Analyzing the Structure of Closed-Loop Supply Chains: A Game Theory Perspective

Abstract

1. Introduction

2. Relevant Works

2.1. Background on Game Theory (GT)

2.2. A Critical Review

3. Methodology

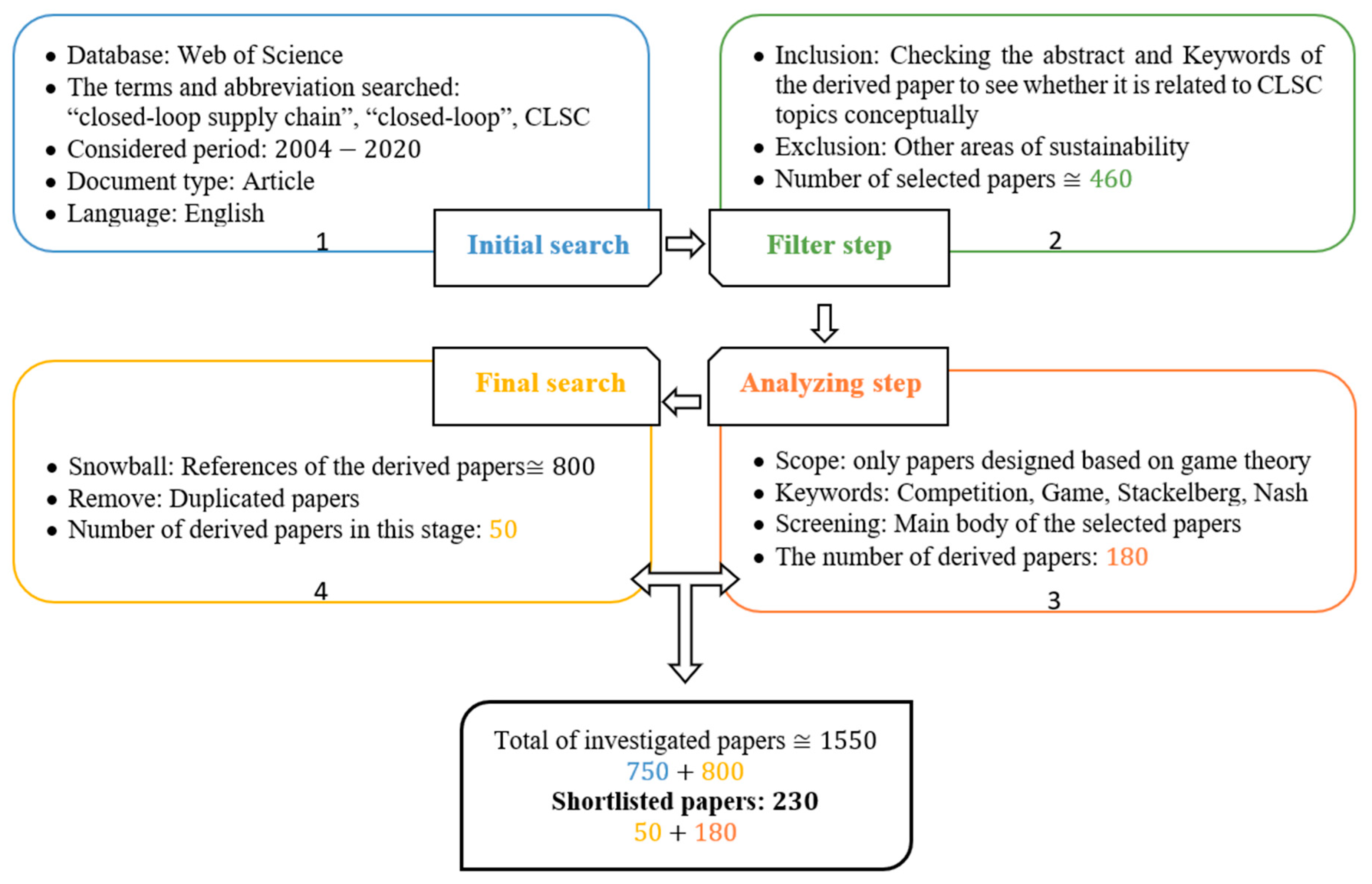

3.1. Material Collection

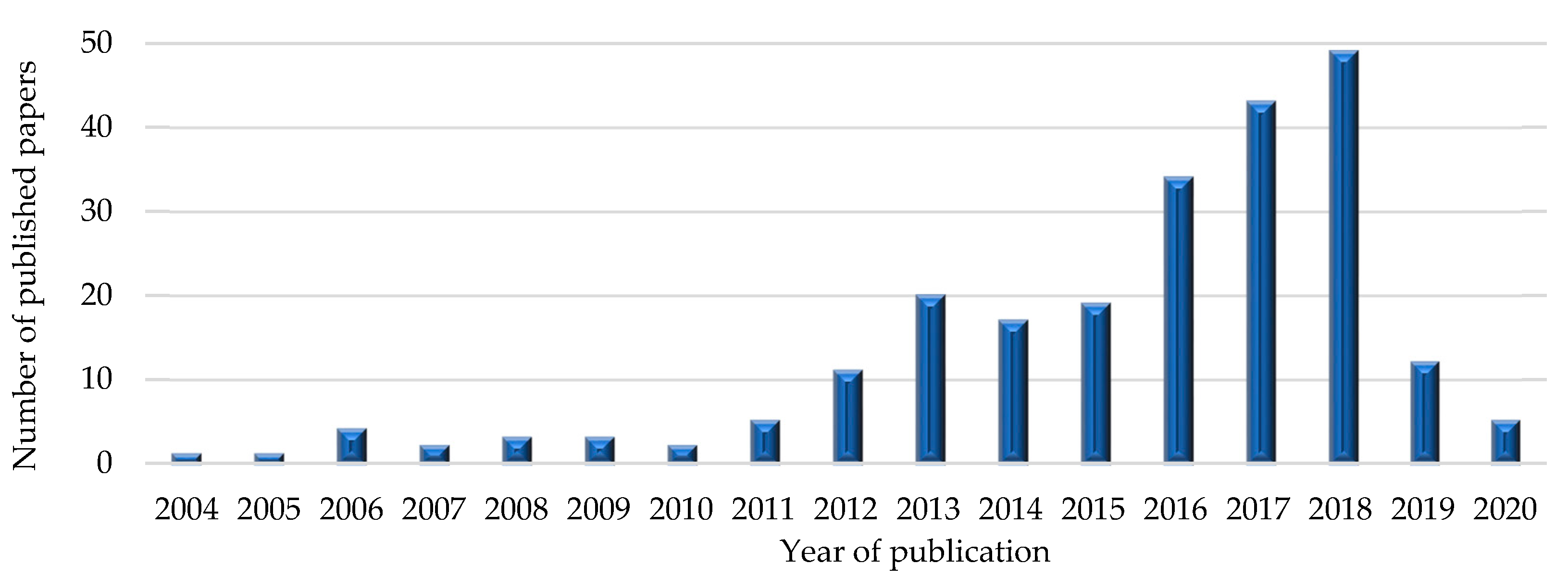

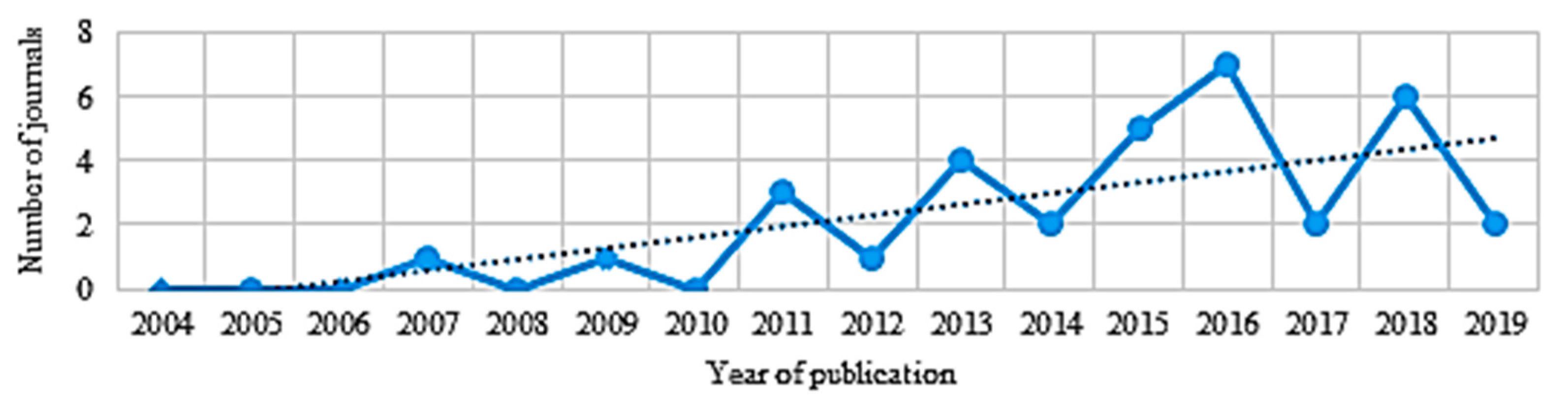

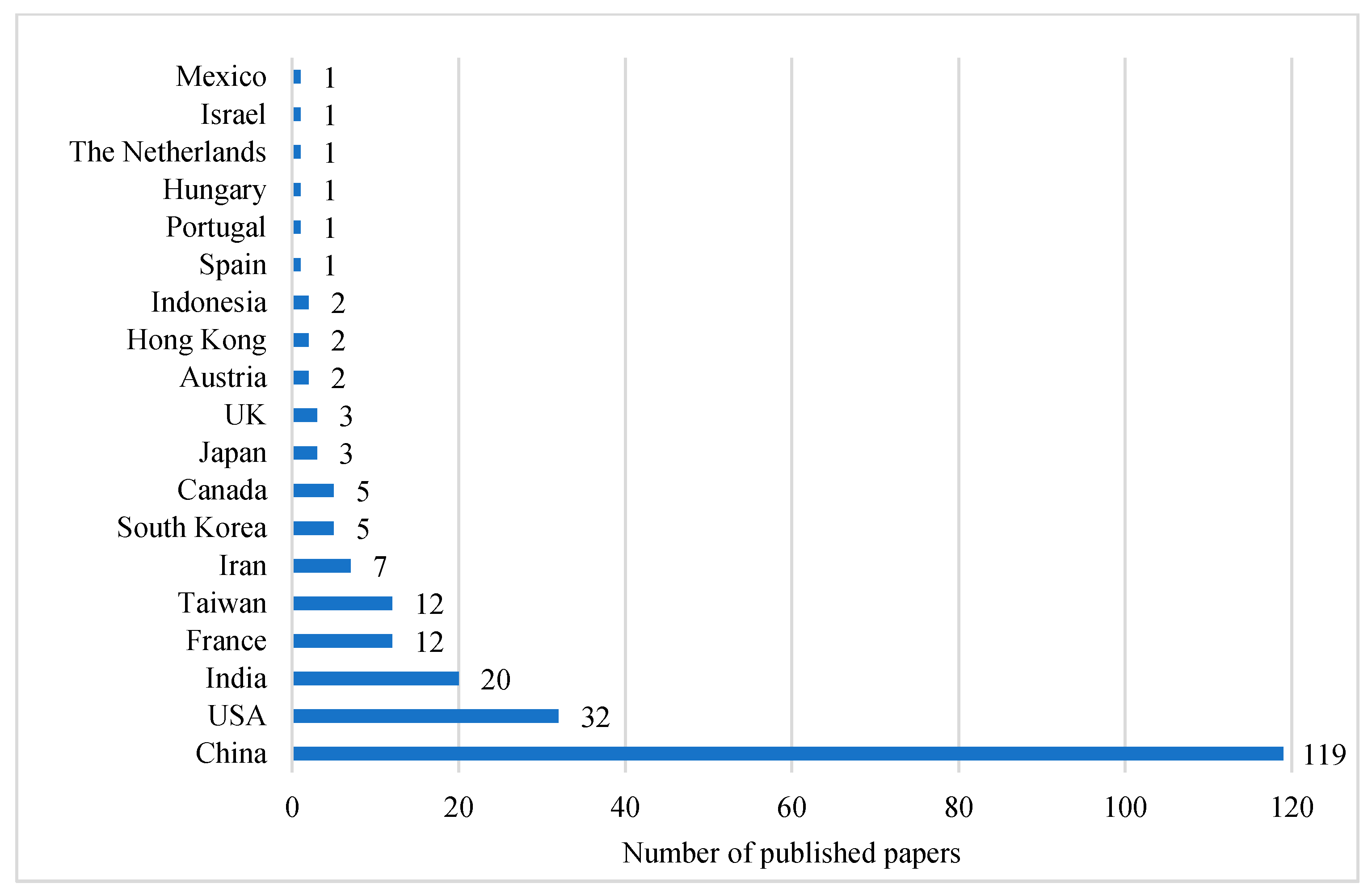

3.2. Descriptive Statistics

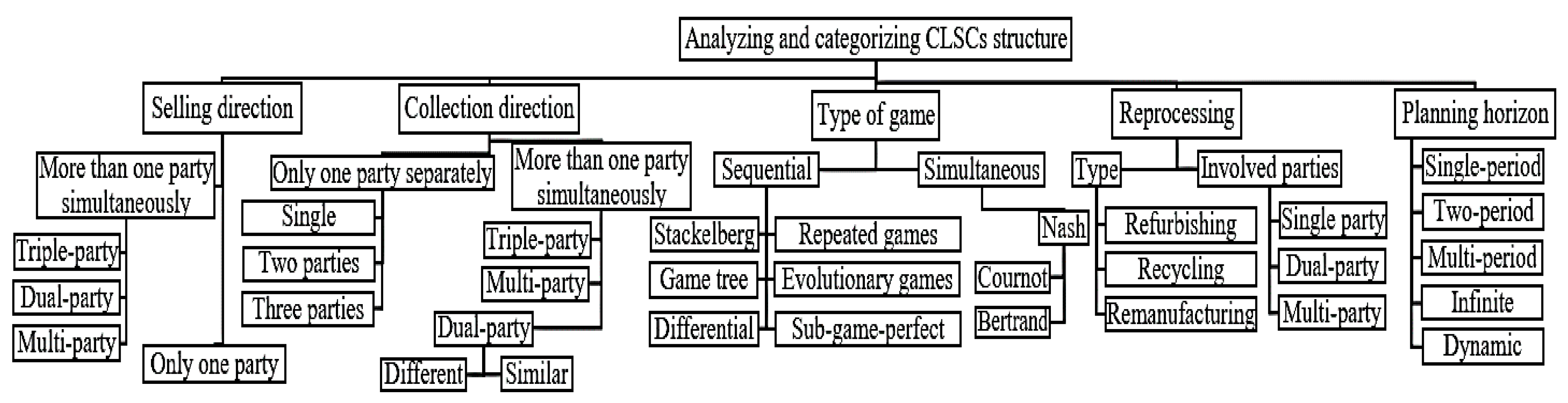

3.3. Category Selection

3.4. Evaluation Stage

4. Results

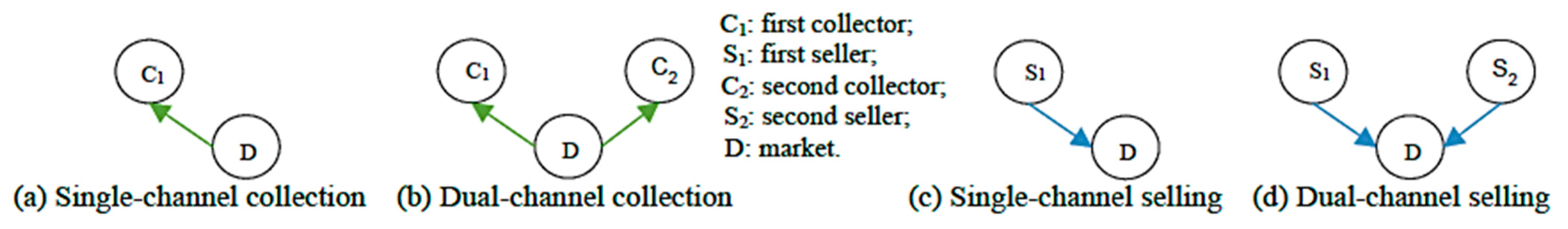

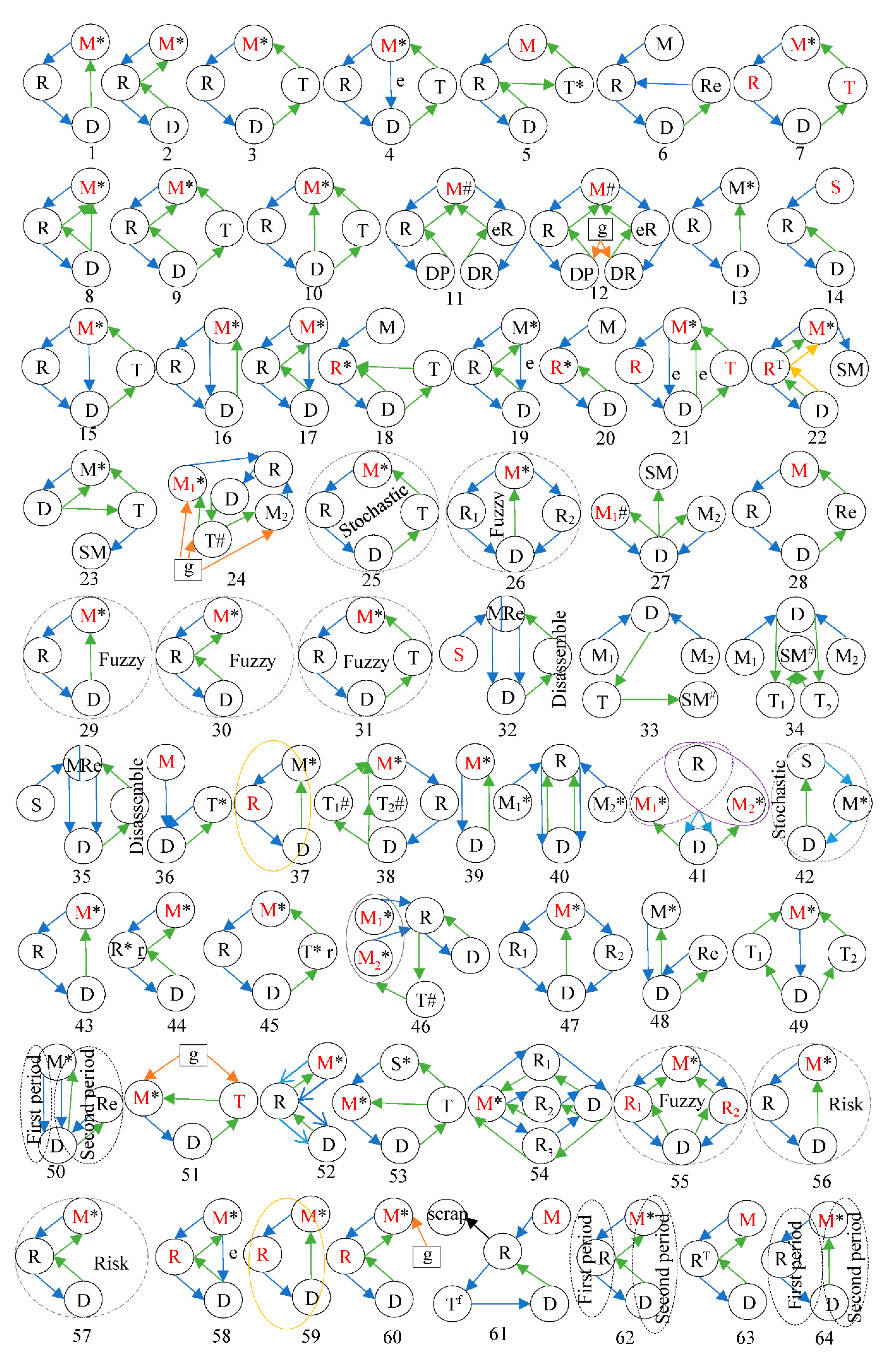

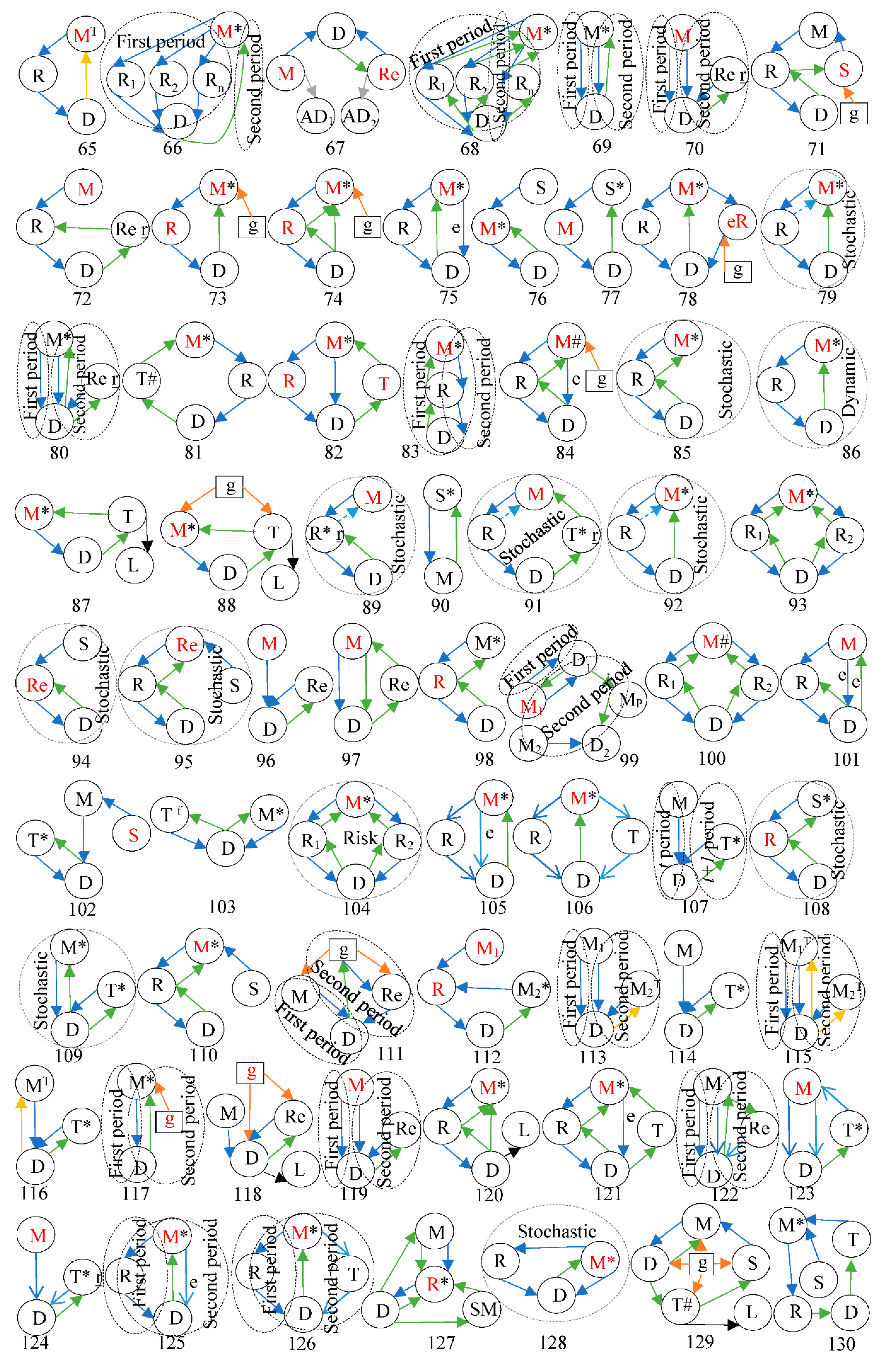

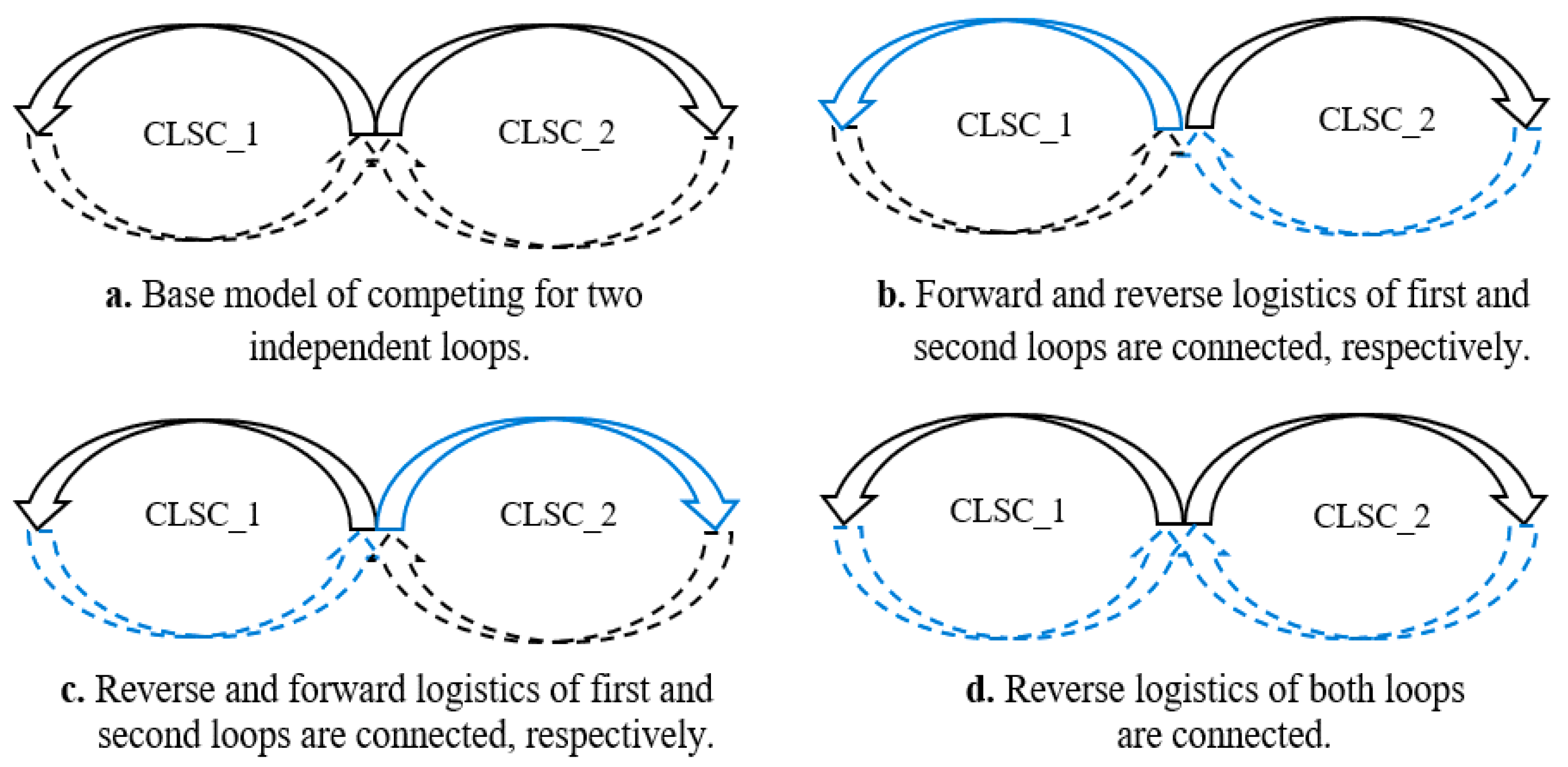

4.1. Closed-Loop Supply Chains (CLSC) Networks

4.2. Game-Based CLSCs

4.3. Reprocessing

4.4. Planning Horizon

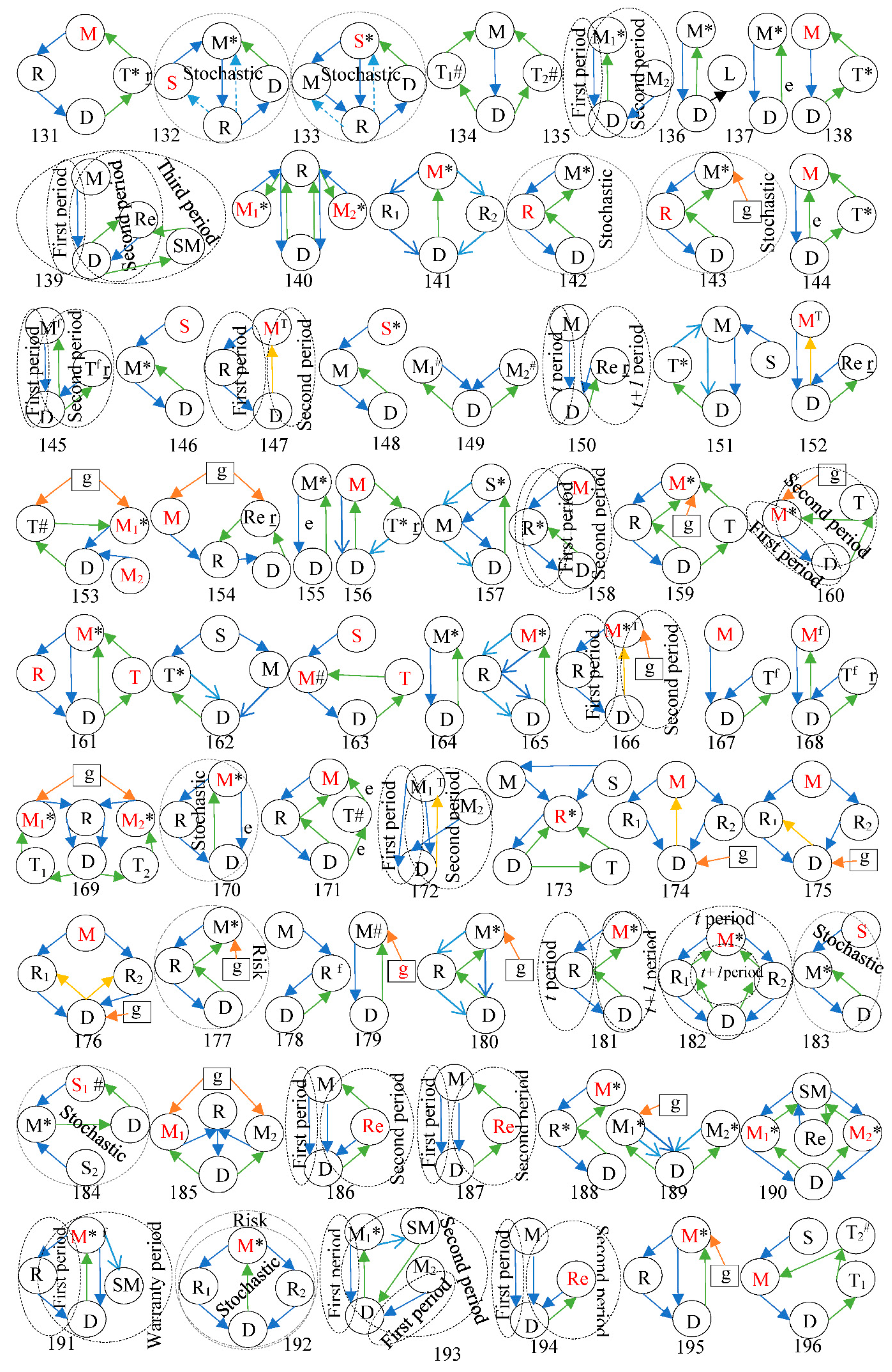

4.5. CLSC Structures

5. Discussion

5.1. Academic Implications

5.2. Practical Implications

6. Conclusions

7. Future Research Directions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fleischmann, M.; Krikke, H.R.; Dekker, R.; Flapper, S.D.P. A characterisation of logistics networks for product recovery. Omega 2000, 28, 653–666. [Google Scholar] [CrossRef]

- Kazemi, N.; Abdul-Rashid, S.H.; Ghazilla, R.A.R.; Shekarian, E.; Zanoni, S. Economic order quantity models for items with imperfect quality and emission considerations. Int. J. Syst. Sci. Oper. Logist. 2018, 5, 99–115. [Google Scholar] [CrossRef]

- Miao, Z.; Fu, K.; Xia, Z.; Wang, Y. Models for closed-loop supply chain with trade-ins. Omega 2017, 66, 308–326. [Google Scholar] [CrossRef]

- Genc, T.S.; De Giovanni, P. Trade-in and save: A two-period closed-loop supply chain game with price and technology dependent returns. Int. J. Prod. Econ. 2017, 183, 514–527. [Google Scholar] [CrossRef]

- De Giovanni, P.; Zaccour, G. A two-period game of a closed-loop supply chain. Eur. J. Oper. Res. 2014, 232, 22–40. [Google Scholar]

- Lee, C.; Realff, M.; Ammons, J. Integration of channel decisions in a decentralized reverse production system with retailer collection under deterministic non-stationary demands. Adv. Eng. Inform. 2011, 25, 88–102. [Google Scholar] [CrossRef]

- Zhang, C.-T.; Ren, M.-L. Closed-loop supply chain coordination strategy for the remanufacture of patented products under competitive demand. Appl. Math. Model. 2016, 40, 6243–6255. [Google Scholar] [CrossRef]

- Esenduran, G.; Kemahlıoğlu-Ziya, E.; Swaminathan, J.M. Impact of take-back regulation on the remanufacturing industry. Prod. Oper. Manag. 2017, 26, 924–944. [Google Scholar]

- Guo, S.; Shen, B.; Choi, T.-M.; Jung, S. A review on supply chain contracts in reverse logistics: Supply chain structures and channel leaderships. J. Clean. Prod. 2017, 144, 387–402. [Google Scholar] [CrossRef]

- De Giovanni, P.; Zaccour, G. A selective survey of game-theoretic models of closed-loop supply chains. 4OR 2019, 17, 1–44. [Google Scholar] [CrossRef]

- Shekarian, E. A review of factors affecting closed-loop supply chain models. J. Clean. Prod. 2019, 253, 119823. [Google Scholar] [CrossRef]

- Savaskan, R.C.; Bhattacharya, S.; Van Wassenhove, L.N. Closed-loop supply chain models with product remanufacturing. Manag. Sci. 2004, 50, 239–252. [Google Scholar]

- Grimes-Casey, H.G.; Seager, T.P.; Theis, T.L.; Powers, S.E. A game theory framework for cooperative management of refillable and disposable bottle lifecycles. J. Clean. Prod. 2007, 15, 1618–1627. [Google Scholar] [CrossRef]

- Zheng, B.; Yang, C.; Yang, J.; Zhang, M. Dual-channel closed loop supply chains: Forward channel competition, power structures and coordination. Int. J. Prod. Res. 2017, 55, 3510–3527. [Google Scholar] [CrossRef]

- Wan, N. The impacts of low carbon subsidy, collection mode, and power structure on a closed-loop supply chain. J. Renew. Sustain. Energy 2018, 10, 065904. [Google Scholar] [CrossRef]

- Cheng, W.; Appolloni, A.; D’Amato, A.; Zhu, Q. Green Public Procurement, missing concepts and future trends—A critical review. J. Clean. Prod. 2018, 176, 770–784. [Google Scholar]

- Rubio, S.; Chamorro, A.; Miranda, F.J. Characteristics of the research on reverse logistics (1995–2005). Int. J. Prod. Res. 2008, 46, 1099–1120. [Google Scholar] [CrossRef]

- Pokharel, S.; Mutha, A. Perspectives in reverse logistics: A review. Resour. Conserv. Recycl. 2009, 53, 175–182. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef]

- Akçalı, E.; Cetinkaya, S. Quantitative models for inventory and production planning in closed-loop supply chains. Int. J. Prod. Res. 2011, 49, 2373–2407. [Google Scholar]

- Govindan, K.; Popiuc, M.N.; Diabat, A. Overview of coordination contracts within forward and reverse supply chains. J. Clean. Prod. 2013, 47, 319–334. [Google Scholar] [CrossRef]

- Sahamie, R.; Stindt, D.; Nuss, C. Transdisciplinary research in sustainable operations–an application to closed-loop supply chains. Bus. Strategy Environ. 2013, 22, 245–268. [Google Scholar] [CrossRef]

- Stindt, D.; Sahamie, R. Review of research on closed loop supply chain management in the process industry. Flex. Serv. Manuf. J. 2014, 26, 268–293. [Google Scholar]

- Atasu, A.; Guide, V.D.R., Jr.; Van Wassenhove, L.N. Product reuse economics in closed-loop supply chain research. Prod. Oper. Manag. 2008, 17, 483–496. [Google Scholar] [CrossRef]

- Akçalı, E.; Çetinkaya, S.; Üster, H. Network design for reverse and closed-loop supply chains: An annotated bibliography of models and solution approaches. Networks 2009, 53, 231–248. [Google Scholar] [CrossRef]

- Guide, V.D.R., Jr.; Van Wassenhove, L.N. OR FORUM—The evolution of closed-loop supply chain research. Oper. Res. 2009, 57, 10–18. [Google Scholar] [CrossRef]

- Souza, G.C. Closed-loop supply chains: A critical review, and future research. Decis. Sci. 2013, 44, 7–38. [Google Scholar] [CrossRef]

- Wang, J.-J.; Chen, H.; Rogers, D.S.; Ellram, L.M.; Grawe, S.J. A bibliometric analysis of reverse logistics research (1992–2015) and opportunities for future research. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 666–687. [Google Scholar] [CrossRef]

- Bensalem, A.; Kin, V. A bibliometric analysis of reverse logistics from 1992 to 2017. In Supply Chain Forum: An International Journal; Taylor & Francis: Abingdon, UK, 2019; pp. 15–28. [Google Scholar]

- Wei, S.; Tang, O.; Sundin, E. Core (product) Acquisition Management for remanufacturing: A review. J. Remanufacturing 2015, 5, 4. [Google Scholar] [CrossRef]

- Cannella, S.; Bruccoleri, M.; Framinan, J.M. Closed-loop supply chains: What reverse logistics factors influence performance? Int. J. Prod. Econ. 2016, 175, 35–49. [Google Scholar] [CrossRef]

- Glock, C.H. Decision support models for managing returnable transport items in supply chains: A systematic literature review. Int. J. Prod. Econ. 2017, 183, 561–569. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H. A review of reverse logistics and closed-loop supply chains: A Journal of Cleaner Production focus. J. Clean. Prod. 2017, 142, 371–384. [Google Scholar] [CrossRef]

- Braz, A.C.; De Mello, A.M.; de Vasconcelos Gomes, L.A.; de Souza Nascimento, P.T. The bullwhip effect in closed-loop supply chains: A systematic literature review. J. Clean. Prod. 2018, 202, 376–389. [Google Scholar] [CrossRef]

- Coenen, J.; Van der Heijden, R.E.; van Riel, A.C. Understanding approaches to complexity and uncertainty in closed-loop supply chain management: Past findings and future directions. J. Clean. Prod. 2018, 201, 1–13. [Google Scholar] [CrossRef]

- Malladi, K.T.; Sowlati, T. Sustainability aspects in Inventory Routing Problem: A review of new trends in the literature. J. Clean. Prod. 2018, 197, 804–814. [Google Scholar] [CrossRef]

- Bressanelli, G.; Perona, M.; Saccani, N. Challenges in supply chain redesign for the Circular Economy: A literature review and a multiple case study. Int. J. Prod. Res. 2019, 57, 7395–7422. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Schenkel, M.; Caniëls, M.C.; Krikke, H.; van der Laan, E. Understanding value creation in closed loop supply chains–Past findings and future directions. J. Manuf. Syst. 2015, 37, 729–745. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; Zanoni, S. A review of mathematical inventory models for reverse logistics and the future of its modeling: An environmental perspective. Appl. Math. Model. 2016, 40, 4151–4178. [Google Scholar] [CrossRef]

- Jena, S.K.; Sarmah, S. Future aspect of acquisition management in closed-loop supply chain. Int. J. Sustain. Eng. 2016, 9, 266–276. [Google Scholar] [CrossRef]

- Diallo, C.; Venkatadri, U.; Khatab, A.; Bhakthavatchalam, S. State of the art review of quality, reliability and maintenance issues in closed-loop supply chains with remanufacturing. Int. J. Prod. Res. 2017, 55, 1277–1296. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of sustainability in supply chain management: A literature review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Gaur, J.; Mani, V. Antecedents of closed-loop supply chain in emerging economies: A conceptual framework using stakeholder’s perspective. Resour. Conserv. Recycl. 2018, 139, 219–227. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N. Reverse logistics and closed-loop supply chain of Waste Electrical and Electronic Equipment (WEEE)/E-waste: A comprehensive literature review. Resour. Conserv. Recycl. 2018, 137, 48–75. [Google Scholar] [CrossRef]

- Larsen, S.B.; Masi, D.; Feibert, D.C.; Jacobsen, P. How the reverse supply chain impacts the firm’s financial performance: A manufacturer’s perspective. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 284–307. [Google Scholar] [CrossRef]

- Moreno-Camacho, C.A.; Montoya-Torres, J.R.; Jaegler, A.; Gondran, N. Sustainability metrics for real case applications of the supply chain network design problem: A systematic literature review. J. Clean. Prod. 2019, 231, 600–618. [Google Scholar]

- Peng, H.; Shen, N.; Liao, H.; Xue, H.; Wang, Q. Uncertainty factors, methods, and solutions of closed-loop supply chain d A review for current situation and future prospects. J. Clean. Prod. 2020, 254, 120032. [Google Scholar] [CrossRef]

- Shekarian, E.; Kazemi, N.; Abdul-Rashid, S.H.; Olugu, E.U. Fuzzy inventory models: A comprehensive review. Appl. Soft Comput. 2017, 55, 588–621. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar]

- Gurtu, A.; Searcy, C.; Jaber, M.Y. An analysis of keywords used in the literature on green supply chain management. Manag. Res. Rev. 2015, 38, 166–194. [Google Scholar] [CrossRef]

- Chu, X.; Zhong, Q.; Li, X. Reverse channel selection decisions with a joint third-party recycler. Int. J. Prod. Res. 2018, 56, 5969–5981. [Google Scholar] [CrossRef]

- Hong, X.; Zhang, H.; Zhong, Q.; Liu, L. Optimal decisions of a hybrid manufacturing-remanufacturing system within a closed-loop supply chain. Eur. J. Ind. Eng. 2016, 10, 21–50. [Google Scholar] [CrossRef]

- Bulmus, S.C.; Zhu, S.X.; Teunter, R. Competition for cores in remanufacturing. Eur. J. Oper. Res. 2014, 233, 105–113. [Google Scholar] [CrossRef]

- De Giovanni, P. State-and control-dependent incentives in a closed-loop supply chain with dynamic returns. Dyn. Games Appl. 2016, 6, 20–54. [Google Scholar] [CrossRef]

- Yi, P.; Huang, M.; Guo, L.; Shi, T. Dual recycling channel decision in retailer oriented closed-loop supply chain for construction machinery remanufacturing. J. Clean. Prod. 2016, 137, 1393–1405. [Google Scholar] [CrossRef]

- Zerang, E.S.; Taleizadeh, A.A.; Razmi, J. Analytical comparisons in a three-echelon closed-loop supply chain with price and marketing effort-dependent demand: Game theory approaches. Environ. Dev. Sustain. 2018, 20, 451–478. [Google Scholar] [CrossRef]

- Li, K.; Li, Y.; Gu, Q.; Ingersoll, A. Joint effects of remanufacturing channel design and after-sales service pricing: An analytical study. Int. J. Prod. Res. 2019, 57, 1066–1081. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, X.; Shi, B.; Cao, J.; Zhou, G. Collection and remanufacturing of waste products under patent protection and government regulation. Sustainability 2018, 10, 1402. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Z. Information sharing in a closed-loop supply chain with technology licensing. Int. J. Prod. Econ. 2017, 191, 113–127. [Google Scholar] [CrossRef]

- Savaskan, R.C.; Van Wassenhove, L.N. Reverse channel design: The case of competing retailers. Manag. Sci. 2006, 52, 1–14. [Google Scholar] [CrossRef]

- Atasu, A.; Toktay, L.B.; Van Wassenhove, L.N. How collection cost structure drives a manufacturer’s reverse channel choice. Prod. Oper. Manag. 2013, 22, 1089–1102. [Google Scholar] [CrossRef]

- Chuang, C.-H.; Wang, C.X.; Zhao, Y. Closed-loop supply chain models for a high-tech product under alternative reverse channel and collection cost structures. Int. J. Prod. Econ. 2014, 156, 108–123. [Google Scholar] [CrossRef]

- Wei, J.; Zhao, J. Reverse channel decisions for a fuzzy closed-loop supply chain. Appl. Math. Model. 2013, 37, 1502–1513. [Google Scholar] [CrossRef]

- Hong, X.; Xu, L.; Du, P.; Wang, W. Joint advertising, pricing and collection decisions in a closed-loop supply chain. Int. J. Prod. Econ. 2015, 167, 12–22. [Google Scholar] [CrossRef]

- Xu, J.; Liu, N. Research on closed loop supply chain with reference price effect. J. Intell. Manuf. 2017, 28, 51–64. [Google Scholar] [CrossRef]

- Modak, N.M.; Modak, N.; Panda, S.; Sana, S.S. Analyzing structure of two-echelon closed-loop supply chain for pricing, quality and recycling management. J. Clean. Prod. 2018, 171, 512–528. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, J.; Li, M. Collecting channel choice and optimal decisions on pricing and collecting in a remanufacturing supply chain. J. Clean. Prod. 2017, 167, 530–544. [Google Scholar]

- Hong, X.; Wang, Z.; Wang, D.; Zhang, H. Decision models of closed-loop supply chain with remanufacturing under hybrid dual-channel collection. Int. J. Adv. Manuf. Technol. 2013, 68, 1851–1865. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z.; Xu, L.; Hong, X.; Govindan, K. Collection effort and reverse channel choices in a closed-loop supply chain. J. Clean. Prod. 2017, 144, 492–500. [Google Scholar] [CrossRef]

- De Giovanni, P. A joint maximization incentive in closed-loop supply chains with competing retailers: The case of spent-battery recycling. Eur. J. Oper. Res. 2018, 268, 128–147. [Google Scholar] [CrossRef]

- Ahn, H. On the profit gains of competing reverse channels for remanufacturing of refillable containers. J. Serv. Sci. 2009, 1, 147–189. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, S.; Zhang, M.; Sun, H.; He, L. A closed-loop supply chain with competitive dual collection channel under asymmetric information and reward–penalty mechanism. Sustainability 2018, 10, 2131. [Google Scholar] [CrossRef]

- Nie, J.; Huang, Z.; Zhao, Y.; Shi, Y. Collective recycling responsibility in closed-loop fashion supply chains with a third party: Financial sharing or physical sharing? Math. Probl. Eng. 2013, 2013, 176130. [Google Scholar] [CrossRef]

- Bernard, S. Remanufacturing. J. Environ. Econ. Manag. 2011, 62, 337–351. [Google Scholar] [CrossRef]

- Ma, J.; Chen, B. The complexity uncertain analysis about three differences old and new product pricing oligarch retailers closed-loop supply chain. Abstr. Appl. Anal. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- Li, W.; Wu, H.; Deng, L. Decision-making based on consumers’ perceived value in different remanufacturing modes. Discret. Dyn. Nat. Soc. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Li, W.; Wu, H.; Jin, M.; Lai, M. Two-stage remanufacturing decision makings considering product life cycle and consumer perception. J. Clean. Prod. 2017, 161, 581–590. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Moshtagh, M.S.; Moon, I. Pricing, product quality, and collection optimization in a decentralized closed-loop supply chain with different channel structures: Game theoretical approach. J. Clean. Prod. 2018, 189, 406–431. [Google Scholar] [CrossRef]

- Ma, Z.-J.; Zhou, Q.; Dai, Y.; Guan, G.-F. To License or Not to License Remanufacturing Business? Sustainability 2018, 10, 347. [Google Scholar] [CrossRef]

- Yang, L.; Wang, G.; Ke, C. Remanufacturing and promotion in dual-channel supply chains under cap-and-trade regulation. J. Clean. Prod. 2018, 204, 939–957. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, Y. Buyer-specific versus uniform pricing in a closed-loop supply chain with third-party remanufacturing. Eur. J. Oper. Res. 2019, 273, 548–560. [Google Scholar] [CrossRef]

- Zhang, X.; Su, Y.; Yuan, X. Government reward-penalty mechanism in closed-loop supply chain based on dynamics game theory. Discret. Dyn. Nat. Soc. 2018, 2018, 3541823. [Google Scholar] [CrossRef]

- Xiong, Y.; Yan, W. Implications of channel structure for marketing remanufactured products. Eur. J. Ind. Eng. 2016, 10, 126–144. [Google Scholar] [CrossRef]

- Wu, H.; Han, X.; Yang, Q.; Pu, X. Production and coordination decisions in a closed-loop supply chain with remanufacturing cost disruptions when retailers compete. J. Intell. Manuf. 2018, 29, 227–235. [Google Scholar]

- Yan, W.; Xiong, Y.; Xiong, Z.; Guo, N. Bricks vs. clicks: Which is better for marketing remanufactured products? Eur. J. Oper. Res. 2015, 242, 434–444. [Google Scholar]

- He, R.; Xiong, Y.; Lin, Z. Carbon emissions in a dual channel closed loop supply chain: The impact of consumer free riding behavior. J. Clean. Prod. 2016, 134, 384–394. [Google Scholar] [CrossRef]

- De Giovanni, P. Environmental collaboration in a closed-loop supply chain with a reverse revenue sharing contract. Ann. Oper. Res. 2014, 220, 135–157. [Google Scholar] [CrossRef]

- Mi, J.; Huang, Z.; Wang, K.; Tsai, S.-B.; Li, G.; Wang, J. The presence of a powerful retailer on dynamic collecting closed-loop supply cain fom a suainable inovation prspective. Sustainability 2018, 10, 2115. [Google Scholar]

- Huang, Z.; Nie, J.; Tsai, S.-B. Dynamic collection strategy and coordination of a remanufacturing closed-loop supply chain under uncertainty. Sustainability 2017, 9, 683. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q.; Liu, Z.; Zheng, X. Static and dynamic pricing strategies in a closed-loop supply chain with reference quality effects. Sustainability 2018, 10, 157. [Google Scholar] [CrossRef]

- Li, J.; Du, W.; Yang, F.; Hua, G. Evolutionary game analysis of remanufacturing closed-loop supply chain with asymmetric information. Sustainability 2014, 6, 6312–6324. [Google Scholar]

- Esmaeili, M.; Allameh, G.; Tajvidi, T. Using game theory for analysing pricing models in closed-loop supply chain from short-and long-term perspectives. Int. J. Prod. Res. 2016, 54, 2152–2169. [Google Scholar] [CrossRef]

- Genc, T.S.; De Giovanni, P. Optimal return and rebate mechanism in a closed-loop supply chain game. Eur. J. Oper. Res. 2018, 269, 661–681. [Google Scholar] [CrossRef]

- Kaushal, R.K.; Nema, A.K. Multi-stakeholder decision analysis and comparative risk assessment for reuse–recycle oriented e-waste management strategies: A game theoretic approach. Waste Manag. Res. 2013, 31, 881–895. [Google Scholar] [CrossRef] [PubMed]

- Kaushal, R.K.; Nema, A.K. Strategic analysis of computer waste management options: Game-theoretic approach. J. Environ. Eng. 2013, 139, 241–249. [Google Scholar] [CrossRef]

- Chung, S.-L.; Wee, H.-M.; Yang, P.-C. Optimal policy for a closed-loop supply chain inventory system with remanufacturing. Math. Comput. Model. 2008, 48, 867–881. [Google Scholar] [CrossRef]

- Yang, P.; Wee, H.-M.; Chung, S.; Ho, P. Sequential and global optimization for a closed-loop deteriorating inventory supply chain. Math. Comput. Model. 2010, 52, 161–176. [Google Scholar] [CrossRef]

- Yuan, K.F.; Ma, S.H.; He, B.; Gao, Y. Inventory decision-making models for a closed-loop supply chain system with different decision-making structures. Int. J. Prod. Res. 2015, 53, 183–219. [Google Scholar] [CrossRef]

- Giri, B.; Sharma, S. Optimizing a closed-loop supply chain with manufacturing defects and quality dependent return rate. J. Manuf. Syst. 2015, 35, 92–111. [Google Scholar] [CrossRef]

- Jung, K.S.; Hwang, H. Competition and cooperation in a remanufacturing system with take-back requirement. J. Intell. Manuf. 2011, 22, 427–433. [Google Scholar] [CrossRef]

- Guo, Y.; Ma, J. Research on game model and complexity of retailer collecting and selling in closed-loop supply chain. Appl. Math. Model. 2013, 37, 5047–5058. [Google Scholar] [CrossRef]

- Shi, L.; Sheng, Z.; Xu, F. Complexity analysis of remanufacturing duopoly game with different competition strategies and heterogeneous players. Nonlinear Dyn. 2015, 82, 1081–1092. [Google Scholar] [CrossRef]

- Gao, J.; Han, H.; Hou, L.; Wang, H. Pricing and effort decisions in a closed-loop supply chain under different channel power structures. J. Clean. Prod. 2016, 112, 2043–2057. [Google Scholar] [CrossRef]

- Assarzadegan, P.; Rasti-Barzoki, M. A game theoretic approach for pricing under a return policy and a money back guarantee in a closed loop supply chain. Int. J. Prod. Econ. 2020, 222, 107–486. [Google Scholar] [CrossRef]

- Chen, J.-M.; Chang, C.-I. The co-opetitive strategy of a closed-loop supply chain with remanufacturing. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 387–400. [Google Scholar] [CrossRef]

- Jacobs, B.W.; Subramanian, R. Sharing responsibility for product recovery across the supply chain. Prod. Oper. Manag. 2012, 21, 85–100. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiong, Y.; Li, G.; Xiong, Z.; Beck, M. The bright side of manufacturing–remanufacturing conflict in a decentralised closed-loop supply chain. Int. J. Prod. Res. 2013, 51, 2639–2651. [Google Scholar] [CrossRef]

- Li, J.; Du, W.; Yang, F.; Hua, G. The carbon subsidy analysis in remanufacturing closed-loop supply chain. Sustainability 2014, 6, 3861–3877. [Google Scholar] [CrossRef]

- Yoo, S.H.; Kim, D.; Park, M.-S. Pricing and return policy under various supply contracts in a closed-loop supply chain. Int. J. Prod. Res. 2015, 53, 106–126. [Google Scholar] [CrossRef]

- Genc, T.S.; De Giovanni, P. Closed-loop supply chain games with innovation-led lean programs and sustainability. Int. J. Prod. Econ. 2020, 219, 440–456. [Google Scholar] [CrossRef]

- Yuan, K.; Gao, Y. Inventory decision-making models for a closed-loop supply chain system. Int. J. Prod. Res. 2010, 48, 6155–6187. [Google Scholar] [CrossRef]

- Han, X.; Wu, H.; Yang, Q.; Shang, J. Reverse channel selection under remanufacturing risks: Balancing profitability and robustness. Int. J. Prod. Econ. 2016, 182, 63–72. [Google Scholar] [CrossRef]

- Huang, M.; Yi, P.; Shi, T. Triple recycling channel strategies for remanufacturing of construction machinery in a retailer-dominated closed-loop supply chain. Sustainability 2017, 9, 2167. [Google Scholar] [CrossRef]

- Long, X.; Shu, T.; Chen, S.; Wang, S.; Lai, K.K.; Yang, Y. Strategy Analysis of Recycling and Remanufacturing by Remanufacturers in Closed-Loop Supply Chain. Sustainability 2017, 9, 1818. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Zhang, Y.-Y. Remanufacturer’s production strategy with capital constraint and differentiated demand. J. Intell. Manuf. 2017, 28, 869–882. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Sane-Zerang, E.; Choi, T.M. The effect of marketing effort on dual-channel closed-loop supply chain systems. IEEE Trans. Syst. Man Cybern. Syst. 2018, 48, 265–276. [Google Scholar]

- Ma, Z.-J.; Hu, S.; Dai, Y.; Ye, Y.-S. Pay-as-you-throw versus recycling fund system in closed-loop supply chains with alliance recycling. Int. Trans. Oper. Res. 2018, 25, 1811–1829. [Google Scholar]

- Ke, H.; Wu, Y.; Huang, H. Competitive pricing and remanufacturing problem in an uncertain closed-loop supply Chain with risk-sensitive retailers. Asia-Pac. J. Oper. Res. 2018, 35, 1850003. [Google Scholar] [CrossRef]

- Choi, T.-M.; Li, Y.; Xu, L. Channel leadership, performance and coordination in closed loop supply chains. Int. J. Prod. Econ. 2013, 146, 371–380. [Google Scholar] [CrossRef]

- Maiti, T.; Giri, B. A closed loop supply chain under retail price and product quality dependent demand. J. Manuf. Syst. 2015, 37, 624–637. [Google Scholar] [CrossRef]

- Giri, B.; Chakraborty, A.; Maiti, T. Pricing and return product collection decisions in a closed-loop supply chain with dual-channel in both forward and reverse logistics. J. Manuf. Syst. 2017, 42, 104–123. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Moshtagh, M.S.; Moon, I. Optimal decisions of price, quality, effort level and return policy in a three-level closed-loop supply chain based on different game theory approaches. Eur. J. Ind. Eng. 2017, 11, 486–525. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y. Closed loop supply chain under power configurations and dual competitions. Sustainability 2018, 10, 1617. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, W.; Wei, J. Pricing and remanufacturing decisions of a decentralized fuzzy supply chain. Discret. Dyn. Nat. Soc. 2013, 2013, 1–10. [Google Scholar] [CrossRef]

- Gao, J.; Wang, X.; Yang, Q.; Zhong, Q. Pricing decisions of a dual-channel closed-loop supply chain under uncertain demand of indirect channel. Math. Probl. Eng. 2016, 2016, 1–13. [Google Scholar] [CrossRef]

- Ferguson, M.E.; Toktay, L.B. The effect of competition on recovery strategies. Prod. Oper. Manag. 2006, 15, 351–368. [Google Scholar] [CrossRef]

- Ferrer, G.; Swaminathan, J.M. Managing new and remanufactured products. Manag. Sci. 2006, 52, 15–26. [Google Scholar] [CrossRef]

- Webster, S.; Mitra, S. Competitive strategy in remanufacturing and the impact of take-back laws. J. Oper. Manag. 2007, 25, 1123–1140. [Google Scholar] [CrossRef]

- Mitra, S.; Webster, S. Competition in remanufacturing and the effects of government subsidies. Int. J. Prod. Econ. 2008, 111, 287–298. [Google Scholar]

- Wu, C.-H. Price and service competition between new and remanufactured products in a two-echelon supply chain. Int. J. Prod. Econ. 2012, 140, 496–507. [Google Scholar] [CrossRef]

- Wu, C.-H. Strategic and operational decisions under sales competition and collection competition for end-of-use products in remanufacturing. Int. J. Prod. Econ. 2015, 169, 11–20. [Google Scholar] [CrossRef]

- Hong, X.; Govindan, K.; Xu, L.; Du, P. Quantity and collection decisions in a closed-loop supply chain with technology licensing. Eur. J. Oper. Res. 2017, 256, 820–829. [Google Scholar] [CrossRef]

- Gu, X.; Ieromonachou, P.; Zhou, L.; Tseng, M.-L. Developing pricing strategy to optimise total profits in an electric vehicle battery closed loop supply chain. J. Clean. Prod. 2018, 203, 376–385. [Google Scholar]

- Gu, X.; Ieromonachou, P.; Zhou, L.; Tseng, M.-L. Optimising quantity of manufacturing and remanufacturing in an electric vehicle battery closed-loop supply chain. Ind. Manag. Data Syst. 2018, 118, 283–302. [Google Scholar]

- Kleber, R.; Reimann, M.; Souza, G.C.; Zhang, W. On the robustness of the consumer homogeneity assumption with respect to the discount factor for remanufactured products. Eur. J. Oper. Res. 2018, 269, 1027–1040. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, M.; Chen, G.; Chen, X. The effect of implementing trade-in strategy on duopoly competition. Eur. J. Oper. Res. 2016, 248, 856–868. [Google Scholar] [CrossRef]

- Mitra, S. Models to explore remanufacturing as a competitive strategy under duopoly. Omega 2016, 59, 215–227. [Google Scholar] [CrossRef]

- Shu, T.; Wang, Y.; Chen, S.; Wang, S.; Lai, K.; Yang, Y. Decisions on remanufacturing with WTP disparity and recycling competition under government subsidies. Sustainability 2017, 9, 1503. [Google Scholar] [CrossRef]

- Huang, Y.-S.; Lin, C.-J.; Fang, C.-C. A Study on Recycle Schedules for Trade-In Rebates With Consideration of Product Life Cycle. IEEE Trans. Eng. Manag. 2018, 66, 475–490. [Google Scholar] [CrossRef]

- Raz, G.; Souza, G.C. Recycling as a Strategic Supply Source. Prod. Oper. Manag. 2018, 27, 902–916. [Google Scholar] [CrossRef]

- Kogan, K. Second-hand markets and intrasupply chain competition. J. Retail. 2011, 87, 489–501. [Google Scholar] [CrossRef]

- Dai, D.; Si, F.; Wang, J. Stability and complexity analysis of a dual-channel closed-loop supply chain with delayed decision under government intervention. Entropy 2017, 19, 577. [Google Scholar] [CrossRef]

- Dobos, I.; Gobsch, B.; Pakhomova, N.; Pishchulov, G.; Richter, K. Design of contract parameters in a closed-loop supply chain. Cent. Eur. J. Oper. Res. 2013, 21, 713–727. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhou, Y.; Li, G.; Chan, H.-K.; Xiong, Z. Don’t forget your supplier when remanufacturing. Eur. J. Oper. Res. 2013, 230, 15–25. [Google Scholar] [CrossRef]

- He, Y. Supply risk sharing in a closed-loop supply chain. Int. J. Prod. Econ. 2017, 183, 39–52. [Google Scholar] [CrossRef]

- Ramani, V.; De Giovanni, P. A two-period model of product cannibalization in an atypical closed-loop supply chain with endogenous returns: The case of DellReconnect. Eur. J. Oper. Res. 2017, 262, 1009–1027. [Google Scholar] [CrossRef]

- Oraiopoulos, N.; Ferguson, M.E.; Toktay, L.B. Relicensing as a secondary market strategy. Manag. Sci. 2012, 58, 1022–1037. [Google Scholar] [CrossRef]

- Panda, S.; Modak, N.M.; Cárdenas-Barrón, L.E. Coordinating a socially responsible closed-loop supply chain with product recycling. Int. J. Prod. Econ. 2017, 188, 11–21. [Google Scholar] [CrossRef]

- Yan, W.; Chai, J.; Qian, Z.; Tsai, S.-B.; Chen, H.; Xiong, Y. Operational Decisions on Remanufacturing Outsourcing Involved with Corporate Environmental and Social Responsibility—A Sustainable Perspective. Sustainability 2018, 10, 1132. [Google Scholar] [CrossRef]

- Yan, W.; Li, H.; Chai, J.; Qian, Z.; Chen, H. Owning or Outsourcing? Strategic Choice on Take-Back Operations for Third-Party Remanufacturing. Sustainability 2018, 10, 151. [Google Scholar] [CrossRef]

- Zou, Z.-B.; Wang, J.-J.; Deng, G.-S.; Chen, H. Third-party remanufacturing mode selection: Outsourcing or authorization? Transp. Res. Part E Logist. Transp. Rev. 2016, 87, 1–19. [Google Scholar] [CrossRef]

- Wu, C.-H. Product-design and pricing strategies with remanufacturing. Eur. J. Oper. Res. 2012, 222, 204–215. [Google Scholar]

- Sabbaghi, M.; Behdad, S.; Zhuang, J. Managing consumer behavior toward on-time return of the waste electrical and electronic equipment: A game theoretic approach. Int. J. Prod. Econ. 2016, 182, 545–563. [Google Scholar] [CrossRef]

- Yoo, S.H.; Kim, B.C. Joint pricing of new and refurbished items: A comparison of closed-loop supply chain models. Int. J. Prod. Econ. 2016, 182, 132–143. [Google Scholar] [CrossRef]

- Atasu, A.; Van Wassenhove, L.N.; Sarvary, M. Efficient take-back legislation. Prod. Oper. Manag. 2009, 18, 243–258. [Google Scholar]

- Toyasaki, F.; Wakolbinger, T.; Kettinger, W.J. The value of information systems for product recovery management. Int. J. Prod. Res. 2013, 51, 1214–1235. [Google Scholar] [CrossRef]

- Modak, N.M.; Panda, S.; Sana, S.S. Two-echelon supply chain coordination among manufacturer and duopolies retailers with recycling facility. Int. J. Adv. Manuf. Technol. 2016, 87, 1531–1546. [Google Scholar]

- Wu, C.-H.; Kao, Y.-J. Cooperation regarding technology development in a closed-loop supply chain. Eur. J. Oper. Res. 2018, 267, 523–539. [Google Scholar] [CrossRef]

- Jena, S.K.; Sarmah, S. Price competition and co-operation in a duopoly closed-loop supply chain. Int. J. Prod. Econ. 2014, 156, 346–360. [Google Scholar] [CrossRef]

- Wu, C.-H.; Wu, H.-H. Competitive remanufacturing strategy and take-back decision with OEM remanufacturing. Comput. Ind. Eng. 2016, 98, 149–163. [Google Scholar] [CrossRef]

- Liu, H.; Lei, M.; Huang, T.; Leong, G.K. Refurbishing authorization strategy in the secondary market for electrical and electronic products. Int. J. Prod. Econ. 2018, 195, 198–209. [Google Scholar] [CrossRef]

- Heese, H.S.; Cattani, K.; Ferrer, G.; Gilland, W.; Roth, A.V. Competitive advantage through take-back of used products. Eur. J. Oper. Res. 2005, 164, 143–157. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Guide, V.D.R.; Wassenhove, L.N. Optimal order quantities with remanufacturing across new product generations. Prod. Oper. Manag. 2006, 15, 421–431. [Google Scholar] [CrossRef]

- Atasu, A.; Sarvary, M.; Van Wassenhove, L.N. Remanufacturing as a marketing strategy. Manag. Sci. 2008, 54, 1731–1746. [Google Scholar] [CrossRef]

- Subramanian, R.; Gupta, S.; Talbot, B. Product design and supply chain coordination under extended producer responsibility. Prod. Oper. Manag. 2009, 18, 259–277. [Google Scholar]

- Wei, J.; Zhao, J. Pricing decisions with retail competition in a fuzzy closed-loop supply chain. Expert Syst. Appl. 2011, 38, 11209–11216. [Google Scholar] [CrossRef]

- Atasu, A.; Subramanian, R. Extended producer responsibility for e-waste: Individual or collective producer responsibility? Prod. Oper. Manag. 2012, 21, 1042–1059. [Google Scholar] [CrossRef]

- Hong, I.-H.; Yeh, J.-S. Modeling closed-loop supply chains in the electronics industry: A retailer collection application. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 817–829. [Google Scholar]

- Li, S.; Shi, L.; Feng, X.; Li, K. Reverse channel design: The impacts of differential pricing and extended producer responsibility. Int. J. Shipp. Transp. Logist. 2012, 4, 357–375. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Cai, X. Quantity decisions in a supply chain with early returns remanufacturing. Int. J. Prod. Res. 2012, 50, 2161–2173. [Google Scholar] [CrossRef]

- Wei, J.; Zhao, J.; Li, Y. Pricing decisions for a closed-loop supply chain in a fuzzy environment. Asia-Pac. J. Oper. Res. 2012, 29, 1240003. [Google Scholar] [CrossRef]

- Yan, N.-N.; Sun, B.-W. Optimal stackelberg strategies for closed-loop supply chain with third-party reverse logistics. Asia-Pac. J. Oper. Res. 2012, 29, 1250026. [Google Scholar] [CrossRef]

- Huang, M.; Song, M.; Lee, L.H.; Ching, W.K. Analysis for strategy of closed-loop supply chain with dual recycling channel. Int. J. Prod. Econ. 2013, 144, 510–520. [Google Scholar] [CrossRef]

- Ma, W.-M.; Zhao, Z.; Ke, H. Dual-channel closed-loop supply chain with government consumption-subsidy. Eur. J. Oper. Res. 2013, 226, 221–227. [Google Scholar] [CrossRef]

- Shi, W.; Min, K.J. A study of product weight and collection rate in closed-loop supply chains with recycling. IEEE Trans. Eng. Manag. 2013, 60, 409–423. [Google Scholar] [CrossRef]

- Si, J.M.W.; Ma, J. Corporation in a closed-loop supply chain based on remanufacturing. WSEAS Trans. Math. 2013, 12, 482–490. [Google Scholar]

- Subramanian, R.; Ferguson, M.E.; Beril Toktay, L. Remanufacturing and the component commonality decision. Prod. Oper. Manag. 2013, 22, 36–53. [Google Scholar] [CrossRef]

- Watanabe, T.; Kusuawa, E.; Arizono, I. Optimal operation for green supply chain in consideration of collection incentive and quality for recycling of used products. Ind. Eng. Manag. Syst. 2013, 12, 317–329. [Google Scholar]

- Wu, C.-H. OEM product design in a price competition with remanufactured product. Omega 2013, 41, 287–298. [Google Scholar] [CrossRef]

- Chen, L.-T. Dynamic co-opetitive approach of a closed loop system with remanufacturing for deteriorating items in e-markets. J. Manuf. Syst. 2014, 33, 166–176. [Google Scholar] [CrossRef]

- Jena, S.K.; Sarmah, S. Optimal acquisition price management in a remanufacturing system. Int. J. Sustain. Eng. 2014, 7, 154–170. [Google Scholar] [CrossRef]

- Ma, J.; Guo, Y. Research on third-party collecting game model with competition in closed-loop supply chain based on complex systems theory. Abstr. Appl. Anal. 2014, 2014, 1–22. [Google Scholar] [CrossRef]

- Ma, J.; Wang, H. Complexity analysis of dynamic noncooperative game models for closed-loop supply chain with product recovery. Appl. Math. Model. 2014, 38, 5562–5572. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, Y.; Cheng, Y.; Choi, T.-M. Cooperation or competition? channel choice for a remanufacturing fashion supply chain with government subsidy. Sustainability 2014, 6, 7292–7310. [Google Scholar] [CrossRef]

- Watanabe, T.; Kusukawa, E. Optimal operation for green supply chain considering demand information, collection incentive and quality of recycling parts. Ind. Eng. Manag. Syst. 2014, 13, 129–147. [Google Scholar] [CrossRef]

- Wilhite, A.; Burns, L.; Patnayakuni, R.; Tseng, F. Military supply chains and closed-loop systems: Resource allocation and incentives in supply sourcing and supply chain design. Int. J. Prod. Res. 2014, 52, 1926–1939. [Google Scholar]

- Xu, C.; Li, B.; Lan, Y.; Tang, Y. A closed-loop supply chain problem with retailing and recycling competition. Abstr. Appl. Anal. 2014, 2014, 1–14. [Google Scholar] [CrossRef]

- Gan, S.-S.; Pujawan, I.N.; Widodo, B. Pricing decision model for new and remanufactured short-life cycle products with time-dependent demand. Oper. Res. Perspect. 2015, 2, 1–12. [Google Scholar] [CrossRef]

- Han, X.; Feng, B.; Pu, X. Modelling decision behaviours in pricing game of closed-loop supply chains. J. Oper. Res. Soc. 2015, 66, 1052–1060. [Google Scholar] [CrossRef]

- He, Y. Acquisition pricing and remanufacturing decisions in a closed-loop supply chain. Int. J. Prod. Econ. 2015, 163, 48–60. [Google Scholar] [CrossRef]

- Kusukawa, E.; Alozawa, S. Optimal operation for green supply chain with quality of recyclable parts and contract for recycling activity. Ind. Eng. Manag. Syst. 2015, 14, 248–274. [Google Scholar] [CrossRef]

- Shi, Y.; Nie, J.; Qu, T.; Chu, L.-K.; Sculli, D. Choosing reverse channels under collection responsibility sharing in a closed-loop supply chain with re-manufacturing. J. Intell. Manuf. 2015, 26, 387–402. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Zhang, K.; Bai, T.; Shang, J. Reward–penalty mechanism for closed-loop supply chains under responsibility-sharing and different power structures. Int. J. Prod. Econ. 2015, 170, 178–190. [Google Scholar] [CrossRef]

- Wei, J.; Govindan, K.; Li, Y.; Zhao, J. Pricing and collecting decisions in a closed-loop supply chain with symmetric and asymmetric information. Comput. Oper. Res. 2015, 54, 257–265. [Google Scholar] [CrossRef]

- Yang, F.; Hu, P.; Zhao, F.; Hu, C. Customer returns model in a dual-channel supply chain. J. Model. Manag. 2015, 10, 360–379. [Google Scholar] [CrossRef]

- Zhang, Z.-Z.; Wang, Z.-J.; Liu, L.-W. Retail services and pricing decisions in a closed-loop supply chain with remanufacturing. Sustainability 2015, 7, 2373–2396. [Google Scholar] [CrossRef]

- Zou, Q.; Ye, G. Pricing-decision and coordination contract considering product design and quality of recovery product in a closed-loop supply chain. Math. Problin Eng. 2015, 2015, 1–14. [Google Scholar] [CrossRef]

- Agrawal, V.V.; Ferguson, M.; Souza, G.C. Trade-in rebates for price discrimination and product recovery. IEEE Trans. Eng. Manag. 2016, 63, 326–339. [Google Scholar] [CrossRef]

- Bhattacharya, R. A closed loop supply chain game between a supplier and a manufacturer in a two-stage scenario. Int. J. Logist. Syst. Manag. 2016, 23, 445–475. [Google Scholar] [CrossRef]

- Chen, H.; Liu, N.; He, Y. Remanufacturing of electronic products in bonded port area across home and foreign markets: Approach based on closed-loop supply chain model. Int. J. Logist. Manag. 2016, 27, 309–334. [Google Scholar] [CrossRef]

- De Giovanni, P.; Reddy, P.V.; Zaccour, G. Incentive strategies for an optimal recovery program in a closed-loop supply chain. Eur. J. Oper. Res. 2016, 249, 605–617. [Google Scholar]

- Hu, D.; Xiao, C.; Chen, X. Carbon quotas, subsidies and engineering machinery remanufacturing. Front. Eng. Manag. 2016, 3, 50–58. [Google Scholar] [CrossRef]

- Li, W.; Ouyang, M. Advertising decisions of new and remanufactured products under direct sales model. Kybernetes 2016, 45, 1452–1471. [Google Scholar] [CrossRef]

- Li, Y.; Yuan, Z.; Wang, Y. A study on manufacturing closed-loop supply chain decisions under risk aversion based on game theory. Int. J. Simul. Syst. Sci. Technol. 2016, 17, 8.1–8.9. [Google Scholar]

- Ran, W.; Chen, F.; Wu, Q.; Liu, S. A Study of the Closed-Loop Supply Chain Coordination on Waste Glass Bottles Recycling. Math. Probl. Eng. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Saha, S.; Sarmah, S.; Moon, I. Dual channel closed-loop supply chain coordination with a reward-driven remanufacturing policy. Int.J. Prod. Res. 2016, 54, 1503–1517. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, N.; Jia, T.; Chen, H. Reverse revenue sharing contract versus two-part tariff contract under a closed-loop supply chain system. Math. Probl. Eng. 2016, 2016, 5464570. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, F. Decision analysis of closed-loop supply chain under competition environment and heterogeneous consumers. Int. J. Simul. Syst. Sci. Technol. 2016, 17, 12.1–12.8. [Google Scholar]

- Weng, T.-C.; Chen, C.-K. Competitive Analysis of collection behavior between retailer and third-party in the reverse channel. RAIRO-Oper. Res. 2016, 50, 175–188. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhao, Q.; Zhou, Y. Manufacturer-remanufacturing vs supplier-remanufacturing in a closed-loop supply chain. Int. J. Prod. Econ. 2016, 176, 21–28. [Google Scholar] [CrossRef]

- Xu, X.; Liu, J.; Li, Y.; Zhou, X. Pricing strategy of closed-loop supply chain under disruptions. Filomat 2016, 30, 4059–4072. [Google Scholar] [CrossRef][Green Version]

- Yenipazarli, A. Managing new and remanufactured products to mitigate environmental damage under emissions regulation. Eur. J. Oper. Res. 2016, 249, 117–130. [Google Scholar]

- Zu-Jun, M.; Zhang, N.; Dai, Y.; Hu, S. Managing channel profits of different cooperative models in closed-loop supply chains. Omega 2016, 59, 251–262. [Google Scholar] [CrossRef]

- De Giovanni, P. Closed-loop supply chain coordination through incentives with asymmetric information. Ann. Oper. Res. 2017, 253, 133–167. [Google Scholar]

- Gan, S.-S.; Pujawan, I.N.; Suparno; Widodo, B. Pricing decision for new and remanufactured product in a closed-loop supply chain with separate sales-channel. Int. J. Prod. Econ. 2017, 190, 120–132. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Z. Closed-loop supply chain models with product take-back and hybrid remanufacturing under technology licensing. J. Clean. Prod. 2017, 142, 3917–3927. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Z. Dual-Recycling Channel Decision in a Closed-Loop Supply Chain with Cost Disruptions. Sustainability 2017, 9, 2004. [Google Scholar]

- Huang, Y.; Wang, Z. Values of information sharing: A comparison of supplier-remanufacturing and manufacturer-remanufacturing scenarios. Transp. Res. Part E Logist. Transp. Rev. 2017, 106, 20–44. [Google Scholar] [CrossRef]

- Jena, S.K.; Sarmah, S.; Sarin, S.C. Joint-advertising for collection of returned products in a closed-loop supply chain under uncertain environment. Comput. Ind. Eng. 2017, 113, 305–322. [Google Scholar]

- Jin, M.; Nie, J.; Yang, F.; Zhou, Y. The impact of third-party remanufacturing on the forward supply chain: A blessing or a curse? Int. J. Prod. Res. 2017, 55, 6871–6882. [Google Scholar] [CrossRef]

- Kong, L.; Liu, Z.; Pan, Y.; Xie, J.; Yang, G. Pricing and service decision of dual-channel operations in an O2O closed-loop supply chain. Ind. Manag. Data Syst. 2017, 117, 1567–1588. [Google Scholar] [CrossRef]

- Li, H.; Wang, C.; Shang, M.; Ou, W. Pricing, carbon emission reduction, low-carbon promotion and returning decision in a closed-loop supply chain under vertical and horizontal cooperation. Int. J. Environ. Res. Public Health 2017, 14, 1332. [Google Scholar]

- Li, H.; Wang, C.; Xu, L.; Ou, W. Pricing, carbon emission reduction, collection decision, and coordination in a low-carbon closed-loop supply chain. J. Renew. Sustain. Energy 2017, 9, 065907. [Google Scholar] [CrossRef]

- Ma, P.; Li, K.W.; Wang, Z.-J. Pricing decisions in closed-loop supply chains with marketing effort and fairness concerns. Int. J. Prod. Res. 2017, 55, 6710–6731. [Google Scholar] [CrossRef]

- Maiti, T.; Giri, B. Two-way product recovery in a closed-loop supply chain with variable markup under price and quality dependent demand. Int. J. Prod. Econ. 2017, 183, 259–272. [Google Scholar] [CrossRef]

- Wang, W.; Fan, L.; Ma, P.; Zhang, P.; Lu, Z. Reward-penalty mechanism in a closed-loop supply chain with sequential manufacturers’ price competition. J. Clean. Prod. 2017, 168, 118–130. [Google Scholar]

- Wang, W.; Zhang, Y.; Li, Y.; Zhao, X.; Cheng, M. Closed-loop supply chains under reward-penalty mechanism: Retailer collection and asymmetric information. J. Clean. Prod. 2017, 142, 3938–3955. [Google Scholar] [CrossRef]

- Xiao, L.; Wang, X.; Chin, K.-S.; Qin, Y. Competitive strategy in remanufacturing and the effects of government subsidy. J. Syst. Sci. Syst. Eng. 2017, 26, 417–432. [Google Scholar] [CrossRef]

- Xie, J.; Liang, L.; Liu, L.; Ieromonachou, P. Coordination contracts of dual-channel with cooperation advertising in closed-loop supply chains. Int. J. Prod. Econ. 2017, 183, 528–538. [Google Scholar]

- Zhang, P.; Xiong, Z. Information sharing in a closed-loop supply chain with asymmetric demand forecasts. Math. Probl. Eng. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, J.; Li, Y. Pricing and remanufacturing decisions for two substitutable products with a common retailer. J. Ind. Manag. Optim. 2017, 13, 1125–1147. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, J.; Sun, X. Coordination of fuzzy closed-loop supply chain with price dependent demand under symmetric and asymmetric information conditions. Ann. Oper. Res. 2017, 257, 469–489. [Google Scholar] [CrossRef]

- Zhou, W.; Zheng, Y.; Huang, W. Competitive advantage of qualified WEEE recyclers through EPR legislation. Eur. J. Oper. Res. 2017, 257, 641–655. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, J.; Tang, J. Recycling pricing and coordination of WEEE dual-channel closed-loop supply chain considering consumers’ bargaining. Int. J. Environ. Res. Public Health 2017, 14, 1578. [Google Scholar] [CrossRef] [PubMed]

- Arshad, M.; Khalid, Q.; Lloret, J.; Leon, A. An efficient approach for coordination of dual-channel closed-loop supply chain management. Sustainability 2018, 10, 3433. [Google Scholar] [CrossRef]

- Giri, B.; Mondal, C.; Maiti, T. Analysing a closed-loop supply chain with selling price, warranty period and green sensitive consumer demand under revenue sharing contract. J. Clean. Prod. 2018, 190, 822–837. [Google Scholar] [CrossRef]

- He, J.; Zhang, L.; Fu, X.; Tsai, F.-S. Fair but Risky? Recycle Pricing Strategies in Closed-Loop Supply Chains. Int. J. Environ. Res. Public Health 2018, 15, 2870. [Google Scholar]

- Famil Alamdar, S.; Rabbani, M.; Heydari, J. Pricing, collection, and effort decisions with coordination contracts in a fuzzy, three-level closed-loop supply chain. Expert Syst. Appl. 2018, 104, 261–276. [Google Scholar] [CrossRef]

- Huang, Y. A closed-loop supply chain with trade-in strategy under retail competition. Math. Probl. Eng. 2018, 2018, 1–16. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Z. Demand disruptions, pricing and production decisions in a closed-loop supply chain with technology licensing. J. Clean. Prod. 2018, 191, 248–260. [Google Scholar] [CrossRef]

- Huang, M.; Yi, P.; Shi, T.; Guo, L. A modal interval based method for dynamic decision model considering uncertain quality of used products in remanufacturing. J. Intell. Manuf. 2018, 29, 925–935. [Google Scholar] [CrossRef]

- Jena, S.K.; Sarmah, S.P.; Padhi, S.S. Impact of government incentive on price competition of closed-loop supply chain systems. INFOR Inf. Syst. Oper. Res. 2018, 56, 192–224. [Google Scholar] [CrossRef]

- Liao, B.-F.; Li, B.-Y. A marketing strategy in a closed-loop supply chain with loss-averse consumers. Math. Probl. Eng. 2018, 2018, 2560153. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, Y.; Chen, H.; Guo, S.; Lu, Y. Selling remanufactured products under one roof or two? A sustainability analysis on channel structures for new and remanufactured products. Sustainability 2018, 10, 2427. [Google Scholar] [CrossRef]

- Shu, T.; Huang, C.; Chen, S.; Wang, S.; Lai, K. Trade-old-for-remanufactured closed-loop supply chains with carbon tax and government subsidies. Sustainability 2018, 10, 3935. [Google Scholar] [CrossRef]

- Shu, T.; Liu, Q.; Chen, S.; Wang, S.; Lai, K. Pricing decisions of CSR closed-loop supply chains with carbon emission constraints. Sustainability 2018, 10, 4430. [Google Scholar] [CrossRef]

- Shu, T.; Xu, J.; Chen, S.; Wang, S.; Lai, K. Remanufacturing decisions with WTP discrepancy and uncertain quality of product returns. Sustainability 2018, 10, 2123. [Google Scholar] [CrossRef]

- Su, J.; Li, C.; Tsai, S.-B.; Lu, H.; Liu, A.; Chen, Q. A sustainable closed-loop supply chain decision mechanism in the electronic sector. Sustainability 2018, 10, 1295. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, L.; Li, Y. Sustainable decisions on product upgrade confrontations with remanufacturing operations. Sustainability 2018, 10, 4090. [Google Scholar] [CrossRef]

- Wang, W.; Ding, J.; Sun, H. Reward-penalty mechanism for a two-period closed-loop supply chain. J. Clean. Prod. 2018, 203, 898–917. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, W.; Liang, L.; Xia, Y.; Yin, J.; Yang, G. The revenue and cost sharing contract of pricing and servicing policies in a dual-channel closed-loop supply chain. J. Clean. Prod. 2018, 191, 361–383. [Google Scholar] [CrossRef]

- Xu, L.; Wang, C. Sustainable manufacturing in a closed-loop supply chain considering emission reduction and remanufacturing. Resour. Conserv. Recycl. 2018, 131, 297–304. [Google Scholar] [CrossRef]

- Yang, L.; Wang, G.; Chai, Y. Manufacturer’s channel selection considering carbon emission reduction and remanufacturing. J. Syst. Sci. Syst. Eng. 2018, 27, 497–518. [Google Scholar] [CrossRef]

- Zhu, X.; Yu, L. Differential Pricing Decision and Coordination of Green Electronic Products from the Perspective of Service Heterogeneity. Appl. Sci. 2018, 8, 1207. [Google Scholar] [CrossRef]

- Zou, H.; Qin, J.; Yang, P.; Dai, B. A coordinated revenue-sharing model for a sustainable closed-loop supply chain. Sustainability 2018, 10, 3198. [Google Scholar] [CrossRef]

- Chen, J.-M.; Chi, C.-Y. Reverse channel choice in a closed-loop supply chain with new and differentiated remanufactured goods. J. Ind. Prod Eng. 2019, 36, 81–96. [Google Scholar] [CrossRef]

- Giri, B.; Mondal, C.; Maiti, T. Optimal product quality and pricing strategy for a two-period closed-loop supply chain with retailer variable markup. RAIRO Oper. Res. 2019, 53, 609–626. [Google Scholar] [CrossRef]

- Giri, B.C.; Dey, S. Game theoretic analysis of a closed-loop supply chain with backup supplier under dual channel recycling. Comput. Ind. Eng. 2019, 129, 179–191. [Google Scholar] [CrossRef]

- Jena, S.K.; Sarmah, S.P.; Sarin, S.C. Price competition between high and low brand products considering coordination strategy. Comput. Ind. Eng. 2019, 130, 500–511. [Google Scholar] [CrossRef]

- Li, H.; Wang, C.; Shang, M.; Ou, W.; Qin, X. Cooperative decision in a closed-loop supply chain considering carbon emission reduction and low-carbon promotion. Environ. Prog. Sustain. Energy 2019, 38, 143–153. [Google Scholar] [CrossRef]

- Liu, Z.; Li, K.W.; Li, B.-Y.; Huang, J.; Tang, J. Impact of product-design strategies on the operations of a closed-loop supply chain. Transp. Res. Part E Logist. Transp. Rev. 2019, 124, 75–91. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, L.; Wu, Y.; Guo, S.; Zhang, H.; Xiao, L. A sustainability analysis on retailer’s sales effort in a closed-loop supply chain. Sustainability 2019, 11, 8. [Google Scholar] [CrossRef]

- Zand, F.; Yaghoubi, S.; Sadjadi, S.J. Impacts of government direct limitation on pricing, greening activities and recycling management in an online to offline closed loop supply chain. J. Clean. Prod. 2019, 215, 1327–1340. [Google Scholar] [CrossRef]

- Zhu, X.; Yu, L. The impact of warranty efficiency of remanufactured products on production decisions and green growth performance in closed-loop supply chain: Perspective of consumer behavior. Sustainability 2019, 11, 1420. [Google Scholar] [CrossRef]

- Han, X.; Wu, H.; Yang, Q.; Shang, J. Collection channel and production decisions in a closed-loop supply chain with remanufacturing cost disruption. Int. J. Prod. Res. 2017, 55, 1147–1167. [Google Scholar] [CrossRef]

- Zhang, P.; Xiong, Y.; Xiong, Z.; Yan, W. Designing contracts for a closed-loop supply chain under information asymmetry. Oper. Res. Lett. 2014, 42, 150–155. [Google Scholar] [CrossRef]

- Shu, T.; Liao, H.; Chen, S.; Wang, S.; Lai, K.K.; Gan, L. Analysing remanufacturing decisions of supply chain members in uncertainty of consumer preferences. Appl. Econ. 2016, 48, 3208–3227. [Google Scholar]

- Tang, S.; Wang, W.; Zhou, G. Remanufacturing in a competitive market: A closed-loop supply chain in a Stackelberg game framework. Expert Syst. Appl. 2020, 161, 113–655. [Google Scholar] [CrossRef]

- Zhao, X.; Bai, X.; Fan, Z.; Liu, T. Game analysis and coordination of a closed-loop supply chain: Perspective of components reuse strategy. Sustainability 2020, 12, 9681. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World: The Story of Lean Production—Toyota’s Secret Weapon in the Global Car Wars that Is Now Revolutionizing World Industry; Simon and Schuster: New York, NY, USA, 2007. [Google Scholar]

- Majumder, P.; Srinivasan, A. Leadership and competition in network supply chains. Manag. Sci. 2008, 54, 1189–1204. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, Y. The optimal reverse channel choice under supply chain competition. Eur. J. Oper. Res. 2017, 259, 63–66. [Google Scholar] [CrossRef]

- Teunter, R.H.; Flapper, S.D.P. Optimal core acquisition and remanufacturing policies under uncertain core quality fractions. Eur. J. Oper. Res. 2011, 210, 241–248. [Google Scholar] [CrossRef]

- Wei, F.; Zhu, Q.; Pourhejazy, P.; Liu, C. Contract vs. recruitment: Integrating an informal waste merchant to a formal collector for collection of municipal solid waste. J. Clean. Prod. 2020, 125004. [Google Scholar] [CrossRef]

| References | Domain and Contribution | Year | No. Paper |

|---|---|---|---|

| Agrawal, et al. [38] | Classification of the RL and CLSC literature regarding implementation disposition, return, and networks | 1986–2015 | 242 |

| Govindan, et al. [39] | Content analysis of CLSC and RL works to find the gaps | 2007–2013 | 382 |

| Schenkel, et al. [40] | Reviewing green, reverse, and closed-loop supply chain literature to synchronize existing knowledge on value creation | 1998–2014 | 144 |

| Bazan, et al. [41] | Reviews the mathematical models for RL and suggesting a potential modeling approach for green RL | 1967–2015 | 183 |

| Jena and Sarmah [42] | Reviewing CLSCs on remanufacturing with special emphasis on literature related to acquisition management of returned items | 2000–2014 | 100 |

| Diallo, et al. [43] | Classification of the CLSCs, with a focus on remanufactured or second-hand products | 1985–2016 | 104 |

| Rajeev, et al. [44] | Classification various factors considering the triple bottom line of sustainability issues (i.e., economic, environmental, and social) including CLSCs | 2000–2015 | 1068 |

| Gaur and Mani [45] | Focusing on CLSCs in emerging economies and suggesting the framework that includes seven driving forces for CLSC | 1992–2015 | 141 |

| Islam and Huda [46] | Categorizing the RL and CLSC of E-waste into designing and planning of reverse distribution, decision making and performance evaluation, conceptual framework, and qualitative studies | 1999–2017 | 157 |

| Larsen, et al. [47] | Identification of distinct opportunities and contingency factors in the area of financial performance for RL and CLSCs | 1995–2016 | 112 |

| Moreno-Camacho, et al. [48] | Identifying indicators used when sustainability is evaluated in real cases for forward, reverse, and closed-loop supply chain network design | 2015–2018 | 113 |

| Peng, et al. [49] | Analyzing the causes of uncertainties at different stages of CLSCs, and identifying appropriate methods for quantifying the impacts of the uncertainties on production processes | 2004–2018 | 302 |

| Present review | Categorizing, analyzing, and figuring the structure of the game-based CLSCs regarding selling and collection directions, type of the game, reprocessing, and planning horizon | 2004–2020 | 230 |

| Year of Publication | Total | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Journals | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

| Sustainability | 3 | 1 | 5 | 16 | 2 | 1 | 28 | |||||||||||

| International Journal of Production Economics | 1 | 1 | 2 | 2 | 4 | 4 | 7 | 1 | 2 | 24 | ||||||||

| Journal of Cleaner Production | 1 | 3 | 6 | 8 | 1 | 1 | 20 | |||||||||||

| European Journal of Operational Research | 1 | 1 | 2 | 2 | 1 | 3 | 3 | 4 | 1 | 18 | ||||||||

| International Journal of Production Research | 1 | 1 | 2 | 1 | 2 | 2 | 4 | 1 | 1 | 15 | ||||||||

| Production and Operations Management | 2 | 2 | 2 | 2 | 1 | 1 | 10 | |||||||||||

| Mathematical Problems in Engineering | 1 | 1 | 3 | 1 | 2 | 8 | ||||||||||||

| Journal of Intelligent Manufacturing | 1 | 1 | 2 | 2 | 6 | |||||||||||||

| Transportation Research Part E | 2 | 1 | 1 | 1 | 5 | |||||||||||||

| Management Science | 1 | 2 | 1 | 1 | 5 | |||||||||||||

| Journal of Manufacturing Systems | 1 | 2 | 1 | 4 | ||||||||||||||

| Applied Mathematical Modelling | 2 | 1 | 1 | 4 | ||||||||||||||

| Computers & Industrial Engineering | 1 | 1 | 2 | 4 | ||||||||||||||

| Omega | 1 | 2 | 1 | 4 | ||||||||||||||

| Annals of Operations Research | 1 | 2 | 3 | |||||||||||||||

| Asia-Pacific Journal of Operational Research | 2 | 1 | 3 | |||||||||||||||

| European Journal of Industrial Engineering | 2 | 1 | 3 | |||||||||||||||

| Abstract and Applied Analysis | 3 | 3 | ||||||||||||||||

| Discrete Dynamics in Nature and Society | 1 | 1 | 1 | 3 | ||||||||||||||

| IEEE Transactions On Engineering Management | 1 | 1 | 1 | 3 | ||||||||||||||

| International Journal of Environmental Research and Public Health | 2 | 1 | 3 | |||||||||||||||

| Industrial Engineering & Management Systems | 1 | 1 | 1 | 3 | ||||||||||||||

| International Journal of Advanced Manufacturing Technology | 1 | 1 | 2 | |||||||||||||||

| Expert Systems with Applications | 1 | 1 | 1 | 3 | ||||||||||||||

| RAIRO Operations Research | 1 | 1 | 2 | |||||||||||||||

| International Journal of Simulation: Systems, Science & Technology | 2 | 2 | ||||||||||||||||

| Journal of Systems Science and Systems Engineering | 1 | 1 | 2 | |||||||||||||||

| Journal of Renewable and Sustainable Energy | 1 | 1 | 2 | |||||||||||||||

| Industrial Management & Data Systems | 1 | 1 | 2 | |||||||||||||||

| Mathematical and Computer Modelling | 1 | 1 | 2 | |||||||||||||||

| Arrows | Definition | Notation | Definition | Notation | Definition |

|---|---|---|---|---|---|

| Forward channel | D | Market | DP | Primary consumer |

| Reverse channel | SM | Second-hand market | DR | Replacement consumer |

| New product channel | M | Manufacturer | AD | Advertising agency |

| Remanufactured product channel | R | Retailer | (party)* | It shows the party is able to remanufacture the cores |

| Disposal to landfill | Re | Remanufacturer | (party)# | It shows the party is able to recycle the cores |

| Trade-in channel | T | Third-party collector | (party)f | It shows the party is able to refurbish the cores |

| Transferring the information | S | Supplier | (party)T | It shows the party is able to replace the cores |

| Government’s effect | g | Government | r | Licensee |

| Outsource advertising services | L | Landfill | e | Online channel |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shekarian, E.; Flapper, S.D. Analyzing the Structure of Closed-Loop Supply Chains: A Game Theory Perspective. Sustainability 2021, 13, 1397. https://doi.org/10.3390/su13031397

Shekarian E, Flapper SD. Analyzing the Structure of Closed-Loop Supply Chains: A Game Theory Perspective. Sustainability. 2021; 13(3):1397. https://doi.org/10.3390/su13031397

Chicago/Turabian StyleShekarian, Ehsan, and Simme Douwe Flapper. 2021. "Analyzing the Structure of Closed-Loop Supply Chains: A Game Theory Perspective" Sustainability 13, no. 3: 1397. https://doi.org/10.3390/su13031397

APA StyleShekarian, E., & Flapper, S. D. (2021). Analyzing the Structure of Closed-Loop Supply Chains: A Game Theory Perspective. Sustainability, 13(3), 1397. https://doi.org/10.3390/su13031397