Designing a Resilient and Sustainable Logistics Network under Epidemic Disruptions and Demand Uncertainty

Abstract

:1. Introduction

- Modelling the integrated logistics network design problem that includes routing, inventory and location–allocation decisions and considers demand fluctuations and epidemic disruptions with ripple effects.

- Applying a Monte Carlo simulation to generate plausible scenarios and model the different sources of uncertainty.

- Considering capacity augmentation and logistics collaboration as a strategy to reduce the risk of disruption.

- Assessing three aspects of sustainability and investigating the interaction between these aspects and resilience in the integrated design of two-echelon logistics networks subject to epidemic disruptions.

2. Literature Review

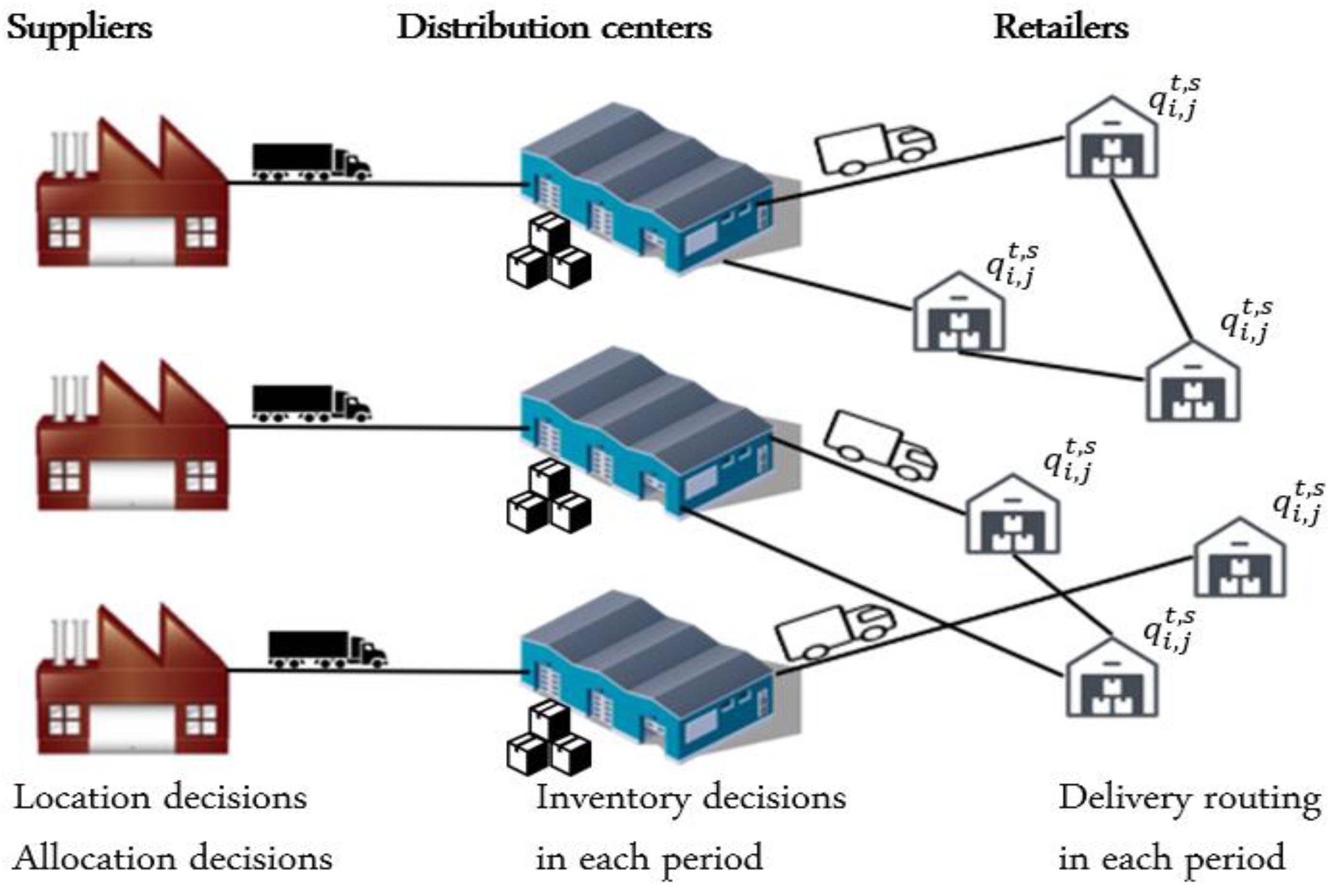

3. Problem Definition and Mathematical Modelling

- Each retailer i can be visited once by one of the vehicles and served from a single distribution center d [54].

- Each supplier has a specific product, but all products are compatible.

- Retailers’ demand is assumed to be stochastic and follows a normal distribution [51].

- Vehicles and semitrailer trucks can conduct several routes in each period scenario [41].

- Location–allocation is a strategic decision, which is independent of the planning periods and plausible scenarios, as stated by Rafie-Majd et al. [56].

3.1. Sustainability Dimensions

3.1.1. Costs Calculation

3.1.2. Environmental Assessment

3.1.3. Social Sustainability Assessment

3.2. Measure of Resilience

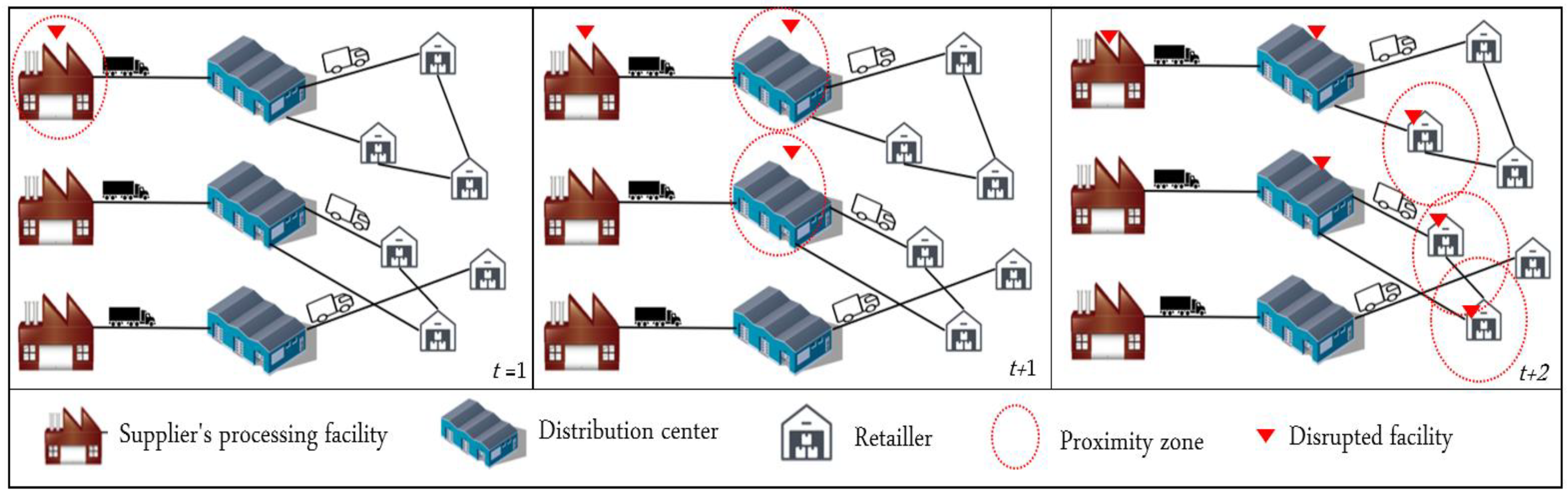

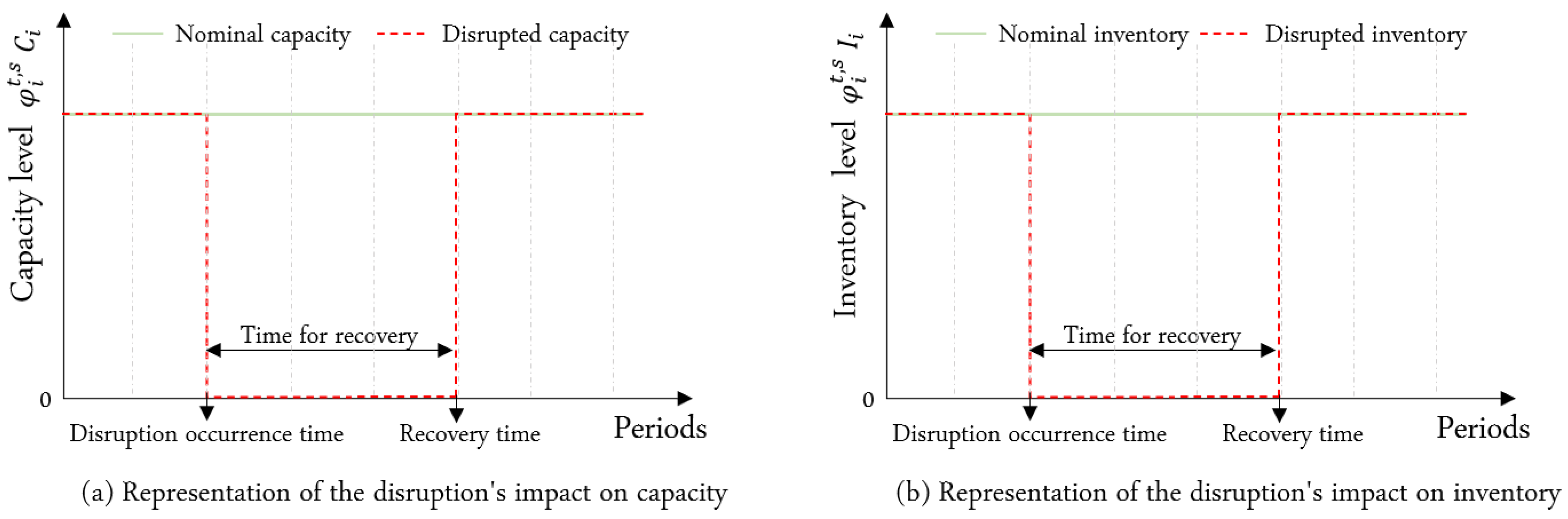

3.3. Epidemic Disruption Modelling

3.4. Stochastic Mathematical Model

3.5. Resiliency and Sustainability Strategies Formulations

3.5.1. Capacity Expansion

3.5.2. Logistics Collaboration

4. Solution Methodology

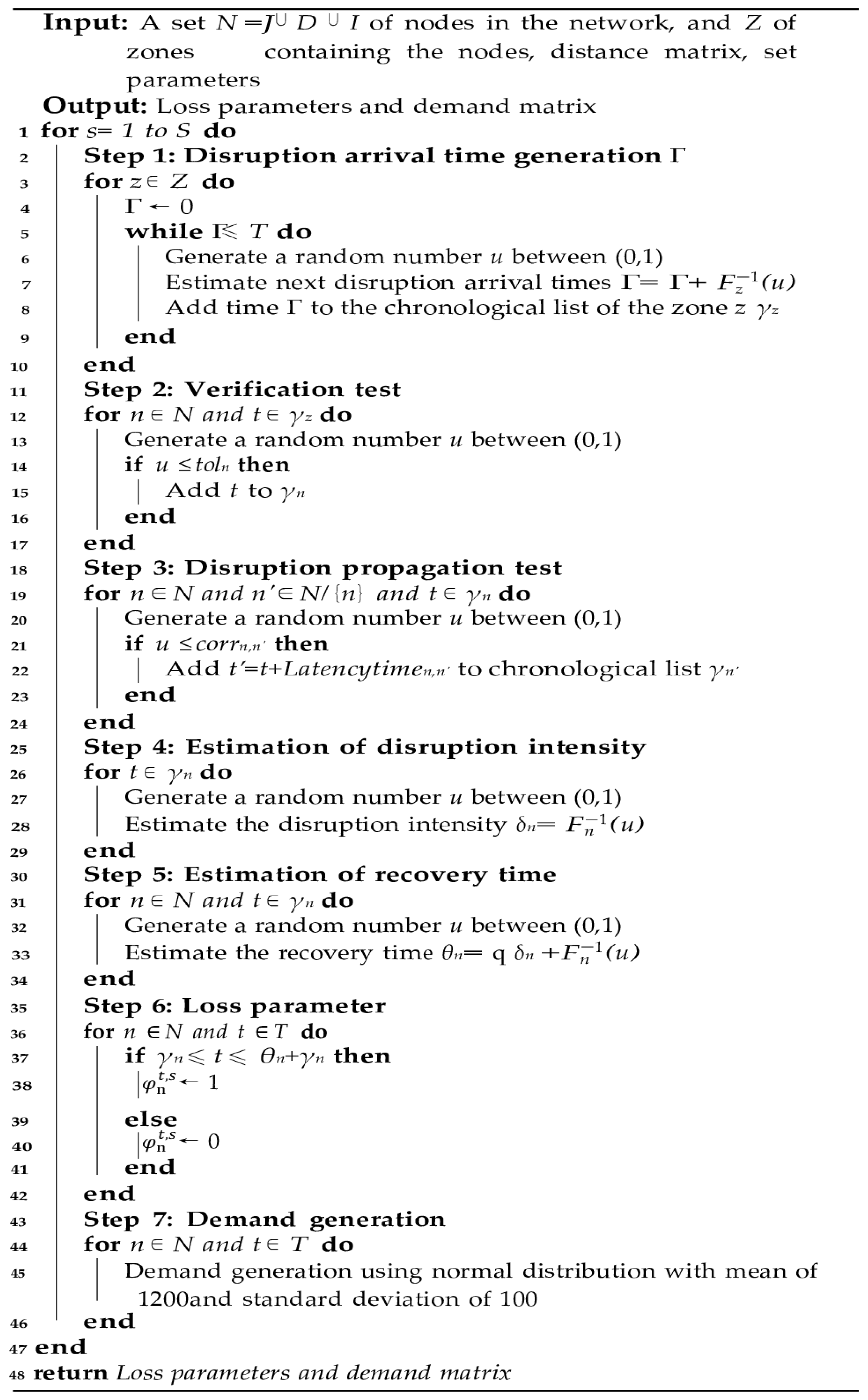

4.1. Scenarios Generation by a Monte Carlo Simulation

4.2. Sample Average Approximation Method

5. Computational Experiments

5.1. Description and Data

5.2. Results and Discussion

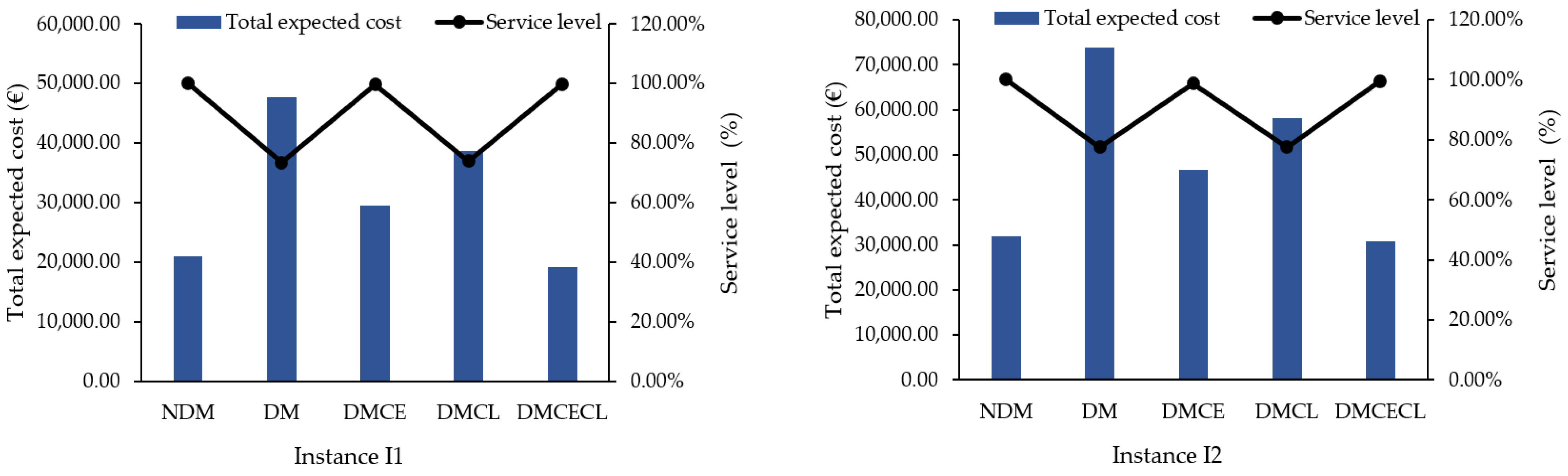

5.2.1. Economic Resilience Performance Analysis

5.2.2. Environmental Resilience Performance Analysis

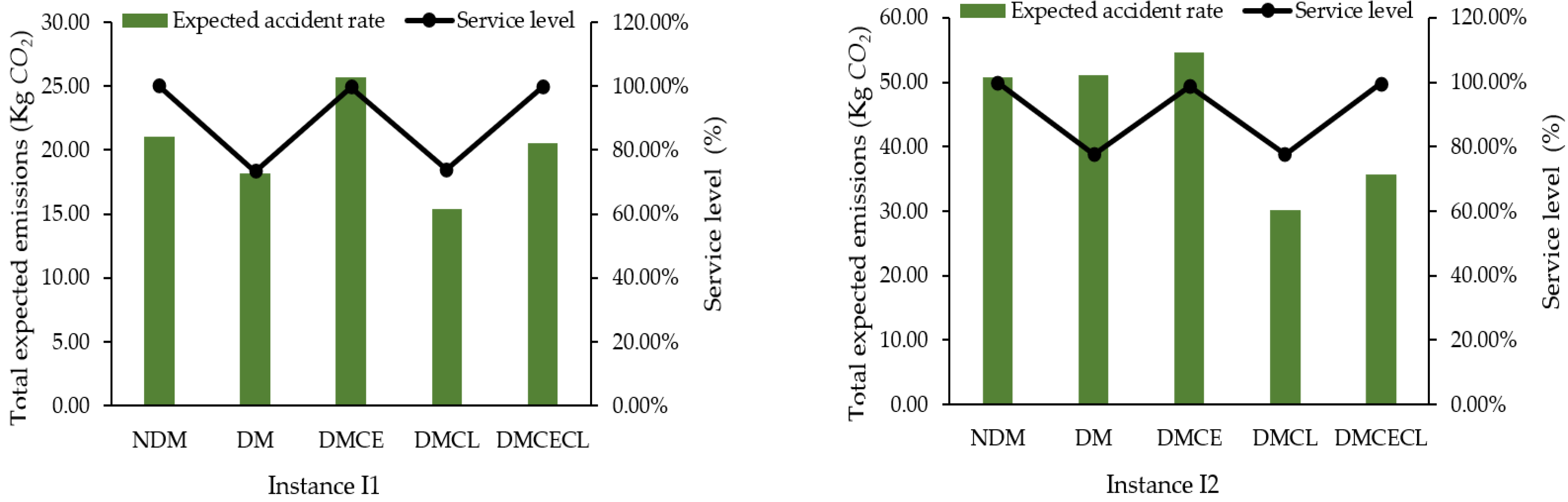

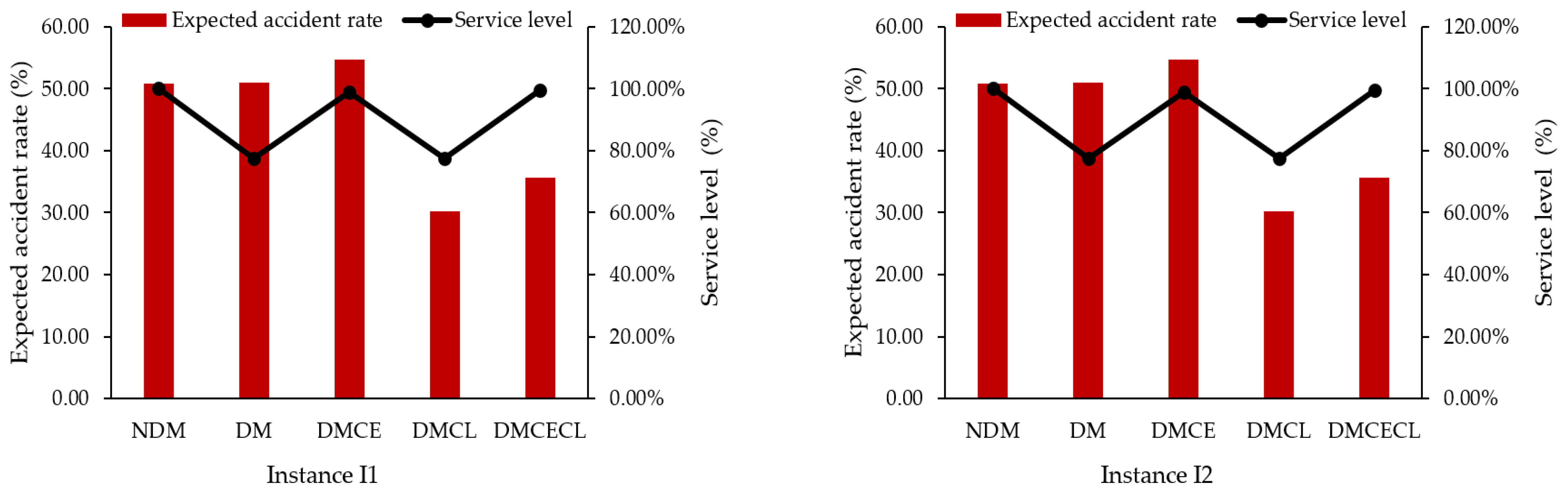

5.2.3. Social Resilience Performance Analysis

5.3. Managerial Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scheibe, K.; Blackhurst, J. Supply chain disruption propagation: A systemic risk and normal accident theory perspective. Int. J. Prod. Res. 2017, 56, 43–59. [Google Scholar] [CrossRef] [Green Version]

- Dey, B.K.; Bhuniya, S.; Sarkar, B. Involvement of controllable lead time and variable demand for a smart manufacturing system under a supply chain management. Expert Syst. Appl. 2021, 184, 115464. [Google Scholar] [CrossRef]

- Turki, S.; Sauvey, C.; Rezg, N. Modelling and optimization of a manufacturing/remanufacturing system with storage facility under carbon cap and trade policy. J. Clean. Prod. 2018, 193, 441–458. [Google Scholar] [CrossRef]

- Turki, S.; Sahraoui, S.; Sauvey, C.; Sauer, N. Optimal Manufacturing-Reconditioning Decisions in a Reverse Logistic System under Periodic Mandatory Carbon Regulation. Appl. Sci. 2020, 10, 3534. [Google Scholar] [CrossRef]

- Tolooie, A.; Maity, M.; Sinha, A.K. A two-stage stochastic mixed-integer program for reliable supply chain network design under uncertain disruptions and demand. Comput. Ind. Eng. 2020, 148, 106722. [Google Scholar] [CrossRef]

- Turki, S.; Rezg, N. Impact of the Quality of Returned-Used Products on the Optimal Design of a Manufacturing/Remanufacturing System under Carbon Emissions Constraints. Sustainability 2018, 10, 3197. [Google Scholar] [CrossRef] [Green Version]

- Dolgui, A.; Ivanov, D.; Sokolov, B. Reconfigurable supply chain: The X-network. Int. J. Prod. Res. 2020, 58, 4138–4163. [Google Scholar] [CrossRef]

- Sharma, A.; Adhikary, A.; Borah, S.B. COVID-19’s impact on supply chain decisions: Strategic insights from NASDAQ 100 firms using Twitter data. J. Bus. Res. 2020, 117, 443–449. [Google Scholar] [CrossRef]

- Ivanov, D. ‘A blessing in disguise’ or ‘as if it wasn’t hard enough already’: Reciprocal and aggravate vulnerabilities in the supply chain. Int. J. Prod. Res. 2019, 58, 3252–3262. [Google Scholar] [CrossRef]

- Butt, A.S. Strategies to mitigate the impact of COVID-19 on supply chain disruptions: A multiple case analysis of buyers and distributors. Int. J. Logist. Manag. 2021. [Google Scholar] [CrossRef]

- Campisi, T.; Basbas, S.; Skoufas, A.; Akgün, N.; Ticali, D.; Tesoriere, G. The Impact of COVID-19 Pandemic on the Resilience of Sustainable Mobility in Sicily. Sustainability 2020, 12, 8829. [Google Scholar] [CrossRef]

- Chamola, V.; Hassija, V.; Gupta, V.; Guizani, M. A Comprehensive Review of the COVID-19 Pandemic and the Role of IoT, Drones, AI, Blockchain, and 5G in Managing its Impact. IEEE Access 2020, 8, 90225–90265. [Google Scholar] [CrossRef]

- Aldrighetti, R.; Battini, D.; Ivanov, D.; Zennaro, I. Costs of resilience and disruptions in supply chain network design models: A review and future research directions. Int. J. Prod. Econ. 2021, 235, 108103. [Google Scholar] [CrossRef]

- Yavari, M.; Zaker, H. Designing a resilient-green closed loop supply chain network for perishable products by considering disruption in both supply chain and power networks. Comput. Chem. Eng. 2020, 134, 106680. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef] [Green Version]

- Tordecilla, R.D.; Juan, A.A.; Montoya-Torres, J.R.; Quintero-Araujo, C.L.; Panadero, J. Simulation-optimization methods for designing and assessing resilient supply chain networks under uncertainty scenarios: A review. Simul. Model. Pract. Theory 2021, 106, 102166. [Google Scholar] [CrossRef] [PubMed]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and Resilient Supply Chain Network Design under Disruption Risks. Sustainability 2014, 6, 6666–6686. [Google Scholar] [CrossRef] [Green Version]

- Hosseini, S.; Morshedlou, N.; Ivanov, D.; Sarder, M.; Barker, K.; Al Khaled, A. Resilient supplier selection and optimal order allocation under disruption risks. Int. J. Prod. Econ. 2019, 213, 124–137. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, D.; Dolgui, A.; Sokolov, B. Ripple Effect in the Supply Chain: Definitions, Frameworks and Future Research Perspectives. In Handbook of Ripple Effects in the Supply Chain; Springer: Singapore, 2019; Volume 276, pp. 1–33. [Google Scholar] [CrossRef]

- Aloui, A.; Hamani, N.; Derrouiche, R.; Delahoche, L. Systematic literature review on collaborative sustainable transportation: Overview, analysis and perspectives. Transp. Res. Interdiscip. Perspect. 2021, 9, 100291. [Google Scholar] [CrossRef]

- Zhu, Q.; Krikke, H. Managing a Sustainable and Resilient Perishable Food Supply Chain (PFSC) after an Outbreak. Sustainability 2020, 12, 5004. [Google Scholar] [CrossRef]

- Seok, H.; Nof, S.Y.; Filip, F.G. Sustainability decision support system based on collaborative control theory. Annu. Rev. Control. 2012, 36, 85–100. [Google Scholar] [CrossRef]

- Habib, M.S.; Tayyab, M.; Zahoor, S.; Sarkar, B. Management of animal fat-based biodiesel supply chain under the paradigm of sustainability. Energy Convers. Manag. 2020, 225, 113345. [Google Scholar] [CrossRef]

- de Oliveira, U.R.; Espindola, L.S.; da Silva, I.R.; da Silva, I.N.; Rocha, H.M. A systematic literature review on green supply chain management: Research implications and future perspectives. J. Clean. Prod. 2018, 187, 537–561. [Google Scholar] [CrossRef]

- Mohammed, A. Towards ‘gresilient’ supply chain management: A quantitative study. Resour. Conserv. Recycl. 2020, 155, 104641. [Google Scholar] [CrossRef]

- Aloui, A.; Hamani, N.; Delahoche, L. An integrated optimization approach using a collaborative strategy for sustainable cities freight transportation: A Case study. Sustain. Cities Soc. 2021, 75, 103331. [Google Scholar] [CrossRef]

- Gholami-Zanjani, M.S.; Jabalameli, M.S.; Klibi, W.; Pishvaee, M.S. A robust location-inventory model for food supply chains operating under disruptions with ripple effects. Int. J. Prod. Res. 2021, 59, 301–324. [Google Scholar] [CrossRef]

- Yavari, M.; Enjavi, H.; Geraeli, M. Demand management to cope with routes disruptions in location-inventory-routing problem for perishable products. Res. Transp. Bus. Manag. 2020, 37, 100552. [Google Scholar] [CrossRef]

- Gholami-Zanjani, S.M.; Jabalameli, M.S.; Pishvaee, M.S. A resilient-green model for multi-echelon meat supply chain planning. Comput. Ind. Eng. 2021, 152, 107018. [Google Scholar] [CrossRef]

- Ullah, M.; Asghar, I.; Zahid, M.; Omair, M.; AlArjani, A.; Sarkar, B. Ramification of remanufacturing in a sustainable three-echelon closed-loop supply chain management for returnable products. J. Clean. Prod. 2021, 290, 125609. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4. Prod. Plan. Control. 2020, 32, 775–788. [Google Scholar] [CrossRef]

- Namdar, J.; Torabi, S.A.; Sahebjamnia, N.; Pradhan, N.N. Business continuity-inspired resilient supply chain network design. Int. J. Prod. Res. 2021, 59, 1331–1367. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Burgos, D.; Ivanov, D. Food retail supply chain resilience and the COVID-19 pandemic: A digital twin-based impact analysis and improvement directions. Transp. Res. Part E Logist. Transp. Rev. 2021, 152, 102412. [Google Scholar] [CrossRef]

- Klibi, W.; Martel, A. Modeling approaches for the design of resilient supply networks under disruptions. Int. J. Prod. Econ. 2012, 135, 882–898. [Google Scholar] [CrossRef]

- Qin, X.; Liu, X.; Tang, L. A two-stage stochastic mixed-integer program for the capacitated logistics fortification planning under accidental disruptions. Comput. Ind. Eng. 2013, 65, 614–623. [Google Scholar] [CrossRef]

- Ivanov, D.; Pavlov, A.; Dolgui, A.; Pavlov, D.; Sokolov, B. Disruption-driven supply chain (re)-planning and performance impact assessment with consideration of pro-active and recovery policies. Transp. Res. Part E Logist. Transp. Rev. 2016, 90, 7–24. [Google Scholar] [CrossRef] [Green Version]

- Haghjoo, N.; Tavakkoli-Moghaddam, R.; Shahmoradi-Moghadam, H.; Rahimi, Y. Reliable blood supply chain network design with facility disruption: A real-world application. Eng. Appl. Artif. Intell. 2020, 90, 103493. [Google Scholar] [CrossRef]

- Kungwalsong, K.; Cheng, C.-Y.; Yuangyai, C.; Janjarassuk, U. Two-Stage Stochastic Program for Supply Chain Network Design under Facility Disruptions. Sustainability 2021, 13, 2596. [Google Scholar] [CrossRef]

- Aloui, A.; Hamani, N.; Derrouiche, R.; Delahoche, L. Assessing the benefits of horizontal collaboration using an integrated planning model for two-echelon energy efficiency-oriented logistics networks design. Int. J. Syst. Sci. Oper. Logist. 2021, 1–22. [Google Scholar] [CrossRef]

- Asl-Najafi, J.; Zahiri, B.; Bozorgi-Amiri, A.; Taheri-Moghaddam, A. A dynamic closed-loop location-inventory problem under disruption risk. Comput. Ind. Eng. 2015, 90, 414–428. [Google Scholar] [CrossRef]

- Farahani, M.; Shavandi, H.; Rahmani, D. A location-inventory model considering a strategy to mitigate disruption risk in supply chain by substitutable products. Comput. Ind. Eng. 2017, 108, 213–224. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K.; Keyvanshokooh, E. Responsive and resilient supply chain network design under operational and disruption risks with delivery lead-time sensitive customers. Transp. Res. Part E Logist. Transp. Rev. 2017, 101, 176–200. [Google Scholar] [CrossRef]

- Zahiri, B.; Suresh, N.C.; de Jong, J. Resilient hazardous-materials network design under uncertainty and perishability. Comput. Ind. Eng. 2020, 143, 106401. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K.; Maihami, R. Stochastic optimization of disruption-driven supply chain network design with a new resilience metric. Int. J. Prod. Econ. 2020, 230, 107755. [Google Scholar] [CrossRef]

- Bairagi, N.; Bhattacharya, S.; Auger, P.; Sarkar, B. Bioeconomics fishery model in presence of infection: Sustainability and demand-price perspectives. Appl. Math. Comput. 2021, 405, 126225. [Google Scholar] [CrossRef]

- Yavari, M.; Geraeli, M. Heuristic method for robust optimization model for green closed-loop supply chain network design of perishable goods. J. Clean. Prod. 2019, 226, 282–305. [Google Scholar] [CrossRef]

- Yavari, M.; Zaker, H. An integrated two-layer network model for designing a resilient green-closed loop supply chain of perishable products under disruption. J. Clean. Prod. 2019, 230, 198–218. [Google Scholar] [CrossRef]

- Hasani, A.; Mokhtari, H.; Fattahi, M. A multi-objective optimization approach for green and resilient supply chain network design: A real-life case study. J. Clean. Prod. 2021, 278, 123199. [Google Scholar] [CrossRef]

- Zahiri, B.; Zhuang, J.; Mohammadi, M. Toward an integrated sustainable-resilient supply chain: A pharmaceutical case study. Transp. Res. Part E Logist. Transp. Rev. 2017, 103, 109–142. [Google Scholar] [CrossRef]

- Mehrjerdi, Y.Z.; Shafiee, M. A resilient and sustainable closed-loop supply chain using multiple sourcing and information sharing strategies. J. Clean. Prod. 2021, 289, 125141. [Google Scholar] [CrossRef]

- Gholami-Zanjani, S.M.; Klibi, W.; Jabalameli, M.S.; Pishvaee, M.S. The design of resilient food supply chain networks prone to epidemic disruptions. Int. J. Prod. Econ. 2021, 233, 108001. [Google Scholar] [CrossRef]

- Aloui, A.; Mrabti, N.; Hamani, N.; Delahoche, L. Towards a collaborative and integrated optimization approach in sustainable freight transportation. IFAC-PapersOnLine 2021, 54, 671–676. [Google Scholar] [CrossRef]

- Govindan, K.; Jafarian, A.; Khodaverdi, R.; Devika, K. Two-echelon multiple-vehicle location–routing problem with time windows for optimization of sustainable supply chain network of perishable food. Int. J. Prod. Econ. 2014, 152, 9–28. [Google Scholar] [CrossRef]

- Rafie-Majd, Z.; Pasandideh, S.H.R.; Naderi, B. Modelling and solving the integrated inventory-location-routing problem in a multi-period and multi-perishable product supply chain with uncertainty: Lagrangian relaxation algorithm. Comput. Chem. Eng. 2018, 109, 9–22. [Google Scholar] [CrossRef]

- Cheng, C.; Yang, P.; Qi, M.; Rousseau, L.-M. Modeling a green inventory routing problem with a heterogeneous fleet. Transp. Res. Part E Logist. Transp. Rev. 2017, 97, 97–112. [Google Scholar] [CrossRef]

- Coelho, L.C.; Laporte, G. An optimised target-level inventory replenishment policy for vendor-managed inventory systems. Int. J. Prod. Res. 2014, 53, 3651–3660. [Google Scholar] [CrossRef]

- Stellingwerf, H.M.; Laporte, G.; Cruijssen, F.C.; Kanellopoulos, A.; Bloemhof, J.M. Quantifying the environmental and economic benefits of cooperation: A case study in temperature-controlled food logistics. Transp. Res. Part D Transp. Environ. 2018, 65, 178–193. [Google Scholar] [CrossRef]

- Pan, S.; Ballot, E.; Fontane, F.; Hakimi, D. Environmental and economic issues arising from the pooling of SMEs’ supply chains: Case study of the food industry in western France. Flex. Serv. Manuf. J. 2014, 26, 92–118. [Google Scholar] [CrossRef]

- Ouhader, H.; El Kyal, M. Combining Facility Location and Routing Decisions in Sustainable Urban Freight Distribution under Horizontal Collaboration: How Can Shippers Be Benefited? Math. Probl. Eng. 2017, 2017, 1–18. [Google Scholar] [CrossRef]

- Ouhader, H.; El Kyal, M. Assessing the economic and environmental benefits of horizontal cooperation in delivery: Performance and scenario analysis. Uncertain Supply Chain. Manag. 2020, 8, 303–320. [Google Scholar] [CrossRef]

- Hacardiaux, T.; Tancrez, J.-S. Assessing the environmental benefits of horizontal cooperation using a location-inventory model. Central Eur. J. Oper. Res. 2020, 28, 1363–1387. [Google Scholar] [CrossRef]

- Moutaoukil, A.; Neubert, G.; Derrouiche, R. Urban Freight Distribution: The impact of delivery time on sustainability. IFAC-PapersOnLine 2015, 48, 2368–2373. [Google Scholar] [CrossRef]

- Cardoso, S.R.; Barbosa-Póvoa, A.P.; Relvas, S.; Novais, A.Q. Resilience metrics in the assessment of complex supply-chains performance operating under demand uncertainty. Omega 2015, 56, 53–73. [Google Scholar] [CrossRef]

- Klibi, W.; Martel, A. Scenario-based Supply Chain Network risk modeling. Eur. J. Oper. Res. 2012, 223, 644–658. [Google Scholar] [CrossRef]

- Wu, W.; Zhou, W.; Lin, Y.; Xie, Y.; Jin, W. A hybrid metaheuristic algorithm for location inventory routing problem with time windows and fuel consumption. Expert Syst. Appl. 2021, 166, 114034. [Google Scholar] [CrossRef]

- Carbone, B. Guide Des Facteurs D’emissions; Janvier: Bromley, UK, 2007; p. 240. [Google Scholar]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; Haijema, R.; van der Vorst, J.G. Modeling a green inventory routing problem for perishable products with horizontal collaboration. Comput. Oper. Res. 2018, 89, 168–182. [Google Scholar] [CrossRef]

- Hickman, J.; Hassel, D.; Joumard, R.; Samaras, Z.; Sorenson, S. MEET-Methodology for Calculating Transport Emissions and Energy Consumption. European Commission, DG VII. Technical Report. 1999. Available online: https://trimis.ec.europa.eu/sites/default/files/project/documents/meet.pdf (accessed on 14 April 2021).

- Tassou, S.; De-Lille, G.; Ge, Y. Food transport refrigeration—Approaches to reduce energy consumption and environmental impacts of road transport. Appl. Therm. Eng. 2009, 29, 1467–1477. [Google Scholar] [CrossRef] [Green Version]

- Chrouta, J.; Chakchouk, W.; Zaafouri, A.; Jemli, M. Modeling and Control of an Irrigation Station Process Using Heterogeneous Cuckoo Search Algorithm and Fuzzy Logic Controller. IEEE Trans. Ind. Appl. 2018, 55, 976–990. [Google Scholar] [CrossRef]

- Mrabti, N.; Hamani, N.; Delahoche, L. The pooling of sustainable freight transport. J. Oper. Res. Soc. 2020, 1–16. [Google Scholar] [CrossRef]

- Ayadi, H.; Hamani, N.; Kermad, L.; Benaissa, M. Novel Fuzzy Composite Indicators for Locating a Logistics Platform under Sustainability Perspectives. Sustainability 2021, 13, 3891. [Google Scholar] [CrossRef]

| References | Decision Problem | Evaluated Sustainability | Disruption | Uncertain Demand | |||||

|---|---|---|---|---|---|---|---|---|---|

| Location | Inventory | Routing | Economic | Environmental | Social | Isolated | Ripple Effect | ||

| [36] | ✓ | ✓ | ✓ | ✓ | |||||

| [37] | ✓ | ✓ | ✓ | ||||||

| [38] | ✓ | ✓ | ✓ | ||||||

| [39] | ✓ | ✓ | ✓ | ✓ | |||||

| [40] | ✓ | ✓ | ✓ | ||||||

| [5] | ✓ | ✓ | ✓ | ✓ | |||||

| [42] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| [43] | ✓ | ✓ | ✓ | ✓ | |||||

| [44] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| [45] | ✓ | ✓ | ✓ | ✓ | |||||

| [46] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| [17] | ✓ | ✓ | ✓ | ✓ | |||||

| [48,49] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| [50] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| [51] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| [52] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| [28,53] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| [30] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| This study | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Symbol | Definition |

|---|---|

| Sets | |

| J | Set of suppliers |

| D | Set of distribution centers |

| I | Set of retailers |

| A1, A2 | Set of pickups and delivery routes arcs |

| T | Set of periods in the planning horizon |

| S | Set of plausible scenarios |

| Independent input parameters of scenarios | |

| Capj | Maximum throughput capacity of the supplier j |

| Capd | Maximum throughput capacity of the distribution center d |

| FOd | Fixed cost of the distribution center d |

| ECd | Average energy consumption of the distribution center d |

| Qs | Semitrailer truck maximum loading capacity |

| Qv | Vehicle loading capacity |

| Fs | Operating cost of a semitrailer truck (by route) |

| Fv | Operating cost of a vehicle (by route) |

| TsE | Fuel consumption rate of an empty semitrailer truck (L/Km) |

| TsL | Fuel consumption rate of a fully loaded semitrailer truck (L/Km) |

| TvE | Fuel consumption rate of an empty vehicle (L/Km) |

| TvL | Fuel consumption rate of a fully loaded vehicle (L/Km) |

| cI | Inventory unit cost in distribution centers (€/Kg) |

| cp | Penalty unit cost (€/Kg) |

| cf | Fuel price per liter (€/L) |

| eF | Fuel CO2 emission factor (Kg CO2/L) |

| ec | CO2 emitted per energy consumption unit (Kg CO2/kwh) |

| Ac | Average number of accidents |

| di,j | Distance between two nodes i and j: |

| Input parameters dependent of scenarios | |

| Demand of retailer i from supplier j in period t under scenario s | |

| ps | Occurrence probability of scenario s, = 1 |

| First-stage decision variables | |

| Binary variable, equal to 1 if the distribution center d is open; 0, otherwise | |

| Binary variable, equal to 1 if node i is assigned to center d; 0, otherwise, i ∈ I ∪ J, d ∈ D | |

| Second-stage decision variables | |

| Quantity delivered by supplier j to center d in period t under scenario s | |

| Product quantity of supplier j delivered by center d to customer i in period t under scenario s | |

| Inventory level of products of supplier j in center d in period t under scenario s | |

| Binary variable, equal to 1 if arc (i; j) is traversed by a vehicle/semitrailer at period t under scenario s; 0, otherwise, | |

| Freight quantity transported by a semitrailer truck/ vehicle on the arc (i; j) if it moves directly from node i to node j in period t under scenario s, (i; j) A2 | |

| Instance | Number of Suppliers | Number of Distribution Centers | Number of Retailers | Number of Periods | Number of Replications | Number of Scenarios |

|---|---|---|---|---|---|---|

| I1 | 2 | 2 | 5 | 12 | 5 | 10 |

| I2 | 3 | 3 | 9 | 12 | 5 | 10 |

| Parameter | Value/Estimation | Source |

|---|---|---|

| Capj | 20,000 Kg | Assumption |

| Capd | 20,000 Kg | Assumption |

| FOd | 6000 € | [67] |

| ECd | 10,000 Kwh | [68] |

| Qs | 20,000 Kg | [69] |

| Qv | 10,000 Kg | [69] |

| Fs | 300 € | [69] |

| Fv | 200 € | [69] |

| TsE | 0.15 L/km | [70] |

| TsL | 0.31 L/km | [70] |

| TvE | 0.13 L/km | [70] |

| TvL | 0.15 L/km | [70] |

| cI | 0.01 €/Kg | [59] |

| cp | 1.5 €/Kg | Assumption |

| cf | 1.5 €/L | [27,41] |

| eF | 2.66 Kg CO2/L | [71] |

| ec | 0.087 Kg CO2/L | [68] |

| Ac | 2768 accidents per year | [54] |

| Instance | Configuration | Expected Cost (€) | Expected Emissions (Kg CO2) | Expected Accident Rate (%) | Average Number of Opened DCs | Service Level (%) |

|---|---|---|---|---|---|---|

| I1 | NDM | 21,067.019 | 3491.360 | 21.050 | 2 | 100.00 |

| DM | 47,765.679 | 3300.762 | 18.211 | 2 | 73.38 | |

| DMCE | 29,517.612 | 4100.046 | 25.724 | 2 | 99.66 | |

| DMCL | 38,742.400 | 2207.619 | 15.368 | 1 | 73.96 | |

| DMCECL | 19,113.490 | 2797.541 | 20.576 | 1 | 99.87 | |

| I2 | NDM | 31,858.988 | 6663.545 | 50.831 | 3 | 100.00 |

| DM | 73,897.477 | 6626.066 | 51.055 | 3 | 77.53 | |

| DMCE | 46,672.017 | 8115.822 | 54.675 | 3 | 98.75 | |

| DMCL | 58,248.953 | 3526.752 | 30.153 | 1 | 77.48 | |

| DMCECL | 30,891.362 | 3902.640 | 35.679 | 1 | 99.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aloui, A.; Hamani, N.; Delahoche, L. Designing a Resilient and Sustainable Logistics Network under Epidemic Disruptions and Demand Uncertainty. Sustainability 2021, 13, 14053. https://doi.org/10.3390/su132414053

Aloui A, Hamani N, Delahoche L. Designing a Resilient and Sustainable Logistics Network under Epidemic Disruptions and Demand Uncertainty. Sustainability. 2021; 13(24):14053. https://doi.org/10.3390/su132414053

Chicago/Turabian StyleAloui, Aymen, Nadia Hamani, and Laurent Delahoche. 2021. "Designing a Resilient and Sustainable Logistics Network under Epidemic Disruptions and Demand Uncertainty" Sustainability 13, no. 24: 14053. https://doi.org/10.3390/su132414053

APA StyleAloui, A., Hamani, N., & Delahoche, L. (2021). Designing a Resilient and Sustainable Logistics Network under Epidemic Disruptions and Demand Uncertainty. Sustainability, 13(24), 14053. https://doi.org/10.3390/su132414053