Screening of Evaluation Index and Construction of Evaluation Index System for Mine Ventilation System

Abstract

:1. Introduction

2. Index Screening Based on R-Cluster and Coefficient of Variation

2.1. Repeated Index Clustering

- Step 1: Consider n evaluation index as n categories.

- Step 2: Any two of the n classes are combined into one class; the others remain unchanged. The total sum of the squared deviations of each scheme is calculated according to Equation (1). The combination scheme with the smallest sum of squares of the total deviation is a new classification. In addition, there is a total of combination schemes.

- Step 3: Repeat step 2 until the preset number of clusters p is reached.

2.2. Selection of Maximum Information Index

2.3. Information Contribution Degree of the Selected Index

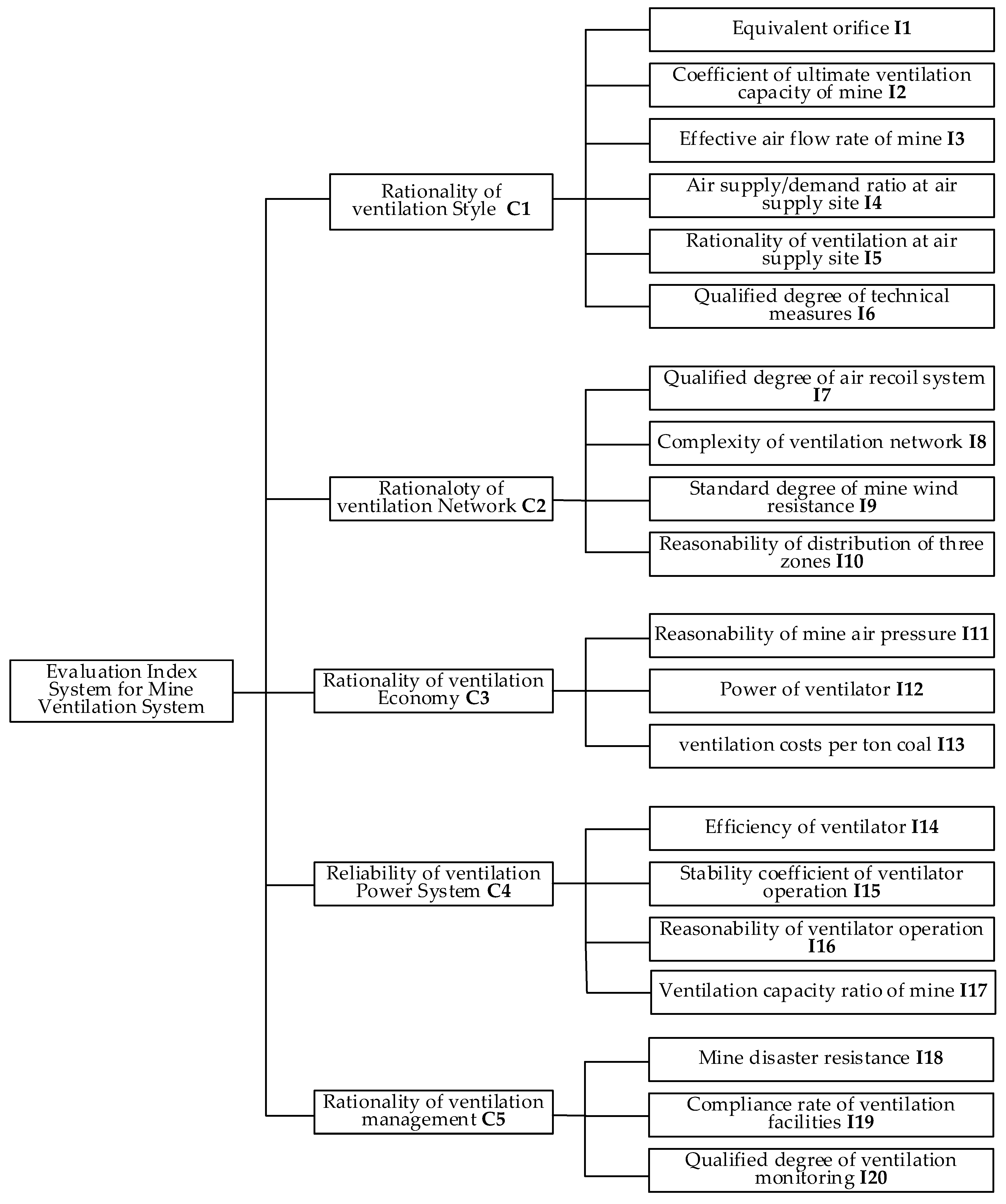

3. Construction of Evaluation Index System for Mine Ventilation System

3.1. Weight Calculation Based on the Entropy Method

3.2. Evaluation Model of TOPSIS

4. Case Analysis

4.1. Selection of Index Data

4.2. Screening of Evaluation Index

4.3. Indicator Calculation of Modification Scheme

4.4. Evaluation Index Weight Assignment

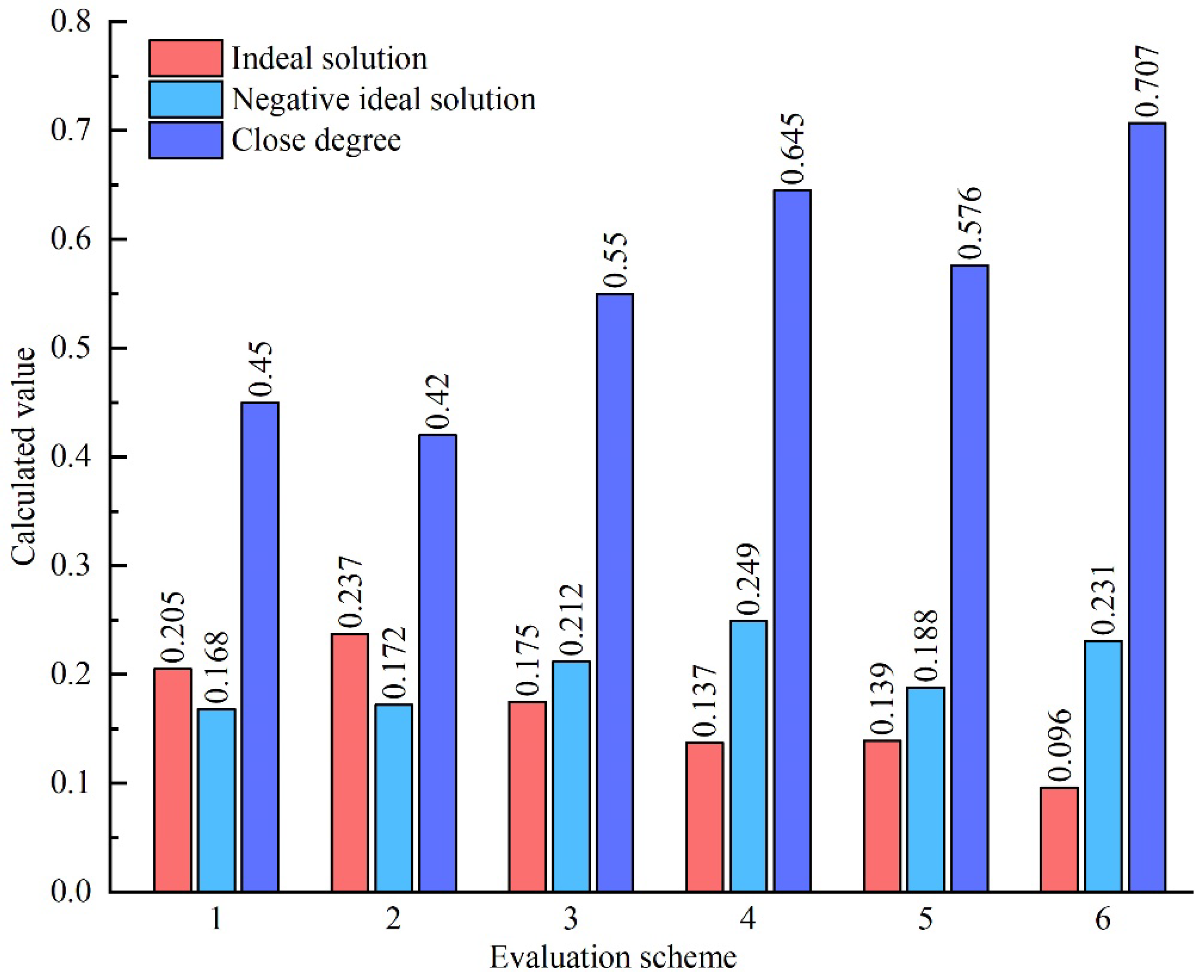

4.5. Result and Discussion

- After renovation of the ventilation system, the Q3 area was equipped with ventilation tasks by the No. 3 RAS and the No. 2 RAS. The return air volume of the No. 3 RAS was 11,318 m3/min. The operating negative pressure was 2030 Pa, and the equivalent orifice was 4.87 m2. The return air volume of the No. 2 RAS was 25,218 m3/min. The operating negative pressure was 2436 Pa, and the equivalent orifice 8.98 m2. Both the No. 2 RAS and the No. 3 RAS belong to ventilated easy mines. Moreover, according to the “Technical Conditions of Ventilation for Coal Mine Worker Mining” [30], the relationship between resistance and air volume of the mine ventilation system in the production mine was specified. The return air volume of the No. 3 RAS was 11,318 m3/min, and its ventilation resistance value should be less than 2940 Pa; the actual pressure was 2030 Pa. The return air volume of the No. 2 RAS was 25,218 m3/min, and its ventilation resistance value should be less than 3920 Pa; the actual pressure was 2436 Pa. Thus, the ventilation system of the Sihe Coal Mine conforms to the provisions of “Technical Conditions of Ventilation for Coal Mine Worker Mining” after renovation. Considering the air demand of the long-distance tunneling roadway in the northern EMA, the Supply/Demand Ratio of the No. 3 RAS and the No. 2 RAS was increased in order to avoid inadequate air volume and excessive waste of air volume.

- In addition, after renovation of the ventilation system, the ventilation resistance of the inlet section, using section, and return section of the No. 2 RAS revealed a situation of low resistance in the inlet section, high resistance in the return section and moderate resistance in the using section. The average 100 m resistance (36.15 Pa) of the total ventilation route was low, indicating that the distribution of system resistance was reasonable and the ventilation system was reasonable. Since the No. 3 RAS was only used to eliminate gas, the inlet air route was long and the return air route was the length of the wellbore. The resistance in the inlet and return areas showed the special situation of the high inlet section and low return section. After renovation of the ventilation system, the effective air volume of the mine was 29,910 m3/min. The total air inlet volume of the mine was 33,532 m3/min, and the effective air volume was 89.2%, which met the requirements of the regulation and effectively utilized the air volume. Moreover, the equivalent orifice was 13.7 m2, which was an easy ventilation system.

- Before renovation of the ventilation system, the exhaust volume of the fan in the No. 1 RAS was 14,460 m3/min. The negative pressure was 2080 Pa. The operating power was 501.3 kW, and the average daily power consumption was 12,031.2 kWh. After changing the No. 1 RAS to AIS, at least USD 679,000 per year would be saved in power consumption for fan operation. In addition, it could also save the maintenance cost of fan and auxiliary facilities and labor costs for about ten personnel, including post and maintenance personnel. In general, about USD 773,000 in various costs would be saved each year.

- There was a large disturbance intensity between the No. 1 RAS fan and the No. 3 RAS fan before renovation, which was calculated to be 33.85% in excess of the fan disturbance cut-off value [31]. After renovation, the resistance in the common section between the No. 1 RAS and the No. 3 RAS was 251.48 Pa and the disturbance intensity of the fan was 11.9%, which fulfilled the relevant requirements.

5. Conclusions

- The 20 evaluation indexes of mine ventilation were selected through expert consultation and reference summary. Then the primary index was screened through R-clustering and the coefficient of variation method. The results showed that 80% of the indicators after screening could reflect 84.05% of the original information. Apparently, our method is improved by approximately 4% compared with Gao [26].

- Because the original data of the index was derived from a questionnaire and had a specific subjective willingness, this paper utilized the entropy weight method to determine index weight. This method decreased the influence of subjective factors on the weight of indicators as much as possible, so that the weight of indicators was more acceptable and the evaluation results were more scientific.

- Aiming at the properties of enormous sample data, a complex indicator system and the possibility of future ventilation evaluation system expansion, the TOPSIS method was utilized to evaluate the mine ventilation evaluation system. The ventilation evaluation system was applied to the Sihe mine. The ventilation simulation results showed that Scheme 4; Scheme 6 had lower negative pressure and higher air volume compared to other schemes. Compared with Scheme 4, Scheme 6 was more time-saving and labor-saving in the renovation project. Compared with Scheme 5, Scheme 6 had great advantages in terms of system power consumption, effective air volume rate, and equivalent orifice. The actual test results were essentially consistent with the simulation results of Scheme 6. The correctness of the optimized scheme is verified by simulation results and practical renovation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lechner, A.M.; Kassulke, O.; Unger, C. Spatial assessment of open cut coal mining progressive rehabilitation to support the monitoring of rehabilitation liabilities. Resour. Policy 2016, 50, 234–243. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, D.; Zhang, X.; He, M. Analysis and Optimization of Entry Stability in Underground Longwall Mining. Sustainability 2017, 9, 2079. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.H.; Wang, L.G.; Feng, X.L. Fuzzy integrated evaluation for safety of metal mine ventilation system. China Min. Mag. 2010, 19, 93–96. [Google Scholar]

- Lee, D.-K. Optimal design of mine ventilation system using a ventilation improvement index. J. Min. Sci. 2016, 52, 762–777. [Google Scholar] [CrossRef]

- Bai, Y.Y.; Wen, C.P.; Chen, Z.H. Evaluation of mine ventilation system working condition based on catastrophe progression method. Electron. J. Geotech. Eng. 2016, 21, 7517–7525. [Google Scholar]

- Ren, S.; Wang, X.S.; Jiang, D.Y. Multiple fuzzy integrated evaluation for safety of mine ventilating system. China Saf. Sci. J. 2009, 19, 127–131. [Google Scholar]

- Li, X.F.; Wu, Y.; Zhao, Z.Y.; Liu, Y.; Xie, P.; Zou, J.; Xuan, P.; Zhu, J.; Huang, L. Research on index system and comprehensive evaluation method of China’s electricity spot market. In Proceedings of the 8th Renewable Power Generation Conference, Shanghai, China, 24–25 October 2019; pp. 1–7. [Google Scholar]

- Jing, G.X.; Yao, R.; Zhang, F.R. Grey comprehensive judgement for the reliability of mining ventilation system. China Saf. Sci. J. 2001, 11, 65–68. [Google Scholar]

- Shi, X.Z.; Zhou, J. Reliability assessment for mine ventilation system safety using Fisher discriminant analysis. J. Min. Saf. Eng. 2010, 27, 562–567. [Google Scholar]

- Su, Y.Y.; Liu, X.H.; Li, J.Z. Mine ventilation system index system reduction and its safety evaluation. China Saf. Sci. J. 2013, 23, 83–89. [Google Scholar]

- Liu, H.T.; Li, L.L. Comprehensive Evaluation Analysis of Mine Gas Safety Based on Integrated Method. In Proceedings of the 2009 International Conference on Computational Intelligence and Software Engineering, Wuhan, China, 11–13 December 2009; IEEE: Washington, DC, USA, 2009; pp. 1–4. [Google Scholar]

- Xiao, P.; Ding, Y.; Li, S.G. Evaluation of Gas Prevention and Control System Based on Unascertained Measurement Mode. China Saf. Sci. J. 2017, 27, 98–103. [Google Scholar]

- Zhu, W. A comprehensive benefit evaluation model of multi energy complementary system operation for different applica-tion scenarios. In Proceedings of the IEEE Power & Energy Society Innovative Smart Grid Technologies Conference, Washington, DC, USA, 16–18 February 2021; 2021; pp. 1–5. [Google Scholar]

- Yi, D.F.; Liu, D. Construction of the Coal Mine Production Safety Management Evaluation System Based on the Sustainable Development. In Proceedings of the Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012; pp. 1–5. [Google Scholar] [CrossRef]

- Li, Y.M.; Chen, Z. Evaluation Index System and Evaluation Method of China’s Regional Potential for Electrical Energy Sub-stitution. Math. Probl. Eng. 2018, 2018, 3834921. [Google Scholar]

- Zhang, K.; Zhu, R.; Song, R.; Shi, F.; Shi, S.; Fang, C. A Mesh Analysis Model and the Coherent Evaluation Index System for Urban Distribution Network Planning. In Proceedings of the 2021 3rd Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 26–29 March 2021; pp. 443–447. [Google Scholar] [CrossRef]

- Guo, S.; Feng, P.; Hu, W.; Xu, C.; Xiao, J.; Xu, J. Multi-index Comprehensive Evaluation for the River Source Heat Pump Energy Supply System Based on Dynamic Weighting. In Proceedings of the 2021 3rd Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 26–29 March 2021; IEEE: Washington, DC, USA, 2021; pp. 1177–1184. [Google Scholar]

- Zhao, T.; Wang, S.; Zuo, J.; Duan, X.; Wang, X. Performance Evaluation of Smart Meters Based on Grey Relational Analysis. In Proceedings of the 2018 10th International Conference on Intelligent Human-Machine Systems and Cybernetics (IHMSC), Hangzhou, China,, 25–26 August 2018; IEEE: Washington, DC, USA, 2018; Volume 2, pp. 312–315. [Google Scholar]

- Zhang, Z.; Lu, H. Research on Power Spot Market Comprehensive Index System and Evaluation Method. In Proceedings of the 2020 IEEE 4th Conference on Energy Internet and Energy System Integration (EI2), Wuhan, China, 30 October–1 November 2020; IEEE: Washington, DC, USA, 2020; pp. 3479–3484. [Google Scholar] [CrossRef]

- Shi, H. A Method Used for Quality Assessment of Construction Project Based on FCE and Group-decision AHP. In Proceedings of the 2009 Second International Symposium on Electronic Commerce and Security, Nanchang, China, 22–24 May 2009; IEEE: Washington, DC, USA, 2009; pp. 333–336. [Google Scholar] [CrossRef]

- Jia, N.P.; You, Y.Q.; Lu, Y.J.; Guo, Y.; Yang, K.W. Research on the Search and Rescue System-of-Systems Capability Evalua-tion Index System Construction Method Based on Weighted Supernetwork; IEEE Access: Washington, DC, USA, 2019; Volume 7, pp. 97401–97425. [Google Scholar]

- Jiang, F.; Guo, J.T.; Li, X.Y.; Chen, G.; Yang, W.C.; Wang, X.L.; Zhang, S.; Li, M. Evaluation of a Lead-Zinc Mine’s Ventilation System Based on Unascertained Measurement Model. In Proceedings of the 11th International Symposium on Computational Intelligence and Design, Hangzhou, China, 8–9 December 2018; pp. 208–211. [Google Scholar]

- Cheng, J.; Luo, Y. Mathematical models for optimizing and evaluating mine ventilation systems. In Proceedings of the 13th United States/North American Mine Ventilation Symposium, Sudbury, ON, Canada, 13–16 June 2010; pp. 387–393. [Google Scholar]

- Zhou, Z.-Y.; Kizil, M.; Chen, Z.-W.; Chen, J.-H. A new approach for selecting best development face ventilation mode based on G1-coefficient of variation method. J. Cent. South Univ. 2018, 25, 2462–2471. [Google Scholar] [CrossRef]

- Yan, F.; Li, Z.-J.; Dong, L.-J.; Huang, R.; Cao, R.-H.; Ge, J.; Xu, K.-L. Cloud model-clustering analysis based evaluation for ventilation system of underground metal mine in alpine region. J. Cent. South Univ. 2021, 28, 796–815. [Google Scholar] [CrossRef]

- Gao, J.J. Establishments and Applications of Evaluation Index System for Complex Ventilation Network Optimization. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2017. [Google Scholar]

- Liu, Y.; Liu, J.; Shao, G.; Yu, J. Research on Construction of Evaluation Index System of R&D Platform. In Proceedings of the 2021 IEEE Asia-Pacific Conference on Image Processing, Electronics and Computers (IPEC), Dalian, China, 14–16 April 2021; IEEE: Washington, DC, USA, 2021; pp. 891–894. [Google Scholar]

- Yu, H.; Li, L.; Zhang, Z.; Jin, M. Screening of Effectiveness Evaluation Index and Construction of Network Index System of Command and Control System. In Proceedings of the 2019 IEEE 3rd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 March 2017; IEEE: Washington, DC, USA, 2019; pp. 417–424. [Google Scholar]

- Li, X.R.; Zhou, J.C.; Li, B.Y.; Wang, F. Integrated assessment of Mine Ventilation System Safety. Coal Technol. 2013, 32, 80–81. [Google Scholar]

- State Administration of Work Safety of China. Technical Conditions of Ventilation for Coal Mine Worker Mining(AQ1028-2006); State Administration of Work Safety of China: Beijing, China, 2006.

- State Administration of Work Safety; State Administration of Coal Mine Safety. The Safety Regulation for Coal Mining; Coal Industry Press: Beijing, China, 2016.

| Scheme | Description | Modification Works |

|---|---|---|

| 1 | Close the No. 3 RAS, otherwise no change | Construction of closed wall on both sides of the No. 3 ventilation shaft bottom |

| 2 | Change the No. 3 RAS to AIS, otherwise no change | Dismantle fan and auxiliary devices in the No. 3 RAS; Add heating air room and other relevant facilities. |

| 3 | Close the No. 1 RAS, otherwise no change | Dismantle two closed walls in the No. 2 RAS; Open one wind bridge between the No. 1 RAS and the No. 2 RAS; Apply a closed wall on the north and south sides of the No. 1 RAS. |

| 4 | Change the No. 1 RAS to AIS, otherwise no change | Dismantle two closed walls between the No. 1 RAS and the No. 2 RAS; Apply one closed wall on the north and south sides of the bottom of the No. 1 RAS; Dismantle four closed walls between the general return wind roadway and the shunting yard in EMA. |

| 5 | Close the No. 1 RAS and modify the Q4 area, otherwise no change | Dismantle the air door between Lane 3015 and the North Transport on the basis of Scheme 3; Dismantle the air door between the east auxiliary tape roadway and the north tape roadway; Build one air door in the front of the second and third lanes of the No. 2 RAS, respectively. |

| 6 | Change the No. 1 RAS to AIS and modify the Q4 area, otherwise no change | Dismantle the air door between Lane 3015 and the North Transport on the basis of Scheme 4; Dismantle the air door between the east auxiliary tape roadway and the north tape roadway; Build one air door in the front of the second and third lanes of the No. 2 RAS, respectively. |

| Criterion Level | Index Code | Clustering Categories | Nonparametric Test | Coefficient of Variation | Retain or Delete |

|---|---|---|---|---|---|

| C1 | I1 | 2 | 0.493 | 0.2315 | Retain |

| I2 | 2 | 0.1886 | Retain | ||

| I3 | 1 | 0.453 | 0.1783 | Retain | |

| I4 | 1 | 0.1876 | Retain | ||

| I5 | 1 | 0.1876 | Retain | ||

| I6 | 1 | 0.1586 | Delete | ||

| C2 | I7 | 5 | 0.493 | 0.2559 | Retain |

| I10 | 5 | 0.2285 | Retain | ||

| I9 | 4 | 0.695 | 0.2583 | Retain | |

| I8 | 4 | 0.2295 | Retain | ||

| C3 | I11 | 2 | 0.655 | 0.1723 | Delete |

| I13 | 2 | 0.1843 | Retain | ||

| I12 | 3 | 0.2392 | Retain | ||

| C4 | I14 | 3 | 0.2536 | Retain | |

| I15 | 4 | 0.2289 | Retain | ||

| I16 | 5 | 0.2395 | Retain | ||

| I17 | 1 | 0.2014 | Delete | ||

| C5 | I18 | 2 | 1 | 0.1799 | Delete |

| I19 | 2 | 0.2048 | Retain | ||

| I20 | 3 | 0.2142 | Retain |

| Indicator | Scheme 1 | Scheme 2 | Scheme 3 | Scheme 4 | Scheme 5 | Scheme 6 |

|---|---|---|---|---|---|---|

| I1 | 12.25 | 12.53 | 14.15 | 14.8 | 13.79 | 14.44 |

| I2 | 1.43 | 1.43 | 1.83 | 1.83 | 1.83 | 1.83 |

| I3 | 0.85 | 0.851 | 0.893 | 0.882 | 0.857 | 0.862 |

| I4 | 2.57 | 2.60 | 2.73 | 2.76 | 2.72 | 2.76 |

| I5 | 95.2 | 95.2 | 91.9 | 93.5 | 98.4 | 100 |

| I7 | 0.17 | 0.17 | 0.17 | 0.17 | 0.17 | 0.17 |

| I8 | 5.27 | 5.28 | 5.27 | 5.28 | 5.27 | 5.28 |

| I9 | 38.59 | 36.98 | 26.50 | 24.07 | 29.90 | 27.13 |

| I10 | 0.000566 | 0.000373 | 0.002312 | 0.002601 | 0.002331 | 0.002818 |

| I12 | 1343.3 | 1319.1 | 1194.4 | 1135.3 | 1239.9 | 1177.6 |

| I13 | 1.638 | 1.622 | 1.633 | 1.633 | 1.637 | 1.616 |

| I14 | 80.3 | 79.2 | 69.1 | 64.2 | 73.6 | 70.3 |

| I15 | 0.785 | 0.818 | 0.715 | 0.852 | 0.754 | 0.85 |

| I16 | 29.38 | 30.55 | 17.24 | 19.89 | 21.87 | 23.75 |

| I19 | 1 | 1 | 1 | 1 | 1 | 1 |

| I20 | 1 | 1 | 1 | 1 | 1 | 1 |

| Scheme | 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|---|

| No. 3 RAS | Negative Pressure (Pa) | \ | \ | 1795.7 | 1712.0 | 1719.6 | 1633.1 |

| Service Rating (KW) | \ | \ | 463.8 | 449.9 | 451.2 | 436.2 | |

| Air volume (m3/s) | \ | \ | 258.3 | 262.8 | 262.4 | 267 | |

| No. 1 RAS | Negative Pressure (Pa) | 1780.2 | 1742 | \ | \ | \ | \ |

| Service Rating (KW) | 428.1 | 425 | \ | \ | \ | \ | |

| Air volume (m3/s) | 240.5 | 244 | \ | \ | \ | \ | |

| No. 2 RAS | Negative Pressure (Pa) | 2250.8 | 2184.9 | 1740.9 | 1596.1 | 1910.3 | 1762.7 |

| Service Rating (KW) | 915.2 | 894.1 | 742.3 | 689.2 | 802.1 | 741.4 | |

| Air volume (m3/s) | 406.6 | 409.2 | 426.4 | 431.8 | 419.9 | 425.5 | |

| Total Power (KW) | 1343.3 | 1319.1 | 1194.4 | 1135.3 | 1239.9 | 1177.6 | |

| Effective Air Flow Rate of Mine (%) | 85% | 85.1% | 89.3% | 88.2% | 85.7% | 86.2% | |

| Distribution of Three Zones | 0.000566 | 0.000373 | 0.002312 | 0.002601 | 0.002331 | 0.002818 | |

| Equivalent Orifice | 12.25 | 12.53 | 14.15 | 14.80 | 13.79 | 14.44 | |

| Items | Before Renovation | After Renovation | |||||

|---|---|---|---|---|---|---|---|

| No. 1 RAS | No. 2 RAS | No. 3 RAS | No. 1 RAS | No. 2 RAS | No. 3 RAS | ||

| Air Supply/Demand | Demand Airflow (m3/min) | 10,800 | 10,800 | 7200 | None | 8000 | 6800 |

| Supplying Airflow (m3/min) | 14,460 | 22,860 | 10,140 | None | 20,068 | 11,318 | |

| Supply/Demand Ratio | 1.34:1 | 2.12:1 | 1.41:1 | None | 2.51:1 | 1.67:1 | |

| Rationality of Resistance | Percentage of Inlet Section Resistance | 18.1% | 33.14% | 41.41% | None | 18.62% | 67.01% |

| Percentage of Return Section Resistance | 33.2% | 33.19% | 58.59% | None | 35.68% | 32.99% | |

| Percentage of Using Section Resistance | 48.7% | 33.67% | 0% | None | 45.70% | 0% | |

| Rationality of Economic | Exhaust Air Rate (m3/min) | 14,460 | 22,860 | 9900 | None | 25,218 | 11,318 |

| Negative Pressure (Pa) | 2080 | 3120 | 2330 | None | 2436 | 2030 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, Q.-P.; Li, Y.-C.; Shen, C. Screening of Evaluation Index and Construction of Evaluation Index System for Mine Ventilation System. Sustainability 2021, 13, 11810. https://doi.org/10.3390/su132111810

Bi Q-P, Li Y-C, Shen C. Screening of Evaluation Index and Construction of Evaluation Index System for Mine Ventilation System. Sustainability. 2021; 13(21):11810. https://doi.org/10.3390/su132111810

Chicago/Turabian StyleBi, Qiu-Ping, Yu-Cheng Li, and Cheng Shen. 2021. "Screening of Evaluation Index and Construction of Evaluation Index System for Mine Ventilation System" Sustainability 13, no. 21: 11810. https://doi.org/10.3390/su132111810

APA StyleBi, Q.-P., Li, Y.-C., & Shen, C. (2021). Screening of Evaluation Index and Construction of Evaluation Index System for Mine Ventilation System. Sustainability, 13(21), 11810. https://doi.org/10.3390/su132111810