Energy Efficiency Measurement: A VO TFEE Approach and Its Application

Abstract

1. Introduction

2. Literature Review

2.1. Energy Intensity

2.2. The Existing TFEE

3. Materials and Methods

3.1. SBM with Undesirable Output

3.2. The VO TFEE Approach to Measuring Energy Efficiency

4. Empirical Results and Comparisons

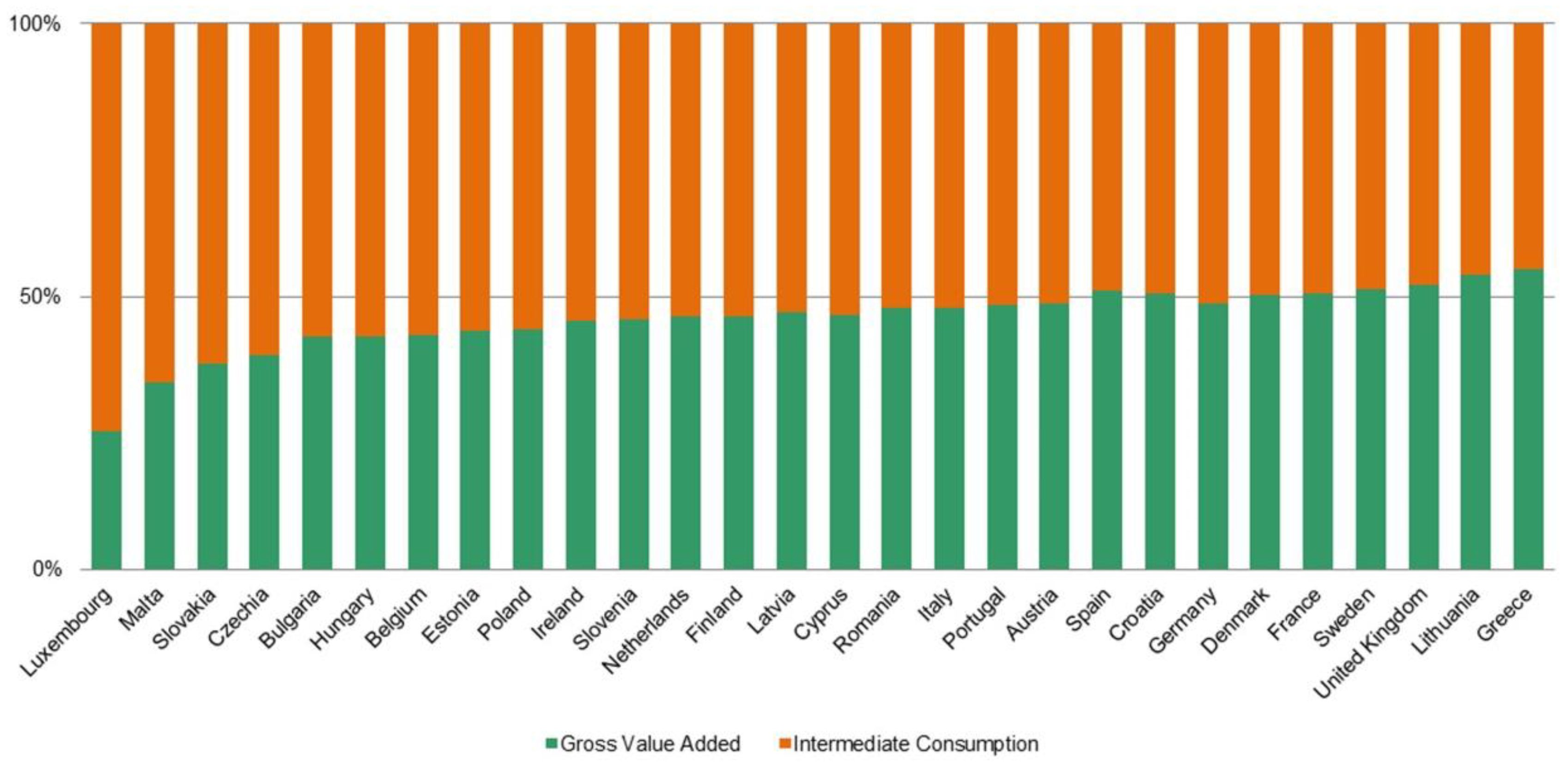

4.1. Data

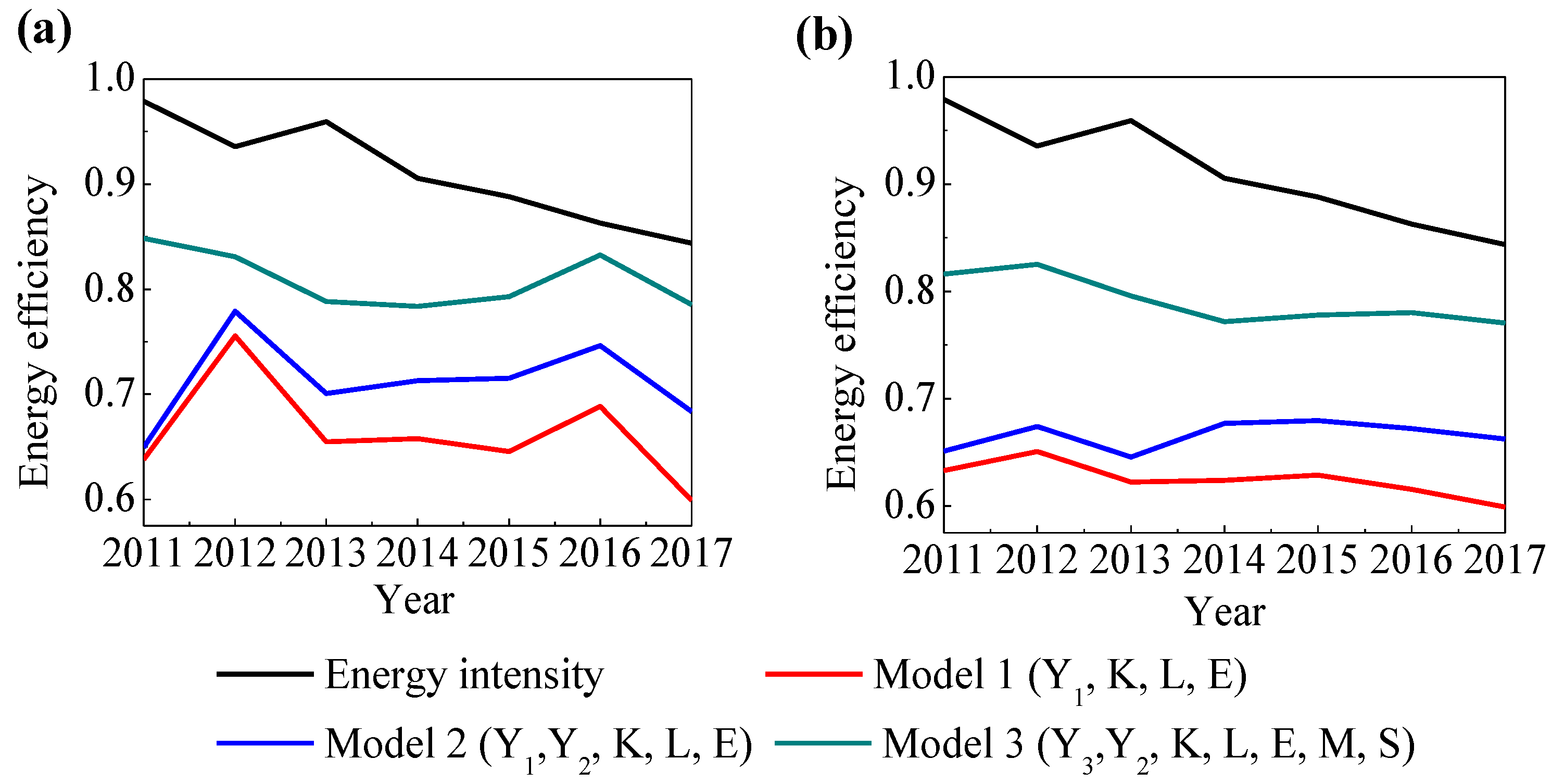

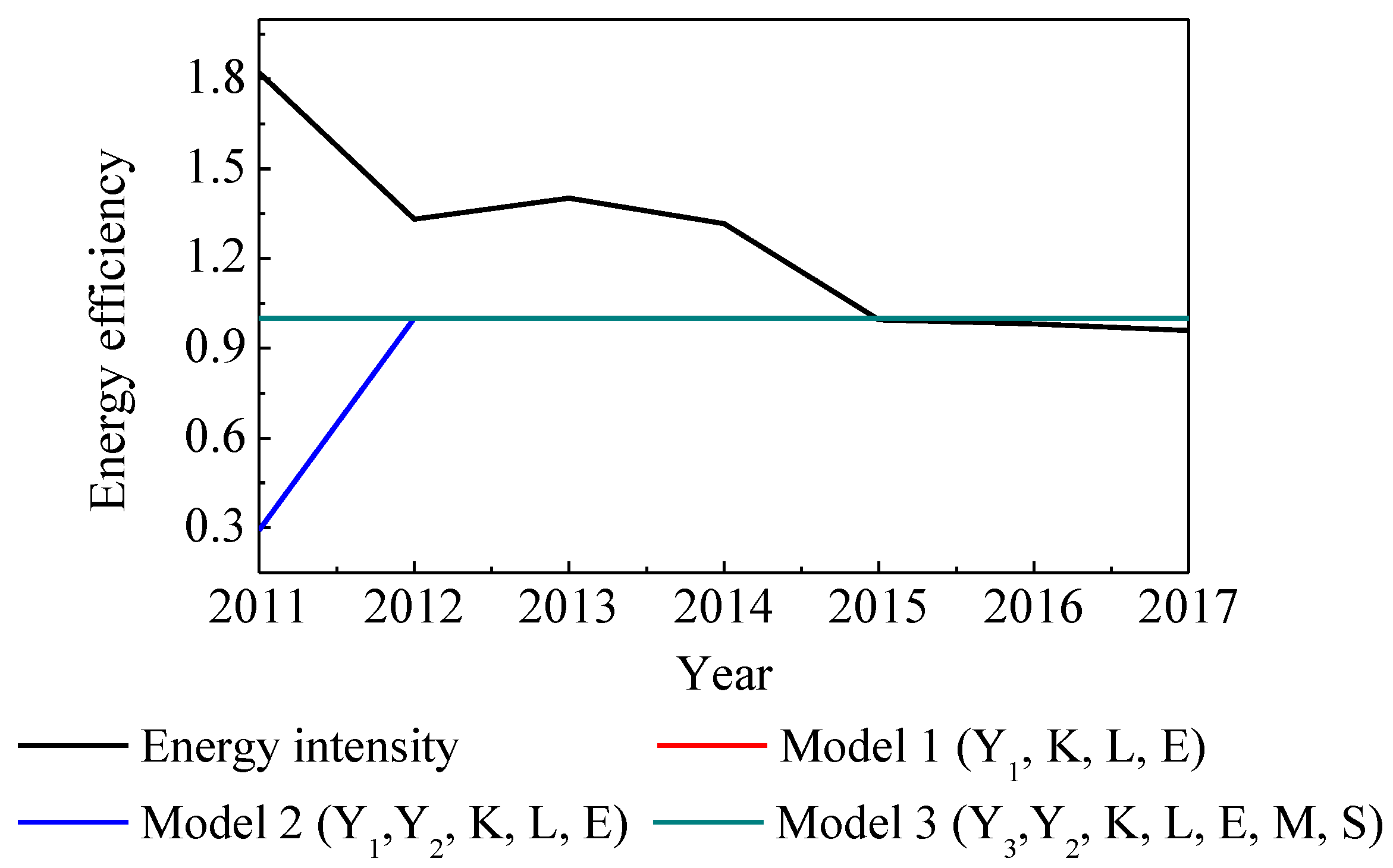

4.2. Results and Comparisons

5. Discussion and Conclusions

5.1. Discussion

5.2. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| IEA | International Energy Agency |

| EIA | Energy Information Administration |

| SDG | Sustainable Development Goal |

| SFEE | Single factor energy efficiency |

| TFEE | Total factor energy efficiency |

| SNA | System of National Accounts |

| DEA | Data Envelopment Analysis |

| SBM | Slacks-based Measure |

| Production feasible plans | |

| VO, | Value of output |

| GVA | Gross value added |

| DMU | Decision making unit |

| CRS | Constant returns to scale |

| PIM | Perpetual inventory method |

| K | Capital |

| L | Labor |

| E | Energy consumption |

| M | Intermediate materials |

| S | Intermediate services |

| VA, | Value added such as GDP |

| Undesirable output | |

| The production set of energy intensity | |

| Model 1, a production set of TFEE | |

| Model 2, a production set of TFEE | |

| Model 3, the production set of VO TFEE | |

| Input vectors | |

| Desirable output vectors | |

| Undesirable output vectors | |

| Nonnegative vector | |

| matrix of input vectors | |

| matrix of desirable output vectors | |

| matrix of undesirable output vectors | |

| Potential reduction of inputs | |

| Potential reduction of energy consumption | |

| Potential reduction of undesirable output | |

| Potential expansion of desirable output | |

| The objective value of SBM |

| Input | Output | |

|---|---|---|

| TFEE without pollution | ||

| Hu and Wang [20] | (1) Capital; (2) Labor; (3) Energy consumption; (4) Total sown area of farm crops | GDP |

| Hu and Kao [23] | (1) Capital; (2) Labor; (3) Energy consumption | GDP |

| Zhang et al. [36] | (1) Capital;(2) Labor;(3) Energy consumption | GDP |

| Song et al. [37] | (1) Capital formulation; (2) Labor; (3) Energy consumption | GDP |

| Lin and Du [38] | (1) Capital; (2) Labor; (3) Energy consumption | GDP |

| Bian et al. [39] | (1) Capital; (2) Labor; (3) Energy consumption | GDP |

| Borozan [40] | (1) Capital; (2) Employment; (3) Energy consumption | GDP |

| Jebali et al. [41] | (1) Capital; (2) Labor; (3) Energy consumption | GDP |

| Eguchi et al. [42] | (1) Capital; (2) Coal consumption | (1) Net electricity production; (2) sample size |

| Haider et al. [43] | (1) Capital; (2) Labor; (3) Energy consumption; (4) Material | output |

| TFEE with pollution | ||

| Zhou and Ang [44] | (1) Capital; (2) Labor; (3) Coal consumption; (4) Oil consumption; (5) Gas consumption; (6) Other energy consumption | (1) GDP; (2) CO2 |

| Li and Hu [45] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) SO2; (3) CO2 |

| Wang et al. [46] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) CO2 |

| Wang et al. [47] | (1) Capital stock; (2) Labor; (3) Energy consumption | (1) GDP; (2) CO2 |

| Apergis et al. [48] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) CO2 |

| Wang and Feng [49] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) COD; (3) SO2; (4) Ammonia nitrogen |

| Wang et al. [50] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) CO2 |

| Wang and Wei [51] | (1) Capital; (2) Labor; (3) Total energy (Coal, Oil, Natural gas, Electricity) | (1) GDP;(2) CO2 |

| Li and Lin [52] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) CO2; (3) SO2; (4) COD |

| Zhou et al. [53] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) CO2 |

| Zhou et al. [54] | (1) Capital stock; (2) Labor force; (3) Oil; (4) Natural gas; (5) Coal; (6) Non-fossil energy | (1) GDP; (2) CO2 |

| Sueyoshi et al. [55] | (1) Capital; (2) Labor; (3) Energy consumption | (1) Gross regional product; (2) SO2; (3) soot (dust); (4) waste water; (5) COD; (6) Ammonia nitrogen |

| Yang et al. [56] | (1) Capital; (2) Labor; (3) Energy consumption (4) SO2; (5) NOX | GDP |

| Yang and Wei [57] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) Waste water; (3) SO2; (4) Smoke and dust |

| Özkara and Atak [58] | (1) Capital; (2) Employment; (3) Electricity | (1) Production value; (2) CO2 |

| Camioto et al. [59] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) CO2 |

| Fathi et al. [60] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) CO2 |

| Iftikhar et al. [61] | (1) Capital; (2) Labor; (3) Energy consumption | (1) GDP; (2) CO2 |

| Moon and Min [62] | (1) Capital; (2) Employee; (3) Energy consumption | (1) Cost of goods sold; (2) GHG |

| Moutinho et al. [63] | (1) Population density; (2) labor productivity; (3) municipal waste; (4) number of registered cars; (5) number of companies | (1) GDP/PM10; (2) GDP/CO2 |

| Mohsin et al. [64] | (1) Labor; (2) Energy consumption | (1) GDP; (2) CO2 per capita |

Appendix B

| Country | Energy Intensity | TFEE with Model 1 | TFEE with Model 2 | TFEE with Model 3 | ||||

|---|---|---|---|---|---|---|---|---|

| Score | Rank | Score | Rank | Score | Rank | Score | Rank | |

| Bulgaria | 1.1169 | 16 | 0.4337 | 17 | 0.4337 | 17 | 0.5439 | 17 |

| Czechia | 1.7034 | 19 | 0.2781 | 19 | 0.2781 | 19 | 0.3980 | 19 |

| Germany | 0.8435 | 9 | 1 | 1 | 1 | 1 | 1 | 1 |

| Estonia | 1.0272 | 13 | 0.4770 | 15 | 0.4770 | 15 | 0.6542 | 13 |

| Ireland | 1.3714 | 18 | 0.3512 | 18 | 0.3512 | 18 | 0.4801 | 18 |

| Greece | 0.8285 | 8 | 0.5809 | 11 | 0.9026 | 6 | 1 | 1 |

| Spain | 0.4811 | 2 | 0.9880 | 3 | 0.9880 | 5 | 1 | 1 |

| Italy | 0.5805 | 3 | 0.8162 | 6 | 0.8192 | 10 | 1 | 1 |

| Cyprus | 0.4032 | 1 | 0.9883 | 2 | 0.9883 | 4 | 1 | 1 |

| Latvia | 0.9509 | 10 | 0.5062 | 13 | 0.5062 | 13 | 0.5813 | 16 |

| Lithuania | 0.7652 | 7 | 0.6208 | 10 | 0.8270 | 9 | 0.9519 | 10 |

| Hungary | 0.9644 | 11 | 0.5341 | 12 | 0.5394 | 12 | 0.6492 | 14 |

| Netherlands | 1.0597 | 15 | 0.4475 | 16 | 0.4475 | 16 | 0.6556 | 12 |

| Austria | 1.0442 | 14 | 0.7967 | 8 | 1 | 1 | 1 | 1 |

| Poland | 0.5953 | 4 | 0.7980 | 7 | 0.8421 | 8 | 1 | 1 |

| Portugal | 0.9743 | 12 | 0.4901 | 14 | 0.4901 | 14 | 0.6081 | 15 |

| Romania | 0.6764 | 6 | 0.8385 | 5 | 1 | 1 | 1 | 1 |

| Slovakia | 0.6569 | 5 | 0.7492 | 9 | 0.7492 | 11 | 0.8470 | 11 |

| United Kingdom | 1.2579 | 17 | 0.8989 | 4 | 0.8989 | 7 | 1 | 1 |

| Country | Labor Productivity | Rank | Country | Labor Productivity | Rank |

|---|---|---|---|---|---|

| Bulgaria | 0.1270 | 12 | Lithuania | 0.1355 | 11 |

| Czechia | 0.0594 | 18 | Hungary | 0.0928 | 15 |

| Germany | 0.8927 | 1 | Netherlands | 0.2319 | 8 |

| Estonia | 0.1962 | 9 | Austria | 0.6727 | 3 |

| Ireland | 0.1759 | 10 | Poland | 0.1125 | 13 |

| Greece | 0.0737 | 16 | Portugal | 0.2386 | 7 |

| Spain | 0.4407 | 4 | Romania | 0.3982 | 5 |

| Italy | 0.3844 | 6 | Slovakia | 0.1091 | 14 |

| Cyprus | 0.0453 | 19 | United Kingdom | 0.7321 | 2 |

| Latvia | 0.0736 | 17 |

References

- International Energy Agency (IEA). From Hidden Fuel to World’s First Fuel? Available online: https://www.iea.org/news/from-hidden-fuel-to-worlds-first-fuel (accessed on 5 November 2020).

- International Energy Agency (IEA). Energy Efficiency: A Key Tool for Boosting Economic and Social Development. Available online: https://www.iea.org/news/energy-efficiency-a-key-tool-for-boosting-economic-and-social-development (accessed on 5 November 2020).

- United Nations (UN). Transforming our World: The 2030 Agenda for Sustainable Development. Available online: https://sustainabledevelopment.un.org/post2015/transformingourworld/publication (accessed on 5 November 2020).

- Energy Information Administration (EIA). Measuring Energy Efficiency in the United States’ Economy: A Beginning; Superintendent of Documents; U.S. Government Printing Office: Washington, DC, USA, 1995. [Google Scholar]

- Cook, W.D.; Tone, K.; Zhu, J. Data envelopment analysis: Prior to choosing a model. Omega 2014, 44, 1–4. [Google Scholar] [CrossRef]

- Samuelson, P.A.; Nordhaus, W.D. Economics, 19th ed.; McGraw-Hill: New York, NY, USA, 2010. [Google Scholar]

- Jehle, G.A.; Reny, P.J. Advanced Microeconomic Theory, 3rd ed.; Prentice Hall: Harlow, UK, 2011. [Google Scholar]

- Varian, H.R. Microeconomic Analysis, 3rd ed.; W. W. Norton & Company: New York, NY, USA, 1992. [Google Scholar]

- Mas-Colell, A.; Whinston, M.D.; Green, J.R. Microeconomic Theory; Oxford University Press: New York, NY, USA, 1995. [Google Scholar]

- Färe, R.; Grosskopf, S.; Lovell, C.A.K. The Measurement of Efficiency of Production; Kluwer-Nijhoff Publishing: Boston, MA, USA, 1985. [Google Scholar]

- Borenstein, S. A Microeconomic Framework for Evaluating Energy Efficiency Rebound and Some Implications. In NBER Working Paper No. 19044; National Bureau of Economic Research: Cambridge, MA, USA, 2013. [Google Scholar]

- Patterson, M.G. What is energy efficiency? Concepts, indicators and methodological issues. Energy Policy 1996, 24, 377–390. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). The 1.7% Improvement in Energy Intensity of the Global Economy in 2017 Marked the Second Consecutive Year of Slowing Improvements. Available online: https://www.iea.org/reports/sdg7-data-and-projections/energy-intensity (accessed on 5 November 2020).

- Taylor, P.G.; Abdalla, K.; Quadrelli, R.; Vera, I. Better energy indicators for sustainable development. Nat. Energy 2017, 2. [Google Scholar] [CrossRef]

- Proskuryakova, L.; Kovalev, A. Measuring energy efficiency: Is energy intensity a good evidence base? Appl. Energy 2015, 138, 450–459. [Google Scholar] [CrossRef]

- Renshaw, E.F. Energy efficiency and the slump in labour productivity in the USA. Energy Econ. 1981, 3, 36–42. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Progress with Implementing Energy Efficiency Policies in the G8. Available online: https://www.iea.org/reports/progress-with-implementing-energy-efficiency-policies-in-the-g8 (accessed on 5 November 2020).

- Wilson, B.; Trieu, L.H.; Bowen, B. Energy efficiency trends in Australia. Energy Policy 1994, 22, 287–295. [Google Scholar] [CrossRef]

- International Atomic Energy Agency (IAEA). Energy indicators for sustainable development: Guidelines and methodologies. Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1222_web.pdf (accessed on 5 November 2020).

- Hu, J.-L.; Wang, S.-C. Total-factor energy efficiency of regions in China. Energy Policy 2006, 34, 3206–3217. [Google Scholar] [CrossRef]

- Farrell, M.J. The measurement of productive efficiency. J. R. Stat. Soc. 1957, 120, 253–290. [Google Scholar] [CrossRef]

- Ferrier, G.D.; Lovell, C.K. Measuring cost efficiency in banking: Econometric and linear programming evidence. J. Econom. 1990, 46, 229–245. [Google Scholar] [CrossRef]

- Hu, J.-L.; Kao, C.-H. Efficient energy-saving targets for APEC economies. Energy Policy 2007, 35, 373–382. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Fukuyama, H.; Weber, W.L. A directional slacks-based measure of technical inefficiency. Socioecon. Plann. Sci. 2009, 43, 274–287. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W.; Wang, H. Energy and CO2 emission performance in electricity generation: A non-radial directional distance function approach. Eur. J. Oper. Res. 2012, 221, 625–635. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Tone, K. Dealing with undesirable outputs in DEA: A slacks-based measure (SBM) approach. Nippon Opereshonzu Risachi Gakkai Shunki Kenkyu Happyokai Abusutorakutoshu 2004, 2004, 44–45. [Google Scholar]

- Kohl, S.; Brunner, J.O. Benchmarking the benchmarks—Comparing the accuracy of data envelopment analysis models in constant returns to scale settings. Eur. J. Oper. Res. 2020, 285, 1042–1057. [Google Scholar] [CrossRef]

- European Commission; International Monetary Fund; Organisation for Economic Co-operation and Development; United Nations; World Bank. System of National Accounts 2008; United Nations: New York, NY, USA, 2009. [Google Scholar]

- European Commission. Available online: https://ec.europa.eu/eurostat/web/main/data/database (accessed on 13 January 2021).

- Central Statistics Office (CSO). Output and Value Added by Activity 2017. Available online: https://www.cso.ie/en/releasesandpublications/ep/p-naova/outputandvalueaddedbyactivity2017/ (accessed on 13 January 2021).

- Li, S.; Li, C. Modification and application of total factor energy efficiency measurement. J. Quant. Tech. Econ. 2018, 9, 110–125. [Google Scholar]

- Goldsmith, R.W. A Perpetual Inventory of National Wealth. In Studies in Income and Wealth; Conference on Research in Income and Wealth; National Bureau of Economic Research: Cambridge, MA, USA, 1951; Volume 14, pp. 5–73. [Google Scholar]

- Filippini, M.; Hunt, L.C. US residential energy demand and energy efficiency: A stochastic demand frontier approach. Energy Econ. 2012, 34, 1484–1491. [Google Scholar] [CrossRef]

- Zhang, X.-P.; Cheng, X.-M.; Yuan, J.-H.; Gao, X.-J. Total-factor energy efficiency in developing countries. Energy Policy 2011, 39, 644–650. [Google Scholar] [CrossRef]

- Song, M.-L.; Zhang, L.-L.; Liu, W.; Fisher, R. Bootstrap-DEA analysis of BRICS’ energy efficiency based on small sample data. Appl. Energy 2013, 112, 1049–1055. [Google Scholar] [CrossRef]

- Lin, B.; Du, K. Technology gap and China’s regional energy efficiency: A parametric metafrontier approach. Energy Econ. 2013, 40, 529–536. [Google Scholar] [CrossRef]

- Bian, Y.; Hu, M.; Wang, Y.; Xu, H. Energy efficiency analysis of the economic system in China during 1986–2012: A parallel slacks-based measure approach. Renew. Sust. Energy Rev. 2016, 55, 990–998. [Google Scholar] [CrossRef]

- Borozan, D. Technical and total factor energy efficiency of European regions: A two-stage approach. Energy 2018, 152, 521–532. [Google Scholar] [CrossRef]

- Jebali, E.; Essid, H.; Khraief, N. The analysis of energy efficiency of the Mediterranean countries: A two-stage double bootstrap DEA approach. Energy 2017, 134, 991–1000. [Google Scholar] [CrossRef]

- Eguchi, S.; Takayabu, H.; Lin, C. Sources of inefficient power generation by coal-fired thermal power plants in China: A metafrontier DEA decomposition approach. Renew. Sust. Energy Rev. 2020. [Google Scholar] [CrossRef]

- Haider, S.; Danish, M.S.; Sharma, R. Assessing energy efficiency of Indian paper industry and influencing factors: A slack-based firm-level analysis. Energy Econ. 2019, 81, 454–464. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W. Linear programming models for measuring economy-wide energy efficiency performance. Energy Policy 2008, 36, 2911–2916. [Google Scholar] [CrossRef]

- Li, L.-B.; Hu, J.-L. Ecological total-factor energy efficiency of regions in China. Energy Policy 2012, 46, 216–224. [Google Scholar] [CrossRef]

- Wang, K.; Lu, B.; Wei, Y.-M. China’s regional energy and environmental efficiency: A Range-Adjusted Measure based analysis. Appl. Energy 2013, 112, 1403–1415. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, P.; Zhou, D.Q. Scenario-based energy efficiency and productivity in China: A non-radial directional distance function analysis. Energy Econ. 2013, 40, 795–803. [Google Scholar] [CrossRef]

- Apergis, N.; Aye, G.C.; Barros, C.P.; Gupta, R.; Wanke, P. Energy efficiency of selected OECD countries: A slacks based model with undesirable outputs. Energy Econ. 2015, 51, 45–53. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, C. Sources of production inefficiency and productivity growth in China: A global data envelopment analysis. Energy Econ. 2015, 49, 380–389. [Google Scholar] [CrossRef]

- Wang, Q.; Su, B.; Zhou, P.; Chiu, C.-R. Measuring total-factor CO2 emission performance and technology gaps using a non-radial directional distance function: A modified approach. Energy Econ. 2016, 56, 475–482. [Google Scholar] [CrossRef]

- Wang, K.; Wei, Y.-M. Sources of energy productivity change in China during 1997–2012: A decomposition analysis based on the Luenberger productivity indicator. Energy Econ. 2016, 54, 50–59. [Google Scholar] [CrossRef]

- Li, J.; Lin, B. Ecological total-factor energy efficiency of China’s heavy and light industries: Which performs better? Renew. Sust. Energy Rev. 2017, 72, 83–94. [Google Scholar] [CrossRef]

- Zhou, P.; Sun, Z.R.; Zhou, D.Q. Optimal path for controlling CO2 emissions in China: A perspective of efficiency analysis. Energy Econ. 2014, 45, 99–110. [Google Scholar] [CrossRef]

- Zhou, D.Q.; Meng, F.Y.; Bai, Y.; Cai, S.Q. Energy efficiency and congestion assessment with energy mix effect: The case of APEC countries. J. Clean. Prod. 2017, 142, 819–828. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M.; Wang, D. Malmquist index measurement for sustainability enhancement in Chinese municipalities and provinces. Energy Econ. 2017, 67, 554–571. [Google Scholar] [CrossRef]

- Yang, L.; Wang, K.-L.; Geng, J.-C. China’s regional ecological energy efficiency and energy saving and pollution abatement potentials: An empirical analysis using epsilon-based measure model. J. Clean. Prod. 2018, 194, 300–308. [Google Scholar] [CrossRef]

- Yang, Z.; Wei, X. The measurement and influences of China’s urban total factor energy efficiency under environmental pollution: Based on game cross-efficiency DEA. J. Clean. Prod. 2019, 209, 439–450. [Google Scholar] [CrossRef]

- Özkara, Y.; Atak, M. Regional total-factor energy efficiency and electricity saving potential of manufacturing industry in Turkey. Energy 2015, 93, 495–510. [Google Scholar] [CrossRef]

- Camioto, F.D.C.; Moralles, H.F.; Mariano, E.B.; Rebelatto, D.A.D.N. Energy efficiency analysis of G7 and BRICS considering total-factor structure. J. Clean. Prod. 2016, 122, 67–77. [Google Scholar] [CrossRef]

- Fathi, B.; Ashena, M.; Bahari, A.R. Energy, environmental, and economic efficiency in fossil fuel exporting countries: A modified data envelopment analysis approach. Sustain. Prod. Consum. 2021, 26, 588–596. [Google Scholar] [CrossRef]

- Iftikhar, Y.; Wang, Z.; Zhang, B.; Wang, B. Energy and CO2 emissions efficiency of major economies: A network DEA approach. Energy 2018, 147, 197–207. [Google Scholar] [CrossRef]

- Moon, H.; Min, D. A DEA approach for evaluating the relationship between energy efficiency and financial performance for energy-intensive firms in Korea. J. Clean. Prod. 2020, 255, 120283. [Google Scholar] [CrossRef]

- Moutinho, V.; Madaleno, M.; Macedo, P. The effect of urban air pollutants in Germany: Eco-efficiency analysis through fractional regression models applied after DEA and SFA efficiency predictions. Sustain. Cities Soc. 2020, 59, 102204. [Google Scholar] [CrossRef]

- Mohsin, M.; Hanif, I.; Taghizadeh-Hesary, F.; Abbas, Q.; Iqbal, W. Nexus between energy efficiency and electricity reforms: A DEA-Based way forward for clean power development. Energy Policy 2021, 149, 112052. [Google Scholar] [CrossRef]

| Energy Intensity | TFEE | |

|---|---|---|

| Definition | Energy consumption per unit of output | Ratio of target energy input to the actual energy input |

| Expression | ||

| Value | ||

| Production set | or |

| Output | Input | |||||||

|---|---|---|---|---|---|---|---|---|

| Y1 (GDP) | Y2 (Undesirable Output) | Y3 (VO) | K | L | E | M | S | |

| Model 1 | ||||||||

| Model 2 | ||||||||

| Model 3 | ||||||||

| Variable | Year | Mean | Std. Dev. | Maximum | Minimum |

|---|---|---|---|---|---|

| Capital stock (million euro in 2011 constant price) | 2011 | 3453.4781 | 7423.7787 | 32,491.2794 | 28.4215 |

| 2012 | 3223.2817 | 6833.8923 | 29,924.6587 | 25.6215 | |

| 2013 | 3064.7756 | 6340.6949 | 27,755.3726 | 22.4527 | |

| 2014 | 2912.6722 | 5856.4242 | 25,625.1090 | 20.3401 | |

| 2015 | 2727.2914 | 5327.3256 | 23,221.0915 | 17.1161 | |

| 2016 | 2664.8664 | 5077.9500 | 22,101.6250 | 16.3665 | |

| 2017 | 2582.6287 | 4865.3463 | 21,173.1128 | 15.2973 | |

| Labor (number) | 2011 | 10,330.9474 | 14,571.6624 | 64,464 | 350 |

| 2012 | 10,100.6316 | 14,253.3114 | 63,359 | 323 | |

| 2013 | 9883.4211 | 13,694.4961 | 61,062 | 319 | |

| 2014 | 9851.2632 | 13,362.3141 | 59,237 | 300 | |

| 2015 | 9892.3684 | 13,112.3126 | 57,966 | 301 | |

| 2016 | 10,029.2105 | 13,026.2877 | 57,333 | 297 | |

| 2017 | 10,061.6842 | 13,173.5549 | 57,946 | 292 | |

| Energy consumption (gigawatt-hour) | 2011 | 2563.9073 | 3639.3322 | 13,854.6110 | 7 |

| 2012 | 2442.7075 | 3616.6730 | 13,966.5560 | 6 | |

| 2013 | 2359.7405 | 3470.9314 | 13,568.2780 | 6 | |

| 2014 | 2295.3536 | 3372.2446 | 13,230.2500 | 5 | |

| 2015 | 2206.1046 | 3213.9547 | 12,868.2220 | 5 | |

| 2016 | 2198.7072 | 3167.9340 | 12,776.4170 | 5 | |

| 2017 | 2197.9739 | 3288.8097 | 13,528.4290 | 5.1990 | |

| Intermediate materials and services except energy (million euro in 2011 constant price) | 2011 | 6157.8244 | 14,090.9352 | 61,712.4470 | 25.2765 |

| 2012 | 5707.8845 | 13,025.8529 | 57,306.2758 | 22.4154 | |

| 2013 | 5590.2348 | 12,726.0652 | 55,955.4625 | 17.2142 | |

| 2014 | 5712.8812 | 12,765.0353 | 56,061.5849 | 17.5662 | |

| 2015 | 5712.5177 | 12,496.6908 | 54,955.9977 | 20.8218 | |

| 2016 | 5552.3837 | 12,029.4338 | 52,830.7348 | 21.7496 | |

| 2017 | 5638.1871 | 12,210.8510 | 53,656.9266 | 23.0158 | |

| Value added (million euro in 2011 constant price) | 2011 | 3219.4526 | 5638.6789 | 24,015.5000 | 19.8000 |

| 2012 | 3060.2258 | 5299.9012 | 22,453.9019 | 14.9453 | |

| 2013 | 3045.5897 | 5320.9381 | 22,560.5364 | 11.3442 | |

| 2014 | 3112.3434 | 5406.1415 | 22,873.9963 | 11.6339 | |

| 2015 | 3135.9951 | 5439.6331 | 22,974.3233 | 12.4878 | |

| 2016 | 3171.4093 | 5484.7226 | 23,105.5088 | 13.5916 | |

| 2017 | 3213.1149 | 5617.6459 | 23,674.6272 | 15.2851 | |

| Value of output (million euro in 2011 constant price) | 2011 | 9633.5263 | 20,004.3888 | 87,314.4000 | 46.3000 |

| 2012 | 9023.7522 | 18,600.7112 | 81,403.7046 | 38.6414 | |

| 2013 | 8874.5489 | 18,280.0911 | 79,999.6538 | 29.7538 | |

| 2014 | 9052.4330 | 18,393.4531 | 80,314.8931 | 30.0458 | |

| 2015 | 9046.5775 | 18,116.4941 | 79,090.8805 | 33.8808 | |

| 2016 | 8904.7753 | 17,652.7959 | 76,952.1779 | 35.8324 | |

| 2017 | 9017.9260 | 17,972.7684 | 78,386.3512 | 38.9719 | |

| Greenhouse gases (tonnes in CO2 equivalent) | 2011 | 406,554.7321 | 667,948.9286 | 2,458,099.8800 | 1611.5900 |

| 2012 | 371,783.6905 | 579,871.4227 | 2,022,994.3700 | 1432.0400 | |

| 2013 | 400,717.0995 | 671,627.1423 | 2,558,221.7100 | 1271.9300 | |

| 2014 | 377,705.1632 | 621,028.9253 | 2,307,487.3500 | 1157.7900 | |

| 2015 | 392,675.9005 | 703,096.2549 | 2,871,121.3600 | 1254.1300 | |

| 2016 | 383,712.2342 | 658,729.9127 | 2,644,937.0000 | 1272.9000 | |

| 2017 | 370,583.2774 | 627,648.5870 | 2,509,165.5200 | 1408.1200 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Diao, H.; Wang, L.; Li, C. Energy Efficiency Measurement: A VO TFEE Approach and Its Application. Sustainability 2021, 13, 1605. https://doi.org/10.3390/su13041605

Li S, Diao H, Wang L, Li C. Energy Efficiency Measurement: A VO TFEE Approach and Its Application. Sustainability. 2021; 13(4):1605. https://doi.org/10.3390/su13041605

Chicago/Turabian StyleLi, Shuangjie, Hongyu Diao, Liming Wang, and Chunqi Li. 2021. "Energy Efficiency Measurement: A VO TFEE Approach and Its Application" Sustainability 13, no. 4: 1605. https://doi.org/10.3390/su13041605

APA StyleLi, S., Diao, H., Wang, L., & Li, C. (2021). Energy Efficiency Measurement: A VO TFEE Approach and Its Application. Sustainability, 13(4), 1605. https://doi.org/10.3390/su13041605