Biomethane from Manure, Agricultural Residues and Biowaste—GHG Mitigation Potential from Residue-Based Biomethane in the European Transport Sector

Abstract

:1. Introduction

1.1. Background

1.2. Scope of the Study

2. Materials and Methods

2.1. Model Concepts

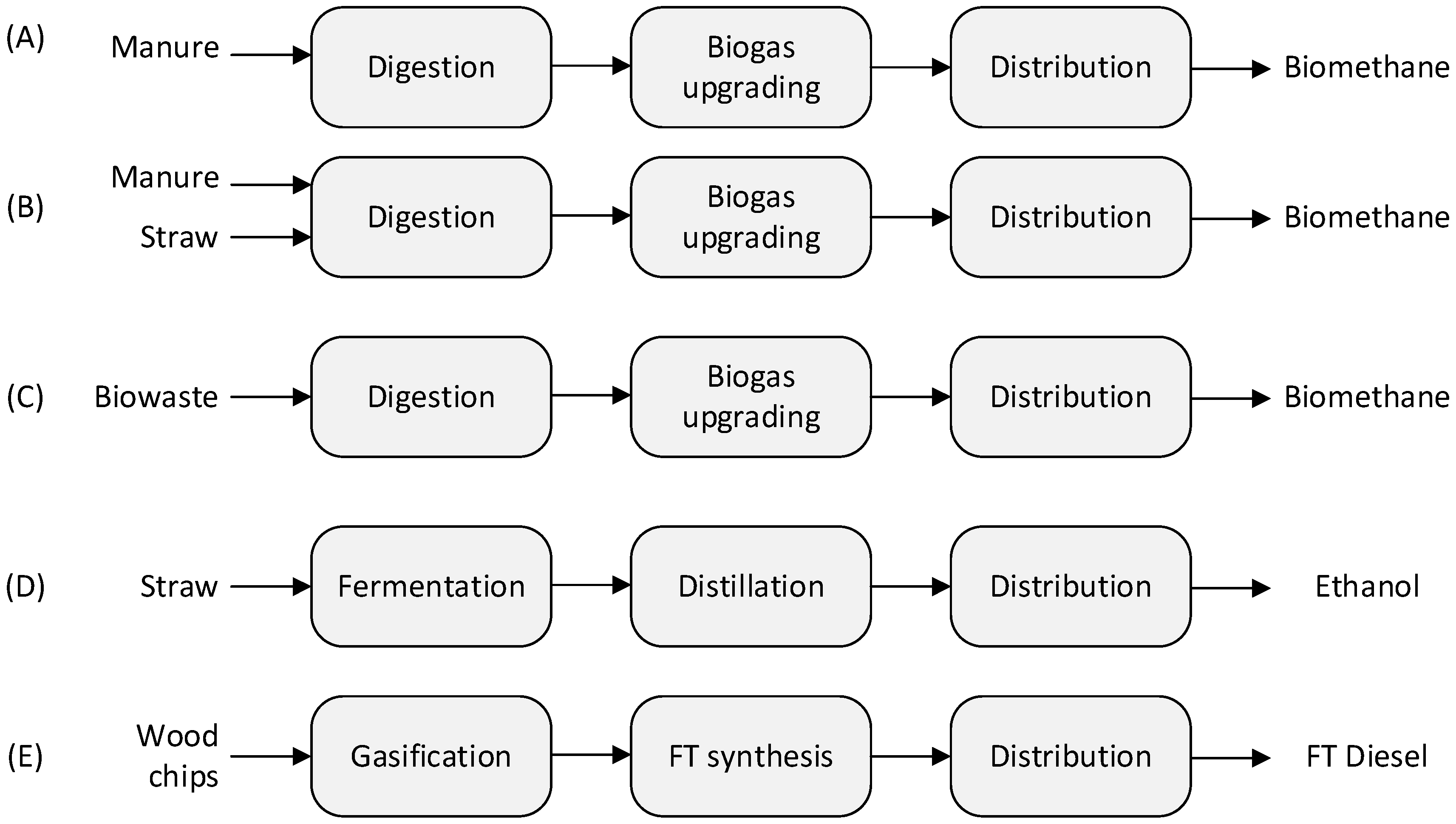

2.1.1. Biomethane Concepts

2.1.2. Bioethanol from Straw

2.1.3. Biomass-to-Liquid (BtL) from Woodchips

2.2. Scenarios for GHG Mitigation Costs

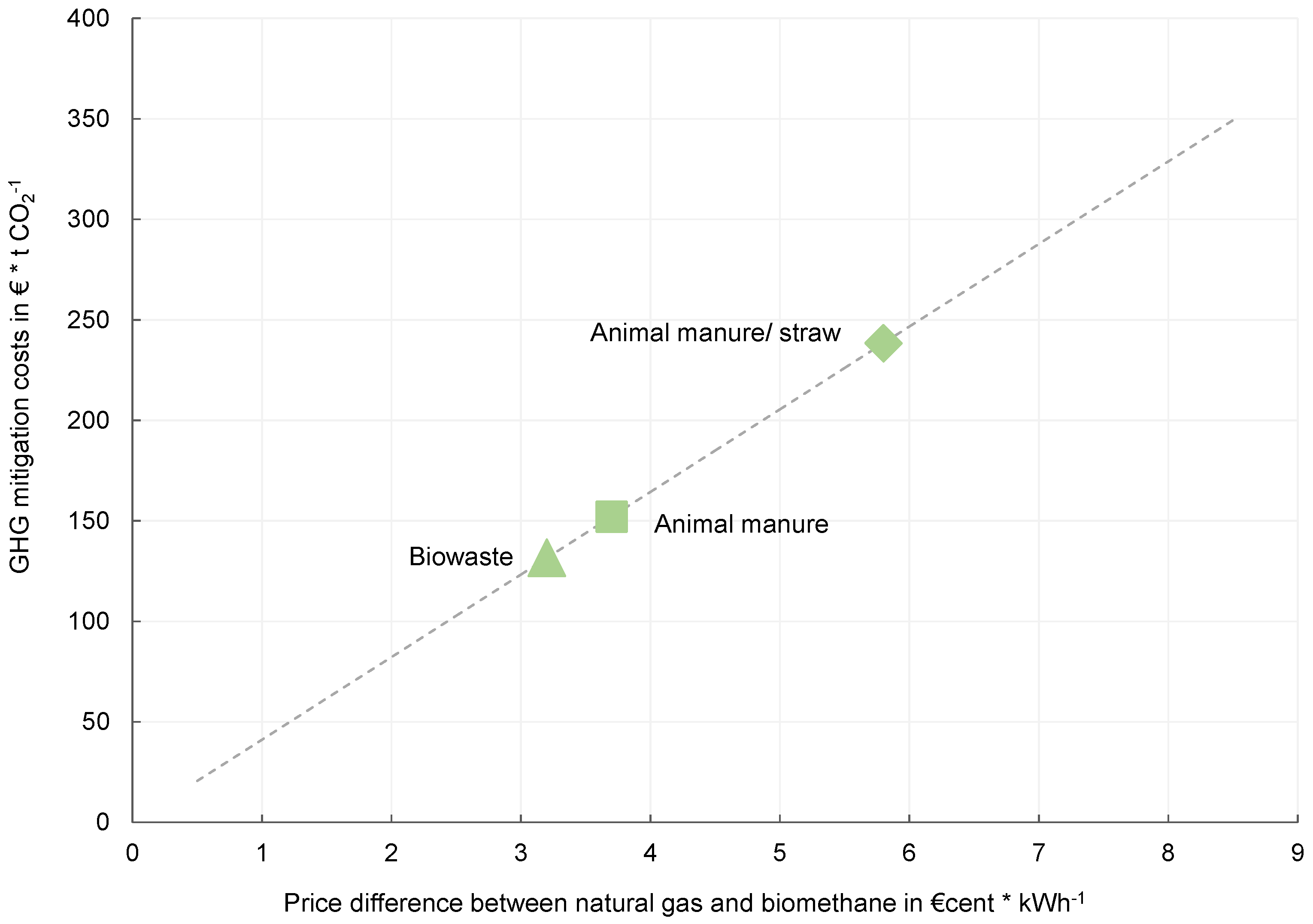

- In scenario 1, the GHG mitigation costs for the biomethane concepts are assessed and compared with the values for the competing advanced biofuels as defined by RED II. In this case, the GHG emission values for the biomethane under consideration and other advanced biofuels include the complete lifecycle emissions calculated according to the methodology set out in the directive.

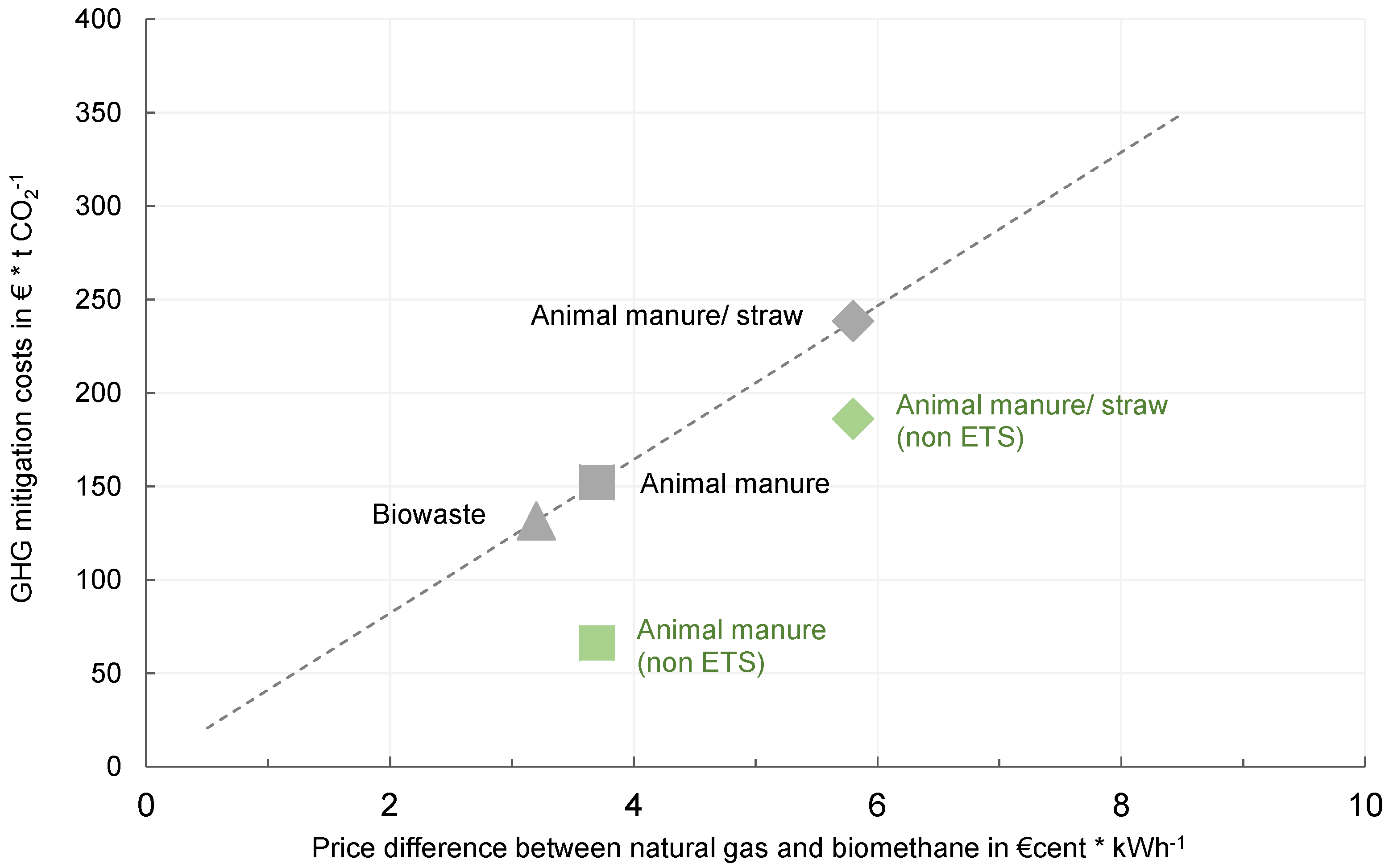

- In scenario 2, we assessed the GHG mitigation costs for biomethane concepts in the context of the EU ETS and calculated the CO2 certificate price at which the advanced provision costs are competitive with the natural gas price. A crucial factor in this scenario is that the EU ETS defines GHG emissions from bioenergy as zero. Therefore, the differences between the GHG mitigation costs for the various biomethane value chains are the result of the different production costs.

- Scenario 3 aims to investigate the potential impact on the GHG mitigation costs for biomethane when the GHG mitigation effects from improved animal manure management (non-ETS agricultural sector) and the overall GHG emissions are taken into account. Here, we assumed that emission savings in the agricultural sector from biomethane production could be monetized within the EU ETS. Consequently, the corresponding GHG emission savings associated with the production of biomethane from manure is incorporated in the GHG emission values relevant for calculating the GHG mitigation costs.

2.3. Calculating the GHG Mitigation Costs

2.4. Database

3. Results of GHG Mitigation Costs

3.1. Scenario 1: Comparison of the GHG Mitigation Costs for Biomethane and Other Advanced Biofuels as Competitors in the Advanced Fuels Market within the RED II Framework

3.2. Scenario 2: GHG Mitigation Costs for Biomethane in the EU ETS

3.3. Scenario 3: GHG Mitigation Costs for Biomethane in the EU ETS Including Non-ETS Sectors

4. Discussion

4.1. RED II Perspective

4.2. EU ETS Perspective

4.3. Limitations of the Study

5. Conclusions

- In general, there are significant differences in the GHG mitigation costs for the various advanced biofuels pathways investigated. Because of lower GHG emissions per MJ, biomethane based on animal manure tends to have lower GHG mitigation costs compared to other advanced biofuels. This is a competitive advantage within the protected market for advanced fuels set out by RED II. Sufficient production capacities and biomass potentials are available to serve this defined market with biomethane from waste and residues. However, the current low rate of gaseous fuels in the German and European transport sectors reveals the existing limitations for the use of biomethane. An expansion of the gas-fueled fleet and the filling station infrastructure could be one measure to unlock the unused potential of GHG mitigation by using biomethane from waste and residues, in particular animal manure, in the transport sector.

- Under the current conditions, the EU ETS is not an effective instrument for increasing the costs of carbon-intensive energy carriers to reach a breakeven between the costs for natural gas and biomethane. Considering the current price for CO2 certificates, we propose taking into account the GHG reduction potential of the non-ETS agricultural sector in order to unlock unused GHG mitigation potential for the reduction of GHG emissions. The mitigation costs for biomethane from animal manure would thus decrease from 164 EUR*t CO2-eq.−1 to 75 EUR*t CO2-eq.−1.

- Due to the flexibility in terms of the types of substrates used for biomethane production, this technology can, in theory, tap great potentials for GHG mitigation in sectors outside the EU ETS (e.g., agriculture, waste treatment, and disposal). Internalizing, and thus capitalizing on, these effects will significantly decrease the GHG mitigation costs for the respective biomethane pathways in the EU ETS.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. Directive 2001/77/EC of the European Parliament and of the Council of 27 September 2001 on the Promotion of Electricity Produced from Renewable Energy Sources in the Internal Electricity Market; European Commission: Brussels, Belgium, 2001.

- European Commission. Directive 2009/30/EC of the European Parliament and of the Council of 23 April 2009 Amending Directive 98/70/EC as Regards the Specification of Petrol, Diesel and Gas-Oil and Introducing a Mechanism to Monitor and Reduce Greenhouse Gas Emissions and Amending Council Directive 1999/32/EC as Regards the Specification of Fuel Used by Inland Waterway Vessels and Repealing Directive 93/12/EEC; European Commission: Brussels, Belgium, 2009.

- European Commission. Directive (EU) 2018/ 2001 of the European Parliament and of the Council—Of 11 December 2018—On the Promotion of the Use of Energy from Renewable Sources; European Commission: Brussels, Belgium, 2018.

- European Commission. Directive (EU) 2015/1513 of the European Parliament and of the Council of 9 September 2015 Amending Directive 98/70/EC Relating to the Quality of Petrol and Diesel Fuels and Amending Directive 2009/28/EC on the Promotion of the Use of Energy from Renewable Sources September 2015; European Commission: Brussels, Belgium, 2015.

- Federal Government of Germany. Act on Granting Priority to Renewable Energy Sources (Renewable Energy Sources Act-EEG); Federal Government of Germany: Berlin, Germany, 2012.

- Giuntoli, J.; Agostini, A.; Edwards, R.; Marelli, L. Solid and Gaseous Bioenergy Pathways: Input Values and GHG Emissions. Calculated According to the Methodology set in COM(2010) 11 and SWD(2014) 259, Version 1a; Joint Research Center (JRC): Luxembourg, 2015. [Google Scholar] [CrossRef]

- Haenel, H.-D.; Claus, R.; Ulrich, D.; Eike, P.; Annette, F.; Sebastian, W.; Brigitte, E.-M.; Helmut, D.; Carsten, S.; Beate, B.; et al. Calculations of Gaseous and Particulate Emis-sions from German Agriculture 1990–2012; Thünen Report 17; Thünen Institut: Braunschweig, Germany, 2014. [Google Scholar]

- Dämmgen, U.; Webb, J. The development of the EMEP/CORINAIR Guidebook with respect to the emissions of different ni-trogen and carbon species from animal production. Agric. Ecosyst. Environ. Mitig. Greenh. Gas Emiss. Livest. Prod. 2006, 2–3, 241–248. [Google Scholar]

- Oehmichen, K.; Thrän, D. Fostering renewable energy provision from manure in Germany: Where to implement GHG emis-sion reduction incentives. Energy Policy 2017, 110, 471–477. [Google Scholar] [CrossRef]

- Scheftelowitz, M.; Thrän, D. Unlocking the Energy Potential of Manure—An Assessment of the Biogas Production Potential at the Farm Level in Germany. Agriculture 2016, 6, 20. [Google Scholar] [CrossRef] [Green Version]

- van Melle, T.; Peters, D.; Cherkasky, J.; Wessels, R.; Mir, G.; Hofsteenge, W. Gas for Climate: How Gas Can Helpto Achievethe Paris Agreement Target in an Affordable Way; European Biogas Association: Brussels, Belgium, 2018. [Google Scholar]

- DBFZ. Resource Data Repository, Webapplicaton, Leipzig. 2021. Available online: https://webapp.dbfz.de/resource-database/?lang=en (accessed on 26 October 2021).

- European Parliament and Council. Proposal for a Directive of the European Parliament and of the Council Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council Directive (EU) 2015/652; European Commission: Brussels, Belgium, 2021.

- Brosowski, A.; Krause, T.; Mantau, U.; Mahro, B.; Noke, A.; Richter, F.; Raussen, T.; Bischof, R.; Hering, T.; Blanke, C.; et al. How to measure the impact of biogenic residues, wastes and by-products: Development of a national resource monitoring based on the example of Germany. Biomass Bioenergy 2019, 127, 105275. [Google Scholar] [CrossRef]

- Bartoli, A.; Hamelin, L.; Rozakis, S.; Borzęcka, M.; Brandão, M. Coupling economic and GHG emission accounting models to evaluate the sustainability of biogas policies. Renew. Sustain. Energy Rev. 2019, 106, 133–148. [Google Scholar] [CrossRef]

- Agostini, A.; Battini, F.; Padella, M.; Giuntoli, J.; Baxter, D.; Marelli, L.; Amaducci, S. Economics of GHG emissions mitigation via biogas production from Sorghum, maize and dairy farm manure digestion in the Po valley. Biomass Bioenergy 2016, 89, 58–66. [Google Scholar] [CrossRef]

- Vetter, A.; Arnold, K. Klima- und Umwelteffekte von Biomethan, Anlagentechnik und Substratauswahl; Wuppertal Institut: Wuppertal, Germany, 2010. [Google Scholar]

- Rana, R.; Ingrao, C.; Lombardi, M.; Tricase, C. Greenhouse gas emissions of an agro-biogas energy system: Estimation under the Renewable Energy Directive. Sci. Total Environ. 2016, 550, 1182–1195. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manninen, K.; Koskela, S.; Nuppunen, A.; Sorvari, J.; Nevalainen, O.; Siitonen, S. The applicability of the renewable energy directive calculation to assess the sustainability of biogas production. Energy Policy 2013, 56, 549–557. [Google Scholar] [CrossRef]

- Long, A.; Bose, A.; O’Shea, R.; Monaghan, R.; Murphy, J.D. Implications of European Union recast Renewable Energy Directive sustainability criteria for renewable heat and transport: Case study of willow biomethane in Ireland. Renew. Sustain. Energy Rev. 2021, 150, 111461. [Google Scholar] [CrossRef]

- Kraussler, M.; Pontzen, F.; Müller-Hagedorn, M.; Nenning, L.; Luisser, M.; Hofbauer, H. Techno-economic assessment of biomass-based natural gas substitutes against the background of the EU 2018 renewable energy directive. Biomass Conv. Bioref. 2018, 8, 935–944. [Google Scholar] [CrossRef] [Green Version]

- KTBL. Leistungs-Kostenrechnung Pflanzenbau; Web-Application. 2020. Available online: https://daten.ktbl.de/dslkrpflanze/postHV.html (accessed on 26 October 2021).

- GasNZV. Verordnung über den Zugang zu Gasversorgungsnetzen; Deutscher Bundestag: Berlin, Germany, 2017.

- Johann Heinrich von Thünen-Institut. Biogas-Messprogramm II; Johann Heinrich von Thünen-Institut: Gülzow, Germany, 2010. [Google Scholar]

- BioGrace II Calculation Rules. Harmonised Greenhouse Gas Calculations for Electricity, Heating and Cooling from Biomass. Version 4a. Available online: www.biograce.net (accessed on 8 June 2021).

- Edwards, R.; Padella, M.; Giuntoli, J.; Koeble, R.; O’Connell, A.; Bulgheroni, C.; Marelli, L.; Lonza, L. Definition of Input Data to Assess GHG Default Emissions from Biofuels in EU Legislation: Version 1d—2019; Publications Office of the European Union: Luxembourg, 2019. [CrossRef]

- Majer, S.; Oehmichen, K. Comprehensive Methodology on Calculating Entitlement to CO2 Certificates by Biomethane Producers: BIOSURF Deliverable D5.5; DBFZ: Leipzig, Germany, 2017. [Google Scholar]

- Daniel-Gromke, J.; Rensberg, N.; Denysenko, V.; Barchmann, T.; Oehmichen, K.; Beil, M.; Beyrich, W.; Krautkremer, B.; Trommler, M.; Reinholz, T.; et al. Optionen für Bio-Gas-Bestandsanlagen bis 2030 aus Ökonomischer und Energiewirtschaftlicher Sicht: Abshlussbericht; Umweltbundesamt: Dessau-Roßlau, Germany, 2019.

- Majer, S.; Kornatz, P.; Daniel-Gromke, J.; Rensberg, N.; Brosowski, A.; Oehmichen, K.; Liebetrau, J. Stand und Perspektiven der Bio-gaserzeugung aus Gülle; DBFZ: Leipzig, Germany, 2019. [Google Scholar]

- Meisel, K.; Millinger, M.; Naumann, K.; Majer, S.; Müller-Langer, F.; Thrän, D. Untersuchungen zur Ausgestaltung der Biokraftstoffgesetzgebung, Abschlussbericht; DBFZ Deutsches Biomasseforschungszentrum Gemeinnützige GmbH: Leipzig, Germany, 2019. [Google Scholar]

- Zech Konstantin, M.; Meisel, K.; Brosowski, A.; Toft, L.V.; Müller-Langer, F. Environmental and economic assessment of the Inbicon lignocellulosic ethanol technology. Appl. Energy 2016, 171, S347–S356. [Google Scholar] [CrossRef]

- Millinger, M.; Ponitka, J.; Arendt, O.; Thrän, D. Competitiveness of advanced and conventional biofuels. Results from least-cost modelling of biofuel competition in Germany. Energy Policy 2017, 107, S394–S402. [Google Scholar] [CrossRef]

- Albrecht Friedemann, G.; König Daniel, H.; Baucks, N.; Dietrich, R. A standardized methodology for the techno-economic evaluation of alternative fuels—A case study. Fuel 2017, 194, S511–S526. [Google Scholar] [CrossRef] [Green Version]

- EUROSTAT. Natural Gas Price Values for Europe. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Natural_gas_price_statistics/de&oldid=363671#Erdgaspreise_f.C3.BCr_Industriekunden (accessed on 8 June 2021).

- Giuntoli, J.; Agostini, A.; Edwards, R.; Marelli, L. Solid and Gaseous Bioenergy Pathways: Input Values and GHG Emissions: Calculated According to Methodology Set in COM(2016) 767: Version 2; Joint Research Center (JRC): Luxembourg, 2017. [Google Scholar] [CrossRef]

- Purr, K.; Günther, J.; Lehmann, H.; Nuss, P. Wege in Eine Ressourcenschonende Treibhausgasneutralität. RESCUE-Studie. Hg. v. Umweltbundesamt. Dessau-Roßlau (CLIMATE CHANGE, 36/2019). Available online: https://www.umweltbundesamt.de/sites/default/files/medien/376/publikationen/rescue_studie_cc_36-2019_wege_in_eine_ressourcenschonende_treibhausgasneutralitaet.pdf (accessed on 6 October 2021).

- Kemmler, A.; Kirchner, A.; Auf der Maur, A.; Ess, F.; Kreidelmeyer, S.; Pjégsa, A.; Spillmann, T.; Wünsch, M.; Ziegenhagen, I. Energiewirtschaftliche Projektionen und Folgeabschätzungen 2030/2050: Dokumentation vonReferenzszenariound Szenario mit Klimaschutzprogramm; Prognos: Berlin, Germany, 2020. [Google Scholar]

- Concawe’s Transport and Fuel Outlook towards EU 2030 Climate Targets. Concawe Brussels. April 2021. Available online: https://www.concawe.eu/wp-content/uploads/Rpt_21-2.pdf (accessed on 25 November 2021).

- USDA Foreign Agricultural Service. EU-28: Biofuels Annual—EU Biofuels Annual. 2019. Available online: https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=Biofuels%20Annual_The%20Hague_EU-28_7-15-2019.pdf (accessed on 26 October 2021).

- Deutsche Energie-Agentur GmbH (Dena). Dena Analyse Branchenbarometer Biomethan 2020; Deutsche Energie-Agentur: Berlin, Germany, 2020. [Google Scholar]

- Bundesministerium für Wirtschaft und Energie (BMWi). Zeitreihen zur Entwicklung der Erneuerbaren Energien in Deutschland unter Verwendung der Daten der Arbeitsgruppe Erneuerbare Energien-Statistik (AGEE-Stat) Mit Stand Februar 2020; Bundesministerium für Wirtschaft und Energie (BMWi): Berlin, Germany, 2020. [Google Scholar]

- Radke, S. Verkehr in Zahlen 2019/2020; Bundesministerium für Verkehr und digitale Infrastruktur: Berlin, Germany, 2019. [Google Scholar]

- EUROSTAT. Complete Energy Balances. NRG_BAL_C. Hg. v. Eurostat. 2021. Available online: https://ec.europa.eu/eurostat/databrowser/view/NRG_BAL_C__custom_1071932/default/table?lang=de (accessed on 26 October 2021).

- Pääkkönen, A.; Aro, K.; Aalto, P.; Konttinen, J.; Kojo, M. The Potential of biomethane in replacing fossil fuels in heavy transport—A case study on Finland. Sustainability 2019, 11, 4750. [Google Scholar] [CrossRef] [Green Version]

| Advanced Biofuels | |||||

|---|---|---|---|---|---|

| Biomethane from Manure | Biomethane from Manure (80%) and Straw (20%) | Biomethane from Biowaste | Bioethanol from Straw | BtL from Woodchips | |

| Overall GHG emissions in g CO2-eq./MJ (for biofuels: calculated according the methodology set out in RED II [3]) | −76 (own calculations based on [22,27,28]) | −10 (own calculations based on [22,27,28]) | 13 (own calculations based on [22,27,28]) | 13.7 [26] | 13.7 [26] |

| GHG emissions from improved manure management in g CO2-eq./MJ | −88 (own calculations based on [22,27,28]) | −19 (own calculations based on [22,27,28]) | - | - | - |

| Costs in EUR ct/kWh | 6.7 [27]–11 [29] | 8.8 [27]–12.85 [29] | 6.2 [27]–9.2 [28] | 6.3 [30]–14 [31] | 7.5 [32]–12, 45 [33] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oehmichen, K.; Majer, S.; Thrän, D. Biomethane from Manure, Agricultural Residues and Biowaste—GHG Mitigation Potential from Residue-Based Biomethane in the European Transport Sector. Sustainability 2021, 13, 14007. https://doi.org/10.3390/su132414007

Oehmichen K, Majer S, Thrän D. Biomethane from Manure, Agricultural Residues and Biowaste—GHG Mitigation Potential from Residue-Based Biomethane in the European Transport Sector. Sustainability. 2021; 13(24):14007. https://doi.org/10.3390/su132414007

Chicago/Turabian StyleOehmichen, Katja, Stefan Majer, and Daniela Thrän. 2021. "Biomethane from Manure, Agricultural Residues and Biowaste—GHG Mitigation Potential from Residue-Based Biomethane in the European Transport Sector" Sustainability 13, no. 24: 14007. https://doi.org/10.3390/su132414007

APA StyleOehmichen, K., Majer, S., & Thrän, D. (2021). Biomethane from Manure, Agricultural Residues and Biowaste—GHG Mitigation Potential from Residue-Based Biomethane in the European Transport Sector. Sustainability, 13(24), 14007. https://doi.org/10.3390/su132414007