1. Introduction

Increasing population, urbanization, and living standards have become major environmental challenges to the sustainable management of municipal solid waste (MSW), which affects people worldwide [

1]. The latest World Bank report states that 2.01 billion tons of MSW are generated globally each year, and this value is predicted to reach 3.4 billion tons by 2025 [

2,

3]. Appropriate MSW management is therefore a crucial matter not only for environmental and human health concerns but also in terms of remaining a step ahead with regard to waste sustainability and circular economy [

4,

5].

Landfilling is by far the most common waste disposal method adopted worldwide because of its easy execution and low operation expenditures [

6]. However, leachate leaks are inevitable and can contaminate the surface water, groundwater, and soil [

7]. Moreover, CH

4 generated through the decomposition of organic matter in landfills accounts for the third largest anthropogenic source of global CH

4 emissions, which are strongly positively correlated with climate change [

8]. Composting is a viable alternative to landfilling because the decomposed organic portions of MSW can improve soil properties through compost applications, help to avoid manufactured mineral fertilizer treatments, and achieve environmental and economic benefits. Even though, incineration offers advantages with regard to land consumption and energy recovery, its application remains in its infancy in developing countries due to high construction and operation costs and professional management needs [

9,

10]. MSW management strategies using single or integrated approaches normally depend on the individual situations. Life cycle assessment (LCA) and life cycle cost (LCC) are used to systematically evaluate the environmental and economic feasibility and identify optimal MSW management strategies.

LCA and/or LCC have been widely applied to compare alternative MSW management approaches and/or to analyze existing management policies in terms of environmental and economic sustainability [

8]. Some previous studies focused on the potential of incineration to replace landfills in the form of mixed MSW management [

11,

12]. Organic matter separation, such as food waste (FW), has also been suggested for digestion or composting, and the remaining MSW is incinerated or landfilled [

3,

10]. The integration of MSW management with sewage treatment is also considered feasible where FW is treated with sewage at a sewage treatment plant [

13,

14] or co-digested with sewage sludge for resource recovery [

15]. These studies were mainly conducted using current MSW data, in which the optimal MSW management strategies were only accessed from the current situation. However, the purpose of an MSW management strategy is to analyze and determine policies for use in the following decades or beyond. The total generated MSW increases with growth in the population, urbanization, and living standards, and MSW compositions also tend to change. The increased amount of MSW will influence the use of current treatment works, such as decreasing the landfill lifespan and requiring alternative treatment facilities. The use of current treatment facilities to the ends of their lifespans or the direct switching from current to alternative facilities is the key issue to be considered. Additionally, the proportion of FW (organic matters) in MSW decreases with increasing urbanization and living standards, which supports the application of incineration [

16]. Variations in the generation of MSW affect the uses of the current and proposed waste treatment facilities; therefore, the best MSW management plan based on the current situation may not be the most feasible option when considering the numerous interlinked factors that will affect MSW management strategies in the future. Previous studies have not yet considered the dynamic nature of MSW generation and the interactions between major variables that affect the environmental and economic sustainability of MSW management over the long term.

System dynamics (SD), which was originated by Forrester [

17], is defined to address large-scale and complex systems and understand the inter-relationships between behaviors within a specific system over time and the underlying structure and decision rules [

18]. SD models have been used to forecast MSW generation and plan sustainable MSW management schemes by qualifying the aspects of MSW separation and recycling at the source [

19] from the costs of produced and disposed MSW [

20]. SD has been used to simulate changes in the amounts of MSW under different policies by determining the dynamic interactions in the MSW management process [

21]. The comparison of reviewed publications is listed in

Table 1. The total MSW generation and composition are influenced by variables that are interlinked within social and economic activities, and these affect feasible disposal approaches using the SD model and influence environmental and economic sustainability. However, the mechanisms by which dynamic interactions influence economic and environmental sustainability in MSW management remain poorly understood. To address this issue, SD is used here to forecast the generation and composition of MSW, identify the long-term interactions between various activities, and evaluate the environmental and economic performance based on various activities using LCA/LCC models. To the best of our knowledge, this is the first study to analyze the environmental and economic sustainability of MSW management strategies involving dynamic interactions among various activities over time.

The newly developed LCC/LCA + SD model was conducted for MSW management in the South Tai Lake Watershed (STLW) in China. The current MSW strategy in the STLW includes 50% incineration, 40% landfilling, and 10% composting for use in land applications. To identify more sustainable MSW management strategies, five alternative scenarios are proposed to consider the optimal use of the current MSW treatment facilities. The environmental and economic sustainability of the proposed scenarios were evaluated using LCA and LCC approaches that involve the dynamic interactions of various activities affecting MSW generation and composition in an SD model between 2007 and 2030. This study provides new insights for policymakers regarding the optimal MSW management scenarios that involve dynamic interactions among social activities in the future.

3. Results and Discussion

3.1. Predicted MSW Generation (2020–2030)

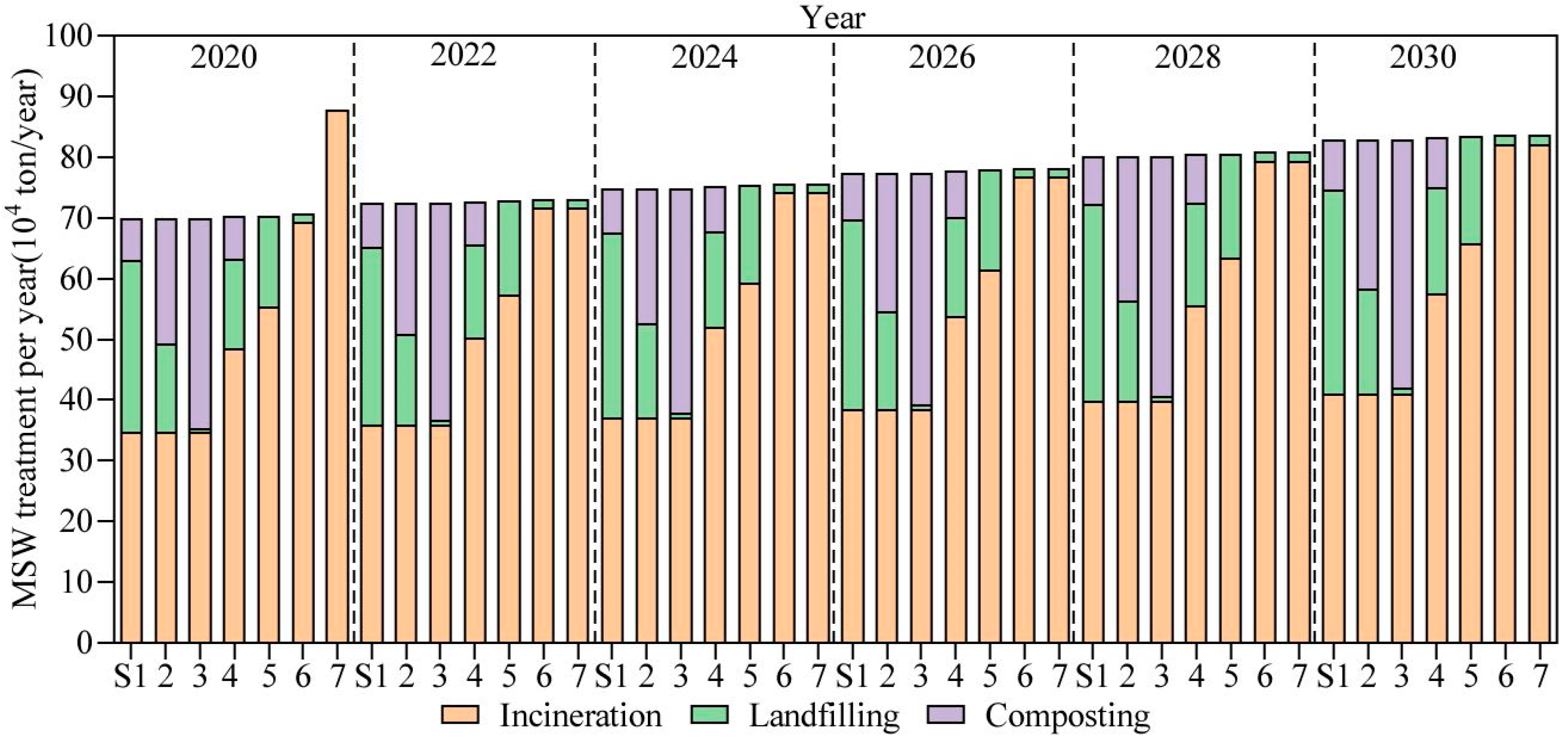

As shown in

Figure 4, the total amount of MSW increases from 701,540 tons in 2020 to 831,450 tons in 2030, with an annual increase of 1.7%. There is an exception in S7 in 2020, because the undecomposed waste in existing landfill is co-processed with fresh MSW at an incineration plant in 2020. The increase from 2020 to 2030 is positively interlinked with the increase in the population growth and living standard, and the total MSW generation is proportional to the population and MSW per capita. Improved public environmental awareness decreases total MSW generation and enhances MSW recycling and reduction. Although public environmental awareness increases with urbanization, the total generated MSW also increases annually, as predicted for the next decade in

Table 3. The proportion of FW decreases annually from 62.63% in 2019 to 58.74% in 2030, consistent with other studies that showed that urbanization growth decreases the proportion of FW in the total generated MSW [

16]. The contributions from paper, wood, textiles, garments, and glass increase annually. Variations in the MSW composition may influence the sustainability of MSW management. For instance, moisture contained within FW consumes more energy during self-incineration, as the water content must be reduced, and this inevitably reduces the energy recovery efficiency and ultimately decreases the environmental and economic sustainability. Urbanization of the STLW, therefore, decreases the FW proportion of the total MSW, which facilitates the improvement of MSW management using incineration.

3.2. Remaining Landfill Capacity

The remaining landfill capacity is affected by the amount of MSW disposed in the landfill. The current landfill space for the STLW was reported to be 7.7 × 10

5 m

3 in 2019 [

24], and the space used for the disposed MSW accounted for 118.65 kg MSW/m

3 [

36]. The remaining landfill capacity was calculated considering dynamic influences using the SD model from 2019 to 2030, as shown in

Figure 5.

The remaining landfill capacity decreases slightly in S4, S6, and S7, and significantly in S1–S3 and S5. For the current MSW strategy in the STLW (S1), the existing landfill will be completely depleted by 2022, and a new landfill site should be built to accept more MSW after this time. Planning for a new landfill site should therefore be put on the agenda as soon as possible. Using the current MSW strategy in the STLW for the next decade, a landfill site with a capacity of at least 2.2 × 10

6 m

3 will be required in 2030, and this will compete with the increasing space demands for residential and commercial development. To alleviate this space occupation stress, alternative strategies (S2–S7) are recommended. Of these, S7 uses the least space with 7 × 10

5 m

3 because the landfilled waste in landfill is co-processed with fresh MSW at incineration plant, thus, it saves more space than other scenarios. In S4 and S6, the remaining land space in 2020 was 5 × 10

5 m

3, and there is sufficient space for residual incineration ash over the next decade when using scenarios S4, S6, and S7. In S2, S3, and S5, the current landfill will be completely depleted in 2024, and a new landfill site with a capacity of 8 × 10

5 m

3 will be needed in 2030. However, space occupation is not the only criteria used to evaluate the optimal MSW management strategies. Incineration will also introduce high construction and operational costs, as well as tail gas treatment [

6], and composting recovers less energy than incineration and landfilling. The comprehensive evaluation is explained in the following sections.

3.3. Environmental Impacts of GHG and Energy

3.3.1. GHG Emissions

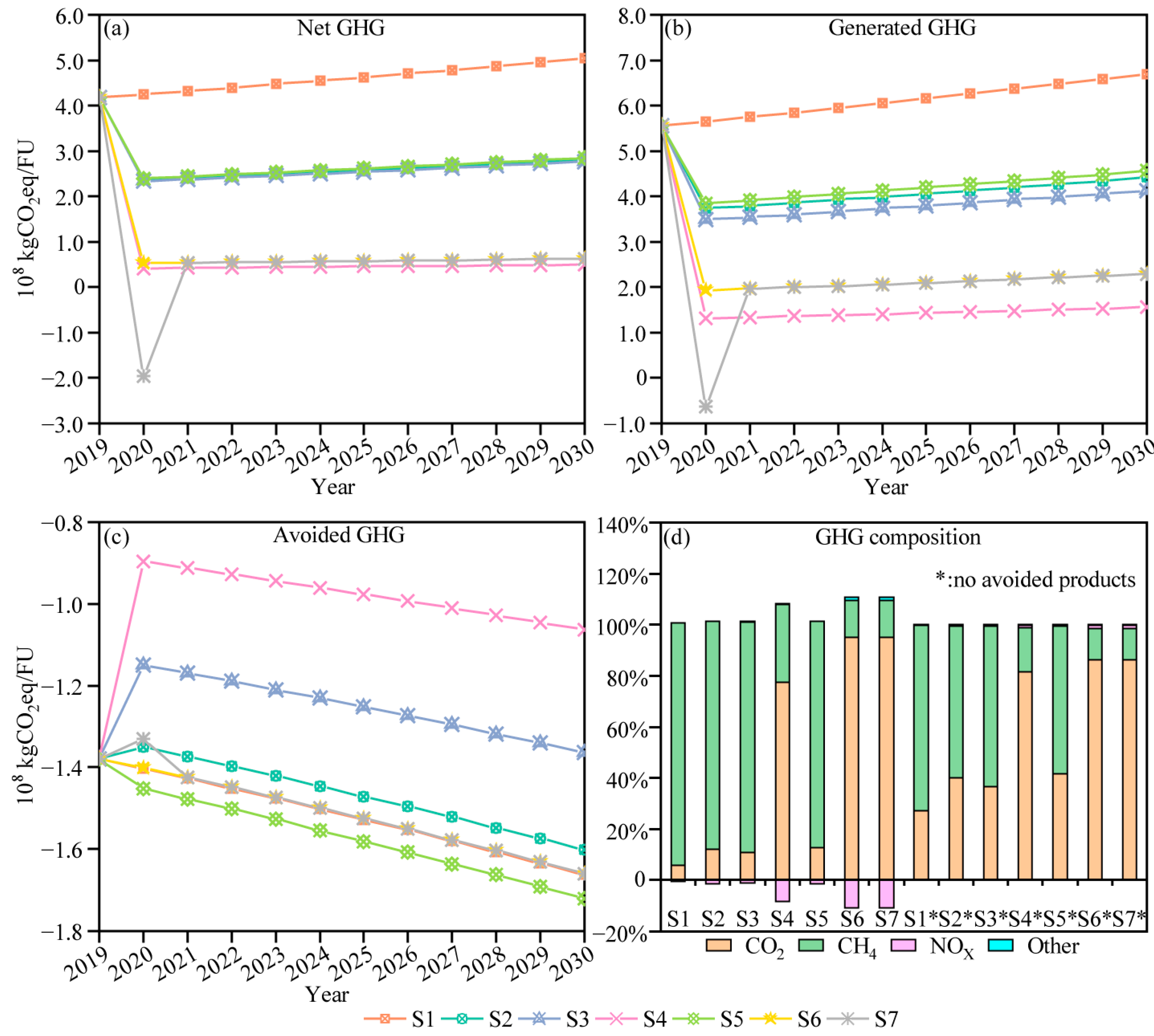

The GHG emissions and composition are illustrated in

Figure 6. The current MSW management strategy, S1, generates the highest net GHG emissions at a trend that will continue from 2020 to 2030. There are two main reasons for the higher net GHG emissions from S1. First, the GHG generated using S1 is higher than the emissions generated using the other alternatives because it is mainly derived from CH

4 produced by organic matter decomposition, which accounts for more than 90% of the total GHG generation (

Figure 6d). The CH

4 collection efficiency in landfills is 40%, and the remaining 60% of CH

4 is emitted into atmosphere, resulting in high GHG emissions. Second, the avoided GHG is the second lowest among the proposed alternatives because 40% of the MSW is landfilled, which produces less energy than incineration (

Figure 6c) [

11]. The high net GHG emissions indicate the need to seek alternative management strategies.

Among the alternatives, S7 produces the lowest net GHG emissions in 2020, after that S7 performs the same as S4 and S6. The net GHG emissions remain stable from 2021 to 2030, which mainly results from the minimal GHG generation (

Figure 6b). Incineration and/or composting are the main MSW disposal approaches in S4, S6, and S7, and these generate less CH

4 than landfilling. GHG from composting is emitted for land applications as fertilizer, where most of the carbon is converted to CO

2 and released into the air [

37]. However, 0.05% of carbon in the composter is emitted as CH

4 [

38], and the emitted CH

4 from composting is higher than that from incineration (

Figure 6d). The time frame is also considered for the GHG emission generated on the land based on the total time and carbon content in the fertilizer. More GHG is avoided in S7 and S6 than S4 due to higher energy recovery in the incineration process than in composting [

3]. The net GHG emissions for S4, S6, and S7 are stable, at approximately 5 × 10

7 kg CO

2 eq/FU from 2021 to 2030. Even though the generated GHG increases from 2019 to 2030 (

Figure 6b), the avoided GHG also increases (

Figure 6c), which results in relatively steady net GHG emissions over time.

The net GHG emissions from S2, S3, and S5 are similar; the net GHG emission performances of these strategies are better than that of S1 but worse than those of S4 and S6. The GHG emissions are highly associated with landfilling, rather than incineration or compositing [

3]. A higher proportion of MSW disposal in the landfill would therefore produce higher GHG emissions. In S2, S3, and S5, 20% of the MSW is landfilled; this is 40% less than in S1 and 20% higher than in S4 and S6, which do not use landfilling. The results in

Figure 6a–c indicate that the current MSW management strategy is not favorable in terms of GHG emissions, whereas S4 and S6 produce the lowest GHG emissions.

3.3.2. Energy Consumption Performance

The simulated energy consumption with dynamic behavior over the next decade is shown in

Figure 7. The net energy balance demonstrates that the current MSW management yields the worst performance. Although the net energy balance of S1 performs slightly better over time, its performance remains worse than that of the other scenarios, mainly because of the low energy recovery in S1. The recovered energy from S1 is 3.3 × 10

9 MJ/FU in 2020 and increases to 3.8 × 10

9 MJ/FU in 2030, which is less than the other alternatives. Even though the energy consumption is not the highest in S1, its low energy recovery results in the worst performance in terms of the net energy balance. In this context, the alternatives with higher energy recoveries and lower energy consumption are recommended.

Among the alternatives, S7 yields the best performance. Regarding energy consumption, S7 uses the most energy with 3.3 × 10

9 MJ/FU in 2020 because it incinerated both undecomposed landfilled waste and fresh waste in 2020. In 2021, the consumed energy for S7 is sharply decreased and increased again to 3.3 × 10

9 MJ/FU in 2030 in

Figure 7b. The performance of S7 is the same as that of S6 during 2021 to 2030. The higher energy consumption is used for drying processes to reduce moisture content. The optimum moisture content of MSW for self-incineration is 15% [

39], and additional energy is needed to reduce the moisture from approximately 57% (

Table S5) to the required 15%. Even though the energy consumption is high in S6 and S7, the gained energy totally recovers this consumption, and the surplus can be exported to the public electricity network. Other studies have reported that approximately five times more energy is gained than consumed by incineration [

3]. The variable ratio for energy recovery and consumption is due to different system boundaries and MSW compositions. For instance, excluding transportation from the system boundary and a lower FW proportion in the MSW will increase the energy recovery efficiency. The advantage of incineration in terms of energy recovery increases over time, from −2.5 × 10

9 MJ/FU in 2021 to −2.9 × 10

9 MJ/FU in 2030.

The net energy balances of S2–S5 are in the medium range, as illustrated in

Figure 7a. Besides incineration, MSW is also disposed in landfills or used for composting, which recover less energy than MSW via incineration alone. S4 produces the lowest GHG emissions; however, the net energy balance is not optimal (

Figure 6a). Because 50% of the MSW is composted and the rest is incinerated, the energy recovery of S4 is less than that of the fully incinerated approach in S6 and S7. Overall, the environmental impacts of GHG emissions and energy consumption indicate that the current MSW management strategy S1 generates the most GHG and gains the least net energy, making it environmentally unsustainable. The alternative S7 is recommended. Replacing S1 with S7 will reduce the GHG emissions to 6.1 × 10

8 kg CO

2 eq/FU in 2020, and the reduction will progress to 4.5 × 10

8 kg CO

2 eq/FU in 2030. Considering the energy balance, using S7 will provide 3.2 × 10

9 MJ/FU of surplus energy to the public electricity network in 2020 and 2.9 × 10

9 MJ/FU of surplus energy in 2030. In 2008, the energy consumed for residential purposes was 1.13 × 10

10 MJ in the STLW [

22], and this is expected to increase to 1.19 × 10

10 MJ in 2020 and 1.84 × 10

10 MJ in 2030. The recovered energy from S6 can support 27% and 16% of the energy used for residential needs in 2020 and 2030, respectively, which would significantly relieve the energy stress in competition with industrial demand.

3.4. Economic Impacts

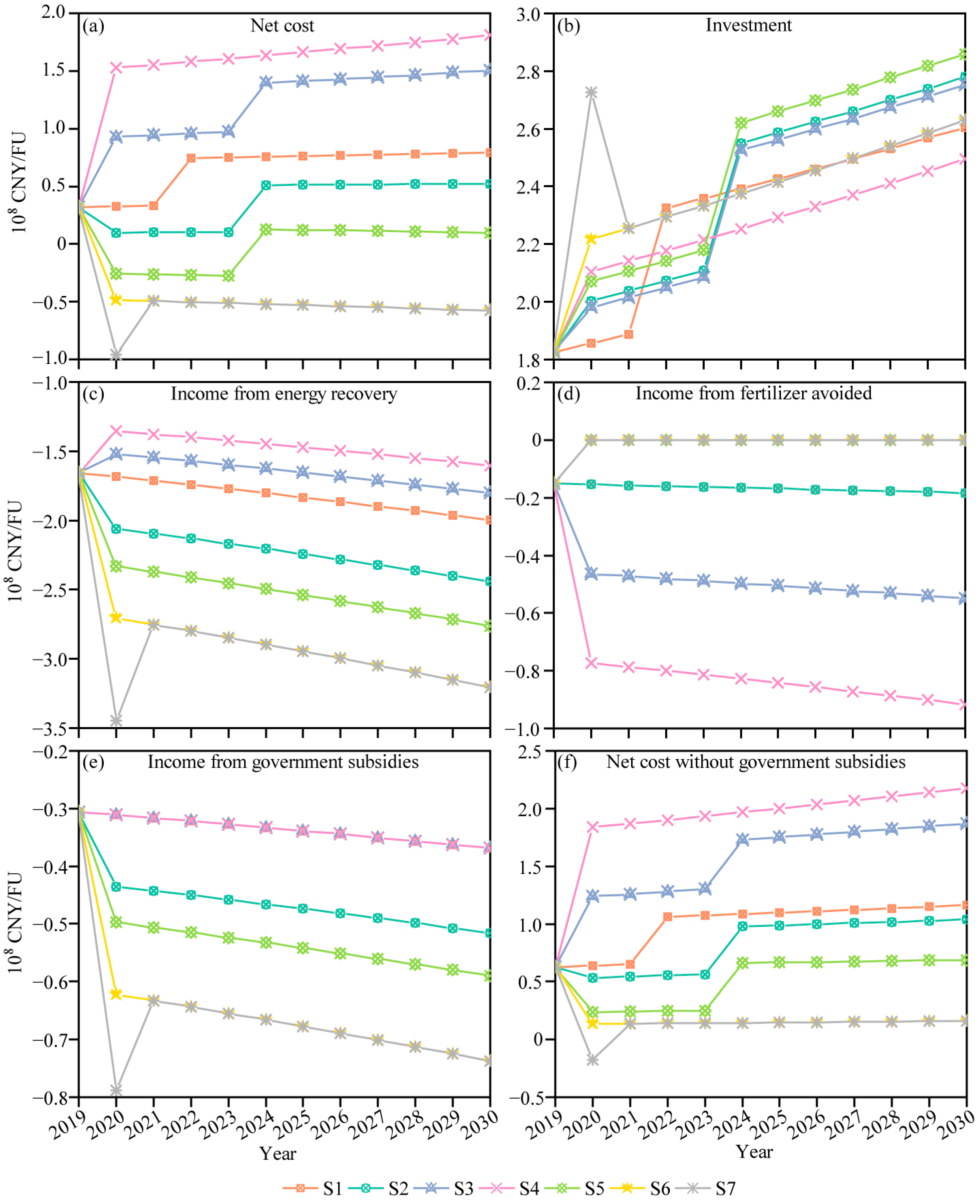

Simulations of the economic impacts of S1–S7 are illustrated in

Figure 8. For the net cost (

Figure 8a), the current MSW management strategy, S1, receives a median ranking. A sharp increase is observed in 2022 because the remaining landfill capacity will be depleted, and additional investments will be required for the design, construction, and purchase of new facilities for the new landfill site. The net cost for S1 therefore increases from 0.38 × 10

8 CNY/FU in 2020 to 0.9 × 10

8 CNY/FU in 2022. The investment required to build a new landfill in S1 significantly increases to 2.36 × 10

8 CNY/FU in 2022. S1 can obtain benefits from selling surplus energy to the electricity network (

Figure 8c), avoiding fertilizer (

Figure 8d), and using government surpluses to support the incineration applications (

Figure 8e). However, this income does not overcome the investment required to build a new landfill site.

S7 performs the best among the alternatives with regard to net cost in 2020, and S7 performs the same as S6 between 2021 to 2030 (

Figure 8a). The advantages of S6 and S7 are mostly attributed to the low investment and the achievement of the highest incomes from energy recovery (

Figure 8c) and government subsidies (

Figure 8e). In the STLW, government subsidies are provided at 90 CNY/ton MSW to facilitate incineration. These government subsidies are external costs that can be changed or canceled according to government policy. S7 economically remains the most attractive scenario, even in the worst-case scenario involving canceled government subsidies (

Figure 8f). S7 can obtain benefits of 1.0 × 10

8 CNY/FU in 2020. Between 2021 to 2030, S6 and S7 can save around 5.0 × 10

7 CNY/FU per year with government subsidies (

Figure 8a) and 1.0 × 10

7 CNY/FU per year without government subsidies (

Figure 8f).

S2 and S5 are also more economically attractive than S1 (

Figure 8a) under similar investment conditions. However, S2 and S5 benefit from exporting recovered energy to the electricity network at rates of 2.1–2.4 × 10

8 CNY/FU and 2.3–2.8 × 10

8 CNY/FU between 2020 and 2030 for S2 and S5, respectively. S2 also obtains approximately 2.3–2.4 × 10

7 CNY/FU from fertilizer avoidance between 2020 and 2030, and another 4.4–5.1 × 10

7 CNY/FU from government subsidies. S5 obtains 5.0–6.0 × 10

7 CNY/FU from government subsidies over this time period. S3 and S4 are more expensive than S1 because these generate less income from energy recovery (

Figure 8c).

These economic findings are in contrast with some previous studies, which determined that landfills with recycling are the most economic MSW management strategy [

40] or that integrated MSW management with landfills and anaerobic digestion is the most economic [

41]. Others suggested an integrated MSW management system involving landfills, composting, and incineration as the most economic scenario [

42]. The economic performances of the proposed MSW management schemes strongly depend on the expenditures of disposal options under their specific situations. In the STLW, the construction and operation expenditures for incineration are low, and government subsidies support the installation of incineration plants. In countries with high costs to install and operate incineration plants, such high investment expenditures would impede the application of this approach [

9].

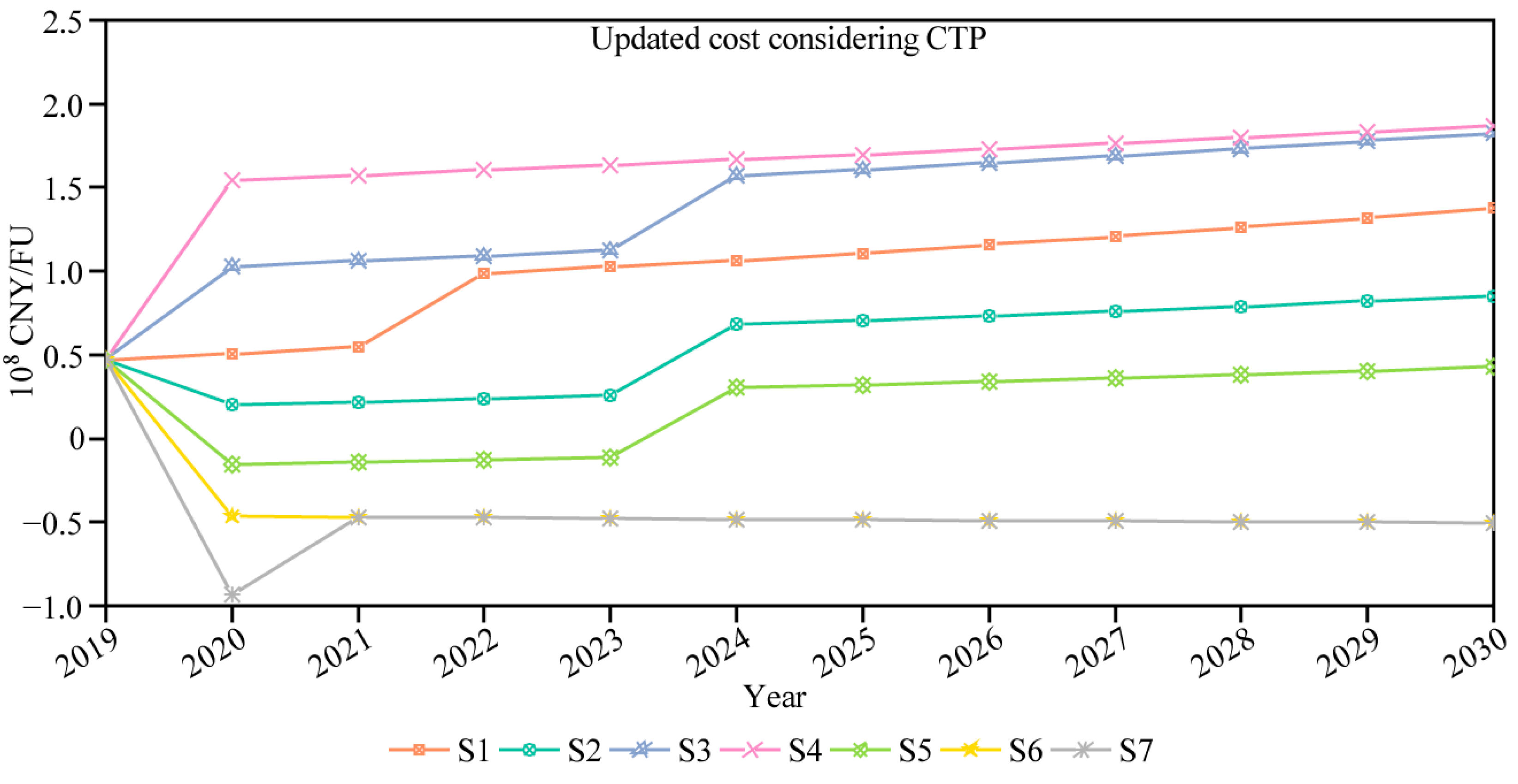

3.5. Cost with Carbon Trading Price

GHG emissions presently affect human safety and the environment and will continue to do so in the future. Carbon pricing is a method that quantifies the external costs of GHG emissions and ties these to their sources through a unit price. The carbon trading price (CTP) helps to shift the burden of GHG emissions back on those who generate them to achieve the most flexible and cost-effective approach for societies. Therefore, the CTP in China was incorporated in the calculations to evaluate the economic impacts. The influence of CTP was assessed at rates of 30 CNY/ton CO

2 in 2020, 75 CNY/ton CO

2 in 2025, and 115 CNY/ton CO

2 in 2030 [

43], and linear interpolation was used to estimate the CTP for the remaining years. S6 remains the most economic scenario (

Figure 9). When considering CTP, the advantages of S7 are more than the private cost without CTP (

Figure 8a) because less GHG is generated from S1 than from other scenarios. As time progresses from 2021 to 2030, S6 and S7 are the two scenarios in which benefits are increased, whereas S1–S5 obtain fewer benefits or generate increased expenses over time. The CTP is expected to increase in the future. A 50–100 US

$/ton CTP has been proposed to achieve the temperature goal of the Paris Agreement [

44]. S6 will achieve more benefits at this value than the other scenarios because it produces less GHG.

3.6. Environmental and Economic Impacts by Increasing Recycling Ratios

The environmental and economic impacts were varied by increasing the recycling ratios predicted for 2030, as shown in

Figure 10. The recycling process only takes into account items that can be recycled (e.g., paper, plastic, metal, textiles, glass) and excludes putrescible materials. The results show that the GHG emissions decrease and expenditures are saved with increasing recycling ratios. However, this approach also reduces the energy recovery. The current recycling ratio in the STLW is only 8%, which is substantially lower than that for developed countries, including 20% in Japan, 26% in the USA, 27% in the UK, and 28% in Australia [

45]. Approximately 16% of the GHG emissions or expenditures can be reduced or saved, respectively, if the recycling ratio is increased to 20% as in Japan. Even though less energy will be recovered, the energy is considered in transition and is ultimately expressed by the improved performance in GHG or the net cost when raising the recycling ratio. If the recycling ratio is increased to 28%, as in Australia, another 21% of GHG and expenditures will be reduced or saved, respectively.

Nevertheless, it is challenging for the STLW to increase the recycling ratio to as high a rate as that in Australia, and more efforts should be made to increase environmental awareness among the public. Education and economic penalties are approaches that encourage the public to participate in waste separation and recycling [

21], and these will obtain both environmental and economic gains in regions with limited resources and economic problems, especially in developing countries. However, long-term efforts are required to achieve these goals.

3.7. Perturbation Analysis

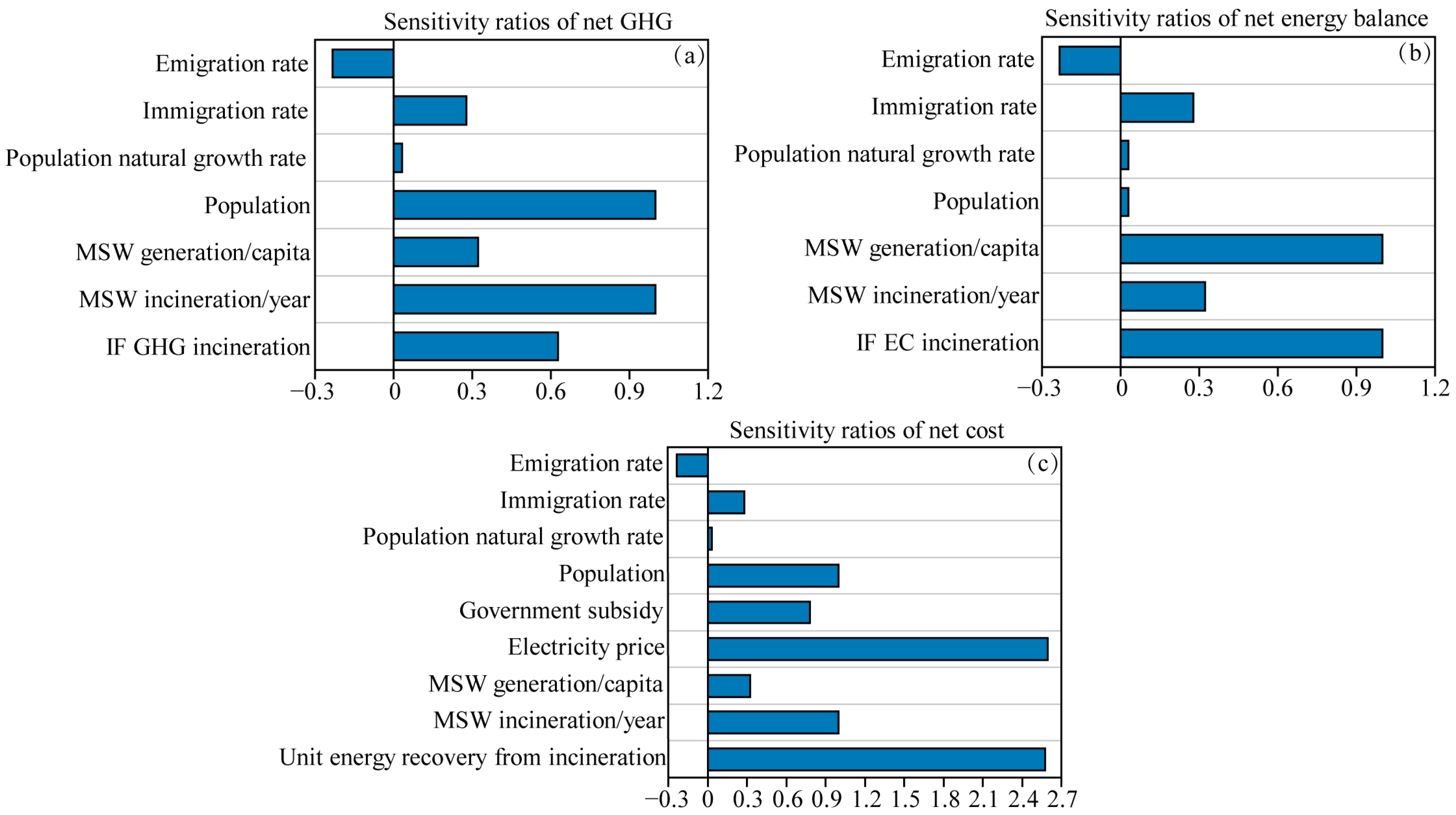

Perturbation analysis is conducted to examine the sensitivity of the selected parameters related to the SD model. Sensitivity ratio (SR) represents the ratio of relative changes in the results to relative changes in the parameters [

3].

Figure 11a indicates the most sensitive parameters for GHG are population and amount of MSW incineration/year with the same SR of 1.0. The amount of MSW generation/capita and impact factor of energy consumption (IF EC) in incineration also indicate an SR of 1.0 for net energy balance in

Figure 11b. Meanwhile,

Figure 11c indicates that electricity price and energy recovery in incineration are the most sensitive with the same SR of 2.5 for net cost, followed by population and amount of MSW incineration with the same SR of 1.0. These sensitive parameters illustrate that they will significantly influence the final results and should be carefully taken into account in the MSW management works.

3.8. Perspectives

This study comprehensively evaluates the GHG, energy, and economic performances of alternative MSW management strategies by considering the interactions between social variables from 2020 to 2030 in the STLW. The results show that the current MSW management strategy (S1) is less favorable than the alternatives. Additionally, the current landfill capacity will be depleted in 2022 and a new landfill site with a capacity of 2.2 × 106 m3 will be required if the landfill is still relied upon in 2030, and this will inevitably be in high land competition with the commercial and residential sectors. More importantly, landfilling deteriorates the environment by generating more GHG, consuming more energy, and requiring more expenditures than the other alternatives.

In contrast, co-processing the landfilled waste with fresh MSW at incineration plants (S7) has the potential to resolve these problems. After incineration, the residual ash accounts for only 2% of the MSW, which significantly extends the landfill lifespan. Incineration also generates the lowest GHG emissions, with a reduction of up to 90% compared with landfilling. In terms of the energy balance, S7 can generate surplus energy of 3.2 × 10

9 MJ in 2020 and 2.9 × 10

9 MJ in 2030, or approximately twice the amount of surplus energy as S1 during 2021 to 2030. In terms of expenditure, S7 obtains the most benefits by exporting surplus energy to the electricity network and from government subsidies. Considering the CTP proposed for the future, the S7 yields the greatest economic benefits. Incineration also avoids the adverse effects of leachate generation. Even in a well-managed landfill, 5–10% of the leachate remains uncollected [

46,

47], and the contaminants (e.g., toxic metal, unbiodegradable organics) can pollute the soil and ultimately enter the aquatic environment. The circular economy and re-integration of by-products from MSW is considered as the eco-friendly strategy to enhance MSW management [

48,

49].

However, there are several limitations to the SD model integrated with GHG, energy, and economic analysis used in this study. The first limitation lies in the charges for MSW generation collected by households in the STLW, which cannot facilitate a reduction in the residential MSW generation. The more effective approach is to charge the MSW generation per capita; however, the model does not effectively reflect this issue. Second, the techniques used in this study follow the current disposal technics in the STLW. The development of new techniques will allow the current facilities to be upgraded, for example, to improve energy conversion efficiency. These advances cannot be predicted in the current SD model and are beyond the scope of this study. Third, only GHG and energy consumption are considered here, and other impacts with adverse effects on the environment and human health, such as particulate matter, ozone depletion, and acidification, should be considered in future studies to obtain a more comprehensive environmental evaluation. Overall, the combination of SD and the LCC/LCA analysis reveals the interactions between social activities to predict the MSW generation and composition over the upcoming decades, and the changes in MSW generation are evaluated using environmental and economic assessments to determine the optimal MSW management strategy. However, such limitations should not be overlooked in future studies.

4. Conclusions

This study used interlinked SD to evaluate the optimal MSW management strategy for GHG production and energy and economic performance from 2020 to 2030 in the STLW. The results indicate that, using the current MSW management strategy (S1), the landfill capacity will be depleted in 2022, and a new landfill site will be required. S1 also generates the most GHG, consumes the most energy, and requires the highest expenditure, and all these variables will increase from 2020 to 2030. S7, which co-processes the undecomposed waste in existing landfill with fresh MSW at incineration plant, performs best among the proposed scenarios. Compared to S1, the implementation of S7 saves 2.5 × 105 and 3.0 × 106 m3 greater space, reduces 6.1 × 108 and 4.5 × 108 kg CO2 eq/FU more GHG, recovers 1.8 × 109 and 1.0 × 109 MJ/FU more energy, and benefits 1.4 × 108 and 1.1 × 108 CNY/FU in cost in 2020 and 2030, respectively. Considering future carbon trading price, S7 benefits even more in terms of GHG, energy, and cost. Moreover, the advantages of S7 increase steadily from 2021 to 2030. S6 is the second-best scenario, which performs as well as S7 between 2021 to 2030. Perturbation analysis identified that the most sensitive factors are population size, MSW generation per capita, GHG/energy recovery in incineration, and electricity price. These parameters should get careful attention when performing GHG, energy, and cost evaluation. This study provides new insights regarding the involvement of social activity via SD and evaluates the sustainability of MSW management practices in the future.