Abstract

The effect of sargassum particle size on the final properties of sargassum-modified asphalt is investigated in this article. Seaweed sargassum particles were first obtained and characterized through elemental analysis, thermogravimetric analysis (TGA), X-ray diffraction, and FTIR spectroscopy. Additionally, pure and sargassum-modified asphalt blends were evaluated through physical and rheological tests such as penetration, softening point, thermal stability, dynamic viscosity, failure temperature, and epifluorescence microscopy. Modified asphalt blends were prepared by the hot mixing technique using different proportions of sargassum particles of two maximum sizes: 500 μm and 850 μm. Incorporating 3.0 wt.% of sargassum particles under 500 μm into the asphalt increased the viscosity of the original binder by a factor of 2.5 and its complex modulus by a factor of 1.9. At the same time, its failure temperature was 11 °C higher than the reference asphalt, which implies an improved viscoelastic behavior and rutting resistance at high temperatures. The study results suggest that the particles under 500 μm were responsible for the most significant effect on the final properties of the asphalt. Moreover, the storage stability test revealed that the modified asphalt blends are stable when the sargassum particle content was kept below 3.0 wt.%. The statistical analysis of the effect of sargassum particle size and concentration on the modified asphalt properties revealed that the rheological behavior is more affected by the modifier particle size; in contrast, the conventional physical properties were more determined by its concentration. Therefore, using low proportions of fine sargassum particles is efficient for improving the physical and rheological properties of the original asphalt, which is not only positive from the asphalt modification technology point of view but also from a sustainable perspective, since seaweed sargassum has become a useless plague in many coastal regions.

1. Introduction

The most important application of asphalt is road pavement construction, owing to its chemical composition as well as to its physical properties and viscoelastic nature [1]. However, the mechanical behavior of viscoelastic materials is strongly affected by temperature as well as by the size and time of load application [2]. For instance, at high temperatures, asphalt becomes soft and eventually acquires the properties of a fluid, while at low temperatures, it becomes rigid and brittle. Therefore, several kinds of modifiers have been studied in order to improve the asphalt behavior in terms of enhancing its durability and broadening the range of its service temperature [3]. However, special attention should be taken in order to select the appropriate amount and type of modifier since an extreme amount of them would produce fragile and rutting-prone asphalts, while insufficient modifier would lead to unstable and soft binders with increased empty volume, which favor the deformation of asphaltic roads [4].

Although polymeric materials have been one of the most important asphalt modifiers, they have also shown some disadvantages, such as their disproportionate effect on the asphalt viscosity, high cost, and incompatibility with the asphalt matrix [5]. Consequently, other varieties of materials have been explored in order to replace polymers, at least to some extent, as asphalt modifiers. Special attention has been paid on investigating potential modifiers that come from byproducts or waste materials. For example, chicken feather particles [6], clays [5,7], palm fibers [8], glass and cellulose fibers [1], polyester and wool fibers [9], oyster shell powder [10], corn cob waste-lignin [11], organic imidazolines [12], and rubber crumbs from tires [13], have been successfully used as modifier materials.

Some of these natural waste materials, known as asphalt biomodifiers, have resulted attractive because they contain several hydrophobic and hydrophilic functional groups that contribute to modify the properties of asphalt binders, for example, producing a hardening effect which improves their adhesive and bonding behavior when mixed with mineral aggregates to build paved roads [14,15].

In this context, sargassum, which is considered a plague of no commercial significance, was studied by our group as an asphalt modifier.

Since 2011, West African shores and the Caribbean coasts have experimented large influxes of sargassum, which initially started as an episodic event, but it rapidly became increasingly frequent and massive [16]. For instance, in the Caribbean and Equatorial Atlantic, sargassum arrivals have been reported at a rate of 5 million tons in 2011, 15 million tons in 2017, and 20 million tons in 2018 [17]. The accumulation of sargassum in coastal regions is so massive that, for example, during the peak sargassum beaching times along the Mexican shores in 2015, a volume of 9 726 m3, equivalent to 817 tons of sargassum, accumulated monthly per kilometer of coastline [18].

Sargassum accumulation in coastal regions has adverse effects on the environment, affecting the tourism and fishing industries and human health as well. For example, an excessive sargassum density affects the water quality since the algae decompose in potentially toxic compounds such as ammonium and hydrogen sulfide. At the same time, it reduces light penetration, depletes oxygen in water, modifies its pH, and increases its turbidity and temperature [17]. Additionally, due to its strong adsorption properties, heavy metals content has been reported on sargassum [19,20], and thus, this plague has also been described as a “health issue” [16].

Recently, our group was the first to show that seaweed sargassum powder can be used for asphalt modification. However, the effect of its particle size has not been assessed [21]. Other researchers have found that the modifier particle size has a significant effect on the asphalt properties, such as waste carbon particles from printers [22], crumb rubber [23], and phosphorus slag [24]. Therefore, in this study, modified asphalt blends were produced by the hot mixing technique, using sargassum particles under 500 μm (35-mesh sieve) and under 850 μm (20-mesh sieve), in order to evaluate the effect of particle size in the viscoelastic properties and high-temperature storage stability of the modified asphalt.

2. Materials and Methods

2.1. Materials

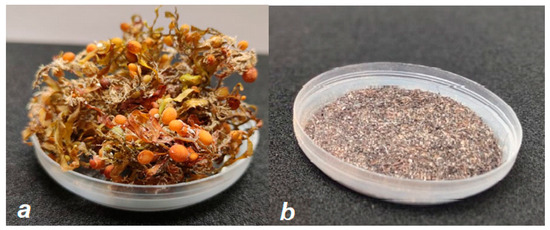

The asphalt used in this study was provided by Ergon Asfaltos México. The seaweed sargassum was collected in summer season at Miramar beach, in Madero City, Tamaulipas, México. The sargassum was washed with distilled water to remove the excess impurities, and then it was dried at 60 °C for 24 h. Afterward, it was grounded and sieved using the ASTM 35-mesh and 20-mesh sieves to obtain two maximum particle sizes: 500 μm and 850 μm, respectively. The seaweed sargassum and the particles (SGP) obtained from it are shown in Figure 1.

Figure 1.

Seaweed sargassum (a) and sargassum particles (SGP) after milling (b).

The chemical composition and physical properties of the pure asphalt used in this study are shown in Table 1. This virgin asphalt is composed by 86.65 wt.% of maltenes and 13.35 wt.% of asphaltenes. According to its physical properties, as well as the quality certificate provided by the supplier, the classification of this asphalt is AC20, PG64-22.

Table 1.

Chemical composition and physical properties of pure asphalt.

The asphalt binder is a fundamental component of the asphaltic blends used for the construction of road pavements, and thus, it significantly affects the quality and performance of the pavement during its service life [25].

2.2. Preparation and Characterization of Asphalt Blends

Asphalt blends were prepared at different sargassum (SGP) concentrations, 0.0, 1.0, 1.5, 2.0, 2.5, and 3.0 wt.%, at a temperature of 180 °C and a 1500 rpm mixing rate using an IKA RW16 low shear stirrer for 90 min. The heating device used for keeping constant temperature was homemade, designed for this purpose. It consists of a cast stainless steel block of 16 × 16 × 14 cm, with a cylindrical well in its center of 8.5 cm-diameter and 6 cm-height. It is equipped with two Hotwatt power resistors of 200 W and 115 V linked to a Yokogawa temperature controller, YT14E model, and a thermocouple type K. The two maximum sizes of SGP were considered for preparing the modified asphalt blends: 20-mesh sieve (850 μm) and 35-mesh sieve (500 μm). At the end of the mixing process, the asphalt blends were filtered using the 20-mesh sieve. The asphalt samples were named according to the codes included in Table 2.

Table 2.

Identification of asphalt samples.

2.3. Evaluation Methods

2.3.1. Elemental Analysis

In order to determine the elemental profile of the sargassum collected and used in this study, the elemental analysis of sargassum particles (SGP) was determined by energy-dispersive X-ray fluorescence (EDXRF) on a Xenemetrix EX3600 spectrometer, which consists of an X-ray tube with a selection of 1-No, 2-Ti, and 3-Fe anodes, as the X-rays source, with a 50 V, 1 mA power supply (regulated according to the selected source), and a Si(Li) detector with a resolution of 143 eV to 5.9 keV, in an air atmosphere. An X-ray sample turret in the equipment allows us to analyze 10 samples at a time, and the quantitative analysis was carried out by the in-built software nEXT [26]. The SARA (saturates, aromatics, resins, asphaltenes) chemical composition of the pure asphalt was determined employing an MK-6 Iatroscan equipment [27].

2.3.2. FTIR Spectroscopy

Infrared spectroscopy was carried out in a Spectrum One equipment using an ATR accessory with a Se–Zn plate with a resolution of 12 scans in the wavenumber range between 4000 and 400 cm−1. This technique was useful for determining if the modification process led to physical or chemical changes, by comparing the functional groups observed in the FTIR spectrum of a modified asphalt sample, with those of the original binder and the SGP before mixing.

2.3.3. Thermogravimetric Analysis

Thermogravimetric analysis (TGA) measurements were performed to evaluate the thermal stability of SGP, employing a TA Instruments, SDT Q600 model equipment, using a heating rate of 10 °C/min in a temperature range from room temperature to 700 °C.

2.3.4. X-ray Diffraction

The X-ray diffraction (XRD) pattern of SGP was obtained by monitoring the intensity of the d001 peak in an X-ray diffractometer with a Cu radiation source of 1.54 Å. This spectrum provides information about the physical characterization of the sargassum used in this study and allows us to compare it with sargassum obtained from different regions. The angular range was fixed at 10–110°, which was explored at a scanning rate of 0.05°/s, with an angular resolution of 0.05°.

2.3.5. Conventional Physical Tests

The conventional physical tests of the original and modified asphalt blends were performed under standardized methods. The penetration test was carried out to evaluate the consistency of the asphalt, using a Khoehler digital penetrometer according to the ASTM D5-86/64 method. For this test, the asphalt samples were poured into standard containers kept at 25 °C in a thermal bath.

The softening point of the asphalt blends was determined according to the ASTM D36/D36M-14 method, using a ring-and-ball system immersed in USP glycerin [28]. The softening point is useful for detecting the required temperature to induce a phase change in the modified asphalt mixtures.

The dynamic viscosity was measured in a Brookfield DV-II +Pro viscosimeter according to the ASTM ASTM D-4402/D4402M-15 method, using an SC4-27 rotor at 20 rpm and 160 °C; the viscosity measurements were carried out in triplicate for each sample, at a torque level of 50% (torque should be kept between 10 and 98% so that the measurement is considered valid), and the reported values correspond to the average viscosity of the samples.

The thermal stability was evaluated according to the ASTM D5892-00/M-MMP-4-05-022/02 method in order to assess if the modifiers and the asphalt form a long-lasting homogenous blend.

2.3.6. Rheology

The rheological properties of the pure and modified asphalt samples were evaluated according to the AASHTO T315-12 method using an Anton Paar MCR 301 rheometer, with the purpose of measuring the effect of the modification process on the viscoelastic nature of the asphalt, as well as to determine its high-temperature behavior. The tests were performed under sinusoidal shear stress using a parallel plate geometry of 25 mm diameter at a constant frequency of 1.585 Hz (ω = 10 rad/s) in a temperature range from 52 to 94 °C and deformation of 10%, as recommended by SHRP [29]. The shear stress was fixed to lay into the material linear viscoelastic region. All measurements were performed in duplicate.

2.3.7. Epifluorescence Microscopy

Epifluorescence microscopy was used to investigate the modifier dispersion in the asphalt mixtures using an Axiotech Carl Zeiss microscope. A drop of each modified asphalt sample was placed between two glass slides for visualizing it in the microscope, fixing the magnification lens at three levels: 5×, 10×, and 20×.

Finally, multifactor analyses of variance (ANOVA) were carried out in order to find out which of the physical and rheological properties of the SGP-modified asphalts were significantly affected by the SGP size and content. Therefore, general linear models were obtained in Minitab v.18.1 for the complex modulus gain, failure temperature, viscosity, softening point, phase separation, penetration index, and penetration, taking SGP wt.% and particle size as the independent factors of the models at a significance level of α = 0.05; if the p-values calculated for each factor are less than the significance level (p<α = 0.05), then the factor is considered responsible for the variation of the mean measured properties.

3. Results and Discussion

3.1. Chemical Composition of Sargassum Particles

3.1.1. Elemental Analysis

Table 3 shows the variation in concentration of elements such as Ne, Al, Si, P, and S, in the sargassum particles (SGP). This study is an elemental analysis that uses gamma radiation to determine the content of essential and non-essential elements in the sample; however, the selected anode limits the elements’ detection. This study was designed to investigate the elemental profile of seaweed sargassum using the EDXRF technique [26,30]. Shekhar et al. [30] and Rodríguez-Martínez et al. [31] also used this technique to determine the elemental composition of sargassum. In our study, the most abundant elements were S, K, Al, P, Si, and Cl, which is consistent with the results reported by Shekhar et al. [30] who found that Cl, K, S, Ca, P, and Al were the most abundant elements in their sample (plus Na and Mg, which were not determined in our study), as well as those of Rodríguez-Martínez et al. [31], who reported Ca, Cl, K, S, Si, and P as the most abundant elements in sargassum collected along the Mexican Caribbean coasts (in addition to Mg and Sr, which were not determined in our study).

Table 3.

Elemental profile of seaweed sargassum using the EDXRF technique.

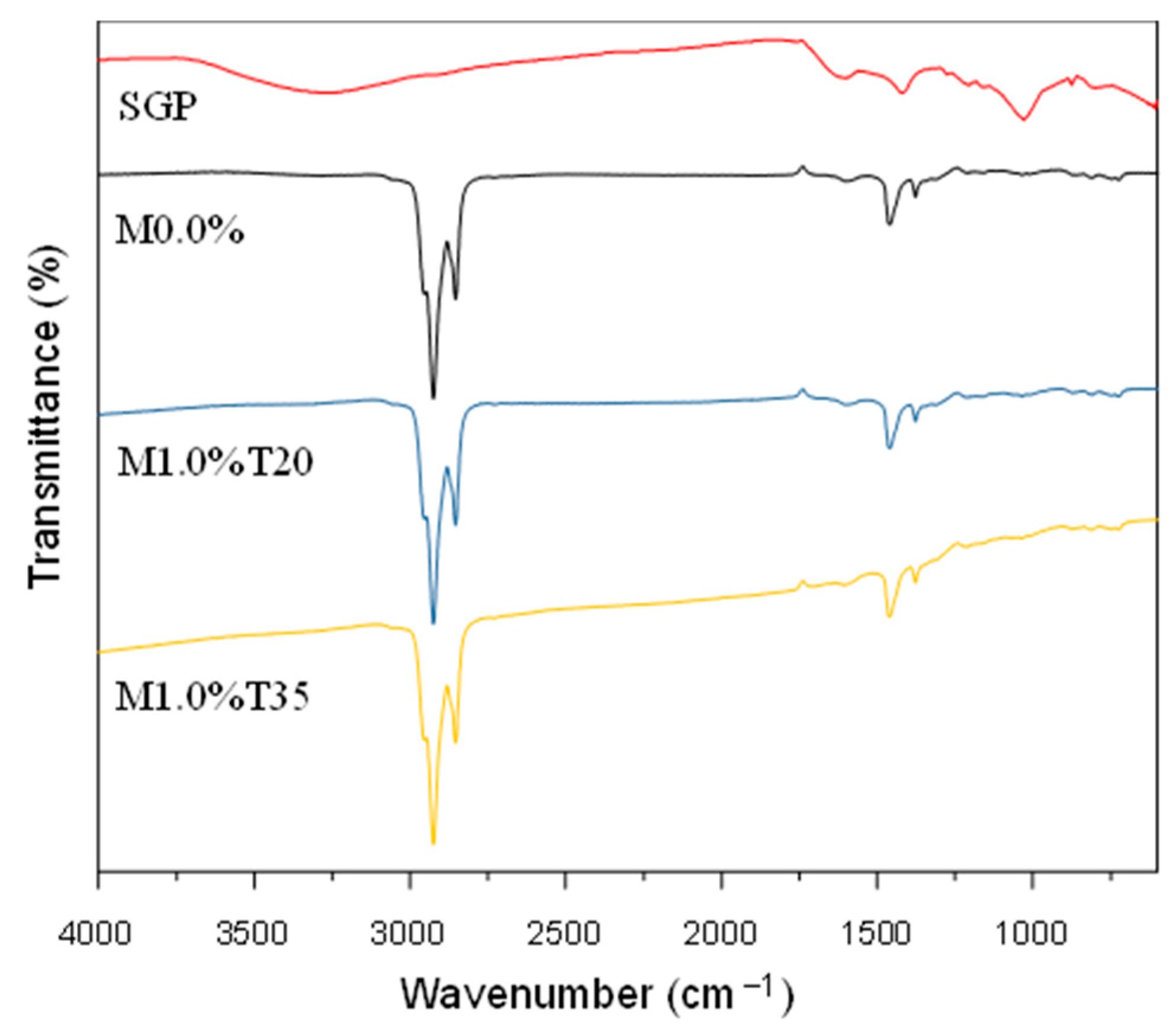

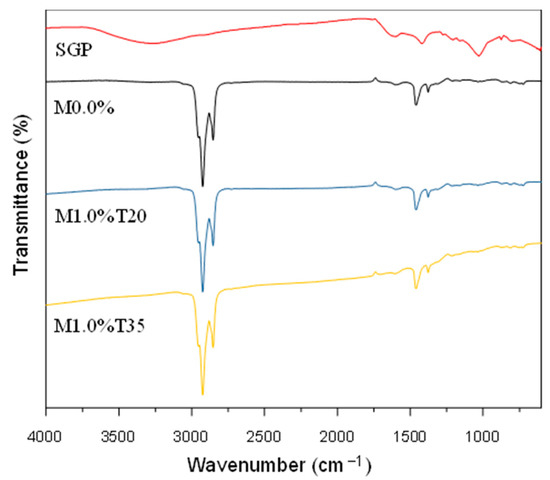

3.1.2. Infrared Spectroscopy

Figure 2 shows the FTIR spectra of sargassum particles (SGP), pure asphalt (M0.0%), and modified asphalt blends with sargassum particles of 500 μm (M1.0%T20) and 850 μm (M1.0%T35). The SGP spectrum shows a strong absorption band centered at 3250 cm−1, attributed to the N–H and O–H bending modes; this observation is consistent with the presence of polysaccharides and amino acids in the alginate, which is the most abundant constituent of brown seaweed (representing about 40 wt.% of its dry weight) and consists of cellulose arrays that form its cellular walls [32]. The band located at 2890 cm−1 in the spectra of pure and modified asphalts is attributed to the vibration of aliphatic bonds such as -CH2- and -CH3-. The bands located at 1651 and 1620 cm−1 are related to the bending modes of the C=O and O–H bonds characteristic of the ester groups. At 1560 cm−1, a medium band attributed to the C=C stretching of the SGP lignin groups is observed. The absorption band centered at 1250 cm−1 reveals the presence of S=O groups, which are related to sulfated polysaccharides known as fucans. The strong absorption bands located at 1100 cm−1 in the fingerprint region correspond to C–F stretching modes associated with the cellulose molecule. Finally, the band observed at 670 cm−1 corresponds to the tension vibrations of C–S and C=S of sulfated compounds [33]. According to the results of this analysis, no organic arsenates were found in SGP, which, if present, would have exhibited strong absorption bands in the region between 820 and 470 cm−1; this is a consequence of the fact that seaweed absorbs water nutrients from the place where it is found, and it implies that this sargassum has no toxic compounds on it [31].

Figure 2.

Infrared spectra of SGP, pure asphalt, and modified asphalt mixtures with sargassum particles of 20-mesh and 35-mesh sizes.

In the modified asphalts, the contact between the asphalt matrix and SGP takes place on the modifier surface as a result of a physical adsorption phenomenon. The FTIR results confirm that no new functional groups show up other than those already present in either the asphalt or the SGP individual spectra; therefore, no chemical changes take place during the modification process. However, the union between the SGP and the asphalt constituents occurs as a result of physical interactions, such as the van der Waals or electrostatic forces, between the polysaccharides and amino acids of sargassum and between the hydroxy and amino groups of some of the aromatic molecules of the adsorbed asphalt phase [10,34].

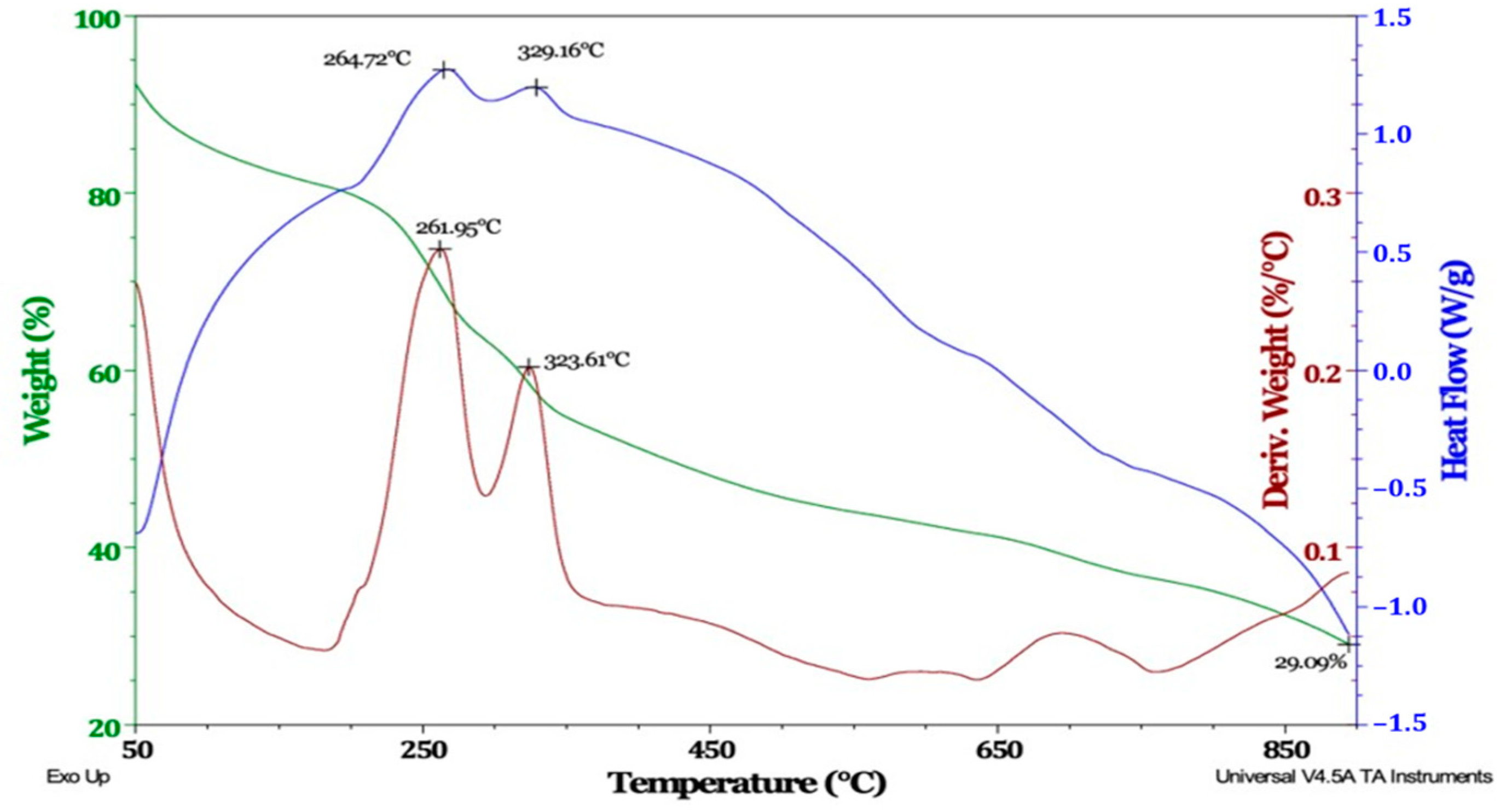

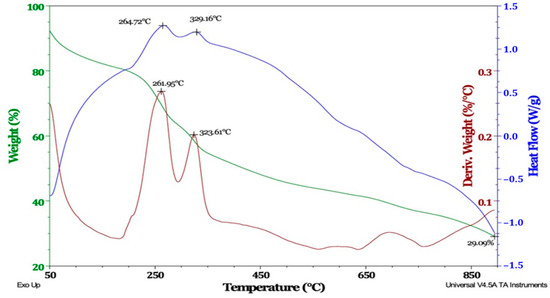

3.1.3. Thermogravimetry (TGA)

According to Figure 3, sargassum particles show a weight loss step between 250 °C and 800 °C, with a residue of 29 wt.%. The initial step down, between 50 °C and 150 °C, is attributed to the moisture loss of the sample. Then, owing to the low decomposition temperature of hemicellulose, lignin, and pectin, a degradation temperature close to 262 °C is observed, which ends up with a significant drop around 324 °C, showing a residual mass corresponding to carbonous compounds [34,35,36]. This is consistent with the observations of Sharifi and Pirsa [37] who found that the complete degradation of pectin occurs in the temperature range of 180 to 450 °C.

Figure 3.

SDT (DSC/TGA) thermograms of SGP.

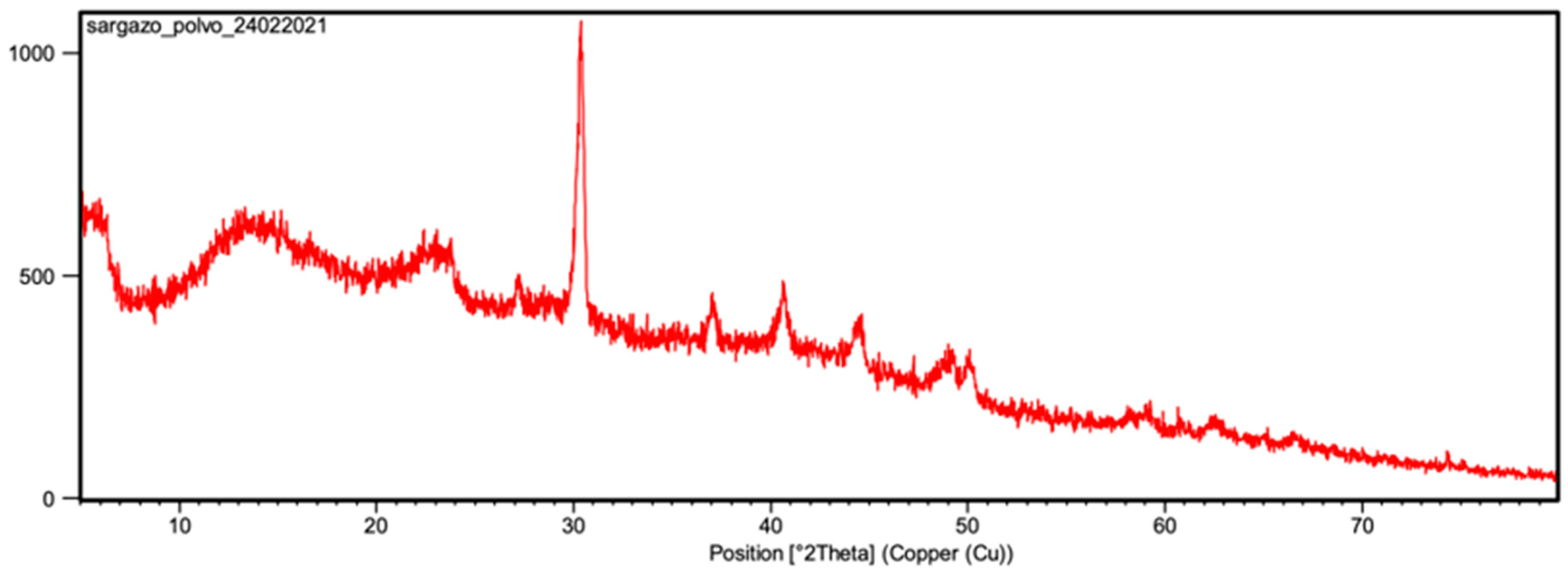

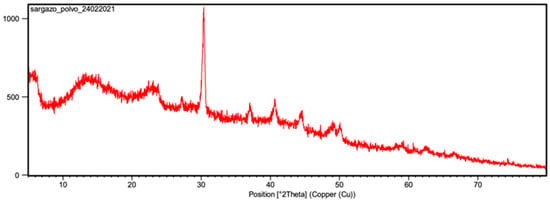

3.1.4. X-ray Diffraction (XRD)

Figure 4 shows the crystalline model of SGP in the range between 10° and 110°, where the structure of both amorphous and crystalline fractions may be observed. The X-ray pattern of Figure 5 reveals a crystalline network attributed to the cellulose in SGP, exhibiting its typical diffraction peaks at 2θ = 16.0° and 22.6° [34,38,39]. The sharp peaked displayed at 2θ = 30° is consistent with crystalline sulphated polysaccharides found in brown seaweed sargassum [40].

Figure 4.

X-ray diffractogram of SGP.

Figure 5.

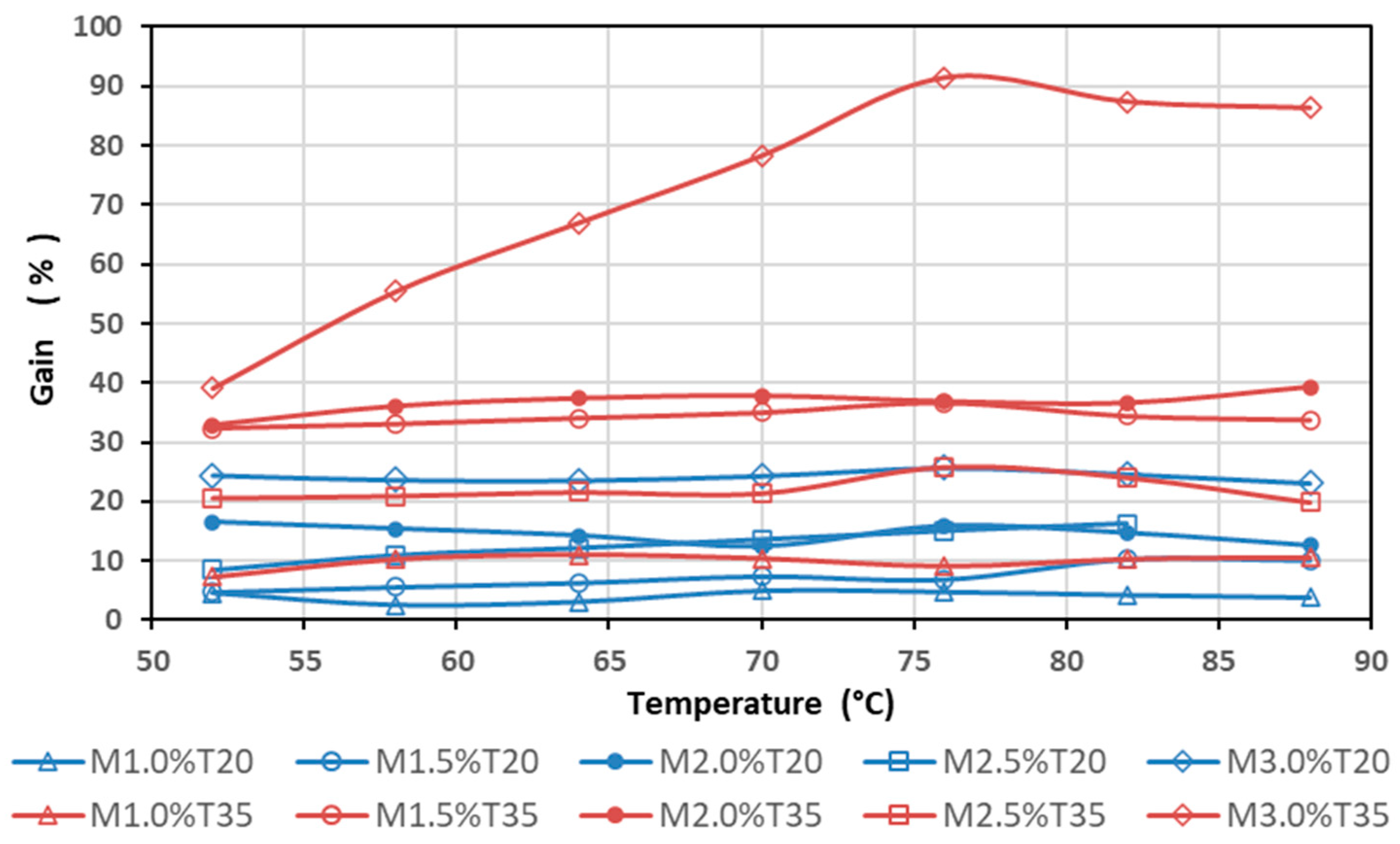

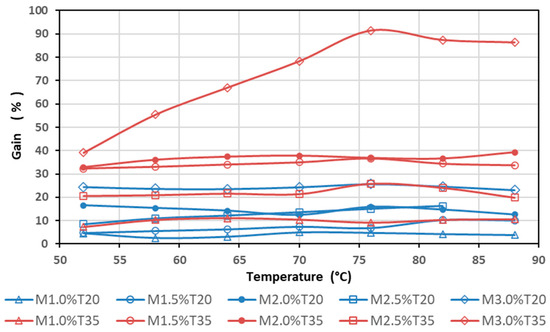

Complex modulus gain of asphalt–SGP mixtures at different concentrations and particle sizes at a frequency of 1.585 Hz.

3.2. Effect of SGP on the Complex Modulus of Modified Asphalt

Asphaltic materials exhibit a viscoelastic behavior, which is related to its molecular structure, as well as to the specific formulation of the asphalt mixture; therefore, a precise evaluation of the relationship between the structure and the viscoelastic behavior of a material demands the performance of rheological measurements on it.

In order to assess the effect of the sargassum particles on the rheological properties of the asphalt matrix, especially towards the high service temperature range, the gain percentage was calculated as a function of the complex modulus, as defined by Equation (1):

where is the complex modulus of the sargassum-modified asphalt blend, while is the complex modulus of the pure asphalt; the pure asphalt sample was subjected to a mixing period of 2 h at 180 °C in order to evaluate the sole influence of the modifier on the asphalt, without considering the possible aging effect involved by the mixing process.

Finally, the high-temperature resistance was evaluated by determining the parameter, which should not exceed 1.0 kPa, as this value is related to vehicle traffic of 80 km·h−1 [8,29]. The purpose of this analysis is to reveal the failure temperature of the asphalt blends, which indicates how the varying SGP concentration influences the permanent deformation resistance of the asphalt.

Figure 5 shows the complex modulus gain (calculated through Equation (1)) of the modified asphalt samples as a function of the SGP size. According to Figure 5, when a low content of SGP is added to the asphalt (e.g., 1.0 wt.%), the complex modulus gain is low, ranging from 4% to 9%, and the influence of the particle size of the modifier is not significant; however, when a medium content of SGP is considered (e.g., 1.5 wt.% or 2.0 wt.%) the complex modulus gain, as well as the effect of particle size on it, becomes significant, as evidenced by the 35-mesh sieve SGP (500 μm) results, which reaches an average gain of 38%. Additionally, as shown in Figure 5, the highest complex modulus gain corresponds to the asphalt mixture containing 3.0 wt.% of 500 μm SGP, which presented a gain of up to 90%. These results are consistent with other asphalt modification studies that have also found similar behavior in the complex modulus gain as a function of the modifier content. For example, adding 2 wt.% of palm fibers produces a modification gain of 10%, while using 6 wt.% of fibers increases the gain up to 43% [8]. However, other studies that have also used natural fibers as asphalt modifiers have found that keeping the modifier content below an optimum concentration is necessary to avoid producing brittle asphalt mixtures [1]. Finally, according to the results shown in Figure 5, the best gain values are obtained by the samples prepared with medium and high 500 μm SGP concentrations, which suggests that the smaller particle size is better for achieving the good dispersion of the SGP in the asphalt.

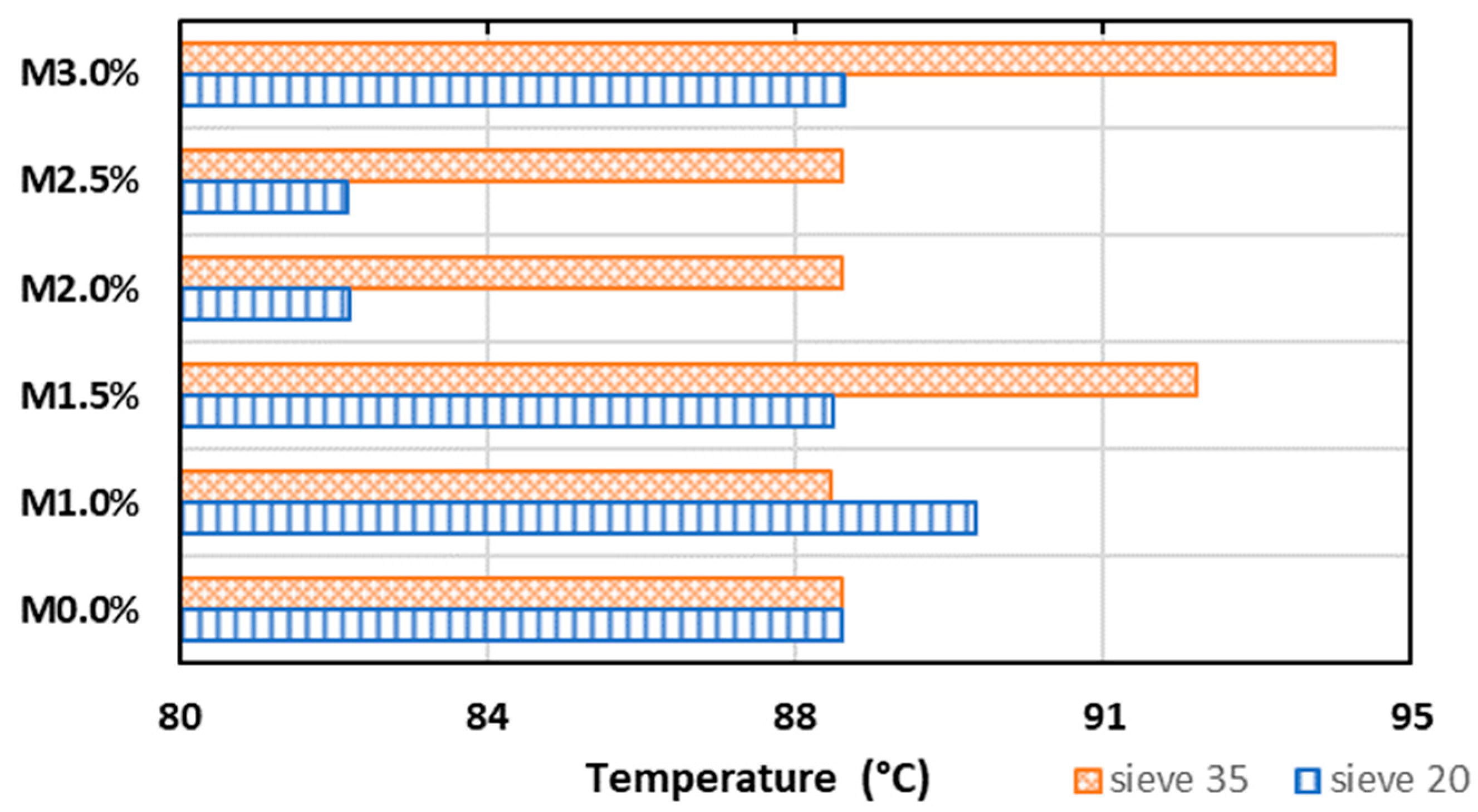

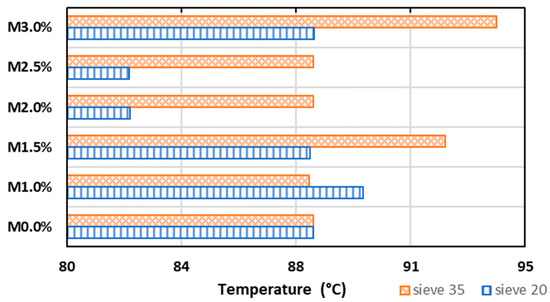

The deformation parameter of the asphalt increases as the content of SGP grows, until the failure temperature is reached when = 1 kPa; the higher the failure temperature, the better the permanent deformation resistance achieved by the SGP-modified asphalt blend [8,29]. Figure 6 reveals that sargassum particles can significantly improve the deformation resistance compared to that of pure asphalt, especially the 500 μm SGP, since the failure temperature of the samples modified with that size of SGP at 1.0, 1.5, and 3.0 wt.% are higher than that of the unmodified asphalt [21].

Figure 6.

Failure temperature of pure and SGP-modified asphalt binders.

3.3. Effect of the SGP Concentration and Size on the Asphalt Viscosity

According to the results shown in Table 3, all SGP-modified asphalts present higher viscosities compared to those of the pure and aged asphalts, which is important to enhance the asphalt’s permanent deformation resistance. The increment in viscosity was even more pronounced in the samples containing 500 μm SGP. The improved viscosity results from the physicochemical constitution of the modifier, its texture, and surface area, resulting in a fiber network where the fibers interact throughout the asphalt matrix. As observed in Table 4, from a concentration of 1.5 wt.%, the viscosity increases by a factor of 350%; therefore, the SGP is able to form a localized network structure that acts as a support, reinforcing the binder’s matrix and improving its deformation resistance. However, the change in viscosity in the samples containing less than 1.5 wt.% SGP is limited since the modifier particles are not in enough concentration to form a continuous network, but they are instead dispersed in the asphalt with minimum opportunities to interact with each other. On the other hand, special attention should be taken if a concentration greater than 1.5 wt.% of SGP is used because a supersaturation of SGP may lead to form agglomerates which are associated with poor properties on the asphalt blend. Therefore, the concentration of 1.5 wt.% of SGP is considered as the optimum content in this study. This observation is confirmed by Chen and Lin [9] who found that high fiber concentrations induce fiber–fiber interactions that result in brittle asphalt mixtures.

Table 4.

Viscosity of pure and SGP-modified asphalt binders.

The results in Table 4 are also helpful for pointing out that the viscosity is related to the content and size of SGP in the asphalt, and, consequently, SGP improves the deformation resistance of the asphalt mixture since a high viscosity is an indicator of greater flow resistance. It is important to note that the effect of hardening is significant at high temperatures, which is advantageous for the bitumen as the risk of permanent deformation is increased at higher temperatures and heavily loaded roads.

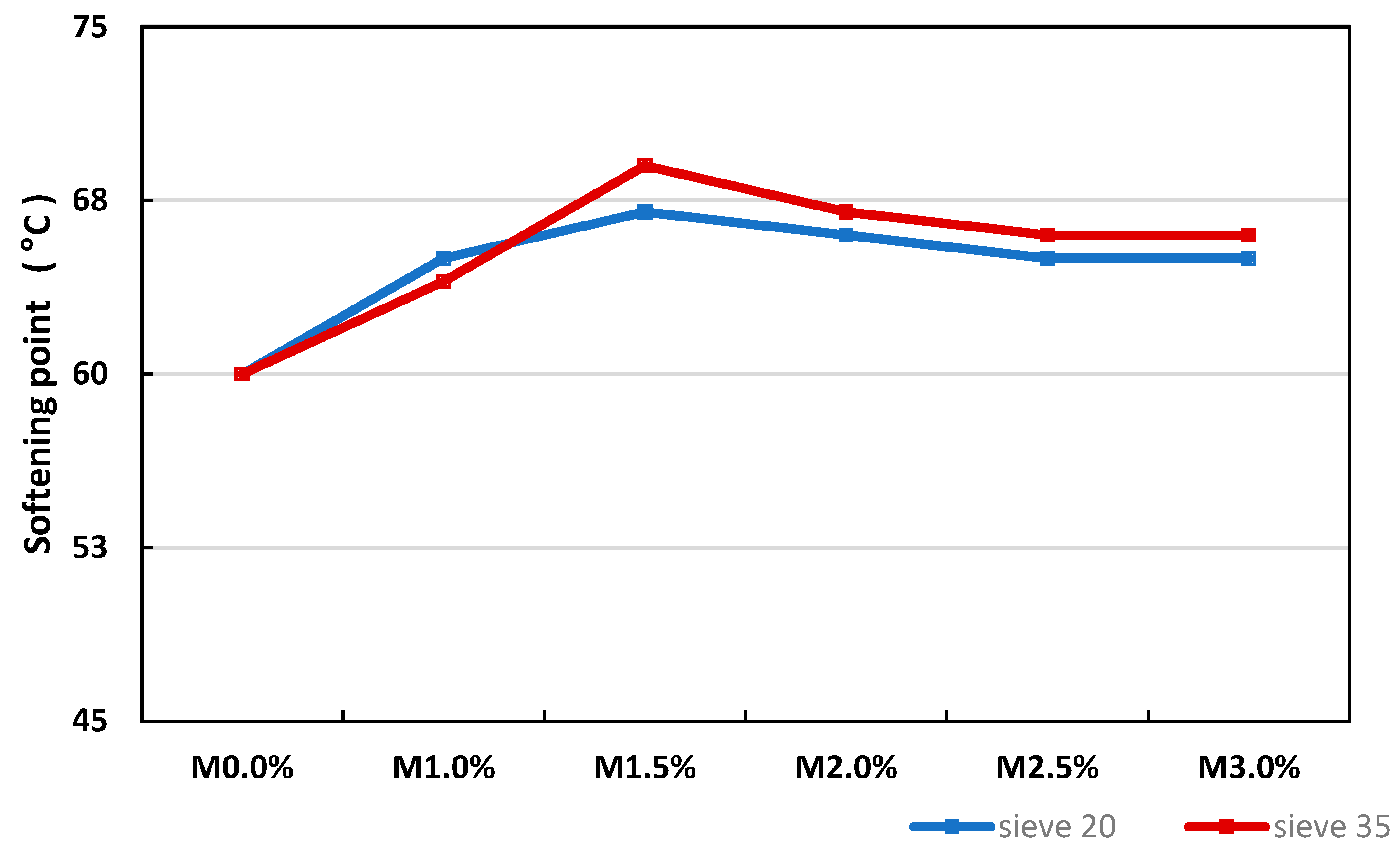

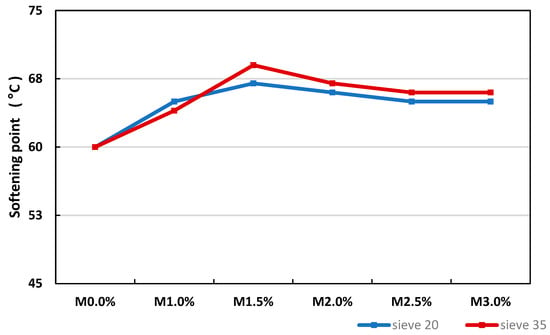

3.4. Softening Point of SGP-Asphalt Mixtures

Figure 7 shows the softening point of asphalt mixtures as a function of their SGP content. An increase in the softening point is observed as the SGP concentration grows in the mixture, especially with the 500-μm particles. The maximum softening point (69 °C) corresponds to the sample containing 1.5 wt.% of 500 μm SGP, 15% greater than the softening point of pure asphalt (60 °C). Therefore, the SGP is responsible for improving the tenacity of the asphalt. As observed in Figure 7, using SGP concentrations above 1.5 wt.% are not useful for increasing the softening point of the modified asphalt since it levels off at around 65 to 67 °C.

Figure 7.

Softening point of pure and SGP-modified asphalt binders.

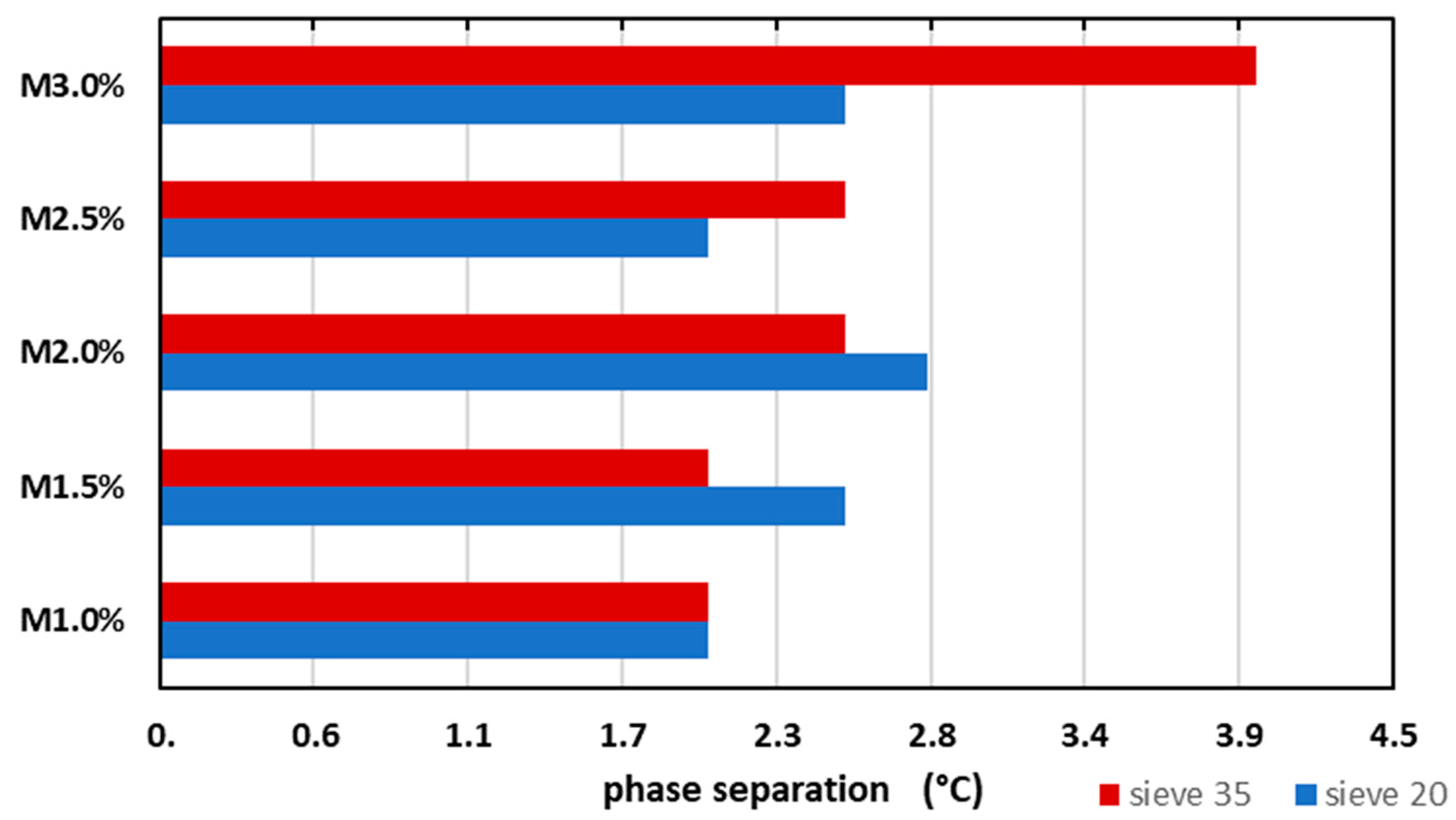

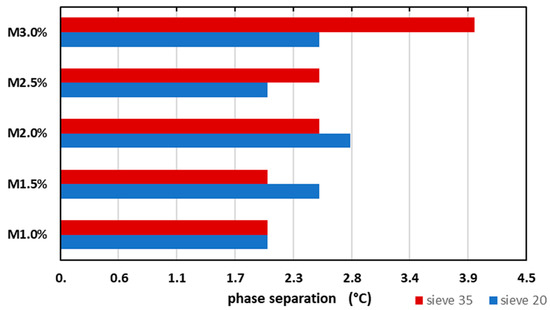

3.5. Storage Stability Test

The thermal storage stability test is used to determine if the additives are well dispersed into the modified asphalt matrix, and thus, it is considered a reasonable criterion for assessing the quality of modified asphalt blends. Figure 8 shows the results of this test.

Figure 8.

Phase separation of SGP-modified asphalt binders, reported as the difference between the softening points of the top and bottom sections of the storage stability test tubes.

The results presented in Figure 8 reveal good compatibility between the asphalt and SGP, mainly when the concentrations are kept below 2.5 wt.%; the maximum temperature difference is 2.7 °C, which is an acceptable value for concluding that no significant phase separation is taking place in the modified asphalt samples, but instead, the SGP is homogeneously dispersed in the asphalt matrix. As demonstrated in Figure 8, the only outlier corresponds to the highest concentration of SGP of 850 μm. The modified asphalt blends can be regarded as suspensions, where the suspended modifier particles are subjected to buoyancy, gravity, and drag forces, and their sedimentation velocity can be calculated through the Stokes’ Law [3]. This sedimentation tendency is the reason why one of the main disadvantages of modified asphalts is their instability when stored at high temperatures, where the asphalt becomes more fluid, and the modifier particles tend to deposit on the bottom of the reservoir, inducing a phase separation between the asphalt and the sedimented modifier-rich phase. This problem is particularly severe when the modifier is a polymer [8].

The homogeneous behavior of the SGP-modified asphalt samples suggests that the suspended SGP particles interact through their cellulosic and polysaccharide groups with the polar fractions of the asphalt (resins and asphaltenes). These SGP-asphalt interactions result from the complex chemical composition of the SGP and its surface area, which allows the particles dispersion and favors an improved mechanical and thermal stability on the modified asphalt.

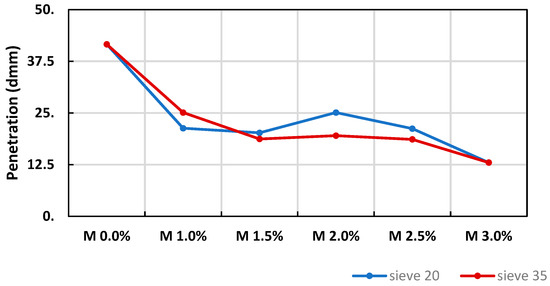

3.6. Penetration Test

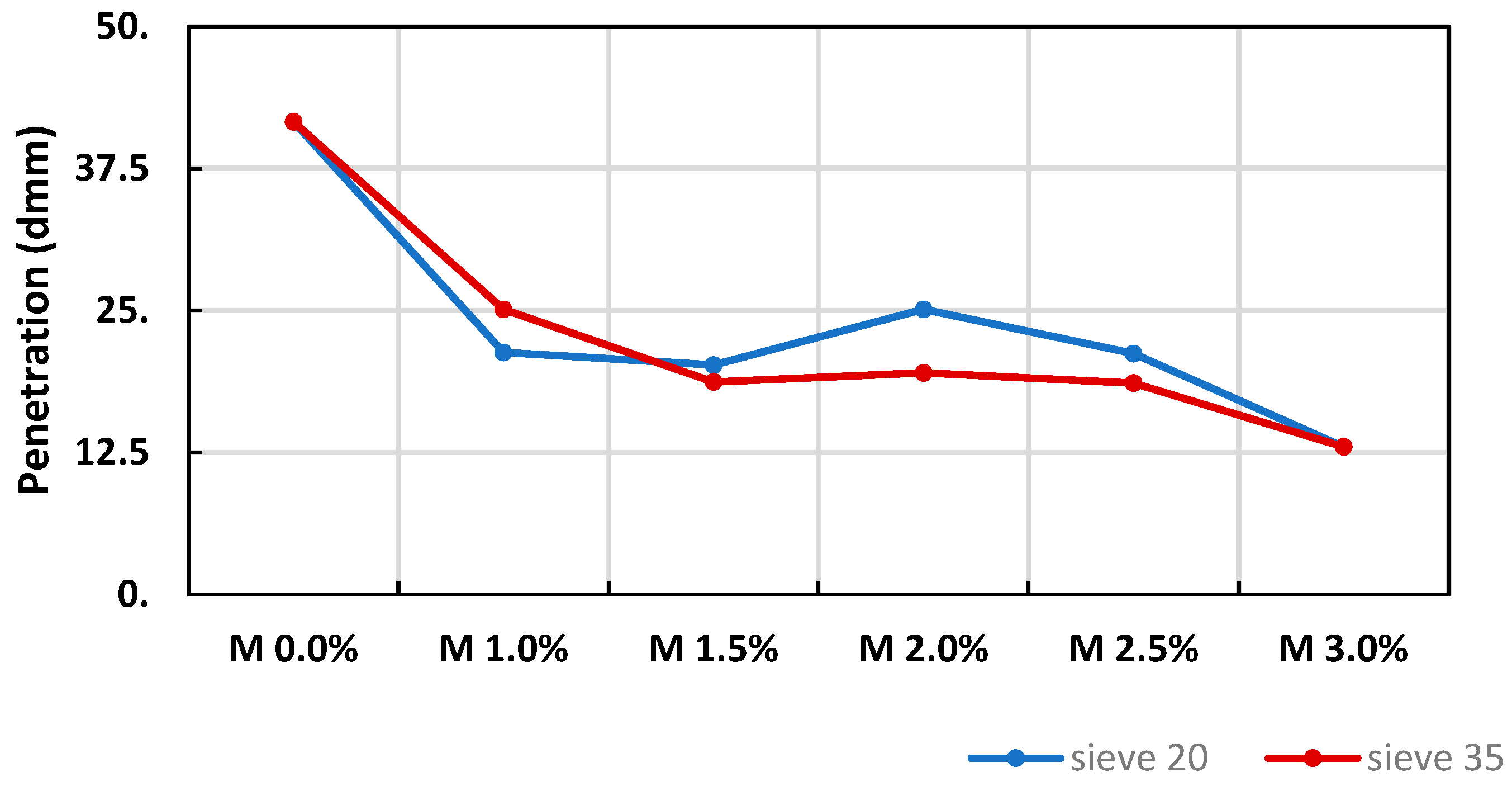

Penetration test was carried out in a digital penetrometer, and additionally, the penetration index (PI) was determined according to Equation (2), which establishes a mathematical relationship between the penetration value of a sample (PEN, in dmm) and its softening point (SP, in °C). The PI is usually considered an indicator of the thermal susceptibility of the asphalt, and it assumes values in the range between −3 and +7; the lower the PI, the higher the thermal susceptibility of the asphalt [10,41,42,43]:

Figure 9 shows the effect of the incorporation of SGP on the penetration values of the asphalt, which lowers as the SGP content increases. The penetration reduction is more evident at SGP concentrations lower than 1.0 wt.%, where the asphalt phase is predominant. However, the increased surface area of the 500 μm SGP is beneficial for having lower penetration values compared to the 850 μm SPG at concentrations above 1.0 wt.%.

Figure 9.

Penetration values of pure and SGP-modified asphalt binders.

The asphalt changes its physical behavior because as more SGP is added to the asphalt, its penetration value decreases, and simultaneously, its softening point increases. Therefore, the calculation of PI values turns out essential to assess the thermal susceptibility of the asphalt, and it also gives information on its rutting resistance. As evidenced by the results presented in Table 5, all PI values lie down inside the range between −3 and +7 [3], which is evidence for concluding that the volume and surface area of SGP enhances the thermal susceptibility and rutting resistance in the modified asphalts, especially when 20-mesh sieve SGP (500 μm) is incorporated at concentrations between 1.5 wt.% and 2.5 wt.%.

Table 5.

Penetration index of pure and SGP-modified asphalt binders.

Low concentrations of SGP achieve similar PI values compared to other studies where higher modifier proportions are required. For example, PI values of −0.11 and 0.80 were reported by Nciri et al. [10] for asphalt modified by 5.0 wt.% and 10 wt.% of oyster shell powder, respectively. The stiffer behavior of modified asphalts is a consequence of the SGP acting as a filler. The reinforced mechanism of asphalt modifiers has been described in the literature to act in three ways: filling the free volume of the binder with rigid particles, structuring the modifier particles into a skeletal framework, and inducing physicochemical interactions between the filler and the asphalt [10,44].

3.7. ANOVA Tests

Table 6 shows the p-values for the SGP content and particle size resulting from the general linear models of the properties measured in this study. Since their p-values are less than the significance level (α = 0.05), the SGP content of the modified asphalts significantly affects their complex modulus gain, dynamic viscosity, and penetration index; similarly, the SGP particle size is responsible for the changes observed in the mean complex modulus gain and dynamic viscosity. Although some of the p-values are greater than the selected significance level, it is evident that the conventional physical properties such as the softening point, phase separation, penetration index, and penetration exhibit more significant variations in their mean values as a result of changes in the SGP concentration, rather than in the SGP particle size. However, the SGP particle size becomes vital for explaining the observed changes in the rheological properties of the modified asphalts (complex modulus gain, failure temperature, and dynamic viscosity) since the rheological parameters are sensitive to the surface activation energy of the modifier particles [24], which increases as the specific surface area of the SGP increases due to a size reduction.

Table 6.

Calculated p-values for SGP wt.% and particle size in the ANOVA tests of SGP-modified asphalts.

The former observation is consistent with the results obtained by Yu et. Al. [24], who found that using smaller particles of phosphorus slag increased the complex shear modulus, decreased the phase angle, increased the elastic component, and improved the rutting resistance, failure temperature, and fatigue performance of modified asphalt preparations.

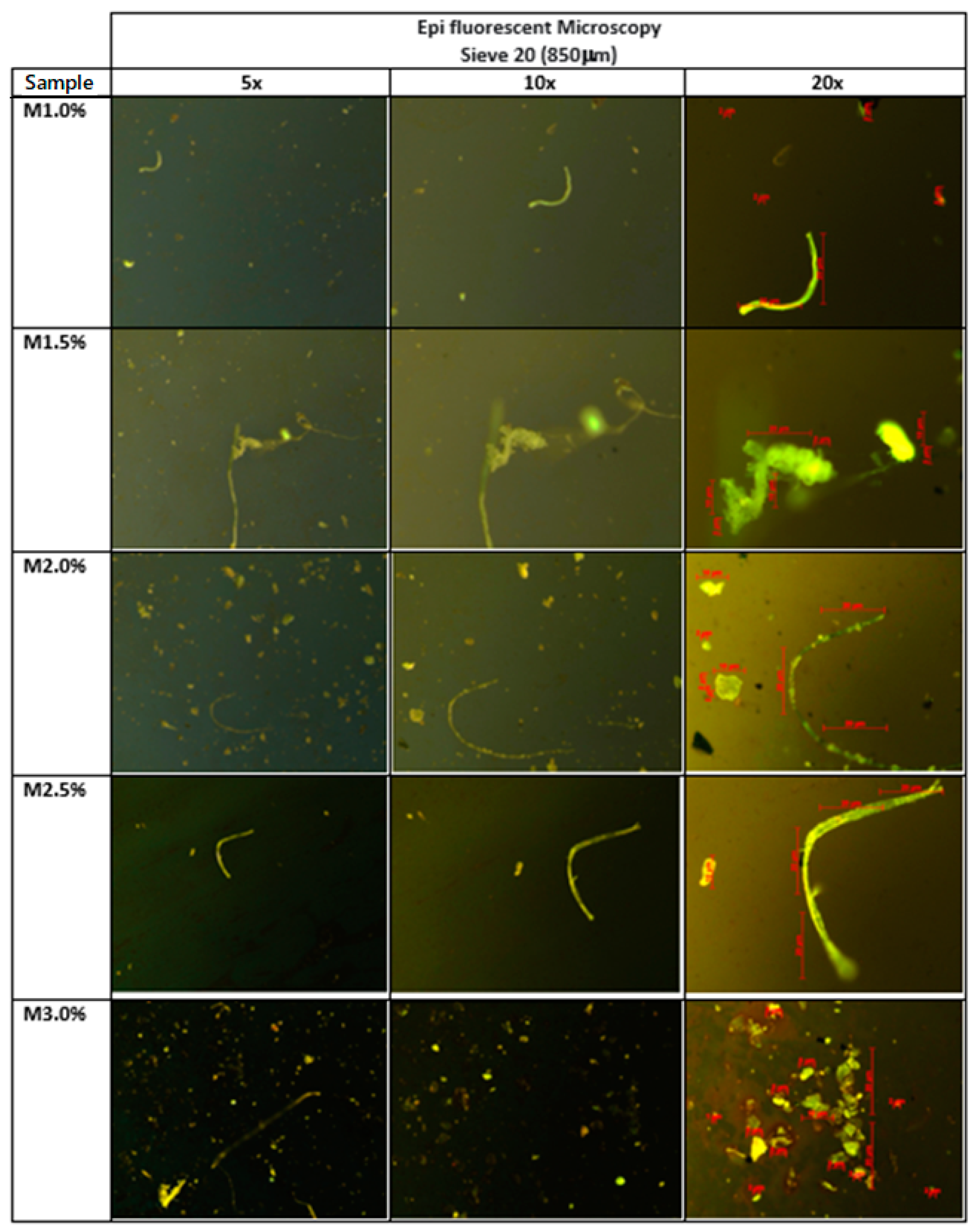

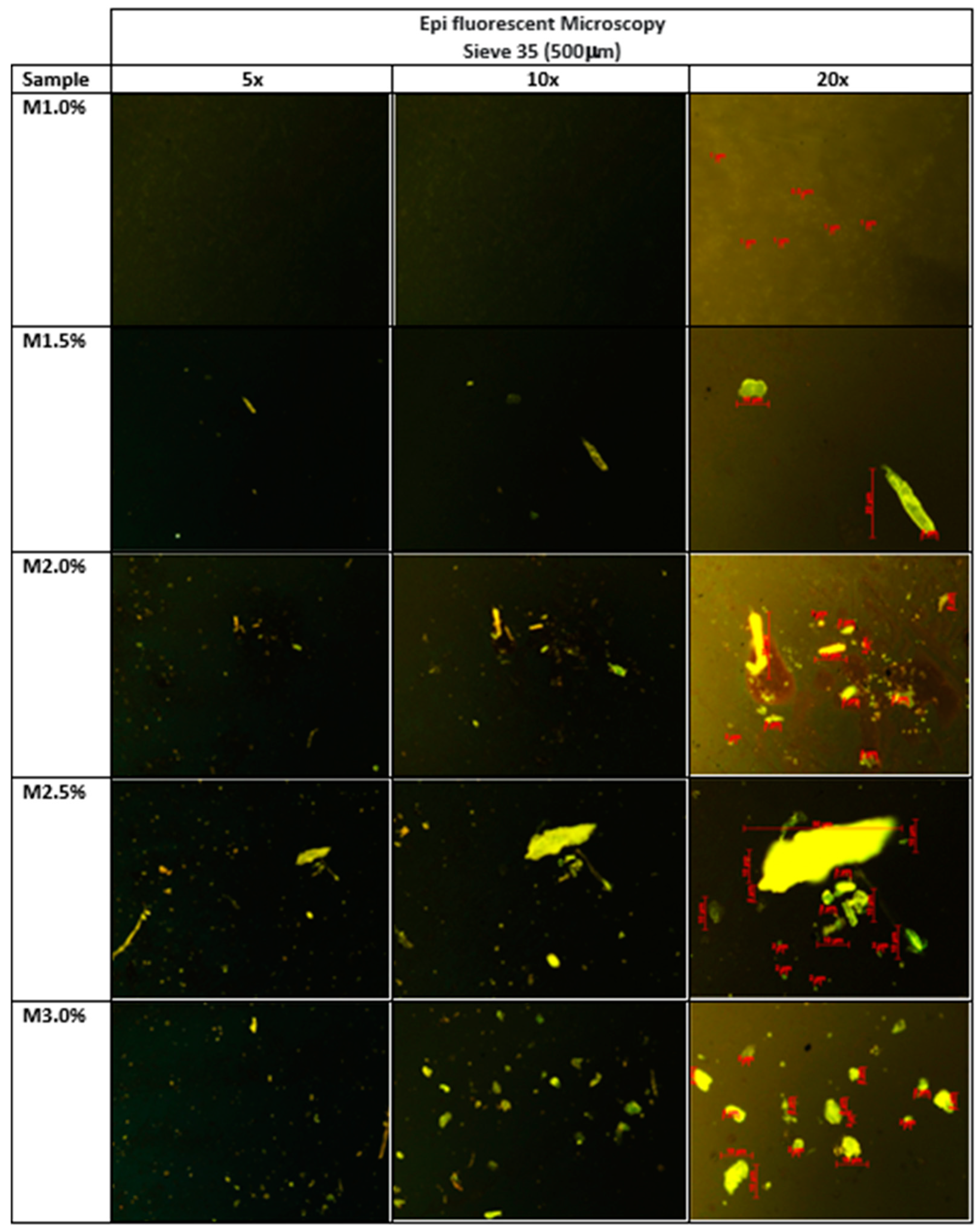

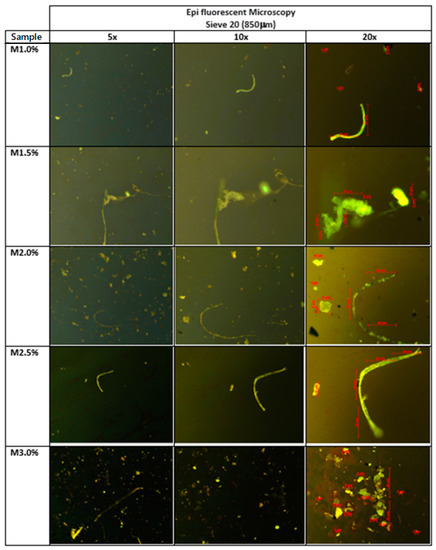

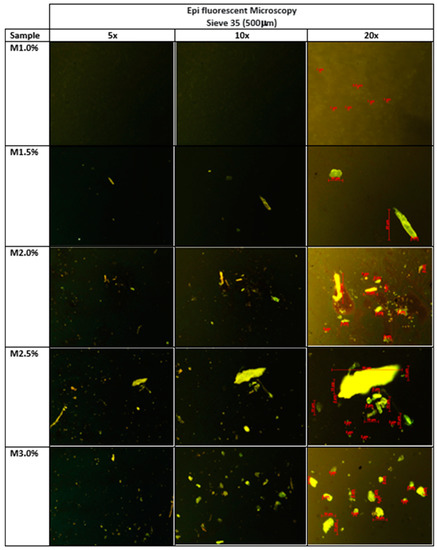

3.8. Morphology of the SGP Dispersion in the Asphalt Binders

The morphology of the dispersed modifier particles in the asphalt matrix is presented in Figure 10 and Figure 11as a function of the SGP concentration of the samples. In this test, a low fluorescent image implies a good dispersion pattern of the particles in the asphalt matrix [45,46]. Therefore, the dark regions observed in the micrographs of Figure 10 and Figure 11 correspond to the asphalt matrix, while the fluorescent dots represent the SGP [21]; the more uniform the micrograph, the better dispersed the SGP in the asphalt matrix. According to the results, it is evident that using high SGP concentrations leads to the agglomeration of the modifier particles, as observed in the 20× images of the samples containing 2.5 and 3.0 wt.% SGP. The micrographs show that the uniformity of the dispersion significantly depends on the concentration and particle size of SGP, where the lower concentrations and sizes tend to favor more continuous phases.

Figure 10.

Epifluorescence micrographs of modified asphalts with 850 μm SGP at different concentrations and magnifications.

Figure 11.

Epifluorescence micrographs of modified asphalts with 500 μm SGP at different concentrations and magnifications.

4. Conclusions

In order to reutilize natural wastes in asphalt modification, such as seaweed sargassum, their properties must be evaluated to know their potential uses and limitations. This study established a process to use seaweed sargassum particles in asphalt modification for pavement construction. The effects of the sargassum concentration (1.0, 1.5, 2.0, 2.5, 3.0 wt.%) and particle size (500 and 850 μm) on the physical and rheological properties of modified asphalts were evaluated. The FTIR spectra showed that the modification process induced no chemical changes. Therefore, the interaction between sargassum and asphalt is regarded as physical adsorption resulting from the van der Waals and electrostatic forces established between the polysaccharides and amino acids of sargassum and the aromatic molecules of the asphalt. On the other hand, the sargassum particles of elevated surface area, and therefore, small particle size, were able to establish more contact points between the modifier particles and the asphalt matrix, reinforcing the binder and improving its physical and mechanical properties. The asphalt mixtures prepared with 500-μm sargassum particles at concentrations below 3.0 wt.% showed better softening points, penetration, thermal storage stability, and deformation resistance than their counterparts containing 850-μm sargassum particles. The statistical analysis revealed that the rheological behavior of the asphalt mixtures is more affected by the modifier particle size, while the physical conventional properties were more determined by the sargassum concentration. The epifluorescence microscopy revealed that high sargassum concentrations, starting from 1.5 wt.%, leads to agglomerate formation, which affects the morphology and microstructure of modified asphalts. The overall analysis allows us to conclude that sargassum particles may efficiently be used as a sustainable alternative for asphalt modification applied to road construction. Future investigations on this topic would involve more rheological and dynamic viscosity characterization for widening the scope of applicable conditions of sargassum-modified asphalt.

Author Contributions

Conceptualization, J.L.R.-A. and B.A.S.-C.; methodology, F.J.E.-M. and G.H.-Z.; validation, J.L.R.-A., B.A.S.-C., and C.G.F.-H.; formal analysis, S.Z.-C.; investigation, F.J.E.-M. and B.A.S.-C.; resources, J.L.R.-A. and B.A.S.-C.; data curation, G.H.-Z. and C.G.F.-H.; writing—original draft preparation, F.J.E.-M. and S.Z.-C.; writing—review and editing, J.L.R.-A. and B.A.S.-C.; visualization, J.L.R.-A.; supervision, project administration, funding acquisition, J.L.R.-A. and B.A.S.-C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Consejo Nacional de Ciencia y Tecnología CONACYT, grant number 1005268, and Tecnológico Nacional de México TNM Project “Evaluación de las condiciones de pruebas reológicas de mezclas desarrolladas con desechos sólidos orgánicos”, Project No. 1008.21P.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank Carlos Alberto Montaño-Salazar for his valuable social work in collecting and processing the seaweed sargassum used in this study. The authors also thank Consejo Nacional de Ciencia y Tecnología (CONACYT) for the M. Sc. grant (F.E.-M., CVU number 1005268), as well as the TNM Project “Evaluación de las condiciones de pruebas reológicas de mezclas desarrolladas con desechos sólidos orgánicos” 1008.21P, for the financial support.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- AASHTO T315–12: Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); AASHTO: Washington, DC, USA, 2016.

- Abdul Khalil, H.P.S.; Tye, Y.Y.; Saurabh, C.K.; Leh, C.P.; Lai, T.K.; Chong, E.W.N.; Nurul Fazita, M.R.; Hafiidz, J.M.; Banerjee, A.; Syakir, M.I. Biodegradable polymer films from seaweed polysaccharides: A review on cellulose as a reinforcement material. Express Polym. Lett. 2017, 11, 244–265. [Google Scholar] [CrossRef]

- Asphalt Institute. Asphalt Binder Testing, Technician’s Manual for Specification Testing of Asphalt Binder. MS-25; Asphalt Institute, EUA: Lexington, KY, USA, 2014. [Google Scholar]

- ASTM D-36-95: Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); ASTM: West Conshohocken, PA, USA, 2015.

- Azarhoosh, A.; Koohmishi, M. Investigation of the rutting potential of asphalt binder and mixture modified by styrene-ethylene/propylene-styrene nanocomposite. Constr. Build. Mater. 2020, 255, 119363. [Google Scholar] [CrossRef]

- Bellatrache, Y.; Ziyani, L.; Dony, A.; Taki, M.; Haddadi, S. Effects of the addition of date palm fibers on the physical, rheological and thermal properties of bitumen. Constr. Build. Mater. 2020, 239, 117808. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.; Hassan, N.; Haloul, M.; Modibbo, S. Influence of crumb rubber size particles on moisture damage and strength of the hot mix asphalt. Mater. Today Proc. 2021, 42, 2387–2391. [Google Scholar] [CrossRef]

- Cao, Y.; Li, H.; Zhang, Y.; Zhang, J.; He, J. Structure and Properties of Novel Regenerated Cellulose Films Prepared from Cornhusk Cellulose in Room Temperature Ionic Liquids Yan. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Caro, S.; Vega, N.; Husserl, J.; Alvarez, A.E. Studying the impact of biomodifiers produced from agroindustrial wastes on asphalt binders. Constr. Build. Mater. 2016, 126, 369–380. [Google Scholar] [CrossRef]

- Chen, J.S.; Lin, K.Y.I. Mechanism and behavior of bitumen strength reinforcement using fibers. J. Mater. Sci. 2005, 40, 87–95. [Google Scholar] [CrossRef]

- Colunga-Sánchez, L.M.; Salazar-Cruz, B.A.; Rivera-Armenta, J.L.; Morales-Cepeda, A.B.; Ramos-Gálvan, C.E.; Chávez-Cinco, M.Y. Evaluation of chicken feather and styrene-butadiene/chicken feather composites as modifier for asphalts binder. Appl. Sci. 2019, 9, 5188. [Google Scholar] [CrossRef] [Green Version]

- Devault, D.A.; Modestin, E.; Cottereau, V.; Vedie, F.; Stiger-Pouvreau, V.; Pierre, R.; Coynel, A.; Dolique, F. The silent spring of Sargassum. Environ. Sci. Pollut. Res. 2021, 28, 15580–15583. [Google Scholar] [CrossRef]

- Devault, D.A.; Pierre, R.; Marfaing, H.; Dolique, F.; Lopez, P.J. Sargassum contamination and consequences for downstream uses: A review. J. Appl. Phycol. 2021, 33, 567–602. [Google Scholar] [CrossRef]

- Ding, Z.; Li, P.; Zhang, J.; Bing, H.; Yue, X. Analysis of viscosity test conditions for crumb-rubber-modified asphalt. Constr. Build. Mater. 2020, 245, 118454. [Google Scholar] [CrossRef]

- Doh, H.; Dunno, K.D.; Whiteside, W.S. Preparation of novel seaweed nanocomposite film from brown seaweeds Laminaria japonica and Sargassum natans. Food Hydrocoll. 2020, 105, 105744. [Google Scholar] [CrossRef]

- Hataf, N.; Ghadir, P.; Ranjbar, N. Investigation of soil stabilization using chitosan biopolymer. J. Clean. Prod. 2018, 170, 1493–1500. [Google Scholar] [CrossRef]

- Ju, X.; Bowden, M.; Brown, E.E.; Zhang, X. An improved X-ray diffraction method for cellulose crystallinity measurement. Carbohydr. Polym. 2015, 123, 476–481. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kannan, S. FT-IR and EDS analysis of the seaweeds Sargassum wightii (brown algae) and Gracilaria corticata (red algae). Int. J. Curr. Microbiol. Appl. Sci. 2014, 3, 341–351. [Google Scholar]

- Kim, M.; Buttlar, W.G. Stiffening Mechanisms of Asphalt–Aggregate Mixtures: From Binder to Mixture. Transp. Res. Rec. J. Transp. Res. Board. 2010, 2181, 98–108. [Google Scholar] [CrossRef]

- Kolsi, R.B.A.; Salah HBen Jardak, N.; Chaaben, R.; Jribi, I.; Feki AEl Rebai, T.; Jamoussi, K.; Allouche, N.; Blecker, C.; Belghith, H.; Belghith, K. Sulphated polysaccharide isolated from Sargassum vulgare: Characterization and hypolipidemic effects. Carbohydr. Polym. 2017, 170, 148–159. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.-Y. The Effect of Filler on Asphalt Cement Mastics; Iowa State University of Science and Technology: Ames, IA, USA, 1964. [Google Scholar]

- Li, C.; Zou, J.; Ke, W.; Wang, G.; Li, T.; Li, Y.; Li, S.; Shu, B.; Li, C. Laboratory evaluation of asphalt binder modified by waste carbon particles (WCP) reclaimed from printers. Int. J. Pavement Res. Technol. 2021, 14, 204–212. [Google Scholar] [CrossRef]

- Li, J.; Zhang, F.; Muhammad, Y.; Liu, Y.; Wei, Y.; Chen, H. Fabrication and properties of wide temperature domain pavement seaweed modified bio-bitumen. Constr. Build. Mater. 2019, 227, 117079. [Google Scholar] [CrossRef]

- Luo, G.; James Strong, P.; Wang, H.; Ni, W.; Shi, W. Kinetics of the pyrolytic and hydrothermal decomposition of water hyacinth. Bioresour. Technol. 2011, 102, 6990–6994. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Anzures, J.D.; Zapién-Castillo, S.; Salazar-Cruz, B.A.; Rivera-Armenta, J.L.; del Carmen Antonio-Cruz, R.; Hernández-Zamora, G.; Méndez-Hernández, M.L. Preparation and properties of modified asphalt using branch SBS/nanoclay nanocomposite as a modifier. Road Mater. Pavement Des. 2019, 20, 1275–1290. [Google Scholar] [CrossRef]

- Marx, U.C.; Roles, J.; Hankamer, B. Sargassum blooms in the Atlantic Ocean—From a burden to an asset. Algal Res. 2021, 54, 102188. [Google Scholar] [CrossRef]

- Mohammed, M.; Parry, T.; Grenfell, J. Influence of fibres on rheological properties and toughness of bituminous binder. Constr. Build. Mater. 2018, 163, 901–911. [Google Scholar] [CrossRef]

- Nciri, N.; Shin, T.; Lee, H.; Cho, N. Potential of waste oyster shells as a novel biofiller for hot-mix asphalt. Appl. Sci. 2018, 8, 415. [Google Scholar] [CrossRef] [Green Version]

- Norgbey, E.; Huang, J.; Hirsch, V.; Liu, W.J.; Wang, M.; Ripke, O.; Li, Y.; Takyi Annan, G.E.; Ewusi-Mensah, D.; Wang, X.; et al. Unravelling the efficient use of waste lignin as a bitumen modifier for sustainable roads. Constr. Build. Mater. 2020, 230, 116957. [Google Scholar] [CrossRef]

- Pamplona, T.F.; De CAmoni, B.; De Alencar, A.E.V.; Lima, A.P.D.; Ricardo, N.M.P.S.; Soares, J.B.; De A Soares, S. Asphalt binders modified by SBS and SBS/nanoclays: Effect on rheological properties. J. Braz. Chem. Soc. 2012, 23, 639–647. [Google Scholar] [CrossRef] [Green Version]

- Read, J.; Whiteoak, D. The Shell Bitumen Handbook, 5th ed.; Thomas Telford Publishing: London, UK, 2003. [Google Scholar]

- Rodríguez-Martínez, R.E.; Roy, P.D.; Torrescano-Valle, N.; Cabanillas-Terán, N.; Carrillo-Domínguez, S.; Collado-Vides, L.; García-Sánchez, M.; van Tussenbroek, B.I. Element concentrations in pelagic Sargassum along the Mexican Caribbean coast in 2018–2019. PeerJ 2020, 8, e8667. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Muñoz, R.; Muñiz-Castillo, A.I.; Euán-Avila, J.I.; Hernández-Núñez, H.; Valdés-Lozano, D.S.; Collí-Dulá, R.C.; Arias-González, J.E. Assessing temporal dynamics on pelagic Sargassum influx and its relationship with water quality parameters in the Mexican Caribbean. Reg. Stud. Mar. Sci. 2021, 48, 102005. [Google Scholar] [CrossRef]

- Salazar-Cruz, B.A.; Zapien-Castillo, S.; Hernández-Zamora, G.; Rivera-Armenta, J.L. Investigation of the performance of asphalt binder modified by sargassum. Constr. Build. Mater. 2021, 271, 121876. [Google Scholar] [CrossRef]

- Sharifi, K.A.; Pirsa, S. Biodegradable film of black mulberry pulp pectin/chlorophyll of black mulberry leaf encapsulated with carboxymethylcellulose/silica nanoparticles: Investigation of physicochemical and antimicrobial properties. Mater. Chem. Phys. 2021, 267, 124580. [Google Scholar] [CrossRef]

- Shekhar, S.H.S.; Lyons, G.; McRoberts, C.; McCall, D.; Carmichael, E.; Andrews, F.; McCormack, R. Brown seaweed species from Strangford Lough: Compositional analyses of seaweed species and biostimulant formulations by rapid instrumental methods. J. Appl. Phycol. 2012, 24, 1141–1157. [Google Scholar] [CrossRef]

- Sudarshan, M.; Ram, S.S.; Majumdar, S.; Maity, J.P.; Ray, J.G.; Chakraborty, A. Energy-dispersive X-ray fluorescence—A tool for interdisciplinary research. Pramana J.Phys. 2011, 76, 241–247. [Google Scholar] [CrossRef]

- Technical Bulletin DGST No. 2/2020: Origin Asphalt Cement and Classification for Use in Road Infrastructure Works; Secretaría de Comunicaciones y Transportes: Mexico City, Mexico, 2020.

- Thiripura Sundari, M.; Ramesh, A. Isolation and characterization of cellulose nanofibers from the aquatic weed water hyacinth—Eichhornia crassipes. Carbohydr. Polym. 2012, 87, 1701–1705. [Google Scholar] [CrossRef]

- Vanavil, B.; Selvaraj, K.; Aanandhalakshmi, R.; Usha, S.K.; Arumugam, M. Bioactive and thermostable sulphated polysaccharide from Sargassum swartzii with drug delivery applications. Int. J. Biol. Macromol. 2020, 153, 190–200. [Google Scholar]

- Vázquez-Delfín, E.; Freile-Pelegrín, Y.; Salazar-Garibay, A.; Serviere-Zaragoza, E.; Méndez-Rodríguez, L.C.; Robledo, D. Species composition and chemical characterization of Sargassum influx at six different locations along the Mexican Caribbean coast. Sci. Total Environ. 2021, 795, 148852. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Q.; Jiang, X.; Han, X.; Ji, H. Compositional analysis of bio-oil derived from pyrolysis of seaweed. Energy Convers. Manag. 2013, 68, 273–280. [Google Scholar] [CrossRef]

- Wróbel, M.; Woszuk, A.; Ratajczak, M.; Franus, W. Properties of reclaimed asphalt pavement mixture with organic rejuvenator. Constr. Build. Mater. 2021, 271, 121514. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, X.; Qian, G.; Gong, X.; Nie, X. Evaluation of phosphorus slag (PS) content and particle size on the performance modification effect of asphalt. Constr. Build. Mater. 2020, 256, 119334. [Google Scholar] [CrossRef]

- Yu, J.; Zeng, X.; Wu, S.; Wang, L.; Liu, G. Preparation and properties of montmorillonite modified asphalts. Mater. Sci. Eng. A 2007, 447, 233–238. [Google Scholar] [CrossRef]

- Zapién-Castillo, S.; Rivera-Armenta, J.L.; Chávez-Cinco, M.Y.; Salazar-Cruz, B.A.; Mendoza-Martínez, A.M. Physical and rheological properties of asphalt modified with SEBS/montmorillonite nanocomposite. Constr. Build. Mater. 2016, 106, 349–356. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).