Thermal Behavior and Energy Efficiency of Modified Concretes in the Tropical Climate: A Systemic Review

Abstract

1. Introduction

2. Tropical Climate and Issues

2.1. Tropical Climate General Description

2.2. Urban Heat Island (UHI)

2.2.1. Factors Contributing to UHI

2.2.2. UHI in Tropical Climate

2.3. Heat Propagation Mechanisms

2.4. Building Envelope for Indoor Thermal Comfort

3. Concrete Thermal Behaviour

3.1. Thermal Conductivity

| Ref. | Mix Description | Measurement | Density, kg/m3 | k-Value, W/m °C | Referred Guideline |

|---|---|---|---|---|---|

| [82] | Self-Compacting Concrete with Perlite | Steady-state hot plate | 2227 2253 2279 2292 | 2.09430–40–0.71570–80 2.17930–40–0.76170–80 2.35530–40–0.76170–80 2.43030–40–0.79370–80 | ASTM C177 |

| [83] | Oil palm shell foamed concrete with fly ash and silica fume | Steady-state hot plate | 1156 1192 1354 1409 1506 1594 | 0.40 0.41 0.50 0.54 0.55 0.57 | BS EN12664 |

| [84] | Oil palm shell foamed geopolymer concrete with POFA and fly ash | Steady-state hot plate | 1300–1800 | 0.47–0.58 | BS EN12664 |

| [85] | Polystyrene foamed concrete | Steady-state hot plate | 150 200 250 400 | 0.0848 0.0864 0.0927 0.1566 | Not specified |

| [86] | Lightweight aggregate and glass bead | Transient hot wire | 1800 | 1.1–1.4 | ASTM D5334 |

| [87] | Lightweight aggregate concrete with diatomite and pumice | Transient hot wire | 1500 900 | 0.44 0.13 | ASTM C1113 |

| [88] | Modified waste expanded polystyrene lightweight aggregate concrete | Transient hot wire | 876–1956 | 0.6–1.99 | ASTM C1113 |

| [89] | Expanded perlite lightweight aggregate concrete with silica fume and fly ash | Transient hot wire | 509 493 485 511 498 483 | 0.1720 0.1552 0.1558 0.1676 0.1643 0.1472 | ASTM C1113 |

| [90] | Autoclaved aerated concrete | Transient plane source | 415 520 630 | 0.1–0.2 | Not specified |

3.1.1. Theoretical Model

3.1.2. Steady-State Approach

3.1.3. Transient Method

3.2. Other Thermal Behaviours

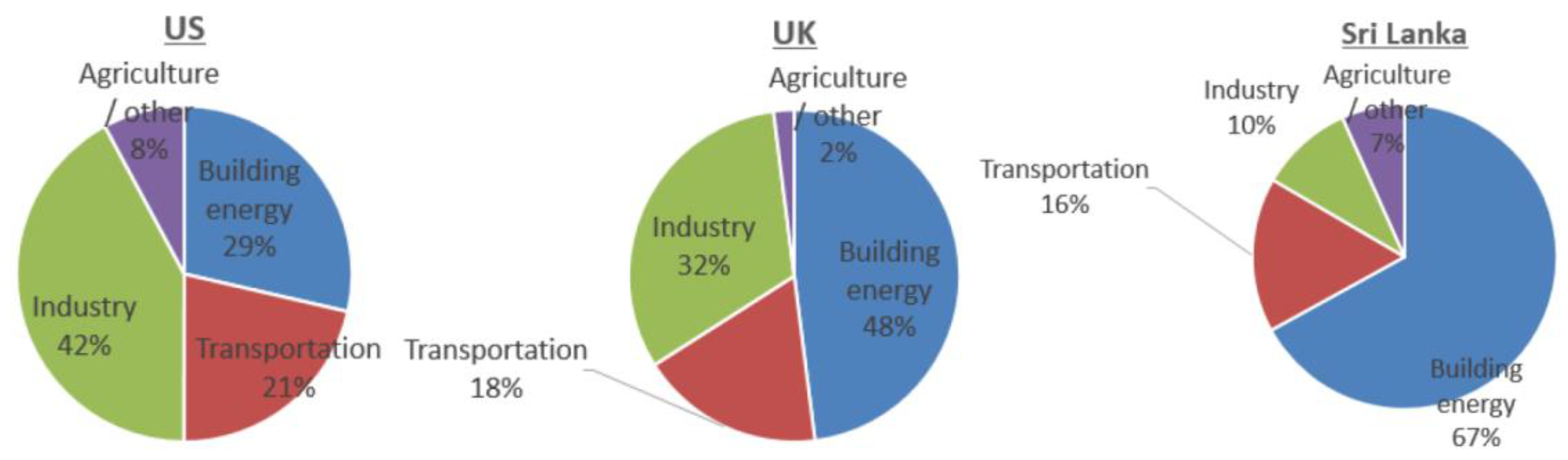

4. Energy Consumption

4.1. Sustainability in Concrete Construction

4.2. Prediction Models for Residential Energy Consumption

4.3. Concrete Properties in Energy Consumption

| Ref. | Investigated Method/Parameter | Building Performance/Prediction Model | Remark |

|---|---|---|---|

| [116] | Sensor measurements collected every 15 min | Linear Regression; Feed Forward Neural Network (FFNN); Support Vector Regression (SVR); Least Squares Support Vector Machines (LS-SVM); Hierarchical Mixture of Experts (HME) with Linear Regression Experts; HME with FFNN Experts; and Fuzzy C-Means with FFNN. | Least squares support vector machine is the best for future electrical consumption prediction |

| [117] | Building global heat loss coefficient (G), the south equivalent surface (SES), and the difference between the indoor set point temperature and the sol-air temperature | Multiple regression prediction model | Three inputs and one output, simplicity, large applicability, good match with the simulations and the energy certification calculations plus the inclusion of human behaviour correction |

| [118] | Day-ahead electricity load forecasting | Seasonal Autoregressive Integrated Moving Average | Ability to capture a variety of input factors that influence load behaviour and to enable a dynamic trade-off between them, as well as between different model parameter values |

| [119] | Total energy and total electricity consumptions | Artificial Neural Network (ANN) model, Grey models, Regression model, Polynomial Model, and Polynomial regression model | ANN is the most acceptable forecasting method |

| [120] | Different material thicknesses and insulation properties | Extreme Learning Machine (ELM) and Artificial Neural Network (ANN) | ELM algorithm can achieve the smallest training error and also normalise the weights |

| [121] | Hourly prediction of building electricity consumption | Improved Particle Swarm Optimisation algorithm (iPSO) and Genetic Algorithm Artificial Neural Networks (ANNs), iPSO-ANN, and GA-ANN | iPSO-ANN model has a shorter modelling time |

| [122] | HVAC hot water energy consumptions | Change-point regression model, Gaussian process regression model (GPM), Gaussian Mixture Regression Model (GMM), and Artificial Neural Network model (ANN) | GMR model shows slightly better statistical performance; insufficient data training of ANN results in an inaccurate prediction |

| [123] | Temperature-dependent change point model selection | Change point model | Able to select the most appropriate temperature-dependent change point model for all 48 cases tested |

| [124] | Daily residential energy use | Change-point models for residential energy use | Evaluated the differences in energy slope when compared with energy audit data; increasing the thickness of the duct insulation |

| [125] | Heating and cooling loads of residential buildings | Geometric Semantic Genetic Programming (GSGP) | Integrating a local searcher and linear scaling in GSGP can speed up the convergence of the search process |

| [126] | Whole-building energy | Three-parameter change-point regression model | 36.9% global CV (RMSE) of the initial simulation was improved to 8.8% after a calibrated simulation |

| [127] | Optimal ON/OFF status for home appliances | Lightning Search Algorithm (LSA)-based Artificial Neural Network (ANN) | Reduce the peak-hour energy consumption |

| [128] | Feasible Time-of-Use (ToU) tariffs | Gaussian Mixture Model | Grouping half-hour interval flat-rate tariffs within a day into clusters to determine ToU tariffs |

| [129] | Electricity consumption with three consumption profiles | Constrained Gaussian Mixture Model | Consumer behaviour evolves over time depending on the contextual variables |

| [130] | Weather, time of day, and previous consumption | Support Vector Regression (SVR) | Impact of temporal and spatial granularity |

| Ref. | Type of Concrete | Density, kg/m3 | Compressive Strength, MPa | Thermal Conductivity, W/mK | Specific Heat Capacity, kJ/kgK | Thermal Diffusivity, ×10−6 m2/s | Remark |

|---|---|---|---|---|---|---|---|

| [131] | Foamed concrete | - | - | FA = Fly ash, F = foam | |||

| FA0-F30 | 1346.25 | 1.62 | 0.086 | ||||

| FA10-F30 | 1403.661 | 2.76 | 0.088 | ||||

| FA20-F30 | 1489.345 | 2.93 | 0.089 | ||||

| FA30-F30 | 1524.345 | 3.505 | 0.09 | ||||

| FA0-F40 | 855.57 | 0.26 | 0.0842 | ||||

| FA10-F40 | 908.3 | 0.36 | 0.0853 | ||||

| FA20-F40 | 980.98 | 0.53 | 0.0863 | ||||

| FA30-F40 | 1010.74 | 0.62 | 0.0875 | ||||

| [115] | Different grades of normal weight concrete with different proportions, water/cement ratios, and superplasticiser contents | 2205 to 2498 | 15.8 to 62.1 | 1.6 | 1.04 | 0.69 | |

| 2.2 | 1.1 | 0.87 | |||||

| 2.5 | 1 | 1.06 | |||||

| 2.7 | 0.95 | 1.19 | |||||

| 2.4 | 1.04 | 1 | |||||

| 2.9 | 1.01 | 1.18 | |||||

| 2.3 | 0.99 | 1.02 | |||||

| 1.8 | 1.16 | 0.7 | |||||

| 2.3 | 1.03 | 0.93 | |||||

| 2.7 | 0.94 | 1.2 | |||||

| 2.4 | 1.11 | 0.94 | |||||

| 2.5 | 1.04 | 1.01 | |||||

| 3.2 | 0.95 | 1.34 | |||||

| 2.9 | 0.92 | 1.29 | |||||

| [132] | Formcrete | 650 | 0.23 | - | - | ||

| Cement:sand = 2:1 | 700 | 0.24 | |||||

| Water/cement = 0.5 | 800 | 0.26 | |||||

| 900 | 0.28 | ||||||

| 1000 | 0.31 | ||||||

| 1100 | 0.34 | ||||||

| 1200 | 0.39 | ||||||

| [133] | Concrete with expanded glass granules (GG) | - | - | GG300 = expanded glass granules 300 g GG400-S100 = expanded glass granules 300 g + sand 100 g | |||

| GG300 | 685 | 5.8 | 0.163 | ||||

| GG400 | 561 | 4.1 | 0.141 | ||||

| GG500 | 558 | 4 | 0.14 | ||||

| GG400-S100 | 523 | 3.2 | 0.138 | ||||

| GG400-S200 | 645 | 3.8 | 0.161 | ||||

| GG400-S300 | 699 | 4.5 | 0.177 |

5. Concrete in Tropical Climate

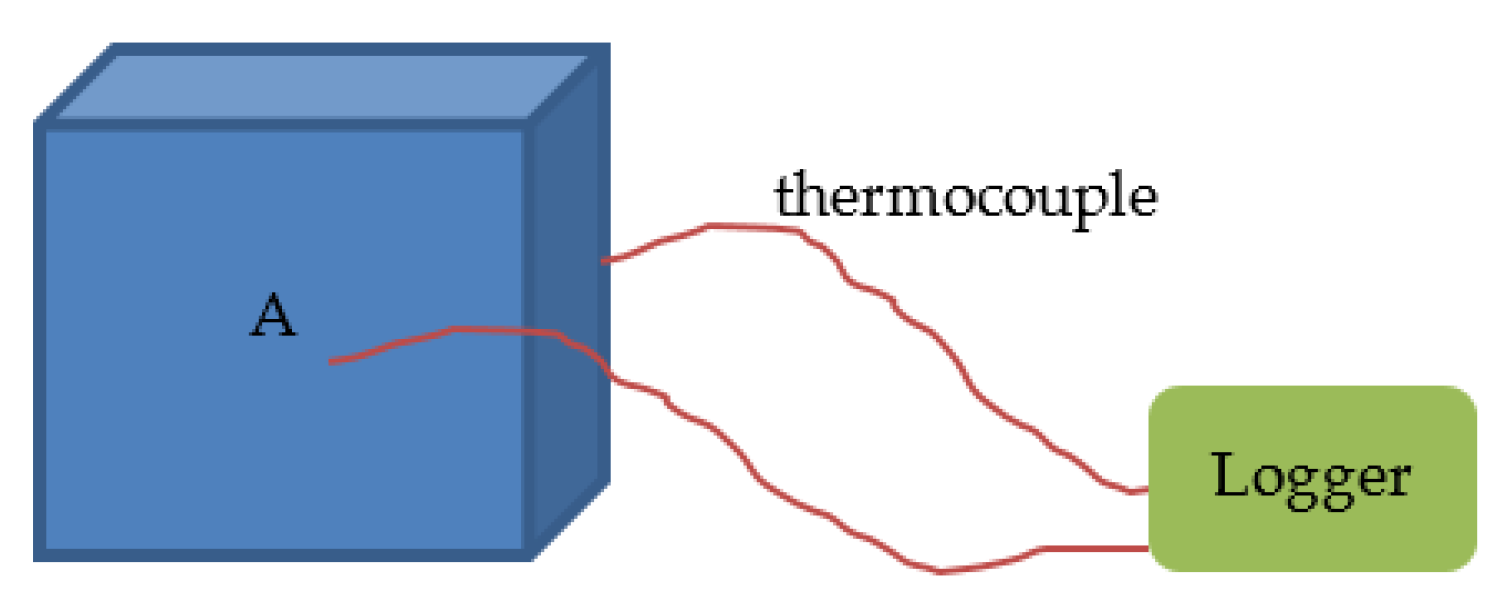

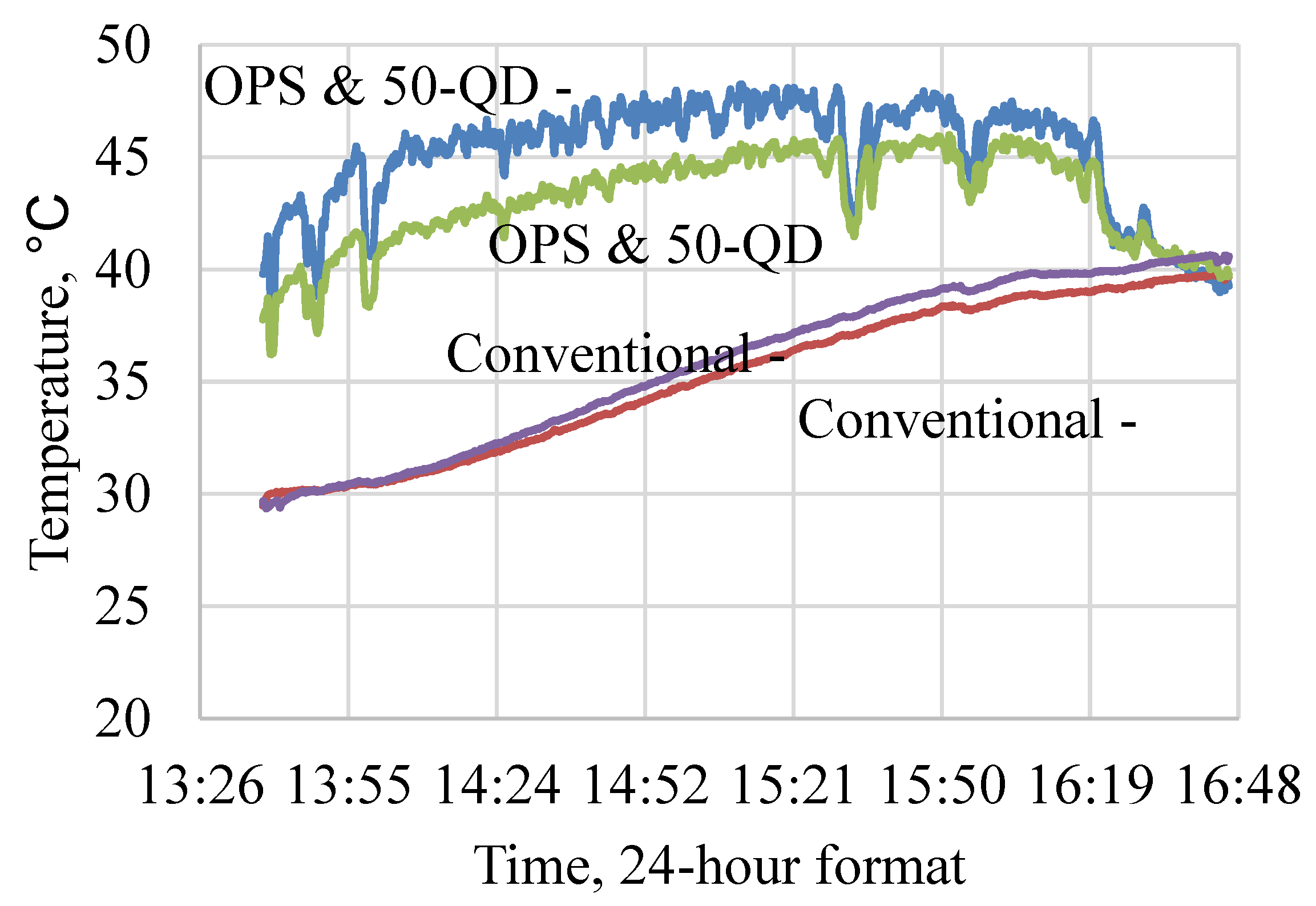

5.1. Preliminary Study

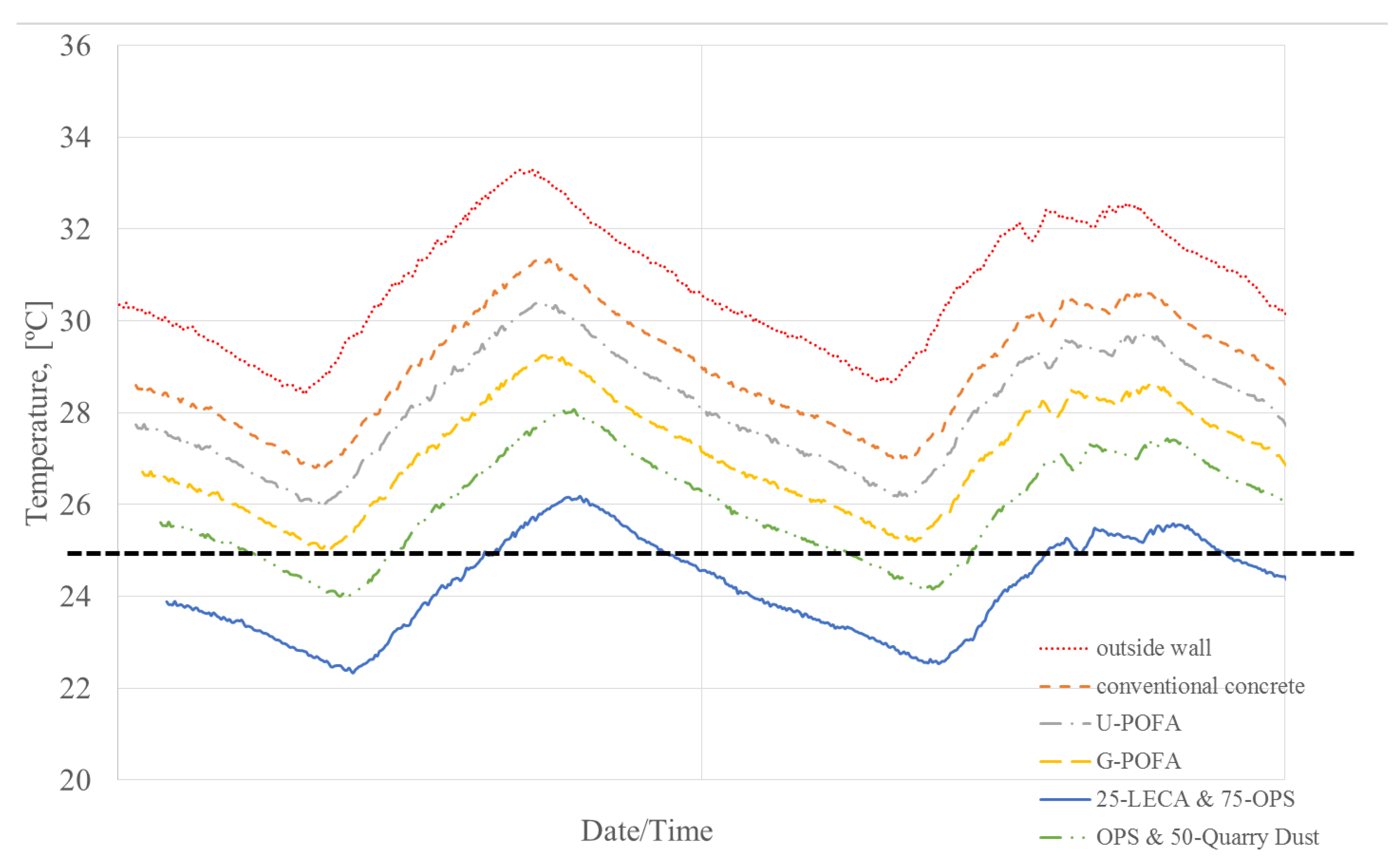

5.2. Case Study on a Residential House

5.3. Further Investigation and Application

6. Conclusions

- i.

- Temperature differences observed in UHIs of tropical countries have been highlighted.

- ii.

- The building envelope is used to maintain the indoor temperature from outside temperature fluctuation and achieve human thermal comfort. Building materials are the sources of the heat regulation for the building envelope. Heat is transferred through conduction, convection, and radiation within the envelope before reaching indoors.

- iii.

- Concrete thermal behaviours, such as thermal conductivity and thermal inertia, in terms of heat diffusivity, heat capacity, time lag, and the decrement factor can be determined and utilised for building materials to minimise heat transfer, and thus reduce energy consumption since residential energy consumption contributes predominantly to the energy consumption of the overall country.

- iv.

- Residential energy consumption remains the highest amongst all building energy expenditure performances in one tropical case study.

- v.

- Current residential energy consumption models are still under the development and are far from maturity for real scenario application. Further study is warranted.

- vi.

- Due to hot and humid weather conditions in the tropics, low specific heat and thermal conductivity are required to minimise the heat transfer through the building envelope. In other words, high time lag and a low decrement factor should be achieved for optimal energy efficiency in this weather condition.

- vii.

- From a case study of a residential house located in Johor Bahru, Malaysia, a lower density concrete with a low decrement factor displays a superior thermal performance attributed to the lowest cooling load required to maintain the indoor temperature. Reducing the consumed energy paves the way towards the sustainability of human comfort in the tropical zone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Jhatial, A.A.; Goh, W.I.; Mohamad, N.; Rind, T.A.; Sandhu, A.R. Development of Thermal Insulating Lightweight Foamed Concrete Reinforced with Polypropylene Fibres. Arab. J. Sci. Eng. 2020, 45, 4067–4076. [Google Scholar] [CrossRef]

- Shahmohamadi, P.; Che-Ani, A.I.; Maulud, K.N.A.; Tawil, N.M.; Abdullah, N.A.G. The Impact of Anthropogenic Heat on Formation of Urban Heat Island and Energy Consumption Balance. Urban Stud. Res. 2011, 2011, 497524. [Google Scholar] [CrossRef]

- Real, S.; Gomes, M.G.; Rodrigues, A.M.; Bogas, J.A. Contribution of structural lightweight aggregate concrete to the reduction of thermal bridging effect in buildings. Constr. Build. Mater. 2016, 121, 460–470. [Google Scholar] [CrossRef]

- Korsun, V.I.; Vatin, N.; Korsun, A.; Nemova, D. Physical-Mechanical Properties of the Modified Fine-Grained Concrete Subjected to Thermal Effects up to 200 °C. Appl. Mech. Mater. 2014, 633-634, 1013–1017. [Google Scholar] [CrossRef]

- Korsun, V.; Korsun, A.; Volkov, A. Characteristics of mechanical and rheological properties of concrete under heating conditions up to 200 °C. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2013. [Google Scholar] [CrossRef]

- Korsun, V.I.; Khon, K.; Ha, V.Q.; Baranov, A.O. Strength and deformations of high-strength concrete under short-term heating conditions up to + 90 °C. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020. [Google Scholar] [CrossRef]

- Garay, R.; Uriarte, A.; Apraiz, I. Performance assessment of thermal bridge elements into a full scale experimental study of a building façade. Energy Build. 2014, 85, 579–591. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S. Energy performance of residential buildings in Singapore. Energy 2010, 35, 667–678. [Google Scholar] [CrossRef]

- Zingre, K.T.; Wan, M.P.; Tong, S.; Li, H.; Chang, V.W.-C.; Wong, S.K.; Toh, W.B.T.; Lee, I.Y.L. Modeling of cool roof heat transfer in tropical climate. Renew. Energy 2015, 75, 210–223. [Google Scholar] [CrossRef]

- Lapillonne, B.; Sebi, C.; Pollier, K.; Mairet, N. Energy Efficiency Buildings in the EU Trends—Lessons from the ODYSSEE MURE Project; ADEME: Paris, France, 2012. [Google Scholar]

- Amran, M.; Fediuk, R.; Vatin, N.; Lee, Y.H.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-Reinforced Foamed Concretes: A Review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef]

- Amran, M.; Lee, Y.H.; Vatin, N.; Fediuk, R.; Poi-Ngian, S.; Lee, Y.Y.; Murali, G. Design Efficiency, Characteristics, and Utilization of Reinforced Foamed Concrete: A Review. Crystals 2020, 10, 948. [Google Scholar] [CrossRef]

- Amran, Y.M.; El-Zeadani, M.; Lee, Y.H.; Lee, Y.Y.; Murali, G.; Feduik, R. Design innovation, efficiency and applications of structural insulated panels: A review. Structures 2020, 27, 1358–1379. [Google Scholar] [CrossRef]

- Bierregaard, R.O., Jr.; Lovejoy, T.E.; Kapos, V.; dos Santos, A.A.; Hutchings, R.W. The biological dynamics of tropical rainforest fragments: A prospective comparison of fragments and continuous forest. Bioscience 1992, 42, 859–866. [Google Scholar] [CrossRef]

- McKnight, T.L. Climate zones and types. Phys. Geogr. Landsc. Apprec. 2000, 42, 859–866. [Google Scholar]

- Iwai, C.B.; Oo, A.N.; Topark-Ngarm, B. Soil property and microbial activity in natural salt affected soils in an alternating wet–dry tropical climate. Geoderma 2012, 189-190, 144–152. [Google Scholar] [CrossRef]

- Masumoto, K. Urban heat islands. In Environmental Indicators; Springer: Dordrecht, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Ghazanfari, S.; Naseri, M.; Faridani, F.; Aboutorabi, H.; Farid, A. Evaluating the effects of UHI on climate parameters (A case study for Mashhad, Khorrasan). WSEAS Trans. Environ. Dev. 2009, 5, 508–517. [Google Scholar]

- Din, M.F.M.; Lee, Y.Y.; Ponraj, M.; Ossen, D.R.; Iwao, K.; Chelliapan, S. Thermal comfort of various building layouts with a proposed discomfort index range for tropical climate. J. Therm. Biol. 2014, 41, 6–15. [Google Scholar] [CrossRef]

- Zong-Ci, Z.; Yong, L.; Jian-Bin, H. Are There Impacts of Urban Heat Island on Future Climate Change? Adv. Clim. Chang. Res. 2013, 4, 133–136. [Google Scholar] [CrossRef]

- Morris, K.I.; Chan, A.; Morris, K.J.K.; Ooi, M.C.G.; Oozeer, M.Y.; Abakr, Y.A.; Nadzir, M.S.M.; Mohammed, I.Y.; Al-Qrimli, H.F. Impact of urbanization level on the interactions of urban area, the urban climate, and human thermal comfort. Appl. Geogr. 2017, 79, 50–72. [Google Scholar] [CrossRef]

- Ooi, M.; Chan, A.; Ashfold, M.; Morris, K.; Oozeer, M.; Salleh, S.A. Numerical study on effect of urban heating on local climate during calm inter-monsoon period in greater Kuala Lumpur, Malaysia. Urban Clim. 2017, 20, 228–250. [Google Scholar] [CrossRef]

- Wang, K.; Aktas, Y.D.; Stocker, J.; Carruthers, D.; Hunt, J.; Malki-Epshtein, L. Urban heat island modelling of a tropical city: Case of Kuala Lumpur. Geosci. Lett. 2019, 6, 4. [Google Scholar] [CrossRef]

- Ahmad, S.; Hashim, N.M. Effects of Soil Moisture on Urban Heat Island Occurrences: Case of Selangor, Malaysia. Humanit. Soc. Sci. J. 2007, 2, 132–138. [Google Scholar]

- Yusuf, Y.A.; Pradhan, B.; Idrees, M.O. Spatio-temporal Assessment of Urban Heat Island Effects in Kuala Lumpur Metropolitan City Using Landsat Images. J. Indian Soc. Remote Sens. 2014, 42, 829–837. [Google Scholar] [CrossRef]

- Rahaman, S.; Jahangir, S.; Haque, S.; Chen, R.; Kumar, P. Spatio-temporal changes of green spaces and their impact on urban environment of Mumbai, India. Environ. Dev. Sustain. 2021, 23, 6481–6501. [Google Scholar] [CrossRef]

- Tso, C.; Chan, B.; Hashim, M.A. An improvement to the basic energy balance model for urban thermal environment analysis. Energy Build. 1990, 14, 143–152. [Google Scholar] [CrossRef]

- Tso, C. A survey of urban heat island studies in two tropical cities. Atmos. Environ. 1996, 30, 507–519. [Google Scholar] [CrossRef]

- Elsayed, I.S.M. Mitigation of the urban heat island of the city of Kuala Lumpur, Malaysia. Middle East J. Sci. Res. 2012, 11, 1602–1613. [Google Scholar] [CrossRef]

- Elsayed, I.S.M. International, the Effects of Urbanization on the Intensity of the Urban Heat Island: A Case Study on the City of Kuala Lumpur. Ph.D. Thesis, International Islamic University, Ampang Jaya, Malaysia, 2006. [Google Scholar]

- Elsayed, I.S.M. The Effects of Urbanization on the Intensity of the Urban Heat Island of Kuala Lumpur City. Ph.D. Thesis, International Islamic University, Ampang Jaya, Malaysia, 2012. [Google Scholar]

- Elsayed, I.S.M. Effects of Population Density and Land Management on the Intensity of Urban Heat Islands: A Case Study on the City of Kuala Lumpur, Malaysia. Appl. Geogr. Inf. Syst. 2012, 8, 267–283. [Google Scholar] [CrossRef]

- Elsayed, I.S.M. A Study on the Urban Heat Island of the City of Kuala Lumpur, Malaysia. J. King Abdulaziz Univ. Meteorol. Environ. Arid Land Agric. Sci. 2012, 23, 121–134. [Google Scholar] [CrossRef]

- Wong, N.H.; Yu, C. Study of green areas and urban heat island in a tropical city. Habitat Int. 2005, 29, 547–558. [Google Scholar] [CrossRef]

- Kotharkar, R.; Ramesh, A.; Bagade, A. Urban Heat Island studies in South Asia: A critical review. Urban Clim. 2018, 24, 1011–1026. [Google Scholar] [CrossRef]

- Salleh, S.A.; Abd.Latif, Z.; Mohd, W.M.N.W.; Chan, A. Factors Contributing to the Formation of an Urban Heat Island in Putrajaya, Malaysia. Procedia Soc. Behav. Sci. 2013, 105, 840–850. [Google Scholar] [CrossRef]

- Morris, K.I.; Salleh, S.A.; Chan, A.; Ooi, M.C.G.; Abakr, Y.A.; Oozeer, M.Y.; Duda, M. Computational study of urban heat island of Putrajaya, Malaysia. Sustain. Cities Soc. 2015, 19, 359–372. [Google Scholar] [CrossRef]

- Amanollahi, J.; Tzanis, C.; Ramli, M.F.; Abdullah, A.M. Urban heat evolution in a tropical area utilizing Landsat imagery. Atmos. Res. 2016, 167, 175–182. [Google Scholar] [CrossRef]

- Shaharuddin, A.; Noorazuan, M.H.; Takeuchi, W.; Noraziah, A. The effects of Urban Heat Islands on Human Comfort: A case of Klang Valley Malaysia. Glob. J. Adv. Pure Appl. Sci. 2014, 2, 268–293. [Google Scholar]

- Amorim, M.C.D.C.T.; Dubreuil, V. Intensity of Urban Heat Islands in Tropical and Temperate Climates. Climate 2017, 5, 91. [Google Scholar] [CrossRef]

- Molina, L.E.T.; Morales, S.; Carrión, L.F. Urban Heat Island Effects in Tropical Climate. In Vortex Dynamics Theories and Applications; Harun, Z., Ed.; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Bi, Z. Applications—Heat Transfer Problems. In Finite Element Analysis Applications; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Dahoo, P.R.; Khettab, M.; Chong, C.; Girard, A.; Pougnet, P. Impact of Voids in Interconnection Materials. In Embedded Mechatronic Systems 2; Elsevier: Amsterdam, The Netherlands, 2015; pp. 79–106. [Google Scholar] [CrossRef]

- Šadauskiene, J.; Buska, A.; Burlingis, A.; Bliudzius, R.; Gailius, A. The Effect of Vertical Air Gaps to Thermal Transmittance of Horizontal Thermal Insulating Layer. J. Civ. Eng. Manag. 2009, 15, 309–315. [Google Scholar] [CrossRef]

- Alyasari, H.I.; Ameen, R.F.M.; Altaweel, M.D. Thermal Performance through the Use of Radiant Barrier and Phase Change Material in Concrete Flat Roofs. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar] [CrossRef]

- Mohamed, H.; Chang, J.D.; Alshayeb, M. Effectiveness of High Reflective Roofs in Minimizing Energy Consumption in Residential Buildings in Iraq. Procedia Eng. 2015, 118, 879–885. [Google Scholar] [CrossRef]

- Asadi, S.; Hassan, M.M. Evaluation of the thermal performance of a roof-mounted radiant barrier in residential buildings: Experimental study. J. Build. Phys. 2013, 38, 66–80. [Google Scholar] [CrossRef]

- Michels, C.; Lamberts, R.; Guths, S. Evaluation of heat flux reduction provided by the use of radiant barriers in clay tile roofs. Energy Build. 2008, 40, 445–451. [Google Scholar] [CrossRef]

- Zhang, Y.; Long, E.; Li, Y.; Li, P. Solar radiation reflective coating material on building envelopes: Heat transfer analysis and cooling energy saving. Energy Explor. Exploit. 2017, 35, 748–766. [Google Scholar] [CrossRef]

- Field, C.B.; Barros, V.R.; Mastrandrea, M.D.; Mach, K.J.; Abdrabo, M.K.; Adger, N.; Yohe, G.W. Summary for policymakers. In Climate Change 2014: Impacts, Adaptation, and Vulnerability. Part A: Global and Sectoral Aspects. Contribution of Working Group II to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2014; pp. 1–32. [Google Scholar]

- Capozzoli, A.; Gorrino, A.; Corrado, V. A building thermal bridges sensitivity analysis. Appl. Energy 2013, 107, 229–243. [Google Scholar] [CrossRef]

- Kontoleon, K.; Eumorfopoulou, E. The influence of wall orientation and exterior surface solar absorptivity on time lag and decrement factor in the Greek region. Renew. Energy 2008, 33, 1652–1664. [Google Scholar] [CrossRef]

- Ruivo, C.R.; Ferreira, P.M.; Vaz, D.C. On the error of calculation of heat gains through walls by methods using constant decrement factor and time lag values. Energy Build. 2013, 60, 252–261. [Google Scholar] [CrossRef]

- Yumrutaş, R.; Ünsal, M.; Kanoğlu, M. Periodic solution of transient heat flow through multilayer walls and flat roofs by complex finite Fourier transform technique. Build. Environ. 2005, 40, 1117–1125. [Google Scholar] [CrossRef]

- Lee, Y.; Chua, N.; Amran, M.; Lee, Y.Y.; Kueh, A.H.; Fediuk, R.; Vatin, N.; Vasilev, Y. Thermal Performance of Structural Lightweight Concrete Composites for Potential Energy Saving. Crystals 2021, 11, 461. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.; Murali, G.; Vatin, N.; Klyuev, S.; Ozbakkaloglu, T.; Vasilev, Y. Use of Recycled Concrete Aggregates in Production of Green Cement-Based Concrete Composites: A Review. Crystals 2021, 11, 232. [Google Scholar] [CrossRef]

- Tolstoy, A.; Lesovik, V.; Fediuk, R.; Amran, M.; Gunasekaran, M.; Vatin, N.; Vasilev, Y. Production of Greener High-Strength Concrete Using Russian Quartz Sandstone Mine Waste Aggregates. Materials 2020, 13, 5575. [Google Scholar] [CrossRef] [PubMed]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; Alaskar, A.; Alrshoudi, F. Properties and water penetration of structural concrete wrapped with CFRP. Results Eng. 2020, 5, 100094. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Khalid, N.H.A.; Fediuk, R.; Ozbakkaloglu, T.; Lee, Y.H.; Haruna, S.; Lee, Y.Y. Slag uses in making an ecofriendly and sustainable concrete: A review. Constr. Build. Mater. 2021, 272, 121942. [Google Scholar] [CrossRef]

- Sabapathy, L.; Mohammed, B.S.; Al-Fakih, A.; A Wahab, M.M.; Liew, M.S.; Amran, Y.H.M. Acid and Sulphate Attacks on a Rubberized Engineered Cementitious Composite Containing Graphene Oxide. Materials 2020, 13, 3125. [Google Scholar] [CrossRef] [PubMed]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Amran, Y.M.; Soto, M.G.; Alyousef, R.; El-Zeadani, M.; Alabduljabbar, H.; Aune, V. Performance investigation of high-proportion Saudi-fly-ash-based concrete. Results Eng. 2020, 6, 100118. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Fediuk, R.; Vatin, N.; Vasilev, Y.; Abdelgader, H. Palm Oil Fuel Ash-Based Eco-Efficient Concrete: A Critical Review of the Short-Term Properties. Materials 2021, 14, 332. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Johari, M.A.M.; Alharbi, Y.R.; Abadel, A.A.; Amran, Y.M.; Tayeh, B.A.; Abutaleb, A. Influence of steam curing regimes on the properties of ultrafine POFA-based high-strength green concrete. J. Build. Eng. 2021, 38, 102204. [Google Scholar] [CrossRef]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Siddika, A.; Amin, R.; Rayhan, A.; Islam, S.; Al Mamun, A.; Alyousef, R.; Amran, Y.H.M. Performance of sustainable green concrete incorporated with fly ash, rice husk ash, and stone dust. Acta Polytech. 2021, 61, 279–291. [Google Scholar] [CrossRef]

- Gomes, M.G.; Flores-Colen, I.; Manga, L.; Soares, A.; de Brito, J. The influence of moisture content on the thermal conductivity of external thermal mortars. Constr. Build. Mater. 2017, 135, 279–286. [Google Scholar] [CrossRef]

- Taoukil, D.; El Bouardi, A.; Sick, F.; Mimet, A.; Ezbakhe, H.; Ajzoul, T. Moisture content influence on the thermal conductivity and diffusivity of wood-concrete composite. Constr. Build. Mater. 2013, 48, 104–115. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H. Determination of Structural Behavior of Precast Foamed Concrete Sandwich Panel. Ph.D. Thesis, Universiti Putra Malaysia (UPM), Ampang Jaya, Malaysia, 2016. [Google Scholar]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; Alrshoudi, F.; Rashid, R.S.M. Influence of slenderness ratio on the structural performance of lightweight foam concrete composite panel. Case Stud. Constr. Mater. 2019, 10, e00226. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Rashid, R.S.M.; Hejazi, F.; Ali, A.A.A.; Safiee, N.A.; Bida, S.M. Structural Performance of Precast Foamed Concrete Sandwich Panel Subjected to Axial Load. KSCE J. Civ. Eng. 2017, 22, 1179–1192. [Google Scholar] [CrossRef]

- Amran, Y.M.; Rashid, R.S.; Hejazi, F.; Safiee, N.A.; Ali, A.A. Response of precast foamed concrete sandwich panels to flexural loading. J. Build. Eng. 2016, 7, 143–158. [Google Scholar] [CrossRef]

- Saheed, S.; Aziz, F.; Amran, M.; Vatin, N.; Fediuk, R.; Ozbakkaloglu, T.; Murali, G.; Mosaberpanah, M. Structural Performance of Shear Loaded Precast EPS-Foam Concrete Half-Shaped Slabs. Sustainability 2020, 12, 9679. [Google Scholar] [CrossRef]

- Rudenko, A.; Biryukov, A.; Kerzhentsev, O.; Fediuk, R.; Vatin, N.; Vasilev, Y.; Klyuev, S.; Amran, M.; Szelag, M. Nano- and Micro-Modification of Building Reinforcing Bars of Various Types. Crystals 2021, 11, 323. [Google Scholar] [CrossRef]

- Pásztory, Z.; Horváth, T.; Glass, S.V.; Zelinka, S. Experimental investigation of the influence of temperature on thermal conductivity of multilayer reflective thermal insulation. Energy Build. 2018, 174, 26–30. [Google Scholar] [CrossRef]

- Vosteen, H.-D.; Schellschmidt, R. Influence of temperature on thermal conductivity, thermal capacity and thermal diffusivity for different types of rock. Phys. Chem. Earth Parts A B C 2003, 28, 499–509. [Google Scholar] [CrossRef]

- Fediuk, R.; Amran, M.; Vatin, N.; Vasilev, Y.; Lesovik, V.; Ozbakkaloglu, T. Acoustic Properties of Innovative Concretes: A Review. Materials 2021, 14, 398. [Google Scholar] [CrossRef] [PubMed]

- Fedyuk, R.; Baranov, A.; Amran, Y.M. Effect of porous structure on sound absorption of cellular concrete. Constr. Mater. Prod. 2020, 3, 5–18. [Google Scholar] [CrossRef]

- Amran, Y.H.M. Influence of structural parameters on the properties of fibred-foamed concrete. Innov. Infrastruct. Solut. 2020, 5, 1–18. [Google Scholar] [CrossRef]

- Lesovik, V.; Chernysheva, N.; Fediuk, R.; Amran, M.; Murali, G.; de Azevedo, A.R. Optimization of fresh properties and durability of the green gypsum-cement paste. Constr. Build. Mater. 2021, 287, 123035. [Google Scholar] [CrossRef]

- Asadi, I.; Shafigh, P.; Bin Abu Hassan, Z.F.; Mahyuddin, N.B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Gandage, A.S.; Rao, V.V.; Sivakumar, M.; Vasan, A.; Venu, M.; Yaswanth, A. Effect of Perlite on Thermal Conductivity of Self Compacting Concrete. Procedia Soc. Behav. Sci. 2013, 104, 188–197. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Al Muhit, B.A.; bin Jumaat, M.Z.; Jing, M.L.Y. A comparison of the thermal conductivity of oil palm shell foamed concrete with conventional materials. Mater. Des. 2013, 51, 522–529. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 2014, 72, 238–245. [Google Scholar] [CrossRef]

- Sayadi, A.A.; Tapia, J.V.; Neitzert, T.R.; Clifton, G.C. Effects of expanded polystyrene (EPS) particles on fire resistance, thermal conductivity and compressive strength of foamed concrete. Constr. Build. Mater. 2016, 112, 716–724. [Google Scholar] [CrossRef]

- Yun, T.S.; Jeong, Y.J.; Han, T.-S.; Youm, K.-S. Evaluation of thermal conductivity for thermally insulated concretes. Energy Build. 2013, 61, 125–132. [Google Scholar] [CrossRef]

- Topçu, I.B.; Uygunoğlu, T. Properties of autoclaved lightweight aggregate concrete. Build. Environ. 2007, 42, 4108–4116. [Google Scholar] [CrossRef]

- Demirboğa, R.; Kan, A. Thermal conductivity and shrinkage properties of modified waste polystyrene aggregate concretes. Constr. Build. Mater. 2012, 35, 730–734. [Google Scholar] [CrossRef]

- Demirboǧa, R.; Gül, R. Thermal conductivity and compressive strength of expanded perlite aggregate concrete with mineral admixtures. Energy Build. 2003, 35, 1155–1159. [Google Scholar] [CrossRef]

- Jin, H.-Q.; Yao, X.-L.; Fan, L.-W.; Xu, X.; Yu, Z.-T. Experimental determination and fractal modeling of the effective thermal conductivity of autoclaved aerated concrete: Effects of moisture content. Int. J. Heat Mass Transf. 2016, 92, 589–602. [Google Scholar] [CrossRef]

- Cavanaugh, K.; Speck, J.F. Guide to Thermal Properties of Concrete and Masonry Systems Reported; ACI Committee 122, Concrete; ACI Committee: Farmington Hills, MI, USA, 2002. [Google Scholar]

- ASTM:C1363-97. Standard Test Method for the Thermal Performance of Building Assemblies; Means of a Hot Box Apparatus 1, C1363-97; ASTM: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Belkharchouche, D.; Chaker, A. Effects of moisture on thermal conductivity of the lightened construction material. Int. J. Hydrog. Energy 2016, 41, 7119–7125. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate; ASTM Stand. C177-13; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar] [CrossRef]

- Maglić, K.D.; Cezairliyan, A.; Peletsky, V.E. Compendium of Thermophysical Property Measurement Methods: Volume 2 Recommended Measurement Techniques and Practices; Springer: Berlin/Heidelberg, Germany, 1992. [Google Scholar] [CrossRef]

- Wongkeo, W.; Thongsanitgarn, P.; Pimraksa, K.; Chaipanich, A. Compressive strength, flexural strength and thermal conductivity of autoclaved concrete block made using bottom ash as cement replacement materials. Mater. Des. 2012, 35, 434–439. [Google Scholar] [CrossRef]

- Collet, F.; Pretot, S. Thermal conductivity of hemp concretes: Variation with formulation, density and water content. Constr. Build. Mater. 2014, 65, 612–619. [Google Scholar] [CrossRef]

- Bederina, M.; Marmoret, L.; Mezreb, K.; Khenfer, M.; Bali, A.; Quéneudec, M. Effect of the addition of wood shavings on thermal conductivity of sand concretes: Experimental study and modelling. Constr. Build. Mater. 2007, 21, 662–668. [Google Scholar] [CrossRef]

- Fathipour, R.; Hadidi, A. Analytical solution for the study of time lag and decrement factor for building walls in climate of Iran. Energy 2017, 134, 167–180. [Google Scholar] [CrossRef]

- Baggs, D. Thermal Mass and Its Role in Building Comfort and Energy Efficiency, Technical Guide; EcoSpecifier: Cannon Hill, Australia, 2013. [Google Scholar]

- Marshall, A. The thermal properties of concrete. Build. Sci. 1972, 7, 167–174. [Google Scholar] [CrossRef]

- Kodur, V. Properties of Concrete at Elevated Temperatures. ISRN Civ. Eng. 2014, 2014, 468510. [Google Scholar] [CrossRef]

- Ahuja, A.; Mosalam, K.M. Evaluating energy consumption saving from translucent concrete building envelope. Energy Build. 2017, 153, 448–460. [Google Scholar] [CrossRef]

- Gan, W.; Cao, Y.; Jiang, W.; Li, L.; Li, X. Energy-Saving Design of Building Envelope Based on Multiparameter Optimization. Math. Probl. Eng. 2019, 2019, 5261869. [Google Scholar] [CrossRef]

- Shehadi, M. Energy Consumption Optimization Measures for Buildings in the Midwest Regions of USA. Buildings 2018, 8, 170. [Google Scholar] [CrossRef]

- Ghabra, N.; Rodrigues, L.; Oldfield, P. The impact of the building envelope on the energy efficiency of residential tall buildings in Saudi Arabia. Int. J. Low Carbon Technol. 2017, 12, 411–419. [Google Scholar] [CrossRef]

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. A Comparative Simulation Study of the Thermal Performances of the Building Envelope Wall Materials in the Tropics. Sustainability 2020, 12, 4892. [Google Scholar] [CrossRef]

- Bentz, D.P.; Turpin, R. Potential applications of phase change materials in concrete technology. Cem. Concr. Compos. 2007, 29, 527–532. [Google Scholar] [CrossRef]

- Adesina, A. Use of phase change materials in concrete: Current challenges. Renew. Energy Environ. Sustain. 2019, 4, 9. [Google Scholar] [CrossRef]

- Drissi, S.; Ling, T.-C.; Mo, K.H. Thermal performance of a solar energy storage concrete panel incorporating phase change material aggregates developed for thermal regulation in buildings. Renew. Energy 2020, 160, 817–829. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; Khudhair, M.H.R.; Hejazi, F.; Alaskar, A.; Alrshoudi, F.; Siddika, A. Performance properties of structural fibred-foamed concrete. Results Eng. 2020, 5, 100092. [Google Scholar] [CrossRef]

- Tay, L.T.; Lee, Y.Y.; Lee, Y.H.; Kueh, A.B.H. Compressive and Flexural Strengths of Mortar with Silica Aerogel Powder. In Proceedings of the International Conference on Civil, Offshore and Environmental Engineering; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Lee, Y.H.; Lim, M.H.; Lee, Y.L.; Lee, Y.Y.; Tan, C.S.; Mohammad, S.; Ma, C.K. Compressive strength of lightweight foamed concrete with charcoal as a sand replacement. Indian J. Eng. Mater. Sci. 2018, 25, 98–108. [Google Scholar] [CrossRef]

- Do, H.; Cetin, K.S. Residential Building Energy Consumption: A Review of Energy Data Availability, Characteristics, and Energy Performance Prediction Methods. Curr. Sustain. Energy Rep. 2018, 5, 76–85. [Google Scholar] [CrossRef]

- Talebi, H.R.; Kayan, B.A.; Asadi, I.; Hassan, Z.F.B.A. Investigation of thermal properties of normal weight concrete for different strength classes. J. Environ. Treat. Tech. 2020, 8, 908–914. [Google Scholar]

- Edwards, R.E.; New, J.; Parker, L.E. Predicting future hourly residential electrical consumption: A machine learning case study. Energy Build. 2012, 49, 591–603. [Google Scholar] [CrossRef]

- Catalina, T.; Iordache, V.; Caracaleanu, B. Multiple regression model for fast prediction of the heating energy demand. Energy Build. 2013, 57, 302–312. [Google Scholar] [CrossRef]

- Jetcheva, J.G.; Majidpour, M.; Chen, W.-P. Neural network model ensembles for building-level electricity load forecasts. Energy Build. 2014, 84, 214–223. [Google Scholar] [CrossRef]

- Farzana, S.; Liu, M.; Baldwin, A.; Hossain, U. Multi-model prediction and simulation of residential building energy in urban areas of Chongqing, South West China. Energy Build. 2014, 81, 161–169. [Google Scholar] [CrossRef]

- Naji, S.; Keivani, A.; Shamshirband, S.; Alengaram, U.J.; Jumaat, M.Z.; Mansor, Z.; Lee, M. Estimating building energy consumption using extreme learning machine method. Energy 2016, 97, 506–516. [Google Scholar] [CrossRef]

- Li, K.; Hu, C.; Liu, G.; Xue, W. Building’s electricity consumption prediction using optimized artificial neural networks and principal component analysis. Energy Build. 2015, 108, 106–113. [Google Scholar] [CrossRef]

- Zhang, Y.; O’Neill, Z.; Dong, B.; Augenbroe, G. Comparisons of inverse modeling approaches for predicting building energy performance. Build. Environ. 2015, 86, 177–190. [Google Scholar] [CrossRef]

- Paulus, M.T.; Claridge, D.E.; Culp, C. Algorithm for automating the selection of a temperature dependent change point model. Energy Build. 2015, 87, 95–104. [Google Scholar] [CrossRef]

- Perez, K.X.; Cetin, K.; Baldea, M.; Edgar, T.F. Development and analysis of residential change-point models from smart meter data. Energy Build. 2017, 139, 351–359. [Google Scholar] [CrossRef]

- Castelli, M.; Trujillo, L.; Vanneschi, L.; Popovič, A. Prediction of energy performance of residential buildings: A genetic programming approach. Energy Build. 2015, 102, 67–74. [Google Scholar] [CrossRef]

- Kim, K.H.; Haberl, J.S. Development of methodology for calibrated simulation in single-family residential buildings using three-parameter change-point regression model. Energy Build. 2015, 99, 140–152. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Mohamed, A.; Homod, R.Z.; Shareef, H. Hybrid LSA-ANN Based Home Energy Management Scheduling Controller for Residential Demand Response Strategy. Energies 2016, 9, 716. [Google Scholar] [CrossRef]

- Li, R.; Wang, Z.; Gu, C.; Li, F.; Wu, H. A novel time-of-use tariff design based on Gaussian Mixture Model. Appl. Energy 2016, 162, 1530–1536. [Google Scholar] [CrossRef]

- Melzi, F.N.; Same, A.; Zayani, M.H.; Oukhellou, L. A Dedicated Mixture Model for Clustering Smart Meter Data: Identification and Analysis of Electricity Consumption Behaviors. Energies 2017, 10, 1446. [Google Scholar] [CrossRef]

- Jain, R.K.; Smith, K.M.; Culligan, P.J.; Taylor, J.E. Forecasting energy consumption of multi-family residential buildings using support vector regression: Investigating the impact of temporal and spatial monitoring granularity on performance accuracy. Appl. Energy 2014, 123, 168–178. [Google Scholar] [CrossRef]

- Habsya, C.; Diharjo, K.; Setyono, P.; Satwiko, P. Physical, mechanical and thermal properties of lightweight foamed concrete with fly ash. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar] [CrossRef]

- Mydin, M.A.O. Effective thermal conductivity of foamcrete of different densities. Concr. Res. Lett. 2011, 2, 181–189. [Google Scholar]

- Bumanis, G.; Bajare, D.; Korjakins, A. Mechanical and Thermal Properties of Lightweight Concrete Made from Expanded Glass. J. Sustain. Arch. Civ. Eng. 2013, 2, 19–25. [Google Scholar] [CrossRef]

- Amran, Y.M.; Rashid, R.S.; Hejazi, F.; Safiee, N.A.; Ali, A.A. Structural behavior of laterally loaded precast foamed concrete sandwich panel. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2016, 10, 255–263. [Google Scholar]

- Chua, N. Thermal Performance of Lightweight Concrete; Curtin University Malaysia: Sarawak, Malaysia, 2020. [Google Scholar]

- Lee, Y.Y.; Lee, Y.H.; Mohammad, S.; Shek, P.N.; Ma, C.K. Thermal characteristics of a residential house in a new township in Johor Bahru. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017. [Google Scholar] [CrossRef]

| Tropical Rainforest [14] | Tropical Monsoon [15] | Savanna [16] | |

|---|---|---|---|

| Location | North and south latitudinal ranges of 5–10 degrees from the equator | Between the latitude of 10 degrees north and the Tropic of Cancer | Between 10° and 20° north–south latitude |

| Average temperature | 21–30 °C | 27.1 °C ± 3.6 °C | 20–30 °C |

| Total precipitation | 2540 mm | 3409.2 mm | 700–1000 mm |

| Ref. | Country | Area | Year of Assessment | Method | Temperature Difference, °C |

|---|---|---|---|---|---|

| [34] | Singapore | Singapore | July–September, 2002 | Temperature traverse | AT–4.01 |

| [36] | Malaysia | Putrajaya | 1999–2009 | Satellite | ST–6.75 |

| [37] | Malaysia | Putrajaya | 2012 | Numerical simulation | AT–3.10 |

| [38] | Malaysia | Klang | 2000 & 2010 | Satellite | ST–21.50 & ST–22.70 |

| [39] | Malaysia | Kuala Lumpur | 2008–2009 | Satellite & GIS | ST–14.50 |

| [33] | Malaysia | Kuala Lumpur | 2004 | Temperature traverse & weather stations | AT–5.50 |

| [40] | Brazil | Presidente Prudente | 2016 | Weather station | AT–2.40 (mean), 4.10 (monthly), 6.40 (hourly) |

| [41] | US | Puerto Rico | 2008–2018 | Weather station | 2.06–3.04 |

| Material | Density kg/m3 | Specific Heat, kJ/kg.K | Thermal Mass, kJ/m3.K | Time Lag | |

|---|---|---|---|---|---|

| Hour | Thickness, mm | ||||

| Water | 1000 | 4.186 | 4186 | - | - |

| Concrete | 2240 | 0.920 | 2060 | 6.9 | 250 |

| AAC | 500 | 1.100 | 550 | 7.0 | 200 |

| Brick | 1700 | 0.920 | 1360 | 5.0 | 125 |

| Sand stone | 2000 | 0.900 | 1800 | - | - |

| Compressed FC sheet | 1700 | 0.900 | 1530 | - | - |

| Earth wall (Adobe) | 1550 | 0.837 | 1300 | 9.2 | 250 |

| Rammed earth | 2000 | 0.837 | 1673 | 10.3 | 250 |

| Compressed earth blocks | 2080 | 0.837 | 1740 | 10.5 | 250 |

| Ref. | Location | Concrete Property/Building Model | Energy Consumption | Remark |

|---|---|---|---|---|

| [103] | Berkeley | Translucent concrete | Reduction of 18% HVAC energy in office room compared to a completely sunlight-deprived room | Reduce 50% of lighting energy |

| [104] | Chengdu, Sichuan | Normal concrete, different parameters | Two sets of solutions were selected from 1000 available solutions based on low energy consumption on HVAC and lighting systems. | Case study on the library building |

| [105] | Midwest regions of USA | 20 cm hollow concrete block (HCB) when combined with fluorescent lights and double pane heat-absorbing glazing for windows | Reduction of cooling loads | Higher initial cost |

| [106] | Saudi Arabia | Thermal block and 32 mm glazing | 77% difference for energy consumption | Low shading coefficient |

| [107] | Tropics | Different shape/space factors | Energy consumption increases with surface area and volume of the building | Decrement factor and time lag affect the building thermal performance |

| Mix Design | U-Value, W/m2K | Cooling Load, W/m2 | Remarks |

|---|---|---|---|

| Structural lightweight concrete with expanded clay and oil palm shells [55,135] | 6.62–7.18 | 55.5–60.16 | New proposed equation: Uc = transmittance value and σc = concrete compressive strength, applicable to concrete strength ≥ 17 MPa |

| Normal structural concrete | 21.96 | 175.68 | |

| Clay brick | 7.69 | 61.52 | 100 mm thickness |

| Concrete block | 11.11 | 88.88 | 100 mm thickness |

| Non-structural foamed concrete [83] | 3.92–5.29 | 31.36–42.32 | 102 mm thickness |

| Specimen | Density, kg/m3 | Compressive Strength, MPa | Decrement Factor (f) | Time Lag (ϕ), min. | Cooling Load, % |

|---|---|---|---|---|---|

| Conventional | 2480 | 56.1 | 0.941 | 45 | 100 |

| U-POFA | 2360 | 55.3 | 0.913 | 45 | 100 |

| G-POFA | 2340 | 52.4 | 0.897 | 60 | 100 |

| 25-LECA & 75-OPS | 1780 | 17.2 | 0.786 | 120 | 65 |

| OPS & 50-QD | 1880 | 19.3 | 0.834 | 105 | 29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.H.; Amran, M.; Lee, Y.Y.; Kueh, A.B.H.; Kiew, S.F.; Fediuk, R.; Vatin, N.; Vasilev, Y. Thermal Behavior and Energy Efficiency of Modified Concretes in the Tropical Climate: A Systemic Review. Sustainability 2021, 13, 11957. https://doi.org/10.3390/su132111957

Lee YH, Amran M, Lee YY, Kueh ABH, Kiew SF, Fediuk R, Vatin N, Vasilev Y. Thermal Behavior and Energy Efficiency of Modified Concretes in the Tropical Climate: A Systemic Review. Sustainability. 2021; 13(21):11957. https://doi.org/10.3390/su132111957

Chicago/Turabian StyleLee, Yeong Huei, Mugahed Amran, Yee Yong Lee, Ahmad Beng Hong Kueh, Siaw Fui Kiew, Roman Fediuk, Nikolai Vatin, and Yuriy Vasilev. 2021. "Thermal Behavior and Energy Efficiency of Modified Concretes in the Tropical Climate: A Systemic Review" Sustainability 13, no. 21: 11957. https://doi.org/10.3390/su132111957

APA StyleLee, Y. H., Amran, M., Lee, Y. Y., Kueh, A. B. H., Kiew, S. F., Fediuk, R., Vatin, N., & Vasilev, Y. (2021). Thermal Behavior and Energy Efficiency of Modified Concretes in the Tropical Climate: A Systemic Review. Sustainability, 13(21), 11957. https://doi.org/10.3390/su132111957