1. Introduction

Organizational sustainability is a multifaceted concept that “implies a simultaneous focus on economic, social, and environmental performance” [

1] (p. 21) of organizations [

2] to create value consistent with the long-term preservation and enhancement of financial, environmental, social, and human capital [

3] (p. 39).

Sustainable organizations should balance this triple bottom line [

4,

5] across all the relevant activities at both intraorganizational and interorganizational level. In fact, several studies focus on organizational sustainability in relation to internal management—i.e., to corporate social responsibility (CSR) strategy, as a way to contribute to “brand, image, reputation, cost reduction, risk management and access to capital” [

3] (p. 41)—as well as to the supply chain (SC) management—for example, with the analysis of environmentally sustainable practices such as green logistics [

6] and green product design [

7]—as to relationship management towards external stakeholders, oriented to meeting their expectations [

8].

A recently proposed practical application of sustainability-oriented development is identified within the circular economy (CE) approach [

9,

10], which gives a specific focus on sustainability as the reduction, reuse, recycle, and recovery of materials and waste along supply chains [

11] as opposed to the linear economy. As in the general sustainable approach, CE envisions environmental, social, and economic benefits [

12] at organizational, interorganizational, and external level, such as resource optimization and minimization of waste and emissions, supply chain and logistics efficiency, and social development [

13].

Organizations might become sustainable by implementing circular business models (CBMs), however a limited understanding of the related definitions, practical applications, and evaluation tools is quite evident from the literature [

14,

15,

16,

17,

18], thus prospecting a difficult application of CBMs at the intraorganizational and interorganizational level.

Accordingly, we propose that organizations, and particularly SMEs, need to activate organizational learning (OL) processes [

19,

20] with a specific orientation towards CE to fruitfully implement CBMs. OL processes should encourage organizational sustainability supporting the CE transition from context-specific barriers to the related enablers with the activation of knowledge dynamics among key actors at intraorganizational and interorganizational levels. Thus, intraorganizational and interorganizational learning activities appear to be essential for two main objectives: First, to overcome specific CBM-related barriers that might hinder their implementation; second, to detect and capitalize on CE-oriented enablers in specific contexts for the practical application of CBMs.

Considering the importance of SMEs in the European (EU) landscape [

21], and the peculiar characteristics that influence the related learning processes [

22] and CE application [

23], the study focuses on this type of organizations, specifically in the context of SC management. In addition, we concentrate on the construction sector, in order to offer an in-depth analysis of a specific industry that has a major impact on the environment [

24]—thus a prominent need to perform a transition towards sustainability-oriented activities [

25]—inside an advanced country in terms on CE application: Italy [

26]. In particular, the Italian construction sector shows a significant number of SMEs, which represented 95.3% of all firms in 2018 [

27].

In sum, the paper offers multiple contributions. First, the study offers an original theoretical perspective in the analysis of CE, which is based on OL theory, as we propose learning processes to represent the key step in CBM implementation in a specific context; second, the analysis singles out a set of contextual elements that might act as barriers and drivers for CBM-oriented OL processes in a particular industry; third, the paper points out the role of OL processes in supporting CBM use with the development of a CE-oriented OL-model, offering an enhanced understanding of the interrelation among contextual elements and OL processes, and possible CBM-oriented OL dynamics; and, finally, it identifies a set of OL processes that could be activated by SME managers to prospect a simplified intraorganizational and interorganizational implementation of CBMs in specific contexts.

2. Theoretical Background

The OL theory encompasses different theoretical approaches that focus on the understanding of the learning phenomenon, moving across the individual, group, organizational [

28], and interorganizational levels [

29]. Actually, a consensus on what learning is and how it occurs is not at present reached [

30,

31] and a shared multilevel theory is still missing [

32], even though the multilevel nature of the phenomena is a common knowledge [

33].

Here, we conceive OL as a set of knowledge creation (KC), transfer (KT), and retention (KR) processes [

19,

20] that enable learning across the different OL levels. In this conceptualization, learning processes encompass interrelated cognitive and behavioral changes in individuals [

34] and might be institutionalized through “non-human repositories such as routines, systems, structures, culture, and strategy” [

35] (p. 154) at the organizational level. Going beyond the organizational boundaries, learning might also occur among different organizations through several interorganizational configurations, such as alliances and networks [

36,

37,

38] that provide contexts for interaction. This conceptualization capitalizes on the alignment to knowledge management (KM) theory [

35]—in particular with the organic view of KM, which “emphasizes the role of people, group dynamics, social and cultural factors, and networks” [

35] (p. 156)—to complement the understanding of the processes and instruments through which knowledge is created, transferred, and retained to create value [

39]. Recent publications have identified taxonomies of KM practices related to SMEs that are aligned to the above-mentioned OL processes (KC, KT, and KR processes) [

40,

41,

42], confirming the fruitful union of the two research fields for the enquiry as discussed in this paper.

Moving to the concept of CE-oriented—thus, sustainable—business models, CBMs are defined in this study as the way companies “create, capture, and deliver value with the value creation logic designed to improve resource efficiency through contributing to extending the useful life of products and parts (…) and closing material loops” [

16] (p. 12) in collaboration with related SC actors. In particular, CBMs suggests to adopt circularity along two major dimensions at the same time: Firstly, in the “customer value proposition & interface”, that identifies the organizational-level product or service designed to deliver value to stakeholders in a circular approach, also through the internal activities; secondly, in the “value network”, that identifies the activities and structures developed among the organization and related SC actors oriented to collaboratively contribute to the “closure of the loop” at a SC level [

43].

Several types of CBMs are presently discussed among scholar [

14,

18] also in specific relation to sustainable business models [

44], however a univocal understanding is not actually available [

10,

16] and a limited number of frameworks are at disposal for CE practical application and evaluation [

17,

45]. In this context, organizations on the one hand, need to identify, adapt, and implement industry-specific CBMs (with an unclear academic’s and/or consultants’ guidance), and, on the other hand, are asked to face the intraorganizational and interorganizational barriers that could be encountered in relation to CE in the process [

46], especially small and medium enterprises (SMEs) [

23]. In addition, SMEs should identify and exploit contextual elements that might encourage specific CBM implementation at both intraorganizational and interorganizational levels [

47] to prospect a more successful outcome and, thus, to reach organizational sustainability.

Under this conceptualization, the role of OL processes inside SMEs for the implementation of CBMs is highlighted while addressing the main contributions of OL literature in relation to KC, KT, and KR processes at the intraorganizational and interorganizational levels. The three processes are not linearly sequential, but are commonly assumed to be interrelated in a dynamic manner [

48]; in addition, the three processes might be overlapping and thus conceptually included under different definitions according to the theoretical perspective used. However, for the clarity of exposition of the theoretical background of this study, and using the conceptualizations offered in relevant previous OL studies, three separated clusters of KC, KT, and KR are presented in the analysis.

Starting from knowledge creation (KC) processes, some studies emphasize the relevance of OL activities oriented to create new knowledge inside SMEs both from external sources as well as internally. As for the external sources, benchmarking activities among competitors [

40,

41,

42], the use of consultants [

49,

50], and of professional service firms (or PSF, [

51]) identify possible KC activities as stimulators to create specific knowledge through an indirect contact with external competitors and partners. For the intraorganizational sources, internal brainstorming [

52], simulations [

53,

54], job rotation [

55], and learning-by-doing activities [

56] are commonly used to generate ideas, to frame proposals, and to explain internal processes. In relation to CE and CBM application, the creation of context-specific knowledge regarding those concepts appears to be essential, especially in relation to the complexity related to the construction sector [

57], and to the intraorganizational and interorganizational challenges that CBMs demand.

After the creation of CE and CBM-related knowledge, the adaptation of CBMs to the organizational context and the related value chain is required to practically apply the chosen models. This phase requests dynamic confrontations among internal and external organizational actors, thus for KT processes. Several configurations of organizational groups might contribute to individual, team-level, organizational, and interorganizational learning processes to occur. In particular, the community of practice (CoP) [

58,

59,

60] might stimulate KT, as it represents groups of people characterized by trust and common identity, who share concerns and problems, and who deepen their knowledge by interacting on a regular basis. This community might be found also in virtual configurations (i.e., “virtual” CoP, or VCoP) [

61], and sometimes appears to be aligned—but not limited—to formal working groups [

28] and project teams [

62], which represent other contexts for KT. A recent contribution from Nicolletti et al. [

31] underlines the importance of CoPs in the intraorganizational understanding in the context of sustainability and climate concepts, impacts and adaptation actions, thus envisage a beneficial effect also in the CE-oriented transition. Especially in the construction industry, CoPs and single and multi-project teams are particularly important; in fact, the typical construction organizations’ project-based structure asks for recurrent confrontations among workers, physicians, architects, and sub-contractors through verbal interactions and interpretation of formal documents and instructions for specific projects development [

63]. Additional KT activities, such as coaching and training [

64], focus group [

40,

41,

42], seminar and meeting [

65] are widely used to spread specific knowledge across organizational actors, both within and beyond organizational boundaries.

In addition, specific KT process take place in more or less structured interorganizational contexts, where partners gain benefits from the exploitation of complementary competences, shared resources, and supplementary structures. In this orientation, the concept of interorganizational CoPs is particularly relevant as it includes several configurations, such as “interorganizational consortia, relationships with universities, professional associations, and learning networks of firms that collaborate on shared problems (..)” as the “ideal vehicles for realizing the knowledge potential that exists across firms” [

59] (p. 223). Following Wenger [

59], also other studies have focused on the professional association context as a possible configuration of a CoP [

66], shedding light on the potential role of this interorganizational setting for learning scopes. Specific interorganizational learning processes are at the disposal of organizations to evolve into a sustainable and CE approach, such as alliances and networks [

67]; in addition, those interorganizational solutions appear to be specifically useful to minimize the structural limitations of SMEs as they might offer resource and structure sharing [

68]. Other networking solutions for organizations are represented by the participation in research projects carried out by universities or research centers [

69] or activated by partner firms [

70], which could be related to the development of OL processes focused on specific industrial applications.

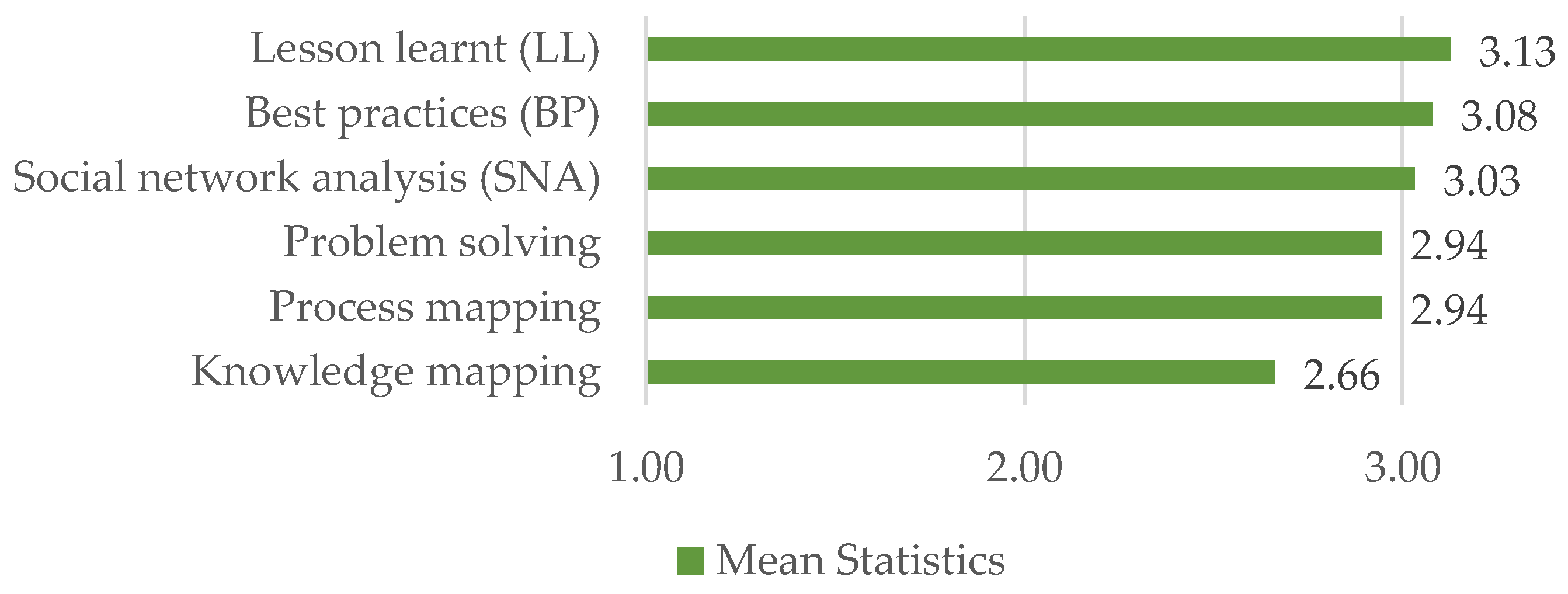

As last OL process, KR identifies those processes oriented to preserve and reuse knowledge at an organizational level, through specific processes that move across the OL levels, from the individual to the interorganizational level. In relation to CBM implementation, KR processes appear to have a double valence; in fact, organizational knowledge and process mapping [

40,

41,

42] and social network analysis [

71] could be useful in the identification and development of specific circular solutions in specific context, through the analysis of the internal and external organizational knowledge, processes, and relations as a starting point. In this context, problem-solving [

72] and the use of lesson learned from the past (or LL, [

54]), and internal and external best practices (or BP, [

73]) would also contribute to guide the definition of the most sustainable CE-oriented solution.

In sum, the above-mentioned OL processes could be activated in the context of CBM implementation, to envision CE-oriented knowledge creation, transfer, and retention processes among actors within and beyond organizational boundaries. Although those processes appear to positively impact the routine organizational activity, they gain more importance in the context of CBM introduction, as they could require disruptive changes in the interorganizational and interorganizational activities of a firm. In addition, the presently unclear scientific guidance in relation to the definition of CBM and evaluation frameworks, and the lack of practical best practices in relation to some industries—such as the construction sector—make the role of OL processes more relevant in CE application than in other contexts. In this sense, both intraorganizational and interorganizational processes might be envisioned to fully create, capture, and deliver value [

16] to direct stakeholders and towards the value networks [

43].

Proposition 1. OL processes—denoted here as knowledge creation, transfer, and retention processes—need to be activated by SME managers as a preliminary step in view of CBM implementation, to understand how to create, capture, and deliver value at intraorganizational and interorganizational level under a CE approach.

Confirming the role of OL processes, specifically the intraorganizational and interorganizational learning processes (drawing on the academic OL literature [

19,

20,

25,

37]), one of the objectives of the present study refers to the identification of the mostly used OL processes related to a specific context of analysis, which is the Italian construction sector. This research focus aims at identifying those OL processes that could be easily activated inside construction SMEs to sustain the CE-oriented transition. Considering the resistance of construction firms to innovation and organizational changes [

74,

75], the activation of known learning processes would envision a more acceptable way to implement CBMs in this traditional sector. In addition, the analysis of CBM-oriented OL processes inside SMEs identifies a still uncovered gap in the literature in relation to CE and CBM application [

18,

76]. As such, we propose RQ1 as follows:

RQ1: Which specific OL processes are mostly used—thus, could be easily activated for CBM implementation—by the Italian construction SMEs?

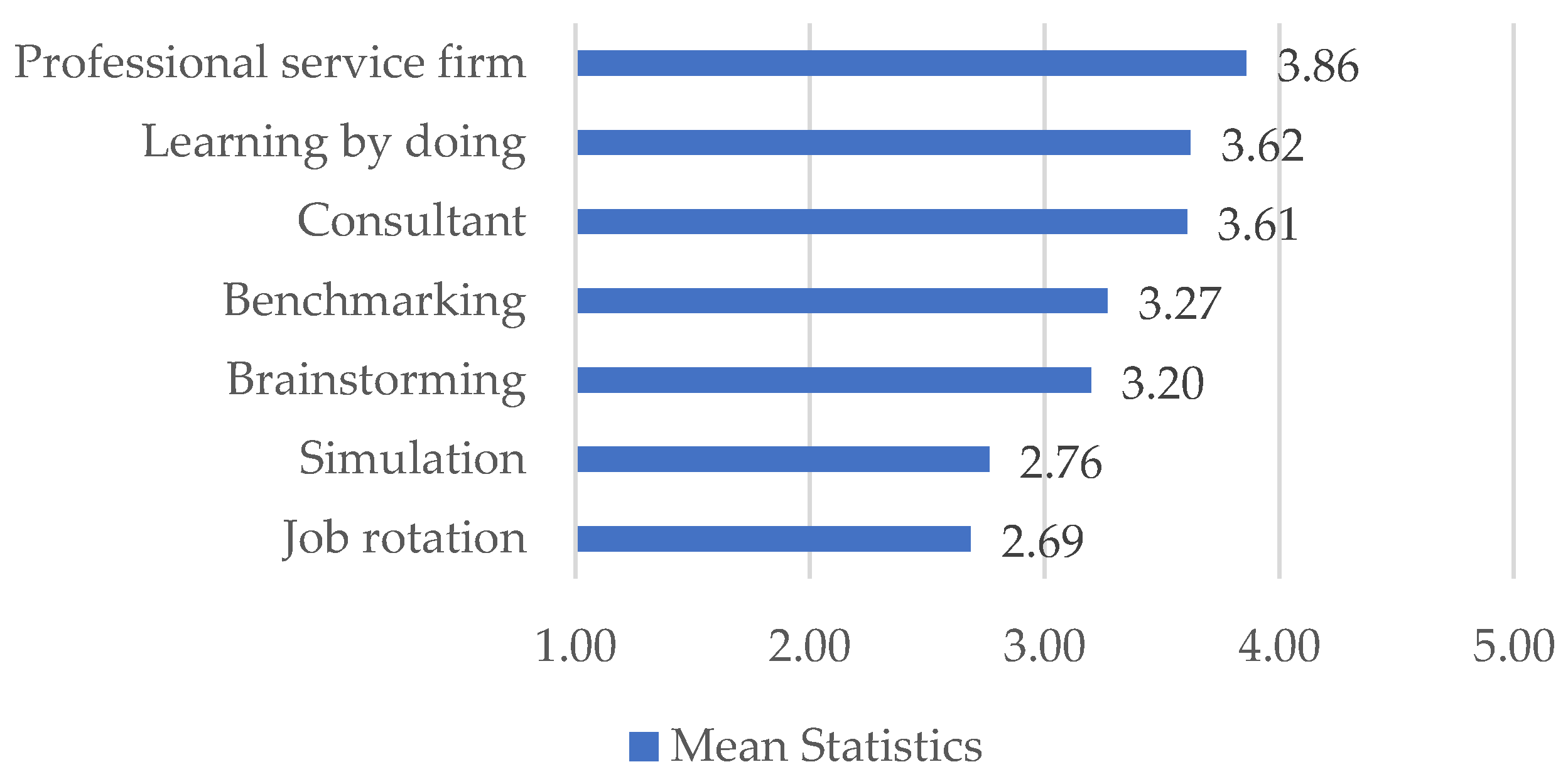

In addition, the understanding of the relative actual occurrence of KC, KT, and KR processes could be useful for the construction’s SMEs. It seems that the SMEs usually focus on verbal confrontations (KT) and learning-by-doing activities (KC) “through embodies interactions (..) rather than various forms of decoded and written forms (KR) and computer-mediated learning” [

63] (p. 83). In this sense, RQ2 specifically analyze this aspect, comparing the three clusters of KC, KR, and KT processes in the Italian construction SMEs.

RQ2: Which OL processes are comparatively used more—among KC, KT, and KR processes—by the Italian construction SMEs?

As a last specific focus for the quantitative analysis, the relative evaluation of intraorganizational and interorganizational learning processes would complete the understanding of the customary attention to OL processes implemented within the organizational boundaries, and those developed in collaboration with external partners. This aspect is particularly important in the context of CE, considering that CBM implementation requires the joined actions of SC actors in order to fully convey the expected environmental, economic, and social outcome [

9,

14,

74,

77]. Therefore, RQ3 comparatively confront intraorganizational and interorganizational learning processes utilization inside Italian construction SMEs.

RQ3: Which OL processes are comparatively used more—among intraorganizational and interorganizational learning processes—by the Italian construction SMEs?

The occurrence of the described processes, and the potentially related organizational benefits, are related to the influence of specific OL contextual elements, such as the external environment, organizational features, and organizational culture [

78] referred to as the multiple levels involved in OL processes (e.g., [28, 33]). Here, we build on seminal contributions on OL contextual elements [

78] to propose specific factors that influence the occurrence of CBM-oriented OL processes, and thus the organizational sustainability inside SMEs: External environment, supply chain context, organizational features, and a multi-level notion of culture. Some of the above-mentioned contextual elements are aligned to the barriers and drivers highlight from recent literature as influencing CE implementation and sustainable transition inside organizations [

46,

68], and particularly SMEs (e.g., [

23]).

In particular, following the OL and CE literature [

23,

28,

45,

68,

78], we suggest that the proposed contextual elements might act at the same time as barriers and drivers for CBM-oriented OL processes; in this context, the activation of knowledge dynamics among organizational and external actors could contribute to transform the contextual elements acting as barriers into potential enablers for the organizational sustainability under a circular approach.

Starting from the Fiol and Lyles’ external environment [

78], this dimension generally influences the activation of OL processes in relation to the pressure related to external stakeholders, such as customers, competitors, and institutional bodies [

79]. Expanding this conceptualization, we propose to identify two different dimensions relatively to the environment in which a SME is inserted in: The general external environment, and the supply chain context. In fact, CBM implementation is not limited to the organizational-level application of CE principles, but it requires the engagement of SC stakeholders in the design, development, and implementation of this type of sustainable business model [

14]. Thus, in a CE-related study, it appears significant to analyze the supply chain context as a separated dimension deferential from the general external environment.

The external environment is here conceived as the macro-level environment composed of external stakeholders, ranging from institutional bodies to customers and competitors, that represents the dimension in which both supply chain and SMEs are embedded in. In the context of CBM implementation, the external environment gains importance as the stakeholders might ask for or refuse circular practices in relation to the level of diffusion of environmental culture and awareness in relation to CE [

80], thus mutually acting as external driver or barriers. In addition, the external environment includes institutional pressure from national, regional, and local regulatory bodies that might enable or constrain CE application at the supply chain and organizational level. This aspect is particularly relevant for SMEs and the construction sectors, as they are actually under the pressure of new environmental regulations at an EU level [

57,

81], and at a national level (i.e., Italian regulation [

82]).

Proposition 2. The external environment—composed of cultural and regulatory factors related to the included stakeholders—represents a contextual element that influence intraorganizational and interorganizational CBM-oriented OL processes occurrence both as a barrier and as a driver.

Although embedded in the external environment, we distinctly address here the supply chain context, here defined as “a network of connected and interdependent organizations mutually and co-operatively working together to control, manage and improve the flow of materials and information from suppliers to end users” [

83] (p. 4) as a separate dimension of contextual factors. The definition of this dimension is sustained by the need to collaboratively manage a sustainable-oriented supply chain, under a CE approach [

84]. Specific components of this dimension might act as barriers and enablers of CBM implementation, such as the collaborative culture of SC actors that might be established among the different actors, that might envision or constrain the identification and development of shared CBMs and generally sustainability initiatives along specific supply chains [

85]. Together with the collaborative culture, the lack or presence of collaboration structures (e.g., virtual interorganizational CoP, [

59]) and interorganizational processes (e.g., interorganizational R&D projects, [

70]) might hinder or facilitate the collaborative development of CE-oriented learning practices beyond the organizational boundaries, with a particular relevance for the construction sector [

74].

Proposition 3. The supply chain context—composed of collaborative culture, structures, and processes among the supply chain stakeholders—represents a contextual element that influence intraorganizational and interorganizational CBM-oriented OL processes occurrence both as a barrier and as a driver.

At the organizational level, embedded in both the supply chain context and external environment, some specific element related to SMEs might mutually act as barriers and drivers in relation to CBM-oriented OL processes implementation. First, the organizational culture—which in SMEs might be aligned to the top-management culture, as it usually has a major impact in new business strategies and product development [

86]—largely influences the hindrance or occurrence of specific OL processes, especially in relation to innovation processes [

87], as it stimulates the overall organizational capacity of acquiring new knowledge [

88], and of opening up the organization towards external collaborations [

89]. Second, the availability of dedicated internal organizational structures influences the activation of OL processes, mainly in relation to of the scarce economic, IT resources, and personnel [

90] that could be allocated to OL-related activities. This aspect represents a typical SME limitation [

91], with a specific relevance in CE-oriented innovation [

23]. The importance of the organizational features is also underlined in the conceptualization of organizational resilience [

92], which highlights how the resourcefulness of internal personnel and the redundancies of structures [

93] are able to enable organizations to redesign SCs and adapt BMs to radical and disruptive situations. As a third element, the available processes might positively or negatively influence the development of CBM-oriented OL processes, such as organizational routines and internal operations [

94]. Especially in CBM implementation, the available internal processes might propose a more or less adaptability of the SME in a CE approach, thus influencing also the related OL processes.

Proposition 4. Organizational features—i.e., organizational culture, structures, and processes among organizational actors—represent contextual elements that influence intraorganizational and interorganizational CBM-oriented OL processes occurrence both as a barrier and as a driver.

As a last contextual element, a multi-level concept of culture [

95] is presented to identify a critical element as in the OL process implementation [

96,

97], as in CE-oriented transition [

23], and as a precursor for organizational sustainability [

98,

99]. In particular, the three sub-dimensions of external stakeholder culture in the external environment, the collaborative culture in the supply chain context, and the organizational culture at a SME level compose the three levels of a transversal cultural element that can positively or negatively influence the occurrence of interorganizational and intraorganizational CBM-oriented OL processes.

Proposition 5. The multi-level notion of culture—composed of cultural elements embedded in the external environment, the supply chain context, and the SME dimensions—represents a transversal contextual element that influence intraorganizational and interorganizational CBM-oriented OL processes occurrence both as a barrier and as a driver.

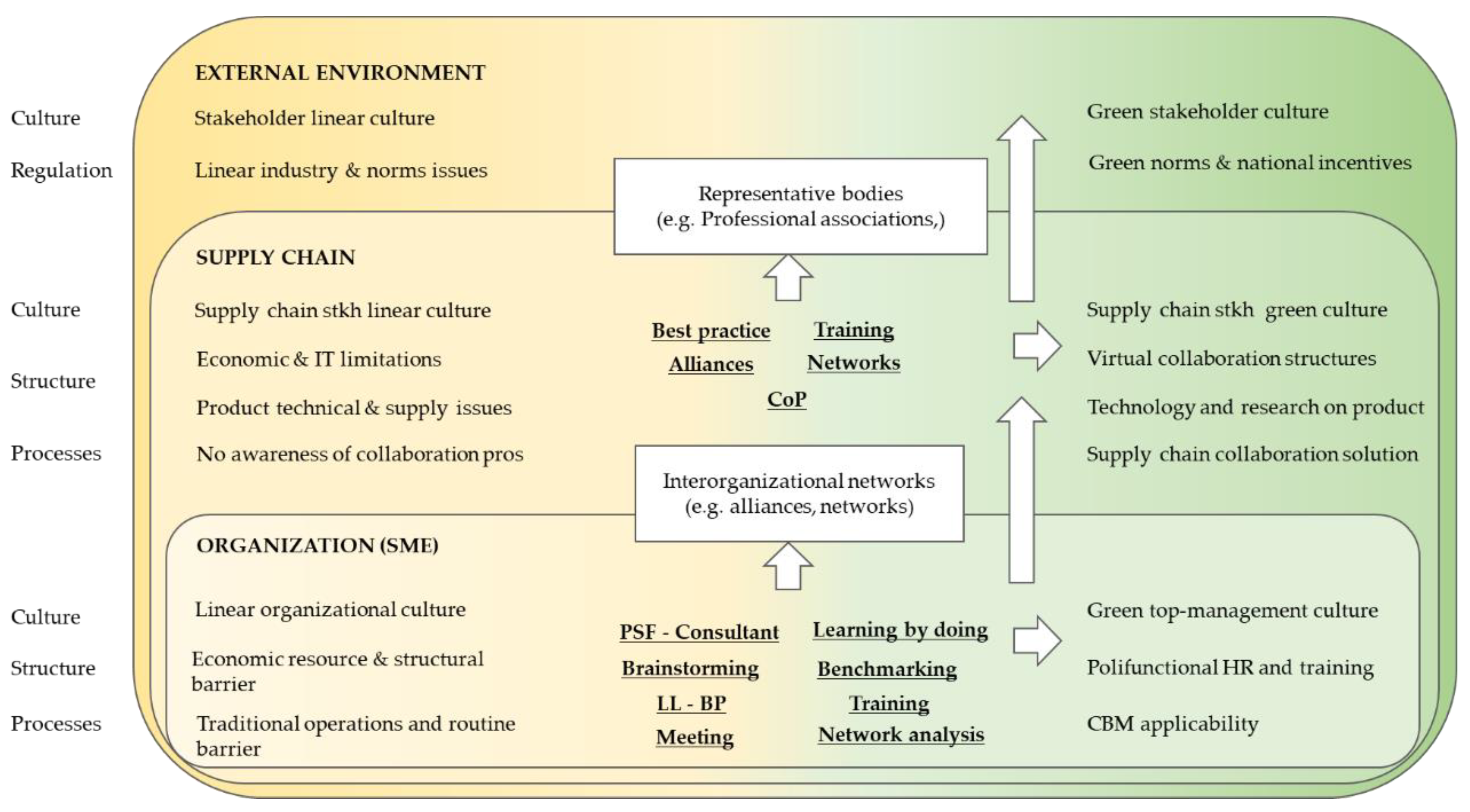

Figure 1 reports the CE-oriented OL model composed of the interorganizational and intraorganizational CBM-oriented OL processes, together with the influence of the proposed contextual elements (i.e., external environment, supply chain, organizational features, and the multi-level cultural factor) and the related sub-element on the processes.

In the model, the OL processes take place in the organizational context—represented by the SME dimension—and in the interorganizational setting—here specifically identified in the SC level. The identification of interorganizational learning processes as confined to the SC dimension is strictly related to the high relevance of SC collaborative solutions in CBM implementation, as CE requires the inclusion of the value network in the creation, development, and delivery of value towards stakeholders [

43]. Thus, for the scope of this study, the proposed model comprises only the interorganizational processes that take place at the SC level.

The interrelation among the interorganizational and intraorganizational processes is clarified from the arrows inserted in

Figure 1. On the one hand, intraorganizational CBM-oriented OL processes might be activated independently from the SC context or, in a top-down logic, as a dynamic result of CBM-oriented OL processes among SC actors. On the other hand, the organizational-level CBM-oriented OL processes might stimulate related SC interorganizational CBM-oriented OL processes in a bottom-up direction. The same logic applies to the interorganizational level, and might envision the identification of multiple patterns of OL processes inside and across the two levels.

3. Materials and Methods

To investigate the above-mentioned propositions and research questions, the study employs a mixed method approach, thus the collection, analysis, and integration of both qualitative and quantitative data [

100] inside a wider intervention design oriented to propose OL processes aimed at implementing CBMs in the Italian construction sector.

Firstly, a qualitative analysis of industry-specific contextual elements in relation to CE-oriented OL processes implementation was carried out. Specifically, we performed the evaluation of a selected sample of SME managers from the identified sector,—construction,—inside a specific country,—Italy,—which holds one of the highest EU ranking positions in terms of CE implementation [

26]. The use of a qualitative method is necessary to capture the detailed perception of contextual elements in a specific environment through the analysis of a specific sample—construction SME top managers—which is scarcely analyzed in relation to CE [

77]. In addition, the identification of CE-related OL contextual elements requires a preliminary conceptualization of both CE and CBMs that is more concisely conveyed to the participants through a qualitative design. The top managers’ evaluation is specifically required from the CE-related literature, as in SMEs they represent the essential link among the organizational and interorganizational level for reaching CBM goals [

101].

In particular, the focus group methodology [

102] was used to investigate the different perspectives on the topic and initiate in-depth conversations among informed participants [

102,

103,

104]. During the 2020 spring, four sessions, over two days, were arranged among four groups of six construction SME managers, to ensure an adequate discussion on the topic. The final sample of 24 managers was identified (following previous studies, [

103,

104]), and balanced to ensure the representation of the whole national territory. The health emergency situation related to the COVID-19 pandemic influenced the planned data collection methodology, posing a relevant challenge over the research activity [

105]. Nonetheless, the focus groups took place virtually on the Zoom platform, which allowed a fruitful video and audio interaction among the participants. One researcher was responsible to coordinate the sessions and moderate the discussion, while another researcher was responsible for providing technical support and managing time. Each session was conducted for approximately 90 min.

To gather the participants’ perspective in relation to CBM-oriented OL contextual elements, the focus group discussion encompassed the evaluation of a list of CBM as proposed in the “BS 8001:2017 Framework for implementing the principles of the circular economy in organizations” [

45] integrated with an additional CBM focused on the use of renewable energy [

106], as proposed by earlier studies [

43]. After the definition and presentation of each CBMs, the discussion focused on the possible implementation in the Italian construction sector, and the related OL processes and contextual elements that might support or hinder the application.

The full transcriptions of the sessions (i.e., primary data) were double-coded and interpreted by two researchers using the NVIVO 12 plus software. Informed by the logic of grounded theory [

107], the primary data were in their original language (Italian) and then interpreted following a non-mechanical process [

108] for in-context validation in terms of used terminology, words, and expressions. The transcriptions have been analyzed to uncover deeper structures of meaning inspired by the research design oriented to simultaneously question theory and interpret data with the theory. Specifically, this interpretation process resulted in the identification of first-order concepts (

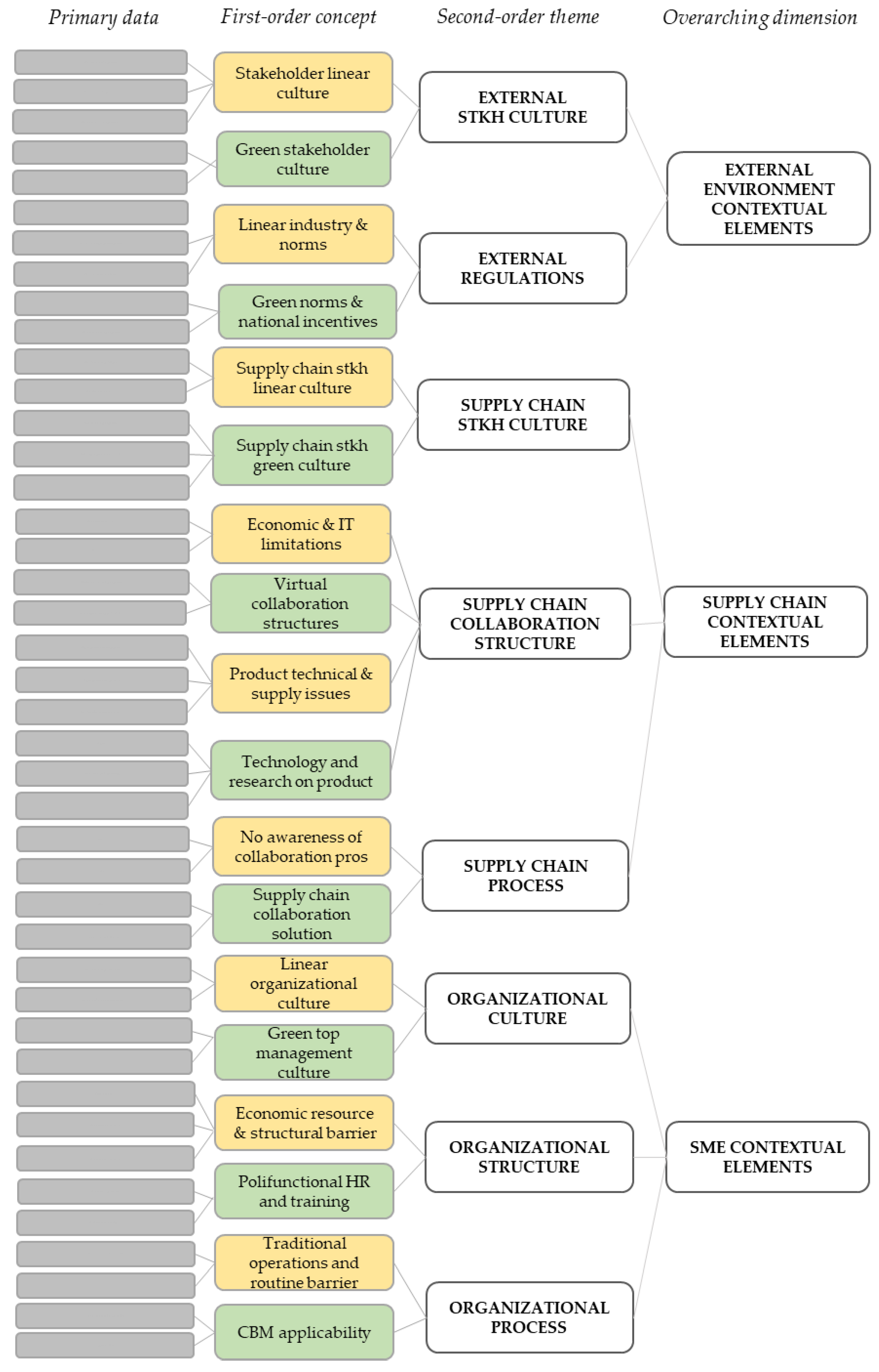

Figure 2) in light of the proposed OL and CE theoretical background. Subsequently, eight second-order themes were defined through the aggregation of the first-order concepts in wider structures of meanings, labelled in agreement between the two researchers. Finally, three overarching dimensions were identified by the grouping of second-order themes into main theoretical elements.

As a second research method, a quantitative investigation of OL processes utilization at interorganizational and interorganizational level inside Italian construction SMEs was carried out through a close-ended survey administered on a national scale. The decision to use a quantitative method for the OL processes evaluation was related, first, to the need to draw conclusions from a larger number of participants in relation to KC, KT, and KM processes utilization, adapting from previous studies [

70]. Second, OL processes are described using commonly used terminology, thus prospecting significant results through quantitative methods due to the ease of communication. During April 2020, the survey was sent to 500 companies using the Italian building construction professional association (ANCE) territorial mailing list, selected to balance the coverage of northern, central, and southern Italy. The use of official ANCE channel was essential to guarantee a higher probability of managers’ responses as from a known source. A final sample of 127 fully responded survey was used for the evaluation (25%), which represents a higher response rate in comparison with previous studies on SME managers (e.g., [

109]).

The survey is composed of two main sections. The first part reports the questions related to the respondent and the represented SME, oriented to capture firm size, main organizational activities, area of activity, and the role covered by the respondent. Due to privacy restrictions related to the professional association internal rules, it was not allowed to ask for other personal information, such as age, gender, and firms’ financial performance. The second section presents the questions on KC, KT, and KR processes utilization, evaluated by respondents using a 1–5 Likert scale.

Table 1 and

Table 2 specifically report the items included in the developed survey and the related references. The obtained results were analyzed through SPSS Statistics 20 and Excel 2016 software, in order to gather means and medians of OL processes frequency from the evaluated SME managers.

The qualitative and quantitative data developed from the two research methods were used to contextualize and define the OL model proposed in the theoretical background, in order to contribute to a comprehensive definition of CBM-oriented OL processes and contextual elements for the circular transition of Italian construction SME.

5. Discussion

The qualitative and quantitative data analyses offer several insights on the role of learning processes and related contextual elements in the introduction of CE principles among construction SMEs. As a first implication of the study, the presented results informed the development of a more refined theoretical model that proposes the interrelation among the identified CBM-oriented OL contextual elements and the actually employed OL processes within the Italian construction SMEs. In particular, the three overarching dimensions (external environment, supply chain, and SME) identify three progressively embedded clusters of contextual elements, and are composed by the sub-factors identified through the qualitative analysis (culture, regulation, structure, process). The second-order themes are arranged according to the sub-elements of the overarching dimensions to which they belong and inserted in the model as follows: The themes that represent CBM-oriented OL processes barrier are inserted in the left part of the model, while those referring to potential drivers are listed in the right part. In the central part, the OL processes that present above-the-median values (see

Figure 7) are inserted in the SC and SME dimensions, as referring to interorganizational and intraorganizational learning processes identified with the quantitative analysis.

Figure 8 graphically describes the proposed model.

In fact, the analysis underlines that the recognition of CBM-oriented OL drivers appears possible only through the activation of intraorganizational and interorganizational learning processes, thus at both the SC and SME level. The partial understanding of CBM applications, the lack of univocal definitions, and the limited knowledge of the related advantages appears to hinder the application from the start; Thus, the qualitative analysis fully supported the proposed pivotal role of KC, KT, and KR processes in relation to CE and CBM, as important preliminary activities oriented to understand the related definitions, to develop applicable context-specific implementation, and identify the collaborative and organizational benefits of the related innovative solutions (

Proposition 1). The activation of KC (e.g., knowledge-oriented confrontation among stakeholders), KT (e.g., training activities), and KR processes (e.g., the diffusion of CBM best practices) is fostering a wider evaluation and implementation of sustainable-oriented solutions, both within and beyond the organizational boundaries. Accordingly, the central position given to OL processes in

Figure 8—halfway through OL barriers and drivers—underlines the essential role of interorganizational and intraorganizational learning processes in transitioning barriers into enablers for CBM-oriented OL processes implementation, as illustrated by the qualitative analysis. Even though analyzed in a specific context, the essential role of CE-related OL processes might be potentially generalized in other contexts, as the lack of shared understanding on CE definitions (see for example the 117 definitions reported in [

10]), CBMs conceptualization [

14,

16,

18], and diffused evaluation frameworks [

45,

57]; and the limited availability of construction sector’s applications [

15,

76] is an actual common issue across Europe. On a policy level, the development of specific OL processes—KC, KT, and KR processes—oriented to a common understanding of accepted CE and CBM definitions across the key stakeholders might envision a coordinated and purposeful evolution of the whole construction sector in a circular economy perspective, also in consideration and support of the environmental policy stringency of OECD countries (e.g., [

120]). Equally, from an organizational and SC perspective, SME managers that envision the transition towards a sustainable management of a construction SME should consider the activation of specific interorganizational and intraorganizational learning processes that are oriented to identify, evaluate, and develop CBMs within and across organizational borders.

To contribute to the identification of interorganizational and intraorganizational learning processes related to the Italian construction sector, the quantitative analysis reports the actual higher intensity of OL processes use, thus possible learning solutions that would be easily accepted and, thus, implemented in this sector in the CBM use orientation (

RQ1). From the survey results, OL processes generally appear not to be intensively used in the construction SME normal activity, with the highest frequency of use of 3.86 (for professional service firm activities), and a median value of 2.82, over a 1–5 Likert scale. This aspect appears to underline that OL processes are not extensively activated (without a specific stimulus from the external environment), in contrast with other organizations, which usually invest in innovations and learning processes to maintain competitive advantages over competitors (e.g., high-technology firms, [

121]). Additionally, among the highly ranked OL processes, professional service firm-related and consultants’ activities, and external training underline the relevance of informed external source in KC and KT processes, in alignment with specific literature focused on construction SMEs [

122]. However, the scarce use of other types of external sources and related interorganizational KT processes—such as partners in network contracts, and collaborative R&D projects that present the lowest values—highlight a clear preference of “neutral” source of knowledge, in contrast with partner-based collaborative solutions.

Considering in detail the comparative analysis of OL processes that present above-the-median values (

Figure 7), the KC processes appear to be more frequently used in this context respectful to KT and KR processes (

RQ2), thus applicable in relation to CBM implementation. This aspect is aligned with earlier literature, since the usual activity related to construction firms involves continuous confrontations among different figures, such as external professionals, institutional bodies, and generally stakeholders [

63]. However, since the different OL processes might be possibly overlapping and closely joint,—e.g., KC processes activated from KT processes from external sources, or from knowledge related to internal and external KR processes—the comparative analysis appears useful to identify possible connections among mostly used OL processes. In particular, as the highly evaluated KC processes, —learning-by-doing, benchmarking, brainstorming, and problem-solving activities,—appear to be widely applicable at organizational level to develop specific CE and CBM-related knowledge, it would be fruitful to connect those processes with specific KR processes,—such as the use of CE-related best practice and lesson learnt,—and KT processes—i.e., internal and external training, and meetings—to fully benefit from OL processes. In addition, social network analysis and process mapping KR processes would be useful to explore possible applications of CBMs both at interorganizational level, —through the identification of key actors along the related supply chains and social network, —and at organizational level,—identifying and then adapting internal operations and functions to innovative CBMs requirements.

Since the application of CBMs requires the development of sustainable collaborative solutions across the supply chain [

7,

77], the comparative analysis of intraorganizational and interorganizational processes has singled out the comparatively most used interorganizational learning processes, in the orientation of a wider utilization of those processes in a CE-oriented transition of construction SMEs. As already mentioned above, this evaluation highlights the clear prevalence of OL processes within the organizational boundaries (

RQ3). This aspect is confirmed also from the qualitative analysis, as the internal employees’ and managers’ formation is underlined as a competitive advantage for SMEs, which need to invest on internal polifunctional figures to efficiently invest the limited economic resources at disposal (see

Section 4.1.3). In particular, the above-the-median values of interorganizational learning processes reported by the comparative analysis (see

Section 4.2.5) highlight that external training and the use of best practice appears to be the most probable KT and KR activities to be developed in a first transition towards CBM applications, followed by the exploitation of shared environments, such as professional associations, alliances, and generally interorganizational CoPs. In this sense, less formalized contexts appear to be preferred in contrast with formal solutions—e.g., network contracts, R&D projects, thus the exploitation of informal interorganizational environment would envision a more effective context for the development of interorganizational learning processes.

As a second implication, from the analysis of the Italian contextual elements in relation to the development of CBM-oriented OL processes, SME managers have highlighted the important role of the external environment, both from a stakeholder cultural perspective and from the governmental point of view. In fact, inside the external environment, the crucial role of national regulation is underlined, by SME managers’ assessment, as one of the main barriers for the development and promotion of sustainable-oriented organizational and interorganizational solutions. At the same time, the pivotal function of governments is recently highlighted in the literature as they might act as “facilitators of value creation”, shaping a “pro-businesses” environment where organizations and governments interact to “solving society’s problems, and inventing new ways to create value for all their stakeholders” [

123] (pp. 16–17) in a sustainable orientation. Furthermore, the interrelation among stakeholder-oriented incentive campaign and a fine-tuning of the developing and actual regulation on construction materials and operations appears to contribute both to the cultural openness of external stakeholders—customers, commissioners—as on a wider SC and organizational cultural acceptance of sustainable solutions, such as the CBM implementation. In this sense, governments have a decisive role in the promotion and support of sustainable organization-oriented policies, and in the development of awareness-raising campaigns within the society. This result, thus, fully supports our proposition (

Proposition 2), identifying the influence of external environment on both the SC and the organizational level. In addition, the presented implication on the role of the external environment—even if developed in a specific country and sector—might be cautiously generalized in other contexts as probable CE barriers and drivers to be found at an external level, as it is aligned with—even tough partly expanding—on previous studies [

23,

46,

80]. With a favorable external environment characterized by national and local CE-oriented regulations, SMEs might effectively contribute to an overall sustainable development of the sector, through the application of CBMs encouraged and accepted by the related stakeholders.

As a third main implication, the triple sub-articulation of supply chain contextual elements—SC stakeholder culture, SC collaborative structures, and process—refines the identification of those factors that influence the occurrence of CBM-oriented OL processes at a SC level both in a negative and positive way. In addition, the analysis supports the identification of the SC context as a relevant sub-articulation of the external environment where interorganizational CBM-oriented OL processes take place (

Proposition 3). Specifically, a first cultural obstacle appears to identify the major barrier to the activation of collaborative CE-oriented OL processes across SC actors. The not-shared understanding of applicable CE-oriented collaborative solutions and related benefits—mainly linked to the reliance on traditional solutions against innovations [

25]—is capable of hindering the activation of CBM-related learning processes, thus prospecting a limited interorganizational cooperation inside the SC. Conversely, the proposed OL processes (mainly KC and KT processes) are highlighted as essential to knowledge diffusion, such as through the promotion of best practice, as the activation of sustainability-oriented practices and trainings to practically demonstrate the effectiveness of collaborative CBMs among potential partners. This series of OL activities would be possibly stimulated from representative organizations, such as professional associations, CE-oriented networks, unions, and institutional bodies. In fact, representative groups are capable of sustaining SMEs in the development of learning processes “endorsing local innovations and shaping their diffusion” [

124] (p. 58), and they might also act as interorganizational CoPs [

59] offering a shared environment for professionals, managers, and employees for the activation of shared OL processes. In particular, professional association might prevalently “act more as lobbying or advocacy entities than communities of practice” through the development of beneficial activities reserved to the associates, “though they may include specialized subgroups that create practice-development relationships among members” [

59] (p. 44), in a looser form than formal alliances and networks.

Linked to the cultural formation of SC firms, the participation in sharing platforms would facilitate the activation of KC and KR processes oriented to virtually and practically explore CBM application at a SC level among the involved SC actors, as to share technological solutions and knowledge related to green products. Furthermore, the use of collaborative structures, such as virtual platforms and specialized networks for a joint development of activities, products, and knowledge would address the limited availability of human, economic, and IT resources, enabling the resource sharing in a synergic approach as already pointed out from the SME-related literature [

125]. As mentioned above, the exploitation of the mentioned structures might be envisioned only after the activation of stakeholder engagement activities inside the sector, such as through communication campaigns from platform developers, green marketing strategies by networks and alliances [

126], and the sharing of best practices [

73] and CE-related knowledge diffusion via representative bodies and CoPs [

59,

66,

123]. Those promotional activities among key SC stakeholders are shown to be particularly relevant in the construction sector for the achievement of green business model transformation [

127] and would contribute to obtaining the desired attention and related beneficial outcome from CE-oriented partnership and alliances [

67]. Once a CE-oriented stakeholders’ culture is developed, and SC collaborative structures are exploited, the activation of CBM-related processes appears to be eased and practically applicable both at in the SC context and at organizational level in this specific sector (see for example, a multiple case study analysis from [

15]), and thus also interorganizational CBM-oriented OL processes might be easily implemented (

Proposition 3).

Fourth, the SME-related contextual factors identify important intraorganizational aspects that might act as a barrier or as an enabler for the activation of CBM-oriented OL processes under the influence of specific SC contexts, fully supporting our proposition (

Proposition 4). In particular, the structural limitations in terms of economic resources, internal structures, and essential personnel appear to act as a relevant barrier to CBM-oriented OL processes development, together with the presence of strict traditional routines and processes that hinder the perspective implementation of CBMs. Those structural considerations, together with the need of a cultural transition and practical applications of CBMs, are aligned with previous studies that focus on interorganizational struggle for CE-oriented implementation (e.g., [

23,

46]). However, the perceived limitations could be reinterpreted as potential advantages, as the limited number of employees and managers might contribute to an easier confrontation oriented to a CE-oriented transition; additionally, the resourcefulness of HR might envision a creative evaluation, development, and implementation of CBMs, as related to the multiple functions covered inside construction SMEs. The CBM-oriented internal KC and KT processes identified from the quantitative analysis at intraorganizational level should raise the awareness of the applicability of innovative CBMs [

15,

45,

106], overcoming the internal process limitation identified as a barrier. In addition, at the organizational level, the SME managers underline that the above-mentioned intraorganizational CE-oriented activities need to be envisioned from a green top-management cultural approach towards the organization, as the overall organizational culture usually follows [

86]. In this sense, as already pointed out by earlier SME-related literature [

68,

91], the role of top-management in the orientation of the whole organization from a cultural point of view gains even more importance in the sustainable transition towards CE, as the

deus ex machina (i.e., the decisive problem-solver, from Latin) of the whole organizational evolution. As from the SC level analysis, to overcome structural and process barriers through a green culture disposition appears to be proved and particularly emphasized also in the organizational context.

As a last main implication, the cultural element appears to be pertinently included in all the three dimensions of the external environment, —i.e., external stakeholders’ linear culture as a barrier, and green culture as a driver, —the supply chain context, —SC stakeholders’ linear culture as an obstacle, and collaborative green culture as an enabler, —and the SME level, —organizational linear culture as a barrier, and green top-management culture as a driver. Among the structural and process contextual elements highlighted from the SC and organizational level, this multi-level cultural element appears to identify the key factor in the activation of CBM-oriented OL processes across the three dimensions, as proposed in the theoretical background (Proposition 5). In fact, the collaborative culture among SC actors is the decisive factor for both the structural positive elements—resource sharing to overcome economic and IT limitation, as the co-exploitation of technology—and the processes related to collaboration—industrial symbiosis, to show collaboration advantages. The lack of a cultural disposition toward innovative and collaborative solutions obstacle the CE transition from the very start. Additionally, at an organizational level, the structural barriers—lack of economic resources, limited internal structures—and process limitations—limited applicability of CBMs along with traditional routines and operations—highlighted from the analysis appear to be overcome from a constructive cultural attitude of SME top management. In fact, top management is capable of positively using the polyfunctionality of its personnel to identify, adapt, and introduce innovative CBMs that, indeed, are already applied in this sector, thus applicable at an organizational level. Even though it is outside the scope of the present paper, the analysis of the relative influences of the identified higher-level contextual factors on the lower ones (e.g., the external environment stakeholders’ culture influence on the SC cultural element, or the effect of SC structures on the organizational ones, and vice versa) represents an important aspect that could be explored in further studies on the topic, to offer complementary viewpoints and thus enrich the presented analysis.

As additional implication of the study, possible dynamic patterns of OL processes in the perspective of CBM application are presented, moving from the SC level (

Figure 9), and from the organizational level (

Figure 10), in relation to the transition from the identified contextual elements acting as barriers towards the proactive enablers of CBM-oriented OL processes.

In the first scenario, CBM-oriented learning processes are stimulated by external environmental pressure, and firstly activated at a SC level. The development of CE-related OL processes might be proposed to the SC partners by the representative bodies (e.g., professional associations) or independently developed by the same SC partners, through the activation of CE-oriented training courses, alliance and networks, or the development of intraorganizational CoPs among the SC actors. Secondly, those processes might stimulate, on the one hand, additional CBM-oriented interorganizational learning processes at SC level, and, on the other hand, the activation of CE-related intraorganizational learning processes at a single SME level. The link among the SC and organizational level might be facilitated by the interorganizational networks through the exploitation of preexisting social relations or might be directly realized by the specific SC partners in the SME social network. As explained in the previous paragraphs, the OL processes oriented to stimulate the cultural transition from a linear culture toward a green cultural disposition of SC managers, which might thus influence the respective single SMEs, identify the first essential learning process activated by the promoters, followed by the identification of the most useful collaborative structures and processes (

Figure 9). This scenario presents a dynamic pattern of learning processes encouraged from the interorganizational to the organizational level in a top-down direction, underlying the relevance of SC level in CBM application in relation to the organizational level.

Conversely, the SME level might act independently driven by a preliminary activation of interorganizational CBM-oriented OL processes. A second scenario (

Figure 10) proposes possible OL dynamics that move from the organizational to the interorganizational level, following a bottom-up logic. In this setting, organizational-level learning processes oriented to the identification, evaluation, and development of CBMs might be first activated by the SME actors,—more probably, by the top-managers, in view of the above-mentioned important role inside this type of organizations,—that would influence the internal personnel, structures, and processes in a circular perspective. The organizational level CE-transition would probably stimulate the engagement of SC partners, in order to ensure the full beneficial effect of this sustainable evolution [

14,

84], starting from a cultural raising-awareness campaign, or other stakeholder engagement practices. The movement from the organizational to the SC level might be facilitated by the exploitation of existing interorganizational networks that include the relevant SC actors that would be involved in the identified CBM, as it might envision direct contact to the key actors. In addition, in this scenario, the cultural transition is essential to subsequently exploit collaborative structures and processes oriented to the development of specific CBM-oriented OL processes. As the CBM is fully implemented both at the organizational and interorganizational level, representative bodies should be useful to spread the related practices across the sector and other supply chains, to contribute to a wider understanding of CE-related implementations, as to stimulate other proactive actions in similar organizations.

Limitations and Future Research

The study has some limitations; first, the choice of a single context of analysis, the Italian construction sector. This decision was justified by the access that one of the authors had to the sector key constituents and also was informed by the relevant position covered from the Italian context in the overall EU CE-related ranking [

26,

116], and the presence of several CE-oriented studies in other sectors (e.g., in the agri-food sector, in [

128]), which prospected a peculiar environment to perform the analysis. In addition, the construction sector and SMEs are actually required to perform a considerably important transition towards sustainability [

11,

24,

81], thus identify an important specific context of analysis. Second, the focus group methodology might limit the generalizability and replicability of results, as participants’ possibly dominant positions in the discussion risk limiting the overall interaction [

103,

129]. To manage this possible bias, during the data collection processes one researcher coordinated and moderated the participants’ discussions, while another was responsible for providing technical support and time management. Similarly, this methodology envisioned a possible subjectivity bias of the interpretations; in this orientation, the iterative confrontation among the two researchers would contribute the study’s methodological efficacy [

102,

103,

104]. Furthermore, the use of the NVIVO software in the interpretation and coding processes would additionally reduce the intrinsic subjectivity of qualitative research.

Regarding the quantitative analysis, the use of descriptive analyses of the evaluated items, without the inclusion of other more refined methodologies and instruments, was strictly joined by the specific focus of the analysis, that was oriented to identify the mostly used OL processes in the sector, without the evaluation to specific related effects (e.g., on performance, or organizational factors). Further research would possibly use other quantitative methods to evaluate the role of OL processes in relation to the CE-related outcomes, that are the environmental, economic, and social effects related to organizational and interorganizational applications of CBMs. In addition, further studies would possibly focus on the role of advanced digital technologies in joining the external, supply-chain, and organizational actors, to support the development of virtual CoPs [

61]. However, since the results inferred from the multi-method analysis are aligned—and partially expand—on previous conceptualizations and conclusions from CE-related and OL literature, the results might be, under specific assumptions, generalized to other contexts such as other EU and OECD countries already advanced in CE practices (e.g., The Netherlands, Sweden, UK, or Spain; [

130]). The reproduction of the presented study in different national settings would increase the generalizability of the results, and it would contribute to the development of widely applicable guidelines for CE implementation across contexts.

Further studies on the topic should deepen the analysis of the relative influences of specific OL contextual elements across the dimensions, as the variation in the relevance of OL processes in the specific setting of sustainable business model implementation. In this sense, action research designs and longitudinal studies are suggested as they offer the possibility to assure a real-time evaluation of learning-related conceptualizations and perceived contextual elements, as the long-term effects resulting from the applied theoretical approach.