Google Scholar]

- Uusitalo, L. Advantages and challenges of Bayesian networks in environmental modelling. Ecol. Modell. 2007, 203, 312–318. [Google Scholar] [CrossRef]

- Li, J. Scaling up concentrating solar thermal technology in China. Renew. Sustain. Energy Rev. 2009, 13, 2051–2060. [Google Scholar] [CrossRef]

- Hosseini, S.; Barker, K. A Bayesian network model for resilience-based supplier selection. Int. J. Prod. Econ. 2016, 180, 68–87. [Google Scholar] [CrossRef]

- Catlett, J. On changing continuous attributes into ordered discrete attribute. In Proceedings of the Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics), European Working Session on Learning, Porto, Portugal, 6–8 March 1991; Volume 482 LNAI, pp. 164–178. [Google Scholar]

- Lima, M.D.C. Método de Discretização de Variáveis Para Redes Bayesianas Utilizando Algoritmos Genéticos; UFSC: Florianópolis, Brazil, 2014; Volume 30. [Google Scholar]

- Xiuxu, Z.; Wei, K.; Chuanli, Z.; Benhai, L. Technology life cycle forecasting of chinese hydraulic components based on patent analysis the forecasting of chinese hydraulic cylinder patent development. In Proceedings of the 12th International Conference on Innovation and Management, Wuhan, China, 22–25 November 2015; pp. 1123–1127. [Google Scholar]

- Derwent-Innovation Patent Research and Analytics. Available online: https://www.derwentinnovation.com/ (accessed on 9 November 2019).

- WIPO WIPO guide to using patent. Available online: https://patentscope.wipo.int (accessed on 20 August 2020).

- Kabacoff, R.I. R in Action Data Analysis and Graphics with R; Manning Publications Co: New York, NY, USA, 2011; ISBN 9781935182399. [Google Scholar]

- Krispin, R. Hands-On Time Series Analysis with R: Perform Time Series Analysis and Forecasting Using R., 1st ed.; Shetty, S., Ed.; Packt Publishing: Birmingham, UK, 2019; ISBN 9781788629157. [Google Scholar]

- Smith, M.; Agrawal, R. A comparison of time series model forecasting methods on patent groups. In Proceedings of the CEUR Workshop Proceedings, Greensboro, NC, USA, 25–26 April 2015; pp. 167–173. [Google Scholar]

- Team, Rs. RStudio: Integrated Development Environment for R. Available online: https://rstudio.com/products/rstudio/ (accessed on 10 March 2020).

- Petzoldt, T. Growthrates: Estimate growth rates from experimental data. R Packag. Available online: https://cran.r-project.org/package=growthrates (accessed on 20 April 2020).

- Kaufmann, K.W. Fitting and using growth curves. Oecologia 1981, 49, 293–299. [Google Scholar] [CrossRef] [PubMed]

- Phillips, F. On S-curves and tipping points. Technol. Forecast. Soc. Chang. 2007, 74, 715–730. [Google Scholar] [CrossRef]

- Kucharavy, D.; de Guio, R. Application of logistic growth curve. Proc. Procedia Eng. 2015, 131, 280–290. [Google Scholar] [CrossRef]

- Conservation, P. Growth II—A Major Upgrade to Our “Simply Growth” Software. Fits and Plots Von Bertalanffy, Gompertz, Logistic and a Wide Range of Other Growth Curves to Length and/or Weight at Age Data; Pisces Conservation: Hampshire, UK, 2006. [Google Scholar]

- da Costa, G.A.T.F.; Guerra, F. Cálculo I, 2nd ed.; UFSC: Florianópolis, Brazil, 2009; ISBN 9788599379783. [Google Scholar]

- Schot, S.H. Jerk: The time rate of change of acceleration. Am. J. Phys. 1978, 46, 1090–1094. [Google Scholar] [CrossRef]

- Huang, L. Growth kinetics of Listeria monocytogenes in broth and beef frankfurters—Determination of lag phase duration and exponential growth rate under isothermal conditions. J. Food Sci. 2008, 73. [Google Scholar] [CrossRef]

- Bozdogan, H. Model selection and Akaike’s Information Criterion (AIC): The general theory and its analytical extensions. Psychometrika 1987, 52, 345–370. [Google Scholar] [CrossRef]

- Kucharavy, D.; de Guio, R. Logistic substitution model and technological forecasting. Procedia Eng. 2011, 9, 402–416. [Google Scholar] [CrossRef]

- Takata, J.T. Análise do Mercado de Fundição dos Metais Ferrosos No Brasil Banca Examinadora; Fundação Getúlio Vargas—FGV: Rio de Janeiro, Brazil, 2002. [Google Scholar]

- Rathore, A. Defects Analysis and Optimization of Process Parameters Using Taguchi doe Technique for Sand Casting. Int. Res. J. Eng. Technol. 2017, 4, 432–437. [Google Scholar]

- Sturm, J.C.; Schäfer, W. “Cast iron—A predictable material” 25 years of modeling the manufacture, structures and properties of cast iron. In Proceedings of the Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, June 2018; Volume 925 MSF, pp. 451–464. [Google Scholar]

- Lovrenić-Jugović, M.; Glavaš, Z.; Štrkalj, A.; Slokar, L.J.; Radišić, F. Optimization of the circular manhole cover made of ductile cast iron using finite element method. Mach. Technol. Mater. 2018, 12, 225–228. [Google Scholar]

- Cicconi, P.; Landi, D.; Germani, M. An Ecodesign approach for the lightweight engineering of cast iron parts. Int. J. Adv. Manuf. Technol. 2018, 99, 2365–2388. [Google Scholar] [CrossRef]

- Hsu, P.L.; Robbins, H. Complete convergence and the law of large numbers. Proc. Natl. Acad. Sci. USA 1947, 33, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Trappey, C.V.; Wu, H.Y.; Taghaboni-Dutta, F.; Trappey, A.J.C. Using patent data for technology forecasting: China RFID patent analysis. Adv. Eng. Inform. 2011, 25, 53–64. [Google Scholar] [CrossRef]

| Dimension and Methods | Reference | Tools | Examples of Variables |

|---|---|---|---|

| LCA Environmental | [11] | ISO 14040/44 | Energy consumed and CO2 emissions |

| LCC Costing | [12] | Cash flow | Unit cost |

| SLC Social | [13] | Health and safety information; work conventions | Accidents at work |

| Model | Reference | Description | Improvement Points |

|---|---|---|---|

| TRL | [11] | Evaluates technical readiness and is standardized and recognized by the industry. | Reduce subjectivity and expand the scope of the analysis by going beyond the technical aspect. |

| IRL | [12] | Evaluates the integration of components in a system. | Broaden the scope of the analysis by going beyond the technical aspect. |

| SRL | [13] | Combines component readiness and integration. | Broaden the scope of the analysis by going beyond the technical aspect. |

| MRL | [24] | Evaluates manufacturing. | Include market dimension analysis. |

| SRL+ | [25] | Evaluates the technical aspects in a more global view. Covers the concepts of TRL, IRL and MRL. | Include market dimension and technology life cycle analyses. |

| CRL and SRL | [27] | Includes customer and societal views of the product. | Assess market competitiveness and technical aspects. |

| Ward et al., 2018 | [24] | Integrates technical analysis, supply chain and life cycle. | Include analysis of manufacturing and market competitiveness. |

| Darmani and Jullien, 2017 | [26] | Evaluates the most external aspects of the market, intellectual property, consumers and society. | Assess the technical aspects and obsolescence of technology. |

| TLC | [30] | Evaluates the risk and stage in its life cycle. Enables the analysis and anticipation of trends. | Analyze the technical and manufacturing perspectives applied to the LCE study. |

| Variable | NPT: Node probability tables that can be represented by estimated tables or formulas. |

| Description: Reference text to detail the variable, its meaning and reference, if necessary. |

| Technology Sustainability | Upscaling | Yes | No | ||||||

| Supply chain risks | Yes | No | Yes | No | |||||

| Market competition | Yes | No | Yes | No | Yes | No | Yes | No | |

| Yes | 25% | 60% | 65% | 95% | 1% | 10% | 20% | 40% | |

| No | 75% | 40% | 35% | 5% | 99% | 90% | 80% | 60% | |

| Description: Boolean variable that represents the TS and is affected a priori by the variable of upscaling of technology, and by the variables that consolidate Porter’s Five Forces (supply-chain risks and market competition). | |||||||||

| Supply Chain Risks | Bargaining of supplier | Yes | No | ||||||

| Barriers to entry | Yes | No | Yes | No | |||||

| Bargaining of buyers | Yes | No | Yes | No | Yes | No | Yes | No | |

| Yes | 95% | 80% | 85% | 60% | 60% | 40% | 30% | 5% | |

| No | 5% | 20% | 15% | 40% | 40% | 60% | 70% | 95% | |

| Description: Boolean variable that represents the part related to the supply chain of Porter’s Five Forces and is affected a priori by the variables of bargaining of suppliers, barriers to entry, and bargaining of buyers. | |||||||||

| Market Competition | Substitute products | Yes | No | ||||||

| Rivalry among competitors | Yes | No | Yes | No | |||||

| Yes | 95% | 30% | 70% | 5% | |||||

| No | 5% | 70% | 30% | 95% | |||||

| Description: Boolean variable that is affected by the variables of substitute products and rivalry among competitors also referring to Porter’s Five Forces. | |||||||||

| Upscaling of the Technology | Integrated readiness | 1–3 | 4–6 | 7–8 | 9 | ||||

| Structuring capability | Yes | No | Yes | No | Yes | No | Yes | No | |

| Yes | 10% | 1% | 40% | 21% | 70% | 41% | 95% | 55% | |

| No | 90% | 99% | 60% | 79% | 30% | 59% | 5% | 45% | |

| Description: Boolean variable affected by the variables of integrated readiness and structuring capability. | |||||||||

| Structuring Capability | Access to financing | Yes | No | ||

| Access to labor | Yes | No | Yes | No | |

| Yes | 90% | 60% | 40% | 10% | |

| No | 10% | 40% | 60% | 90% | |

| Description: Boolean variable affected by the variables of access to financing and access to labor. | |||||

| Access to Financing | NPT: Yes, No. | ||||

| Description: Boolean variable to be estimated during the application of the model, using the expert opinion [46,47]. | |||||

| Access to Labor | NPT: Yes, No. | ||||

| Description: Boolean variable to be estimated during the application of the model, using the expert opinion [46,47]. | |||||

| Integrated Readiness | NPT: Readiness_Level = Truncate (((MRL + 1) * (TRL + 1)) ^ (1/2)). | ||||

| Description: Function-type variable that is affected a priori by the MRL and TRL variables. The Truncate () function was used to ensure that the number was an integer. | |||||

| MRL | NPT: Distributed and estimated among the categories of the variable, i.e., from MRL 1 to MRL 9 [25]. | ||||

| Description: Discrete variable to be estimated during the application of the model, using the expert opinion [46,47]. | |||||

| TRL | NPT: Distributed and estimated among the categories of the variable, i.e., from TRL 1 to TRL 9 [11]. | ||||

| Description: Discrete variable to be estimated during the application of the model, using the expert opinion [46,47]. | |||||

| Bargaining of suppliers | Access of suppliers | Yes | No | ||

| Few suppliers | Yes | No | Yes | No | |

| Yes | 10% | 60% | 70% | 90% | |

| No | 90% | 40% | 30% | 10% | |

| Description: Boolean variable affected by the variables of access of suppliers and few suppliers. | |||||

| Barriers of entry | Government policy | Yes | No | ||

| Capital requirements | Yes | No | Yes | No | |

| Yes | 90% | 60% | 70% | 20% | |

| No | 10% | 40% | 30% | 80% | |

| Description: Boolean variable affected by the variables of government policy and capital requirements. | |||||

| Bargaining of Buyers | Access to buyers | Yes | No | ||

| Few buyers | Yes | No | Yes | No | |

| Yes | 60% | 5% | 95% | 85% | |

| No | 40% | 95% | 5% | 15% | |

| Description: Boolean variable affected by the variables of access to buyers and few buyers. | |||||

| Substitute Product | Easy-to-imitate product | Yes | No | ||

| Technologies being developed | Yes | No | Yes | No | |

| Yes | 95% | 60% | 50% | 5% | |

| No | 5% | 40% | 50% | 95% | |

| Description: Boolean variable affected by the variables of easy-to-imitate product and technologies being developed. | |||||

| Rivalry among Competitors | Market saturation | Yes | No | ||

| Competitive advantage of competition | Yes | No | Yes | No | |

| Yes | 95% | 70% | 80% | 10% | |

| No | 5% | 30% | 20% | 90% | |

| Description: Boolean variable affected by the variables of market saturation and competitive advantage of competition. | |||||

| Market Saturation | S Curve | Emerging | Growth | Maturity | Saturation |

| Yes | 10% | 30% | 60% | 90% | |

| No | 90% | 70% | 40% | 10% | |

| Description: Discrete variable affected by the S-curve variable. | |||||

| Question. | Options |

|---|---|

| 1. Structuring capability—Does the sector or company have access to financing (own or third party)? | no likely not likely yes yes |

| 2. Structuring capability—Does the sector or company have access to labor? | |

| 3. Do the competitors have a competitive advantage? | |

| 4. Are there technologies that are being developed and can replace the product under evaluation? | |

| 5. Is it easy to imitate or reproduce the product under evaluation? | |

| 6. Does the company have access to customers? | |

| 7. Does the market have few customers? | |

| 8. Do regulations or standards hinder market access? | |

| 9. Does it take a lot of capital to enter the market? | |

| 10. Does the market have few suppliers? | |

| 11. Is it easy to access the suppliers? | |

| 11. What is the TRL of the product being evaluated? | 1 to 9 |

| 12. What is the MRL of the product being evaluated? |

| Typo | Model | Description |

|---|---|---|

| Growth Curves | Logistic | Classic three-parameter growth-curve model [57] used to study and predict future changes [58]. |

| Gompertz | Originally used to estimate human mortality, and has three parameters. It can be written in different ways, including four possible parameters (CONSERVATION, 2006). | |

| Richards | A generalization of the logistical curve whose inflection point is no longer symmetrical. It has four parameters [59]. | |

| Exponential | Classic two-parameter growth curve [59]. |

| Technological Level | Cast Iron | Polymeric Concrete | ||

|---|---|---|---|---|

| TRL | MRL | TRL | MRL | |

| 1 | 0.0% | 0.0% | 0.0% | 0.0% |

| 2 | 0.0% | 0.0% | 0.0% | 0.0% |

| 3 | 0.0% | 0.0% | 0.0% | 16.67% |

| 4 | 0.0% | 0.0% | 33.33% | 33.33% |

| 5 | 0.0% | 0.0% | 16.67% | 33.33% |

| 6 | 0.0% | 0.0% | 16.67% | 0.00% |

| 7 | 0.0% | 0.0% | 16.67% | 0.00% |

| 8 | 16.7% | 16.7% | 16.66% | 16.67% |

| 9 | 83.3% | 83.3% | 0.00% | 0.00% |

| Variable | Cast Iron | Polymeric Concrete | ||

|---|---|---|---|---|

| NO | YES | NO | YES | |

| Access to Financing | 16.67% | 83.33% | 6.67% | 93.33% |

| Access to Labor | 16.67% | 83.33% | 6.67% | 93.33% |

| Competitive advantage of the competition | 26.67% | 73.33% | 26.67% | 73.33% |

| Technologies being developed | 3.33% | 96.67% | 33.33% | 66.67% |

| Product is easy to imitate | 6.67% | 93.33% | 43.34% | 56.66% |

| Access to Customers | 3.33% | 96.67% | 6.67% | 93.33% |

| Few Customers | 70.00% | 30.00% | 70.00% | 30.00% |

| Regulation | 66.66% | 33.34% | 66.66% | 33.34% |

| Capital Requirement | 16.67% | 83.33% | 60.00% | 40.00% |

| Many Suppliers | 16.67% | 83.33% | 23.34% | 76.66% |

| Access to Suppliers | 10.00% | 90.00% | 16.67% | 83.33% |

| Model | (A) Cast Iron | (B) Polymeric Concrete | ||||

|---|---|---|---|---|---|---|

| R2 | RMSE | AIC | R2 | RMSE | AIC | |

| Logistic | 0.9958 | 3.38 | 179.5 | 0.9969 | 39.2 | 336.3 |

| Exponential | 0.9956 | 3.50 | 179.3 | 0.9918 | 64.4 | 362.9 |

| Richards | 0.9955 | 3.52 | 183.5 | 0.9952 | 48.7 | 350.8 |

| Gompertz | 0.9935 | 4.42 | 193.6 | 0.9886 | 77.7 | 375.6 |

| Emerging | Growth | Maturity | Saturation | |

|---|---|---|---|---|

| Cast Iron | 15% | 35% | 15% | 35% |

| Polymeric Concrete | 5% | 30% | 60% | 5% |

| Number of Samples | Technology Sustainability | Absolute Error |

|---|---|---|

| 1 | 0.0% | - |

| 10 | 50% | 50% |

| 100 | 28% | 22% |

| 1000 | 33.9% | 5.9% |

| 10,000 | 35.0% | 1.1% |

| 100,000 | 34.8% | 0.2% |

| 1,000,000 | 34.9% | 0.1% |

| Variable | Polymeric Concrete | Cast Iron |

|---|---|---|

| TRL | 4–6 | 9 |

| MRL | 4–5 | 9 |

| Technology Maturity | 35% | 49% |

| Variable | Polymeric Concrete | Cast Iron |

|---|---|---|

| TRL | 9 | 9 |

| MRL | 4–5 | 9 |

| Technology Maturity | 44% | 50% |

| Variable | Polymeric Concrete | Cast Iron |

|---|---|---|

| TRL | 9 | 9 |

| MRL | 9 | 9 |

| Few Customers | 31% | 31% |

| Technology Maturity | 55% | 50% |

| Variable | Polymeric Concrete | Cast Iron |

|---|---|---|

| TRL | 9 | 9 |

| MRL | 9 | 9 |

| Technologies being Developed | 67% | 96% |

| Technology Maturity | 55% | 53% |

| Polymeric Concrete | Cast Iron | |

|---|---|---|

| Access to Labor | 93% | 83% |

| Access to Financing | 93% | 83% |

| Market saturation | 50% | 53% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, A.S.; Silva, B.C.d.S.; Ferreira, C.V.; Sampaio, R.R.; Machado, B.A.S.; Coelho, R.S. Adding Technology Sustainability Evaluation to Product Development: A Proposed Methodology and an Assessment Model. Sustainability 2021, 13, 2097. https://doi.org/10.3390/su13042097

Oliveira AS, Silva BCdS, Ferreira CV, Sampaio RR, Machado BAS, Coelho RS. Adding Technology Sustainability Evaluation to Product Development: A Proposed Methodology and an Assessment Model. Sustainability. 2021; 13(4):2097. https://doi.org/10.3390/su13042097

Chicago/Turabian StyleOliveira, André Souza, Bruno Caetano dos Santos Silva, Cristiano Vasconcellos Ferreira, Renelson Ribeiro Sampaio, Bruna Aparecida Souza Machado, and Rodrigo Santiago Coelho. 2021. "Adding Technology Sustainability Evaluation to Product Development: A Proposed Methodology and an Assessment Model" Sustainability 13, no. 4: 2097. https://doi.org/10.3390/su13042097

APA StyleOliveira, A. S., Silva, B. C. d. S., Ferreira, C. V., Sampaio, R. R., Machado, B. A. S., & Coelho, R. S. (2021). Adding Technology Sustainability Evaluation to Product Development: A Proposed Methodology and an Assessment Model. Sustainability, 13(4), 2097. https://doi.org/10.3390/su13042097