Modeling Sustainable Risks Mitigation Strategies Using a Morphological Analysis-Based Approach: A Real Case Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Morphological Analysis Approach

- -

- First step: the problem to be solved must be very well formulated.

- -

- Second step: all parameters that might be of importance for the solution of the given problem must be localized and analyzed.

- -

- Third step: the morphological box or multidimensional matrix is constructed, which contains all potential solutions of the given problem.

- -

- Fourth step: all of the solutions contained in the morphological box are closely scrutinized and evaluated with respect to the purposes to be achieved.

- -

- Fifth step: optimal suitable solutions are selected and applied practically, provided that the necessary means are available. This reduction to practice requires, in general, a supplemental morphological study.

2.1.1. The Morphological Field

2.1.2. The Cross-Consistency Matrix

2.2. Evaluate Strategic Choices and Options

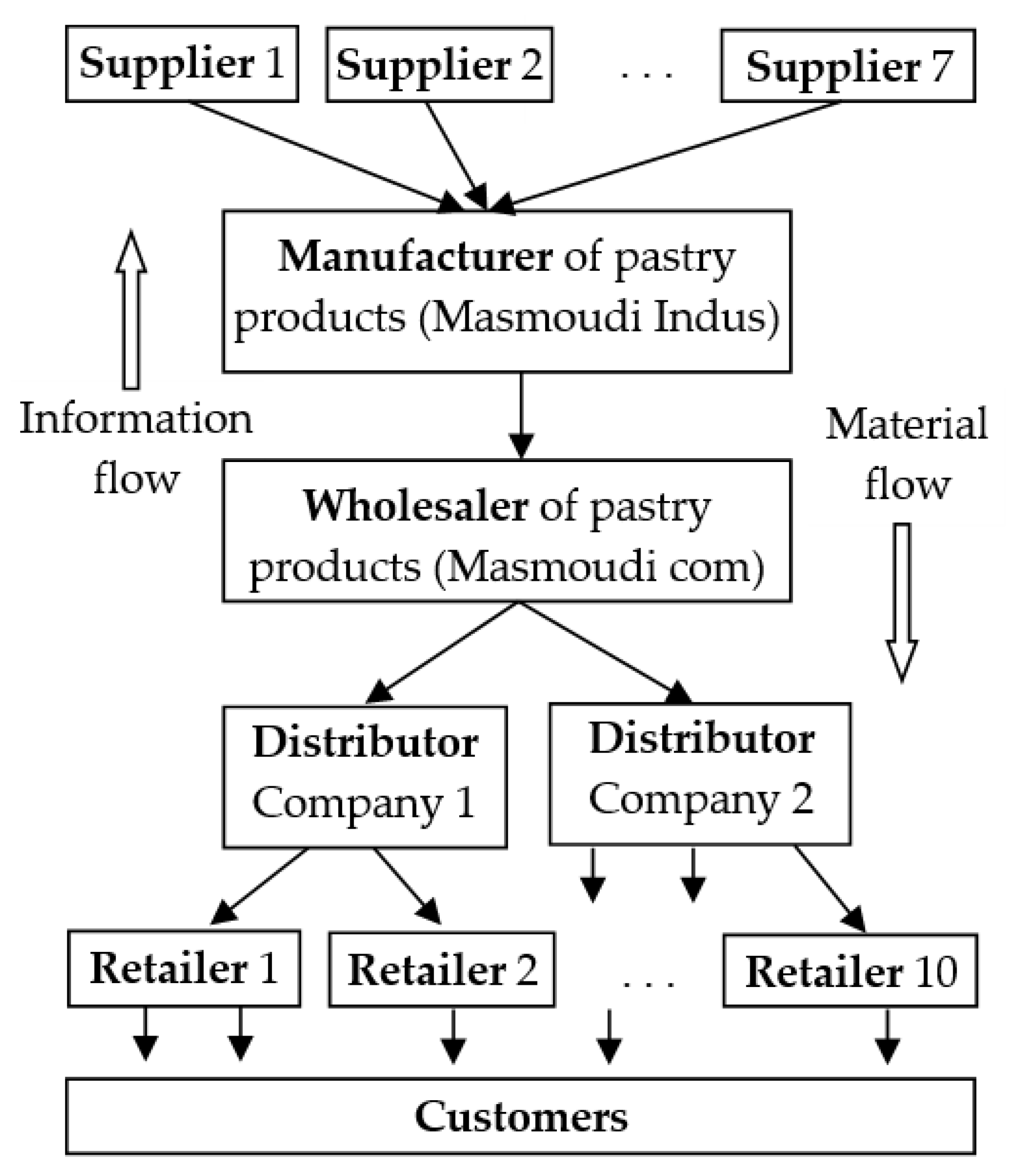

2.3. Case Study

- Retailer order partially delivered;

- Delayed delivery to retailer;

- Inventory and stock failure;

- Productivity and quality failure;

- Error in forecasting;

- Craft and manual production;

- Seasonal production;

- Poor harvest.

3. Results

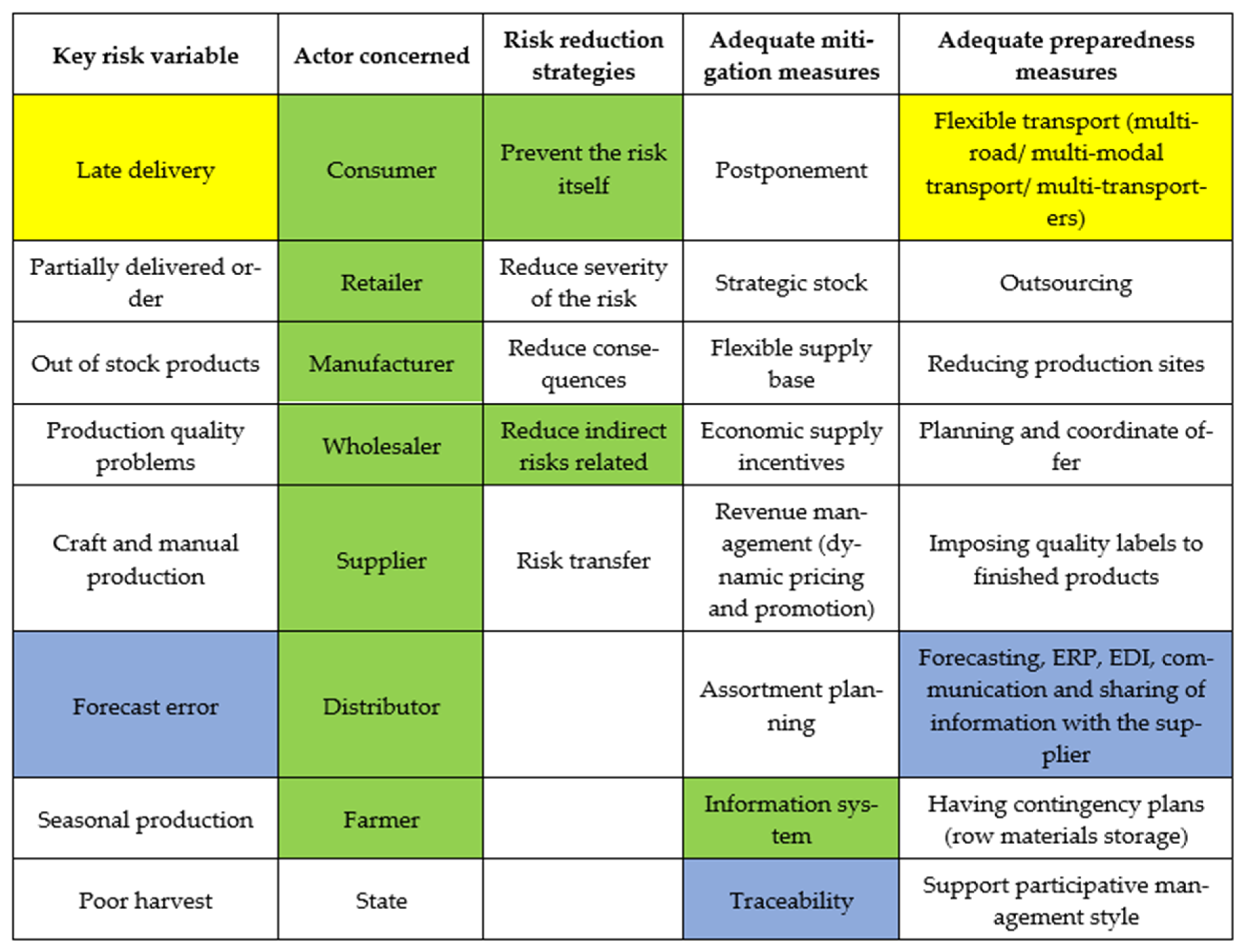

3.1. Selection of Possible Risk Mitigation Strategies

- Postponement: Using product or process design concepts to delay the point of product differentiation;

- Strategic stock: Companies should have additional stock inventories of certain critical components to ensure the continuity of its functions when facing a supply disruption;

- Flexible supply base: This enables a firm to handle regular demand fluctuations and to maintain continuous supply materials;

- Make and buy: Companies should produce their items in-house and outsource other basic items to their suppliers. This allows firms to shift production quickly;

- Economic supply incentives: To gain the flexibility to change production between suppliers, the buyer can provide certain economic incentives to cultivate additional suppliers. As such, the company can share some financial risks with the supplier;

- Flexible transportation: There are three basic approaches explaining this.

- -

- Multimodal transportation: Some companies use a flexible logistics strategy that relies on multiple modes of transportation to prevent supply chain operations from coming to a halt when disruptions occur in the ocean, in the air, on the road, etc.;

- -

- Multi-carrier transportation: Various companies have formed an alliance that will enable them to switch carriers quickly in the event of political disruptions to ensure continuous flow of materials in the case of political disruptions (landing rights, labor strikes, etc.). This alliance provides low-cost global deliveries;

- -

- Multiple routes: Various companies are considering alternative routes to ensure smooth material flows along supply chains. So, it avoids a complete shutdown.

- Revenue management via dynamic pricing and promotion: This can be an effective way to manage demand when the supply of a particular product is disrupted. Specifically, a retailer can use pricing mechanisms to entice customers to choose products that are widely available;

- Dynamic assortment: Enables a firm to influence the demands of different products quickly and increases control of product demand;

- Silent Product Rollover: Substitutable products are very desirable for handling demand fluctuations in both normal circumstances and in a supply disruption.

- -

- Sharing both risks and rewards between members of the supply chain;

- -

- The need for a high degree of interdependence along the supply chain;

- -

- Supply chain partnerships: Moving from open-market negotiations, to cooperation, to coordination and finally to collaboration. In addition to having the buyers develop flexible supply bases, suppliers (contract manufacturers, airline cargo companies, trucking companies, logistics providers) can proactively form strategic alliances with other suppliers in different countries. These partnerships can serve as a ”safety net” for each member, who will receive help from other members if a disturbance strikes;

- -

- Trust among actors, developed through effective communication, creates resources that lead to a competitive advantage and contribute significantly to the long-term stability of an organization and its supply chain;

- -

- Use RFID tags: Some retailers are pushing for auto-ID technology, such as radio frequency identification technology (RFID), to improve supply chain visibility. It can also help the supply chain reduce shrinkage, misplacement, and transaction errors.

3.2. Constructing the Multidimensional Matrix (Table of Scenarios)

3.3. Cross-Consistency Assessment

- -

- Presence of a single risk with a single RM strategy;

- -

- Presence of a single risk with several RM strategies (the actors are in conflict over the choice of the appropriate RM strategy);

- -

- Presence of several risks (more than two) (the actors choose several RM strategies).

- -

- Multimodal transport. There are companies that use a flexible logistics strategy that links between several modes of transport to prevent risks in the oceans, on roads, or in the air;

- -

- Multicarrier transport to ensure the continuity of material flows in the event of a political risk (e.g., work strikes, etc.);

- -

- Multi-route transport. Various companies are considering alternative routes to ensure the flow of material flows along the supply chain.

4. Discussion

- -

- Collective reflections which often prove to be very difficult in the absence of a common language and working method;

- -

- The counterintuitive aspects of the behavior of a system. It is not intended to accurately describe how the system works or to remove risks, but the point is to identify the main organizational elements of the system and prepare for the risks and challenges;

- -

- The design of a useful model for studying complex, unquantified problems that cannot be addressed by causal modeling, simulation and mathematical methods;

- -

- “Cross-consistency assessment (CCA),” which is an effective way to iron out vague concepts, referencing terminological differences, and assessing their internal consistency;

- -

- Creation of an audit trail by the traceability of the formulation and structure process going from the initial formulation of the problem to specific solutions or conclusions of these problems, as well by the documentation of each concept and each evaluation of cross-consistency in a model.

- -

- Summarize all the components of the logistics chain: the key risk variables, the actors involved, risks mitigation measures, and adequate preparedness measures, for better decision-making;

- -

- Choose the most appropriate strategies. Managers can then develop strategy scenarios to mitigate the risk variables of the system;

- -

- Compare different areas of “risk mitigation strategies” to determine whether a strategy of one risk variable conflicts with those of other risk variables.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gurtu, A.; Johny, J. Supply Chain Risk Management: Literature Review. Risks 2021, 9, 16. [Google Scholar] [CrossRef]

- Elmsalmi, M.; Hachicha, W.; Aljuaid, A.M. Prioritization of the Best Sustainable Supply Chain Risk Management Practices Using a Structural Analysis-Based Approach. Sustainability 2021, 13, 4608. [Google Scholar] [CrossRef]

- Li, Z.; Gulati, R.K. Supply Chain Risk Mitigation and the Application Potential of Complex Systems Approaches. In Proceedings of the 18th Asia Pacific Symposium on Intelligent and Evolutionary Systems—Volume 1, Singapore, 10–12 November 2014; Proceedings in Adaptation, Learning and Optimization Series; Handa, H., Ishibuchi, H., Ong, Y.S., Tan, K., Eds.; Springer: Cham, Switzerland, 2015; Volume 1. [Google Scholar]

- Rajagopal, V.; Venkatesan, S.P.; Goh, M. Decision-making models for supply chain risk mitigation: A review. Comput. Ind. Eng. 2017, 113, 646–682. [Google Scholar] [CrossRef]

- Yu, Y.; Xiong, W.; Cao, Y. A conceptual model of supply chain risk mitigation: The role of supply chain integration and organizational risk propensity. J. Coast. Res. 2015, 73, 95–98. [Google Scholar] [CrossRef]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and resilient garment supply chain network design with fuzzy multi-objectives under uncertainty. Sustainability 2016, 8, 1038. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Basset, M.; Mohamed, R. A novel plithogenic TOPSIS-CRITIC model for sustainable supply chain risk management. J. Clean. Prod. 2020, 247, 119586. [Google Scholar] [CrossRef]

- Lis, A.; Sudolska, A.; Tomanek, M. Mapping Research on Sustainable Supply-Chain Management. Sustainability 2020, 12, 3987. [Google Scholar] [CrossRef]

- Amer, M.; Daim, T.U.; Jetter, A. A review of scenario planning. Futures 2013, 46, 23–40. [Google Scholar] [CrossRef]

- Nordström, M.; Engholm, A. The complexity of value of travel time for self-driving vehicles—A morphological analysis. Transp. Plan. Technol. 2021, 44, 400–417. [Google Scholar] [CrossRef]

- Johansen, I. Scenario Modelling with Morphological Analysis. Technol. Forecast. Soc. Chang. 2018, 126, 116–125. [Google Scholar] [CrossRef]

- Liu, Z.; Feng, J.; Wang, J. Resource-Constrained Innovation Method for Sustainability: Application of Morphological Analysis and TRIZ Inventive Principles. Sustainability 2020, 12, 917. [Google Scholar] [CrossRef] [Green Version]

- Wissema, J.G. Morphological analysis: Its application to a company’s TF investigation. Futures 1976, 8, 146–153. [Google Scholar] [CrossRef]

- Aqlan, F.; Lam, S.S. Supply chain risk modelling and mitigation. Int. J. Prod. Res. 2015, 53, 5640–5656. [Google Scholar] [CrossRef]

- Chang, W.; Ellinger, A.E.; Blackhurst, J. A contextual approach to supply chain risk mitigation. Int. J. Logist. Manag. 2015, 26, 642–656. [Google Scholar] [CrossRef]

- Tarei, P.K.; Thakkar, J.J.; Nag, B. Benchmarking the relationship between supply chain risk mitigation strategies and practices: An integrated approach. Benchmark. Int. J. 2020, 27, 1683–1715. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, W.; Lu, J.; Wu, S.; Wang, X. Research on dynamic analysis and Mitigation Strategies of supply chains under Different Disruption Risks. Sustainability 2021, 13, 2462. [Google Scholar] [CrossRef]

- Hsu, C.-H.; Chang, A.-Y.; Zhang, T.-Y.; Lin, W.-D.; Liu, W.-L. Deploying Resilience Enablers to Mitigate Risks in Sustainable Fashion Supply Chains. Sustainability 2021, 13, 2943. [Google Scholar] [CrossRef]

- Ritchey, T. Modeling Multi-Hazard Disaster Reduction Strategies with Computer-Aided Morphological Analysis. In Proceedings of the 3rd International ISCRAM Conference, Newark, NJ, USA, 3 May 2006. [Google Scholar]

- Fernandez, A.L.; Britton, N.R.; Ritchey, T. Application of a prototype morphological model for earthquake disaster risk management. In Proceedings of the 2nd Asia Conference on Earthquake Engineering, Manila, Philippines, 10–11 March 2006. [Google Scholar]

- Jimenez, H.; Stults, I.; Mavris, D. A Morphological Approach for Proactive Risk Management in Civil Aviation Security. In Proceedings of the 47th AIAA Aerospace Sciences Meeting, Orlando, FL, USA, 5–8 January 2009. [Google Scholar]

- Akgun, I. Chapter 3: Likelihood Estimation of Intentional Events in Risk Management: Evidence Based Intelligent Morphological Analysis Approach. In Intelligent Techniques in Engineering Management: Theory and Applications, an Evolution of Morphological Analysis Applications in Systems Engineering, Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010; Jimenez, H., Mavris, D., Eds.; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Lantada, N.; Carreo, M.L.; Jaramillo, N. Disaster risk reduction: A decision-making support tool based on the morphological analysis. Int. J. Disaster Risk Reduct. 2020, 42, 101342. [Google Scholar] [CrossRef]

- Johannessen, S.A. Future Risk Scenarios of the Northern Sea Route. Master’s Thesis, Risk Management and Societal Safety, University of Stavanger, Stavanger, Norway, 15 June 2020. [Google Scholar]

- Zwicky, F. Discovery, Invention, Research—Through the Morphological Approach; The Macmillan Company: Toronto, ON, Canada, 1969. [Google Scholar]

- Álvarez, A.; Ritchey, T. Applications of General Morphological Analysis: From Engineering Design to Policy Analysis. Acta Morphol. Gen. 2015, 4. ISSN 2001-2241. Available online: https://www.researchgate.net/publication/275970050_Applications_of_General_Morphological_Analysis_From_Engineering_Design_to_Policy_Analysis (accessed on 1 November 2021).

- Seuring, S.; Sarkis, J.; Müller, M.; Rao, P. Sustainability and supply chain management an introduction to the special issue. J. Clean. Prod. 2015, 16, 1545–1551. [Google Scholar] [CrossRef]

- Krysiak, F. Risk management as a tool for sustainability. J. Bus. Ethics 2009, 85, 483–492. [Google Scholar] [CrossRef] [Green Version]

- Wenyan, S.; Xinguo, M.; Hu-Chen, L. Identifying critical risk factors of sustainable supply chain management: A rough strength-relation analysis method. J. Clean. Prod. 2016, 143, 100–115. [Google Scholar]

- Harclerode, M.A.; Macbeth, T.W.; Miller, M.E.; Gurr, C.J.; Myers, T.S. Early decision framework for integrating sustainable risk management for complex remediation sites: Drivers, barriers, and performance metrics. J. Environ. Manag. 2016, 184, 57–66. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Buddress, L. Managing Supply Chain Sustainability and Risk: Keys to Success. Int. J. Strateg. Manag. Decis. Support Syst. Strateg. Manag. 2013, 18, 3–16. [Google Scholar]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Impact of supply chain management practices on sustainability. J. Clean. Prod. 2014, 85, 212–225. [Google Scholar] [CrossRef]

- AON. Sustainability—Beyond Enterprise Risk Management. Aon Environmental Services Group; Global Corporate Marketing and Communications: Arlington, MA, USA, 2007; #2919–05/2007. [Google Scholar]

- Willard, M.; Hitchcock, D. The Business Guide to Sustainability: Practical Strategies and Tools for Organizations; Routledge: London, UK, 2009. [Google Scholar]

- Hachicha, W.; Elmsalmi, M. An integrated approach based-structural modeling for risk prioritization in supply network management. J. Risk Res. 2014, 17, 1301–1324. [Google Scholar] [CrossRef]

- Elmsalmi, M.; Hachicha, W. Risk Mitigation Strategies According to the Supply Actors’ Objectives by Using the MACTOR Method. In Proceedings of the International Conference on Advanced Logistics and Transport (ICALT’2014), Hammamet, Tunisia, 1–3 May 2014; pp. 362–367. [Google Scholar]

- Tang, C.S. Robust strategies for mitigating supply chain disruptions. Int. J. Logist. Res. Appl. Lead. J. Supply Chain. Manag. 2006, 9, 33–45. [Google Scholar] [CrossRef]

| Actors | Objectives |

|---|---|

| Consumer | Ensure the planning of deliveries |

| Retailer | Ensure the safety sanitary of products |

| Manufacturer | Ensure the availability of stocks of finished products |

| Suppliers | Assure an effective communication |

| Wholesaler | Ensure the good quality of raw materials |

| Distributor | Maintain the quality of finished products |

| Farmer | Ensure the availability of stock of raw materials |

| State | Establish suitable standards and laws and impose quality labels |

| Key Risk Variable | Actor Concerned | Risk Reduction Strategies | Adequate Mitigation Measures | Adequate Preparedness Measures |

|---|---|---|---|---|

| Late delivery | Consumer | Prevent the risk itself | Postponement | Flexible transport (multi-road/multi-modal transport/multi-transporters) |

| Partially delivered order | Retailer | Reduce severity of the risk | Strategic stock | Outsourcing |

| Out of stock products | Manufacturer | Reduce consequences | Flexible supply base | Reducing production sites |

| Production quality problems | Supplier | Reduce indirect risks related | Economic supply incentives | Planning and coordinate offer |

| Craft and manual production | Wholesaler | Risk transfer | Revenue management via dynamic pricing and promotion | Imposing quality labels to finished products |

| Forecast error | Distributor | Assortment planning | Forecasting, ERP, EDI, communication and sharing of information with the supplier | |

| Seasonal production | Farmer | Information system | Have contingency plans (row material storage) | |

| Poor harvest | State | Traceability | Support participative management style |

| Key Risk Variable | Concerned Actor 1 | Risk Reduction Strategies | Adequate Mitigation Measures | Adequate Preparedness Measures | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Late delivery | 2 Partially delivered order | 3 Out of stock products | 4 Production quality problems | 5 Craft and manual production | 6 Forecast error | 7 Seasonal productions | 8 Poor harvest | 9 Retailer | 10 Manufacturer | 11 wholesalers | 12 Supplier | 13 Prevent the risk itself | 14 Reduce severity of the risk | 15 Reduce consequences | 16 Reduce indirect risks related | 17 Risk transfer | 18 Postponement | 19 Strategic stocks | 20 Flexible supply bases | 21 Economic supply incentives | 22 Revenue management via dynamic pricing and promotion | 23 Assortment planning | 24 Information system | 25 Traceability | 26 Flexible transport (multi-road/multi-modal transport/multi-transporters) | 27 Outsourcing | 28 Reducing production sites | 29 Planning and coordinate offer | 30 Imposing quality labels | 31 Forecasting, ERP, EDI, communication | 32 Have contingency plans | 33 Support participative management style | ||

| Key risk variable | 1 | |||||||||||||||||||||||||||||||||

| 2 | ||||||||||||||||||||||||||||||||||

| 3 | ||||||||||||||||||||||||||||||||||

| 4 | ||||||||||||||||||||||||||||||||||

| 5 | ||||||||||||||||||||||||||||||||||

| 6 | ||||||||||||||||||||||||||||||||||

| 7 | ||||||||||||||||||||||||||||||||||

| 8 | ||||||||||||||||||||||||||||||||||

| Concerned actors | 9 | * | * | * | * | * | * | |||||||||||||||||||||||||||

| 10 | ||||||||||||||||||||||||||||||||||

| 11 | * | * | * | * | ||||||||||||||||||||||||||||||

| 12 | * | * | ||||||||||||||||||||||||||||||||

| Risk reduction strategies | 13 | * | * | |||||||||||||||||||||||||||||||

| 14 | * | * | * | |||||||||||||||||||||||||||||||

| 15 | * | |||||||||||||||||||||||||||||||||

| 16 | * | * | * | |||||||||||||||||||||||||||||||

| 17 | * | * | * | |||||||||||||||||||||||||||||||

| Adequate mitigation measures | 18 | * | * | * | * | * | * | * | * | * | * | |||||||||||||||||||||||

| 19 | * | * | * | * | * | * | * | * | ||||||||||||||||||||||||||

| 20 | * | * | * | * | * | * | * | * | * | * | * | * | ||||||||||||||||||||||

| 21 | * | * | * | * | * | * | * | |||||||||||||||||||||||||||

| 22 | * | * | * | * | * | * | * | * | * | |||||||||||||||||||||||||

| 23 | * | * | * | * | * | * | * | * | * | |||||||||||||||||||||||||

| 24 | * | * | * | * | * | |||||||||||||||||||||||||||||

| 25 | * | * | * | * | ||||||||||||||||||||||||||||||

| Adequate preparedness measures | 26 | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||||||||||||||

| 27 | * | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||||||||||||||||

| 28 | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||||||||||||||

| 29 | * | * | * | * | * | * | * | * | ||||||||||||||||||||||||||

| 30 | * | * | * | * | * | * | * | * | * | * | * | * | * | * | ||||||||||||||||||||

| 31 | * | * | * | * | * | * | * | * | * | * | ||||||||||||||||||||||||

| 32 | * | |||||||||||||||||||||||||||||||||

| 33 | * | * | * | * | * | |||||||||||||||||||||||||||||

| Env. Criteria | Eco. Criteria | Social. Criteria | Total | |

|---|---|---|---|---|

| Retailer | 3 | 3 | 4 | 10 |

| Distributor | 2 | 5 | 3 | 10 |

| Env. Criteria | Economic Criteria | Social Criteria | Average | ||

|---|---|---|---|---|---|

| Distributor | Information system | 5 | 5 | 4 | 4.7 |

| Traceability | 5 | 5 | 3 | 4.4 | |

| Retailer | Information system | 5 | 5 | 5 | 5 |

| Traceability | 5 | 5 | 1 | 3.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elmsalmi, M.; Hachicha, W.; Aljuaid, A.M. Modeling Sustainable Risks Mitigation Strategies Using a Morphological Analysis-Based Approach: A Real Case Study. Sustainability 2021, 13, 12210. https://doi.org/10.3390/su132112210

Elmsalmi M, Hachicha W, Aljuaid AM. Modeling Sustainable Risks Mitigation Strategies Using a Morphological Analysis-Based Approach: A Real Case Study. Sustainability. 2021; 13(21):12210. https://doi.org/10.3390/su132112210

Chicago/Turabian StyleElmsalmi, Manel, Wafik Hachicha, and Awad M. Aljuaid. 2021. "Modeling Sustainable Risks Mitigation Strategies Using a Morphological Analysis-Based Approach: A Real Case Study" Sustainability 13, no. 21: 12210. https://doi.org/10.3390/su132112210

APA StyleElmsalmi, M., Hachicha, W., & Aljuaid, A. M. (2021). Modeling Sustainable Risks Mitigation Strategies Using a Morphological Analysis-Based Approach: A Real Case Study. Sustainability, 13(21), 12210. https://doi.org/10.3390/su132112210