Abstract

The increasing resource pressure and the expanding amount of textile waste have been rising recycling as a clear priority for the fashion and apparel industry. However, textile recycling remains limited and is therefore a targeted issue in the forthcoming EU policies. As the fashion industry is embedded in complex value chains, enhancing textile recycling entails a comprehensive understanding of the existing challenges. Yet, the literature review suggests only limited empirical studies in the sector, and a dedicated state-of-the-art is still lacking. Filling this gap, a Delphi study was conducted supplemented by the Regnier’s Abacus technique. Through an iterative, anonymous, and controlled feedback process, the obstacles collected from the extant literature were collectively discussed with a representative panel of 28 experts, compared to the situation in Europe. After two rounds, the lack of eco-design practices, the absence of incentive policies, and the lack of available and accurate information on the product components emerged as the most consensual statements. Linking theory to practice, this paper aims to improve consistency in the understanding of the current state of textile recycling in Europe, while providing an encompassing outline of the current experts’ opinion on the priority challenges for the sector.

1. Introduction

With the rise of the globalization, the fashion industry has become a significant worldwide business (the global apparel market has been estimated in value to USD 1.5 trillion in 2020 [1]) based upon lengthy and geographically fragmented value chains [2,3]. Production has shifted to southern countries, mainly in Asia, while design, marketing, and distribution activities have remained located in advanced countries [4], with Europe representing an important apparel net importer (over EUR 80 billion of imported goods, mainly from China, Bangladesh, and Turkey, in 2019 [5]). Characterized by a constant growth and driven by the so-called “fast-fashion” phenomenon [3], the industry has resulted in tremendous environmental and social repercussions over the last decades [3,6]. Steadily scrutinized as a substantial impactful sector, a range of estimates have successively evaluated, depending on assumptions, the fashion industry to account for 4% [7], 8% [8], and up to 10% of global CO2 emissions [3] with the main environmental impacts imputed to the raw materials and manufacturing activities [8,10,11]. Correlatively, this accelerated fashion consumption has led to the perception of clothes as disposable items, decreasing the garment’s lifetime [9,12,13,14,15,16]. Such a completely linear or “take make waste” model has resulted in an expanding amount of discarded textiles in Europe [3,12,14,16]. While assessing used textile flows remains challenging [17], the amount of clothes bought in the EU has been estimated to have increased by 40% over the last decades [18,19]; Europeans consuming on average 26 kg and discarding 11 kg of textiles per person per year [20]. Considering the alarming climate state [21], decreasing the resource pressure is crucial to reduce the environmental footprint of the sector while ensuring viable business models in the long term to face up to forthcoming scarcity [14,22]. Therefore, enhancing recycling has been standing as a critical priority in this wider transition towards a “circular economy” [9,14].

The concept of “circular economy” has raised interest since the late 1970s [14,23] and derives from connected background concepts such as the famed cradle-to-cradle design philosophy [23,24]. The most renowned definition has been framed by the Ellen MacArthur Foundation, where the economy is “restorative and regenerative by design, and aims to keep products, components, and materials at their highest utility and value at all times” [25]. Binding economic performance, social inclusiveness, and environmental resilience [26], this new industrial paradigm promotes material flows systems in which resources are optimized, thus enabling “sustainability” covering a broader framing [23]. Indeed, by promoting the reduction of resources extraction, the extension of the product lifecycle, and the minimization of waste production [27,28], the transition to circular business models has the potential to decrease the environmental impact of the industry [2,6,9,29,30]. However, the review suggests that companies are selectively implementing circular actions in their supply chains, rather than disrupting the entire business model [9] and addressing the main environmental impacts of their activities [12]. In fact, by bridging production and consumption activities [12,15,25], “circular economy” involves the implementation of several strategies usually suggested through the “R framework” and requiring radical systemic changes in how products and materials are manufactured, used, and disposed of [29,30,31]. A varying level of detail exist in the literature [32] and up to “10R principles”can be found namely refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, repurpose, recycle, and recover [27,32,33]. Ordered by level of circularity, recycling rationally comes into play among the final options once the materials can no longer be reused, following the existing EU waste hierarchy of optimal treatment solutions [34].

However, it is estimated that only 12% of global material flows for clothing are recycled, mainly into “open-loop” applications [9] (such as insulation material, wiping cloths, or mattress stuffing), also referred to as “cascaded recycling” [35] or “downcycling” [36,37] because of their lesser economic value [38], while much higher rates are noticed in other industries [39]. Only less than 1% of clothing textile material would be recycled into new clothes, referred as “closed-loop recycling” or “textile-to-textile recycling”, the 87% remainder ending up mainly in landfill or being incinerated [9]. Therefore, lifecycle-extending practices are not sufficient in themselves and must be enhanced, along with improving recycling practices [14]. Within this context, the sector is particularly targeted in the upcoming Green Deal strategy [40] aiming to achieve climate neutrality in Europe by 2050, as shown by the foreseeing EU Strategy for Textiles [41] ambitioning to boost the EU market for sustainable and circular textiles. The public consultations launched recently by the European Commission [41,42] reveal a wide range of dedicated policies to enhance textile recycling (i.e., separate collection mandatory by 2025, incorporation of recycled content, digital passport…).

However, despite increasing interest in the industry, textile recycling is still a limited research area [14], which has mostly been explored from a technical perspective, to improve textile recycling processes towards value-added products [36]. An increasing body of research has been also dedicated to the study of the environmental benefits of textile recycling [35]. However, while its improvement is consistently pointed out as requiring a “system-level change” with extensive stakeholders’ collaboration [25], very few comprehensive studies have been conducted. The literature on the topic is fragmented, and empirical studies remain limited, which impedes an explicit evidence-based state-of-the art on the current challenges in the sector. Although a flourishing literature on textile-specific barriers to the implementation of the “circular economy” has advanced knowledge in the industry [12,29,32], these studies do not provide a systematic analysis of the existing issues related to the textile recycling value chain.

Subsequently, this paper aims to answer the following research questions: What are the current impediments in the textile recycling value chain? What are the priority challenges to address in order to enhance textile recycling in the sector? To achieve these research objectives, a systematic review was conducted to identify the recurring challenges acknowledged in the existing literature on textile recycling. Then, a purposely designed qualitative study using the Delphi method [43] and applying the Abaque de Régnier technique (Regnier’s Abacus) [44] was implemented, referred to as “Delphi-Régnier” in the remainder of the paper. With an unprecedented panel of 28 experts in the field representing the different stakeholders of the recycling value chain, the reported challenges in the extant literature were translated into statements and iteratively discussed through this group communication technique, using a color grid to collect experts’ opinions. The study is not strictly limited to textile-to-textile recycling but instead aims to explore the overall challenges related to the optimization of textile recycling, to better comprehend the current collection, sorting, and recycling system.

With regard to previous exhaustive research on the topic [14], the originality of the study resides both in the representativeness of the panel and in the Delphi-Régnier method used. This method differs from a simple interview and helps to advance empirical knowledge on textile recycling with the confrontation of the experts’ opinions between the iterative rounds. Moreover, while barriers of textile recycling have started to be explored in the industry [12,14,29,32], this Delphi-Régnier study provides a holistic analysis of the contextual challenges and addresses the priority concerns in the sector, by allowing consensus and dissensus on the topic to arise. The research focuses on the European situation but still provides general findings advancing the literature on sustainability in the fashion and apparel industry. If the method has inherent limitations, the findings can support relevant initiatives for practitioners or policymakers and research opportunities to advance textile recycling in the sector.

The paper is structured as follows: Section 2 introduces the systematic literature review conducted. Section 3 describes the Delphi method and the Regnier’s Abacus technique, together with the associated research steps. Section 4 is devoted to the presentation and discussion of the results. Section 5 introduces the limitations and research perspectives. At last, Section 6 concludes on the main findings.

2. Literature Review

A prior systematic review [45] was developed on the research problem, to explore the challenges of textile recycling with regards to the fashion and apparel sector. It was done using the databases Scopus, Science Direct, and Web of Science to guarantee an extensive coverage. As a relatively new and transdisciplinary area, we decided not to limit the scope of the review and include empirical studies, review papers, conference proceedings, and book chapters as long as they served the research objective. An additional search was done through Google Scholar to make sure that on-topic publications, unavailable on specific databases, were not omitted. Preliminary research suggested a limited academic literature, corroborated by Sandvik et al. [14]. Following the review protocol from preceding reviews on textile recycling [46], white papers and public reports from well-established organizations or institutions were also considered, after an extensive search on Google. By contrast, we noticed an extensive grey literature, especially several studies that have been published by practitioners for public institutions to improve resource management. However, the priority was given to peer-reviewed journals, and only the most relevant publications were cautiously included. Even if no limitation on the publication date was pre-established, research has significantly increased since 2005 with a clear rise in publications starting from 2018, and only the most recent papers were selected to ensure a contemporary state-of-the-art.

Keyword identification was challenging as in primary enquiries, engineering, material, environmental sciences, and chemistry fields prevailed, confirmed by the review performed by Shirvanimoghaddam et al. [36]. Initial extensive research was conducted using the combination (textile OR apparel OR garment) AND (recycling) AND (challenge OR obstacle OR limit OR complex OR barrier). Numerous papers on wastewater treatment were raised while our research focused on the narrowed understanding of textile recycling as the “breakdown and reclaiming of textile raw materials to new ones” [38]. Following an inductive and flexible process [45], the research protocol was progressively revised based on subsequent findings. We replaced (“recycling”) with the keywords and Boolean connector (“circular” AND “waste”) in the research string to broaden the scope and target papers on textile flows management that were relevant to the research problem. A total number of 1414 articles resulted from those two keyword equations, which were applied to titles, abstracts, and keywords for Scopus and Science Direct, and to “all fields category” for Web of Science.

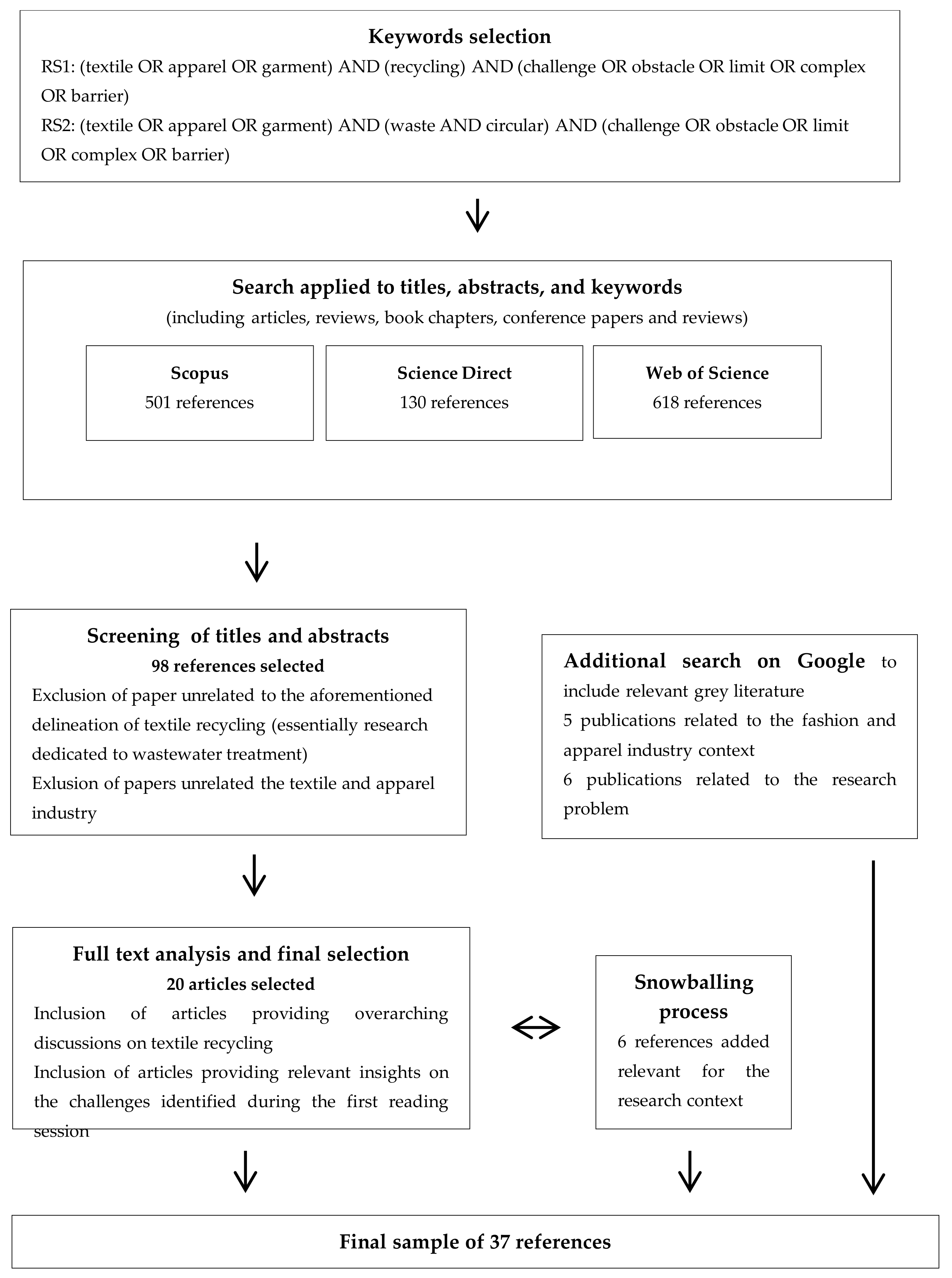

The filtering process was another obstacle due to the fragmented literature. It was initiated by checking titles and abstracts, firstly excluding publications unrelated (1) to the aforementioned delineation of textile recycling and (2) to the textile and apparel industry. After removing the duplicates, this process resulted into 98 references. Then, full reading was performed to successively define inclusion and exclusion criteria. As a lot of papers were related to the aforementioned technical fields, we first only included articles providing overarching discussions on textile recycling, and we started classifying the reported challenges. Based on the initial findings, a second round of reading was carried out, and only publications either providing empirical knowledge or further supporting some of the challenges identified were incorporated, diminishing the sample to 20 publications. A flowchart of the literature review process is shown in Figure 1.

Figure 1.

Flowchart of the systematic literature review.

The review starts with a general discussion on the key findings, supported by a mapping eliciting the outlined challenges and their recurrence rate in the academic literature, presented subsequently in Table 1.

Table 1.

Reported challenges with occurrences in the academic literature.

2.1. Complexity of the Textile Recycling Value Chain

Consistent with the definition from the EU Waste Framework Directive [56], textile recycling is essentially designated from a technical perspective as the “breakdown and reclaiming of textile raw materials to new ones” [25,35,36] involving a degree of deconstruction [49]. However, textile recycling is actually embedded in a broader and complex textile flow management system involving several preceding stages.

Starting with the collection, textiles are usually classified depending on their collection point along the value chain: textile flows are either designated upon “pre-consumer” if collected at the industrial level or “post-consumer” if collected after use [25,32,57]. “Pre-consumer” usually comprises all types of waste from companies resulting from manufacturing and distribution activities, from textile offcuts to unsold products, whereas “post-consumer” refers to used articles discarded by consumers once no longer wanted. Upstream, some also distinguish between the “post-industrial” (side-effect of clothing manufacture) and the “pre-consumer” (inferior quality garments or unsold product at the retail stage) feedstocks depending on the source in the value chain [16,58]. Nevertheless, while the “pre-consumer” fraction in general is underreported [59], the post-consumer part entails the major challenges for the sector. Overall, 15%–20% of clothes have been estimated to be collected for reuse and recycling practices within Europe [35,46], and important disparities of collection schemes are addressed [9,46]. Attempting mappings on textile flows highlights collection rates varying from 22% (Sweden) [60], 39% (France) [61], and 45% (Denmark) [60], up to 75% in Germany [9] of overall textiles put on the market.

Once collected, items undergo thorough manual sorting, which is resting upon a business model towards the second-hand market [46,54] and the quest for high-quality clothing [46], also referred as “diamonds” [57] or “cream” [17,61]. While oversimplified, the reusable feedstock is separated from the nonreusable stock. A significant fraction is exported abroad, while the most valuable part is directed to fine sorting for nearby markets [11,40,41,54]. Still, for the majority being sold in global markets, the question of their subsequent treatment is left untackled, which explains the current low estimates of textile recycling [9]. Moreover, some exports markets are becoming saturated [54,62], and the quality of reusable textiles appears to have fallen [54,61], a situation further exacerbating the primary issue of textile recycling for the coming years in the sector.

Following reuse, the nonreusable fraction is directed across different recovery avenues (recycling, energy recovery, or incineration) or landfilled with varying rates depending on the countries. In preparation for recycling, textiles are further sorted manually based on their composition [61] and color [54], vis-à-vis recyclers’ specifications requirements. In addition, external components (i.e., metallic parts, buttons, zippers) are disassembled prior to recycling mostly through a manual process [38,46]. To put this into perspective, in France, where an Extended Producer Responsibility (ERP) has been in place since 2007 for clothing, linen, and shoes [55], 56.5% of the items sorted in facilities under contract are reused, mainly overseas (95%), 33.3% is recycled, 9.1% is recovered for solid fuel, 0.7% is incinerated for energy recovery, and only 0.4% is disposed, either through incineration or landfill [61]. The ERP is a policy tool for encouraging and enabling recycling by giving financial and/or physical responsibility to producers for treating and disposing of post-consumer products [17], which is particularly considered in the upcoming EU strategy for the textile sector [41].

Even when nonreusable textiles are recycled, the main destinations remain “open-loop” applications such as wipers, nonwoven, or insulation felts towards other industries [9,14,63]. Therefore, a technological barrier is commonly outlined, and a strong technical emphasis has been featured in the literature on textile recycling.

2.2. The Technological Barriers of Textile Recycling

The lack of technologies to support the development of textile-to-textile recycling is identified as a crucial persisting barrier, as attested by the recurrence rate documented in Table 1. Indeed, textile recycling is predominantly based on established mechanical recycling [9,26]. As regards to the existing processing routes, a typical classification is made between mechanical and chemical recycling [38,58].

Mechanical recycling implies cutting the fabric into smaller pieces and then progressively shredding them through a rotating drum until reaching a fibrous state, suitable for re-spinning into new yarn or for other manufacturing products. Less common, “thermal recycling” is occasionally specified [36] to recycle synthetic fibers by melt extrusion, regularly mentioned under “mechanical recycling” as implying prior mechanical processing [35]. The process can be used to recycle fabrics made from natural fibers as well as synthetic fibers [38]. However, the shredding of the fabric during the mechanical process shortens the fiber length and thus, reduces the quality output [37,51,53]. In “fiber recycling” [9], recycled fibers need to be blended with virgin fibers to reach a satisfactory quality level for yarn spinning [38,46]. Therefore, pre-consumer flows are considered more suitable than post-consumer waste for textile-to-textile recycling, as they are more consistent in quality and color [35,38], with exceptions such as wool, made up of long fibers [58]. Polyester and other thermoplastics can be recycled through thermal recycling, also referred as “mechanical polymer recycling” [9], during which the garments are cut and granulated into PET pellets by applying heat [49] with a certain loss of quality [49,64]. Despite being technologically feasible, this process is however not yet applied at scale [9]. Moreover, apparel textiles are often composed of fiber blends, thereby introducing the challenge of separation [14,58,65] and limiting the range of recycled commodities [51]. Consequently, the main destinations remain shredding the textiles to fiber for applications such as nonwoven or insulations, explaining the negligible “textile-to-textile” recycling share previously mentioned [38]. As such, the distinction between “open-loop” and “closed-loop” aims to reflect the outcome level of refinement [35]: “closed-loop recycling” designates “material recycling for a more or less identical product” [17,38] while “open-loop recycling” appoints processes in which the material is used in another product [17,38], typically towards other industries. In this perspective, a body of scientific research has explored potential applications via mechanical recycling, including composites, sound absorber, or thermal insulation [36].

By contrast, “chemical recycling” implies a higher degree of processing through depolymerization (process of breaking polymeric bonds, for synthetics fibers only) or dissolution (for natural or synthetic cellulosic fibers) [35]. However, chemical recycling is still limited [9,62]. Several innovative processes have been developed [52], especially towards pure cotton and cotton–polyester blends [9]. However, the current technological state is ambiguous, the review suggesting a lack of technological maturity, [9] a deficient economic viability, [9] or the need for investment in research and development [46]. Consequently, the market share of recycled fibers was estimated in 2020 at 8.1% of global fiber production, but such incorporation of recycled fibers mainly derives from the recycling of PEF bottles [66] established since the 1970s [38,67]. In addition, it must be noted that this typology appears oversimplified, as recycling operations often comprise a mix of mechanical, chemical, and thermal processes [35]. Therefore, further classifications have been proposed according to the level of disassembly [9,35] and more recently to the polymer structure of the fibers [27] to promote a clearer communication on the technological progress of textile recycling.

Another technological barrier resulting from the sorting stage is reported in the literature [9,17,47,48,50,68]. As previously outlined, sorting is a manual and costly phase, and therefore, there is a need for an economically viable and effective way to recognize and sort textile materials, to further advance textile-to-textile recycling as requiring homogenous feedstocks [48,50]. This current manual sorting is lacking reliability to recognize and sort the items according to their material content, jeopardizing the subsequent recycling process [48]. The item’s composition is often varying over its lifetime, and the care labels are often cut-off or inaccurate. According to a study conducted by Circle Economy, up to 41% of labels on blended materials contain incorrect information [68].

2.3. Systemic Challenges to Enhance Textile Recycling

As part of this complex textile flow management system, textile recycling involves a myriad of other stakeholders [9,35,47,57] such as charities, municipal waste-collection services, or resell organizations. Only a few mappings of textile flows can be found in the academic literature [16,57], and empirical studies investigating textile flows in these sorting facilities are lacking [54]. However, changes are required throughout the whole value chain, as the performance of this eco-system determines the amount of collected textiles than can be further reused and recycled [54]. Therefore, beyond technical matters [14], numerous obstacles are encountered in the optimization of textile recycling, entailing it as a systemic challenge [14,38].

Several studies, both theoretical [16,51] and empirical [26,29,32], have started to explore the textile-specific barriers related to the implementation of circular economy. While some studies provide in-depth analysis [29,32], they investigate the impediments related to the circular economy as a whole and therefore do not enable a holistic and systematic analysis of the recycling value chain. To the best of our knowledge, the most recent extensive research was carried out by Sandvik et al. in 2019 [14]. The study took a qualitative approach through semi structured interviews with 11 stakeholders and investigated the drivers, inhibitors, and enablers of creating a textile-to-textile recycling system in the Scandinavian fashion industry. The main inhibitors found were the limited recycling technology to separate materials, high costs of research and development, supporting logistics, and complexity of supply chains including multiple stakeholders. However, while extending knowledge on the types of systemic and technological changes required, the study does not allow to leverage the amplitude of opinions and the sample’s lack of representativity. Moreover the study only focuses on textile-to-textile recycling, while both closed-loop and open-loop applications have their importance to reintegrate the increasing nonreusable feedstock [38].

The remainder of the research remains theoretical and only looks over some challenges, without further investigation. Therefore, the literature is scattered, as shown by the fluctuated attendance rate in Table 1. Although some challenges stand out more than others, the current analysis is unable to provide a clear vision on the research problem. Among the most comprehensive articles, Filho et al. [46] investigated the socio-economic advantages of textile recycling and provided the most systematic review we found on textile recycling. The review explored the socio-economic advantages of textile recycling and pinpointed barriers to the optimization of textile recycling without specifying if they were arranged by importance: (1) economic viability, (2) composition of textile products, (3) non availability of recyclable textile materials, (4) technological limitations, (5) lack of information and limited public participation, and (6) poor coordination, and weak policies and standards. In comparison, Holes and Holes investigated effective policies and incentives worldwide for increased recycling from other sectors to reveal opportunities for extrapolation to the textile sector. A brief overview over the challenges identified is exposed, respectively: (1) the lack of incentives to motivate consumers for recycling; (2) informational and educational programs; (3) collection options of textile waste; (4) absence of policies and regulations concerning textile recycling; (5) variety of textile fibers and chemicals.

Conversely, several reports and white papers on textile recycling [9,17,62] have been published over the years, providing flourishing grey literature on the topic. Especially, the Ellen MacArthur Foundation identified four priorities to improve textile-to-textile recycling [9]: align clothing design and recycling processes, pursue technological innovation to improve the economics and quality of recycling, stimulate demand for recycled materials, and implement clothing collection at scale. Several other publications have addressed the challenges of textile recycling. For instance, Elander and Ljungkvist investigated through in-depth interviews with fashion companies, textile sorters, and recyclers 43 critical aspects for increasing textile-to-textile recycling [63]. Roos et al. [17] compiled a state-of-the-art on existing technologies while outlining the important factors for the future of textile recycling.

Based on the reported challenges in the academic literature, a thorough mapping was framed, as shown in Table 1. The mapping essentially emphasizes the academic literature to outline the studies conducted so far while highlighting the fragmented state of the research. This literature review supported the implementation of our Delphi-Régnier study, and the challenges are further elaborated together with the findings in the dedicated section.

3. Research Method

Considering the purpose of the research, the combination of the Delphi method and the Regnier’s Abacus technique emerged as the most relevant approach. By allowing consensus and dissensus on a topic to arise, this research approach helps to advance empirical knowledge on textile recycling while outlining the priority challenges to address in the sector with regards to previous research [14,39,46]. It also appeared as the most viable approach to evaluate a series of wide-range assumptions on the topic with a wide panel of experts and generate valid results in a timely manner [43]. The appropriateness of the method was also evaluated within the surrounding industry context [43]. As a spotlighted issue within the sector, anonymity was essential to ensure participation and minimize the risk of bias. In addition, confronting opinions on the topic was decisive to achieve the research objectives, but direct communication between the different experts could have blocked open reflection, due to distinct business interests and unaccustomed exchange of views of the different stakeholders involved.

Hereinafter, the Delphi method and the Regnier’s Abacus technique are introduced, followed by a dedicated focus on the sequential research process of the study.

3.1. Delphi Method and Regnier’s Abacus Technique

3.1.1. Delphi Method

The so-called “Delphi” is a well-acknowledged and widely used method for consensus-building on specific topics, solicited from experts through an iterative multistage process [43]. Named in reference to the Greek oracle, this method was pioneered by the Air-Force-sponsored Rand Corporation in the 1950s and later developed by Dalkey and Helmer [69] to forecast the potential of military technology [70]. At the time, quantitative simulation was primitive and conventional face-to-face experts’ consultations were unable to provide reliable results [70]. Structured around an anonymous and controlled feedback process, this method was designed to minimize the typical group interaction shortcomings (e.g., influences of dominant individuals, group pressure for conformity, standing within a profession) and ensure independent expert’s judgments [43].

While inherently flexible, the Delphi method consists of the following sequential procedure [43]:

- A questionnaire is submitted anonymously to the panel of experts (also referred as “participants”, “respondents”, or “panelists”).

- Responses are counted and processed (also referred as “round” or “iteration” with the submission of the questionnaire).

- Based on these responses, a refined questionnaire is elaborated and submitted to the same participants, along with a summarized report of the prior iteration. Through this controlled feedback process, experts can reassess their initial judgments and additional insights can be provided, allowing the information collected to be thoroughly clarified as the rounds progress.

- This process is iterated until common tends are achieved and are precise (consensus and dissensus).

By facilitating exchanges of opinions, the Delphi process has been progressively used beyond forecasting in diverse application areas such as program planning, needs assessment, policy determination, and resource utilization [43].

With respect to the fashion industry, the methodology has recently received interest in research on sustainability challenges [71] and the underlying issue of traceability [72,73].

Especially, the method appears suitable to investigate complex and multidisciplinary problems [72] by allowing to correlate informed judgements on a topic spanning a wide range of disciplines, to explore or expose underlying assumptions or information leading to differing judgements, and to seek out information that may generate a consensus [74].

The Delphi method being conditioned by its use; different analysis techniques can be used to interpret the data [43] and thus, various forms of Delphi have been applied in the literature. As part of our study, the information investigated is essentially qualitative. Therefore, in coherence with our research objectives, we decided to use the Regnier’s Abacus formalized technique, particularly suitable for collecting and processing qualitative information [75].

3.1.2. The Regnier’s Abacus Technique

The Regnier’s Abacus was developed in the 1970s by P. François Régnier in the medical field, to offset the usual drawbacks of working groups. By using a color panel to collect and share opinions on a topic, this visual communication technique was designed to promote constructive debates and facilitate decision-making. Initially assembled with colored cubes representing the decision scale [44], the available digital tools have further enhanced the possibilities associated with this method by allowing to collect and process data instantly. Thus, the abacus continues to attract interest and is used for many applications, ranging from forecasting research to simple projects evaluation [76].

The modalities are very simple as they are based on the “traffic signals” logic. Statements, also referred to as “items”, are previously defined on the topic investigated to provide an opening framework for reflection, though in precise, concrete, and relevant terms [75]. Experts are invited to react on each item, by selecting one of the following seven colors reflecting the hierarchy of possible opinions:

- Green: the expert strongly agrees with the statement;

- Light green: the expert agrees with the statement;

- Orange: the opinion of the expert is mixed;

- Light red: the expert disagrees with the statement;

- Red: the expert strongly disagrees with the statement;

- White: the expert cannot answer;

- Black: the expert does not want to answer.

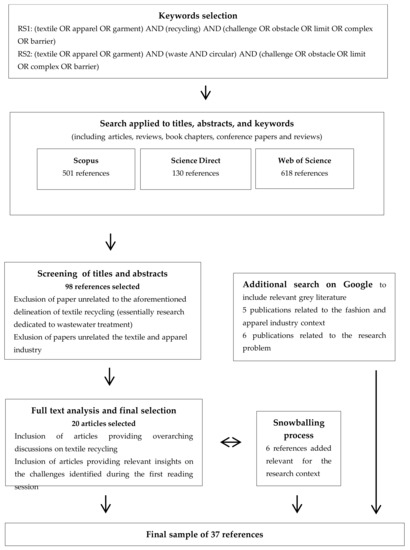

The light color indicates a transparency in answers, while white and black reflect opacity [75]. Therefore, in contrast to other data-gathering or analysis techniques, the colorful matrix produced enables a comprehensive and immediate perception of opinion. To complete this study, the open-source solution Color Insight (http://colorinsight.fr/, accessed on 5 February 2021) was used to generate the questionnaires, collect answers, and process information. An overview of the Color Insight voting platform is provided in the Figure A1 (Appendix A).

The respective steps involved in conducting the study are described in the following subsection.

3.2. The Implementation of the Delphi-Régnier Study

Considering proper planning management and motivation are key when conducting a Delphi study [43], particular attention has been paid to the distinctive research steps, due to the wide variety of stakeholders involved in the panel.

To give an insight of the study’s implementation, Table 2 illustrates the different steps involved in the research process, while the formulation of the initial statements, the selection of experts, and the rounds procedure are further explained successively.

Table 2.

Steps involved in the implementation of the Delphi-Régnier study.

3.2.1. Phase 1: Building the Opening Questionnaire

The first key step was building the initial questionnaire submitted to the experts in the first round, as it significantly guides the areas in which the Delphi-Régnier study will generate ideas [75]. We decided to establish the questionnaire beforehand, in order to target the most competent experts, based on the pre-established statements. During the literature review, a coding process was performed identifying and grouping by coherent themes the challenges reported. Based on this matrix, presented in Table 1, a set of 23 statements, also referred to as “items” in this paper, was formulated, as shown in Appendix B. All statements were carefully examined iteratively by the authors to reduce the risk of misinterpretation.

3.2.2. Phase 2: The Constitution of the Experts’ Panel

The constitution of the panel was the second key step. While no standard number of experts is defined in the literature, it is considered that a Delphi study can generate results from 11 experts [75,77]. Moreover, it likely depends on the research purpose and the reference groups involved [43]. If the sample size is too small, the pooling of judgments will not be representative enough, while if the sample is too large, the completion of the study may be infringed by potential low response rates, due to the inherent time-consuming feedback process [43]. Within our research context, this step was particularly challenging because of the fragmented nature of the textile and fashion value chain, all the way to the recycling stage. Although recruiting experts from homogeneous background entails the risk of producing biased results [43], the involvement of the different stakeholder groups was essential to confront their views on this system-level matter. Given this unprecedent representativeness, we assumed that consensus observed would rather provide substantial results for the sector.

To select the most appropriate individuals, authors recommend proceeding through a rigorous nomination process without further specifications [78]. Therefore, we initially defined relevant stakeholder groups reflecting the different actors involved in the recycling value chain. We also considered it relevant to include academia, confederations, and other active institutions specialized in the field of textile recycling. Based on these stakeholder groups, we progressively built a database of experts by soliciting professional recommendations and by conducting a review process, using a number of sources, including media articles, available reports, web searches, or industry association membership. We anticipated that motivation would be key to the successful implementation of the study [43] and thus, we decided to initially send an email to each nominated expert with a summary document explaining the research objective, the method, and the timeframe, to gauge interest and availability to participate in the study. As we received responses or not from the experts, we continued this process reiteratively until reaching a sufficiently representative panel that would allow the convergence of ideas on the topic.

In total, we contacted 39 experts and we obtained the confirmation of 28 experts, as shown in Table 3. To ensure the most competent experts within the specialized area of knowledge and ensure the quality of the results [43], we mainly selected senior skill-level profiles. The panel is evenly split between women (61%) and men (39%), as well as between the stakeholder groups:

Table 3.

Panel of the 28 experts established following the selection process.

- Group 1: Fashion and apparel companies (18%);

- Group 2: Textile manufacturing companies (11%);

- Group 3: Collecting, sorting, and trading organizations and companies (25%);

- Group 4: Recycling companies (14%);

- Group 5: Institutions and policymakers (14%);

- Group 6: Research, support, and innovation organizations (18%).

3.2.3. Phase 3: The Round’s Procedure

The initial questionnaire of 23 statements was sent to the experts through a dedicated voting link via Color insight, on which they were required to provide their opinion based on the Régnier Abacus color grid, as shown in Figure A1 (Appendix A). To avoid any interpretation during the analysis, participants were also asked to justify each of their answers with a short comment. Moreover, at the end of the questionnaire, experts has the opportunity to submit additional statements if some were missing, thereby strongly enriching the study. As suggested in the literature [43], the timeframe was a challenging aspect to maintain the subject motivation during the completion of the study, notably with the high number of participants. To prevent non-response and avoid a discontinuity in the answers between the rounds, experts were given two weeks to reply, and the same period was planned for the questionnaire review.

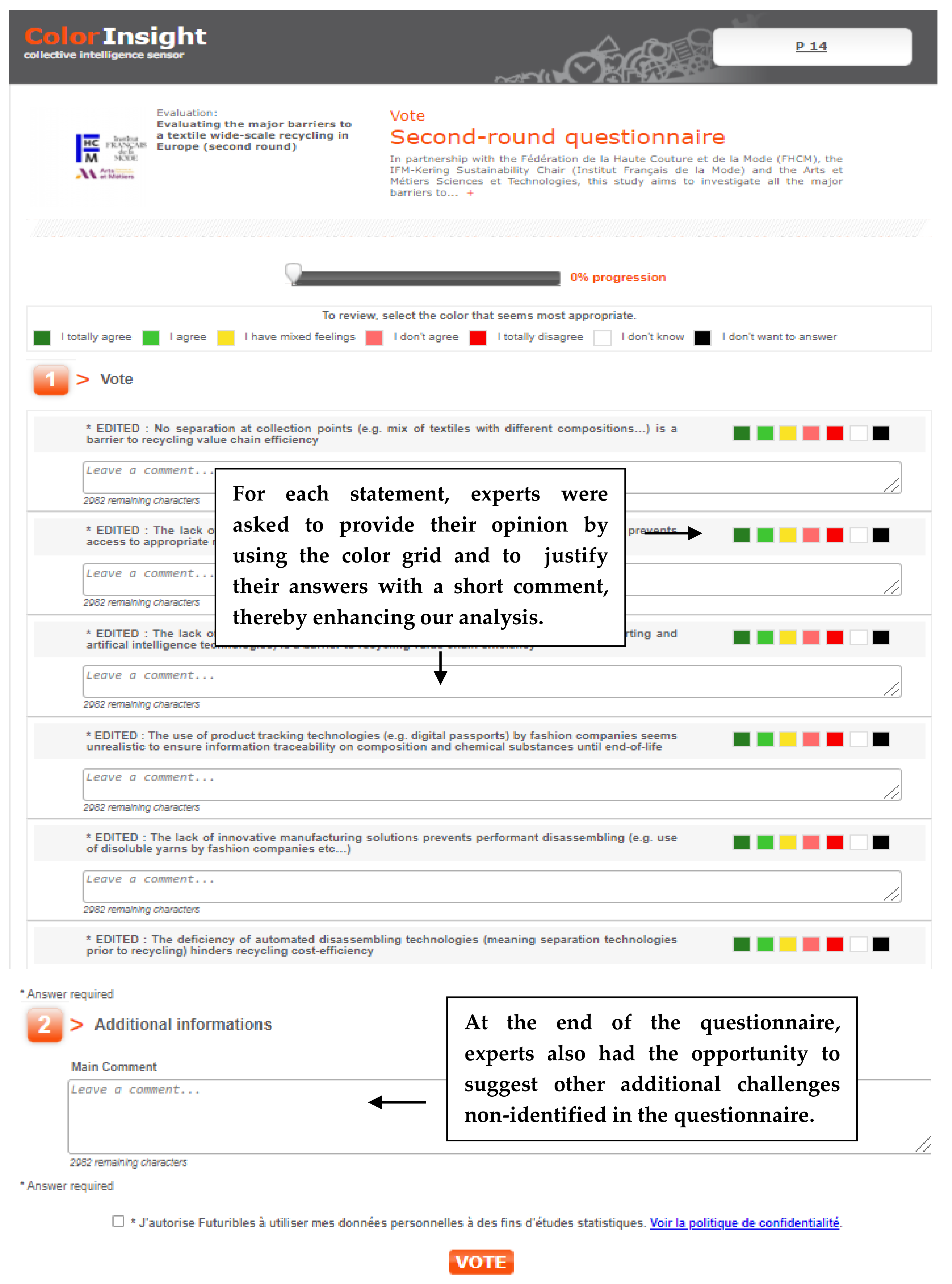

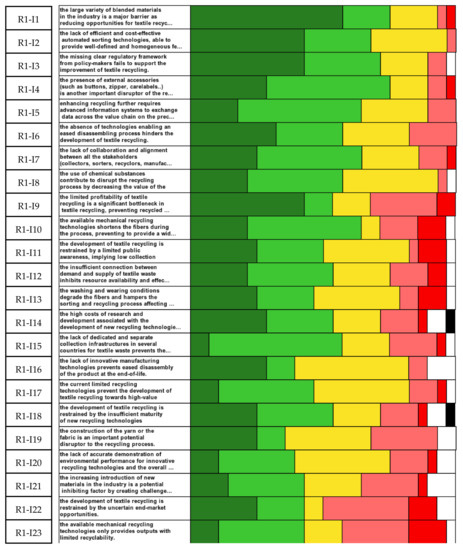

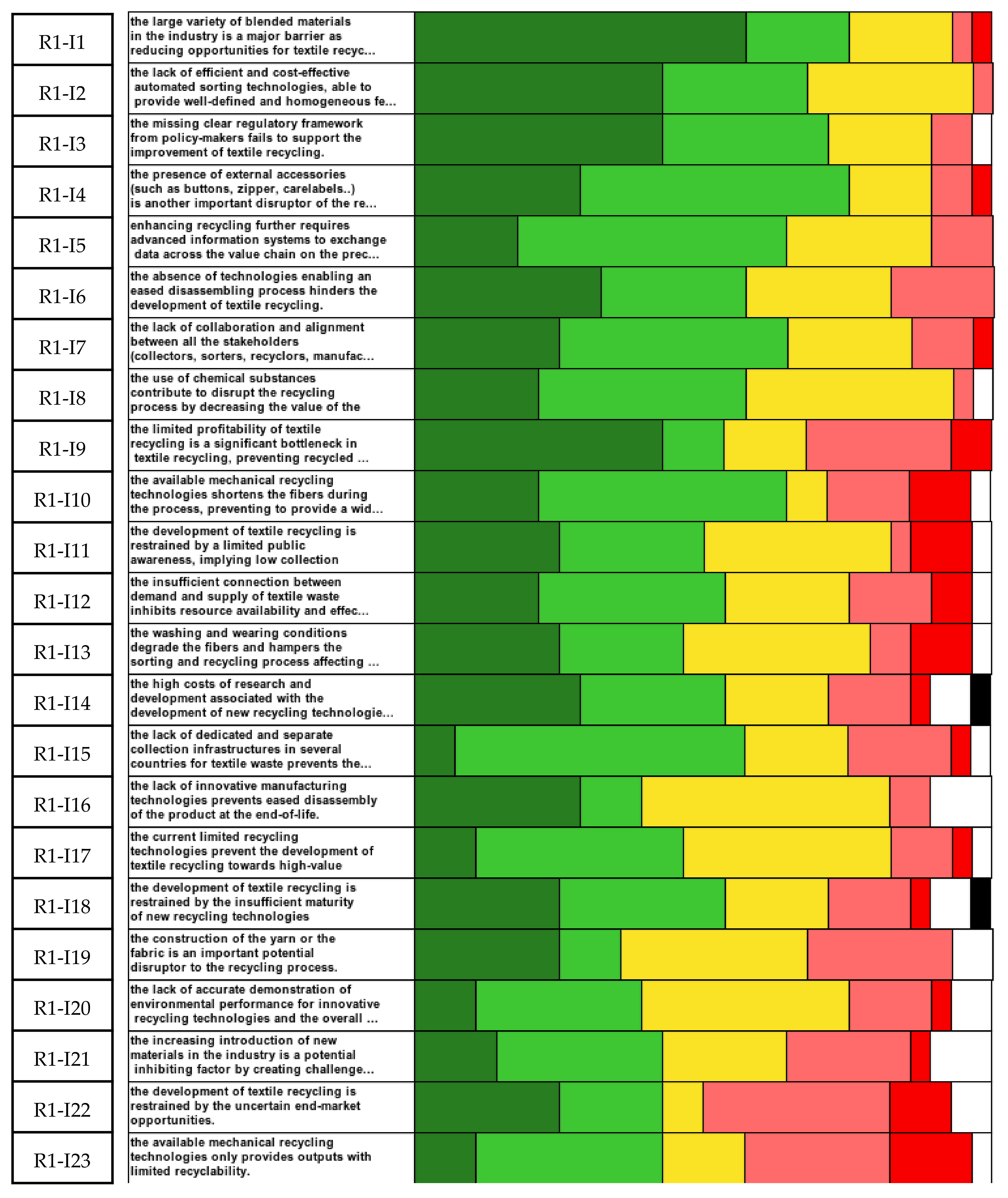

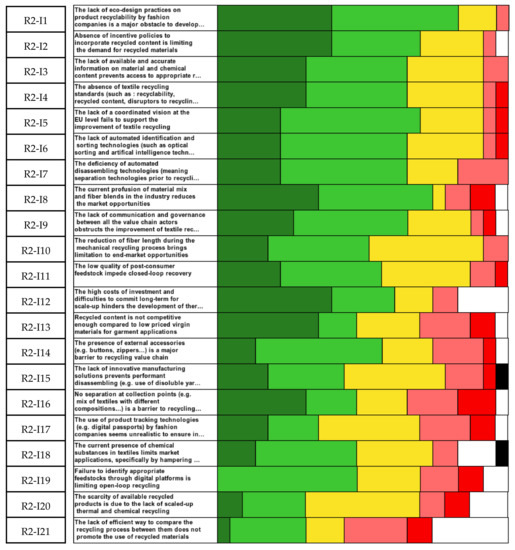

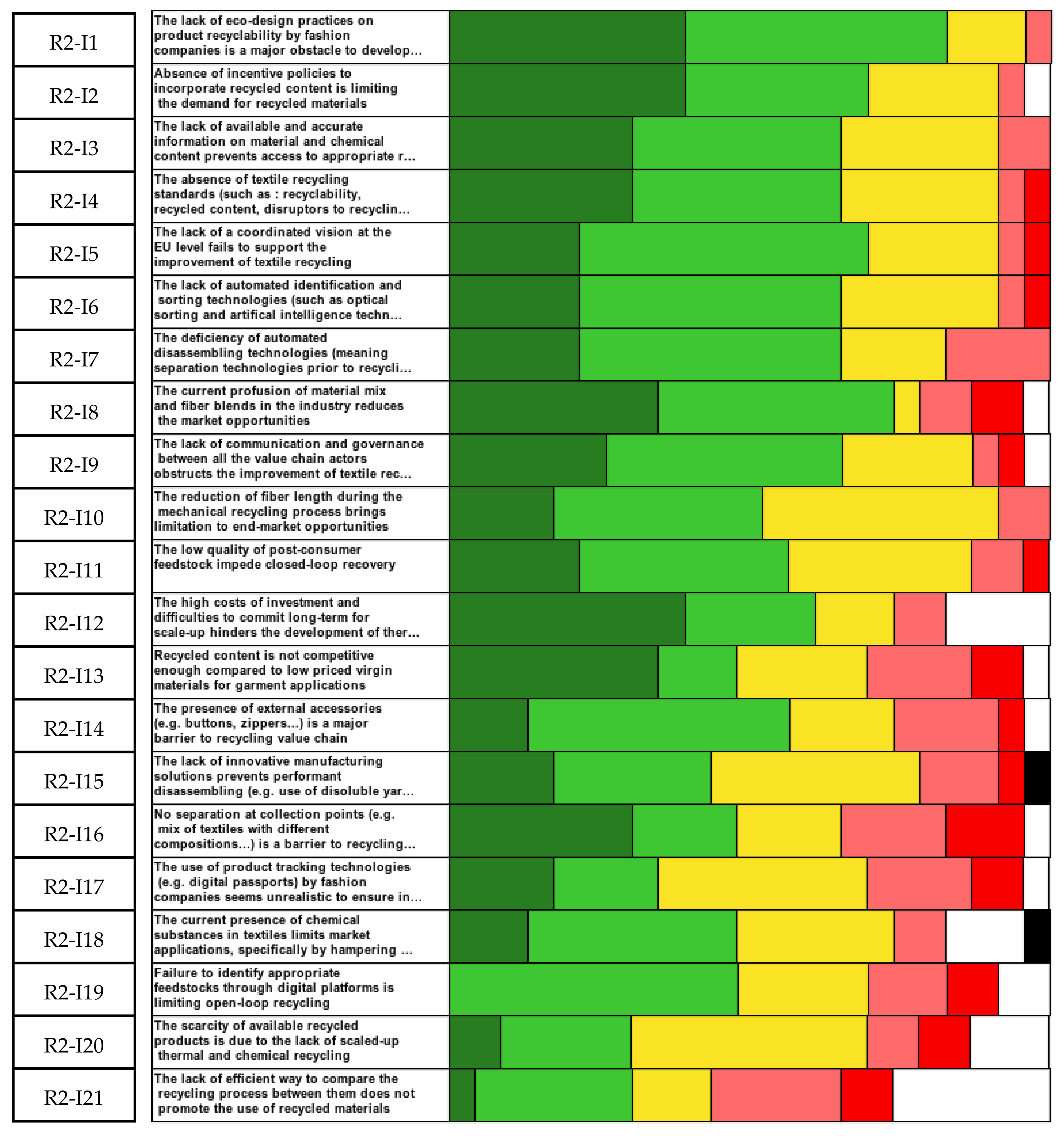

Resulting from the color votes proposed by the experts on each statement submitted in this first questionnaire, an item matrix was generated, as shown in Figure A2 (Appendix D). The items matrix enables to overview, from top to bottom, the most favorable statements to the most unfavorable, with dissensus in the middle of the picture. The matrix was generated according to the “classic mode” proposed by Color Insight: the color weights are 5 for dark green, 4 for light green, 3 for orange, 2 for light red, and 1 for dark red.

Throughout a review process, the authors examined and synthesized the votes and comments from this first round. As there is no standard threshold in the literature, it was decided that a consensus was reached once 60% of answers in favor (green) or against (red) was observed. Based on the comments, 3 statements were added and removed respectively, and all the other items were carefully reworded accordingly. Such modifications were clearly indicated in the second questionnaire, by the respective mentions of “new item” and “edited item” in front of each statement.

The second round was launched with the same participants and included the following:

- The refined questionnaire of 21 items provided in Appendix C.

- A summary document presenting the first-round results, to give the occasion to the experts to confront and reassess their previous answers.

- A full report with the breakdown of votes and the anonymized comments for each item was added to minimize the distortion risk, commonly described in the literature [43].

No new comments emerged during the second round, and the major opinion trends among the experts were confirmed. Therefore, we considered that the majority of convergence was reached, and we decided to end the study.

Only positive consensus was reached following both questionnaires, the remaining statements being subject to dissensus among experts. As shown by the respective matrix Figure A2 (Appendix D) and Figure A3 (Appendix E), the results are not highly pronounced, which complicated the analysis. Therefore, the examination of votes and comments was performed through iterative reviews by the steering committee to limit as much as possible the subjective bias in the interpretation. Nevertheless, favorable consensus and disagreement stand out to a greater extent in the second round. As a result, 10 statements reached positive consensus, out of the 21 submitted, despite the heterogeneity of the panel, and the supporting comments provided further insights, described in the findings.

It should be noticed that 23 of the 28 experts from the first round responded to the revised questionnaire in the second round. While this drop in participation is one of the shortcomings of the research method [43], the representativeness of the panel was maintained, and thus, the findings remained coherent with the preceding results.

4. Findings and Discussion

Following the Delphi-Régnier study, the steering committee synthetized the answers provided by the experts. Considering the refinement and addition of statements, based on received comments in the second round, we attempted to group the opinions by coherent themes. Derived from the study conducted by Elander et al. [63] in 2016, the following five categories were identified as the most relevant for aggregating the statements while ensuring a sufficient level of detail. Although closely connected, the categories encompass critical aspects of textile recycling, thereby allowing to evaluate the reviewed challenges in relation to the value chain described in the first section of the paper. In addition, a significant “organizational” issue emerged during the completion of the study, which resulted in the inclusion of a fifth distinctive category entitled “coordination”.

- Product and material input

- Information

- Technologies

- Markets

- Coordination

The key findings are discussed accordingly, using the subsequent formula to reference the items: (RY-IX)—Y referring to the round’s number and X to the statement’s position in the items’ matrix provided in Appendix D and the Appendix E.

4.1. Product and Material Input

4.1.1. The Lack of Eco-Design Practices

The lack of eco-design practices in the sector is highlighted as a major challenge (R2-I1). While addressed through several design features in the first questionnaire, it was distinctively mentioned in a number of comments, and it emerged as the highest positive consensus of the study (82%). Fashion companies currently do not integrate recycling in the design process, while the end-of-life of the product should be strategically integrated in the design process [12,15,51]. Moreover, eco-design must be addressed as a thought-confronting process including all the value chain, considering both durability and recyclability, which can be conflicting in practice. Several authors highlighted such an issue [14,63], and Sandvik et al. advanced the notion of “conditional design” [14] requiring further understanding of the use context of clothes.

Among the most impactful design features, the profusion of material blends reached the strongest favorable consensus (75%), consistent with the findings from the literature review, while it was slightly mitigated in the second round (R1-I1 and R2-I8). Textile materials can mostly be recycled with current mechanical recycling technologies, but material blends restrain recycling applications mainly to very low value applications. Yet not all blends are problematic, and some are necessary to provide long-lasting products, raising the potential contradiction between durability and recyclability. Moreover, it is likely to be overcome with adapted and efficient technologies, partly explaining the nuanced opinions observed.

The presence of external accessories, also referred to in practice as “hard points” (such as buttons, zippers, rivers…), emerged as an important disruptor of textile recycling (75%), particularly in the first round (R1-I4). Certain external elements (i.e., care labels) are problematic in certain recycling pathways, and especially for closed-loop recycling by contaminating the process, depending on their composition. This is equivalent to the preceding statement relating to material blends. In addition, the presence of external accessories is causing cost inefficiencies due to the manual dismantling process. Yet, other obstacles seem more critical, and the statement received less favorable votes (57%) in the second round (R2-I14).

The other design features enquired about, which are less prevalent in the literature, do not stand out. Yarn and fabric construction can influence the appropriate recycling route, especially for closed-loop applications, but to a lesser extent than material blends (R1-I19). The introduction of new materials is not considered as a potential inhibiting factor (R1-I21). There is rarely an introduction of new materials, and it likely depends on which materials. Even new materials form part of a wider fiber family and can be grouped with similar fiber types, as highlighted by one expert.

Finally, the initial fiber quality is more decisive than the use conditions (i.e., wearing and washing), especially to enable spinnability in closed-loop applications through mechanical recycling, but not with chemical recycling (R1-I13).

4.1.2. The Presence of Chemical Substances

Almost reaching positive agreement (57%) in the first round (R1-I8), the impact related to the use of chemical substances appears confusing (R2-I18). Expressly addressed in the comments by some experts, this lack of clarification is endorsed by the significant share of white votes (“I don’t know”) observed in the second round. Chemical substances hamper some recycling routes by decreasing the output value or by limiting end markets. Yet, it is not clear which exact chemical substances disrupt the process and to what extent. Classifications must be provided linking chemical substances to each specific technology, to advance alternatives in practice.

Refashion accordingly believes that the priority is to focus resources and effort on industrializing the recycling of non-reusable waste, before going all out into raising the collection rate.

4.2. Information

The Lack of Information on Materials Content

Essentially addressed from a technological perspective in the first round (R1-2 and R1-I5) the aspect was submitted distinctively in the second round to unravel opinions on current obstacles and became further explicit (R2-I3). Information availability on the product components is essential in directing to appropriate recycling routes. The current lack of information is considered as one of the critical challenges (65% positive votes and few votes against) in the sector (R2-I3) as labels are cut-off, inaccurate, or variations occur compared to the initial composition following the use phase (as highlighted by Wilting and Van Duijn in 2020 [27]). Therefore, improving identification of non-reusable textile flows is necessary to ensure homogeneous feedstock and enhance recycling applications.

4.3. Technologies

4.3.1. Importance of Technologies Supporting Identification

Overall, the current sorting process emerges as one of the major bottlenecks in the value chain (R1-I2, R1-I5, and R2-I6). The pre-sorting for quality aiming to differentiate reusable items from non-reusable ones will necessarily remain manual, but automated sorting is key to enhance material composition sorting and thus, recycling applications. However, the business model of the current sorting system is based on reuse categories towards second-hand markets and is not set up for composition sortation. Automated sorting machines supported by optical and artificial intelligence technologies are available (i.e., FIBERSORT, CETIA platform, SIPtex, or IMEC were mentioned), but the implementation is trivial to scale-up. Those technological infrastructures involve high investment costs, requiring enough demand for this sorted material and adaptation of the business model, which still needs to be resolved at this stage.

On the other hand, the lack of tracking technologies to convey information up to the end of life is usually identified as a critical challenge [13]. Still, the second round emphasizes a strong dissident among the experts (R2-I17). Quite a few consider the use of product-tracking technologies unrealistic, at least in the short term for mitigated experts, with regards to the fragmentation of the industry hindering data exchange across the value chain. It would not prevent inaccurate information or handle existing variations of content resulting from the use phase. Moreover, it would require the use of the same standards and would risk further impeding the process. Thus, some experts explicitly acknowledge optical sorting technologies as more promising. Opinions are very divided, and there is still a lack of evidence on the ability of tracking systems to overcome the consumer phase until the recycling stage in the sector. This contradicts previous research highlighting the requirement of such technologies to advance recycling (i.e., RFID et blockchain, notably) [9,14,32,46,62].

4.3.2. The Need for an Eased Disassembling Process

The manual dismantling stage prior to recycling is also recognized as a significant obstacle in Europe due to cost inefficiencies (R1-I6 and R2-I7). The iteration process between the two rounds enabled explicit opinions to be identified. While the deficiency of automated disassembling technologies still reaches positive consensus (65%) a persistent share of disagreement is discernible (R2-I7). Yet again, technologies are available (i.e., Picker from Laroche or CETIA platform mentioned) but technological improvement is needed. Some experts are divided on the potential leverage of these technologies, and instead address a design issue related to eco-design strategies. In contrast, the use of innovative manufacturing technologies (i.e., dissoluble yarns...) to smooth the dismantling process is prompting dubiousness (R1-I16/R2-I15).

4.3.3. The Lack of Scale-Up Innovative Recycling Technologies

The statements associated with the current state of recycling technologies nudged disagreements and raised several comments until the end of the study (R1-I17, R1-I18, and R2-I20). By decreasing the fiber length during the process, mechanical recycling limits closed-loop applications necessitating to mix short fibers with virgin ones to reach sufficient quality (as shown by the favorable consensus of 64% in the first round—R1-I17). The constraints associated with the process must be understood to make the best use of the technology. Still, it can provide diverse open-loop applications, and different markets must be considered to absorb all heterogenous feedstock (as reflected by the increasing share of mixed opinions in the second round—R2-I10). Progress for thermal and chemical recycling is underway to improve closed-loop opportunities. Several technologies are available for most material streams, but it is rather a challenge of investment and support to reach industrial scale (R1-I18 and R2-I12), which entails several critical aspects according to the comments (as shown by the disagreement in the second round—R2-I20). While addressed in the literature [14] the lack of environmental performance assessment of recycling technologies raised disagreement among the experts.

4.4. Markets

4.4.1. Insufficient Competitiveness of Recycled Content

The statements related to demand and economic viability of textile recycling stirred up strong disagreements among experts. The current state of demand for recycled textile materials is inconclusive. Still, a market shift is advanced with an increasing demand for textile-to-textile recycled products from brands. Several costs inefficiencies are resulting from the recycling pipeline, but opinion is divided between the low price of virgin materials and the lesser quality resulting from current mechanical recycling to explain the negligible share of closed-loop recycling (R2-I13).

4.4.2. The Lack of Investments and Long-Term Commitment

High investment costs and lack of long-term engagement are currently hindering the development of thermal and chemical recycling and the development of closed-loop recycling at this stage (R2-I12). One expert suggests a lack of economic, environmental, and technical scale-up vision, which discourages future investments. Overall, comments concur with the need for policies and collective actions to increase demand for recycled content.

4.4.3. The Need for Policies to Increase Market Opportunities

The absence of incentive policies to incorporate recycled content arises as the second most consensual statement in the second round (R2-I2) following several comments (R1-I3) and corroborates previous research addressing the need for regulations for the implementation of circular economy in the sector [12,51]. Public policies are needed to increase competitiveness of recycled content and support investments towards recycling technologies. More than incentives, the use of recycled content should be enforced by regulations according to some experts, and the recent Anti-Wastage and Circular Economy Law adopted in February 2020 in France was put forward.

4.5. Coordination

4.5.1. The Lack of Standards on Textile Recycling

At sector level, the lack of standards on notions such as “recyclability”, “recycled content”, or “disrupting factors” is failing to promote eco-design practices (R2-I4). More widely, further clarifications are needed to foster common understanding on textile recycling and disentangle impediments resulting from some disruptors in relation to existing recycling pathways. Yet, a few experts advised that rigid standards could hamper the constant innovation needed on textile recycling.

4.5.2. The Lack of Sector-Coordinated Vision

The lack of coordinated vision at the EU level fails to support the improvement of textile recycling (R2-I5), and a harmonized EU Textiles Strategy from the European Commission is expected. Throughout the study, several measures were mentioned to address either labelling issues or trade barriers, requiring defining up front priorities to enhance textile recycling.

4.5.3. The Deficient Collective Governance

The lack of collaboration and governance between the stakeholders along the value chain is sustained by a steady consensus (R1-I7 and R2-I9). Given the fragmentation of the industry and the correlated shortcomings along the value chain, a decisive organizational challenge is apparent. Comments range from the failure in governance with scattered initiatives, the lack of collaboration and specific actions, to the lack of communication. Altogether, coordination between the actors is crucial, and a few initiatives are mentioned, such as the Telaketju eco-system in Finland or the recent multi-stakeholder ReHubs project launched by EURATEX, aiming to set up an integrated system on five recycling hubs within Europe.

5. Limitations and Research Perspectives

5.1. Limitations

The first limitation of the study derives from the composition of the panel. Despite applying rigorous procedure rules, the selection inevitably entails shortcomings. Due to the wide range of statements and stakeholder groups, expertise was unevenly distributed among the experts, and it likely influenced the results. However, the panel was coherent with regards to the research objective, which did not aim to provide an in-depth exposition of the topic. Moreover, the study did not aim to explore the consumer’s perspective. This limitation inevitably narrows the analysis of some barriers, such as the lack of awareness or the lack of demand for recycled content, requiring further investigations on consumer behaviors [79]. To generate valid results, the study required us to involve high-skilled experts with a substantial experience in the field. However, the opinion of younger generations of professionals should be considered in future research [80] especially to explore enablers to unravel these textile recycling challenges.

Inherent to the Delphi method used, the second limitation is the design of the first questionnaire. Although experts had the possibility to submit comments and propose other statements later on, the orientation of the first questionnaire from the start probably created a subjective bias.

Another limitation results from a diverging interpretation observed on certain terms. We noticed that “textile recycling” was sometimes comprehended as equivalent to “textile-to-textile recycling”. Although the wording of the sentence was carefully reviewed to limit the risk of misinterpretation, it certainly influenced the results. Still, experts were asked to provide comments in support of their votes, which enabled us to limit this shortcoming through a cautious review process.

Finally, a last shortcoming resides in the research approach applied. While the Delphi-Régnier method allowed us to gather empirical data and visualize expert’s opinions to identify the priority challenges of textile recycling, further statistical analysis should be conducted to corroborate the results and to define precise roadmaps for the sector.

5.2. Research Perspectives

Following this research, several perspectives have emerged.

From a theoretical perspective, only a few comprehensive frameworks on textile recycling were found in the extant literature. These frameworks mainly consist in mappings of the different stages of the value chain. Consequently, a significant obstacle was encountered when attempting to delimit the scope of the review.

The paper highlighted a lack of empirical knowledge in the literature. Based on the findings, several case studies could be conducted, allowing deeper level of observation and in-depth results. Case studies could investigate the implementation of traceability solutions in the textile value chain up to the recycling stage, as the technical, economic, and organizational viability of such solutions is still unascertained. Especially, in view of the apparent dissidence, it could advance research on circularity in the industry by investigating the leverage of these technologies in closing the textile loop. Case studies exploring stakeholder projects, such as the Rehubs initiative launched by EURATEX, could provide valuable insights on the governance and collaborative challenges necessitating by such innovative and large-scale management of material streams. Further case studies could research innovative business models to explore the implementation of circular strategies in the industry, especially with regards to the tensions between durability and recyclability. Given the lack of consensus on the demand for recycled products, more research should also be conducted with consumers to explore their perception regarding recycled products [79].

Finally, our study is qualitative and thus only elicits the main consensus among the experts on the existing challenges in the sector. It does not enable to prioritize the obstacles towards a fine roadmap or to suggest interconnections between the different critical aspects. Nevertheless, the findings show evident opportunities for extra research. Other methodologies could be used, such as the multiple-criteria decision analysis (MCDA) or the econometric analysis, to corroborate, invalidate, and further clarify the findings of the study.

6. Conclusions

This paper aimed to deepen understanding of the current challenges of textile recycling and the priority concerns to address in the fashion and apparel sector. To achieve these research objectives, a systematic literature review supplemented by a Delphi-Régnier study was performed.

Regarding the first research question, the coding process applied during the literature review allowed us to discern a set of challenges in the recycling value chain. Through the iterative process of the Delphi-Régnier study, those challenges were discussed and revised, based on experts’ comments between the two rounds, advancing empirical knowledge on the topic. Based on the findings, the lack of eco-design practices emerges consensually as the major barrier preventing the enhancement of textile recycling. Innovative recycling technologies are crucial to develop textile-to-textile recycling and are now available for the main material streams. At this stage, industrialization is rather problematic and is interrelated with several other critical aspects. Beyond requiring substantial investments, recycling technologies entail abundant and suitable textile flows input to scale-up. Yet, the current manual sorting system arises as a significant bottleneck in the value chain, due to discrepancies with the paramount separation for material composition towards recycling applications. The lack of information availability and accuracy on products components hinders directing textile feedstocks to appropriate recycling routes. Hence, improving textile recycling is closely related to the identification of technologies. As one of the main original findings, a strong dissidence prevails on the potential of product-tracking technologies to convey information up to downstream in the value chain, and experts are more inclined to automated sorting technologies. Still, the business case needs to be resolved as the entire management system of used textiles flows is rationally structured around reusability, in accordance with the waste hierarchy. Consequently, more than a technical issue, the study instead suggests an essential restructuring of this complex value chain to support the improvement of this resource management system, highlighted by the strong focus on challenges at the sector level.

Through the emergence of consensus and dissensus on the topic, we were able to answer the second research question. The lack of eco-design practices, the absence of incentive policies, and the lack of available and accurate information on the product components emerge as the most consensual statements in the second round. Based on the results obtained from this iterative process, three dominant challenges distinctively stand out, without specific order of importance: (1) The need to advance eco-design practices consistently with respect to reusability and recyclability strategies; (2) The strong requisite of policies and governance to advance textile recycling; (3) The necessity to unravel the deficiencies related to the current manual sorting system.

Based on a European perspective, the study significantly emphasizes the critical impact of public policies and provides support for several recommendations to enhance textile recycling in the sector. Especially, in the perspective of the mandatory separate collection [41], the findings call for measures endorsing the optimization and industrialization of the recycling value chain, rather than an increased collection of used textiles in Europe. Finally, by refining some general assertions on the topic and providing extensive empirical knowledge on the topic, this paper can help practitioners to advance relevant initiatives. The study also highlights several research opportunities, especially on the leverage of traceability technologies to enhance textile recycling in the industry. However, the method used has inherent limitations, and further statistical analysis should be conducted to further explore the priorities or interrelations between such challenges in the sector.

Author Contributions

Conceptualization, J.R., A.-A.L.; methodology, J.R. and S.L.; writing—original draft preparation, J.R.; writing—review and editing, S.L. and L.G. and A.-A.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to privacy.

Acknowledgments

We would like to thank the 28 experts and their organizations for agreeing to participate in the study by taking the time and involved themself by sharing their expertise to contribute to scientific knowledge.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Figure A1.

Overview of the ColorInsight website used to submit the questionnaires to the experts.

Figure A1.

Overview of the ColorInsight website used to submit the questionnaires to the experts.

Appendix B

First Questionnaire Statements with Their Vote’s Distribution

| 7% | 50% | 18% | 18% |

The lack of dedicated and separate collection infrastructures in several countries for textile waste prevents the development of textile recycling.

| 43% | 25% | 29% |

The lack of efficient and cost-effective automated sorting technologies, able to provide well-defined and homogeneous feedstock (composition, quality and color) is a major barrier to enhance textile recycling.

| 18% | 46% | 25% | 11% |

Enhancing recycling further requires advanced information systems to exchange data across the value chain on the precise composition and chemical inputs of discarded textiles.

| 29% | 11% | 43% | 7% | 11% |

The lack of innovative manufacturing technologies prevents eased disassembly of the product at the end-of-life.

| 32% | 25% | 25% | 18% |

The absence of technologies enabling an eased disassembling process hinders the development of textile recycling.

| 11% | 36% | 36% | 11% |

The current limited recycling technologies prevent the development of textile recycling towards high-value applications.

| 25% | 29% | 18% | 14% | 7% |

The development of textile recycling is restrained by the insufficient maturity of new recycling technologies

| 21% | 32% | 21% | 14% | 7% |

The insufficient connection between demand and supply of textile waste inhibits resource availability and effective trading of recycled materials.

| 57% | 18% | 18% |

The large variety of blended materials in the industry is a major barrier as reducing opportunities for textile recycling.

| 25% | 11% | 32% | 25% | 7% |

The construction of the yarn or the fabric is an important potential disruptor to the recycling process.

| 14% | 29% | 21% | 21% | 11% |

The increasing introduction of new materials in the industry is a potential inhibiting factor by creating challenges with recycling streams.

| 21% | 36% | 36% |

The use of chemical substances contribute to disrupt the recycling process by decreasing the value of the output.

| 29% | 46% | 14% | 7% |

The presence of external accessories (such as buttons, zipper, carelabels..) is another important disruptor of the recycling process.

| 25% | 21% | 32% | 7% | 11% |

The washing and wearing conditions degrade the fibers and hampers the sorting and recycling process affecting the recycled feedstock quality.

| 21% | 43% | 7% | 14% | 11% |

The available mechanical recycling technologies shortens the fibers during the process, preventing to provide a wide range of qualitative recycled output.

| 11% | 32% | 14% | 25% | 14% |

The available mechanical recycling technologies only provides outputs with limited recyclability.

| 43% | 11% | 14% | 25% | 7% |

The limited profitability of textile recycling is a significant bottleneck in textile recycling, preventing recycled materials to compete with virgin ones.

| 29% | 25% | 18% | 14% | 7% |

The high costs of research and development associated with the development of new recycling technologies discourages prospective investments.

| 25% | 18% | 7% | 32% | 11% | 7% |

The development of textile recycling is restrained by the uncertain end-market opportunities.

| 25% | 25% | 32% | 11% |

The development of textile recycling is restrained by a limited public awareness, implying low collection rates.

| 25% | 39% | 21% | 11% |

The lack of collaboration and alignment between all the stakeholders (collectors, sorters, recyclors, manufacturers, brands, policy-makers, consumers) curbs the improvement of textile recycling.

| 43% | 29% | 18% | 7% |

The missing clear regulatory framework from policy-makers fails to support the improvement of textile recycling.

| 11% | 29% | 36% | 14% | 7% |

The lack of accurate demonstration of environmental performance for innovative recycling technologies and the overall end-of-life treatment is a challenge in textile recycling.

Appendix C

Second Questionnaire Statements with Their Vote’s Distribution

| 30% | 17% | 17% | 17% | 13% |

EDITED: No separation at collection points (e.g., mix of textiles with different compositions...) is a barrier to recycling value chain efficiency

| 30% | 35% | 26% | 9% |

EDITED: The lack of available and accurate information on material and chemical content prevents access to appropriate recycling channels

| 22% | 43% | 26% |

EDITED: The lack of automated identification and sorting technologies (such as optical sorting and artifical intelligence technologies) is a barrier to recycling value chain efficiency

| 17% | 17% | 35% | 17% | 9% |

EDITED: The use of product tracking technologies (e.g., digital passports) by fashion companies seems unrealistic to ensure information traceability on composition and chemical substances until end-of-life

| 17% | 26% | 35% | 13% |

EDITED: The lack of innovative manufacturing solutions prevents performant disassembling (e.g., use of disoluble yarns by fashion companies etc...)

| 22% | 43% | 17% | 17% |

EDITED: The deficiency of automated disassembling technologies (meaning separation technologies prior to recycling) hinders recycling cost-efficiency

| 48% | 22% | 13% | 9% | 9% |

EDITED: Failure to identify appropriate feedstocks through digital platforms is limiting open-loop recycling opportunities

| 35% | 39% | 9% | 9% |

EDITED: The current profusion of material mix and fiber blends in the industry reduces the market opportunities

| 13% | 43% | 17% | 17% |

EDITED: The presence of external accessories (e.g., buttons, zippers...) is a major barrier to recycling value chain efficiency

| 13% | 35% | 26% | 9% | 13% |

EDITED: The current presence of chemical substances in textiles limits market applications, specifically by hampering chemical recycling process

| 22% | 35% | 30% | 9% |

EDITED: The low quality of post-consumer feedstock impede closed-loop recovery

| 39% | 43% | 13% |

NEW ITEM: The lack of eco-design practices on product recyclability by fashion companies is a major obstacle to develop textile recycling

| 17% | 35% | 39% | 9% |

EDITED: The reduction of fiber length during the mechanical recycling process brings limitation to end-market opportunities

| 9% | 22% | 39% | 9% | 9% | 13% |

EDITED: The scarcity of available recycled products is due to the lack of scaled-up thermal and chemical recycling technologies

| 35% | 13% | 22% | 17% | 9% |

EDITED: Recycled content is not competitive enough compared to low priced virgin materials for garment applications

| 39% | 22% | 13% | 9% | 17% |

EDITED: The high costs of investment and difficulties to commit long-term for scale-up hinders the development of thermal and chemical recycling technologies

| 26% | 39% | 22% |

EDITED: The lack of communication and governance between all the value chain actors obstructs the improvement of textile recycling

| 22% | 48% | 22% |

EDITED: The lack of a coordinated vision at the EU level fails to support the improvement of textile recycling

| 30% | 35% | 26% |

NEW ITEM: The absence of textile recycling standards (such as: recyclability, recycled content, disruptors to recycling...) fails to promote eco-design practices

| 39% | 30% | 22% |

NEW ITEM: Absence of incentive policies to incorporate recycled content is limiting the demand for recycled materials

| 26% | 13% | 22% | 9% | 26% |

EDITED: The lack of efficient way to compare the recycling process between them does not promote the use of recycled materials

Appendix D

Figure A2.

Items matrix of the first questionnaire (first round).

Figure A2.

Items matrix of the first questionnaire (first round).

Appendix E

Figure A3.

Items matrix of the second questionnaire (second round).

Figure A3.

Items matrix of the second questionnaire (second round).

References

- Statista. Global Apparel Market—Statistics & Facts|Statista. Available online: https://www.statista.com/topics/5091/apparel-market-worldwide/ (accessed on 25 August 2021).

- Gereffi, G.; Frederick, S. The Global Apparel Value Chain, Trade, and the Crisis: Challenges and Opportunities for Developing Countries; Policy Research Working Paper 5281; World Bank: Washington, DC, USA, 2010; Available online: https://openknowledge.worldbank.org/handle/10986/3769 (accessed on 23 May 2021).

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The Environmental Price of Fast Fashion. Nat. Rev. Earth Environ. 2020, 2, 189–200. [Google Scholar] [CrossRef] [Green Version]

- Jacomet, D.; Minvielle, G. De-Industrialisation Re-Industrialisation in the Fashion Industry. Available online: https://www.ifmparis.fr/fr/recherche-academique/desindustrialisation-reindustrialisation-dans-lindustrie-de-la-mode (accessed on 23 May 2021).

- European Commission. International Trade | Internal Market, Industry, Entrepreneurship and SMEs. Available online: https://ec.europa.eu/growth/sectors/fashion/textiles-and-clothing-industries/international-trade_en (accessed on 25 August 2021).

- Kumar, V.; Agrawal, T.K.; Wang, L.; Chen, Y. Contribution of Traceability towards Attaining Sustainability in the Textile Sector. Text. Cloth. Sustain. 2017, 2, 5. [Google Scholar] [CrossRef] [Green Version]

- McKinsey & Company; Global Fashion Agenda. Fashion on Climate: How the Industry Can Urgently Act to Reduce Its Greenhouse Emissions. 2020. Available online: https://www.mckinsey.com/industries/retail/our-insights/fashion-on-climate (accessed on 23 May 2021).

- Quantis. Measuring Fashion Environmental Impact of the Global Apparel and Footwear Industries: Environmental Impact of the Global Apparel and Footwear Industries. 2018. Available online: https://quantis-intl.com/report/measuring-fashion-report (accessed on 23 May 2021).

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future. 2017. Available online: https://ellenmacarthurfoundation.org/a-new-textiles-economy (accessed on 4 October 2021).

- Quantis. Draft Product Environmental Footprint—Representative Product (PEF-RP) Study Report Apparel and Footwear, Version 1.2. PEFCR for Apparel and Footwear—Stakeholder Workspace—EU Environmental Footprint—EC Extranet Wiki. 2021. Available online: https://europa.eu (accessed on 7 July 2021).

- United Nations Environment Programme. Sustainability and Circularity in the Textile Value Chain. 2020. Available online: https://wedocs.unep.org/handle/20.500.11822/34184 (accessed on 10 March 2021).

- Brydges, T. Closing the Loop on Take, Make, Waste: Investigating Circular Economy Practices in the Swedish Fashion Industry. J. Clean. Prod. 2021, 293, 126245. [Google Scholar] [CrossRef]

- Sandvik, I.M.; Stubbs, W. Circular Fashion Supply Chain through Textile-to-Textile Recycling. J. Fash. Mark. Manag. Int. J. 2019, 2, 366–381. [Google Scholar] [CrossRef]

- Allwood, J.M. Well Dressed? The Present and Future Sustainability of Clothing and Textiles in the United Kingdom; University of Cambridge Institute for Manufacturing: Cambridge, UK, 2006; Available online: https://www.researchgate.net/publication/282249347_Well_Dressed_The_Present_and_Future_Sustainability_of_Clothing_and_Textiles_in_the_United_Kingdom (accessed on 29 September 2021).

- D’Adamo, I.; Lupi, G. Sustainability and Resilience after COVID-19: A Circular Premium in the Fashion Industry. Sustainability 2021, 2, 1861. [Google Scholar] [CrossRef]

- Koszewska, M. Circular Economy—Challenges for the Textile and Clothing Industry. Autex Res. J. 2018, 2, 337–347. [Google Scholar] [CrossRef] [Green Version]