Relationships among Perceived Control, Safety Attitude, and Safety Performance: A Case Study on Wastewater Treatment Plant Workers

Abstract

:1. Introduction

2. Literature Review

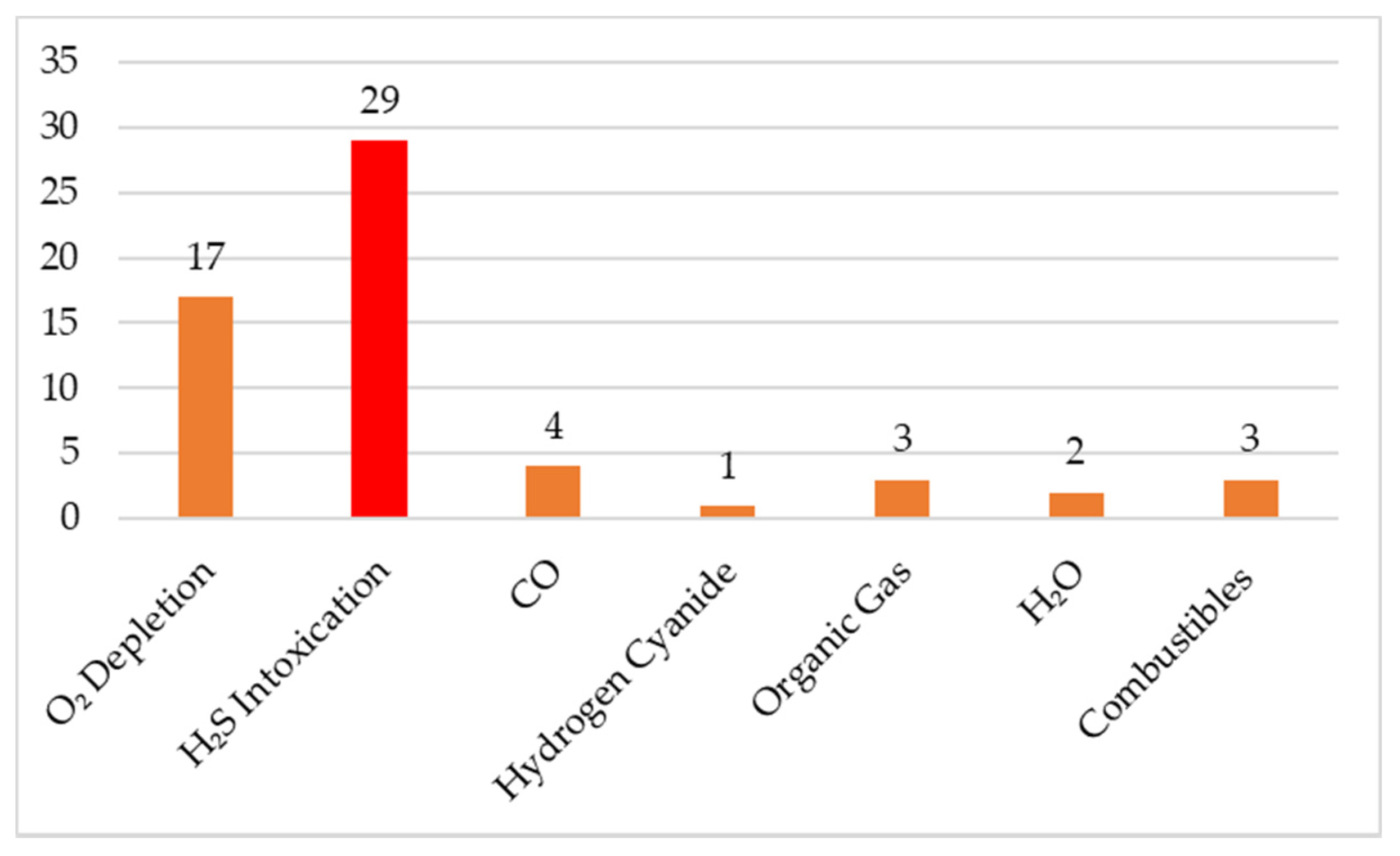

2.1. Operation and Management of WWTPs and Occupational Hazards in Confined Spaces

2.2. Perceived Control

2.3. Safety Attitude

2.4. Safety Performance

3. Research Methods

3.1. Research Hypotheses

3.2. Questionnaire Design and Sampling Method

3.3. Data Analysis Methodology

4. Results

4.1. Descriptive Statistical Analysis

4.2. Correlation Analysis

4.3. Hierarchical Regression Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wilson, M.P.; Madison, H.N.; Healy, S.B. Confined space emergency response: Assessing employer and fire department practices. J. Occup. Environ. Hyg. 2012, 9, 120–128. [Google Scholar] [CrossRef] [PubMed]

- Selman, J.; Spickett, J.; Jansz, J.; Mullins, B. An investigation into the rate and mechanism of incident of work-related confined space fatalities. Saf. Sci. 2018, 109, 333–343. [Google Scholar] [CrossRef]

- Standards Australia International; Standards New Zealand. Safe Working in a Confined Space; Standards Australia International: Sydney, NSW, Australia; Standards New Zealand: Wellington, New Zealand, 2001. [Google Scholar]

- Burlet-Vienney, D.; Chinniah, Y.; Bahloul, A.; Roberge, B. Occupational safety during interventions in confined spaces. Saf. Sci. 2015, 79, 19–28. [Google Scholar] [CrossRef]

- Meyer, S. Fatal occupational injuries involving confined spaces, 1997–2001. Occup. Health Saf. (Waco, Tex.) 2003, 79, 19–28. [Google Scholar]

- Braddee, R.W.; Castillo, D.N.; Helmkamp, J.C.; Pettit, T.A.; Suruda, A.J. Worker deaths in confined spaces. Prof. Saf. 1996, 41, 22–25. [Google Scholar]

- Sahli, B.; Armstrong, C. Confined space fatalities in Virginia. J. Saf. Res. 1993, 24, 124–125. [Google Scholar] [CrossRef]

- Occupational Safety and Health Administration, MOL. Available online: https://www.osha.gov.tw/1106/29647/30708/30709/30715/ (accessed on 14 August 2021).

- Burlet-Vienney, D.; Chinniah, Y.; Bahloul, A. The Need for a Comprehensive Approach to Managing Confined Space Entry: Summary of the Literature and Recommendations for Next Steps. J. Occup. Environ. Hyg. 2014, 11, 485–498. [Google Scholar] [CrossRef]

- Suruda, A.; Agnew, J. Deaths from asphyxiation and poisoning at work in the United States 1984-6. Occup. Environ. Med. 1989, 46, 541–546. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panuwatwanich, K.; Al-Haadir, S.; Stewart, R.A. Influence of safety motivation and climate on safety behaviour and outcomes: Evidence from the Saudi Arabian construction industry. Int. J. Occup. Saf. Ergon. 2016, 23, 60–75. [Google Scholar] [CrossRef]

- Marín, L.S.; Lipscomb, H.; Cifuentes, M.; Punnett, L. Perceptions of safety climate across construction personnel: Associations with injury rates. Saf. Sci. 2019, 118, 487–496. [Google Scholar] [CrossRef]

- Mearns, K.; Flin, R.; Gordon, R.; Fleming, M. Measuring safety climate on offshore installations. Work Stress 1998, 12, 238–254. [Google Scholar] [CrossRef]

- Rundmo, T. Safety climate, attitudes and risk perception in Norsk Hydro. Saf. Sci. 2000, 34, 47–59. [Google Scholar] [CrossRef]

- Smith, A.; Wadsworth, E. Safety Culture, Advice and Performance: The Association between Safety Culture and Safety Performance, Health and Well-Being at an Individual Level, and Safety Culture, Competent Occupational Safety and Health Advice and Safety Performance at a Corporate Level—Report Submitted to the IOSH Research Committee; Institution of Occupational Safety and Health: Wigston, UK, 2009. [Google Scholar]

- White, R.; Lippitt, R. Leader behavior and member reaction in three “social climates”. In Group Dynamics: Research and Theory/[a Cura Di] Dorwin Cartwright, Alvin Zander; Harper & Row: New York, NY, USA, 1953; pp. 385–611. [Google Scholar]

- Thompson, S.C.; Spacapan, S. Perceptions of Control in Vulnerable Populations. J. Soc. Issues 1991, 47, 1–21. [Google Scholar] [CrossRef]

- Ajzen, I. The theory of planned behavior. Organ. Behav. Hum. Decis. Process. 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Ajzen, I. Residual Effects of Past on Later Behavior: Habituation and Reasoned Action Perspectives. Pers. Soc. Psychol. Rev. 2002, 6, 107–122. [Google Scholar] [CrossRef]

- Trafimow, D.; Sheeran, P.; Conner, M.; Finlay, K.A. Evidence that perceived behavioural control is a multidimensional construct: Perceived control and perceived difficulty. Br. J. Soc. Psychol. 2002, 41, 101–121. [Google Scholar] [CrossRef]

- Yu, X.B. The Cause of Accidents from Heinrich Theory. TONGJI SEM (blog). 26 June 2013. Available online: https://sem.tongji.edu.cn/semch/6895.html (accessed on 14 August 2021).

- Ito, J.K.; Brotheridge, C.M. An Examination of the Roles of Career Uncertainty, Flexibility, and Control in Predicting Emotional Exhaustion. J. Vocat. Behav. 2001, 59, 406–424. [Google Scholar] [CrossRef] [Green Version]

- Neal, A.; Griffin, M.A. A study of the lagged relationships among safety climate, safety motivation, safety behavior, and accidents at the individual and group levels. J. Appl. Psychol. 2006, 91, 946–953. [Google Scholar] [CrossRef] [Green Version]

- Oliver, A.; Cheyne, A.; Tomás, J.M.; Cox, S. The effects of organizational and individual factors on occupational accidents. J. Occup. Organ. Psychol. 2002, 75, 473–488. [Google Scholar] [CrossRef]

- Spector, P.E.; O’Connell, B.J. The contribution of personality traits, negative affectivity, locus of control and Type A to the subsequent reports of job stressors and job strains. J. Occup. Organ. Psychol. 1994, 67, 1–12. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Tsaur, C.-C.; Kao, F.-H. Perceived control and work safety: The mediating role of safety culture. J. Occup. Saf. Health 2010, 18, 95–110. [Google Scholar] [CrossRef]

- International Nuclear Safety Advisory Group. Available online: https://www-pub.iaea.org/mtcd/publications/pdf/pub882_web.pdf (accessed on 14 August 2021).

- Donald, I.; Canter, D. Psychological factors and the accident plateau. Health Saf. Inf. Bull. 1993, 215, 5–12. [Google Scholar]

- Heinrich, H.W. Industrial Accident Prevention: A Scientific Approach; McGraw-Hill: New York, NY, USA, 1969. [Google Scholar]

- Reece, M.J.; Gable, R.K. The Development and Validation of a Measure of General Attitudes toward Computers. Educ. Psychol. Meas. 1982, 42, 913–916. [Google Scholar] [CrossRef]

- Eagly, A.H.; Chaiken, S. The Psychology of Attitudes; Harcourt Brace Jovanovich College Publishers: Fort Worth, TX, USA, 1993. [Google Scholar]

- Champoux, J.E. Organizational Behavior: Integrating Individuals, Groups, and Processes; West Publishing: Minneapolis/St. Paul, MN, USA, 1996. [Google Scholar]

- Hannaford, E.S. Supervisors Guide to Human Relations; National Safety Council: Chicago, IL, USA, 1976. [Google Scholar]

- Warmerdam, A.; Newnam, S.; Wang, Y.; Sheppard, D.; Griffin, M.; Stevenson, M. High performance workplace systems’ influence on safety attitudes and occupational driver behaviour. Saf. Sci. 2018, 106, 146–153. [Google Scholar] [CrossRef]

- Chen, W.T.; Merrett, H.C.; Huang, Y.-H.; Lu, S.T.; Sun, W.C.; Li, Y. Exploring the Multilevel Perception of Safety Climate on Taiwanese Construction Sites. Sustainability 2019, 11, 4596. [Google Scholar] [CrossRef] [Green Version]

- Al-Bsheish, M.A. Enhancing Safety Performance by Recognizing the Role of Perceived Management Commitment to Safety in the Jordanian Healthcare Industry: Conceptual Framework. Int. J. Bus. Soc. Res. 2017, 7, 01–10. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.T.; Merrett, H.C.; Huang, Y.-H.; Bria, T.A.; Lin, Y.-H. Exploring the Relationship between Safety Climate and Worker Safety Behavior on Building Construction Sites in Taiwan. Sustainability 2021, 13, 3326. [Google Scholar] [CrossRef]

- Petersen, A.K.; Reynolds, J.H.; Ng, L.W.T. The attitude of civil engineering students towards health and safety risk management: A case study. Eur. J. Eng. Educ. 2008, 33, 499–510. [Google Scholar] [CrossRef]

- Alasamri, H.; Chrisp, M.T.; Bowles, G. A framework for enhancing and improving the safety culture on Saudi construction sites. In Proceedings of the 28th Annual ARCOM Conference; Smith, S.D., Ed.; Association of Researchers in Construction Management: Edinburgh, UK, 2012; pp. 475–485. [Google Scholar]

- Sanni-Anibire, M.O.; Mahmoud, A.S.; Hassanain, M.A.; Salami, B. A risk assessment approach for enhancing construction safety performance. Saf. Sci. 2019, 121, 15–29. [Google Scholar] [CrossRef]

- Burke, M.J.; Sarpy, S.A.; Tesluk, P.E.; Smith-Crowe, K. General safety performance: A test of a grounded theoretical model. Pers. Psychol. 2002, 55, 429–457. [Google Scholar] [CrossRef]

- Snyder, L.A.; Krauss, A.D.; Chen, P.Y.; Finlinson, S.; Huang, Y.-H. Safety performance: The mediating role of safety control. Work 2011, 40, 99–111. [Google Scholar] [CrossRef]

- Loosemore, M.; Malouf, N. Safety training and positive safety attitude formation in the Australian construction industry. Saf. Sci. 2018, 113, 233–243. [Google Scholar] [CrossRef]

- Reason, J.T. Managing the Risks of Organizational Accidents; Routledge, Ashgate Book: Aldershot, UK, 1997. [Google Scholar]

- Mearns, K.; Whitaker, S.M.; Flin, R. Safety climate, safety management practice and safety performance in offshore environments. Saf. Sci. 2003, 41, 641–680. [Google Scholar] [CrossRef]

- Hofmann, D.A.; Stetzer, A. A Cross-Level Investigation of Factors Influencing Unsafe Behaviors and Accidents. Pers. Psychol. 1996, 49, 307–339. [Google Scholar] [CrossRef]

- Reason, J. Human Error; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Barbaranelli, C.; Petitta, L.; Probst, T.M. Does safety climate predict safety performance in Italy and the USA? Cross-cultural validation of a theoretical model of safety climate. Accid. Anal. Prev. 2015, 77, 35–44. [Google Scholar] [CrossRef] [PubMed]

- Clarke, S. Contrasting perceptual, attitudinal and dispositional approaches to accident involvement in the workplace. Saf. Sci. 2006, 44, 537–550. [Google Scholar] [CrossRef]

- Umar, T.; Umeokafor, N. A new safety climate assessment tool for Gulf construction. In Proceedings of the 9th World Construction Symposium, Moratuwa, Sri Lanka, 8–10 July 2021; Sandanayake, Y.G., Gunatilake, S., Waidyasekara, K.G.A.S., Eds.; University of Sri Lanka: Moratuwa, Sri Lanka, 2021; pp. 39–51. [Google Scholar] [CrossRef]

- Kraft, P.; Rise, J.; Sutton, S.; Røysamb, E. Perceived difficulty in the theory of planned behaviour: Perceived behavioural control or affective attitude? Br. J. Soc. Psychol. 2005, 44, 479–496. [Google Scholar] [CrossRef] [PubMed]

- Guastello, S.J. Catastrophe modelling of the accident process: Organizational subunit size. Psychol. Bull. 1988, 103, 246–255. [Google Scholar] [CrossRef]

- Cranny, C.J.; Smith, P.C.; Stone, E.F. Job Satisfaction: How People Feel about their Jobs and how it Affects their Performance; Lexington Books: New York, NY, USA, 1992. [Google Scholar]

- Smith, C.; Kruger, T.; Silverman, G.; Haff, M.; Hayes, B.; Silverman, M.; Mattimore, L. A research method for assessing industrial accidents. In Proceedings of Annual Convention of the Human Factors Society; Sage Publications: Thousand Oaks, CA, USA, 1992. [Google Scholar]

- Wu, T.C.; Kang, T.L. Safety climate in four categories of manufacturing industries in central Taiwan. J. Health Sci. 2002, 4, 203–223. [Google Scholar] [CrossRef]

- Baron, R.M.; Kenny, D.A. The moderator–mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Pers. Soc. Psychol. 1986, 51, 1173. [Google Scholar] [CrossRef]

- Reason, J. Achieving a safe culture: Theory and practice. Work Stress 1998, 12, 293–306. [Google Scholar] [CrossRef] [Green Version]

- Oswald, D.; Sherratt, F.; Smith, S. Exploring factors affecting unsafe behaviours in construction. In Proceedings of the 29th Annual ARCOM Conference, Reading, UK, 2–4 September 2013; pp. 335–344. [Google Scholar]

- Zhou, Q.; Fang, D.; Mohamed, S. Safety Climate Improvement: Case Study in a Chinese Construction Company. J. Constr. Eng. Manag. 2011, 137, 86–95. [Google Scholar] [CrossRef]

- Rodríguez-Garzón, I.; Lucas-Ruiz, V.; Martínez-Fiestas, M.; Delgado-Padial, A. Association between Perceived Risk and Training in the Construction Industry. J. Constr. Eng. Manag. 2015, 141, 04014095. [Google Scholar] [CrossRef]

- Zohar, D. Safety climate in industrial organizations: Theoretical and applied implications. J. Appl. Psychol. 1980, 65, 96–102. [Google Scholar] [CrossRef] [PubMed]

- Hinze, J.; Hallowell, M.R.; Baud, K. Construction-Safety Best Practices and Relationships to Safety Performance. J. Constr. Eng. Manag. 2013, 139, 04013006. [Google Scholar] [CrossRef]

| Attribute | Classification | No. | Ratio (%) |

|---|---|---|---|

| Gender | Male | 109 | 88.6 |

| Female | 14 | 11.4 | |

| Age | <30 | 24 | 19.5 |

| 30 to 39 | 36 | 29.3 | |

| 40 to 49 | 34 | 27.6 | |

| ≥50 | 29 | 23.6 | |

| Educational Level | High School/Vocational High School | 14 | 11.4 |

| Junior College | 53 | 43.1 | |

| Technical/Vocational College | 21 | 17.1 | |

| University | 22 | 17.9 | |

| Graduate School or Higher | 13 | 10.6 | |

| Major | Engineering (Civil Engineering, Architecture, Hydraulic, Environmental, Mechanic/ Electrical Engineering, etc.) | 95 | 77.9 |

| Others | 27 | 22.1 | |

| Employer | Civil Servants for WWTP | 51 | 41.8 |

| WWTP Operation Contractor | 49 | 40.2 | |

| Maintenance & Repair Contractor | 22 | 18.0 | |

| Payroll | Full-time Employee | 91 | 76.5 |

| Contract Employee | 28 | 23.5 | |

| Work Position | On-site Maintenance/Repair Worker or Operator (Technician) | 74 | 60.7 |

| Office Worker (Administrative Assistant, Engineering Assistant, Office Manager, etc.) | 32 | 26.2 | |

| Supervisor (Section Chief, Team Chief, Site Manager, etc.) | 16 | 13.1 | |

| Total Years of Working Experience | ≤5 Years | 58 | 47.2 |

| 6 to 15 Years | 17 | 13.8 | |

| 16 to 25 Years | 39 | 31.7 | |

| >25 Years | 9 | 7.3 | |

| Total Years for the Current Employer | ≤5 Years | 77 | 62.6 |

| 6 to 15 Years | 12 | 9.8 | |

| 16 to 25 Years | 27 | 22.0 |

| Dimension | Cronbach’s α | |

|---|---|---|

| Perceived Control | 0.686 | |

| Safety Attitude | Personal Safety | 0.591 |

| Co-worker Safety | 0.851 | |

| Supervisor Support | 0.755 | |

| Safety Understanding | 0.614 | |

| Safety Performance | Predictive Safety | 0.877 |

| Perceived safety | 0.934 | |

| Items | Average Score | S.D. |

|---|---|---|

| I believe that nothing will go wrong at work as long as I follow my own judgement. * | 2.04 | 0.918 |

| I believe accidents on the work site are often caused by issues with devices and/or equipment. * | 1.93 | 0.773 |

| I believe that skipping some steps of the standard work procedure will not actually affect work safety. * | 1.73 | 0.747 |

| I feel that accidents will never happen to me. * | 1.55 | 0.749 |

| Work safety management is the responsibility of the safety and health department of the company and has nothing to do with me. * | 1.43 | 0.544 |

| Overall Dimension | 1.74 | 0.505 |

| Sub-Dimension | Items | Average Score | S.D. | Average Score of Sub-Dimension |

|---|---|---|---|---|

| Personal Safety | I believe wearing safety shoes and helmet can help to prevent occupational hazards. | 4.34 | 0.876 | 4.04 |

| I frequently keep passageways on the work site clean and free of obstruction. | 4.33 | 0.719 | ||

| To ensure safety, I thoroughly understand how to use the protective gear properly and wear it all the time on the work site. | 4.30 | 0.852 | ||

| I believe that the safety rules of the company will reduce my work efficiency. * | 3.75 | 1.083 | ||

| I believe that it is highly hazardous to work on the work site. | 3.44 | 1.160 | ||

| Co-worker Safety | I am very willing to accept reminders about work safety from colleagues. | 4.48 | 0.605 | 4.35 |

| I pay attention to the safety of my colleagues or other workers on the work site and remind them to follow safety rules. | 4.38 | 0.621 | ||

| My colleagues pay attention to on-site safety and remind me of following safety rules. | 4.20 | 0.746 | ||

| Supervisor Support | My direct supervisor make frequent round checks and, when finding any hazardous action taken by my colleagues or employees of contractors, will immediately stop it. | 4.24 | 0.728 | 4.14 |

| My direct supervisor will give warnings to those employees who continue to violate safety rules or have unsafe behaviors after several times of exhortation against such actions. | 4.17 | 0.721 | ||

| When a worker is in poor physical condition, my director supervisor will immediately stop him/her from work. | 4.07 | 0.784 | ||

| My director supervisor frequently check if any of his subordinates has a slack work attitude. | 4.06 | 0.785 | ||

| Safety Understanding | A safe working environment can bring better work performance. | 4.48 | 0.578 | 4.18 |

| If employees take participation in safety training seriously, it is helpful to improve their safety performance. | 4.42 | 0.627 | ||

| Paying attention to how employees feel about their work can help to improve their work performance. | 4.41 | 0.699 | ||

| Providing sufficient safety training can help to reduce the occurrence of accidents. | 4.39 | 0.754 | ||

| Accidents occur to employees mostly because of bad luck. * | 4.25 | 0.911 | ||

| If an employee pays too much attention to the safety procedure, it will impair his/her work efficiency. * | 3.75 | 1.083 | ||

| When an employee is too busy at work, he/she will become negligent about work safety. | 3.57 | 1.160 | ||

| Average Score of the Dimension = 4.18; S.D. of the Dimension = 0.388. | ||||

| Sub-Dimension | Items | Average Score | S.D. | Average Score of Sub-Dimension |

|---|---|---|---|---|

| Predictive Safety | I believe that my company will not have any death caused by occupational hazards in the coming year with its current equipment and environment. | 3.38 | 1.218 | 3.36 |

| I believe that my company will not have any false alarm incident with its current equipment and environment on the work site. | 3.34 | 1.214 | ||

| Perceived Safety | All the employees at my company have received general work safety training. | 4.38 | 0.659 | 4.25 |

| I frequently pay attention to if there is sufficient light, illumination, and ventilation on the work site. | 4.36 | 0.703 | ||

| After each accident, the company will not only have an in-depth investigation about its causes but also announce and compile the investigation findings as materials for safety training. | 4.30 | 0.652 | ||

| The safety and health training of the company meet the safety requirements and I can put what I learn from the training into practice. | 4.27 | 0.690 | ||

| For newly purchased personal protective equipment, the company gives training on how to properly use it. | 4.23 | 0.758 | ||

| I frequently receive reminders of work safety awareness promotion and information about work safety cases from the company. | 4.22 | 0.621 | ||

| The passageways at my work site is clear of obstruction and all the materials and objects are placed in a clean and tidy fashion. | 4.21 | 0.763 | ||

| I strictly implement the measures of access control for contractors’ employees on the work site. | 4.20 | 0.709 | ||

| I believe that the managers of the company frequently analyze work hazards to improve work safety. | 4.13 | 0.724 | ||

| Average Score of the Dimension = 4.09; SD of the Dimension = 0.496 | ||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | |

|---|---|---|---|---|---|---|---|---|---|

| (1) Age | 1 | ||||||||

| (2) Total Years of Working Experience | 0.761 ** | 1 | |||||||

| (3) Perceived Control | −0.068 | −0.067 | 1 | ||||||

| (4) Personal Safety | −0.073 | −0.034 | 0.217 * | 1 | |||||

| (5) Co-worker Safety | −0.207 * | −0.140 | 0.395 ** | 0.463 ** | 1 | ||||

| (6) Supervisor Support | −0.263 ** | −0.284 ** | 0.252 ** | 0.300 ** | 0.629 ** | 1 | |||

| (7) Safety Understanding | 0.038 | 0.033 | 0.254 ** | 0.219 * | 0.380 ** | 0.488 ** | 1 | ||

| (8) Predictive safety | −0.206 * | −0.145 | 0.212 * | 0.093 | −0.025 | 0.014 | −0.041 | 1 | |

| (9) Perceived safety | −0.289 ** | −0.269 ** | 0.327 ** | 0.336 ** | 0.646 ** | 0.711 ** | 0.332 ** | −0.057 | 1 |

| Model 1 | Model 2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Safety Attitude | Safety Performance | ||||||||

| Mode 1 | Mode 2 | ||||||||

| Standardized β | t | VIF | Standardized β | t | VIF | Standardized β | t | VIF | |

| Perceived Control | 0.411 | 4.862 ** | 1.000 | 0.219 | 2.451 * | 1.000 | 0.034 | 0.425 | 1.198 |

| Safety Attitude | - | - | - | - | - | - | 0.624 | 7.680 ** | 1.198 |

| 0.169 | 0.048 | 0.373 | |||||||

| 0.162 | 0.040 | 0.362 | |||||||

| 23.637 ** | 6.006 ** | 33.848 ** | |||||||

| 1.767 | 1.491 | 1.427 | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-F.; Tsai, Y.-L.; Lu, W.-H. Relationships among Perceived Control, Safety Attitude, and Safety Performance: A Case Study on Wastewater Treatment Plant Workers. Sustainability 2021, 13, 12573. https://doi.org/10.3390/su132212573

Huang C-F, Tsai Y-L, Lu W-H. Relationships among Perceived Control, Safety Attitude, and Safety Performance: A Case Study on Wastewater Treatment Plant Workers. Sustainability. 2021; 13(22):12573. https://doi.org/10.3390/su132212573

Chicago/Turabian StyleHuang, Chung-Fah, Yu-Long Tsai, and Wen-Hua Lu. 2021. "Relationships among Perceived Control, Safety Attitude, and Safety Performance: A Case Study on Wastewater Treatment Plant Workers" Sustainability 13, no. 22: 12573. https://doi.org/10.3390/su132212573

APA StyleHuang, C.-F., Tsai, Y.-L., & Lu, W.-H. (2021). Relationships among Perceived Control, Safety Attitude, and Safety Performance: A Case Study on Wastewater Treatment Plant Workers. Sustainability, 13(22), 12573. https://doi.org/10.3390/su132212573