1. Introduction

In present business practice, it is necessary to complement the traditional view of business models with the new sustainable development perspective. The traditional point of view of business models is focused on creating, delivering, and capturing value. Thus, this vision expresses the linear economy’s immediacy and completely forgets the dimension of time, raised by Lozano [

1] regarding sustainable development ambitions. To fill this gap and given the importance of keeping resources value, some authors as Geissdoerfer et al. [

2], Richardson [

3], and Zott et al. [

4] complement the approach of circular business models considering creation, delivery, capture, and maintain value, likewise the value network. Through the latter, this approach considers how the network can recover materials from biological and technical cycles. [

5,

6].

One of the main challenges of today’s economy is to reduce the extraction of natural resources and promote the recovery and reintroduction of materials considered as waste, generating new employment and added value, and inducing the innovation and materialization of economically profitable and environmentally sustainable business models, which are based on a circular economy (CE) system. For example, in 2019, the construction sector accounted for 5.1% in Europe [

7], and it has high growth potential, since the Green Deal includes among its priorities the modernization and renovation of buildings to make them energy-efficient, smart, and in general more sustainable [

8]. The construction sector has received particular attention with the emergence of the CE, because it is one of the largest consumers of natural resources such as energy [

9], and it is also a huge producer of CO2 emissions: “5.7 billion tons in 2009, contributing 23% of the total CO2 emissions produced by the global economics activities. 94% of the total CO2 from the global construction sector are indirect emission” [

10]. Additionally, many of the resources used in this industry are depletable (e.g., minerals, metals, oil, etc.), and in some cases, as the petroleum, all the activities associated to its production value chain may generate high levels of CO2 emissions, especially in petroleum-producing countries such as Colombia [

11], therefore this sector is called to transform towards the CE and incorporate ecological products and technologies.

To understand this transition process, this research describes the case of a Colombian middle company belonging to this sector, which is dedicated to designing and installing special structures of steel and aluminum. This case has great importance for the construction sector in Colombia, because, according to the Administrative Department of National Statistics, DANE, this industry provides job opportunities for about 1.5 million people, who represent around 7% of the total workforce [

12] and contribute to about 7% of total Gross Domestic Product (GDP) of Colombia [

13].

Several attempts have been made to describe the impact of the construction and demolition sector [

9,

10,

14] and present the potential opportunities to make it profitable and sustainable [

14]. However, there is a research gap in identifying how small and medium enterprises and emerging economies can carry out the transition towards a CE. A search in Scopus and Web of Science with the equation Topic: (“circular economy”) AND Topic: (construction) AND Topic: (metal) AND Topic: (case) in November 2020 shows only thirteen publications; none of these cases developed in developing countries, or in Latin America specifically.

The research’s objective is twofold: first, to determine the drivers of success in the CE implementation in the construction sector; and second, to analyze how those drivers can complement any implementation process in SMEs from the construction sector. This study’s key research question was: What are the drivers that facilitate the CE’s success in SMEs from the construction sector?

The paper is structured as follows: in the next section, we introduce an overview of the CE implementation in the construction sector.

Section 3 describes the context in which this study is done and the data collection and analysis. In

Section 4, we present the main results of this research. In

Section 5, we discuss the drivers of success in the implementation of CE in the construction sector, and finally, in

Section 6, we offer some discussions and conclusions.

2. Circular Economy Implementation in the Construction Sector

The European Green Deal includes the construction sector as one of the priorities to achieve a sustainable economy by promoting cleaner construction processes and updating the building infrastructure, especially for social housing, hospitals, and schools. Moreover, green cities’ updating aims to encourage energy-efficient systems, using circular design and digitalization [

8]. Then, projects like Buildings and Materials Banks [

15], which understands the buildings as “materials banks”, are focused on recovering building materials and increasing their value, using Building Information Modelling (BIM) to identify what materials can be recovered, the amount of material used, and how the building can be dismantled [

15].

Lopez-Ruiz et al. [

16] go beyond by identifying 14 strategies for implementing legislative and political CE frameworks, according to five lifecycle stages: (i) preconstruction, (ii) construction and building renovation, (iii) collection and distribution, (iv) end-of-life, and (v) material recovery and production. In preconstruction, the strategies are economic instruments, design for waste prevention, disassembly, and deconstruction to prevent potential environmental damage. It also realizes the impact of using prefabricated elements to facilitate deconstruction and developing construction and demolition waste (CDW) management plans. In the construction and building renovation stage, the development of site waste management plans (SWMP) is key, because the waste in this step mainly comes from damaged materials, imprecise concrete elements, or reinforcement steel bar cut-offs, among others. The collection and distribution include collection and segregation techniques and transport processes. The end-of-life requires selective deconstruction and deconstruction and demolition audits. Finally, material recovery and production include reuse, recycling, energy recovery, and backfilling to recover value from discarded materials in buildings.

Nonetheless, there are significant barriers that hinder the circular supply and materials recovery in the construction sector. Densley Tingley et al. [

17] identified twenty-four barriers, and they highlighted six barriers as the most significant: “the perceived risk in specifying reused materials; cost: reuse could be more expensive; composite construction (for structural steel: concrete and metal deck flooring with shear studs connected to steel floor beams); lack of reuse markets and supply chains; time constraints which favor demolition over deconstruction; and inaccessible/irreversible joints” (Page 644). Additionally, the barriers depend on the context. Likewise, Densley Tingley et al. [

17] found that “for steel construction in Japan and the USA, longer deconstruction times were perceived as the major barriers, while in Canada, a key barrier was the complexity of recertifying structural steel” (Page 644).

In the case of metals, steel, aluminum, and copper have a high significance to ensure building security, and most of them have a high recovery potential. For example, worldwide, the recycling rate of available scrap steel was estimated at 86% in 2014 [

18], recycling rates of aluminum in the transport and building sectors are around 85% to 95% [

19], while 35% of all copper currently in use stems from recycled sources [

20]. In this way, CE’s implementation in structures’ metals suppliers would promote that their entire value system from the supply, the design, and the production would be cleaner and planned from the beginning of the process. Moreover, the environmental performance of steel-framed buildings is superior to the concrete-framed ones [

21].

Particularly in Colombia, the government introduced the Green Growth Policy [

22], which is expected to be implemented between 2018 and 2030. This policy aims to improve productivity and economic competitiveness, prioritizing social well-being, the conservation of natural resources, and climate security. To this end, the action plan to implement said policy is based on establishing strategies to (i) generate new economic opportunities through the bioeconomy, the development of the forestry sector, the penetration of renewable energies and the positioning of green and sustainable businesses as a profitable business for the country; (ii) strengthen the mechanisms that optimize natural resources in production and consumption, through the implementation of guidelines that improve the performance of the agricultural sector, the improvement of water use, the promotion of new technologies that generate sustainable mobility and an efficient use of energy, and the clarification of a route for the transition towards the CE; (iii) develop guidelines to build human capital for green growth; (iv) strengthen technological and innovation capacities for green growth; and (v) improve coordination between the different institutions to manage the information and have the necessary funding for the long-term implementation of the policy.

According to this, it can be interpreted that these five aspects that constitute the strategic axes of the policy integrate institutional management, the incorporation of science and technology, and innovation processes. Still, these actions would be strengthened if individuals assume consumption as a responsible activity that favors the productive sectors that undertake long-term actions and guarantee the sustainability of operations within the policy guidelines. Thus, the environmental impact in economic management is mitigated and reduced.

To operationalize the Green Growth Policy, the National Circular Economy Strategy was launched in 2018 [

22], which emphasizes six lines of action that focus on (i) industrial materials and products, (ii) packaging and packaging materials, (iii) the optimization and use of biomass, (iv) the water circulation, (v) energy sources and flows, and (vi) management of building materials in urban centers. This latter because 96% of construction and demolition waste is not yet recycled [

22]. Thus, the idea is to optimize resources at a micro-level and replace products with services; at the meso level, to promote new business models increase the efficiency and useful life of materials through value chains and industrial parks; and at the macro-level contribute to the conservation of natural resources, economic prosperity, and social equity.

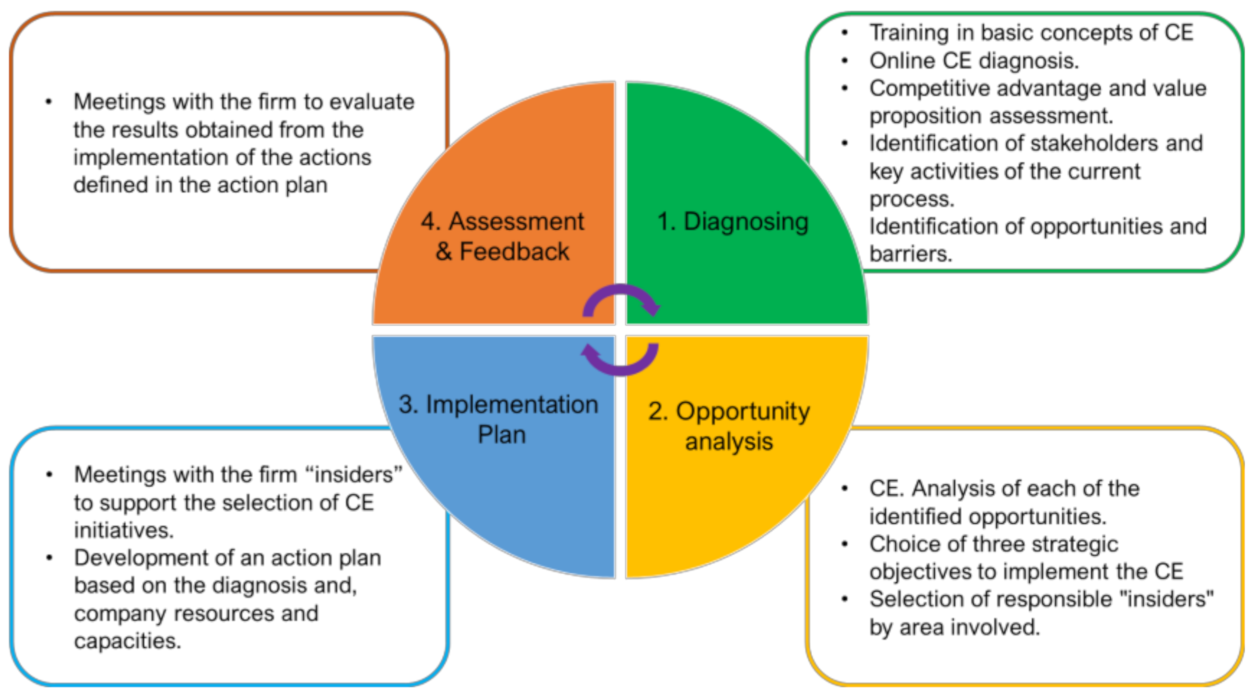

4. Results

In this section, we first describe the diagnosis results on the level of implementation of CE in TECMO, in each of the fields of action of CE. Then, the implementation opportunities identified by the company are presented. Afterward, the implementation plan proposed by the company for each of the identified opportunities is described. Finally, the results of the evaluation and feedback process of the actions implemented by TECMO are explained.

4.1. Diagnosing

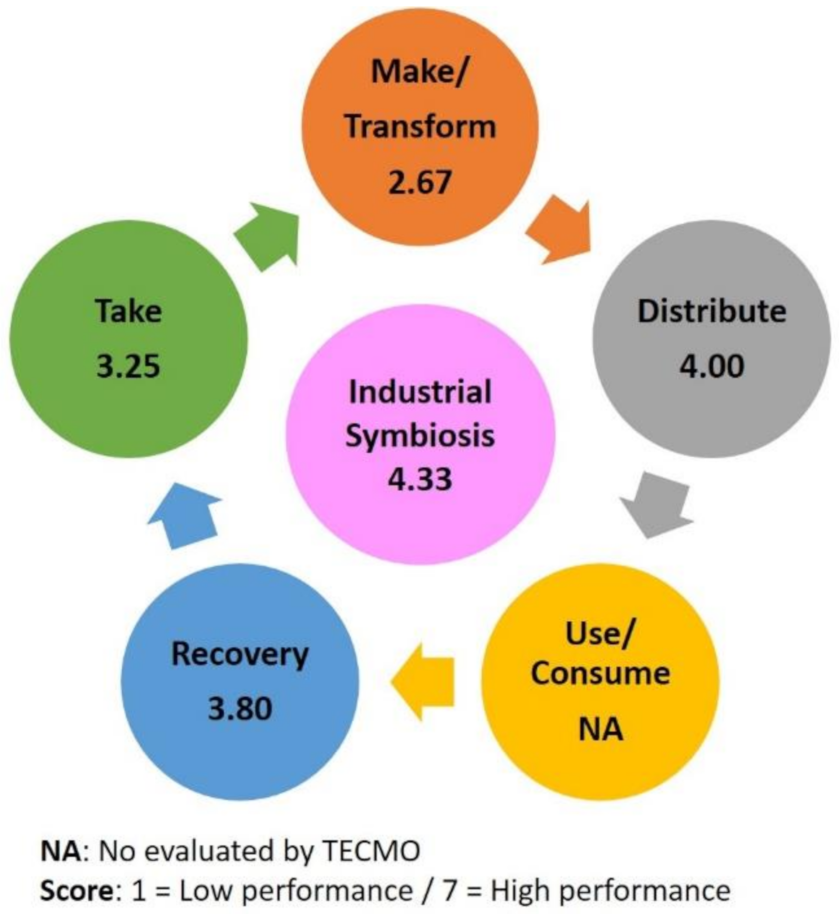

In this first step, the company was analyzed in September 2019, through the six CE fields of action proposed by Jaca and colleagues: take, make/transform, distribute, use, recovery, and industrial symbiosis [

25,

26].

Figure 3 shows the results obtained by TECMO in each of the fields of action. It is essential to state that TECMO graded each field on a scale from 1–7, where 1 meant the low level of performance and 7 high performance levels.

From this stage, one of the main findings is that companies do not start from “zero”. Generally, a company with the intrinsic motivation to implement the CE already has progressed in this regard. The results from this diagnosis show that in the field of “take”, TECMO got 3.25. It results were low because the company does not have defined criteria for the selection of sustainable suppliers and materials. It was also established that the company purchase the primary raw material through a supplier who imports the steel sheets, tube, and beams that they use; therefore, the company does not know if production is done sustainably. Additionally, given the technical requirements of the structures they manufacture, it is impossible to use biodegradable materials with lesser resistance or substitute them easily.

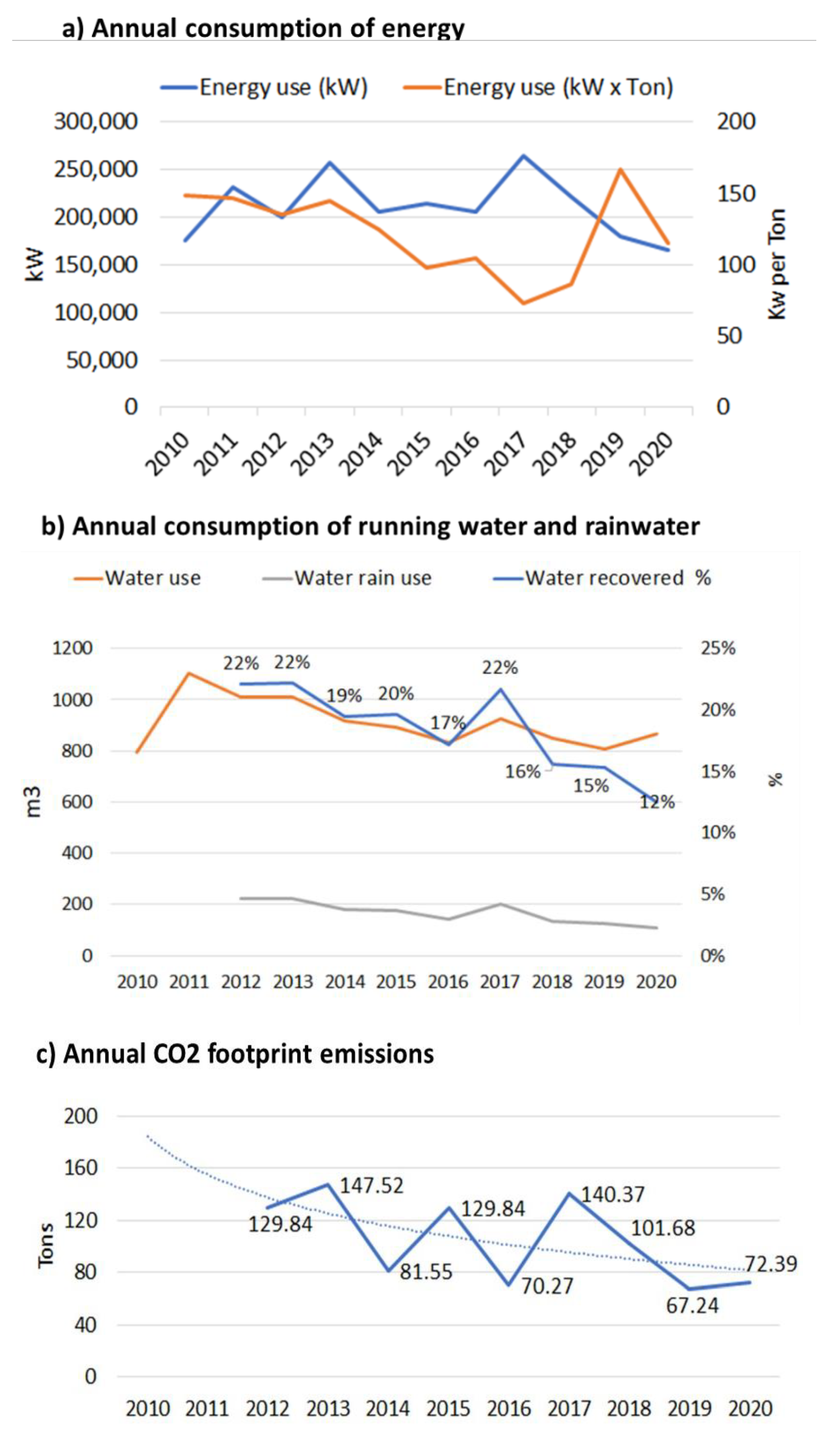

In the field of make/transform, the company got 2.67, mainly because they have a high consumption of water and non-renewable energy in their processes, although they has established a clear and very well-organized production process in the plant. They have also developed some programs oriented to recovery and use of rainwater and a composting plan to use the waste from the garden arrangement and reuse it on the premises. These activities’ performance has been monitored since 2010 through a series of environmental management indicators related to energy and water consumed, rainwater recovery, and carbon footprint reduction. In the following, the respective analysis will be made to the result given by these indicators.

The study of energy consumed both in kilowatts and kilowatts per Ton showed a decreasing behavior, despite having had recovery and growth peaks, especially in the corresponding period between the years 2017 and 2019 (see

Figure 4a). The year 2020 shows that the indicator reaches its lowest point showing the decrease in the company’s energy consumption and great progress in terms of environmental footprint. However, the lockdown caused by the pandemic reduced the activity of the company. Even though the production increase can modify the energy use, the energy use per tons use to be constant.

On the other hand, a careful study was also carried out that evaluated the volume of water that the company was wasting, for which a maximum point of 1104 cubic meters (m

3) was reached, which at first glance may seem a relatively normal figure for a company that is responsible for producing metal structures and carrying out projects that involve material manufacturing (see

Figure 4b). However, if the same constant expense were maintained over time, the result would be a massive and unnecessary loss of water. Considering this, the recovery of rainwater contributed to a significant reduction in water consumption with a difference of 786 m

3 from its maximum reach (2011) to its minimum point (2020). The water rain recovered may vary according to the weather, but it can cover 22% of the total use.

Figure 4c shows the reduction that TECMO has achieved in the carbon footprint since 2010. In average, it has reduced 78.21 tons CO2 eq/year (equivalent to a 41% reduction in the carbon footprint). This was possible thanks to the implementation of several energy efficiency measures and reducing greenhouse gas emissions. Among the measures is the replacement of two 15-ton to 25-ton overhead cranes and three low efficiency, 27-kW piston compressors with a capacity of 36 CFM to a 15-kW 60 CFM screw compressor. Additionally, the 3 ton/h SAND BLASTING system was replaced with a 23 ton/h automatic shot blasting system, a change from the conventional painting system with a 50% yield to an 85% yield AIRLESS system, and a filtering system was installed on the cutting table to reduce particulate matter. Additionally, the 8-kW metal halide type lighting was replaced in the plant with translucent tiles, and 4.7 kW LED and energy-saving lighting.

In distribution, TECMO obtained a score of 4.0, because it has optimized the transportation routes and the space available in the trailers that they use to transport the prefabricated structures to the construction site. Nevertheless, the transportation system is one aspect that can be improved by replacing the use of fossil fuels with biofuel. The company’s field use/consumption was not evaluated by the company, because due to the type of products they sell, they do not influence how they are used.

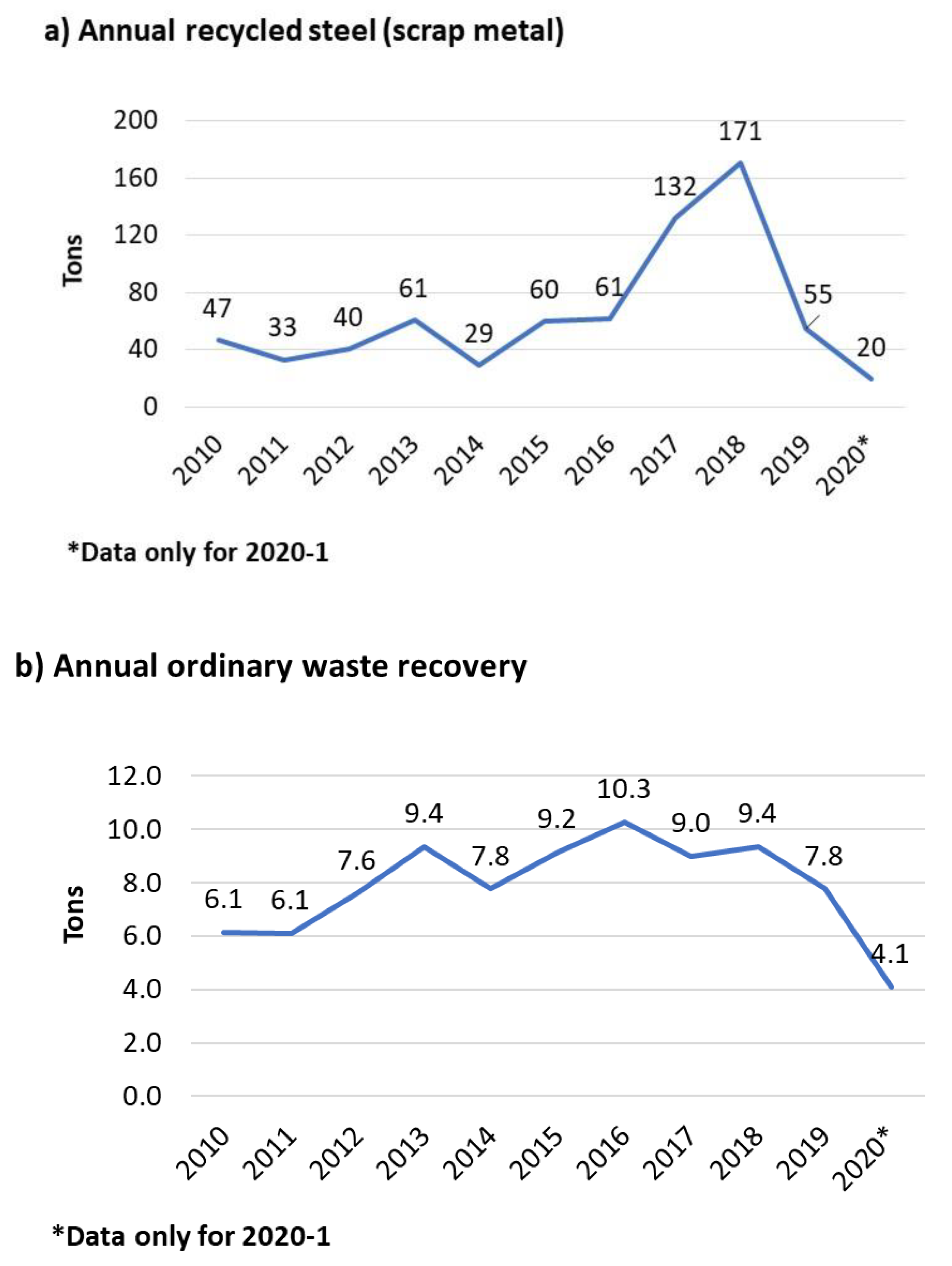

Regarding the field of recovery, TECMO got 3.80. In this regard, we found that TECMO generates around 68 tons of steel waste per year. However, it sells the waste to another company to be recycled and reincorporated into the value chain (see

Figure 5a). The raw material is commercialized as waste quality, which generates a significant reduction in the material’s economic value, generating TECMO losses. Since this stage, the company realized an opportunity to reintroduce the steel waste to the process, generating more profits and contributing to steel recycling.

Moreover, since the prefabricated structures are positioned and assembled on-site to form the requested structures, this phase also generates steel waste that could be used for the manufacture of by-products. The company generates around 8 tons of ordinary waste annually, which includes waste generated in cafeterias, common areas, and office supplies. However, as shown in

Figure 5b, the company has managed to regulate waste production since 2017.

Finally, in the field of industrial symbiosis, TECMO got 4.33. This result is because the company is part of the National Business Association of Colombia (ANDI), which currently groups around 100 companies in the area and helps city governments with various direct and indirect social programs. Additionally, the company belongs to the ANDI committee to make technical standards for the metalworking sector. On the other hand, in recent years, TECMO has worked together with the Corporación Ambiental Empresarial (CAEM, in its acronym in Spanish), a subsidiary of the Bogotá Chamber of Commerce, to carry out programs for measuring the business carbon footprint and energy efficiency. The punctuation would be higher if the company started sharing materials, by-products, and resources with those networks.

Later, in a space for reflection and under the researchers’ guidance, the team of “insiders” recognized that the diagnosis score had been low compared to the progress they have made in terms of sustainable development.

4.2. Action Plan and Implementation

After diagnosis, TECMO identified several opportunities to implement the CE and corresponding strategies according to the CE fields of action: seven in “take”, four in “make”, one in “distribution”, one in “consumption/use”, two in “recovery”, and one in “industrial symbiosis”. According to the potential benefit and effort required to be accomplished, each of them was assessed by the students and firm staff from 1 to 5. Then, the participants reach a consensus and agreed to plans of action (see

Table 1).

Considering the strategic priorities of the firm, only three strategic opportunities were analyzed in-depth to define a strategic objective, action plan, required resources, indicators, deadline, and insiders (see

Table 2). The objective and action are designed according to the environmental management expectation of the firm and its impact on the corporate strategy. In this way, the firm must consider the internal resources required to achieve the strategic objective and make the transition towards a CE economy [

27]. Then, the selection of insiders means the empowerment of a collaborator from the area involved to carry out an action plan. The selection of a specific person has been applied in other CE implementation case studies [

28] and environmental management initiatives in firms like Belcorp with the Ecochampions program [

29] and Beckton Dickinson with “BD Green’ champion” in every site around the word [

30]. Finally, a deadline and at least one indicator are key elements to assess the objectives and plans.

In this stage, the firm develops the three action plans they consider more strategic and feasible to get medium-term results in less than one year. The first initiative was the “waste recovery based on sustainable design”, for the development of this initiative, the company used resources such as industrial supplies, construction waste, and the company’s design area. Additionally, the use of competitive capacities such as staff training and infrastructure is considered essential. The plan consisted of designing the products, developing prototypes, defining the product, defining the cost/benefit relationship, feasibility study and business opportunity in the manufacture and sale of by-products, and commercializing the products, and evaluation and feedback based on profitability. Eco-innovation was reflected in reducing the production of raw materials and increasing the degree of efficiency in raw materials. Thus, CE’s benefits are visible in the increase of the productivity of the employees and the company and the reduction of costs when manufacturing washers and gears that can be integrated into the main activity of TECMO.

As mentioned before, TECMO generates around 50 t of steel waste per year, which is a reasonably representative amount that is wasted by the company, and sells it to another company to be recycled and reintegrated into the value chain. Selling the materials as scrap means a significant reduction in the material’s economic value, generating losses for TECMO, an opportunity that the company itself loses to reintroduce steel waste into the industrial process, to generate more profits and contribute to the steel upcycling process. This strategy does not have a particular focus on one industry sector. It seeks to generate value using waste and transform it into a product that any market could buy. Some of the goods that have already been produced and sold are artwork, cheese cutters, local sports courts, and garden benches.

Second, the firm developed a “Sustainable procurement guide” to create a protocol to buy sustainable products and services, regarding the diversity of supplies and the experience of the company, the “insider” started with the “Sustainable procurement guide” for articles on personal hygiene, and office supplies. Sustainable materials have replaced more than ten items, for example, the office paper that is purchased today is produced with the waste from the production of sugar from the cane. This agro-industrial waste is called “sugarcane bagasse”; besides being used to make paper, it is used to produce biofuels. This initiative requires that sometimes higher investments be made and greater rigor in the selection of suppliers. Eco-innovation is incremental and is evidenced in reducing the generation of polluting non-biodegradable waste. Additionally, the initiative contributes to the EC, because it has generated greater awareness of the company’s staff using resources and less waste disposal. This guide will then be developed in sections, and the insider expects to include production supplies next year.

Third, the firm diagnostic showed that it has proactive environmental management activities, but the customers and stakeholders do not know it. Thus, the firm started a green marketing strategy based on updating the web site with information about environmental management and sustainability awards. Moreover, the firm is writing its first sustainability report to provide information for its stakeholders about its economic, environmental, and social contributions in the sector and the region. The sustainability report is quite important, because it provides information on the companies’ intangibles such as the culture and the management philosophy, which satisfies the demand by the stakeholders towards socially environmentally responsible behavior and creates reputation and trust [

31].

4.3. Assessment and Feedback

At the end of the implementation cycle, the three opportunities for implementing CE in TECMO were almost achieved. First, the firm is exploring waste recovery strategies based on sustainable design with a competency among the staff and a set of awards for the best designs made with TECMO’s by-products. Moreover, the company exceeded this objective’s fulfillment, considering that more than three designs have been commercialized (on a small scale as a pilot), and more than 20% profitability has been obtained from them. On the other hand, the organizational climate has not been measured, but the employees informally commented that this activity had increased their sense of belonging to the company; it makes them feel more valued.

The second plan is in process, and the firm is developing its first “Green procurement handbook”, starting with a set of considerations for green supply, and the substitution of office supplies like paper, personal cleaning, and cleaning implements has started. Moreover, the top manager required a complete Green procurement handbook with a specific description of core materials and the ecological or social certifications they may have.

Third, the company is already working on its green marketing strategy through various initiatives such as updating its website and a first sustainability report that follows some of the GRI standards’ requirements. Moreover, TECMO considers that this study is essential to clarify the knowledge created in its company and consolidate practices that help them be sustainable in the sector and be an inspiring model for the region. After this experience, the firm expects to present this kind of report every year. For the next potential cycle, the firm will work with students to develop a 7p’s marketing mix to highlight its environmental performance.

5. Discussion: Drivers of Success in the Implementation of CE

TECMO is a company dedicated to the construction of large steel structures for buildings. In this sense, it has been essential to rethink the sources for obtaining this resource and reduce its processing’s environmental impact. The importance of recycling steel lies in the fact that recycled steel in its manufacturing process reduces energy consumption by 70% and avoids the extraction and transport of new raw materials (iron and coal). For every ton of used steel that is recycled, one and a half tons of iron ore is saved, and about 500 kg of the coal used to make steel coke, the fuel used to make this metal. The use of water, another increasingly scarce natural good, is reduced by 40%; the emissions of carbon dioxide (CO2), the greenhouse gas involved in climate change, also decrease if this metal is used: for each recycled steel container, its weight in CO2is saved one and a half times. The qualities of steel make it a useful material for many products and packaging and are ideal for recycling.

As part of the company’s commitment to protecting the environment, essential changes have been made, such as updating the technology of production processes and infrastructure to achieve lower energy consumption, less pollution, more efficiency, and better yields. This is in addition to the responsible purchase or acquisition of material or supplies. Improvement processes have been achieved in the management of usable waste, scrap metal, plastics, and other recycling products to minimize the generation of ordinary waste and at the same time achieve the recovery of raw material for other industrial processes. To this end, the company’s collaborators have been involved in generating sustainability awareness in their activities and caring for the environment, both within the company and outside.

Considering this case study process and results, five drivers were identified for implementing CE: fertile ecosystem, management commitment, identification of valuable materials, green teams, and CE Intermediaries.

Figure 6 shows how the drivers are composed and the interaction among them.

The fertile ecosystem is associated with the region, sector, and regulation and policies that may influence and motivate consumers’ and suppliers’ environmental practices by supporting eliminating significant political CE barriers [

32,

33]. Moreover, Xue et al. [

34] show that this driver’s focus could be influenced by the awareness of government officials, who tend to lead economic aspects instead of promoting public awareness and financial support for CE implementation in firms. Local municipalities in countries like Romania are developing CE initiatives to achieve the zero-waste certification “Zero Waste Cities” [

35,

36]. The TECMO case study is developed in Colombia, a country that embraced the CE strategy two years ago and is working on a long-term green growth policy.

A key issue identified in this process was that the top managers share environmental values and authentic concern about the firm’s potential impacts. The study developed by Moktadir et al. [

37] shows that management commitment is one of the most critical success factors (CSFs) needed in the business strategy development of CE practices. This case study confirms this proposal, considering the top manager’s commitment to this research project, the time involved (more than 50 h), and the open access to the firm information without looking for any specific reward. The importance of top managers’ commitment to implementing CE is also confirmed by other studies in supply chain management field [

38,

39]. Moreover, SMEs with high women’s participation in management positions improve sustainability [

40], and women are more sensitive to environmental issues [

41]. This fact was corroborated in TECMO’s case, where the women managers tend to have a more outstanding commitment by demanding sustainability strategies in the firm, approving the resources assignation, and leading environmental management activities.

Then, identifying valuable materials in the case study increases the firm interest on the CE and its potential to increase the economic, social, and environmental benefits. The evident scarcity of resources is changing the concept of “waste”. Nowadays, some authors claim that a significant portion of the current waste may be underutilized raw materials [

42] or potential circular materials in industries [

6,

43]. Additionally, the improvements in design and technology can drive product life extension, reducing the demand for raw materials [

44].

The team members called “insiders” emerged in this research to empower the staff and guarantee the achievement of the goals. Additionally, some literature related to green human resources management (GHRM), which intended to make, augment, and preserve in each employee a green attitude, explain that organization’s environmental management success highly depends on the staff environmental awareness [

45] and contributions [

46]. De Souza Moraes [

47] documents the importance of designing green team works to solve environmental problems, achieve environmental certifications, or strengthen the sustainability strategy according to the company’s environmental management’s maturity level.

Finally, taking into account that CE’s implementation requires eco-innovation, as indicated by Prieto-Sandoval et al. [

42], it also requires public and private intermediaries that cooperate [

48]. Thus, it is possible to talk about CE intermediaries as organizations from diverse origins and with different objectives that support companies reducing the knowledge gap needed to implement CE’s innovative practices. In that sense, they interact through open innovation initiatives nurturing the fertile ecosystems. In this regard, some of those eco-innovation intermediaries, and therefore CE intermediaries, are institutions, governments, universities, incubators, science parks, cluster initiatives, project developers, and business development organizations that have been identified as support actors that assist firms in eco-innovation. In this specific case, the universities are confirmed as critical intermediaries, whose researchers facilitated the implementation process and companies’ accompaniment with the retribution of obtaining new knowledge [

48]. This kind of cooperation is also more straightforward with geographic proximity, which has been a part of successful symbiosis cases such as Kalundborg in Denmark, Campbell Industrial Park in Hawaii, and Guitang Group in China, among others [

49]. All of them have taken advantage of close geographical proximity to compatible partners by sharing resources, reducing transport costs, and achieving more significant collective benefits [

50]. In this case, TECMO and researchers are in the same region, and the firm participates actively in sectorial associations.

All these dynamics corroborate the approach of Geissdoerfer et al. [

2] under which, in the CE, the business models of the companies have the function of creating, delivering, capturing, and maintaining value, as well as participating in a value network. Thus, identifying valuable materials allows the maintenance of value, the management commitment and the green team drive this whole new business model scheme, and the fertile ecosystem and intermediaries shape and give life to the value system that supports the company.

6. Conclusions

To answer the research question, five drivers were identified for implementing CE: fertile ecosystem, management commitment, identification of valuable materials, green teams, and CE Intermediaries. The fertile ecosystem is like a “macro” driver, determined by the contexts and regulation conditions; management commitment is associated with the manager’s willingness to work on CE and their environmental values. Then, the identification of valuable materials, green teams, and CE intermediaries are drivers that are related to the implementation process and operative success.

In this case study, it was interesting to discover that the company directors’ awareness, style, and sustainable values did not allow them to see the progress made in the implementation of the CE. Additionally, it was found that this perspective led them to develop circular initiatives without capitalizing on strengthening the company’s value proposition. This corroborates the importance of CE intermediaries, which provide knowledge and awareness exercises regarding the level of maturity of CE implementation in the organization.

Additionally, it was observed that construction companies have substantial opportunities to implement the CE, but achieving this requires the commitment of management and their willingness to invest time and money. Likewise, it is essential to identify the “priority” fields of action given the system’s most significant inefficiencies or the opportunities to create value capture sources. Moreover, the proper definition of a group of “insiders” who execute the plan can be the key to success, because they are people committed to the organization who have intrinsic motivation to improve the processes’ environmental and social quality.

Second, to overcome the CE barriers, it is proper to prioritize initiatives with less effort and more benefit in the short term to achieve the kick-off of the implementation process. In addition, it is essential to carry out a financial evaluation to identify opportunities for saving materials and increasing profitability. Then, when managers begin to see results such as an improvement in the work environment, increased prestige, and the identification of new business models, more ambitious projects can be started. It was also evidenced that women managers tend to have a more outstanding commitment and spend more time on initiatives or endorsements for their development more easily.

Third, the results of this study contribute to the literature on pollution haven hypothesis, by corroborating Sadik-Zada and Ferrari’s [

51] findings on the validity of this conjecture. In fact, in the case of TECMO, the use of new technologies, the utilization of scrap metal, and the improvement of energy efficiency has allowed it to reduce its CO2 emissions considerably in the last ten years. In addition, the formulation of increasingly efficient environmental policies, together with the implementation of stricter regulations, can not only prevent the increase of pollution by large multinationals from the Global North that have operations in the national territory, but also reduce it considerably. Thus, it is possible to avoid that Colombia will be a pollution haven as occurs with many countries of the South Global.

Finally, this study contributes to teaching the implementation of the CE in companies, since it shows that through the methodology presented, implementation projects can be developed in postgraduate classes that involve companies and benefit them from academic activity. Likewise, it shows that there is abundant room for further progress in determining specificity of management and governance in SMEs as well as specificity of construction industry what is project-based to make the transition towards CE.