Study of the Potential Uses of Hydrochar from Grape Pomace and Walnut Shells Generated from Hydrothermal Carbonization as an Alternative for the Revalorization of Agri-Waste in Chile

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characterization of Biomass Samples

2.2. HTC Process

3. Results and Discussion

3.1. Biomass Characterization

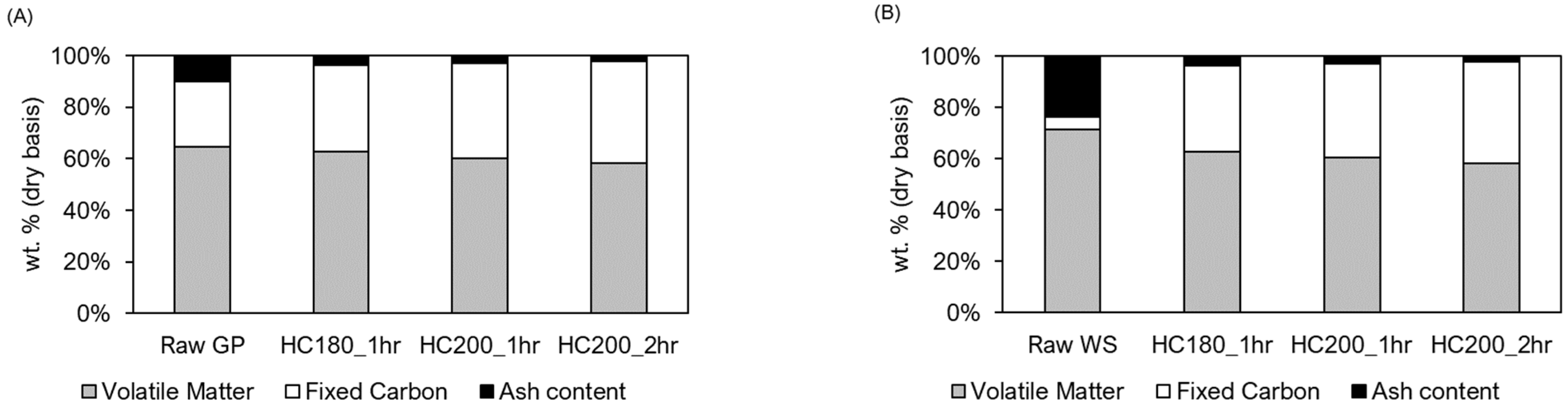

3.2. HTC Yield and Hydrochar Characterization

3.3. Practical Implications of This Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carlino, H. El Acuerdo de París y sus Implicaciones para América Latina y el Caribe; 978-1-4244-1530-4; PNUMA. 2016. Available online: https://www.uncclearn.org/wp-content/uploads/library/acuerdo_de_paris_-_implicaciones_en_alc_-_estudio_1.pdf (accessed on 1 August 2021). [CrossRef]

- Unidas, N. Acuerdo de París; United Nations International Training & Education Center: Paris, France, 2015. [Google Scholar]

- Gómez, M.; Estefanía, V.; Pintó, A. El acuerdo de París: Del Compromiso a la Acción; Oficina Española de Cambio Climático: Madrid, Spain, 2016. [Google Scholar]

- Ambiente, M.d.M. Informe del Estado del Medio Ambiente; Ministerio del Medio Ambiente: Santiago, Chile, 2016.

- República, M.S.G.d.l. Ley 20257; Ley 20257 Introduce Modificaciones a la Ley General de Servicios Eléctricos Respecto de la Generación de Energía Eléctrica con Fuentes de Energías Renovables no Convencionales; Ministerio de Economía: Santiago, Chile, 2008; pp. 1–4.

- Mendez, A.; Gasco, G.; Ruiz, B.; Fuente, E. Hydrochars from industrial macroalgae “Gelidium Sesquipedale” biomass wastes. Bioresour. Technol. 2019, 275, 386–393. [Google Scholar] [CrossRef]

- Shao, Y.C.; Long, Y.Y.; Wang, H.Y.; Liu, D.Y.; Shen, D.S.; Chen, T. Hydrochar derived from green waste by microwave hydrothermal carbonization. Renew. Energy 2019, 135, 1327–1334. [Google Scholar] [CrossRef]

- Takaya, C.A.; Parmar, K.R.; Fletcher, L.A.; Ross, A.B. Biomass-Derived Carbonaceous Adsorbents for Trapping Ammonia. Agriculture 2019, 9, 15. [Google Scholar] [CrossRef] [Green Version]

- Saqib, N.U.; Sharma, H.B.; Baroutian, S.; Dubey, B.; Sarmah, A.K. Valorisation of food waste via hydrothermal carbonisation and techno-economic feasibility assessment. Sci. Total Environ. 2019, 690, 261–276. [Google Scholar] [CrossRef]

- Fang, J.; Zhan, L.; Ok, Y.S.; Gao, B. Minireview of potential applications of hydrochar derived from hydrothermal carbonization of biomass. J. Ind. Eng. Chem. 2018, 57, 15–21. [Google Scholar] [CrossRef]

- Ruan, X.X.; Liu, Y.Y.; Wang, G.Q.; Frost, R.L.; Qian, G.R.; Tsang, D.C.W. Transformation of functional groups and environmentally persistent free radicals in hydrothermal carbonisation of lignin. Bioresour. Technol. 2018, 270, 223–229. [Google Scholar] [CrossRef]

- Weidemann, E.; Niinipuu, M.; Fick, J.; Jansson, S. Using carbonized low-cost materials for removal of chemicals of environmental concern from water. Environ. Sci. Pollut. Res. 2018, 25, 15793–15801. [Google Scholar] [CrossRef] [Green Version]

- Querejeta, N.; Gil, M.V.; Rubiera, F.; Pevida, C. Sustainable coffee-based CO2 adsorbents: Toward a greener production via hydrothermal carbonization. Greenh. Gases Sci. Technol. 2018, 8, 309–323. [Google Scholar] [CrossRef]

- Huang, Y.; Huang, Y.; Wang, W.Q.; Zheng, K. Characterization of hydrogen peroxide (H2O2) modified hydrochars from walnut shell for enhanced adsorption performance of methylene blue from aqueous solution. Desalin. Water Treat. 2018, 109, 221–230. [Google Scholar] [CrossRef]

- Volpe, M.; Fiori, L. From olive waste to solid biofuel through hydrothermal carbonisation: The role of temperature and solid load on secondary char formation and hydrochar energy properties. J. Anal. Appl. Pyrolysis 2017, 124, 63–72. [Google Scholar] [CrossRef]

- Lucian, M.; Fiori, L. Hydrothermal carbonization of waste biomass: Process design, modeling, energy efficiency and cost analysis. Energies 2017, 10, 211. [Google Scholar] [CrossRef] [Green Version]

- Pruksakit, W.; Patumsawad, S. Hydrothermal Carbonization (HTC) of Sugarcane Stranded: Effect of Operation Condition to Hydrochar Production. Energy Procedia 2016, 100, 223–226. [Google Scholar] [CrossRef] [Green Version]

- Ghanim, B.M.; Pandey, D.S.; Kwapinski, W.; Leahy, J.J. Hydrothermal carbonisation of poultry litter: Effects of treatment temperature and residence time on yields and chemical properties of hydrochars. Bioresour. Technol 2016, 216, 373–380. [Google Scholar] [CrossRef]

- Mumme, J.; Titirici, M.M.; Pfeiffer, A.; Luder, U.; Reza, M.T.; Masek, O. Hydrothermal Carbonization of Digestate in the Presence of Zeolite: Process Efficiency and Composite Properties. ACS Sustain. Chem. Eng. 2015, 3, 2967–2974. [Google Scholar] [CrossRef]

- Reza, M.T.; Rottler, E.; Herklotz, L.; Wirth, B. Hydrothermal carbonization (HTC) of wheat straw: Influence of feedwater pH prepared by acetic acid and potassium hydroxide. Bioresour Technol. 2015, 182, 336–344. [Google Scholar] [CrossRef]

- Sarker, T.R.; Pattnaik, F.; Nanda, S.; Dalai, A.K.; Meda, V.; Naik, S. Hydrothermal pretreatment technologies for lignocellulosic biomass: A review of steam explosion and subcritical water hydrolysis. Chemosphere 2021, 284, 131372. [Google Scholar] [CrossRef]

- Sarker, T.R.; Azargohar, R.; Dalai, A.K.; Venkatesh, M. Physicochemical and Fuel Characteristics of Torrefied Agricultural Residues for Sustainable Fuel Production. Energy Fuels 2020, 34, 14169–14181. [Google Scholar] [CrossRef]

- Okolie, J.A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Chemistry and Specialty Industrial Applications of Lignocellulosic Biomass. Waste Biomass Valoriz. 2021, 12, 2145–2169. [Google Scholar] [CrossRef]

- Atabani, A.E.; Ali, I.; Naqvi, S.R.; Badruddin, I.A.; Aslam, M.; Mahmoud, E.; Almomani, F.; Juchelková, D.; Atelge, M.R.; Khan, T.M.Y. A state-of-the-art review on spent coffee ground (SCG) pyrolysis for future biorefinery. Chemosphere 2021, 286, 131730. [Google Scholar] [CrossRef]

- Munawar, M.A.; Khoja, A.H.; Naqvi, S.R.; Mehran, M.T.; Hassan, M.; Liaquat, R.; Dawood, U.F. Challenges and opportunities in biomass ash management and its utilization in novel applications. Renew. Sustain. Energy Rev. 2021, 150, 111451. [Google Scholar] [CrossRef]

- Khan, H.A.; Naqvi, S.R.; Mehran, M.T.; Khoja, A.H.; Khan Niazi, M.B.; Juchelková, D.; Atabani, A. A performance evaluation study of nano-biochar as a potential slow-release nano-fertilizer from wheat straw residue for sustainable agriculture. Chemosphere 2021, 285, 131382. [Google Scholar] [CrossRef]

- Oficina de Estudios y Políticas Agrarias, ODEPA. Panorama de la Agricultura Chilena; ODEPA: Región Metropolitana, Chile, 2019. [Google Scholar]

- Rodríguez-Monroy, C.; Mármol-Acitores, G.; Nilsson-Cifuentes, G. Electricity generation in Chile using non-conventional renewable energy sources—A focus on biomass. Renew. Sustain. Energy Rev. 2018, 81, 937–945. [Google Scholar] [CrossRef]

- Ministerio del Medio Ambiente. Nationally Appropriate Mitigation Action, Catalyzing Industrial Organic Waste Management in Chile; Center for Clean Air Policy (CCAP): Washington, DC, USA, 2013.

- Gaete-Morales, C.; Gallego-Schmid, A.; Stamford, L.; Azapagic, A. Assessing the environmental sustainability of electricity generation in Chile. Sci. Total Environ. 2018, 636, 1155–1170. [Google Scholar] [CrossRef] [Green Version]

- Tapia, D. Biomasa en Chile: En Búsqueda de un Mayor Fortalecimiento. Revista Nueva Minería y Energía. Available online: http://www.nuevamineria.com/revista/biomasa-en-chile-en-busqueda-de-un-mayor-fortalecimiento/ (accessed on 9 November 2021).

- Wong-Pinto, L.S.; Menzies, A.; Ordonez, J.I. Bionanomining: Biotechnological synthesis of metal nanoparticles from mining waste-opportunity for sustainable management of mining environmental liabilities. Appl. Microbiol. Biotechnol. 2020, 104, 1859–1869. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef] [Green Version]

- Lebre, E.; Corder, G. Integrating Industrial Ecology Thinking into the Management of Mining Waste. Resources 2015, 4, 765–786. [Google Scholar] [CrossRef]

- Chryss, A.; Fourie, A.B.; Monch, A.; Nairn, D.; Seddon, K.D. Towards an integrated approach to tailings management. J. S. Afr. Inst. Min. Metall. 2012, 112, 965–969. [Google Scholar]

- Jeldres, R.I.; Piceros, E.C.; Wong, L.S.; Leiva, W.H.; Herrera, N.; Toledo, P.G. Dynamic moduli of flocculated kaolinite sediments: Effect of salinity, flocculant dose, and settling time. Colloid Polym. Sci. 2018, 296, 1935–1943. [Google Scholar] [CrossRef]

- Yáñez, P.A.; Santiago, S. Caracterización Técnico-Económica de la Implementación de un Sistema Biodinámico en un Viñedo Convencional CV. Carbenet Sauvignon en el Valle de Limarí; Universidad de Chile: Santiago, Chile, 2006. [Google Scholar]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.M.; Fühner, C.; Bens, O.; Kern, J.; et al. Hydrothermal carbonization of biomass residuals: A comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef] [Green Version]

- Paul, C.G. Energías Renovables No Convencionales Para uso Domiciliario; Universidad de Chile: Santiago, Chile, 2013; p. 85. [Google Scholar]

- Ferrer, J.; Mujica, D.; Páez, G.; Fennentaciones, L.D.; Facultad, I.; Universidad, D.I. Producción de un Compostaje a Partir de Desechos de uva Composting from Grape Pomace. In Revista Técnica de la Facultad de Ingeniería; Universidad del Zulia: Zulia, Venezuela, 1993; Volume 16, pp. 191–198. [Google Scholar]

- Bordiga, M.; Travaglia, F.; Locatelli, M. Valorisation of grape pomace: An approach that is increasingly reaching its maturity—A review. Int. J. Food Sci. Technol. 2019, 54, 933–942. [Google Scholar] [CrossRef]

- Muhlack, R.A.; Potumarthi, R.; Jeffery, D.W. Sustainable wineries through waste valorisation: A review of grape marc utilisation for value-added products. Waste Manag. 2018, 72, 99–118. [Google Scholar] [CrossRef]

- Barbosa, F.S.; Scavarda, A.J.; Sellitto, M.A.; Marques, D.I.L. Sustainability in the winemaking industry: An analysis of Southern Brazilian companies based on a literature review. J. Clean. Prod. 2018, 192, 80–87. [Google Scholar] [CrossRef]

- Rashtbari, Y.; Afshin, S.; Hamzezadeh, A.; Abazari, M.; Poureshgh, Y.; Fazlzadehdavh, M. Application of powdered activated carbon coated with zinc oxide nanoparticles prepared using a green synthesis in removal of Reactive Blue 19 and Reactive Black-5: Adsorption isotherm and kinetic models. Desalin. Water Treat. 2020, 179, 354–367. [Google Scholar] [CrossRef]

- Li, S.Y.; Zhu, X.F.; Li, S.S.; Zhu, X.F. Improved bio-oil distilling effect by adding additives to enhance downstream bio-oil processing and separation. Sep. Purif. Technol. 2020, 247. [Google Scholar] [CrossRef]

- Kocaman, S. Removal of methylene blue dye from aqueous solutions by adsorption on levulinic acid-modified natural shells. Int. J. Phytoremediation 2020, 22, 885–895. [Google Scholar] [CrossRef]

- Jia, L.X.; Li, C.; Zhang, Y.; Chen, Y.R.; Li, M.Q.; Wu, S.B.; Wu, H.M. Microbial community responses to agricultural biomass addition in aerated constructed wetlands treating low carbon wastewater. J. Environ. Manag. 2020, 270, 110912. [Google Scholar] [CrossRef]

- Grzywacz, P.; Czerski, G.; Gazda-Grzywacz, M. Thermogravimetric characteristic of selected biomass gasification. Przem. Chem. 2020, 99, 386–390. [Google Scholar] [CrossRef]

- Ahmadinejad, S.O.; Naeeni, S.T.O.; Akbari, Z.; Nazif, S. Investigating the performance of agricultural wastes and their ashes in removing phenol from leachate in a fixed-bed column. Water Sci. Technol. 2020, 81, 2109–2126. [Google Scholar] [CrossRef]

- Yuan, X.H.; Zhu, X.F.; Zhang, L.Q.; Luo, Z.J.; Zhu, X.F. Fundamental Insights into Walnut Shell Bio-Oil Electrochemical Conversion: Reaction Mechanism and Product Properties. Bioenergy Res. 2021, 14, 322–332. [Google Scholar] [CrossRef]

- Ricci, F. Producción de Aceite de Pepita de uva, una Herramienta de Creación de Valor Agregado para un Producto Residual; Instituto Tecnologico de Buenos Aires: Buenos Aires, Argentina, 2011; p. 171. [Google Scholar]

- Botella, C.; Diaz, A.; de Ory, I.; Webb, C.; Blandino, A. Xylanase and pectinase production by Aspergillus awamori on grape pomace in solid state fermentation. Process. Biochem. 2007, 42, 98–101. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. Comparative evaluation of torrefaction and hydrothermal carbonization of lignocellulosic biomass for the production of solid biofuel. Energy Convers. Manag. 2015, 105, 746–755. [Google Scholar] [CrossRef]

- Benavente, V.; Calabuig, E.; Fullana, A. Upgrading of moist agro-industrial wastes by hydrothermal carbonization. J. Anal. Appl. Pyrolysis 2015, 113, 89–98. [Google Scholar] [CrossRef] [Green Version]

- Baratieri, M.; Basso, D.; Patuzzi, F.; Castello, D.; Fiori, L. Kinetic and thermal modeling of hydrothermal carbonization applied to grape marc. Chem. Eng. Trans. 2015, 43, 505–510. [Google Scholar] [CrossRef]

- Pala, M.; Kantarli, I.C.; Buyukisik, H.B.; Yanik, J. Hydrothermal carbonization and torrefaction of grape pomace: A comparative evaluation. Bioresour. Technol. 2014, 161, 255–262. [Google Scholar] [CrossRef]

- Atchabarova, A.A.; Tokpayev, R.R.; Kabulov, A.T.; Nechipurenko, S.V.; Nurmanova, R.A.; Yefremov, S.A.; Nauryzbayev, M.K. New Electrodes Prepared from Mineral and Plant Raw Materials of Kazakhstan. Eurasian Chem. -Technol. J. 2016, 18, 141–147. [Google Scholar] [CrossRef] [Green Version]

- Pecchi, M.; Baratieri, M. Coupling anaerobic digestion with gasification, pyrolysis or hydrothermal carbonization: A review. Renew. Sustain. Energy Rev. 2019, 105, 462–475. [Google Scholar] [CrossRef]

- Basso, D.; Weiss-Hortala, E.; Patuzzi, F.; Baratieri, M.; Fiori, L. In Deep Analysis on the Behavior of Grape Marc Constituents during Hydrothermal Carbonization. Energies 2018, 11, 1379. [Google Scholar] [CrossRef] [Green Version]

- Purnomo, C.W.; Castello, D.; Fiori, L. Granular activated carbon from grape seeds hydrothermal char. Appl. Sci. 2018, 8, 331. [Google Scholar] [CrossRef] [Green Version]

- Saha, N.; Volpe, M.; Fiori, L.; Volpe, R.; Messineo, A.; Reza, M.T. Cationic dye adsorption on hydrochars of winery and citrus juice industries residues: Performance, mechanism, and thermodynamics. Energies 2020, 13, 4686. [Google Scholar] [CrossRef]

- Hoffmann, V.; Jung, D.; Zimmermann, J.; Rodriguez Correa, C.; Elleuch, A.; Halouani, K.; Kruse, A. Conductive Carbon Materials from the Hydrothermal Carbonization of Vineyard Residues for the Application in Electrochemical Double-Layer Capacitors (EDLCs) and Direct Carbon Fuel Cells (DCFCs). Materials 2019, 12, 1703. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garrido, R.A.; Reckamp, J.M.; Satrio, J.A. Effects of Pretreatments on Yields, Selectivity and Properties of Products from Pyrolysis of Phragmites australis (Common Reeds). Environments 2017, 4, 96. [Google Scholar] [CrossRef] [Green Version]

- Hammer, N.; Starcevich, J.; Garrido, R.; Coe, C.; Satrio, J. Fast pyrolysis of lignocellulosic biomass by 2-step approach for producing fractionated bio-oil products. In Proceedings of the AIChE Annual Meeting, Atlanta, GA, USA, 16–21 November 2014. [Google Scholar]

- Zmiewski, A.M.; Hammer, N.L.; Garrido, R.A.; Misera, T.G.; Coe, C.G.; Satrio, J.A. Exploring the Products from Pinewood Pyrolysis in Three Different Reactor Systems. Energy Fuels 2015, 29, 5857–5864. [Google Scholar] [CrossRef]

- Hammer, N.L.; Garrido, R.A.; Starcevich, J.; Coe, C.G.; Satrio, J.A. Two-Step Pyrolysis Process for Producing High Quality Bio-oils. Ind. Eng. Chem. Res. 2015, 54, 10629–10637. [Google Scholar] [CrossRef]

- Reckamp, J.M.; Garrido, R.A.; Satrio, J.A. Selective pyrolysis of paper mill sludge by using pretreatment processes to enhance the quality of bio-oil and biochar products. Biomass Bioenerg 2014, 71, 235–244. [Google Scholar] [CrossRef]

- Parikh, J.; Channiwala, S.A.; Ghosal, G.K. A correlation for calculating elemental composition from proximate analysis of biomass materials. Fuel 2007, 86, 1710–1719. [Google Scholar] [CrossRef]

- Parikh, J.; Channiwala, S.A.; Ghosal, G.K. A correlation for calculating HHV from proximate analysis of solid fuels. Fuel 2005, 84, 487–494. [Google Scholar] [CrossRef]

- Bejarano, L.; Aguilar, P. Evaluación del biochar e hidrochar como medios para captura de carbono en el suelo. In Trabajo de Grado Para Optar por el Título de Ingeniería Ambiental; Universidad de La Salle: Bogotá, Colombia, 2017; p. 80. [Google Scholar]

- Petrovic, J.; Perisic, N.; Maksimovic, J.D.; Maksimovic, V.; Kragovic, M.; Stojanovic, M.; Lausevic, M.; Mihajlovic, M. Hydrothermal conversion of grape pomace: Detailed characterization of obtained hydrochar and liquid phase. J. Anal. Appl. Pyrolysis 2016, 118, 267–277. [Google Scholar] [CrossRef]

- Fiori, L.; Basso, D.; Castello, D.; Baratieri, M. Hydrothermal Carbonization of Biomass: Design of a Batch Reactor and Preliminary Experimental Results. Chem. Eng. Trans. 2014, 37, 55–60. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Y.; Wan, C.; Li, D.; Mao, Z. Effect of Hot Water Pretreatment Severity on the Degradation and Enzymatic Hydrolysis of Corn Stover. Trans. ASABE 2010, 53, 1929–1934. [Google Scholar] [CrossRef]

- Overend, R.P.; Chornet, E. Fractionation of lignocellulosics by steam-aqueous pretreatments. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Sci. 1987, 321, 523–536. [Google Scholar]

- Wang, T.; Zhai, Y.; Zhu, Y.; Li, C.; Zeng, G. A review of the hydrothermal carbonization of biomass waste for hydrochar formation: Process conditions, fundamentals, and physicochemical properties. Renew. Sustain. Energy Rev. 2018, 90, 223–247. [Google Scholar] [CrossRef]

- Savage, P.E. Organic Chemical Reactions in Supercritical Water. Chem Rev. 1999, 99, 603–622. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Rodriguez-Jasso, R.M.; Fernandes, B.D.; Vicente, A.A.; Teixeira, J.A. Hydrothermal processing, as an alternative for upgrading agriculture residues and marine biomass according to the biorefinery concept: A review. Renew. Sustain. Energ Rev. 2013, 21, 35–51. [Google Scholar] [CrossRef] [Green Version]

- Bobleter, O. Hydrothermal degradation of polymers derived from plants. Prog. Polym. Sci. 1994, 19, 797–841. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Robbins, C.; Zielinska, B.; Felix, L. Hydrothermal carbonization (HTC) of selected woody and herbaceous biomass feedstocks. Biomass Convers. Biorefinery 2012, 3, 113–126. [Google Scholar] [CrossRef]

- Zhao, P.T.; Shen, Y.F.; Ge, S.F.; Chen, Z.Q.; Yoshikawa, K. Clean solid biofuel production from high moisture content waste biomass employing hydrothermal treatment. Appl. Energy 2014, 131, 345–367. [Google Scholar] [CrossRef] [Green Version]

- Hoekman, S.K.; Broch, A.; Robbins, C. Hydrothermal Carbonization (HTC) of Lignocellulosic Biomass. Energy Fuels 2011, 25, 1802–1810. [Google Scholar] [CrossRef]

- Zhang, T.-Y.; Xu, B.; Hu, C.-Y.; Lin, Y.-L.; Lin, L.; Ye, T.; Tian, F.-X. A comparison of iodinated trihalomethane formation from chlorine, chlorine dioxide and potassium permanganate oxidation processes. Water Res. 2015, 68, 394–403. [Google Scholar] [CrossRef]

- Naderi, M.; Vesali-Naseh, M. Hydrochar-derived fuels from waste walnut shell through hydrothermal carbonization: Characterization and effect of processing parameters. Biomass Convers. Biorefinery 2019, 11, 1443–1451. [Google Scholar] [CrossRef]

| Feedstock | Biomass: Water Ratio | HTC Reaction Temperatures | HTC Reaction Residence Time (hrs) |

|---|---|---|---|

| Grape pomace (GP) Walnut shells (WS) | 5:1 | 180 °C | 1 |

| 200 °C | 1 | ||

| 200 °C | 2 |

| Grape Pomace (GP) | Walnut Shells (WS) | |

|---|---|---|

| Proximate Analysis | ||

| Volatile Matter (VM) | 64.62% ± 0.29% | 71.36% ± 0.98% |

| Fixed Carbon (FC) | 25.29% ± 0.22% | 4.97% ± 0.23% |

| Ash content (AC) | 10.09% ± 0.12% | 23.67% ± 1.21% |

| Elemental Analysis | ||

| C (wt.%) | 45.51% ± 0.06% | 35.63% ± 0.59% |

| H (wt.%) | 5.32% ± 0.01% | 4.68% ± 0.07% |

| O (wt.%) | 38.45% ± 0.08% | 35.48% ± 0.54% |

| N (wt.%) | 0.63% ± 0.001% | 0.53% ± 0.01% |

| HHV (MJ/kg) | 18.94% ± 0.04% | 12.70% ± 0.24% |

| Biomass | Temperature (°C) | Residence Time (min) | %C | %H | %O | %N | HHV (MJ/kg) |

|---|---|---|---|---|---|---|---|

| Grape pomace | 180 | 60 | 49.96 | 5.64 | 40.09 | 0.68 | 21.64 |

| 200 | 60 | 50.82 | 5.65 | 39.86 | 0.68 | 22.36 | |

| 200 | 120 | 51.70 | 5.67 | 39.78 | 0.68 | 23.04 | |

| Walnut shells | 180 | 60 | 35.47 | 4.65 | 35.18 | 0.53 | 12.7 |

| 200 | 60 | 36.22 | 4.77 | 36.21 | 0.54 | 22.36 | |

| 200 | 120 | 35.61 | 4.68 | 35.44 | 0.53 | 23.04 |

| Biomass | Temperature (°C) | Residence Time (min) | Severity Log(R0) | Hydrochar Yield % | H/C Ratio | O/C Ratio |

|---|---|---|---|---|---|---|

| Grape pomace | 180 | 60 | 7.35 | 85.23% ± 7.11% | 1.354 | 0.602 |

| 200 | 60 | 18.45 | 88.50% ± 8.09% | 1.333 | 0.588 | |

| 200 | 120 | 11.13 | 67.22% ± 2.61% | 1.316 | 0.577 | |

| Walnut shells | 180 | 60 | ND | 89.32% ± 9.19% | 1.573 | 0.744 |

| 200 | 60 | ND | 93.10% ± 0.25% | 1.582 | 0.750 | |

| 200 | 120 | ND | 88.89% ± 0.18% | 1.577 | 0.747 |

| Sample Biomass | HTC | Proximate Analysis | Elemental Analysis | pH * | Ref. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temp. (°C) | Time (min) | VM (%) | FC (%) | AC (%) | N (%) | C (%) | H (%) | O (%) | ||||

| Grape pomace | Raw GP | - | - | 67 | 33 | 5.1 | 1.8 | 54.0 | 5.8 | 38.4 | - | [60] |

| HC | 220 | 120 | 53 | 47 | 1.5 | 1.7 | 65.4 | 5.4 | 27.5 | 4.1 | ||

| HC | 240 | 60 | 50 | 50 | 1.7 | 2 | 67.9 | 5.4 | 24.7 | 4.4 | ||

| Walnut shells | Raw WS | - | - | - | - | - | 1.5 | 47.6 | 6.0 | 46.3 | - | [81,82,83] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garrido, R.A.; Lagos, C.; Luna, C.; Sánchez, J.; Díaz, G. Study of the Potential Uses of Hydrochar from Grape Pomace and Walnut Shells Generated from Hydrothermal Carbonization as an Alternative for the Revalorization of Agri-Waste in Chile. Sustainability 2021, 13, 12600. https://doi.org/10.3390/su132212600

Garrido RA, Lagos C, Luna C, Sánchez J, Díaz G. Study of the Potential Uses of Hydrochar from Grape Pomace and Walnut Shells Generated from Hydrothermal Carbonization as an Alternative for the Revalorization of Agri-Waste in Chile. Sustainability. 2021; 13(22):12600. https://doi.org/10.3390/su132212600

Chicago/Turabian StyleGarrido, René A., Camila Lagos, Carolina Luna, Jaime Sánchez, and Georgina Díaz. 2021. "Study of the Potential Uses of Hydrochar from Grape Pomace and Walnut Shells Generated from Hydrothermal Carbonization as an Alternative for the Revalorization of Agri-Waste in Chile" Sustainability 13, no. 22: 12600. https://doi.org/10.3390/su132212600

APA StyleGarrido, R. A., Lagos, C., Luna, C., Sánchez, J., & Díaz, G. (2021). Study of the Potential Uses of Hydrochar from Grape Pomace and Walnut Shells Generated from Hydrothermal Carbonization as an Alternative for the Revalorization of Agri-Waste in Chile. Sustainability, 13(22), 12600. https://doi.org/10.3390/su132212600