Abstract

European self-sufficiency in the battery sector is one of the major EU needs. The key lithium-ion batteries (LIBs) materials demand is expected to increase in the next decade as a consequence of the increment in the LIBs production and a massive amount of spent LIBs will flood global markets. Hence, these waste streams would be a potential source of secondary raw materials to be valorized, under the principle of circular economy. European governments first, and then companies in the battery sector second, are addressing many efforts in improving legislation on batteries and accumulators. This study explores the current legislative aspects, the main perspective from the producer’s point of view, and the possibility to guarantee a proper recycle of spent LIBs. A monitoring proposal by means of a survey has been carried out and the Italian context, which has been taken as an example of the European context, and it was used to evaluate the practical implication of the current legislation. The main result of the survey is that a specific identification as well as regulations for LIBs are needed. The benefit from a cradle-to-cradle circular economy is still far from the actual situation but several industrial examples and ongoing European projects show the importance and feasibility of the reuse (e.g., second life) and recycle of LIBs.

1. Introduction

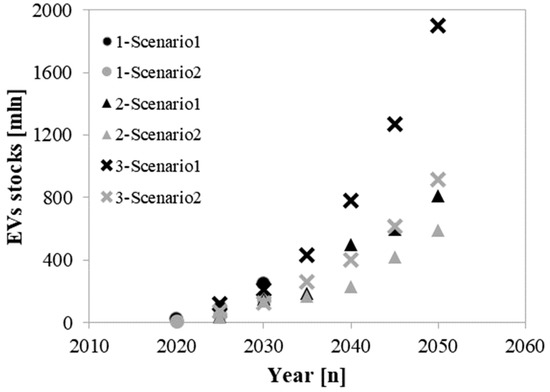

The demand for lithium-ion batteries (LIBs) is increasing worldwide due to their high efficiency as well as due to the versatility of rechargeable batteries [1]. This steep increase has called attention to several challenges that must be faced: on the one hand, the supply of raw materials, and on the other hand, the valorization of end-of-life products. In the case of the electric vehicles (EVs) market, the registration of passenger cars in the European Union (EU) has seen a double-digit growth in most of the Member States. In 2016–2018, EVs comprised from 8.5% (Poland) to 33.4% (Norway) of passenger cars in European Free Trade Association (EFTA) countries [2]. Figure 1 summarizes the total global volume of EVs predicted for 2050 as well as under different scenarios. In 2019, the number of electric and plug-in hybrid cars reached 2 million (3% of the fleet) and it is predicted that it will hit 28 million in 2030 (31% of the fleet) [3,4]. However, the estimations vary because of the several legislative perspectives, the different simulation analyses, and the probable technological evolution.

Figure 1.

Worldwide stock provision of EVs: 1-Scenario1 and 1-Scenario2 data available in [5], 2-Scenario1 and 2-Scenario2 data available in [6], and 3-Scenario1 and 3-Scenario2 data available in [7].

Thus, as the LIB technology advances, many end-of-life products will flood into global markets. The increment is already growing; in Italy, for example, the waste stream of lithium-based accumulators increased from 11% to 25% [8] during 2014 to 2019.

Within the EU, in 2016, it was reported that only 5% of LIBs had been reintegrated into the market after recycling [9], thus revealing incomplete regulation and leading to a non-sustainable scenario. This was also due to the criticality of the raw materials employed [10] to manufacture LIBs. From this point of view, the last revision of the list of Critical Raw Materials (CRMs) by the European Commission included lithium as a strategical CRM [11] and it should be added to the list of elements critical for the EU, such as cobalt or natural graphite [12,13]. This emergency exists worldwide; in fact, Co and Li in electrodes have also both been considered significant strategic and economic values. Hence, because of the increase in LIB production, in 2018, the price per kg of Co reached USD 81 [14]. With the rapid inflation of the new energy vehicles market, the supply of these raw materials from natural resources may be unable to satisfy the future demand unless proper recycling of the retired LIBs is assessed [15].

European self-reliance in the battery field is a major EU objective but the actual market is far from this point because of the high dependency on the supply of both raw materials and battery cells [16]. Table 1 shows the main components of CRMs that are used in batteries and the percentage of reliance of the EU market on the main global producers.

Table 1.

List of main CRMs used in batteries [17].

The LIB recycling industry is working on the batteries from EVs, electronics, and portable instruments nearing their end-of-life. The EU has set a target to improve the collection rate and recycle percentage of LIB raw materials, as shown in Table 2.

Table 2.

European Li-ion battery collection rate and percentage of materials recycling [18].

Actually, the EU is a net importer of nickel-cadmium (NiCd), nickel metal hydride (NiMH), and lithium-based cells; the volume of these products manufactured in the EU is around 5% of the global output, which is lower than the EU’s share of the global gross national product (GNP) [3]. The waste stream of these products is increasing year by year and it is critical that this becomes a new source of raw material.

It must also be considered that the performance of new LIBs usually decreases with use. In the case of EV batteries, for example, when the performance drops to 75–80% of its original value, the battery should be replaced. This means that the battery could have several usages also after these percentages, as technically proven by research projects and industrial application [19].

The absence of raw material and the need to guarantee a sufficient supply of batteries suggest that operators (recyclers) and producers should be directly involved in the treatment and recycling of waste batteries and accumulators. As far as an EU directive is concerned, according to Directive 2006/66/EC on Battery and Accumulators (BaAs), producers of BaAs and associated products are responsible for the related management of wastes in proportion to the products that are introduced into the market, even in the case of LIBs [20]. The corresponding directive was consolidated in 2013 [21] and 2018 [22] as part of larger intent to promote circular economy. Recently, a new document was provided by the European Parliament that established the new EU regulatory framework for batteries. Directive 2006/66/EC is currently under revision and the exponential growth of the LIB market as well as its unique features during recycling processes were considered [23].

A circular economy approach can be summarized in several steps, following the process from cradle-to-cradle. It begins with the design of the battery (standard formats and materials, international and standardized methodology for material labeling, and assembly strategy); followed by a review of the different possibilities of raw materials mining (from traditional extraction to secondary raw material mining, such as recycled materials); next, LIB production and use (implementation of new chemistry and technology for the production of LIBs); post-use collection of spent LIBs (minimum battery collection rate requirement also from EU directives); re-use (the valorization of end-of-life products can represent new business opportunities for second-life applications); and the process ends with recycling (LIB recycling allows for reducing energy consumption and CO2 emissions, saving natural resources by avoiding virgin materials mining and imports, minimizing environmental toxicity, creating an economic gain, decreasing waste, and managing safety issues) [24].

Several promising implementations have already been applied at an industrial scale by producers and recyclers all over the world [24]. The most representative examples, according to the authors’ knowledge and in the interest of this specific research study on industrial scale and patent, adopted by the major companies in the LIB field are listed below:

- Honda Motors Europe and Snam: are studying the feasibility of re-using end-of-life batteries (NiMH batteries) deriving from hybrid vehicles.

- The Volkswagen group (production site in Salzgitter) is designing a pilot plant for the direct production of LIB cells with a specific section for recycling.

- Fortum, BASF, and Nornickel are planning a pilot plant for the recycling of LIBs in Harjavalta, Finland.

- The Sony-Sumimoto process represents one of the best examples of a circular economy approach where the recovered Co(OH)2 from Sony’s spent LIBs from electronic devices is directly re-used in the fabrication of new cells. The process involves the calcination of spent cells and utilizes the cogeneration resulting from burning electrolytes [25].

- Northvolt recently approved the recycling program Revolt that will aim to source 50% of recycled material by 2030 in the recycling plant in Västerås, Sweden, and will target an initial recycling capacity of 100 tons per year due to a hydrometallurgical treatment of LIBs.

- Chinese Green Eco-Manufacture (200,000 ton/year) and Bangpo Ni/Co (30,600 ton/year) obtain regenerated cathodic materials through a hydrometallurgical process (992 MJ/ton) that are required for organic material incineration [24].

- Riciclo Made in Italy is a new patented technology (2018) developed by the collaboration of the Italian consortium COBAT (COBAT RIPA) and CNR ICCOM (Istituto di Chimica dei Composti Organometallici, Firenze) since 2014.

- Umicore patented a pyrometallurgical process to recover Co-alloy (WO, 2011/035915 A1) and a hydrometallurgical process to recover LIB electrolytes (US, EP 2 410 603 A1).

- Duesenfeld (Germany) patented a recovery process for LIBs electrolytes (US, 2018/0301769).

- Avestor Limited Partnership patented a combined process (pyro and hydrometallurgical) to recover high grade purity of Li2CO3 (US 7192654 B2) [24].

Many automotive companies are investing in projects involved in the reuse batteries from EVs for a second life in different applications, as reported in Table 3.

Table 3.

Project of second-life applications of EVs batteries [26].

The clusterification of recycling facilities in a few countries as well as limited areas raises many challenges, including the transportation of significant quantities of spent LIBs, which represents the highest effort [27] among them.

This study reports on the current and future European vision of more sustainable waste prevention and management legislation for LIBs, beginning with an analysis of the producers’ legislative obligation to a practical checklist for its application in several EU Member States to better satisfy both the demand of the European market and the sustainability requirements.

2. Materials and Methods

EU directives on BaAs were considered and analyzed to extrapolate the basic principles for all the EU Member States.

After an analysis of the European legislation, several national laws were taken as examples of significant representations of the issue, at least for the EU countries most historically consolidated (i.e., from 1995, before the inclusion of central and eastern Europe); for this reason, only the current regulations of Finland, France, Germany, Italy, the Netherlands, Portugal, and Spain have been compared.

The practical implication of the legislative acts was assessed by means of a survey and was applied to the collective schemes (consortia) associated with the (Italian) National Coordination Center for Batteries and Accumulators (Centro di Coordinamento Nazionale Pile e Accumulatori (CDCNPA), https://www.cdcnpa.it/) (accessed on 4 September 2021). The Italian case was chosen as it is descriptive at the European level: the legislation has not undergone a substantial change in recent years. Furthermore, the sample is representative because the answers were collected from consortia, but the collection was coordinated by CDCNPA, an independent center. Currently, the consortium CDCNPA includes 16 members, 14 of which are collective systems and two are individual systems. The answers were collected from both oral interviews and online surveys. Comprehensively, 43% of CDCNPA members’ systems completed the survey and both their competent answers and comments represent a very useful contribution to the legislative issue.

This survey was prepared following the most recent EU directive proposal in terms of both legislative adaptation and scientific development, and the practical implication of the legislative acts was assessed and applied to the collective schemes associated with the national CDCNPA. The answers were both oral and from an online survey.

The survey was organized into two main parts: the first was correlated to the relevance of the European Waste Code (EWC) 160605, while the second explored the effectiveness of an efficient valorization of the waste stream by means of a circular economy approach to the battery value chain. The survey is available in the Supplementary Materials.

Then, the current EU project and main initiatives were compared.

3. Results and Discussion

Several EU directives and regulations aim to manage wastes from electric and electronic equipment (WEEE), namely end-of-life vehicles containing LIBs and BaAs. In most cases, a clear regulation connected with Directive 2006/66/EC (and corresponding updates) on managing spent battery flows is missing, hence, it represents a limitation to the industrial treatment mostly because of the lack of data sharing, the uncertainty about extended producer responsibility, and the unrealistic targets for collection and recycling. In fact, LIBs are actually classified as industrial batteries and their take-back, collection, and recycling procedures are regulated as products whose safety issues, market availability, and logistic frameworks are totally different [24]. Following the directive, it appeared appropriate for us to define industrial battery or accumulator, automotive battery or accumulator, and portable battery. More precisely, industrial battery or accumulator is defined as any battery or accumulator that is designed exclusively for industrial or professional uses or is used in any type of electric vehicle; automotive battery or accumulator is defined as any battery or accumulator that is used for automotive starters, lighting, or ignition power; and portable battery or accumulator is defined as any battery, button cell, battery pack, or accumulator that (a) is sealed, (b) can be hand-carried, and (c) is neither an industrial battery or accumulator nor an automotive battery or accumulator [20].

3.1. Analysis of the EU Legislation

The key points of the EU active legislation are summarized as follows:

- Collection scheme for the waste of portable BaAs is ensured by the Member State, wherein producers of industrial BaAs or third parties acting on their behalf will not refuse to take back industrial BaAs waste;

- Producers of automotive BaAs or third parties will set up schemes for the collection of waste automotive BaAs from users or from an accessible collection point in their vicinity;

- Member States shall ensure that producers or third parties acting on their behalf will finance any net costs;

- Producers and users of industrial and automotive BaAs may conclude agreements stipulating financing arrangements (and organizations);

- Member States shall ensure that all economic operators and all competent public authorities may participate in the collection, treatment, and recycling schemes they are referred to;

- These schemes will also apply to BaAs imported from third countries under non-discriminatory conditions and will be designed to avoid barriers to trade or distortions of competition;

- Member States shall ensure that each producer is registered; and

- The technical development of new types of batteries that do not use hazardous substances should also be considered.

It is worth noticing that despite the research progress and development in this field, there are still no common labels or codes for the identification of different types of BaA and their chemistry.

Producers must be registered on the national list, even if they originate from a different country, and the number of registrations should be evident. Furthermore, the total volume of the product that is introduced into the national market should be communicated to evaluate the financial support of the recycling net.

The proposal for the revision was published on 10 December 2020 [28]. The requirements relating to sustainability would become mandatory, for example, concerning the carbon footprint rules, content of recycled materials in being higher than the minimum percentage and durability criteria, and requirements for end-of-life management, safety, and labelling for marketing. The proposal also includes due diligence obligations for economic operators with respect to the sourcing of raw materials. The main goal is to ensure the sustainability and competitiveness of the European battery value chain [23,29]. In fact, the relationship between the BaAs manufacturing and recycling companies is becoming increasingly strong in view of a circular economy approach, guaranteeing a cradle-to-cradle life cycle for LIBs. From this perspective, the newly proposed concept of a Battery Identity Global Passport (BIGP) represents a viable and economic way to manage the forthcoming waste flows, offering the chance to precisely identify battery supply chains from the cradle-to-cradle approach. Furthermore, it perfectly fits within the expected new EU directive for BaAs, although it should be globally implemented so as not to reduce the chances to recycle LIBs in responsible and profitable ways [30]. Nowadays, the management of LIB waste streams in the EU is regulated by the strong connection between the producer and the recycler. This connection is then translated in the Extended Producer Responsibility tool.

3.2. Analysis of the Legislations of the Target Countries

Each EU country can decide how to organize the collection scheme to comply with the Extended Producer Responsibility tool. It is regulated in each Member State law, which represents a translation of the EU directives by their own legislative body. The latest updates for BaAs legislation and the types of adopted collection schemes are shown in Table 4.

Table 4.

Last legislative update and organization of the BaAs collection scheme of the target countries.

All the analyzed countries have a strict definition regarding the Extended Producer Responsibility tool and how to register is precisely described even if the producer is outside the national borders; in that case, it is considered to be an import. The total quantity of materials introduced to the market should include both products and wastes. All countries must provide instructions for the financial scheme that supports the take-back collection schemes, which must permit the free-of-charge return of spent batteries from the end users.

- Finland

‘Valtioneuvoston asetus paristoista ja akuista (520/2014)’ and corresponding updates.

Last Finnish waste decree on BaAs was passed in 2014, but the WEEE Directive 2012/19/EU is employed to manage the responsibility of battery producers. However, it is specified that if a producer has a responsibility that pertains to several areas (for example, electronic and electrical appliances as well as packaging), the company must organize its producer responsibilities separately for each area. Authors have described this as relatively advanced environmental legislation and regulation for e-waste management [31], and the legislative bodies decided to merge both laws. The costs of the producer’s share of the organization must be covered pertaining to their sold product volume and category. Moreover, the decree is also explicit about their responsibility for the portion or its equivalent of so-called orphan products. The portion is determined based on each producer’s market share and the producers are proportionally responsible (based on the sold market volume) for the specific type of products. Spent LIBs are treated at the Akkuser plant in Nivala. According to the Finnish regulation, BaAs should be designed and manufactured as far away as possible to improve their environmental performance throughout the life cycle. To reduce harmful substances, the Pirkanmaa Center for Economic Development, Transport, and the Environment monitors the collection rates of discarded portable batteries and accumulators in accordance with the monitoring system.

Maximization of the separate collection of BaAs is also promoted. All separately collected, identifiable BaAs are recycled to minimize the possibility of the disposal of BaAs as municipal solid waste. An arrangement for the disposal of spent BaAs following a minimum service and accessibility level must be guaranteed with a minimum of one reception point for each municipality.

- France

‘Décret n° 2009-1139 du 22 septembre 2009 relatif à la mise sur le marché des piles et accumulateurs et à l’élimination des piles et accumulateurs usagés et modifiant le code de l’environnement (dispositions réglementaires)’ and corresponding updates.

The annual declaration of the quantity of products placed on the market is mandatory. Batteries must meet removal and treatment requirements through individual systems approved by the public authorities or by collective arrangements approved by the public authorities of two eco-organizations. Costs should be sustained by the producers and there should be no costs for end users. In France, there are the treatment operator’s representative (FEDEREC, FNADE, and SFRAP1), the approved producer responsibility organizations (Corepile and Screlec) and the approved individual system (MOBIVIA Groupe). The information for producers is given by a non-profit organization in order to comply with the legislation. For the industry, it is possible to extend the responsibility individually or to delegate it to a professional end user. Obligations are distributed between the producers in proportion to the number of products placed on the market and the permission must be reviewed and approved by the ministry every six years. The collection of the waste is a principle of the legislation that is intended to improve the collection rate.

- Germany

‘Bundesgesetzblatt Teil I2020Nr. 50 vom 09.11.2020 Erstes Gesetz zur Änderung des Batteriegesetzes’.

In this case, the producers must set up, operate, and declare their own collection systems, requiring the authority’s approval to guarantee the take-back network. Additionally, the take-back systems must publish the following information annually on their websites, in compliance with trade and business privacy:

- the ownership and membership relationships;

- the financial contributions made by the members per battery placed on the market or per mass of batteries placed on the market;

- the procedure for the selection of the disposal service; and

- the recycling efficiencies achieved in their own system.

The responsibilities of the public waste management authorities are also defined. If the authorities offer the option of returning the waste in the case of automotive batteries, this must proceed free of charge for the end user.

Clear and public information is an evident priority.

Within the aim of assessing each contribution made by the producers, the take-back systems are obliged to create incentives. Additionally, there is a strong valorization of the recycling. In fact, the producer’s obligation is considered complete only if it can guarantee the recycling of the take-back material. It is considered to be an effective supporting scheme to correct the lack of critical sources that are necessary for sustainable development [32].

- Italy

’Decreto Legislativo 20 novembre 2008, n. 188’ and corresponding updates.

In 2008, Italian CDCNPA published a guideline for producers, in which they defined a checklist of the main issues for compliance with respect to the Extended Producer Responsibility tool.

According to the definition of a consortium in the Italian regulations, these bodies have the main objective of helping to solve the problem of collecting and recycling scraps [33].

In this legislation, there are no specific obligations for LIB recyclers, nor are there any in the European Waste Code (EWC) for LIBs. Only the separate management and a specific definition for secondary battery (rechargeable one) are indicated.

- Netherlands

‘Regeling van de Minister van Volkshuisvesting, Ruimtelijke Ordening en Milieubeheer van 9 september 2008, nr. K&K 2008088170’ and corresponding updates.

Since 2008 in the Netherlands, battery producers have been obliged to report on how the batteries are collected and processed during their end-of-life. The industrial waste must be collected individually or by delegated professional end users. Moreover, in this case, the Batteries Foundation Stibat, a non-profit organization, helps the producer to comply with the legislative obligations.

Producers should also take measures to design the battery with the smallest possible amounts of substances that are hazardous to human health or the environment, and they must ensure that end users of batteries and accumulators are fully informed about the possibility of returning waste portable batteries or accumulators.

- Portugal

‘Decreto-Lei n.° 152-D/2017’ and corresponding updates.

In Portugal, the legislation currently mandates that the costs of the collection scheme are proportional to the type and quantity of battery (used within the country). A financing system is the obligation of the producers. In the case of third parties, the responsibility is transferred to an integrated licensed system. Portugal increased the collection rates with an emphasis on the role of management entities [34].

There is an indirect diversification of the type of batteries and an explicit request for providing a selective collection service of BaA.

In Portugal, there are currently five entities that manage waste batteries and accumulators with different areas of activity. The producers should promote research and development towards improving the environmental performance of BaAs.

The obligation to receive the respective waste is extended to both traders and retailers.

- Spain

‘Real Decreto 106/2008, de 1 de febrero, Vigente desde 21/Enero/2021’.

Spanish legislation allows for an additional way to operate collection schemes that uses the public scheme already established. This policy can be adopted only if the additional costs derived from the collection and management of batteries and accumulators are assumed by the producer. The procedures are used together with that implied in the collection policy of WEEE but with a separate collection.

The last update of the Spanish legislation has defined spent LIBs as a hazardous waste and a specific European Waste Code (EWC) was assigned to this stream.

Rules are established that must be followed due to a selective collection process established throughout the treatment and recycling process. Rules and standards for the collection are also cited. Economic instruments and research studies are identified as useful tools to promote the collection of spent batteries and ensure environmental sustainability. The recovery or the controlled disposal of used BaAs should be facilitated by means of networks of selective collection points for used batteries. The collection points are managed by the authorities or private parties. Research studies were also conducted in order to choose the appropriate location points in Spain [35].

Limits from the Analysis of the EU Legislative

The most important limitation is related to the obvious and very rapid development of new technologies and products that are not yet specified in the legislation. In addition, the current minimum collection targets and minimum recycling requirements for waste portable batteries are not defined appropriately [36]. At this time, LIBs have no technology specification (except in the Spanish legislation) and they are assimilated into lead-battery specifications. Along with the specifications of the types of battery (rechargeable or not), the specific chemistry [37] of LIB materials has also been reported. This possibility can also bring a higher flexibility to the collective schemes that are nowadays incomplete. Additionally, the lack of a specific definition for LIB waste leads to their misplaced classification as industrial batteries and their take-back, collection, and recycling are regulated as products whose safety issues, market availability, and logistics framework are totally different [24].

Besides battery classification, an appropriate definition of the financing scheme needs to be established. Current schemes are not suitable for the actual spent LIB stream and they are evaluated based on the quantity of batteries placed in the market by a producer without any differences between LIS and lead acid batteries (LAB) because the financing scheme is the same for both type of batteries, despite the substantial differences between them. Thus, when evaluating the best financing scheme, an analytical comparison should be done by considering the efficiency and effectiveness. This problem is also related to the lack of data sharing or a clear and explicit source, as noted previously.

3.3. The Italian Case: Answers from the Survey

The lack of a specific EWC led the consortium to two main conclusions. On one hand, the spent LIB classification as hazardous waste can improve the management of this waste stream when collection, transportation, storage, and the following specific treatments are carried out. On the other hand, the specification of the chemistry can improve the efficiency of the recycling system.

The lack of a specific EWC also has an impact on quantifying the flow of waste from LIBs that are managed by the consortium members, even if CDCNPA asserts that the largest collection flow derives from municipal centers and from the sorting of small equipment such as laptops, telephones, electronic tools, etc.

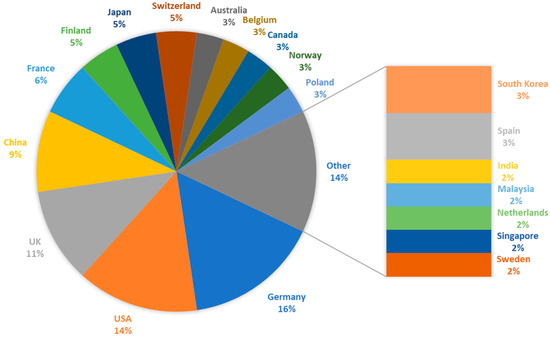

Moreover, the overall national value chain seems unable to adequately respond to the incoming waste stream, which was also foreseen. Concerning this, the locations of the main global companies operating in battery recycling (lithium recycling) consist of 61% outside the EU and 39% in the EU. Figure 2 shows the precise locations and it is evident that no plants are in Italy. These data were collected from an industrial analysis conducted to identify the main worldwide companies that recycle batteries, i.e., LIBs in this case. This was confirmed by the survey, which highlighted that at least the 90% of the waste is exported to other countries to be recycled, since in Italy, there are only plants that sort battery materials, which is itself a critical step to pre-treat spent batteries. Furthermore, the volume of the recycled material is negligible.

Figure 2.

Lithium-ion battery-recycling companies worldwide.

3.4. The European Challenge: Ongoing Projects

The European limits described above can be overcome through careful studies and research processes. Battery2030+ represents the large-scale and long-term European research initiative within the battery field, which also maintains an eye on the forthcoming technologies (not only on LIBs). However, this is just one of the European initiatives/actions and projects are ongoing in the EU. The importance of recycling was defined as a strategic pillar of the European Battery Alliance [29]. Table 5 reports the main ongoing European projects concerning energy storage systems technologies.

Table 5.

Ongoing and recent projects in lithium-ion battery efficiency implementation technologies.

This table depicts the flourishing environment of European in the battery field. In disclosing the future perspectives in the sector of energy storage systems, European governments and research centers are making many efforts towards the post-lithium-ion batteries. Indeed, many projects, launched beginning in 2017, are focused on the development of innovative materials aimed to reach higher energy and capacity levels (e.g., 057534–LiAnMAT, 950038—Bi3BoostFlowBat, 771777—FUN POLYSTORE, 770870—MOOiRE, and 864698—SEED). Moreover, along with the challenges regarding the future technologies, more efficient battery systems for electric vehicles and smart grids need to be developed (895337—BatCon, 101009983—ORION PROJECT, 731249—SMILE, and 770019—GHOST). In tandem with scientific innovations, European funds have been allocated to projects focused on sustainability and environmental evaluations (894063—GEVACCON and 875514—ECO2LIB). Thus, as mentioned above, the future challenges in the energy and environmental sectors for Europe, as well as for the whole world, will produce the most diverse fields. Indeed, far from being entirely covered by European governments, a profound transition will materialize in the approach to this progress, focusing on the scientific side and promoting public partnerships with and within universities and research centers. Thus, the ongoing projects within Europe are clear evidence of this trend.

The list of projects proves how important both the search for new technological solutions and the need for proper management truly are. Italian consortium members also monitor the lack of valorization concerning second-life use for batteries and this kind of use is only now the objective of an innovation project in the framework of the EIT Climate KIC (https://erion.it/it/ricerca-e-innovazione/lions2life/, accessed on 4 September 2021).

If the project outcome increases the battery durability, health, safety, and life, the pillars of a circular economy will be completely satisfied. Member States should also consider the Circular Economy Business Model when writing the legislation that will soon be necessary.

4. Conclusions

In order to guarantee the sustainability and the optimum EU management of LIBs, the unification and communication among the different stakeholders within the whole value chain are of utmost importance.

This goal becomes fully clear considering that the needs and the challenges of the legislation in various countries acquire more relevance if tied to the generalized overview of circular economy needs/challenges. In 2015, the European Commission adopted “The missing link: a European action plan for the Circular Economy”, in which the interdependence of all the processes in the value chain were analyzed, from the extraction of raw materials to product design; from production to distribution; and from consumption to reuse and recycling, inserting measures aimed precisely at designing products in an intelligent way. The commitment of the European Commission to these issues is also contained in the European New Green Deal presented by the new president of the European Commission in September 2019. Subsequently, on 11 March 2020, the Action Plan was updated and, in this version, the European Commission identified some production sectors as priorities, including the sectors of batteries and vehicles.

In this context, indeed, electric mobility represents one of the main areas requiring the implementation of circular economy logic, making it necessary to develop best practices to achieve sustainable mobility.

There is a clear need to apply a “Life Cycle Thinking” type approach that covers the entire life cycle of the vehicle and its components, and not only that of the LIB. The main issues to be addressed for a transition to a circular economy by the electric mobility sector consist of interventions along the entire electric mobility chain, such as (i) the development of charging infrastructures; (ii) the adoption of an eco-design logic through the choice of materials on the basis of their availability, recyclability, and ease of reprocessing; (iii) the spread of innovative and sustainable technologies based on “product as a service” business models, sharing platforms, and auxiliary services (“vehicle to grid” technology); (iv) an effective end-of-life management and regeneration system of the equipment and components; and (v) the development in each national territory of skills throughout the value chain (production of new vehicles, systems for assistance and repairs, and end-of-life treatment, where a second-life battery use system as well as LIB recycling and disposal processes are only one of the issues).

The Extended Producer Responsibility is recognized as an optimum tool to summon the various parties operating in the LIBs sector. However, after an analysis of the legislation (both European and of the target state), the following limits were detected:

- the financing systems for the collection schemes are not unique and a comparative analysis must be performed in order to identify the most effective and efficient systems;

- there is an absence of identification or codes that easily recognize LIBs, thus difficulties in sorting and recycling them are increasing; and

- there is an absence of specific regulations dedicated to LIBs, implying the loss of volume that is potentially detectable and valorized.

The upload of directives has been devoted to increasing the sustainability of LIBs but, at the same time, a revolution in the industrial sector is needed to guarantee the benefit of a cradle-to-cradle cycle for LIBs. Urgent innovation and legislative adaptation have been made more difficult considering the awareness that the use of accumulators cannot be the definitive or long-term solution.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/su132011154/s1, Main point of the survey.

Author Contributions

Conceptualization, C.G.; methodology, C.G.; validation, M.C. (Matteo Cavalletti) and R.I.; formal analysis, C.G., M.L.R. and M.C. (Massimo Conti); investigation, C.G.; resources, C.G., M.C. (Matteo Cavalletti), M.C. (Massimo Conti) and D.M.; data curation, S.O.; writing—original draft preparation, C.G., D.M., M.L.R. and P.S.; writing—review and editing, D.M., M.L.R., P.S., C.G., M.C. (Massimo Conti) and S.O.; supervision, P.S.; project administration, P.S. and M.C. (Massimo Conti); funding acquisition, M.C. (Massimo Conti). All authors have read and agreed to the published version of the manuscript.

Funding

This research study received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are openly available in all cited references as reported in the References.

Acknowledgments

Special thanks is given to the national Centro di Coordinamento Nazionale Pile e Accumulatori CDCNPA https://www.cdcnpa.it/ (accessed on 4 September 2021) for their contribution and collaboration, and to Fondazione Cariverona for providing the grant for the research fellow activities.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Giegerich, M.; Akdere, M.; Freund, C.; Fühner, T.; Grosch, J.L.; Koffel, S.; Schwarz, R.; Waldhör, S.; Wenger, M.; Lorentz, V.R.H.; et al. Open, flexible and extensible battery management system for lithium-ion batteries in mobile and stationary applications. In Proceedings of the 2016 IEEE 25th International Symposium on Industrial Electronics (ISIE), Santa Clara, CA, USA, 8–10 June 2016. [Google Scholar]

- Eurostat. Passenger Cars in the EU. Stat. Explain. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Passenger_cars_in_the_EU (accessed on 4 September 2021).

- European Commission. COMMISSION STAFF WORKING DOCUMENT on the Evaluation of the Directive 2006/66/EC on Batteries and Accumulators and Waste Batteries and Accumulators and Repealing Directive 91/157/EEC. Available online: https://ec.europa.eu/environment/pdf/waste/batteries/evaluation_report_batteries_directive.pdf (accessed on 4 September 2021).

- Engel, H.; Hensley, R.; Knupfer, S.; Sahdev, S. Charging Ahead: Electric-Vehicle Infrastructure Demand. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/charging-ahead-electric-vehicle-infrastructure-demand (accessed on 4 September 2021).

- IEA. Global EV Outlook 2019 to Electric Mobility. Available online: https://doi.org/10.1787/35fb60bd-en (accessed on 4 September 2021).

- Ghandi, A.; Paltsev, S. Global CO2 impacts of light-duty electric vehicles. Transp. Res. Part D Transp. Environ. 2020, 87, 102524. [Google Scholar] [CrossRef]

- Xu, C.; Dai, Q.; Gaines, L.; Hu, M.; Tukker, A.; Steubing, B. Future material demand for automotive lithium-based batteries. Commun. Mater. 2020, 1, 1–10. [Google Scholar] [CrossRef]

- CDCNPA. 6 Rapporto Annuale. Available online: https://cdcnpa.it/presentazione-6-rapporto-annuale/ (accessed on 4 September 2021).

- Heelan, J.; Gratz, E.; Zheng, Z.; Wang, Q.; Chen, M.; Apelian, D.; Wang, Y. Current and Prospective Li-Ion Battery Recycling and Recovery Processes. Jom Miner. Met. Mater. Soc. Curr. 2016, 68, 2632–2638. [Google Scholar] [CrossRef] [Green Version]

- Girtan, M.; Wittenberg, A.; Grilli, M.L.; de Oliveira, D.P.S.; Giosuè, C.; Ruello, M.L. The Critical Raw Materials Issue between Scarcity, Supply Risk, and Unique Properties. Materials 2021, 14, 1826. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Study on the EU’s List of Critical Raw Materials (2020) Final Report. Available online: https://ec.europa.eu/docsroom/documents/42883/attachments/1/translations/en/renditions/native (accessed on 4 September 2021).

- European Commission COM(2008) 699 Final, The Raw Materials Initiative—Meeting our Critical Needs for Growth and Jobs in Europe 6. 2008. Available online: https://www.eumonitor.eu/9353000/1/j9vvik7m1c3gyxp/vikqhmxxruzl (accessed on 4 September 2021).

- European Commission COM(2014) 297 Final, On the Review of the List of Critical Raw Materials for the EU a 2014. 2014. Available online: https://www.eumonitor.eu/9353000/1/j9vvik7m1c3gyxp/vjk3t59dq1zk (accessed on 4 September 2021).

- Turcheniuk, K.; Bondarev, D.; Singhal, V.; Yushin, G. Ten years left for redesign of Li battery. Nature 2018, 559, 467–471. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; An, N.; Wen, L.; Wang, L.; Jiang, X.; Hou, F.; Yin, Y.; Liang, J. Recent progress on the recycling technology of Li-ion batteries. J. Energy Chem. 2021, 55, 391–419. [Google Scholar] [CrossRef]

- Lebedeva, N.; Di Persio, F.; Boon-Brett, L. Lithium Ion Battery Value Chain and Related Opportunities for Europe; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-66948-4. [Google Scholar]

- European Commission COM(2020) 474 Final, Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability. 2020. Available online: https://www.eumonitor.eu/9353000/1/j9vvik7m1c3gyxp/vlbrebsa5yxl (accessed on 4 September 2021).

- European Commission. Batteries Europe: Strategic Research Agenda for 2020. Available online: https://ec.europa.eu/energy/sites/default/files/documents/batteries_europe_strategic_research_agenda_december_2020__1.pdf (accessed on 4 September 2021).

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A Review on Battery Market Trends, Second-Life Reuse, and Recycling. Sustain. Chem. 2021, 2, 167–205. [Google Scholar] [CrossRef]

- European Commission. Directive 2006/66/EC of the European Parliament and of the Council of 6 September 2006 on Batteries and Accumulators and Waste Batteries and Accumulators and Repealing Directive 91/157/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32006L0066 (accessed on 4 September 2021).

- European Commission. Directive 2013/56/EU of the European Parliament and of the Council of 20 November 2013 Amending Directive 2006/66/EC of the European Parliament and of the Council on Batteries and Accumulators and Waste Batteries and Accumulators as Regards the Placing on. 2013. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32013L0056 (accessed on 4 September 2021).

- European Commission. Directive (EU) 2018/849 of the European Parliament and of the Council of 30 May 2018 Amending Directives 2000/53/EC on End-of-Life Vehicles, 2006/66/EC on Batteries and Accumulators and Waste Batteries and Accumulators, and 2012/19/EU on Waste Electrical. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32018L0849 (accessed on 4 September 2021).

- European Parliament. EU Legislation in Progress New EU Regulatory Framework for Batteries Setting Sustainability Requirements. 2021. Available online: https://www.europarl.europa.eu/thinktank/en/document.html?reference=EPRS_BRI (accessed on 4 September 2021).

- Mossali, E.; Picone, N.; Gentilini, L.; Rodrìguez, O.; P, J.M.; Colledani, M. Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments. J. Environ. Manag. 2020, 264, 110500. [Google Scholar] [CrossRef] [PubMed]

- Bernardes, A.M.; Espinosa, D.C.R.; Tenório, J.A.S. Recycling of batteries: A review of current processes and technologies. J. Power Sources 2004, 130, 291–298. [Google Scholar] [CrossRef]

- Where 3 Million Electric Vehicle Batteries Will Go When They Retire. Available online: https://www.bloomberg.com/news/features/2018-06-27/where-3-million-electric-vehicle-batteries-will-go-when-they-retire. (accessed on 6 August 2021).

- Chen, M.; Ma, X.; Chen, B.; Arsenault, R.; Karlson, P.; Simon, N.; Wang, Y. Recycling End-of-Life Electric Vehicle Lithium-Ion Batteries. Joule 2019, 3, 2622–2646. [Google Scholar] [CrossRef]

- European Commission. Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020PC0798 (accessed on 4 September 2021).

- Danino-Perraud, R. The Recycling of Lithium-Ion Batteries. A Strategic Pillar for the European Battery Alliance. Available online: https://www.ifri.org/sites/default/files/atoms/files/danino_recycling_batteries_2020.pdf. (accessed on 6 August 2021).

- Bai, Y.; Muralidharan, N.; Sun, Y.K.; Passerini, S.; Stanley Whittingham, M.; Belharouak, I. Energy and environmental aspects in recycling lithium-ion batteries: Concept of Battery Identity Global Passport. Mater. Today 2020, 41, 304–315. [Google Scholar] [CrossRef]

- Levänen, J.; Lyytinen, T.; Gatica, S. Modelling the Interplay Between Institutions and Circular Economy Business Models: A Case Study of Battery Recycling in Finland and Chile. Ecol. Econ. 2018, 154, 373–382. [Google Scholar] [CrossRef]

- Bongartz, L.; Shammugam, S.; Gervais, E.; Schlegl, T. Multidimensional criticality assessment of metal requirements for lithium-ion batteries in electric vehicles and stationary storage applications in Germany by 2050. J. Clean. Prod. 2021, 292, 126056. [Google Scholar] [CrossRef]

- Sancilio, C. COBAT: Collection and recycling spent lead/acid batteries in Italy. J. Power Sources 1995, 57, 75–80. [Google Scholar] [CrossRef]

- Vieceli, N.; Margarido, F.; Durão, F.; Guimarães, C.; Nogueira, C.A. Collection of waste batteries in Portugal and Brazil. In WASTES 2015-Solutions, Treatments and Opportunities: Selected Papers from the 3rd Edition of the International Conference on Wastes: Solutions, Treatments and Opportunities, Viana Do Castelo, Portugal, 14–16 September 2015 (1st ed.); CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2015; p. 349. [Google Scholar]

- Ponce-Cueto, E.; Manteca, J.Á.G.; Carrasco-Gallego, R. Reverse logistics for used portable batteries in Spain-An analytical proposal for collecting batteries. Environ. Sci. Eng. 2011, 593–604. [Google Scholar] [CrossRef]

- Pouikli, K. Concretising the role of extended producer responsibility in European Union waste law and policy through the lens of the circular economy. ERA Forum 2020, 20, 491–508. [Google Scholar] [CrossRef] [Green Version]

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).