Machine Learning Aided Design and Prediction of Environmentally Friendly Rubberised Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Collection

- Mandatory Elements (ME)

- Characteristic Elements (CE)

- Output Elements (OE)

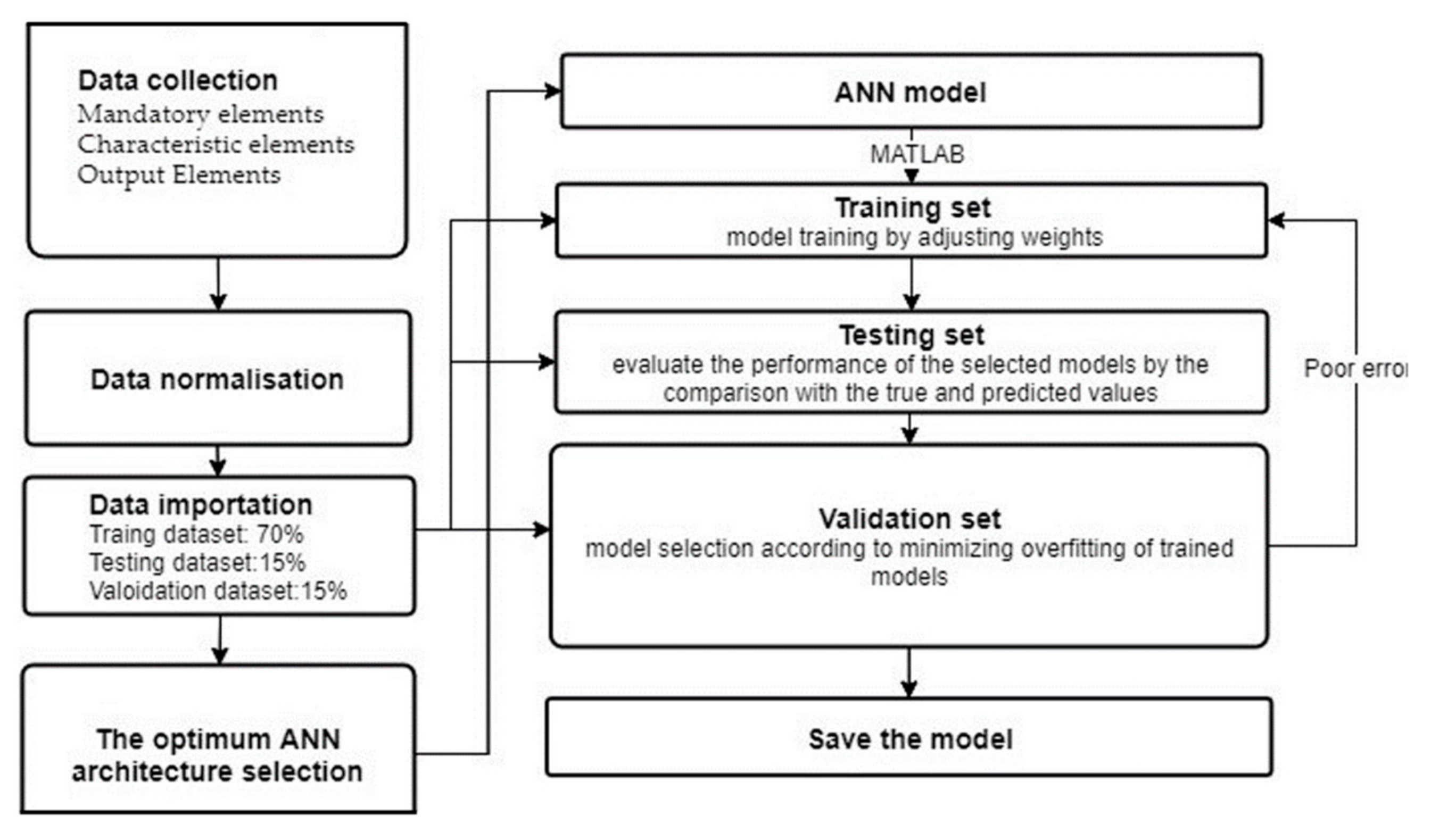

2.2. Data Processing

2.2.1. Data Normalisation

2.2.2. Data Importation

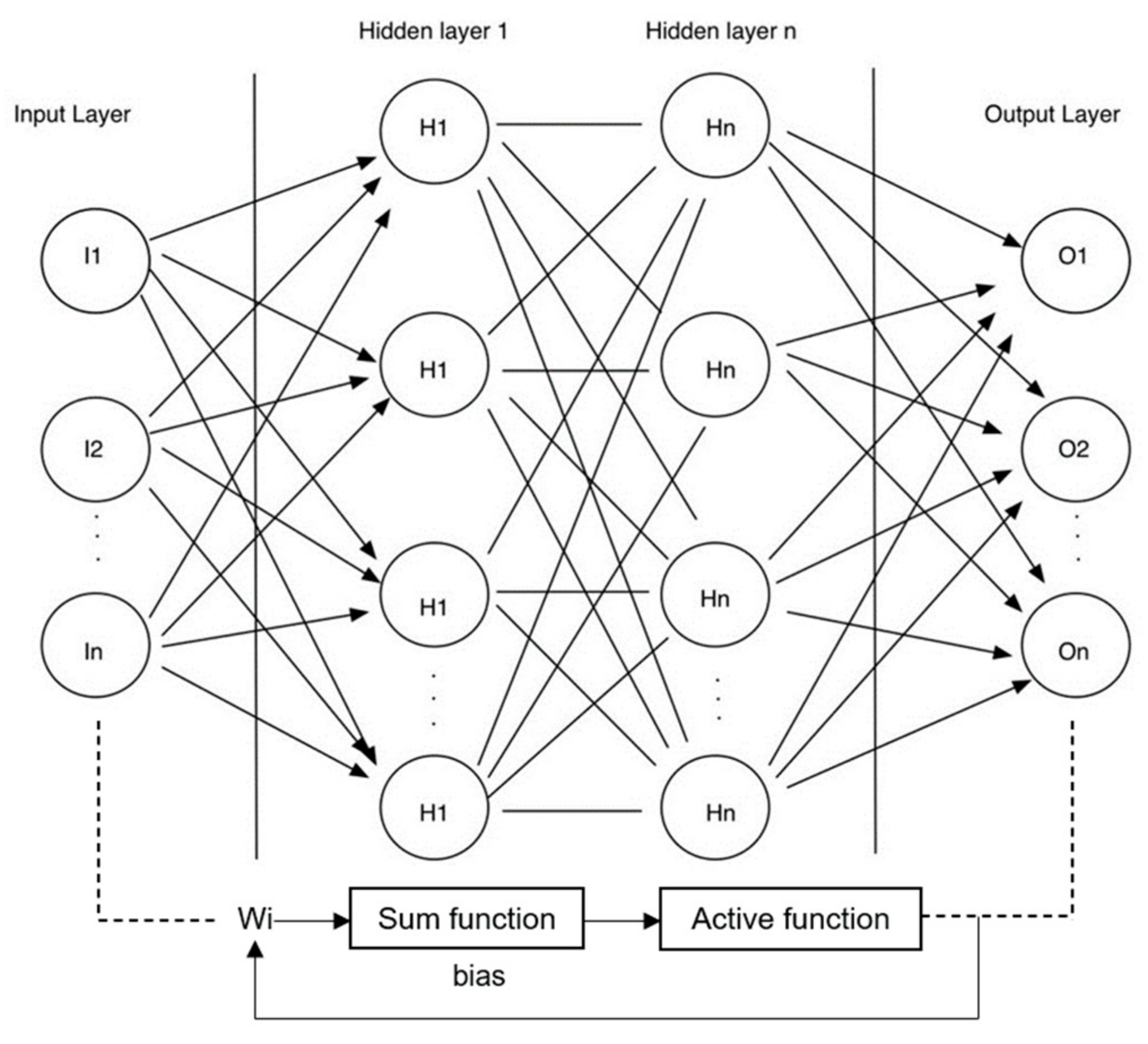

2.3. The Optimum ANN Architecture Selection

2.3.1. Toolbox Selection

2.3.2. Hidden Layers and Neurons Determination

- The number of hidden neurons should be between the size of the input layer and the size of the output layer.

- The number of hidden neurons should be 2/3 of the size of the input layer plus 2/3 of the size of the output layer.

- The number of hidden neurons should be less than double the size of the input layer.

2.3.3. Algorithms Selection

- LM

- BR

- SCG

2.3.4. Performance Evaluation of ANN Architectures

3. Results and Discussion

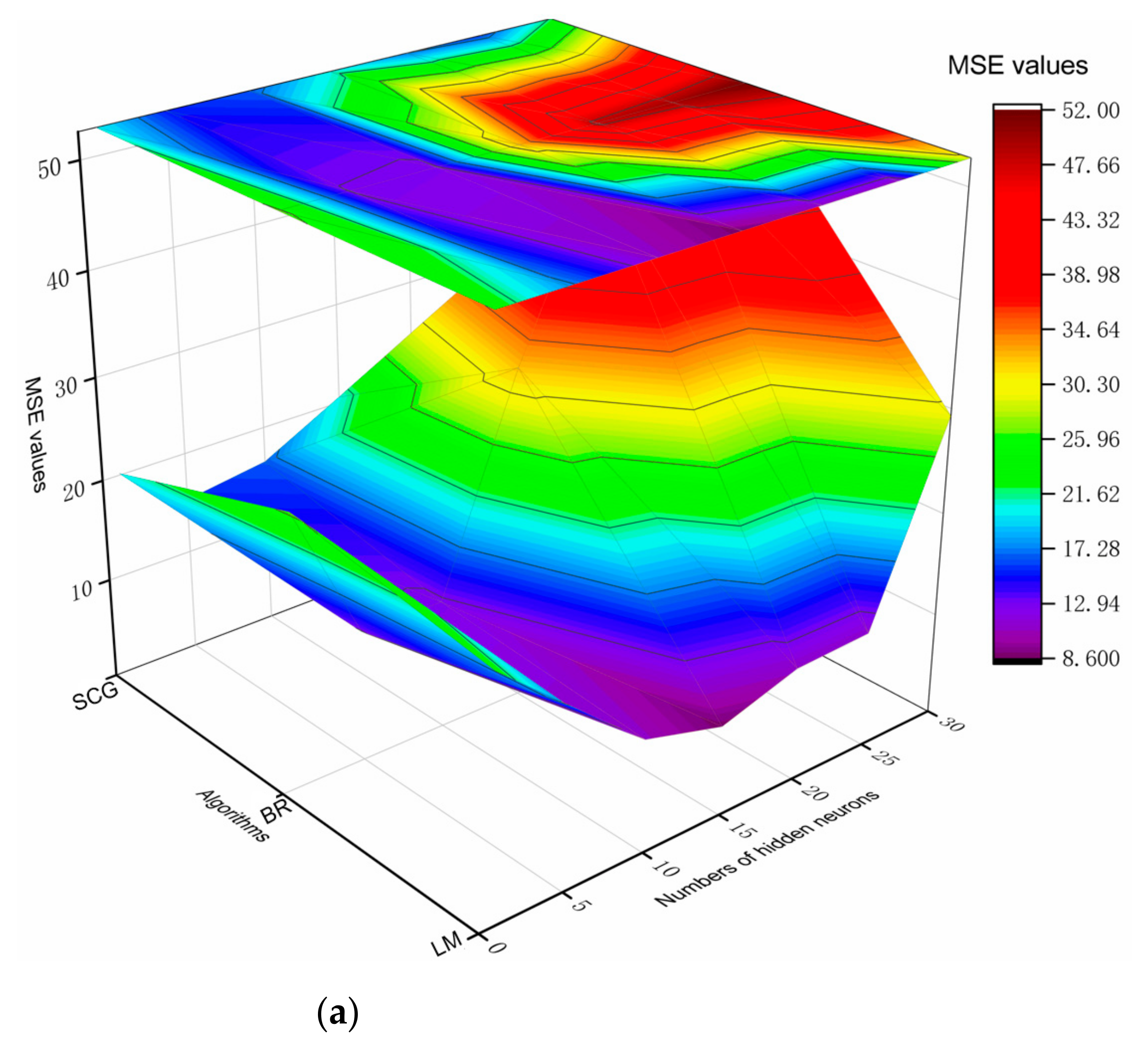

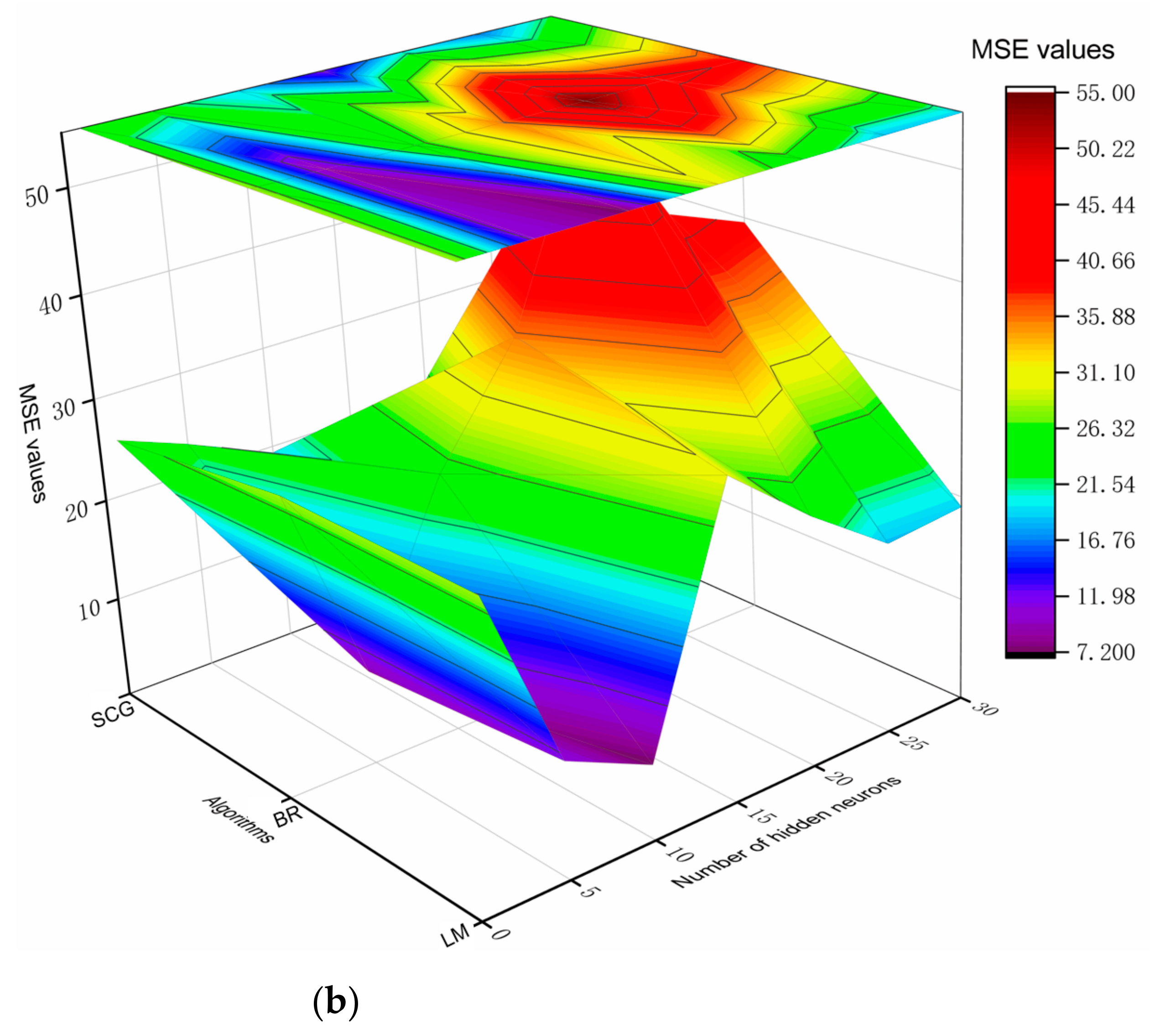

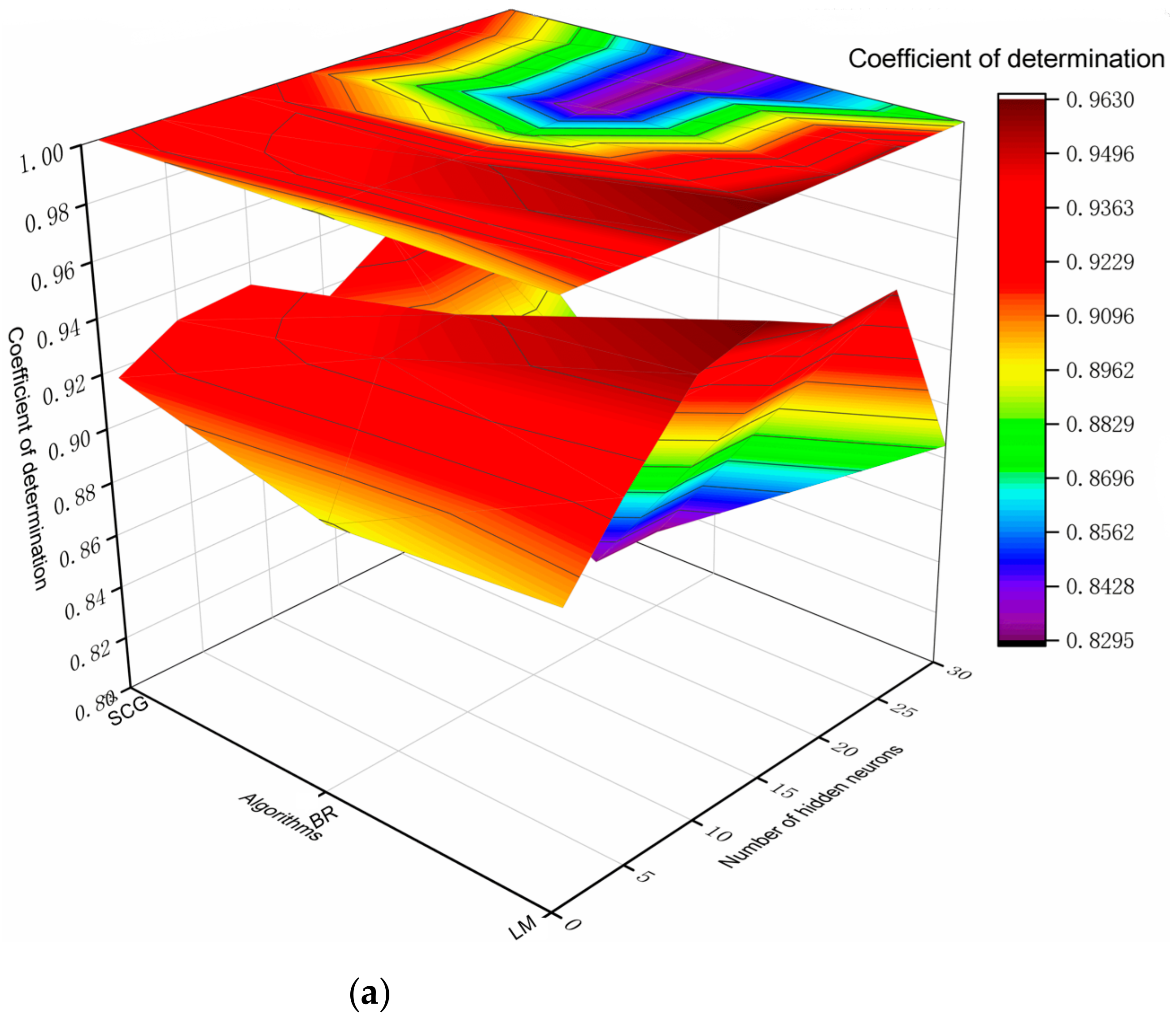

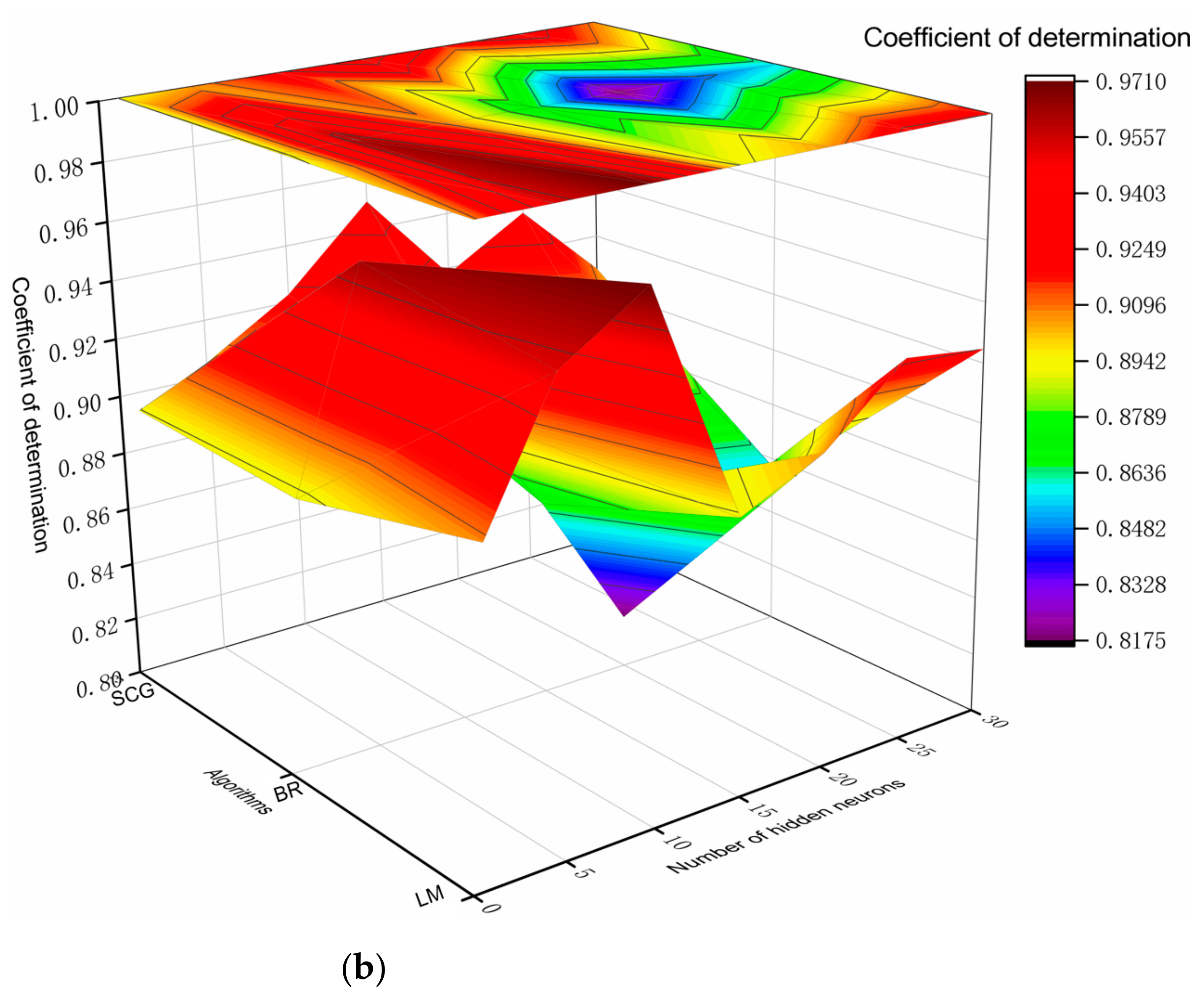

3.1. Optimum ANN Architecture Determination

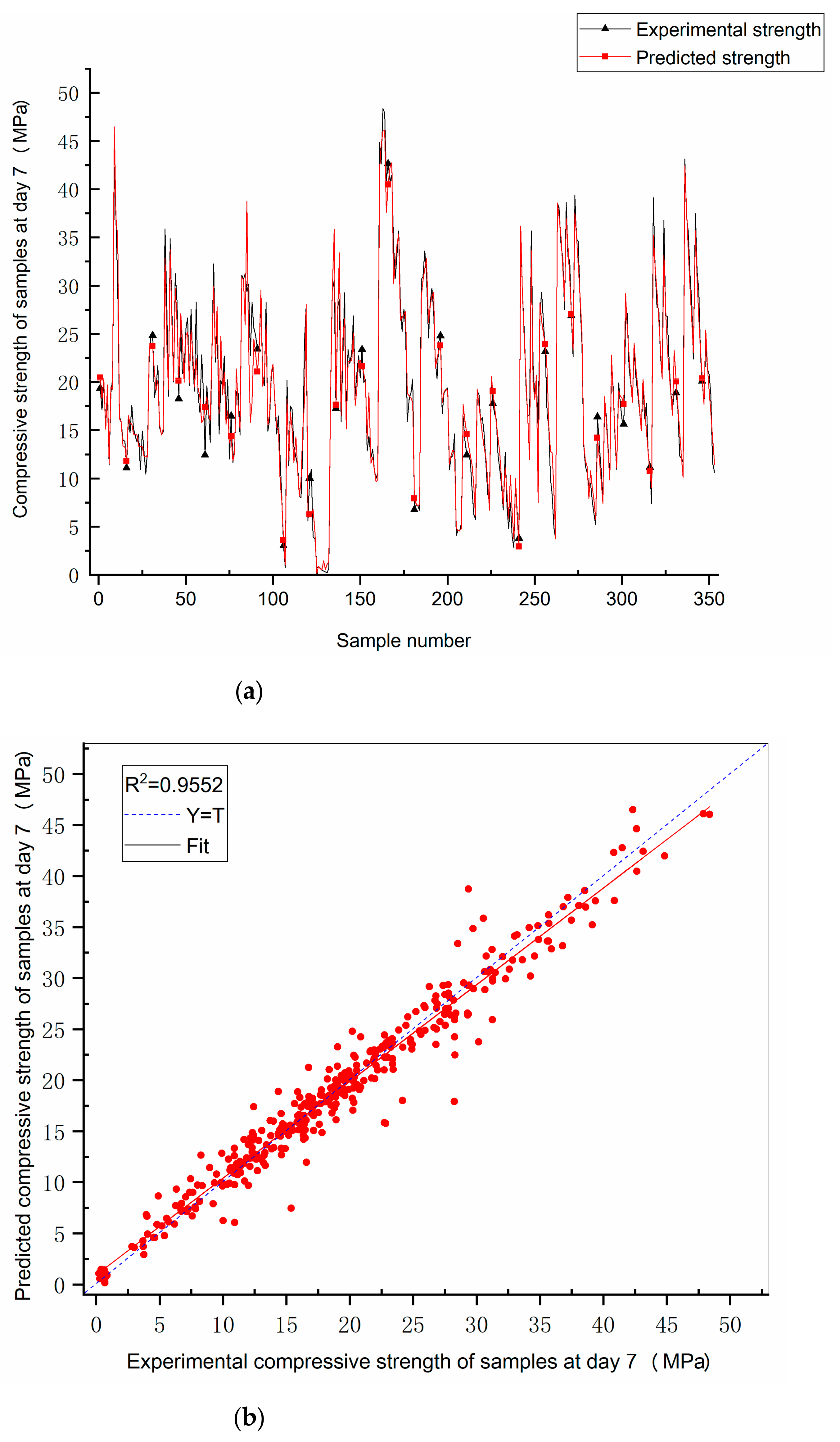

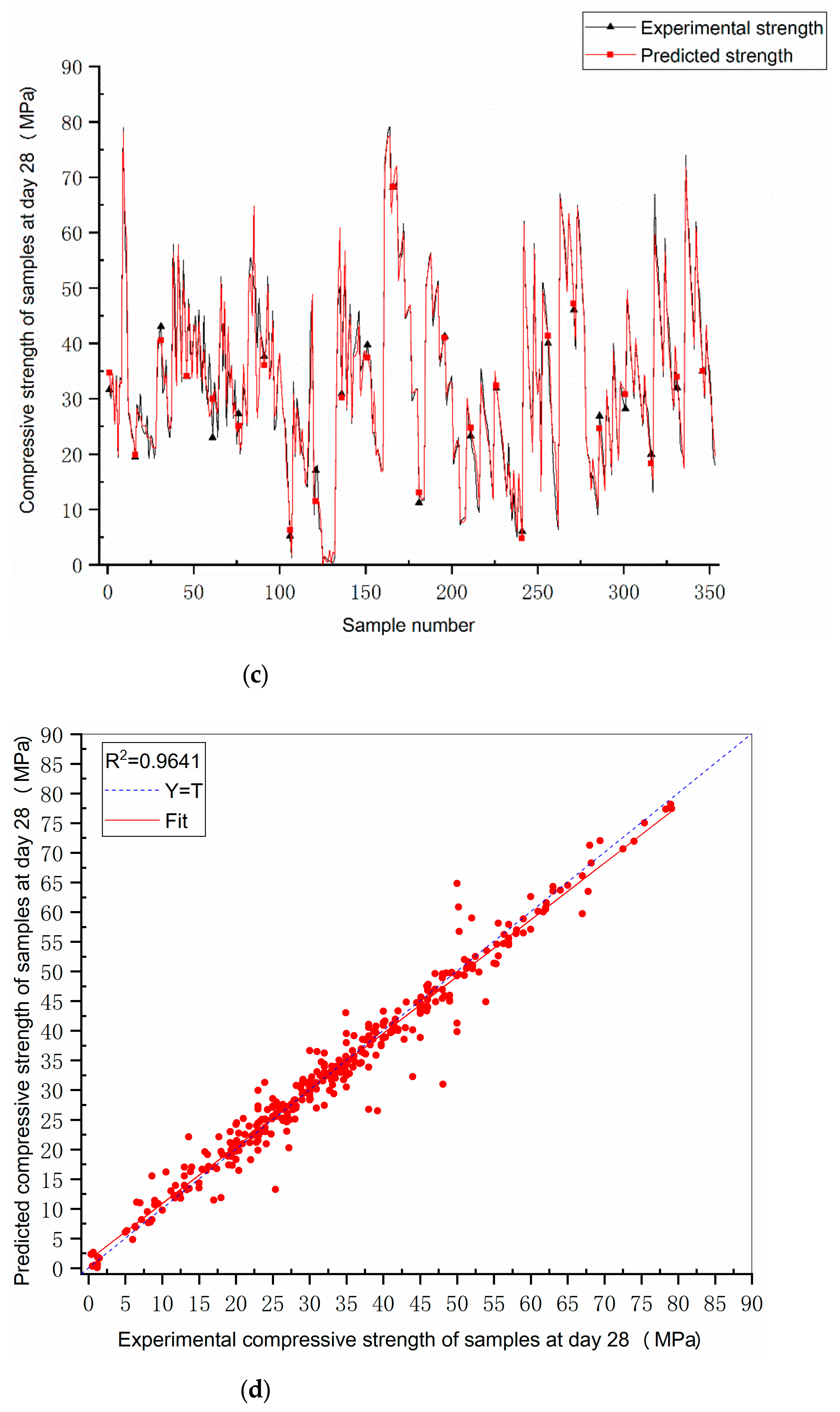

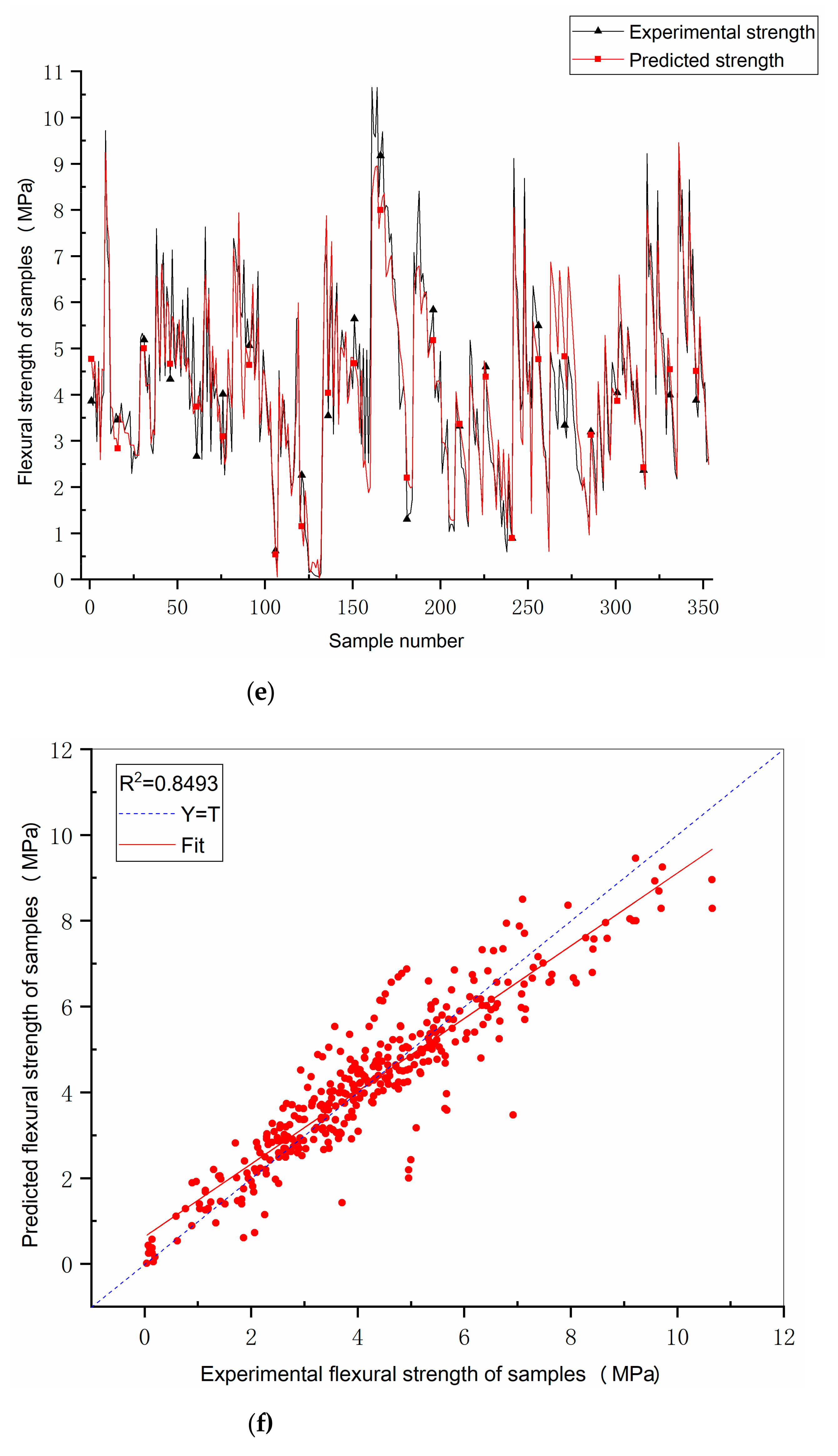

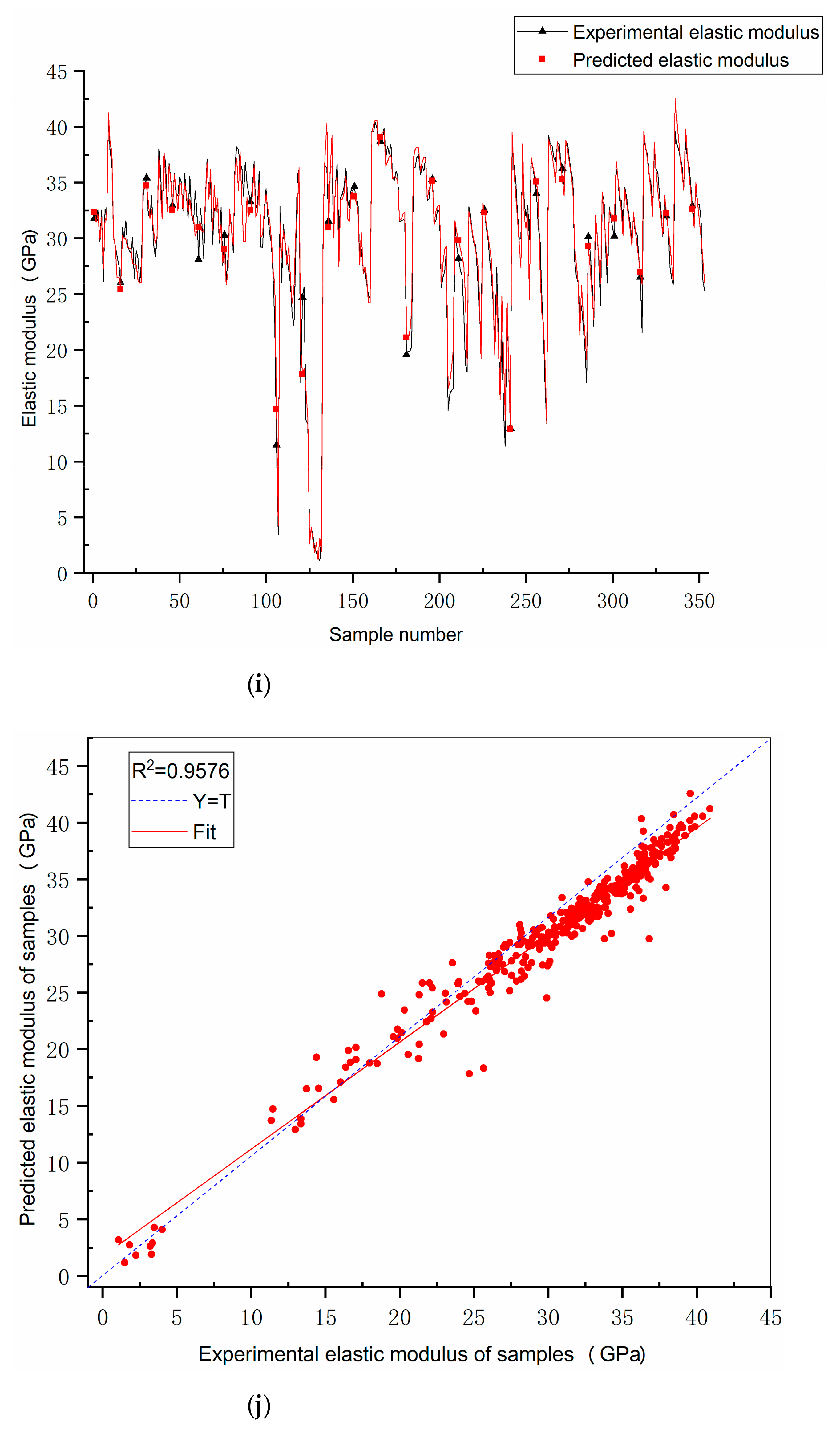

3.2. Comparative Analysis

4. Conclusions

- The ANN architecture with LM algorithm, two hidden layers and ten hidden neurons in each hidden layer is the optimal option for simultaneously predicting multiple mechanical properties of eco-friendly rubberised concrete.

- Based on the MSE (7.2420) and (0.9710) values of the optimal ANN architecture, excellent prediction accuracy of the machine learning can be attained.

- The value of MLR is relatively lower than that of the optimal ANN model. This traditionally implies that the prediction accuracy of the ANN model is relatively higher than that of MLR.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Training Group | ANN Architecture | MSE Value | Average Value | R2 Value | Average Value |

|---|---|---|---|---|---|

| LM-17-1-5 | LM-17-1-5-1 | 19.608 | 23.1850 | 0.915 | 0.9026 |

| LM-17-1-5-2 | 27.179 | 0.889 | |||

| LM-17-1-5-3 | 23.363 | 0.906 | |||

| LM-17-1-5-4 | 20.507 | 0.907 | |||

| LM-17-1-5-5 | 25.268 | 0.895 | |||

| BR-17-1-5 | BR-17-1-5-1 | 24.124 | 26.4407 | 0.908 | 0.8955 |

| BR-17-1-5-2 | 27.455 | 0.889 | |||

| BR-17-1-5-3 | 26.468 | 0.889 | |||

| BR-17-1-5-4 | 24.760 | 0.896 | |||

| BR-17-1-5-5 | 29.395 | 0.895 | |||

| SCG-17-1-5 | SCG-17-1-5-1 | 28.627 | 20.1789 | 0.880 | 0.9166 |

| SCG-17-1-5-2 | 28.075 | 0.882 | |||

| SCG-17-1-5-3 | 13.612 | 0.946 | |||

| SCG-17-1-5-4 | 13.645 | 0.944 | |||

| SCG-17-1-5-5 | 16.935 | 0.930 | |||

| LM-17-5-5 | LM-17-5-5-1 | 45.467 | 17.7134 | 0.816 | 0.9281 |

| LM-17-5-5-2 | 15.738 | 0.937 | |||

| LM-17-5-5-3 | 9.336 | 0.961 | |||

| LM-17-5-5-4 | 7.743 | 0.973 | |||

| LM-17-5-5-5 | 10.283 | 0.953 | |||

| BR-17-5-5 | BR-17-5-5-1 | 13.150 | 12.7931 | 0.932 | 0.9437 |

| BR-17-5-5-2 | 11.543 | 0.955 | |||

| BR-17-5-5-3 | 11.961 | 0.950 | |||

| BR-17-5-5-4 | 16.931 | 0.931 | |||

| BR-17-5-5-5 | 10.381 | 0.950 | |||

| SCG-17-5-5 | SCG-17-5-5-1 | 16.181 | 15.3224 | 0.927 | 0.9289 |

| SCG-17-5-5-2 | 14.924 | 0.935 | |||

| SCG-17-5-5-3 | 14.129 | 0.938 | |||

| SCG-17-5-5-4 | 16.267 | 0.918 | |||

| SCG-17-5-5-5 | 15.111 | 0.926 | |||

| LM-17-10-5 | LM-17-10-5-1 | 6.384 | 10.9459 | 0.973 | 0.9560 |

| LM-17-10-5-2 | 12.171 | 0.948 | |||

| LM-17-10-5-3 | 8.397 | 0.964 | |||

| LM-17-10-5-4 | 17.776 | 0.933 | |||

| LM-17-10-5-5 | 10.002 | 0.963 | |||

| BR-17-10-5 | BR-17-10-5-1 | 10.045 | 12.5805 | 0.956 | 0.9479 |

| BR-17-10-5-2 | 12.745 | 0.946 | |||

| BR-17-10-5-3 | 12.889 | 0.947 | |||

| BR-17-10-5-4 | 12.937 | 0.945 | |||

| BR-17-10-5-5 | 14.286 | 0.946 | |||

| SCG-17-10-5 | SCG-17-10-5-1 | 14.474 | 16.4983 | 0.940 | 0.9317 |

| SCG-17-10-5-2 | 20.373 | 0.915 | |||

| SCG-17-10-5-3 | 15.608 | 0.944 | |||

| SCG-17-10-5-4 | 13.072 | 0.945 | |||

| SCG-17-10-5-5 | 18.964 | 0.914 | |||

| LM-17-15-5 | LM-17-15-5-1 | 9.135 | 8.7459 | 0.965 | 0.9626 |

| LM-17-15-5-2 | 9.664 | 0.958 | |||

| LM-17-15-5-3 | 10.259 | 0.952 | |||

| LM-17-15-5-4 | 6.710 | 0.973 | |||

| LM-17-15-5-5 | 7.961 | 0.965 | |||

| BR-17-15-5 | BR-17-15-5-1 | 20.356 | 32.3697 | 0.919 | 0.8795 |

| BR-17-15-5-2 | 40.857 | 0.861 | |||

| BR-17-15-5-3 | 22.650 | 0.920 | |||

| BR-17-15-5-4 | 40.554 | 0.858 | |||

| BR-17-15-5-5 | 37.433 | 0.839 | |||

| SCG-17-15-5 | SCG-17-15-5-1 | 14.682 | 20.5665 | 0.946 | 0.9146 |

| SCG-17-15-5-2 | 21.556 | 0.910 | |||

| SCG-17-15-5-3 | 29.309 | 0.878 | |||

| SCG-17-15-5-4 | 13.980 | 0.936 | |||

| SCG-17-15-5-5 | 23.306 | 0.904 | |||

| LM-17-20-5 | LM-17-20-5-1 | 10.841 | 11.0165 | 0.954 | 0.9509 |

| LM-17-20-5-2 | 14.187 | 0.946 | |||

| LM-17-20-5-3 | 9.020 | 0.956 | |||

| LM-17-20-5-4 | 8.129 | 0.968 | |||

| LM-17-20-5-5 | 12.905 | 0.930 | |||

| BR-17-20-5 | BR-17-20-5-1 | 47.893 | 48.5124 | 0.840 | 0.8315 |

| BR-17-20-5-2 | 54.524 | 0.813 | |||

| BR-17-20-5-3 | 36.495 | 0.865 | |||

| BR-17-20-5-4 | 39.970 | 0.858 | |||

| BR-17-20-5-5 | 63.679 | 0.781 | |||

| SCG-17-20-5 | SCG-17-20-5-1 | 22.263 | 17.2641 | 0.915 | 0.9315 |

| SCG-17-20-5-2 | 13.949 | 0.946 | |||

| SCG-17-20-5-3 | 21.249 | 0.914 | |||

| SCG-17-20-5-4 | 17.420 | 0.935 | |||

| SCG-17-20-5-5 | 11.439 | 0.948 | |||

| LM-17-25-5 | LM-17-25-5-1 | 8.471 | 11.267 | 0.970 | 0.9522 |

| LM-17-25-5-2 | 10.370 | 0.957 | |||

| LM-17-25-5-3 | 14.410 | 0.931 | |||

| LM-17-25-5-4 | 10.994 | 0.950 | |||

| LM-17-25-5-5 | 12.090 | 0.953 | |||

| BR-17-25-5 | BR-17-25-5-1 | 69.336 | 49.6730 | 0.761 | 0.8305 |

| BR-17-25-5-2 | 59.611 | 0.811 | |||

| BR-17-25-5-3 | 43.495 | 0.846 | |||

| BR-17-25-5-4 | 35.384 | 0.864 | |||

| BR-17-25-5-5 | 40.540 | 0.870 | |||

| SCG-17-25-5 | SCG-17-25-5-1 | 11.784 | 15.9628 | 0.944 | 0.9271 |

| SCG-17-25-5-2 | 12.815 | 0.942 | |||

| SCG-17-25-5-3 | 18.111 | 0.910 | |||

| SCG-17-25-5-4 | 17.119 | 0.925 | |||

| SCG-17-25-5-5 | 19.986 | 0.914 | |||

| LM-17-30-5 | LM-17-30-5-1 | 20.039 | 29.3399 | 0.909 | 0.8847 |

| LM-17-30-5-2 | 24.060 | 0.904 | |||

| LM-17-30-5-3 | 29.875 | 0.871 | |||

| LM-17-30-5-4 | 36.002 | 0.855 | |||

| LM-17-30-5-5 | 36.724 | 0.884 | |||

| BR-17-30-5 | BR-17-30-5-1 | 50.004 | 51.8540 | 0.828 | 0.8298 |

| BR-17-30-5-2 | 54.383 | 0.819 | |||

| BR-17-30-5-3 | 44.388 | 0.882 | |||

| BR-17-30-5-4 | 52.017 | 0.824 | |||

| BR-17-30-5-5 | 58.478 | 0.796 | |||

| CG-17-30-5 | SCG-17-30-5-1 | 19.643 | 21.8357 | 0.916 | 0.9115 |

| SCG-17-30-5-2 | 20.886 | 0.904 | |||

| SCG-17-30-5-3 | 17.442 | 0.925 | |||

| SCG-17-30-5-4 | 23.130 | 0.919 | |||

| SCG-17-30-5-5 | 28.078 | 0.894 | |||

| LM-17-1-1-5 | LM-17-1-1-5-1 | 23.061 | 21.5373 | 0.897 | 0.9078 |

| LM-17-1-1-5-2 | 16.666 | 0.922 | |||

| LM-17-1-1-5-3 | 15.999 | 0.940 | |||

| LM-17-1-1-5-4 | 21.057 | 0.915 | |||

| LM-17-1-1-5-5 | 30.904 | 0.865 | |||

| BR -17-1-1-5 | BR-17-1-1-5-1 | 28.043 | 28.2334 | 0.895 | 0.8914 |

| BR-17-1-1-5-2 | 26.079 | 0.903 | |||

| BR-17-1-1-5-3 | 29.380 | 0.889 | |||

| BR-17-1-1-5-4 | 31.593 | 0.886 | |||

| BR-17-1-1-5-5 | 26.073 | 0.884 | |||

| SCG -17-1-1-5 | SCG-17-1-1-5-1 | 29.392 | 25.4727 | 0.884 | 0.8937 |

| SCG-17-1-1-5-2 | 22.598 | 0.892 | |||

| SCG-17-1-1-5-3 | 21.492 | 0.904 | |||

| SCG-17-1-1-5-4 | 26.143 | 0.896 | |||

| SCG-17-1-1-5-5 | 27.738 | 0.892 | |||

| LM-17-5-5-5 | LM-17-5-5-5-1 | 9.222 | 11.1077 | 0.958 | 0.9522 |

| LM-17-5-5-5-2 | 11.546 | 0.945 | |||

| LM-17-5-5-5-3 | 8.044 | 0.967 | |||

| LM-17-5-5-5-4 | 14.946 | 0.933 | |||

| LM-17-5-5-5-5 | 11.780 | 0.958 | |||

| BR -17-5-5-5 | BR-17-5-5-5-1 | 6.122 | 9.1582 | 0.980 | 0.9623 |

| BR-17-5-5-5-2 | 7.082 | 0.974 | |||

| BR-17-5-5-5-3 | 7.614 | 0.966 | |||

| BR-17-5-5-5-4 | 6.123 | 0.973 | |||

| BR-17-5-5-5-5 | 18.850 | 0.919 | |||

| SCG -17-5-5-5 | SCG-17-5-5-5-1 | 22.845 | 22.9340 | 0.912 | 0.9049 |

| SCG-17-5-5-5-2 | 21.129 | 0.910 | |||

| SCG-17-5-5-5-3 | 24.037 | 0.902 | |||

| SCG-17-5-5-5-4 | 22.576 | 0.905 | |||

| SCG-17-5-5-5-5 | 24.083 | 0.896 | |||

| LM-17-10-10-5 | LM-17-10-10-5-1 | 7.694 | 7.2420 | 0.970 | 0.9710 |

| LM-17-10-10-5-2 | 6.067 | 0.974 | |||

| LM-17-10-10-5-3 | 5.669 | 0.978 | |||

| LM-17-10-10-5-4 | 8.088 | 0.964 | |||

| LM-17-10-10-5-5 | 8.692 | 0.969 | |||

| BR -17-10-10-5 | BR-17-10-10-5-1 | 26.057 | 25.1978 | 0.906 | 0.9071 |

| BR-17-10-10-5-2 | 18.578 | 0.927 | |||

| BR-17-10-10-5-3 | 35.363 | 0.877 | |||

| BR-17-10-10-5-4 | 25.603 | 0.906 | |||

| BR-17-10-10-5-5 | 20.387 | 0.919 | |||

| SCG -17-10-10-5 | SCG-17-10-10-5-1 | 18.176 | 19.3592 | 0.934 | 0.9227 |

| SCG-17-10-10-5-2 | 22.484 | 0.930 | |||

| SCG-17-10-10-5-3 | 19.166 | 0.911 | |||

| SCG-17-10-10-5-4 | 18.794 | 0.916 | |||

| SCG-17-10-10-5-5 | 18.177 | 0.923 | |||

| LM-17-15-15-5 | LM-17-15-15-5-1 | 29.132 | 30.3840 | 0.892 | 0.8923 |

| LM-17-15-15-5-2 | 40.439 | 0.861 | |||

| LM-17-15-15-5-3 | 15.351 | 0.941 | |||

| LM-17-15-15-5-4 | 34.254 | 0.884 | |||

| LM-17-15-15-5-5 | 32.744 | 0.884 | |||

| BR -17-15-15-5 | BR-17-15-15-5-1 | 30.100 | 35.5664 | 0.908 | 0.8674 |

| BR-17-15-15-5-2 | 48.677 | 0.824 | |||

| BR-17-15-15-5-3 | 30.691 | 0.899 | |||

| BR-17-15-15-5-4 | 43.835 | 0.791 | |||

| BR-17-15-15-5-5 | 24.530 | 0.915 | |||

| SCG -17-15-15-5 | SCG-17-15-15-5-1 | 12.935 | 11.6450 | 0.942 | 0.9500 |

| SCG-17-15-15-5-2 | 11.981 | 0.951 | |||

| SCG-17-15-15-5-3 | 7.689 | 0.970 | |||

| SCG-17-15-15-5-4 | 12.935 | 0.940 | |||

| SCG-17-15-15-5-5 | 12.687 | 0.946 | |||

| LM-17-20-20-5 | LM-17-20-20-5-1 | 22.755 | 23.9056 | 0.903 | 0.9053 |

| LM-17-20-20-5-2 | 29.075 | 0.885 | |||

| LM-17-20-20-5-3 | 25.528 | 0.891 | |||

| LM-17-20-20-5-4 | 25.748 | 0.911 | |||

| LM-17-20-20-5-5 | 16.422 | 0.936 | |||

| BR -17-20-20-5 | BR-17-20-20-5-1 | 60.931 | 54.9310 | 0.795 | 0.8179 |

| BR-17-20-20-5-2 | 45.471 | 0.857 | |||

| BR-17-20-20-5-3 | 70.394 | 0.796 | |||

| BR-17-20-20-5-4 | 42.445 | 0.829 | |||

| BR-17-20-20-5-5 | 55.414 | 0.813 | |||

| SCG -17-20-20-5 | SCG-17-20-20-5-1 | 13.649 | 20.3014 | 0.939 | 0.9178 |

| SCG-17-20-20-5-2 | 24.836 | 0.900 | |||

| SCG-17-20-20-5-3 | 29.018 | 0.876 | |||

| SCG-17-20-20-5-4 | 16.613 | 0.935 | |||

| SCG-17-20-20-5-5 | 17.391 | 0.939 | |||

| LM-17-25-25-5 | LM-17-25-25-5-1 | 29.484 | 18.4144 | 0.899 | 0.9285 |

| LM-17-25-25-5-2 | 18.306 | 0.930 | |||

| LM-17-25-25-5-3 | 16.619 | 0.933 | |||

| LM-17-25-25-5-4 | 13.342 | 0.941 | |||

| LM-17-25-25-5-5 | 14.321 | 0.940 | |||

| BR -17-25-25-5 | BR-17-25-25-5-1 | 62.883 | 42.4919 | 0.768 | 0.8455 |

| BR-17-25-25-5-2 | 48.863 | 0.804 | |||

| BR-17-25-25-5-3 | 39.218 | 0.872 | |||

| BR-17-25-25-5-4 | 35.220 | 0.882 | |||

| BR-17-25-25-5-5 | 26.276 | 0.902 | |||

| SCG -17-25-25-5 | SCG-17-25-25-5-1 | 19.483 | 16.5416 | 0.926 | 0.9346 |

| SCG-17-25-25-5-2 | 13.245 | 0.943 | |||

| SCG-17-25-25-5-3 | 18.428 | 0.929 | |||

| SCG-17-25-25-5-4 | 14.322 | 0.947 | |||

| SCG-17-25-25-5-5 | 17.231 | 0.928 | |||

| LM-17-30-30-5 | LM-17-30-30-5-1 | 6.665 | 19.0260 | 0.975 | 0.9247 |

| LM-17-30-30-5-2 | 21.629 | 0.918 | |||

| LM-17-30-30-5-3 | 25.859 | 0.892 | |||

| LM-17-30-30-5-4 | 6.398 | 0.975 | |||

| LM-17-30-30-5-5 | 34.579 | 0.864 | |||

| BR -17-30-30-5 | BR-17-30-30-5-1 | 49.909 | 39.5577 | 0.823 | 0.8571 |

| BR-17-30-30-5-2 | 31.449 | 0.874 | |||

| BR-17-30-30-5-3 | 49.542 | 0.824 | |||

| BR-17-30-30-5-4 | 31.739 | 0.893 | |||

| BR-17-30-30-5-5 | 35.149 | 0.871 | |||

| SCG -17-30-30-5 | SCG-17-30-30-5-1 | 20.650 | 22.2361 | 0.908 | 0.9074 |

| SCG-17-30-30-5-2 | 18.320 | 0.921 | |||

| SCG-17-30-30-5-3 | 23.257 | 0.903 | |||

| SCG-17-30-30-5-4 | 15.679 | 0.935 | |||

| SCG-17-30-30-5-5 | 33.275 | 0.869 |

References

- Wright, B.; Garside, M.; Allgar, V.; Hodkinson, R.; Thorpe, H. A large population-based study of the mental health and wellbeing of children and young people in the North of England. Clin. Child Psychol. Psychiatry 2020, 25, 877–890. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Ding, Y.; Jalali, S. Properties and durability of concrete containing polymeric wastes (tyre rubber and polyethylene terephthalate bottles): An overview. Constr. Build. Mater. 2012, 30, 714–724. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo, F.; Canavate, J. Composites reinforced with reused tyres: Surface oxidant treatment to improve the interfacial compatibility. Compos. Part A Appl. Sci. Manuf. 2007, 38, 44–50. [Google Scholar] [CrossRef]

- Toutanji, H.A. The use of rubber tire particles in concrete to replace mineral aggregates. Cem. Concr. Compos. 1996, 18, 135–139. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Alam, I.; Mahmood, U.A.; Khattak, N. Use of rubber as aggregate in concrete: A review. Int. J. Adv. Struct. Geotech. Eng. 2015, 4, 92–96. [Google Scholar]

- Kaewunruen, S.; Ngamkhanong, C.; Lim, C.H. Damage and failure modes of railway prestressed concrete sleepers with holes/web openings subject to impact loading conditions. Eng. Struct. 2018, 176, 840–848. [Google Scholar] [CrossRef]

- Rashad, A.M. A comprehensive overview about recycling rubber as fine aggregate replacement in traditional cementitious materials. Int. J. Sustain. Built Environ. 2016, 5, 46–82. [Google Scholar] [CrossRef]

- Sukontasukkul, P. Use of crumb rubber to improve thermal and sound properties of pre-cast concrete panel. Constr. Build. Mater. 2009, 23, 1084–1092. [Google Scholar] [CrossRef]

- You, R.; Goto, K.; Ngamkhanong, C.; Kaewunruen, S. Nonlinear finite element analysis for structural capacity of railway prestressed concrete sleepers with rail seat abrasion. Eng. Fail. Anal. 2019, 95, 47–65. [Google Scholar] [CrossRef]

- Thomas, B.S.; Kumar, S.; Mehra, P.; Gupta, R.C.; Joseph, M.; Csetenyi, L.J. Abrasion resistance of sustainable green concrete containing waste tire rubber particles. Constr. Build. Mater. 2016, 124, 906–909. [Google Scholar] [CrossRef]

- Benazzouk, A.; Mezreb, K.; Doyen, G.; Goullieux, A.; Quéneudec, M. Effect of rubber aggregates on the physico-mechanical behaviour of cement–rubber composites-influence of the alveolar texture of rubber aggregates. Cem. Concr. Compos. 2003, 25, 711–720. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. Long term behaviour of cement concrete containing discarded tire rubber. J. Clean. Prod. 2015, 102, 78–87. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Rubber-tire particles as concrete aggregate. J. Mater. Civ. Eng. 1993, 5, 478–496. [Google Scholar] [CrossRef]

- Roychand, R.; Gravina, R.J.; Zhuge, Y.; Ma, X.; Youssf, O.; Mills, J.E. A comprehensive review on the mechanical properties of waste tire rubber concrete. Constr. Build. Mater. 2020, 237, 117651. [Google Scholar] [CrossRef]

- Youssf, O.; Mills, J.E.; Benn, T.; Zhuge, Y.; Ma, X.; Roychand, R.; Gravina, R. Development of Crumb Rubber Concrete for Practical Application in the Residential Construction Sector–Design and Processing. Constr. Build. Mater. 2020, 260, 119813. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Kazmi, S.M.S.; Munir, M.J.; Zhou, Y.; Xing, F. Effect of compression casting method on the compressive strength, elastic modulus and microstructure of rubber concrete. J. Clean. Prod. 2020, 264, 121746. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F. Application of waste tire rubber and recycled aggregates in concrete products: A new compression casting approach. Resour. Conserv. Recycl. 2021, 167, 105353. [Google Scholar] [CrossRef]

- Vieira, S.; Gong, Q.-Y.; Pinaya, W.H.; Scarpazza, C.; Tognin, S.; Crespo-Facorro, B.; Tordesillas-Gutierrez, D.; Ortiz-García, V.; Setien-Suero, E.; Scheepers, F.E. Using machine learning and structural neuroimaging to detect first episode psychosis: Reconsidering the evidence. Schizophr. Bull. 2020, 46, 17–26. [Google Scholar] [CrossRef]

- Michie, D.; Spiegelhalter, D.J.; Taylor, C. Machine learning. Neural Stat. Classif. 1994, 13, 1–298. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A.; Bengio, Y. Deep Learning; MIT Press: Cambridge, UK, 2016; Volume 1. [Google Scholar]

- Goharzay, M.; Noorzad, A.; Ardakani, A.M.; Jalal, M. Computer-aided SPT-based reliability model for probability of liquefaction using hybrid PSO and GA. J. Comput. Des. Eng. 2020, 7, 107–127. [Google Scholar] [CrossRef]

- Chaabene, W.B.; Flah, M.; Nehdi, M.L. Machine learning prediction of mechanical properties of concrete: Critical review. Constr. Build. Mater. 2020, 260, 119889. [Google Scholar] [CrossRef]

- Dantas, A.T.A.; Leite, M.B.; de Jesus Nagahama, K. Prediction of compressive strength of concrete containing construction and demolition waste using artificial neural networks. Constr. Build. Mater. 2013, 38, 717–722. [Google Scholar] [CrossRef]

- Behnood, A.; Golafshani, E.M. Predicting the compressive strength of silica fume concrete using hybrid artificial neural network with multi-objective grey wolves. J. Clean. Prod. 2018, 202, 54–64. [Google Scholar] [CrossRef]

- Erdal, H.I.; Karakurt, O.; Namli, E. High performance concrete compressive strength forecasting using ensemble models based on discrete wavelet transform. Eng. Appl. Artif. Intell. 2013, 26, 1246–1254. [Google Scholar] [CrossRef]

- Tanarslan, H.; Secer, M.; Kumanlioglu, A. An approach for estimating the capacity of RC beams strengthened in shear with FRP reinforcements using artificial neural networks. Constr. Build. Mater. 2012, 30, 556–568. [Google Scholar] [CrossRef]

- Barbuta, M.; Diaconescu, R.-M.; Harja, M. Using neural networks for prediction of properties of polymer concrete with fly ash. J. Mater. Civ. Eng. 2012, 24, 523–528. [Google Scholar] [CrossRef]

- Gencel, O.; Kocabas, F.; Gok, M.S.; Koksal, F. Comparison of artificial neural networks and general linear model approaches for the analysis of abrasive wear of concrete. Constr. Build. Mater. 2011, 25, 3486–3494. [Google Scholar] [CrossRef]

- Yoon, J.Y.; Kim, H.; Lee, Y.-J.; Sim, S.-H. Prediction model for mechanical properties of lightweight aggregate concrete using artificial neural network. Materials 2019, 12, 2678. [Google Scholar] [CrossRef]

- Khademi, F.; Jamal, S.M.; Deshpande, N.; Londhe, S. Predicting strength of recycled aggregate concrete using artificial neural network, adaptive neuro-fuzzy inference system and multiple linear regression. Int. J. Sustain. Built Environ. 2016, 5, 355–369. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Sarıdemir, M. Prediction of mechanical properties of recycled aggregate concretes containing silica fume using artificial neural networks and fuzzy logic. Comput. Mater. Sci. 2008, 42, 74–82. [Google Scholar] [CrossRef]

- Grekousis, G. Artificial neural networks and deep learning in urban geography: A systematic review and meta-analysis. Comput. Environ. Urban Syst. 2019, 74, 244–256. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Jiao, Y.; Sha, T. Experimental investigation of the mechanical and durability properties of crumb rubber concrete. Materials 2016, 9, 172. [Google Scholar] [CrossRef]

- Hernández-Olivares, F.; Barluenga, G. Fire performance of recycled rubber-filled high-strength concrete. Cem. Concr. Res. 2004, 34, 109–117. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Meesit, R. Eco-friendly High-Strength Concrete Engineered by Micro Crumb Rubber from Recycled Tires and Plastics for Railway Components. Adv. Civ. Eng. Mater. 2020, 9, 210–226. [Google Scholar] [CrossRef]

- Yung, W.H.; Yung, L.C.; Hua, L.H. A study of the durability properties of waste tire rubber applied to self-compacting concrete. Constr. Build. Mater. 2013, 41, 665–672. [Google Scholar] [CrossRef]

- Najim, K.B.; Hall, M.R. Mechanical and dynamic properties of self-compacting crumb rubber modified concrete. Constr. Build. Mater. 2012, 27, 521–530. [Google Scholar] [CrossRef]

- Choudhary, S.; Chaudhary, S.; Jain, A.; Gupta, R. Assessment of effect of rubber tyre fiber on functionally graded concrete. Mater. Today Proc. 2020, 28, 1496–1502. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K. Hardened properties of concrete mixtures containing pre-coated crumb rubber and silica fume. J. Clean. Prod. 2014, 82, 125–131. [Google Scholar] [CrossRef]

- Xue, J.; Shinozuka, M. Rubberized concrete: A green structural material with enhanced energy-dissipation capability. Constr. Build. Mater. 2013, 42, 196–204. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Li, D.; Chen, Y.; Xiang, Z. Enhancement of Dynamic Damping in Eco-Friendly Railway Concrete Sleepers Using Waste-Tyre Crumb Rubber. Materials 2018, 11, 1169. [Google Scholar] [CrossRef]

- Liu, F.; Zheng, W.; Li, L.; Feng, W.; Ning, G. Mechanical and fatigue performance of rubber concrete. Constr. Build. Mater. 2013, 47, 711–719. [Google Scholar] [CrossRef]

- Issa, C.A.; Salem, G. Utilization of recycled crumb rubber as fine aggregates in concrete mix design. Constr. Build. Mater. 2013, 42, 48–52. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Tiamlom, K. Expansion under water and drying shrinkage of rubberised concrete mixed with crumb rubber with different size. Constr. Build. Mater. 2012, 29, 520–526. [Google Scholar] [CrossRef]

- Pelisser, F.; Zavarise, N.; Longo, T.A.; Bernardin, A.M. Concrete made with recycled tire rubber: Effect of alkaline activation and silica fume addition. J. Clean. Prod. 2011, 19, 757–763. [Google Scholar] [CrossRef]

- Khaloo, A.R.; Dehestani, M.; Rahmatabadi, P. Mechanical properties of concrete containing a high volume of tire–rubber particles. Waste Manag. 2008, 28, 2472–2482. [Google Scholar] [CrossRef] [PubMed]

- Balaha, M.; Badawy, A.; Hashish, M. Effect of Using Ground Waste Tire Rubber as Fine Aggregate on the Behaviour of Concrete Mixes. Indian J. Eng. Mater. Sci. 2007, 14, 6. [Google Scholar]

- Youssf, O.; ElGawady, M.A.; Mills, J.E.; Ma, X. An experimental investigation of crumb rubber concrete confined by fibre reinforced polymer tubes. Constr. Build. Mater. 2014, 53, 522–532. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F. Waste tyre rubberised concrete: Properties at fresh and hardened state. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Özturan, T. Properties of rubberised concretes containing silica fume. Cem. Concr. Res. 2004, 34, 2309–2317. [Google Scholar] [CrossRef]

- Ling, T.-C. Prediction of density and compressive strength for rubberised concrete blocks. Constr. Build. Mater. 2011, 25, 4303–4306. [Google Scholar] [CrossRef]

- AbdelAleem, B.H.; Hassan, A.A. Development of self-consolidating rubberised concrete incorporating silica fume. Constr. Build. Mater. 2018, 161, 389–397. [Google Scholar] [CrossRef]

- Medina, N.F.; Flores-Medina, D.; Hernández-Olivares, F. Influence of fibers partially coated with rubber from tire recycling as aggregate on the acoustical properties of rubberised concrete. Constr. Build. Mater. 2016, 129, 25–36. [Google Scholar] [CrossRef]

- Hilal, N.N. Hardened properties of self-compacting concrete with different crumb rubber size and content. Int. J. Sustain. Built Environ. 2017, 6, 191–206. [Google Scholar] [CrossRef]

- Khalil, E.; Abd-Elmohsen, M.; Anwar, A.M. Impact resistance of rubberised self-compacting concrete. Water Sci. 2015, 29, 45–53. [Google Scholar] [CrossRef]

- Gerges, N.N.; Issa, C.A.; Fawaz, S.A. Rubber concrete: Mechanical and dynamical properties. Case Stud. Constr. Mater. 2018, 9, e00184. [Google Scholar] [CrossRef]

- Bisht, K.; Ramana, P. Evaluation of mechanical and durability properties of crumb rubber concrete. Constr. Build. Mater. 2017, 155, 811–817. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Mechanical and durability properties of waste rubber fiber concrete with and without silica fume. J. Clean. Prod. 2016, 112, 702–711. [Google Scholar] [CrossRef]

- Naderpour, H.; Rafiean, A.H.; Fakharian, P. Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J. Build. Eng. 2018, 16, 213–219. [Google Scholar] [CrossRef]

- Dogan, E.; Ates, A.; Yilmaz, E.C.; Eren, B. Application of artificial neural networks to estimate wastewater treatment plant inlet biochemical oxygen demand. Environ. Prog. 2008, 27, 439–446. [Google Scholar] [CrossRef]

- Heaton, J. Introduction to the Math of Neural Networks (Beta-1); Heaton Research, Inc.: Chesterfield, MO, USA, 2011. [Google Scholar]

- Brownlee, J. Deep Learning for Time Series Forecasting: Predict the Future with MLPs, CNNs and LSTMs in Python; Machine Learning Mastery: Vermont, Australia, 2018. [Google Scholar]

- Tamura, S.I.; Tateishi, M. Capabilities of a four-layered feedforward neural network: Four layers versus three. IEEE Trans. Neural Netw. 1997, 8, 251–255. [Google Scholar] [CrossRef] [PubMed]

- Li, J.-Y.; Chow, T.W.; Yu, Y.-L. The estimation theory and optimisation algorithm for the number of hidden units in the higher-order feedforward neural network. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; pp. 1229–1233. [Google Scholar]

- Sheela, K.G.; Deepa, S.N. Review on methods to fix number of hidden neurons in neural networks. Math. Probl. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Atici, U. Prediction of the strength of mineral admixture concrete using multivariable regression analysis and an artificial neural network. Expert Syst. Appl. 2011, 38, 9609–9618. [Google Scholar] [CrossRef]

- Duan, Z.-H.; Kou, S.-C.; Poon, C.-S. Using artificial neural networks for predicting the elastic modulus of recycled aggregate concrete. Constr. Build. Mater. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- Bilim, C.; Atiş, C.D.; Tanyildizi, H.; Karahan, O. Predicting the compressive strength of ground granulated blast furnace slag concrete using artificial neural network. Adv. Eng. Softw. 2009, 40, 334–340. [Google Scholar] [CrossRef]

- Chou, J.-S.; Chiu, C.-K.; Farfoura, M.; Al-Taharwa, I. Optimising the prediction accuracy of concrete compressive strength based on a comparison of data-mining techniques. J. Comput. Civ. Eng. 2011, 25, 242–253. [Google Scholar] [CrossRef]

- Chithra, S.; Kumar, S.S.; Chinnaraju, K.; Ashmita, F.A. A comparative study on the compressive strength prediction models for High Performance Concrete containing nano silica and copper slag using regression analysis and Artificial Neural Networks. Constr. Build. Mater. 2016, 114, 528–535. [Google Scholar] [CrossRef]

- Dao, D.V.; Ly, H.-B.; Trinh, S.H.; Le, T.-T.; Pham, B.T. Artificial intelligence approaches for prediction of compressive strength of geopolymer concrete. Materials 2019, 12, 983. [Google Scholar] [CrossRef]

- Baghirli, O. Comparison of Lavenberg-Marquardt, Scaled Conjugate Gradient and Bayesian Regularisation Backpropagation Algorithms for Multistep Ahead Wind Speed Forecasting Using Multilayer Perceptron Feedforward Neural Network. Master’s Thesis, Uppsala University, Uppsala, Sweden, 2015. [Google Scholar]

- Levenberg, K. A method for the solution of certain nonlinear problems in least squares. Q. Appl. Math. 1944, 2, 164–168. [Google Scholar] [CrossRef]

- Marquardt, D.W. An algorithm for least-squares estimation of nonlinear parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Yue, Z.; Songzheng, Z.; Tianshi, L. Bayesian regularisation BP Neural Network model for predicting oil-gas drilling cost. In Proceedings of the 2011 International Conference on Business Management and Electronic Information, Guangzhou, China, 13–15 May 2011; pp. 483–487. [Google Scholar]

- Eren, B.; Yaqub, M.; Eyüpoğlu, V. Assessment of neural network training algorithms for the prediction of polymeric inclusion membranes efficiency. Sak. Üniversitesi Fen Bilimleri Enstitüsü Derg. 2016, 20, 533–542. [Google Scholar] [CrossRef][Green Version]

- Møller, M.F. A scaled conjugate gradient algorithm for fast supervised learning. Neural Netw. 1993, 6, 525–533. [Google Scholar] [CrossRef]

- Watrous, R.L. Learning Algorithms for Connectionist Networks: Applied Gradient Methods of Nonlinear Optimization; MIT Press: Cambridge, MA, USA, 1988. [Google Scholar]

- Kaewunruen, S.; Sussman, J.M.; Matsumoto, A. Grand challenges in transportation and transit systems. Front. Built Environ. 2016, 2. [Google Scholar] [CrossRef]

| Number | Representation |

|---|---|

| 1 | No special treatment |

| 2 | Pre-treated with NaOH |

| 3 | Pre-coated with limestone |

| Number | Representation |

|---|---|

| 1 | Portland Cement of Grade 32.5 |

| 2 | CEMI High Strength Portland Cement (52.5 MPa) |

| 3 | Ordinary Portland Cement grade 42.5 |

| 4 | ASTM C150 I (Ordinary Portland Cement Type I) |

| 5 | Portland Cement (42.5 MPa) |

| 6 | ASTM C150 II (Ordinary Portland Cement Type II) |

| 7 | AS 3972 for Type GB (Blended) cement |

| Data Set Size | Cement Type | Replacement by Rubber | Reference |

|---|---|---|---|

| 8 | 1 | 1%, 3%, 5%, 10%, 15%, 20% | [34] |

| 3 | 2 | 3%, 5%, 8% | [35] |

| 5 | 3 | 5%, 10%, 15%, 20%, 30% | [36] |

| 12 | 4 | 5%, 10%, 15%, 20% | [37] |

| 9 | 2 | 5%, 10%, 15% | [38] |

| 27 | 5 | 5%, 10%, 15%, 20%, 25%, 30% | [39] |

| 6 | 4 | 5%, 10%, 15% | [40] |

| 8 | 4 | 5%, 10%, 15%, 20% | [41] |

| 3 | 6 | 5%, 7.5%, 10% | [42] |

| 9 | 3 | 5%, 10%, 20% | [43] |

| 9 | 4 | 5%, 10%, 15% | [40] |

| 3 | 5 | 5%, 10%, 15% | [44] |

| 5 | 1 | 9%, 15%, 30%, 58.80%, 100% | [45] |

| 9 | 4 | 10%, 20%, 30% | [46] |

| 6 | 6 | 10% | [47] |

| 10 | 4 | 25%, 50%, 75%, 100% | [48] |

| 12 | 4 | 5%, 10%, 15%, 20% | [49] |

| 9 | 7 | 20% | [50] |

| 7 | 1 | 15%, 25%, 30%, 50%, 75%, | [51] |

| 48 | 4 | 2.5%, 5%, 10%, 15%, 25%, 50% | [52] |

| 24 | 1 | 5%, 10%, 15%, 25%, 30%, 40%, 50% | [53] |

| 9 | 1 | 10%, 20%, 30% | [46] |

| 11 | 4 | 5%, 10%, 15%, 20%, 40% | [54] |

| 5 | 4 | 5%, 10%, 15%, 20%, 30% | [6] |

| 5 | 5 | 20%, 40%, 60%, 80%, 100% | [55] |

| 15 | 5 | 5%, 10%, 15%, 20%, 25% | [56] |

| 4 | 4 | 10%, 20%, 30%, 40% | [57] |

| 16 | 4 | 5%, 10%, 15%, 20% | [58] |

| 4 | 3 | 4%, 4.5%, 5%, 5.5% | [59] |

| 53 | 4 | 5%, 10%, 15%, 20%, 25% | [60] |

| Parameter | Unit | Minimum | Maximum |

|---|---|---|---|

| RR | (%) | 1.00 | 100.00 |

| PSR | (mm) | 0.00 | 21.50 |

| FA | (kg/m3) | 0.00 | 1116.00 |

| MCFA | (%) | 1.00 | 9.00 |

| PSFA | (mm) | 2.00 | 5.00 |

| R | (kg/m3) | 9.00 | 549.00 |

| PR | |||

| C | (kg/m3) | 280.00 | 540.00 |

| CT | |||

| W | (kg/m3) | 115.00 | 453.00 |

| WRM | (kg/m3) | 0.00 | 15.00 |

| SG | (kg/m3) | 0.00 | 165.00 |

| FA | (kg/m3) | 0.00 | 156.00 |

| SF | (kg/m3) | 0.00 | 362.80 |

| CA | (kg/m3) | 0.00 | 1493.00 |

| CAPS | (mm) | 6.00 | 20.00 |

| WCR | 0.25 | 0.70 | |

| CS28 | (N/mm2) | 0.37 | 79.10 |

| CS7 | (N/mm2) | 0.20 | 48.30 |

| FS | (N/mm2) | 0.04 | 10.65 |

| STS | (N/mm2) | 0.15 | 14.80 |

| EM | (kN/mm2) | 1.10 | 40.90 |

| ANN Architecture | Output | Statistical Index | Ref |

|---|---|---|---|

| (2-5)-(4-6)-1 | Compressive strength | R, MSE | [68] |

| 16-40-1 | Elastic modulus | R2, RMSE, MAPE | [69] |

| 8-9-8-2 | Tensile strength | RMSE, R2, MAPE | [32] |

| 6-15-1 | Compressive strength | R2 | [70] |

| 8-17-17-17-1 1 | Compressive strength | R2, RMSE, MAPE | [71] |

| 6-10-1 | Compressive strength | R, R2, RMSE, MAPE | [72] |

| 4-5-1 | Compressive strength | R2, RMSE, MAE | [73] |

| Parameter | Value |

|---|---|

| Training function | LM, BR, SCG |

| Hidden layer | 1;2 |

| Hidden neurons | 1,5,10,15,20,25,30 |

| Epochs | 1000 |

| Performance evaluation | MSE, |

| Transfer function | Tansig 1 |

| Performance goal | 0 |

| Predicted Mechanical Properties | MLR | ANN (LM-17-10-10-5) |

|---|---|---|

| CS7 | 0.660 | 0.9552 |

| CS28 | 0.673 | 0.9641 |

| FS | 0.601 | 0.8493 |

| STS | 0.460 | 0.6545 |

| EM | 0.773 | 0.9576 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Zhang, J.; Sresakoolchai, J.; Kaewunruen, S. Machine Learning Aided Design and Prediction of Environmentally Friendly Rubberised Concrete. Sustainability 2021, 13, 1691. https://doi.org/10.3390/su13041691

Huang X, Zhang J, Sresakoolchai J, Kaewunruen S. Machine Learning Aided Design and Prediction of Environmentally Friendly Rubberised Concrete. Sustainability. 2021; 13(4):1691. https://doi.org/10.3390/su13041691

Chicago/Turabian StyleHuang, Xu, Jiaqi Zhang, Jessada Sresakoolchai, and Sakdirat Kaewunruen. 2021. "Machine Learning Aided Design and Prediction of Environmentally Friendly Rubberised Concrete" Sustainability 13, no. 4: 1691. https://doi.org/10.3390/su13041691

APA StyleHuang, X., Zhang, J., Sresakoolchai, J., & Kaewunruen, S. (2021). Machine Learning Aided Design and Prediction of Environmentally Friendly Rubberised Concrete. Sustainability, 13(4), 1691. https://doi.org/10.3390/su13041691