Methodology for Assessing the Degree of Occupational Safety Specific to Hydrotechnical Construction Activities, in Order to Increase Their Sustainability

Abstract

1. Introduction

- ○

- Methods based on the questionnaire technique: They have as a principle the finding of deficiencies concerning the norm, but they differ in the degree of formalization. The minimum tool required to perform the analysis is a questionnaire that records, in a more or less detailed manner, the key points to be observed to a reference system—the legal provisions. Questionnaires are local in character and can rarely be generalized. Among the main methods we can mention: the checklist designed by Thony, France, 1986, and the observation guide developed within the National Plant Management Renault—France.

- ○

- DCT method (Diagnostique des conditions du travail): proposed by French researchers Piotet and Mabile in 1984 and involves five steps.

- ○

- DST (Diagnosis Safety Form) method: developed in 1974 by a group of American researchers, aiming to identify a set of deficiencies existing in a given activity that determine the safety performance, for analysis and evaluation occupational safety issues common to a set of similar jobs or activities characterized by common risks.

- ○

- Nosa method: It is applicable at company level and analyses the absence of preventive measures provided by legal regulations. The working principle is the comparison of the situation in the field with a checklist of key articles, representing the basic elements of any prevention program [15].

- ○

- WorkWell method: used for external audits and was developed by the Commission on Occupational Safety and Insurance (Workplace Safety & Insurance Board (WSIB)—Canada). By assessing compliance with legal requirements and principles of good practice in the industry, the method allows the evaluation of occupational safety and health management of the organization.

- ○

- Alberta method: was developed in 2002 by the authorities of the Canadian province of Alberta, as part of a partnership program with employers to improve occupational safety and health.

- ○

- CHASE method (Complete Health and Safety Evaluation Method): was developed by the British company HASTAM and has a modular character. It comprises the following basic modules: CHASE EME, CHASE SMi 18001, CHASE SMS 18001, CHASE SMi HSG65, CHASE SMS HSG65, and DSE Self Assessment.

- ○

- OSHA method (Occupational Safety and Health Administration Method): It is an internal audit method, which was developed by the Administration for Safety and Health at Work (OSHA) in the United States of America and small businesses.

- ○

- INCDPM method (National Institute for Research and Development of Occupational Safety Method): developed within the National Research and Development Institute for Work Protection in Romania, having as a principle the examination and systematic analysis, independent and documented, of the existing conditions in a company, to determine if and to what extent they comply with the requirements of safety legislation and occupational health in force.

- -

- The preventive activity must result in the control of the injury risks and occupational diseases specific to the hydrotechnical constructions activities, at such a level as to eliminate the possibility of their action on workers, the most objective guarantee regarding the achievement of this desideratum being offered by the audit of occupational health and safety.

- -

- In order to have permanent information on the control degree of occupational risks in the hydrotechnical field, the most effective and efficient solution is to organize the internal occupational safety audit as a function of the company; in this sense, there are many advantages, namely [18]:

- The use of external audit is limited by the current financial possibilities of the hydro-construction company that wants to audit and by the auditor’s availability;

- the internal audit has a strong preventive character, performing controls that guarantee the OSH objectives’ achievement, respectively, the prevention of the weakness gettting worse, while the external audit finds and monitors, first of all, their existence;

- internal auditors can more quickly identify non-compliances, due to the knowledge they already have about the hydrotechnical activities of the company they belong to;

- internal auditors are practically doubly interested in increasing the organization’s performance in occupational safety and health, as auditors and employees of the hydro-construction company who must contribute to the implementation of occupational safety and health policy promoted by the top management of this institution.

2. Synthesis of the Specialized Method for Assessing the Degree of Occupational Safety Applicable to Hydrotechnical Construction Companies

2.1. General Checklist for Occupational Safety and Health Audit

2.2. Specific Checklists for Occupational Safety and Health Audit

2.3. Nonconformity Identification and Analysis Sheet

2.4. Grid of Weighting Coefficients for Assessing Overall Compliance

2.5. Assessment Sheet of the Global Degree of Compliance with Occupational Safety and Health Requirements

2.6. Summary Sheet of Nonconformities

2.7. Final Audit Report

3. Procedure for Applying the Specialized Method for Assessing the Degree of Occupational Safety

3.1. Information on the Object of the Audit

3.2. Establishing Working Tools

3.3. Checklists Application

3.4. Calculation of Quantitative Indicators to Assess Conformity

3.4.1. Overall Compliance with Occupational Safety and Health Regulations

3.4.2. Degree of Compliance with Occupational Safety and Health Regulations for an Activity or a Risk of Occupational Injury and Illness

3.5. Overall Assessment of the Level of Safety and Health at Work

3.6. Synthesis of Non-Conformities and Establishment of Prevention Measures

3.7. Preparation of the Audit Report

4. Procedure for Applying the Specialized Method for Assessing the Degree of Occupational Safety

4.1. General Information on the Object of the Audit

4.2. Establishing Working Tools

4.3. Application of Checklists

4.4. Calculation of Quantitative Indicators to Assess Conformity

4.5. Overall Assessment of the Level of Safety and Health at Work

4.6. Synthesis of Nonconformities

- If K = 0, then there is a perfect fit, which is not recommended to be given full confidence, because in theory it is unlikely.

- If K > 0, then the two distributions are different. The K value is then compared with the Kolmogorov function quantile, and the following is concluded: if K < , variations between distributions are due to chance and the assumption of adequacy is not to be rejected at the risk threshold, so the adjustment is accepted; if K > , the hypothesis of good adequacy between the sample and the theoretical law must be rejected.

- Based on the results obtained from the occupational safety and health audit, the following aspects found at the level of the analyzed entities can be highlighted: implementation and maintenance of an occupational safety and health management system; management’s concern for the functioning and improvement of the occupational safety and health management system; the existence of a complete system of documents and records adequate to the legal and internal requirements regarding the achievement of safety and health at work; improving occupational hygiene conditions; training of first aid workers; and concern for health monitoring; equipping workers with personal protective equipment, purchased only from accredited companies. There are also shortcomings at the level of the entities analyzed in terms of red low knowledge of workers on appropriate behavior in terms of occupational health insurance:

- Empirical determination of generalized probability density, and the generalized distribution function, :

- Determining the objective medium security risk, :

- Determining the objective average vulnerability, :

- 5.

- Assessing the uncertainty of the results obtained using the Kolmogorov–Smirnov statistical adequacy test:

- 6.

- Various estimates:

- -

- Determining the value of exceeding a state of insecurity to which a probability of a certain order corresponds (ex. P = 10−1):x p= 10.0614–7.1673 × ln(–ln(1–10−1)) = 26.19 P(x > 26.19) = 1–F(26.19) = 0.11 (a probability of the order 10−1)

- -

- Determination of the 95% confidence interval, according to J. Bernier. Ex. For p = 0.1; n = 21; α = 0.05; xp= 26.19; T2(0.1;21;0.05) = −0.75; T1xσ = −6.8940; T1(0.1;21;0.05) = 1.03; T2xσ = 9.4678; i0.95 = [19.29;35.65];

- -

- Determining the probability of exceeding a value associated with a state of insecurity: P(x > 16.27) = 1–F(16.27) = 1–0.6566 = 0.3433 (Medium level security risk, according to the risk assessment grid).

4.7. Audit Report

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Audiffren, T.; Rallo, J.-M.; Guarnieri, F. The contribution of case law to com pliance management in Occupational Health and Safety (OHS) in France. In Proceedings of the PSAM11 & ESREL, Helsinki, Finland, 25–29 June 2012; Volume 2, pp. 1320–1328, ISBN 978-162276436-5. [Google Scholar]

- Chang, K.T. Introduction to Geographic Information System, 7th ed.; McGraw-Hill Education: New York, NY, USA, 2014; pp. 293–315. ISBN 978-0-07-352290-6. [Google Scholar]

- Kent, J.N. Improving safety culture through the health and safety organization: A case study. J. Saf. Res. 2014, 48, 7–17. [Google Scholar]

- British Standards Institution (BSI). BS 8800:1996—Guide to Occupational Health and Safety Management Systems; BSI: London, UK, 1996; pp. 1–70. ISBN 0-580-25859-9. [Google Scholar]

- British Standards Institution (BSI). BS EN 30011–1:1993—Guide to Quality Systems Auditing; BSI: London, UK, 1993. [Google Scholar]

- British Standards Institution (BSI). BS EN 30011–2:1993—Qualification Criteria for Auditors; BSI: London, UK, 1993. [Google Scholar]

- British Standards Institution (BSI). BS EN ISO 14001:1996—Environmental Management Systems—Specifications with Guidance for Use; BSI: London, UK, 1996. [Google Scholar]

- British Standards Institution (BSI). BS EN 30011–3:1993—Guidelines for Auditing Quality Systems ó Managing an Audit Programme; BSI: London, UK, 1996. [Google Scholar]

- International Organization for Standardization (ISO). ISO 45001:2015—Occupational Health & Safety Management System; ISO: Vernier, Geneva, Switzerland, 2015. [Google Scholar]

- AuSQ—Australian Society for QualityTM. Certification Criteria for Occupational Health and Safety Auditors. Available online: https://www.ausq.org/ (accessed on 6 October 2020).

- International Labour Organization. ILO-OSH 2001—Guidelines on Occupational Safety and Health Management Systems SafeWork; ILO: Geneva, Switzerland, 2001; ISBN 92-2-211634-8. [Google Scholar]

- Improving health and safety in the construction industry. In Report by the Comptroller and Auditor General; HC 531 2003-2004; National Audit Office Press Notice: Londra, UK, 2004; Available online: https://www.nao.org.uk/wp-content/uploads/2004/05/0304531es.pdf (accessed on 6 October 2020).

- National Occupational Safety Association. The Nosa MBO Safety System with Star Grading Recognition; National Occupational Safety Association: Sandton, South Africa, 1986; ISBN 9780620077545. [Google Scholar]

- Bracker, S.; Kinki, A. Strategic Management, Plent Clasing and Social Responsabilitees; An Integrative Process Mode, Emploee. Responsab. Right J. 1988, 1, 201–213. [Google Scholar]

- Albarracin, B.; Carlos, J. Primer modelo de excelencia preventive. Available online: https://www.auditec.com (accessed on 2 June 2002).

- Barbet, J.F. Les méthodes d’analyse de la sécurité des systèmes. Révue Générale de Prévention. 1984, 30, 42. [Google Scholar]

- Barthod, P. Check-list d’observation pour l’analyse d’un poste de travail. Une méthode de recherche de facteurs de risque a priori. Revue des Conditions de Travail. 1985, 16, 25. [Google Scholar]

- Turney, R. Audits and Inspections: How can we maximise effectiveness? Presented at the OECD Workshop on Audits and Inspections related to Chemical Accident Preparedness and Response, Madrid, Spain, 5–9 March 2001. [Google Scholar]

- SEAI. Energy Auditing Scheme Guidance Note, Sustainable Energy Authority of Ireland, version 004; Sustainable Energy Authority of Ireland: Dublin, Ireland, 2015. [Google Scholar]

- Fleiter, T.; Gruber, E.; Eichhammer, W.; Worrell, E. The German energy audit programme for firms: A cost-effective way to improve energy efficiency? Energy Effic. 2012, 5, 447–469. [Google Scholar] [CrossRef]

- Vasilescu, D.; Drăghici, A.; Popescu, L. Development of methods for the analisys and evaluation of occupational risk aiming at the prevention and fight against causes which may generate occupational accidents and diseases. In Proceedings of the First International Conference Research People and Actual Tasks on Multidisciplinary Sciences, Lozenec, Bulgaria, 6–8 June 2007. [Google Scholar]

- Group Shell. Internal Audit Guidelines. December 1995. Shell Global. Available online: https://www.shell.com/ (accessed on 6 October 2020).

- The Institute of Internal Auditor. Standards for the Professional Practice of Internal Auditing; The Institute of Internal Auditor: Altamonte Springs, FL, USA, 2016. [Google Scholar]

- Institute of Internal Auditors. 2002. Available online: www.theiia.org (accessed on 6 October 2020).

- Legea nr. 319/2006 a Securităţii şi Sănătăţii în Muncă—M.O. nr. 646/26.07.2006. Available online: http://www.mmuncii.ro/pub/imagemanager/images/file/Legislatie/LEGI/L319-2006.pdf (accessed on 6 October 2020).

- Pacca, S.; Horvath, A. Greenhouse gas emissions from building and operating electric power plants in the Upper Colorado River Basin. Environ. Sci. Technol. 2002, 36, 3194–3200. [Google Scholar] [CrossRef] [PubMed]

- Good, L. Methodology for Conducting Energy Audits on Small Hydroelectric Power Plants (SHPPs); Ad Hoc Expert Facility under the INOGATE project Support to Energy Market Integration and Sustainable Energy in the NIS (SEMISE); Inogate: Kiev, Ukraine, 2011. [Google Scholar]

- Ting, J.; Zhenzhong, S.; Yang, L.; Yiyang, H. Carbon Footprint Assessment of Four Normal Size Hydropower Stations in China. Sustainability 2018, 10, 2018. [Google Scholar] [CrossRef]

- Remy, J. Les méthodes d’analyse et les objectifs de recherche. In Méthodes D’analyse Contenu Sociologie; Presses de l’Université Saint-Louis: Bruxelles, Belgium, 1990; pp. 191–202. [Google Scholar]

- Bird, F.E.; Cecchi, F.; Tilche, A.; Mata-Alvarez, J. Management Guide to Loss Control; Institute Press: Loganville, GA, USA, 1974; ISBN 978-1-900222-26-6. [Google Scholar]

- Elsea, K.; Conger, D. MORT User’s Manual; EG&G Services: Woodstock, GA, USA, 1987. [Google Scholar]

- Ho, M.M.T. Réflexions sur l’analyse de la sécurité des systèmes. Ses méthodes et ses problems. Cahiers de Notes Documentaires 1976, 85, 571. [Google Scholar]

- WorkSafe. Department of Mines, Industry Regulation and Safety. Available online: https://www.commerce.wa.gov.au/worksafe/ (accessed on 6 October 2020).

- Kearney, M. Managementul procesului de protecţia muncii. Prof. Saf. 1993, 8, 16. [Google Scholar]

- March, J. Continuity and Change in Theories of Organisational Action. Adm. Sci. Q. 1996, 41, 278–287. [Google Scholar] [CrossRef]

- Los Registros Deben Ser Mantenidos De Acuerdo A Lo Que Sea Apropiado Para El. Course Hero. Available online: https://www.coursehero.com/file/p7jigjnv/Los-registros-deben-ser-mantenidos-de-acuerdo-a-lo-que-sea-apropiado-para-el/ (accessed on 6 October 2020).

- A Guideline for Occupational Health and Safety Audits. Available online: https://www.ilo.org/wcmsp5/groups/public/---dgreports/---dcomm/---publ/documents/publication/wcms_publ_9221116344_en.pdf (accessed on 6 October 2020).

- Audit Regulations and Guidance, Institute of Chartered Accountants in England and Wales. Available online: https://www.icaew.com/-/media/corporate/files/technical/audit-and-assurance/audit/working-in-the-regulated-area-of-audit/audit-regulations-010612.ashx?la=en (accessed on 6 October 2020).

- Audits & Inspections: Audit Tool for ILO-OHS 2001 Occupational Healt & Safety. Available online: https://risknowlogy.com/ (accessed on 6 October 2020).

- Audits De Sécurité. Comité International De L’aiss Pour La Prévention Des Risques Professionels Dans L’industrie Chimique. Available online: https://veille-travail.anact.fr/osiros/result/notice.php?queryosiros=id:25298&referer=permalien (accessed on 6 October 2020).

| No. | Requirement | The Element of the Work System to Which It Refers |

|---|---|---|

| 10.00 | Personnel selection and control | Worker |

| 11.00 | Occupational safety and health training and information | |

| 12.00 | Personal protective equipment | |

| Total | ||

| 9.00 | Establishing and allocating work tasks | Work task |

| Total | ||

| 1.00 | Buildings and rooms where work processes take place | Means of production and work environment |

| 2.00 | Stairs, steps, level differences, scaffolding, platforms | |

| 3.00 | Location of technical equipment | |

| 4.00 | Protection against mechanical risks | |

| 5.00 | Electrosecurity | |

| 6.00 | Loading, unloading, transport, handling, and storage of materials | |

| 7.00 | Portable equipment and hand tools | |

| 8.00 | Fire prevention and control | |

| Total | ||

| 13.00 | Organization of prevention and protection activity | Work system Worker |

| 14.00 | First aid in case of injury | |

| Total |

| Maximum Possible Consequence to Be Avoided by Complying with the Requirement | Score Awarded |

|---|---|

| Accidents at work and/or occupational diseases resulting in temporary incapacity for work | 40 |

| Accidents at work and/or occupational diseases resulting in disability | 80 |

| Accidents at work and/or fatal occupational diseases | 100 |

| No. | Criteria for Penalizing the Maximum Score | Gravity | Penalizing (%) |

|---|---|---|---|

| 1. | Non-compliance that results in partial non-compliance with the requirement in the checklist, but cannot constitute a cause or a favorable factor for the occurrence of an accident and/or occupational disease. | low | 5 |

| 2. | Non-compliance that results in partial non-compliance and may be a factor in the occurrence of an accident and/or occupational disease | medium | 10 |

| 3. | Non-compliance that results in partial non-compliance with the requirement and may be the cause of occupational injury and/or illness | high | 20 |

| No. | Requirement | The Element of the Work System to Which It Refers | Weighting Coefficient |

|---|---|---|---|

| 10.00 | Personnel selection and control | Worker | 0.08 |

| 11.00 | Occupational safety and health training and information | 0.08 | |

| 12.00 | Personal protective equipment | 0.08 | |

| Total | 0.24 | ||

| 9.00 | Establishing and allocating work tasks | Working task | 0.24 |

| Total | 0.24 | ||

| 1.00 | Buildings and rooms where work processes take place | Means of production and working environment | 0.07 |

| 2.00 | Stairs, steps, level differences, scaffolding, platforms | 0.05 | |

| 3.00 | Location of technical equipment | 0.07 | |

| 4.00 | Protection against mechanical risks | 0.07 | |

| 5.00 | Electrosecurity | 0.07 | |

| 6.00 | Loading, unloading, transport, handling and storage of materials | 0.05 | |

| 7.00 | Portable equipment and hand tools | 0.03 | |

| 8.00 | Fire prevention and control | 0.07 | |

| Total | 0.48 | ||

| 13.00 | Organization of prevention and protection activity | Work system Worker | 0.03 |

| 14.00 | First aid in case of injury | 0.01 | |

| Total | 1.00 |

| Category | Weighting Coefficient | Average Indices by Category | Weighted Average Indices | ||||

|---|---|---|---|---|---|---|---|

| Case 2 | Case 3 | Case 4 | Case 2 | Case 3 | Case 4 | ||

| 1 | 0.07 | 100% | 50% | 50% | 0.07 | 0.035 | 0.035 |

| 2 | 0.05 | 100% | 50% | 30% | 0.05 | 0.025 | 0.015 |

| 3 | 0.07 | 100% | 50% | 20% | 0.07 | 0.035 | 0.014 |

| 4 | 0.07 | 100% | 50% | 10% | 0.07 | 0.035 | 0.007 |

| 5 | 0.07 | 100% | 50% | 100% | 0.07 | 0.035 | 0.07 |

| 6 | 0.05 | 100% | 50% | 20% | 0.05 | 0.025 | 0.01 |

| 7 | 0.03 | 100% | 50% | 40% | 0.03 | 0.015 | 0.012 |

| 8 | 0.07 | 100% | 50% | 30% | 0.07 | 0.035 | 0.021 |

| 9 | 0.24 | 100% | 50% | 60% | 0.24 | 0.12 | 0.144 |

| 10 | 0.08 | 100% | 50% | 100% | 0.08 | 0.04 | 0.08 |

| 11 | 0.08 | 100% | 50% | 70% | 0.08 | 0.04 | 0.056 |

| 12 | 0.08 | 100% | 50% | 80% | 0.08 | 0.04 | 0.064 |

| 13 | 0.03 | 100% | 50% | 100% | 0.03 | 0.015 | 0.03 |

| 14 | 0.01 | 100% | 50% | 100% | 0.01 | 0.005 | 0.071 |

| Global degree of compliance | Case 2 | Case 3 | Case 4 | ||||

| weighted amount: | 100% | 50% | 56.8% | ||||

| arithmetic average: | 100% | 50% | 57.86% | ||||

| Global Degree of Compliance | Security and Occupational Health Level | |

|---|---|---|

| GCF = 100% | Maximum | 6 |

| 100% > GCF > 80% | Very high | 5 |

| 80% > GCF > 70% | High | 4 |

| 70% > GCF > 60% | Medium | 3 |

| 60% > GCF > 50% | Low | 2 |

| GCF > 50% | Very low | 1 |

| Categories of Requirements | Average Compliance Index by Category of Requirements (%):— | ||||||

|---|---|---|---|---|---|---|---|

| <50 | 51–60 | 61–70 | 71–80 | 81–90 | 91–100 | ||

| Unsatisfactory | Low | Medium | Good | Very Good | Excelent | ||

| 1.00 | Buildings and rooms where work processes take place | 89.26 | |||||

| 2.00 | Stairs, steps, level differences, scaffolding | 85.71 | |||||

| 3.00 | Location of machinery, machines, and installations | 86.67 | |||||

| 4.00 | Protection against mechanical risks | 84.29 | |||||

| 5.00 | electro | 98.18 | |||||

| 6.00 | Loading, unloading, transport, handling, and storage of materials | 82.76 | |||||

| 7.00 | Portable equipment and hand tools | 97.50 | |||||

| 8.00 | Prevention and firefighting | 100 | |||||

| 9.00 | Establishing and allocating work tasks | 100 | |||||

| 10.00 | Medical selection and control | 80 | |||||

| 11.00 | Occupational safety and health training and information | 93.33 | |||||

| 12.00 | Personal protective equipment | 86.67 | |||||

| 13.00 | Organization of prevention and protection activity | 90 | |||||

| 14.00 | First aid in case of injury | 100 | |||||

| = 91.94% | |||||||

|  | ||||||

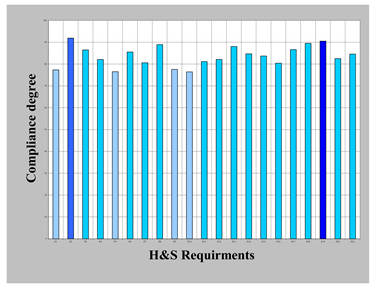

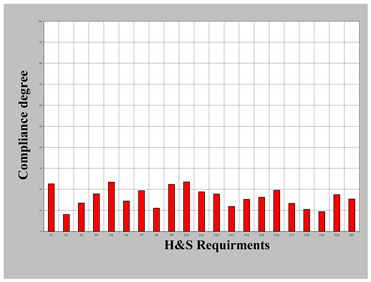

| Histogram of the average values of the global/specific degree of conformity | Histogram of the average values of the global/specific degree of non-conformity | ||||||

| No | General And Specific Checklists For Verifying Occupational Safety And Health Requirements | Average Values of the Global Degree/Specific Compliance * (%) | Average Values of The Global/Specific Degree of Non-Compliance (%) |

|---|---|---|---|

| 0. | 1. | 2. | 3. |

| 1. | Checklist of Compliance With The Requirements of the Occupational Safety and Health Management System (Cj = 14 Requirements Categories) | ||

| 77.34 | 22.66 | ||

| 2. | General Checklist For Occupational Safety and Health Audit Specific to the Work System and Its Components (Cj = 20 Categories Of Requirements) | ||

| 91.93 | 8.07 | ||

| 3. | Checklist For Excavation Activities For Urban Works and Civil Constructions (j = 21 Requirements) | ||

| 86.49 | 13.51 | ||

| 4. | Checklist For Concrete Preparation Activity (j = 7 Requirements) | ||

| 82.14 | 17.86 | ||

| 5. | Checklist For Masonry, Finishing, Painting and Painting In Construction (j = 21 Requirements) | ||

| 76.54 | 23.46 | ||

| 6. | Checklist For Metalwork (j = 16 Requirements) | ||

| 85.54 | 14.46 | ||

| 7. | Checklist For The Manufacture Of Doors, Windows, Prefabricated Houses, and Building Panels (j = 21 Requirements) | ||

| 80.60 | 19.40 | ||

| 8. | Checklist For Prefabricated Installation Works, Including Sewer Pipes (j = 22 Requirements) | ||

| 88.95 | 11.05 | ||

| 9. | Checklist For Painting Activities and Working With Toxic And/Or Hazardous Substances (j = 34 Requirements) | ||

| 77.60 | 22.40 | ||

| 10. | Checklist For Work Performed At Height (j = 27 Requirements) | ||

| 76.45 | 23.55 | ||

| 11. | Checklist For Internal Transport Activities (j = 40 Requirements) | ||

| 81.16 | 18.84 | ||

| 12. | Checklist For Handling, Carrying By Transport, and With Non-Mechanized Means and Storage of Materials (j = 18 Requirements) | ||

| 82.17 | 17.83 | ||

| 13. | Checklist For Welding Work (j = 42 Requirements) | ||

| 88.09 | 11.91 | ||

| 14. | Checklist For Explosive Shooting/Demolition Work (j = 39 Requirements) | ||

| 84.74 | 15.26 | ||

| 15. | Checklist For Storage Of Explosives and Their Transport Underground (j = 22 Requirements) | ||

| 83.73 | 16.27 | ||

| 16. | Checklist For Road Works (j = 16 Requirements) | ||

| 80.43 | 19.57 | ||

| 17. | Checklist For Underground Mining (j = 43 Requirements) | ||

| 86.64 | 13.36 | ||

| 18. | Checklist For Operation Of Lifting Installations (j = 34 Requirements) | ||

| 89.53 | 10.47 | ||

| 19. | Checklist For the Use of Electrically Operated Equipment (j = 12 Requirements) | ||

| 90.56 | 9.44 | ||

| 20. | Vehicle Maintenance and Repair Checklist (j = 12 Requirements) | ||

| 82.52 | 17.48 | ||

| 21. | Checklist For Activities Carried Out In PECO Warehouses And Stations (j = 20 Requirements) | ||

| 84.60 | 15.40 | ||

| * αj represents the weighting coefficient of the Cj requirements category; Icj represents the compliance index of the Cj requirements category; βj represents the weighting coefficient of the j requirement; Ij- represents the compliance index of the j requirement | |||

Histogram of the Average Values of the Global/Specific Degree of Conformity |  Histogram of the Average Values of the Global/Specific Degree of Non-Conformity | ||

| Risk assessment grid | 0.00 0.33 (High) |

| 0.33 0.66 (Medium) | |

| 0.66 1.00 (Low) |

| Economic Operator with Activity in the Field of Hydrotechnical Constructions | Audit Report—Extras |

|---|---|

| Date: September 1, 2019 | Chief Auditor: dr.habil.eng. Gabriel Vasilescu |

| 1. Context and Objectives of the Mission | Background: The mission was established in the context of the audit process of the economic operator with activity in the field of hydro-constructions. |

| The main objective of the mission: to audit occupational safety and health for the economic operator operating in the field of hydro-construction. During the audit, the objective was to assess compliance with the applicable occupational safety and health regulations for two activities—work performed at height and the use of electrically operated equipment—in which the application of the general checklist led to the assumption that there may be significant non-compliances. | |

| Mission requirement: The validity of the applied method requires the verification of several elements: - whether the checklists are sufficiently concrete and, at the same time, exhaustive to cover all aspects relevant to the effectiveness of occupational safety and health; - if the calculation method of the quantitative indicators leads to a value that reflects as much as possible the reality. The existence of a previous audit of the economic operator operating in the field of hydro-construction provides an objective basis for comparison to answer these questions. Mission area: the entire activity carried out in the construction sites related to the economic operator. The audit team consisted of one person—dr.habil.eng. Gabriel Vasilescu, as chief auditor. During the mission, site managers were consulted, as well as workers from various jobs. | |

| 2. Audited Organizational Entities | The sites related to the audited economic operator are representative for the hydro-construction activities carried out. |

| 3. Audit Synthesis | Overall, the economic operator with activity in the field of hydro-construction has a very good situation of safety and health at work, the overall degree of compliance calculated being 91.94%. The following positive aspects are highlighted: - implementing and maintaining an occupational safety and health management system; - management’s concern for the functioning and improvement of the occupational safety and health management system; - the existence of a complete system of documents and records and adequate to the legal and internal requirements regarding the achievement of safety and health at work; - general improvement of working conditions; - improving occupational hygiene conditions by restoring toilets and sanitizing living rooms; - training of workers for first aid; - concern for health monitoring; and - equipping workers with personal protective equipment, purchased only from accredited companies. There are also some negative aspects, among which the most significant are: - the absence of clear responsibilities for workers responsible for safety and health at work in connection with the maintenance of work equipment; - insufficient training of workers on issues specific to working at height; - low knowledge of workers on appropriate behavior in terms of health insurance at work; - inadequate organization of the registration and periodic verification of electrically operated mobile equipment; - insufficient security measures in relation to workers of other organizations carrying out various activities within the economic operator. |

| 4. Performance of the Mission | Tools: The proposed method of auditing occupational safety and health in the hydro-construction activity was used to carry out the mission. Both types of questionnaires were applied—the general checklist and two specific checklists, as well as the interview method and field visits (Table 11 and Table 12). Interviewed positions: director for production quality, occupational safety and health inspector, site managers, and heads of functional departments (mechanization office, supply service). |

| 5. Findings and Recommendations | During the mission, a number of 12 non-conformities were identified; for each one, a recommendation was formulated. |

| No. |

Category Occupational Safety and Health Requirement | Maximum Score | Score Awarded | Average Compliance Index (%) | |

|---|---|---|---|---|---|

| For “I” Requirement | For the “J” Category | ||||

| 0 | 1 | 2 | 3 | 4 | 5 |

| 1.00 | BUILDINGS AND ROOMS | 2560 | 2285 1 | x 2 | 89.26 |

| 1.01 | The buildings are not damaged or otherwise repaired. | 40 | 35 | 87.50 | x |

| 1.02 | Adequate drinking water supply is ensured. | 100 | 80 | 80 | x |

| 1.03 | Sewerage systems for the collection and transport of industrial wastewater with toxicity characteristics shall be provided with installations to prevent the ingress of gas and aerosol emissions into the premises of the enterprise or in neighboring public spaces. | 100 | 90 | 90 | x |

| 1.04 | There are used wastewater detoxification facilities that can generate toxic, flammable, or explosive gases. | 100 | 100 | 100 | x |

| 1.05 | The dimensions of the work rooms, the volume, and the work area of a worker are appropriate. | 80 | 70 | 87.50 | x |

| 1.06 | The surfaces of the work rooms allow the storage of materials to be processed, auxiliary, etc., and processed materials, without affecting the movement of personnel and means of transport. | 80 | 70 | 87.50 | x |

| 1.07 | The maximum permissible floor load is known, displayed, and observed, as well as the resistance to dynamic stresses and vibrations. | 100 | 90 | 90 | x |

| 1.08 | The floors are suitable for the technological process. | 300 | 260 | 86.67 | x |

| Flat, smooth, non-slip surface. Wear-resistant material and mechanical stress. Non-combustible and non-sparking material in rooms where there is a risk of explosion. Material resistant to the action of chemical agents, water repellent, poor heat conductor, sound insulation, and vibro-insulation, depending on the risk factors specific to the work processes in the rooms. | 40 40 100 80 | ||||

| The floors are kept clean and well maintained. | 40 | ||||

| 1.09 | Moving and parking indoors is safe. | 300 | 240 | 80 | x |

| The number and size of access and escape routes, as well as the arrangement of workspaces, allow the safe movement of staff, as well as the rapid evacuation in case of danger. The emergency evacuation and intervention plan is drawn up, displayed, and known. The access, escape, and storage areas are properly marked. | 100 100 100 | ||||

| 1.10 | Proper lighting is provided. | 200 | 200 | 100 | x |

| Natural lighting is completed with artificial lighting systems. There is emergency and safety lighting. | 100 100 | ||||

| 1.11 | The microclimate conditions are appropriate; ventilation and natural and artificial ventilation are provided. | 80 | 80 | 100 | x |

| 1.12 | The workplace atmosphere does not present chemical / explosion hazards. | 600 | 600 | 100 | x |

| The average concentrations of toxic substances and dust in the workplace atmosphere are within limits. There is the necessary equipment and installations for the detection, measurement, and signaling of explosive gas concentrations. There are dust collection facilities at workplaces. Processes for filtering, capturing, or depositing dust particles resulting from the technological process are used. Installations, pipes, vessels, etc., through which substances producing harmful, explosive or explosive vapors, gases, or dusts are circulated or transported are appropriately marked. All installations which ensure that the level of concentration of toxic substances and dusts is maintained within the permitted limits are properly maintained and operated | 100 100 100 100 100 100 | ||||

| 1.13 | Noise exposure requirements are met. | 240 | 180 | 75 | x |

| The level of exposure to noise at work is within the maximum allowed limit. Sources that generate noise above the maximum permissible limit are housed and soundproofed. The means of collective noise protection are in place and maintained in good condition. | 80 80 80 | ||||

| 1.14 | Requirements for vibration exposure are met. | 160 | 120 | 75 | x |

| The vibration level is maintained at the workplace below the maximum permitted limits. Sources which generate vibrations above the maximum permissible limits are fitted with sound-insulating housings and other means of collective protection, maintained in a suitable condition. | 80 80 | ||||

| 1.15 | Conditions for occupational hygiene are ensured. | 80 | 70 | 87,50 | x |

| There are appropriate arrangements for ensuring individual hygiene (locker rooms, social groups, etc.). The aim is to comply with the rules of individual hygiene. | 40 40 | ||||

| 2.00 | STAIRS, STEPS, LEVEL DIFFERENCES, Scaffolding, PLATFORMS | 280 | 240 | x | 85.71 |

| 2.01 | Stairs and level differences are provided with handrails. | 100 | 80 | 80 | x |

| 2.02 | Fixed and escalators are checked periodically. | 80 | 80 | 100 | x |

| 2.03 | Pits, canals, platforms, or openings in the wall or floors are provided with guards to prevent people and vehicles from falling and are properly signposted. | 100 | 80 | 80 | x |

| 3.00 | LOCATION OF TECHNICAL EQUIPMENT | 300 | 260 | x | 86.67 |

| 3.01 | The technical equipment is located in such a way as to allow the normal movement of personnel and internal means of transport. | 100 | 100 | 100 | x |

| 3.02 | Hazardous areas of technical equipment are properly isolated and signaled. | 100 | 80 | 80 | x |

| 3.03 | Equipment which has elements placed at height, to which staff must have access, shall be provided with access stairs and platforms with sturdy railings. | 100 | 80 | 80 | x |

| 4.00 | PROTECTION AGAINST MECHANICAL RISKS | 700 | 590 | x | 84.29 |

| 4.01 | All moving machine parts in the work area are completely covered and fenced or are provided with guards. | 100 | 80 | 80 | x |

| 4.02 | All installations, equipment, machinery, and means of transport are fitted with locking/locking systems or other means of protection, which are in good working order. | 100 | 60 | 60 | x |

| 4.03 | There are and are written procedures for the operation of technical equipment under normal conditions and for interventions in case of danger. | 100 | 90 | 90 | x |

| 4.04 | The pressure equipment complies with the regulations and is properly operated and maintained. | 100 | 80 | 80 | x |

| 4.05 | The circulation of internal means of transport is regulated by traffic indicators; hazardous areas are properly signposted. | 100 | 100 | 100 | x |

| 4.06 | The means of transport are equipped with functional braking, safety, and signaling devices. | 100 | 80 | 80 | x |

| 4.07 | The means of transport and lifting are provided with stroke and load limiters and are operated in accordance with the regulations. | 100 | 100 | 100 | x |

| 5.00 | ELECTROSECURITY | 1100 | 1080 | x | 98.18 |

| 5.01 | Working stresses, accidental contact, and step stresses have values that are within the legal limits. | 100 | 100 | 100 | x |

| 5.02 | All current conductors, which are part of the working current circuits, are inaccessible to a direct accidental touch. | 100 | 80 | 80 | x |

| 5.03 | Additional insulation protection against direct contact is provided, as well as insulation of workplaces. | 100 | 100 | 100 | x |

| 5.04 | Installations or places where electrical equipment exists or is operated are equipped with electrical insulating means and are adequately signaled. | 100 | 100 | 100 | x |

| 5.05 | Personnel used for the execution, operation, maintenance, and repair of electrical equipment are authorized. | 100 | 100 | 100 | x |

| 5.06 | At high voltage installations, there are and are in operation mechanical or electrical locks, which do not allow the opening of the housings and the removal of the protective fences only after the de-energization. | 100 | 100 | 100 | x |

| 5.07 | Protection against overload and fault currents is ensured. | 100 | 100 | 100 | x |

| 5.08 | Checks on installations and means of protection against the danger of electric shock, as well as on insulation resistances, are carried out periodically. | 100 | 100 | 100 | x |

| 5.09 | Works where there is a risk of electric shock are performed under the supervision of an authorized driver. | 100 | 100 | 100 | x |

| 5.10 | Measures to protect against indirect damage are applied. | 100 | 100 | 100 | x |

| 5.11 | Explosion protection is provided. | 100 | 100 | 100 | x |

| 6.00 | LOADING, UNLOADING, TRANSPORTATION, HANDLING, AND STORAGE MATERIALS | 580 | 480 | x | 82.76 |

| 6.01 | Physical effort requirements are met for manual transport. | 80 | 60 | 75 | x |

| 6.02 | Loads on means of transport are insured against uncontrolled movement, overturning, or falling. | 100 | 80 | 80 | x |

| 6.03 | The tilting platforms of the means of transport are equipped with fastening devices in good working order. | 100 | 80 | 80 | x |

| 6.04 | When loading, unloading, transporting and storing flammable, toxic, caustic, corrosive products, etc. the legal requirements are observed. | 100 | 100 | 100 | x |

| 6.05 | Materials stacked in warehouses and workplaces do not exceed the maximum permissible floor load and the stacks are stable. | 100 | 100 | 100 | x |

| 6.06 | Areas permanently intended for loading—unloading and storage operations are properly arranged and maintained. | 100 | 60 | 60 | x |

| 7.00 | PORTABLE EQUIPMENT AND HAND TOOLS | 200 | 195 | x | 97.50 |

| 7.01 | Portable equipment and electrically or pneumatically operated hand tools are equipped with devices for fixing the tool, to prevent uncontrolled operation, with guards against direct contact of the active elements, with devices for measuring and regulating the flow pressure. | 100 | 100 | 100 | x |

| 7.02 | Portable equipment and hand tools are checked. | 100 | 95 | 95 | x |

| 8.00 | PREVENTION AND FIREFIGHTING | 300 | 300 | x | 100 |

| 8.01 | There is a plan of action on how to act in case of fire, and the personnel designated to implement it are trained and trained. | 100 | 100 | 100 | x |

| 8.02 | There is adequate equipment, machinery, materials, and protective equipment necessary for extinguishing fires. | 100 | 100 | 100 | x |

| 8.03 | There are alarm systems in case of fires. | 100 | 100 | 100 | x |

| 9.00 | DETERMINATION AND DISTRIBUTION OF WORK LOADS | 300 | 300 | x | 100 |

| 9.01 | The staff is assigned to jobs in relation to the results of the medical examination at employment and the regular ones. | 100 | 100 | 100 | x |

| 9.02 | Professional requirements correspond to the physical, physiological, and psychological abilities of employees. | 100 | 100 | 100 | x |

| 9.03 | The personnel used is authorized according to the law. | 100 | 100 | 100 | x |

| 10.00 | PERSONNEL SELECTION AND CONTROL | 300 | 240 | x | 80 |

| 10.01 | Medical examination of the staff is ensured. | 100 | 80 | 80 | x |

| 10.02 | There is the necessary equipment for first aid. | 100 | 100 | 100 | x |

| 10.03 | The health status of workers is constantly monitored. | 100 | 60 | 60 | x |

| 11.00 | TRAINING AND INFORMATION | 300 | 280 | x | 93.33 |

| 11.01 | Occupational safety and health training is provided. | 100 | 80 | 80 | x |

| 11.02 | The training and improvement of the personnel with attributions regarding safety and health at work is carried out. | 100 | 100 | 100 | x |

| 11.03 | Workers are kept informed of all occupational safety and health situations and changes. | 100 | 100 | 100 | x |

| 12.00 | PERSONAL PROTECTIVE EQUIPMENT | 300 | 260 | x | 86.67 |

| 12.01 | There is an internal list of equipment with personal protective equipment. | 100 | 100 | 100 | x |

| 12.02 | Personal protective equipment is granted and is of the quality and quantity corresponding to the risk factors existing in the work processes. | 100 | 80 | 100 | x |

| 12.03 | The equipment is checked, maintained, and cleaned (detoxified). | 100 | 80 | 95 | x |

| 13.00 | ORGANIZATION OF PREVENTION AND PROTECTION ACTIVITY | 100 | 90 | x | 90 |

| 13.01 | There is an occupational safety and health department. | 20 | 20 | 100 | x |

| 13.02 | Tasks on occupational safety and health are set out in the job description. | 20 | 15 | 75 | x |

| 13.03 | The risks of occupational injury and illness were assessed. | 20 | 15 | 20 | x |

| 13.04 | There is an annual work safety program, and it is being implemented. | 20 | 20 | 20 | x |

| 13.05 | The registration, communication, research, and record of work accidents and occupational diseases are organized and carried out. | 10 | 10 | 10 | x |

| 13.06 | An occupational safety and health committee is organized; staff are trained and consulted on specific issues. | 10 | 10 | 10 | x |

| 14.00 | FIRST AID IN CASE OF INJURY | 100 | 100 | x | 100 |

| 14.01 | There are post and first aid kits, properly equipped. | 30 | 30 | 100 | x |

| 14.02 | There are written provisions for first aiders; people are properly trained. | 30 | 30 | 100 | x |

| 14.03 | All workers are trained in specific first aid measures. | 10 | 10 | 100 | x |

| 14.04 | There is a station/rescue team, adequately equipped; the related staff is well trained and trained. | 30 | 30 | 100 | x |

| No. | Requirement | Maximum Score | Score Awarded | Average Compliance Index (%) |

|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 |

| 1 | Access to and from workplaces located at height are ensured against the fall of workers | 100 | 80 | 80 |

| 2 | Execution of work at height is carried out under the direct supervision of the work point manager or the work manager | 100 | 100 | 100 |

| 3 | Check that all necessary safety measures have been ensured to prevent accidents before starting work at height. | 100 | 60 | 80 |

| 4 | The places located at height and the access roads to and from these jobs are marked and signalized | 100 | 40 | 40 |

| 5 | The floors are made of wood corresponding to the execution project; the metal ones are covered with expanded or ribbed sheet | 100 | 95 | 95 |

| 6 | Slip-resistant slats are fixed on the surface of sloping or curved floors at a distance of 300–400 mm | 100 | 80 | 80 |

| 7 | Workers are equipped with personal protective equipment appropriate to the actual conditions of the workplace | 100 | 100 | 100 |

| 8 | Workers use the personal protective equipment provided at work, as well as access to and from the workplace located at height. | 100 | 100 | 100 |

| 9 | The instructions issued by the manufacturer must be observed when using personal protective equipment | 100 | 100 | 100 |

| 10 | The maximum length of the unfolded safety ropes is 2 m | 100 | 100 | 100 |

| 11 | The fastening of the seat belt is made of rigid construction elements | 100 | 100 | 100 |

| 12 | The mechanism of the fall arrest system operates so that the worker does not fall more than 0.5 m | 100 | 100 | 100 |

| 13 | All persons involved in work at height wear a helmet | 100 | 100 | 100 |

| 14 | Before starting work, the headphones are checked by the workers | 100 | 80 | 80 |

| 15 | At the end of the program, workers hand the seat belts to the workplace manager | 100 | 100 | 100 |

| 16 | There is a safety rope that prevents the worker from entering the danger area throughout the work | 100 | 100 | 100 |

| 17 | At the beginning of the work, the component parts of the belts are checked in detail | 100 | 80 | 80 |

| 18 | The seat belts shall be stored in accordance with the manufacturer’s instructions | 100 | 100 | 100 |

| 19 | There is evidence of training of workers on the use of collective and individual means of protection, installations, devices, and tools used for working at height | 100 | 95 | 95 |

| 20 | The workplace manager daily checks the integrity and operating condition of the installations, devices, and tools used for working at height | 100 | 100 | 100 |

| 21 | Wooden stairs are used by one person only | 80 | 80 | 100 |

| 22 | The maximum length of 5 m of a wooden staircase is observed | 80 | 80 | 100 |

| 23 | Tools used at height are kept in special pockets or sheaths fastened to the seat belt | 100 | 100 | 100 |

| 24 | Work platforms are provided with railings | 100 | 80 | 80 |

| 25 | Stairs inclined above 60°–80° are fixed, and those inclined above 80° are provided with cage guards and interruptions for rest at a maximum of 4 m | 100 | 100 | 100 |

| 26 | Fixed and portable wooden stairs have steps embedded in the longitudinal frames with a threshold of at least 2 cm | 80 | 80 | 80 |

| 27 | Access ramps are 1 m wide in one direction and 1.5 m in both directions | 100 | 100 | 100 |

| Specific degree of compliance: | ||||

| Check-List for Using Electric Power equipment Checklist Referencing: Own safety and health instructions of the economic operator with activity in the field of hydrotechnical constructions: | ||||

| 1 | The register of electrical appliances exists and is updated | 100 | 40 | 40 |

| 2 | All tools and electrical equipment are registered, marked and tested (CS or CE marked) | 100 | 40 | 40 |

| 3 | The tools are inspected and maintained daily | 100 | 60 | 60 |

| 4 | Staff are trained to provide first aid in the event of an electric shock | 100 | 100 | 100 |

| 5 | There are identification plates containing data related to the electrical part | 100 | 100 | 100 |

| 6 | All necessary earthworks are in place and are periodically checked | 100 | 100 | 100 |

| 7 | The power cords are protected or laid in pipes | 100 | 100 | 100 |

| 8 | The switches are suitable for the tripping current | 100 | 100 | 100 |

| 9 | Personal protective equipment has been provided and is worn | 100 | 100 | 100 |

| 10 | The cables are laid in such a way that there is no risk of disconnection | 100 | 100 | 100 |

| 11 | All staff are trained to use electrical equipment | 100 | 100 | 100 |

| 12 | All cables, plugs, and switches are in proper condition | 100 | 95 | 95 |

| Specific degree of compliance: | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasilescu, G.D.; Petrilean, C.D.; Kovacs, A.; Vasilescu, G.V.; Pasculescu, D.; Ilcea, G.I.; Burduhos-Nergis, D.-P.; Bejinariu, C. Methodology for Assessing the Degree of Occupational Safety Specific to Hydrotechnical Construction Activities, in Order to Increase Their Sustainability. Sustainability 2021, 13, 1105. https://doi.org/10.3390/su13031105

Vasilescu GD, Petrilean CD, Kovacs A, Vasilescu GV, Pasculescu D, Ilcea GI, Burduhos-Nergis D-P, Bejinariu C. Methodology for Assessing the Degree of Occupational Safety Specific to Hydrotechnical Construction Activities, in Order to Increase Their Sustainability. Sustainability. 2021; 13(3):1105. https://doi.org/10.3390/su13031105

Chicago/Turabian StyleVasilescu, Gabriel Dragos, Codruț Dan Petrilean, Attila Kovacs, Gabriel Victor Vasilescu, Dragos Pasculescu, Gabriel Ioan Ilcea, Diana-Petronela Burduhos-Nergis, and Costica Bejinariu. 2021. "Methodology for Assessing the Degree of Occupational Safety Specific to Hydrotechnical Construction Activities, in Order to Increase Their Sustainability" Sustainability 13, no. 3: 1105. https://doi.org/10.3390/su13031105

APA StyleVasilescu, G. D., Petrilean, C. D., Kovacs, A., Vasilescu, G. V., Pasculescu, D., Ilcea, G. I., Burduhos-Nergis, D.-P., & Bejinariu, C. (2021). Methodology for Assessing the Degree of Occupational Safety Specific to Hydrotechnical Construction Activities, in Order to Increase Their Sustainability. Sustainability, 13(3), 1105. https://doi.org/10.3390/su13031105