1. Introduction

The Food and Agriculture Organization (FAO) highlights the importance of food supply chain (FSC) management in its 2009, 2011, 2017, 2018, and 2020 reports [

1,

2,

3,

4,

5], and points out that food loss and waste (FLW) reduction is a crucial part of FSC management to which greater attention needs to be paid. The FAO [

4] estimates that one third of edible food for human consumption in the world is lost or wasted, which is equivalent to 1.3 billion tons per year. The target set by the United Nations on FLW is to “halve the per capita global food waste by 2030 at the retail and consumer levels and reduce food loss and waste along the production and supply chains” [

6]. Furthermore, the COVID-19 pandemic is causing serious food crises worldwide, and FLW reduction may work as an effective measure to alleviate the food shortages [

5] and an alternative way to increase accessible food for a growing population [

7], improve long-term economic performance [

8], and reduce environmental influence [

9].

FLW has recently become a high-profile issue and attracted significant attention in academia, from practitioners, and from governments. However, even though the importance of FLW has been highlighted academically and practically, and studies on FLW topics are various and increasing [

10], we are not aware of the studies that provide a systematic and integrated framework to indicate how to analyze FLW issues within FSCs.

We scrutinized existing literature relevant to FLW research up to October 2020 in the databases of Scopes, Springer, and EBSCO. We identified these papers considering various expressions of “FLW” in the keywords list, including “food loss,” “food waste,” “food loss and waste,” “food wastage,” “wastage of food,” and “post-harvest loss.” Within these papers, we selected and studied the articles that were in the field of operations management (OM) as our analytic pool for developing our conceptual framework. In addition, we examined the reports of related organizations, including FAO, the United Nations, and the United States Department of Agriculture.

To enhance the understanding of FLW research, we developed an inductive approach and presented a research framework to help researchers identify possible methods to reduce FLW in the OM field. The contribution of this paper is threefold. First, it proposes a framework to identify FLW problems within FSCs. Second, it helps to comprehensively understand FLW occurrence and stimulate research focusing on FLW from different perspectives. Third, it motivates researchers to discuss and analyze FLW issues by applying different methodologies.

This study is a conceptual analysis based on existing literature. We develop the conceptual framework following the logic steps: literatures review, research scope identification, FLW issue discussion, measures to reduce FLW in OM, analytic methodologies, and future direction projection.

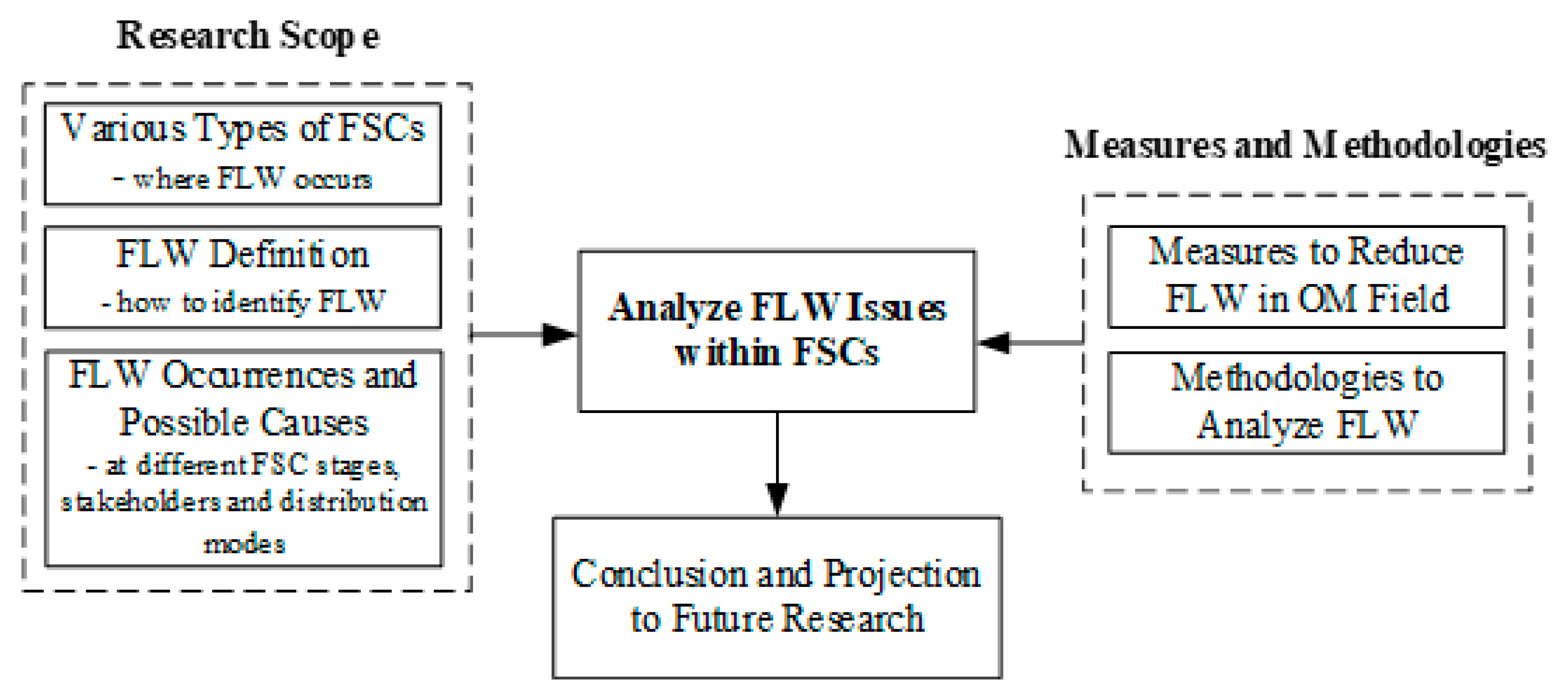

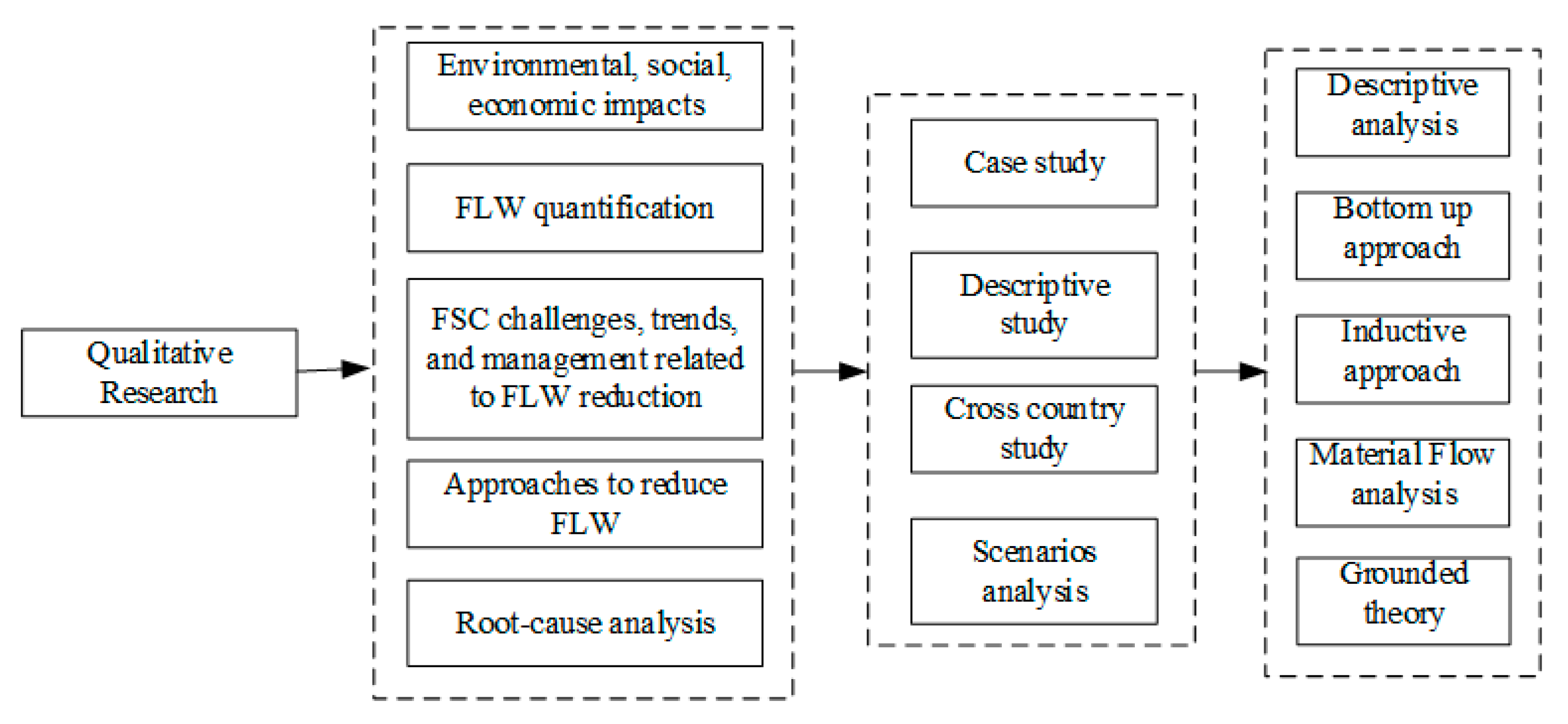

Figure 1 describes the structure of this paper.

In the remainder of this paper,

Section 2 discusses the various types of FSCs and definitions of food loss, food waste, and FLW. Following the definitions,

Section 3 reviews the social, economic, and environmental impacts of FLW.

Section 4 describes FLW occurrences and causes in different FSC stages, stakeholders, and distribution modes.

Section 5 discusses the measures to reduce FLW in the field of OM and

Section 6 introduces some methodologies that can be applied for FLW reduction studies. The conclusion is presented in

Section 7.

2. Various Types of FSCs and Definition of FLW

2.1. Various Types of FSCs

Some studies focus on FLW within FSCs without specific attention on product characteristics [

11], whereas other studies address FLW in various forms of FSCs, such as perishable FSCs [

12], chilled FSCs [

13], sustainable FSCs [

14], and shelf-life FSCs [

15].

There have been some discrepancies in naming FSCs in recent research, such as studies using “agri-FSCs” [

16] or “agri-business supply chains” [

17] to emphasize the importance of the agriculture sector compared to manufacturing supply chains, or “food value chains” to evaluate FLW from the view of value and cost [

18]. These expressions of supply chains in the food industry may or may not examine the same group of products. Generally, characteristics and categorization of food products are two dimensions to be considered when naming FSCs in different studies.

Another group of OM researchers preferred to apply commonly accepted names in their FSC research considering specific categories, such as vegetable supply chains [

19], grain supply chains [

20], fresh fruit supply chains [

21], and dairy supply chains [

22]. Others used more specific food products, such as beef supply chains [

23] and avocado supply chains [

24].

To enhance the understanding of various FSCs and define the scope of the study, some researchers classified food products into kinds of groups with different categorizing methods. For example, Shukla and Jharkharia [

25] divided the food products according to whether they were “durable” or “perishable”; Beretta et al. [

26] specified the food category, such as “fruits,” “vegetables,” or “cereals”; and Behzadi et al. [

27] classified agri-food products into “crops” and “livestock.”

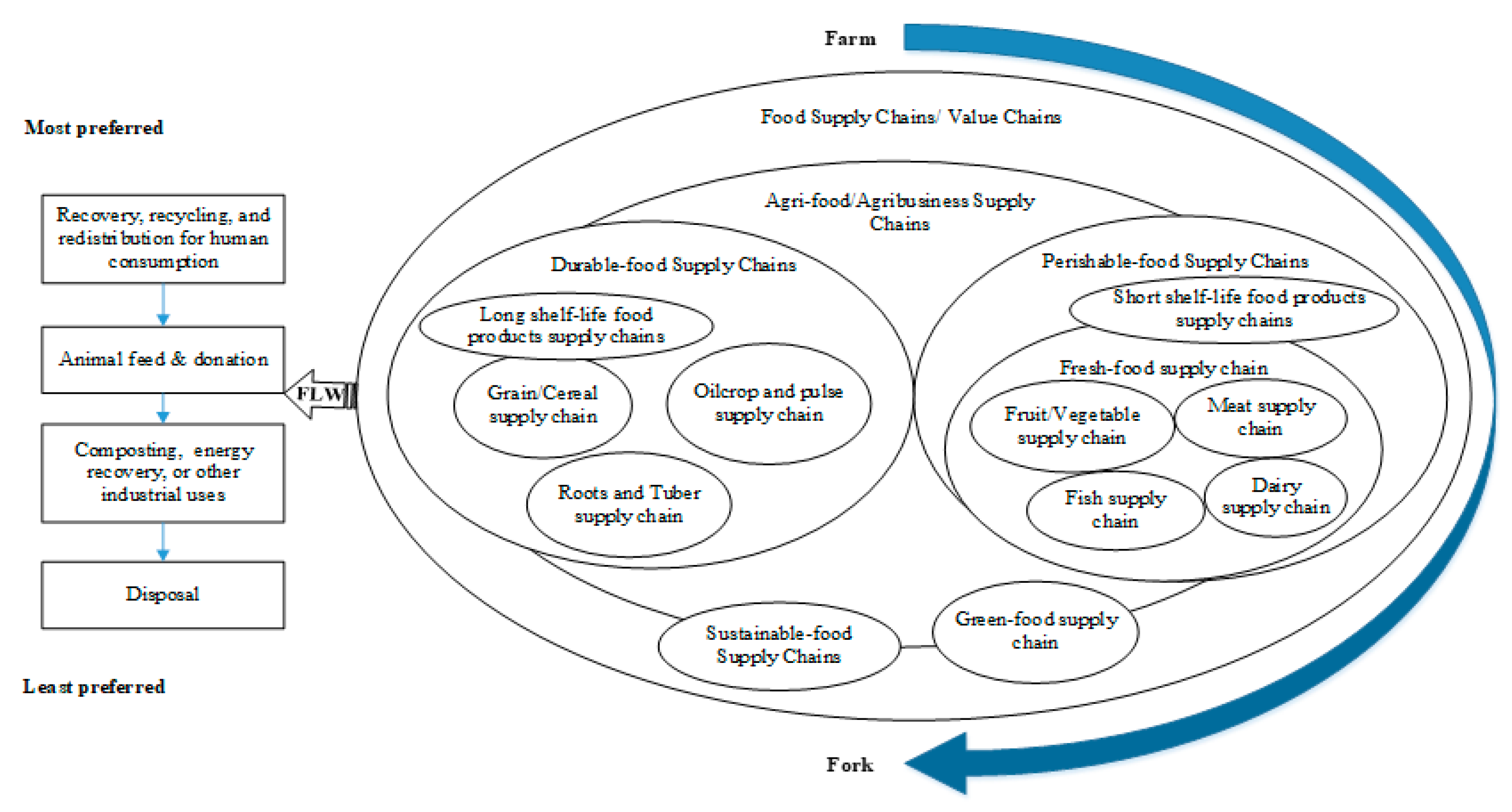

Figure 2 illustrates a categorization and a circulation of FSCs, including the destination of the resource flow. FSCs are used to describe activities that bring the food from farm to fork. To address the value of FSCs, some researchers also used the expression “food value chain.” We could not cover all kinds of FSCs, as there might be thousands of FSCs named by specific food products without mentioning the key word “food.” Thus, we selected seven commodity groups, which are addressed and analyzed in the FAO [

2] report as paradigms. Meanwhile, we also considered different expressions of FSCs, such as agri-food or agribusiness supply chains, durable FSCs, and perishable FSCs. To provide a holistic picture of circulation, we included the food-use hierarchy [

3], which shows the possible destinations of FLW, and indicates the preferred methods for waste management.

2.2. Definition of FLW

Studies in FLW research interchangeably use “food loss,” “food waste,” “food loss and waste,” “food wastage,” and “post-harvest loss”; however, they may or may not have examined the same aspects of the problems. There are over 100 different definitions of “food loss” and “food waste” [

28,

29], and the distinction between these definitions is various in the literature [

26]. The FAO [

2] defines food loss as “the decrease in edible food mass throughout the part of the supply chain that specifically leads to edible food for human consumption,” and food waste as “food losses that are occurring at the end of the food chain.” This definition gives a clear boundary both for food and FSC stages. It segments food by distinguishing edible parts from non-edible parts of food or feed, and unplanned non-food use from planned non-food use. Researchers tend to use different definitions following their own preferences in the context of their research scope, purpose, or research questions.

Adoption of the definitions may impact aspects of the studies such as data collection, model construction, and results interpretation. Each definition has its own focus and may have some limitations or lacking information. For example, the FAO’s definition [

2] is widely used in FLW research, which addresses the usage of food products and edibility. However, this definition may not consider the economic losses and practical problems for FLW measurement [

30]. We illustrate an apple supply chain to explain the missing information of the FAO’s definition, shown in

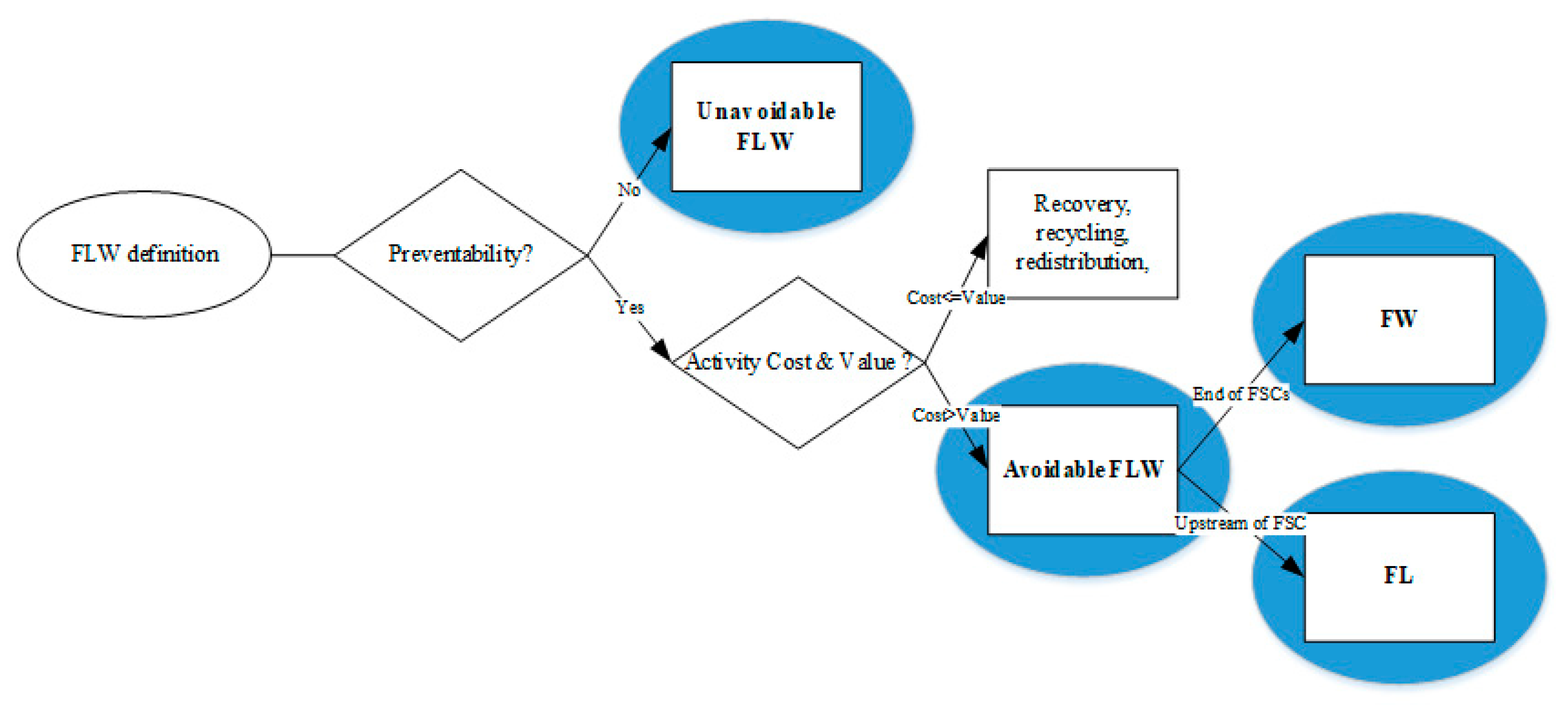

Figure 3.

We describe a two-round consumption flow, which also could have practically infinite rounds. According to the FAO’s definition, if one round of consumption is considered, the apples that go to the disposal stage, even they are still fit for consumption, are counted as FLW. However, in the two-round consumption scenario, whether we should calculate the products generated from food recovery as FLW or non-FLW depends on the next consumption pathway. In this context, the FAO’s definition creates difficulties in FLW cost and volume calculation from tracking and tracing the products’ flow, and different results from open-loop or closed-loop supply chain perspectives.

The key question in

Figure 3’s flow is whether the fertilizer as an input to produce apples is counted as FLW. According to the definition, if the fertilizer, which is a type of recovered food product, goes to human consumption without being disposed of, it should be treated as non-FLW. But what if its output goes to landfill or animal feed? Thus, the FAO’s definition may create some difficulties in FLW calculation from three points: underestimating FLW cost when economics losses occur under the circumstance that the food recovery process costs more than other alternative inputs, tracking and tracing the product flow in each FSC stage, and different results stemming from an open-loop supply chain perspective or closed-loop supply chain perspective. In order to standardize the FLW definition, we suggest considering three points: cost and value, preventability, and the FSC stages, as described in

Figure 4.

3. Social, Economic, and Environmental Impacts of FLW

FLW has a significant impact on society, economics, and the environment [

31], and these three forces are identified as the impetuses behind the FLW reduction studies within FSC management [

32].

3.1. Social Impacts of FLW

Elaborating from ethical and moral dimensions [

9], FLW reduction is recognized having considerable potential to increase the food efficiency [

2] and in turn improve food security and alleviate global poverty [

33]. Pinto et al. [

34] highlighted this impact as a way to reduce “social inequality and misdistribution of resources.” FLW social impacts have been discussed in several perspectives, including corporate social responsibility (CSR), cultural impacts, and changes in the patterns of people’s lives related to one other.

CSR: FLW reduction reflects the CSR strategies of FSC stakeholders [

35] and improves stakeholders’ reputation [

13]. Instead of delivering to secondary markets or reuse, redistribution, and recovery, food donation is another way to demonstrate CSR and FLW management strategy [

36]. However, considering economic efficiency, CSR may fail to motivate all stakeholders to adopt corrective methods and efforts to reduce FLW, which may call for effective intervention from food policy and regulation by governments [

14,

37].

Cultural impacts: FLW reduction is deemed to have limited impacts on cultural changes, as a certain amount of FLW is perceived to be socially acceptable [

33,

38]. Zhang et al. [

39] analyzed this impact, and indicated that the potential cause of the reduced significance of cultural impact is due to the failing proportion of food cost in total household income in pace with the development of society.

Changes in the patterns of people’s lives related to one other: FLW requires close collaboration between stakeholders within the entire food system [

40,

41]. On the other hand, from the individual level, the encouragement for the implementation of FLW reduction motivates people to live sustainably [

42] and changes their behaviors by observing others’ or socially approved behaviors or norms [

43].

3.2. Economic Impacts of FLW

Even though economic impacts are discussed or mentioned in almost all research articles related to FLW reduction, current FSC management research focusing on cost/profit optimization tends to overlook the economic impacts of FLW [

14]. Initiatives in FLW reduction are considered to contribute to FSC stakeholders’ profits by providing more available products to sell [

7], avoiding disposal and input costs [

44] and specifically, the fiscal deduction from food donations [

31]. Given external limitations (e.g., laws and regulations, credit constraints, and insufficient investment in infrastructure), FLW reduction operations by internally improving the efficiency of FSC management is considered an approach to increase the long-term profit of the entire FSC [

45].

In addition, there are some arguments on the economic impacts of FLW. For example, the FAO [

2] report emphasized that the reduction of avoidable FLW has a direct and positive impact on the income of both farmers and consumers, whereas Koester [

46] noted that given specific circumstances, farmers may accept some FLW as being economically efficient. Relevant analysis on economic impacts of FLW that we observed included but was not limited to:

Economic costs of FLW reduction: Due to the costs of implementing, FLW reduction would be higher than the residual value of the product itself [

14], and FLW reduction might be treated as economically infeasible under certain conditions. In this context, it requires researchers to analyze detailed and specific costs of FLW reduction initiatives, such as transportation, processing, and distribution network setup costs for recovery, redistribution, and reuse [

2], and disposal and opportunity costs of resources wasted and lost [

47].

Economic benefits of FLW reduction: Initiatives in FLW reduction are considered to contribute to FSC stakeholders’ profits by providing more available products to sell [

7], avoiding disposal and input costs [

44] and specifically, the fiscal deduction for food donations [

31]. From a consumption perspective, they are regarded as being propitious to lower food prices by reducing the imbalances between food supply and demand [

2], and save money on purchasing food [

48].

3.3. Environmental Impacts of FLW

To not be limited when providing adequate accessible food for a growing population, to improve economic performance, and to be identified as a sustainable solution for FSC by reducing adverse environmental influence [

9], FLW reduction has considerable potential value to be studied and tackled. Many studies are from the field of environmental science, which is the largest subject in FLW research. Studies discussing the environmental impacts of FLW are mainly from two streams: the wastage of upstream production resources, such as water [

49] and land [

50], and waste disposal from downstream, such as greenhouse gas emissions caused by consumption waste [

51,

52,

53,

54]. Proper FLW reduction operations are considered to have high potential to reduce the environmental burden [

55].

Environmental impact could be evaluated by different disposal technologies [

56], life cycle assessment (LCA) methods [

32,

55], and environmentally extended input–output methodology [

57]. The numerical results show that FLW could cause severe environmental problems such as greenhouse gas emissions, natural resources waste, and soil degradation [

58]. However, can the practices of FLW reduction definitely alleviate environmental impacts? Lam et al. [

55] indicated that proper FLW management has a high potential to reduce the environmental burden, otherwise, it may exacerbate environmental problems. Most articles focused on the environmental impacts that were directly linked to FLW disposal, but did not consider those generated during the other steps of FSC, for example, using chemicals to extend the product’s life, which could reduce FLW but harm the environment, or using storage facilities that consume more electricity. A comprehensive assessment of environmental impacts of FLW reduction considering both FLW disposal and FLW treatment is needed.

4. FLW Occurrences and Possible Causes

4.1. FLW at Different FSC Stages

FSCs are complicated networks found between food producers, processors, distributors, and consumers, and are used to describe activities that bring the food from farm to table, from production to consumption. Distinguished from other supply chains, the intrinsic characteristics of FSCs include weather-related variability [

26], uncertain supply and demand [

20], limited and fluctuating shelf life [

15], uncertain degradation process in quality and quantity [

59], and demand for environmental sustainability [

60]. These characteristics make the underlying FSCs more complicated and difficult to manage.

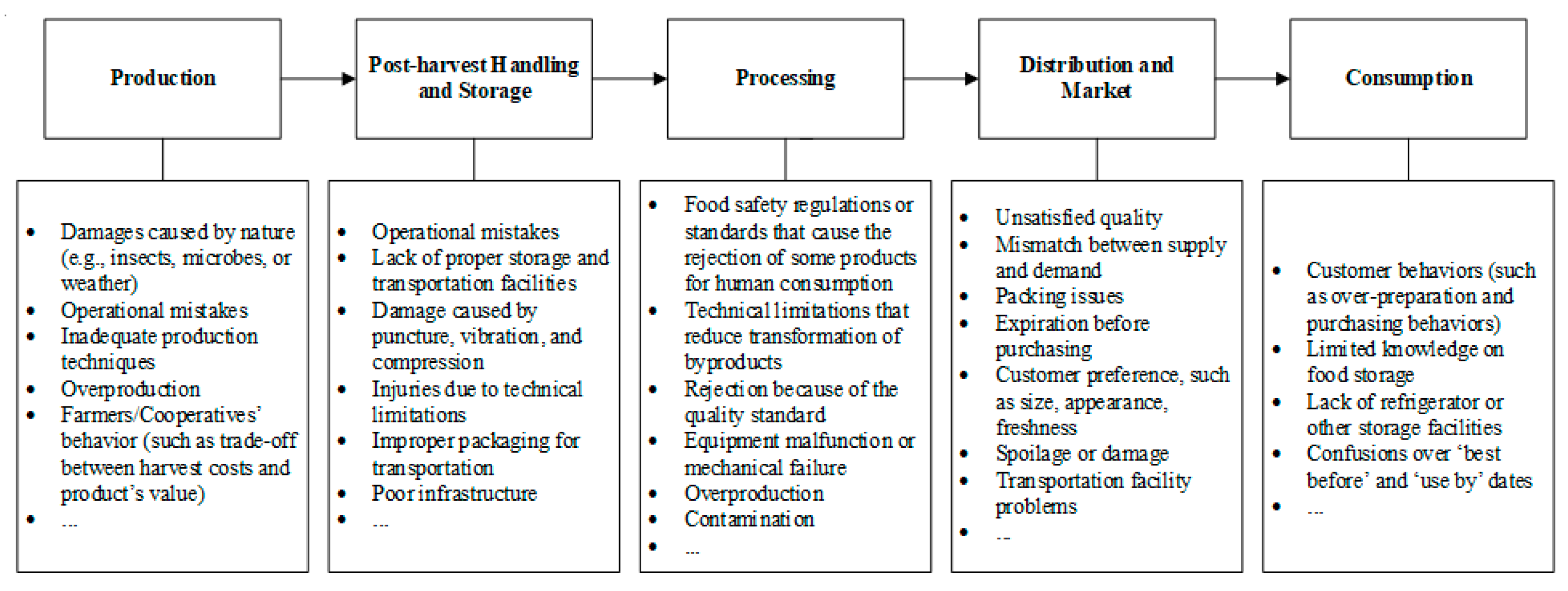

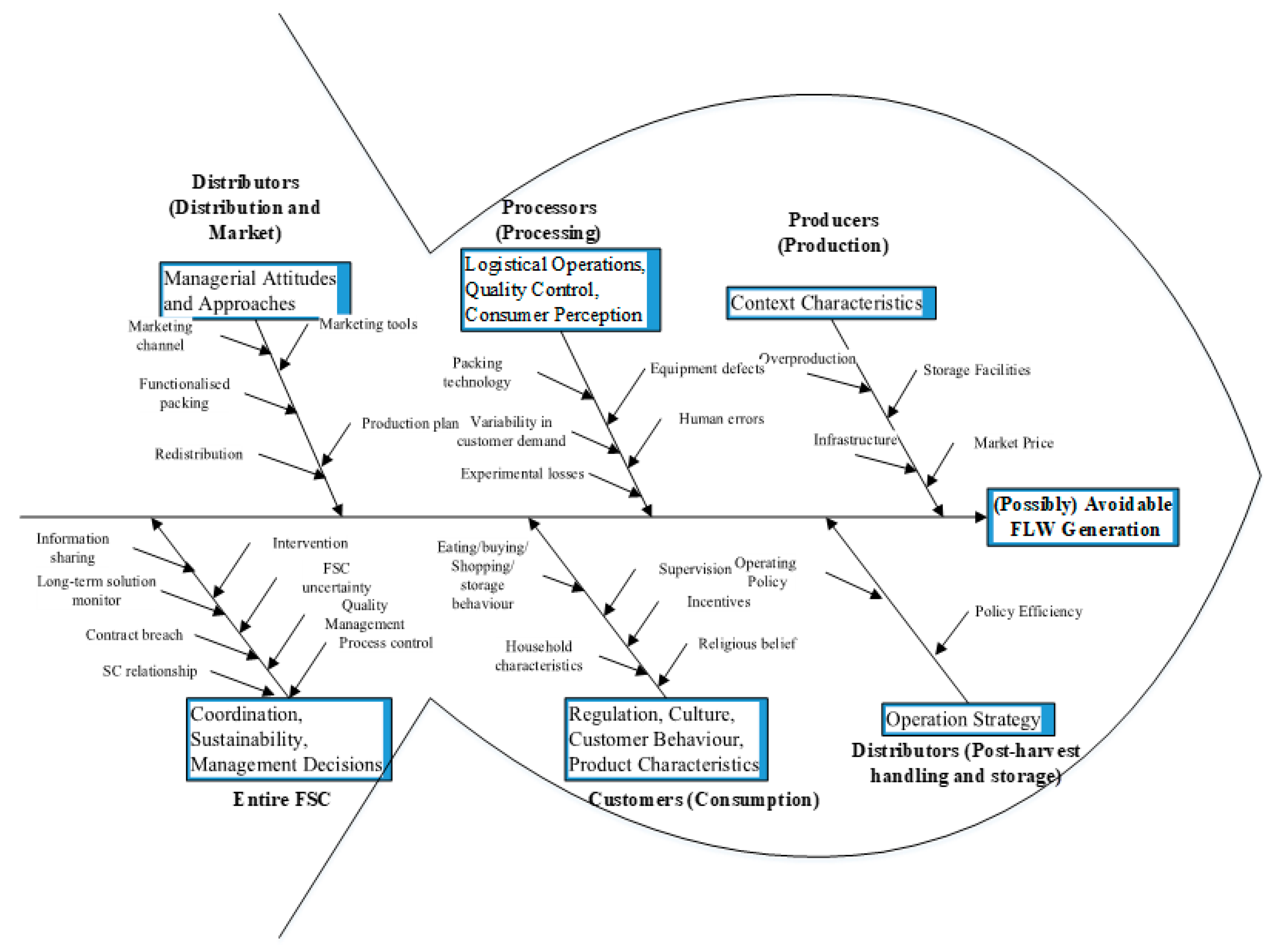

FLW can occur at any stage of FSCs. To provide a view of FLW within FSCs,

Figure 5 illustrates potential FLW occurrences and causes in a typical FSC. We followed the descriptions of the FSC stages provided by the FAO [

4] and summarized potential FLW occurrences and causes from [

8,

47,

50,

61].

4.2. FLW at Different FSC Stakeholders

There are hundreds of types or distribution channels of FSCs. In order to have a holistic illustration of FLW occurrences within FSCs, we provide a general discussion on avoidable FLW for stakeholders and distribution modes. Typically, FSCs are considered to embrace the components of suppliers, processors, and retail outlets [

62]. However, rather than a unique and standard distribution channel including all components, the distribution channels that are associated with different categories of food products are more likely to depend on the market structure and product characteristics in the food sector [

63]. Even in the same industry, different FSCs may include different stakeholders. For example, Tostivint et al. [

64] investigated a dairy supply chain, including milk suppliers, collection points, manufacturers, distributers, and retailers, whereas Kaipia et al. [

65] considered that this industry includes a milk supplier, logistics service provider, wholesaler, and retailer. In the remainder of this section, we discuss avoidable FLW for different FSC stakeholders.

4.2.1. Farmers

FLW occurs at the initial stage of FSCs, and the reasons are varied, including:

Overproduction: For example, due to poor forecasting (lack of technology or experience), food products cannot be sold entirely to wholesalers, retailers, or customers [

46];

Farmers’ rational choice on the acceptance of some FLW [

66]: Farmers may discover that the costs (e.g., harvesting and delivering) of selling their products are higher than the benefits; and

Inadequate technologies for cultivation and harvesting [

67].

4.2.2. Wholesalers

In developing countries, wholesale markets are often characterized as being small scale, crowded, unsanitary, and lacking cooling systems [

2]. Practically, not all distribution channels include wholesalers as intermediaries. For example, online companies may directly contract with farmers, and supermarkets have long and stable relationships with farming co-operatives. However, the wholesale distribution channel is an important aspect of FSCs.

The FLW occurring at wholesalers is often related to poor distribution and storage, and a shortage of a demand for information [

2,

66]. Longer distribution and storage time and poor facilities reduces the quality of most agri-foods and results in FLW.

4.2.3. Retailers

FLW management at retailers involves many impact factors, such as inventory management, quality management, and supplier management. Studies on FLW at the retail level is varied and increasing. The key focuses of FLW at retailers include:

Demand management: Variabilities in demand are one of the significant factors that generate FLW at the retail level. Failures, such as inaccurately forecasting the customers’ demand, unprepared promotions, and over-qualified service level, can result in FLW [

31];

Inventory management: The literature on perishable food products using inventory management methods is vast. Rather than setting FLW reduction as the key objective, most studies used traditional cost minimization or profit maximization objectives, and indirectly examined FLW issues [

68];

Motivation in FLW reduction: Quality management, customer satisfaction, and economic concerns are some of the key factors that impact motivation in FLW reduction at the retail level. For instance, to ensure a high level of freshness and customer satisfaction, retailers may dispose of products even they are still fit for consumption. Another example is associated with food donations. Instead of delivering to secondary markets, or reuse, redistribution, and recovery, food donation is a way to demonstrate CSR and FLW management strategy [

36]. However, considering economic efficiency, CSR may fail to motivate retailers to adopt corrective methods and efforts to reduce FLW, which call for effective intervention from food policy and regulation by governments [

31,

37]; and

Technology limitations: Inappropriate packaging, storage, and display at the retail level can impact the quality, deterioration rate, and shelf-life of the food products.

4.2.4. Customers

Customer behavior has been well examined in FLW studies. Factors, such as the patterns of human life, shopping habits [

69], behavior types [

70], knowledge of FLW, and culture [

71] significantly impact FLW reduction performance [

72].

Besides the key factors above, we summarized other factors coming from the literature; see [

23,

44,

71,

73,

74,

75,

76,

77,

78,

79], shown in

Figure 6. This fish-bone frame helps researchers to comprehensively understand the possible root causes of FLW generation from the perspectives of both a specific FSC stage and the entire FSC.

4.3. FLW at Different FSC Distribution Modes

From a practical and operational perspective, we identified at least four FSC distribution modes that co-existed, and we named them “traditional mode,” “wholesale mode,” “supermarket mode,” and “Internet retail mode.” We conducted a conceptual framework for these forms of FSC and possible FLW occurrence in these modes to provide an illustration on how differently FLW occurs in these four modes. We also acknowledged that for specific products, the stages could be significantly different, and sometimes even for the same products, distribution channels co-existed.

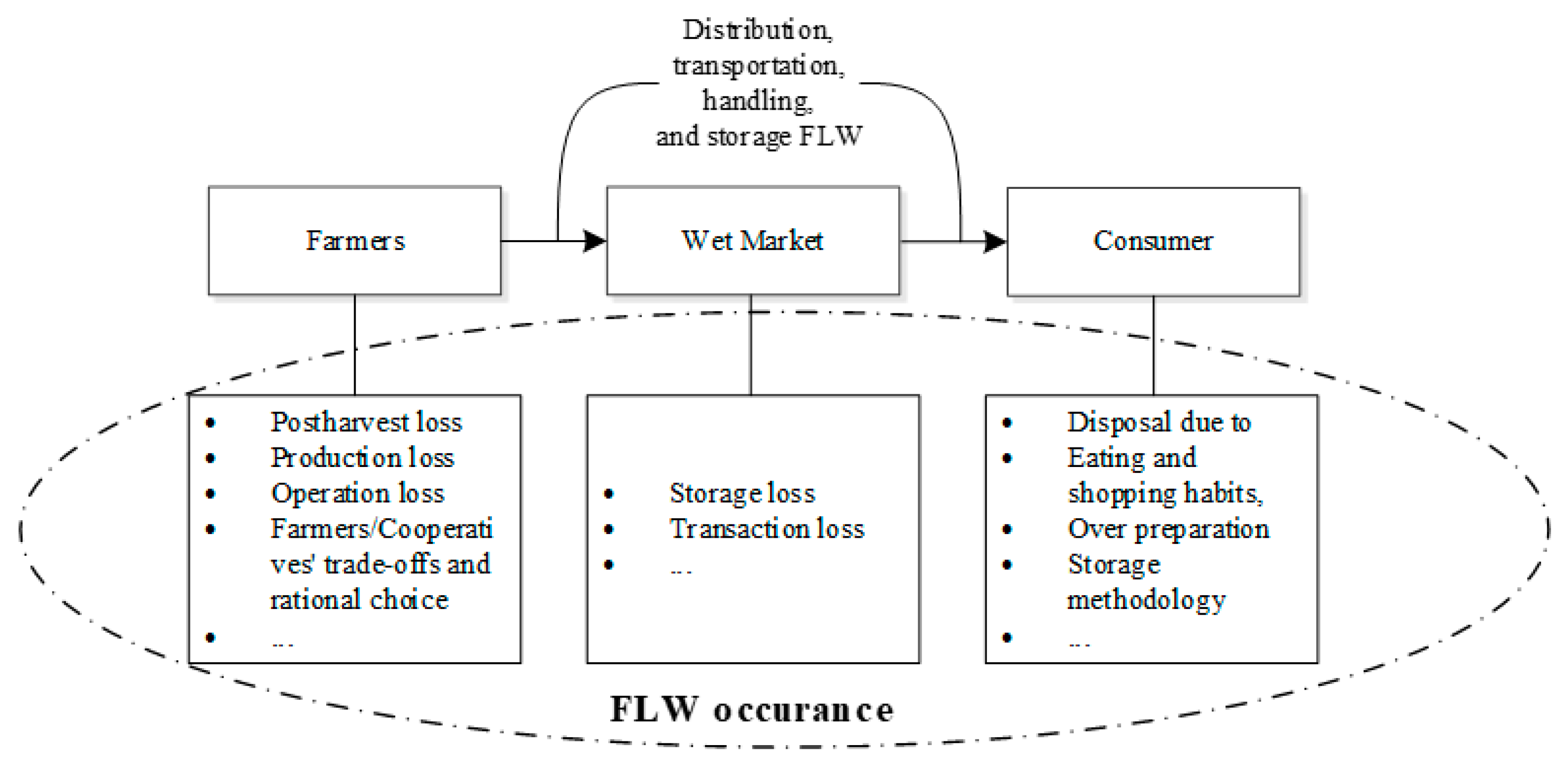

4.3.1. Traditional Mode

A direct and traditional FSC is characterized by a narrow distribution channel, which is normally led by farmers and traders. Direct sales in regional and local wet markets, corner stores, or roadside stands are primarily located close to the production region. The number of intermediaries is small, and Reardon [

80] described it as “geographically short” and “intermediationally short.” The relationships between the seller and buyer are generally limited to simple spot transactions [

1], and products delivered via this FSC are low cost and mainly targeted at lower-income urban and rural people [

81,

82]

Figure 7 describes the FSC in the traditional mode and the possible FLW occurrence.

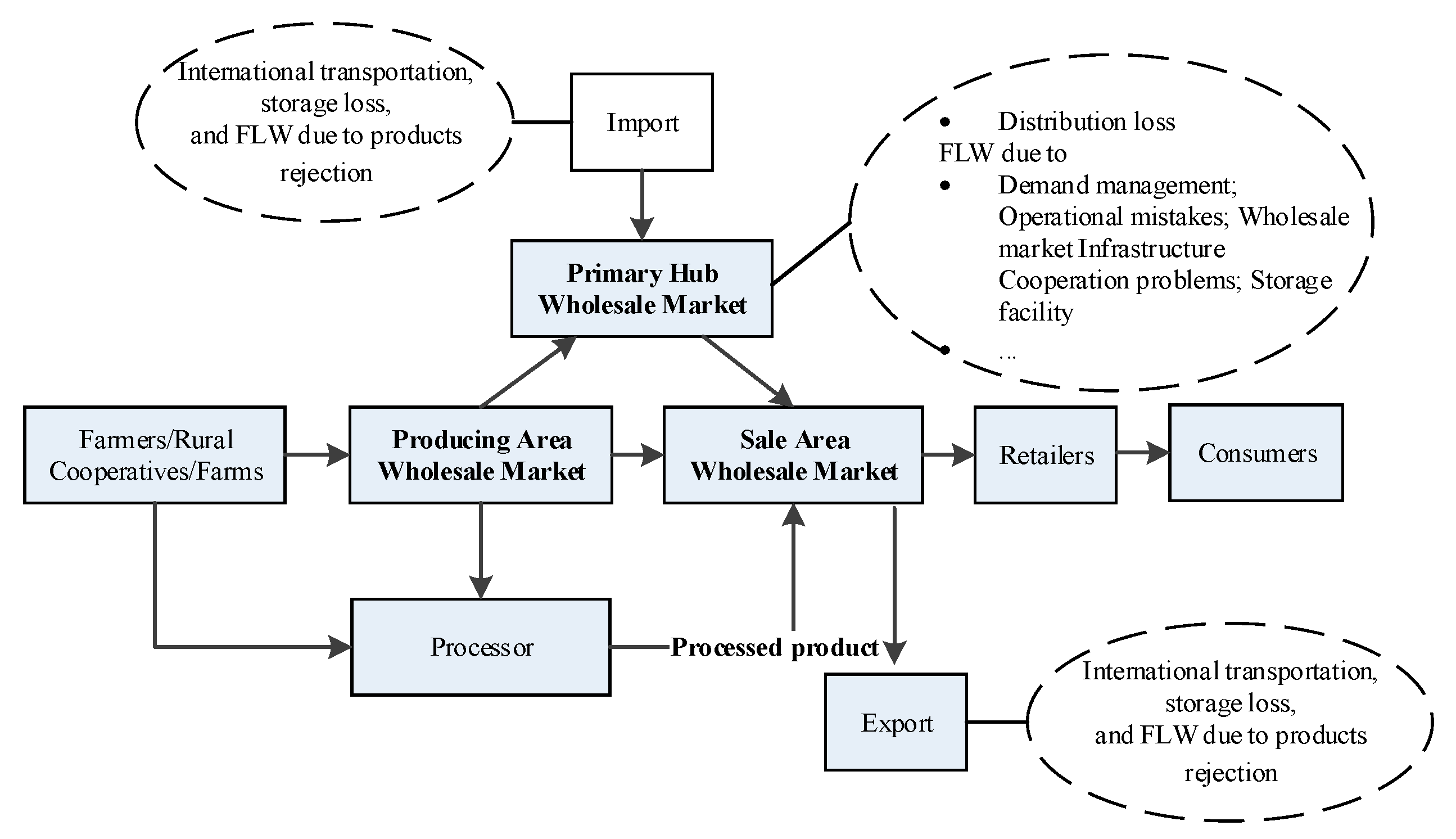

4.3.2. Wholesale Market Mode

The wholesale market mode is an important form of FSC. Jia et al. [

83] suggested that around 70% of vegetables and fruits and 20% of meats are distributed to the end consumer via this mode worldwide. The wholesaler is the key player in this mode, and it could directly deliver the products to the final consumers, such as suppliers to school canteens.

Figure 8 describes the distribution channel of the wholesale market mode. To avoid repetition, we addressed the possible FLW that could be different from other modes.

4.3.3. Supermarket Mode

Figure 9 illustrates a brief FCS in which supermarkets are the core stakeholder. In this distribution mode, food products can be supplied by wholesalers, producers, importers, or even directly by farmers. In some cases, to ensure efficiency and quality, supermarkets, especially hypermarkets, can have their own distribution centers and contract farms. The FLW problems in this mode are to some extent associated with inventory, demand, quality, strategy, and cooperation issues.

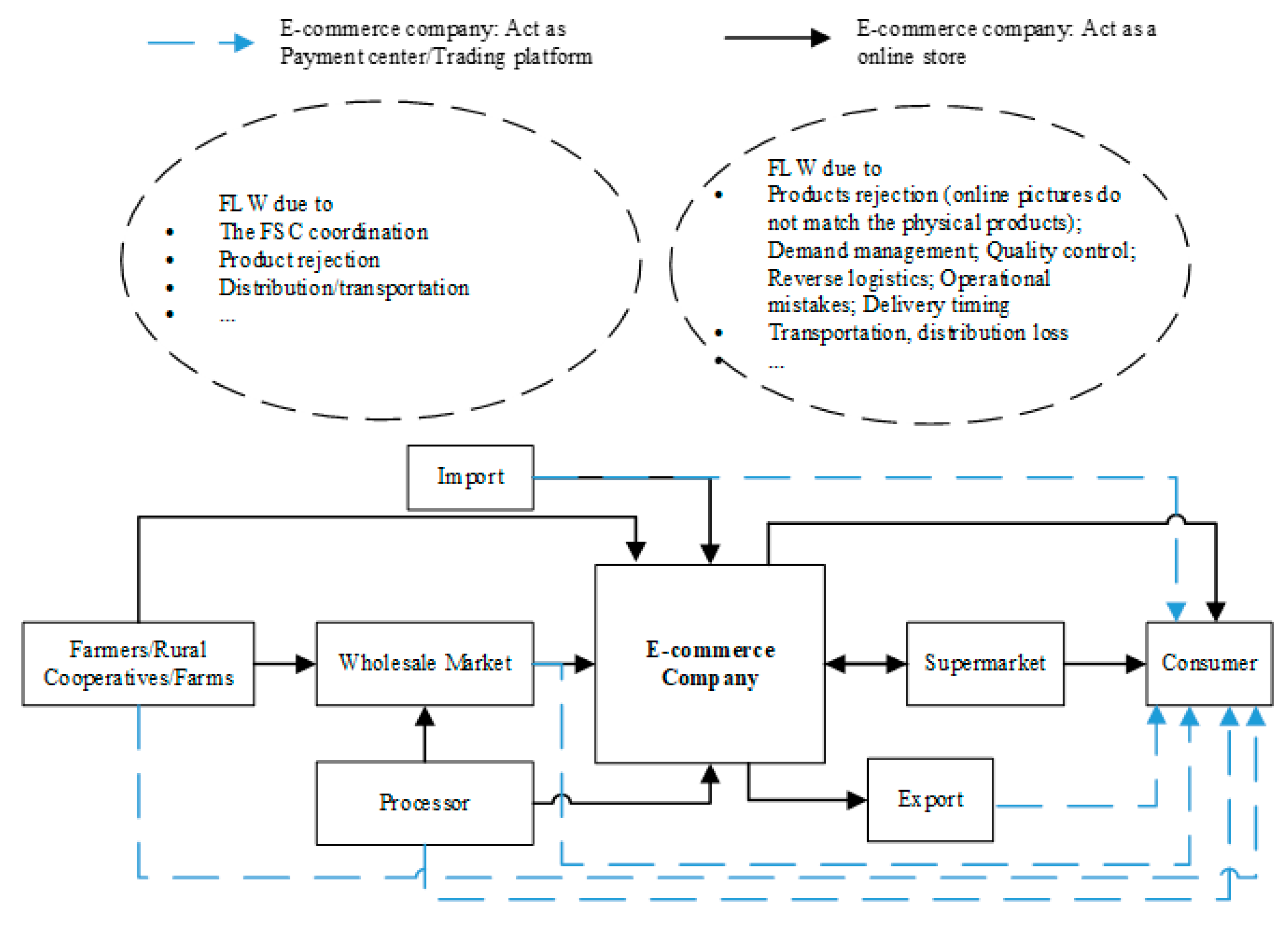

4.3.4. Internet Retail Mode

The booming development of IT and distribution/express delivery enables the implementation of internet retail. This mode is more complex compared to the supermarket mode, shown in

Figure 10. However, even though it involves a new stakeholder in the FSC, this burgeoning business mode supports a platform to direct trade for different stakeholders in FSC, and that may potentially reduce FLW by decreasing the total transaction time of the FSCs.

FLW performs differently in each mode, and this concern provides a lens for researchers to investigate the FLW issues in depth, not only considering a sole distribution mode, but also multiple modes.

5. Measures to Reduce FLW in the Field of Operations Management

What are the measures used in FLW reduction, and how do OM researchers demonstrate the efficiency of their measures? Based on these questions, we summarized the key conclusions from the current literature in the field of operations management.

5.1. Sustainable Business Model

The food-use hierarchy [

3] indicates that FLW prevention and management are preferable to disposal. Compared with conventional business models, creating a sustainable business model is considered a proactive action to achieve a win–win situation both for economic performance and FLW reduction [

55]. Sustainable operations can be realized by constructing closed-loop supply chain models [

13], specifically by adjusting the evaluations matrix for business performance [

40], or by improving the information sharing about the FLW situation [

65].

A sustainable business model that includes an environmental matrix was developed and identified by various methods, such as exploratory case study [

13,

36], survey [

84], LCA analysis [

40], multiple attribute decision making (MADM) model [

85], and material flow analysis [

86]. The results show that through these changes, the performance of FLW reduction can be improved.

5.2. Technological Innovations

Here we considered that “technological innovations” refer not only to the technical improvement of facilities, but also to the innovative actions, methods, and knowledge in practice. For instance, Shearer et al. [

43] investigated an innovative action to encourage household recycling behavior and proved that this method can consistently reduce FLW. Li et al. [

87] compared the choice between a regular and active package, and discussed packaging decisions in a retail interface. Pinto et al. [

34] introduced a method by displaying posters to motivate FLW reduction in university canteens, and indicated that around 15% of FLW was reduced by this new action.

Some studies used quantitative methods instead of qualitative methods. In particular, Haass et al. [

88] applied simulation methods to identify the advantage of using intelligent containers to reduce FLW and carbon emissions. Grunow and Piramuthu [

89] demonstrated the benefit of applying RFID technology in FLW reduction by employing stochastic optimization methods. At the retail level, Janssen et al. [

90] practiced an inventory replenishment model using simulation methods.

5.3. Effective FSC Management

Rather than focusing on the internal structure of individual companies and technological improvement, effectively managing the entire FSC was considered as another approach to reduce FLW. The FAO [

2] highlighted that improvement of the coordination level between FSC stakeholders could have a positive impact on FLW reduction. We noted that despite most articles mentioning the importance of policy improvement and government intervention on FLW reduction, only a few papers examined the influence of external regulation on FLW reduction. For example, Katare et al. [

91] constructed an FLW disposal tax and government incentive mechanism at the household level and interpreted the interrelationship between FLW and external cost.

6. Methodologies to Analyze FLW

Current FLW studies apply quantitative, qualitative, or a mixture of these methods to address FLW questions. In this section, we review seven different methods that are applied to FLW issues.

6.1. Qualitative Research

We used the term “qualitative research” to encompass studies focusing on case studies, scenario analysis, and theory development, and excluded studies using survey and experimental methods.

Figure 11 lists the main topics or research themes of existing studies, along with data analysis tools.

Compared to quantitative research, qualitative research in FLW research not only provides a lens to examine the FLW situation in practice, but also offers a theoretical basis for in-depth research. We scrutinized the qualitative studies, and found some meaningful findings, as described below:

Innovative collaboration within FSC stakeholders can positively affect environmental, social, and economic performance [

23,

42];

Appropriate legislation and economic incentives have a positive impact on FLW reduction at the household level [

92]; and

Logistic solutions that are implemented at different FSC stages are interlinked, which helps to effectively reduce FLW [

93].

The findings of the qualitative studies helped researchers justify their assumptions, generalize hypotheses [

79], and call for further research that may use quantitative methods.

6.2. Empirical Analysis

Empirical analysis is considered an effective method to explore and interpret phenomena, practices, or circumstances. Studies identified as using empirical analysis on FLW topics are shown in

Figure 12.

Survey and experimental methods were used to investigate and explore the research questions. To analyze the data from surveys or experiments, researchers employed various analytical tools and models. Most of the studies used descriptive statistics to describe and summarize the results of their investigations (primarily surveys); others employed regression and SEM models to test the relationships within factors that impact FLW and applied the Trial Evaluation Laboratory (DEMATEL) method to identify key factors [

94]. Other methods, including the Bayesian belief networks model [

95], thematic-discourse analysis [

96], inverse model [

97], and fuzzy cognitive map [

10], were used to further analyze the survey results.

Both the advantages and shortcomings of the empirical analysis were obvious. As a burgeoning research area, exploratory studies in FLW issues could help explain unstructured phenomena and find the key impact factors. However, due to several limitations such as data inaccuracy and inconsistency problems and geographical limitations, the implications from the survey results could be questioned.

6.3. Life Cycle Assessment (LCA)

Unlike other methodologies, LCA applications in FLW mainly focus on two topics: sustainability and environmental impacts. For example, with regard to sustainability, Salemdeeb et al. [

56] used LCA and case study methods to discuss a sustainable business model in Portugal, Lam et al. [

55] analyzed FLW issues from the perspective of sustainable management by employing the LCA method, Secondi et al. [

98] quantified the amount of FLW generated along the tomato-sauce supply chain using the LCA method from the perspective of circular economy, and Pricipato et al. [

99] quantified FLW in the Italian pasta supply chain using LCA. For the environmental impacts, the discussions were various, such as the environmental impact of FLW [

32,

58,

100], and an environmental comparison of packing alternatives [

101]. We further observed that discrepancies in geography, FSC stages, and root causes of FLW created different values in these studies.

6.4. Deterministic Optimization

OM researchers employ deterministic optimization methods to help with decision making in production, transportation, distribution, and other stages. To sharpen the trade-offs in FSC and improve the accuracy of the decisions, we needed to develop models targeting optimal decisions or solutions both for each stage and for the entire FSC.

Distribution problems are one of the significant issues in the production stage [

102]. Orgut et al. [

103] presented a distribution model to achieve the optimal solution for donated food considering the trade-offs between equity and effectiveness. Differentiating from maximizing the distribution amount, Entrup et al. [

104] integrated the product’s shelf-life parameter into the price function, and Ahumada and Villalobos [

102] considered FLW cost in their planning and distribution model. Both works integrated the FLW variables into the objective function, and engaged in maximizing the producer’s total profit. Corresponding to these decisions in production planning, Banasik et al. [

62] developed a multi-objective deterministic model to evaluate the production options and aimed to identify an eco-efficient solution. Using deterministic optimization in FLW research is scarce. Delivery scheduling [

105] pricing and inventory control [

87], tax and government intervention [

91], and transportation and storage trade-offs [

19] are some of the identified topics using this methodology.

6.5. Stochastic Programming and Robust Optimization

Stochastic programming has been applied in various FSC problems, considering different uncertain factors such as yield [

106], shelf life [

14], price [

107], demand [

44,

68,

78,

108], and inventory [

89]. Rather than an application of deterministic approaches in FLW reduction, which tend to integrate FLW as a parameter into the objective function or constraints and indirectly reflect FLW issues, a few studies directly focused on reducing FLW using stochastic programming. The following representative example is given to illustrate how decisions are made under uncertainty, and how these decisions relate to FLW reduction performance. From a gleaning operations perspective, Lee et al. [

18] distinguished their model from other operations settings by considering the uncertain arrival time of donations and gleaners’ attendance. This work presented a stochastic model that aimed to construct a mechanism to improve gleaning operations performance and minimize FLW by considering a trade-off between appointment capacity and gleaner capacity.

Unlike traditional assumptions that the demand is deterministic, demand uncertainty has been discussed as a key factor to enhance the application of FSC management in practice. Dealing with similar uncertainty issues, robust optimization that adopts a different mathematical formalism from stochastic programming is also applicable in FLW reduction problems using the min–max approach. For example, Zhang and Jiang [

109] presented a multi-objective model under the case where the price of biodiesel produced from waste cooking oil was uncertain. Their results provided a treatment of waste cooking oil, in turn reducing FLW. An and Ouyang [

106] employed a robust optimization approach to designing the grain supply chain by considering the trade-offs between FLW and harvest timing.

6.6. Simulation

Here, a simulation approach includes simulation and simulation optimization. The advantages of applying simulation in FLW issues are noticeable: It allows OM researchers to quantify the effects of uncertainties and variabilities [

110], test the different scenarios [

111], measure the performance of a new technology [

88], and study the relationships between causal factors [

112]. It also can be a useful tool to show the effectiveness of technical, logistical, and marketing interventions [

13].

Besides simulating the process, structure, or settings in the FSC, a simulation model is often combined with other methodologies, such as empirical analysis and qualitative research, to analyze FLW problems in depth. Teller et al. [

113] conducted an exploratory research on retail store operation and FLW. To detect the root causes of FLW, that work simulated the operations process, followed by analysis with case study research, and finally confirmed the findings via the results of their investigation. Janssen et al. [

114] developed an inventory model, and further employed simulation methods to demonstrate the improvement of the new decision on the performance of FLW reduction. Fikar [

115] focused on the trade-offs between FLW reduction and minimization of the travel distance in e-grocery delivery. That work constructed a simulation model to optimize the performance of the inventory and delivery operations.

7. Discussion and Conclusions

Practically, we identified that companies are trying to tackle the challenges in reducing FLW through business mode innovation, inventory control, advanced technology adoption, and collaboration. Consumers are converting their consumption behaviors, purchasing habits, and food storage methods. Governments are working on regulations and policies to encourage FLW reduction. However, companies, governments, and consumers alone may not be able to reach the sustainable development goals by reducing FLW, which require efforts and actions from the entire FSC. This raises questions such as how to identify and quantify FLW from the perspective of FSCs, which methodologies are applicable to analyzing FLW issues in FSCs, and how to reduce FLW in different types of FSCs. To answer these questions, our research provides a framework to investigate FLW issues within FSCs.

In this paper, we first discussed various types of FSCs and a definition of FLW, which gave a clear research scope and helped to accurately quantify and report the volume of FLW in different FSCs. Following this discussion, we investigated FLW occurrence and possible causes in different stages, stakeholders, and distribution modes of FSCs, which aimed to motivate OM researchers and practitioners to study FLW problems in-depth by considering different scenarios. We further introduced the methodologies applied in OM research that provide an overview of the applicable methods and stimulate OM research using diversified methodologies.

Although FLW-related studies are increasing, research scope is expanding, and the methods employed are diversifying, compared with other topics, such as FSC management and waste management, FLW reduction from an OM perspective still needs to be further developed, and more research on FLW in OM is called for to address the complex and volatile political, economic, and social situations and rapid scientific technological advancement.

The framework we presented was based on previous research, and future frameworks should focus on filling the existing research gaps and addressing the future challenges. We identified that the possible research opportunities could be as follows.

7.1. Empirical Analysis on FLW Relationships

Practically and academically, the relationship between FLW management practices, FLW reduction performance, and economic performance is vague. Further empirical research focusing on such topics is expected. The variables of FLW management practices, namely, internal FLW management, external FLW management, FL reduction design, and supplier relationship-specific investment, need to be considered.

7.2. FLW Reduction Performance in Different Distribution Modes

To improve the efficiency of FSCs and reduce FLW by decreasing the layers of middlemen, Walmart developed the Direct Farm program in developing countries. However, how can this change help FLW reduction performance? It might need to be further analyzed. Shortening the FSC might reduce the FLW that is due to spoilage during the distribution. Nevertheless, it could also increase FLW due to reasons such as small farmers and producers not being well aware of the market demand regarding quality and quantity compared with large-scale wholesalers, or coordination problems. The trade-offs in the decisions and the comparison for different distribution modes can be included in future qualitative and quantitative research.

7.3. The Impact of Redistribution on FLW Reduction Performance

Studies focusing on the inventory management of perishable food products are vast, however, we identified that as an approach to manage inventory and reduce loss, the research related to the redistribution of food products was limited. Our framework lists four distribution modes that exist or co-exist practically, however, we did not include the redistribution channels, which can be formal or informal food donation, reverse logistics due to cancellation or rejection of food products, etc. Further studies are suggested to examine the impacts of redistribution on FLW reduction [

84], and the comparison of FLW issues in the redistribution channel under different distribution modes.

7.4. FLW Calculation and Quantification

FLW calculation and quantification problems were mentioned in many research papers [

25,

116]. Secondi et al. [

98] quantified the amount of FLW generated along the tomato-sauce food supply chain, and Pricipato et al. [

99] developed an FLW accounting and reporting standard and use it to quantify FLW in the Italian pasta supply chain. However, one of the key questions before solving this problem was how to define FLW. As we discussed, there are hundreds of different definitions of FLW, and this inconsistency has a significant influence on FLW’s magnitude, optimal result comparison, and research scope. Elimelech et al. [

117] presented a new measurement method by measuring daily produced food waste at the household level, van Herpen et al. [

118] assessed five methods to measure household food waste, and Elimelech et al. [

119] discussed the difference between self-reported and measured food wastage. Future research can integrate FLW definition and quantification into the solution, and provide feasible policies and regulation suggestions.

7.5. Comparative Research

Due to the inconsistency in FLW definitions, quantification, and segmentation of food products, cross-country comparative research is considerably difficult. Current studies mainly focus on a specific country or zone. Besides the FAO report, which focused on the global level, more interesting topics can be raised by this direction, such as comparative studies in FLW reduction approaches, potential options and tools, and root causes at a cross-country level.

7.6. Action Research (AR)

AR is a qualitative methodology widely used for research in OM [

120]. AR aims to contribute both to the practical concerns in an immediate problematic situation and to the goals of social science by joint collaboration within a mutually acceptable ethical framework [

121]. However, almost no significant studies using the AR method can be found in FLW research. As an impactful method to contribute both to theory and practice [

122], future studies employing AR have great potential value in FLW research.

7.7. FLW under the COVID-19 Pandemic

The COVID-19 pandemic aggravated the situation of acute global food insecurity. It created huge uncertainties in demands and disruptions in global food supply chains and interrupted the flows of foods or inputs for agricultural production. Fleetwood [

123] discussed social justice, food loss, and the sustainable development goals under COVID-19. To deal with the challenges, many food companies have worked closely with governments and their trading partners to fight the pandemic. A variety of topics can be examined in the context from the perspectives of how to enhance FSCs and reduce FLW through innovations in network structures and business models enabled by digital technologies and big data analytics, including the adoption of digital technologies, FSC restructure, collaboration with FSC partners and stakeholders, adoption of omni-channel by food processors and retailers, food service model innovations, best practices in FLW, and bullwhip effects caused by the pandemic, etc. Moreover, there are some contradictory results within existing studies, which calls for further research on FLW under the COVID-19 pandemic. For example, one study showed that during lockdown most households in Italy reported a reduction in food waste [

124], whereas another study based on a survey in Japan revealed that the influences on household food waste were different between high- and low-impact regions [

125].

Author Contributions

Conceptualization, N.L.; methodology, N.L. and Y.L.; writing—original draft preparation, N.L., T.L.O., and Y.L.; writing—review and editing, N.L., T.L.O., and Y.L.; supervision, T.L.O.; project administration, T.L.O.; funding acquisition, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Humanities and Social Science Project of the Chinese Ministry of Education, Grant Number 17YJAZH055, the National Social Science Fund of China, Grant Number 19BGL090, and the Asia Research Center in Nankai University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

The authors are grateful to the valuable comments of the two anonymous reviewers and the great support of the editors.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- FAO. The State of Food and Agriculture; FAO: Rome, Italy, 2009. [Google Scholar]

- FAO. Global Food Losses and Food Waste-Extent, Causes and Prevention; FAO: Rome, Italy, 2011. [Google Scholar]

- FAO. FAO Activities on Food Waste Measurement and SDG Reporting; FAO: Brussels, Belgium, 2016. [Google Scholar]

- FAO. Food Loss and Waste and the Right to Adequate Food: Making the Connection; FAO: Rome, Italy, 2018. [Google Scholar]

- FAO. Addressing the Impacts of COVID-19 in Food Crises; FAO: Rome, Italy, 2020. [Google Scholar]

- United Nations Goal 12: Ensure Sustainable Consumption and Production Patterns. Available online: https://www.un.org/sustainabledevelopment/sustainable-consumption-production (accessed on 19 November 2020).

- Steur, D.H.; Wesana, J.; Dora, M.K.; Pearce, D.; Gellynck, X. Applying value stream mapping to reduce food losses and wastes in supply chains: A systematic review. Waste Manag. 2016, 58, 359–368. [Google Scholar] [CrossRef] [PubMed]

- Stangherlin, I.D.C.; Barcellos, M.D.D. Drivers and barriers to food waste reduction. Br. Food J. 2018, 120, 2364–2387. [Google Scholar] [CrossRef]

- Girotto, F.; Alibardi, F.; Cossu, R. Food waste generation and industrial uses: A review. Waste Manag. 2015, 45, 32–41. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Jiang, W.; Yang, Y.; Yang, Y.; Man, X. State of the art on food waste research: A bibliometrics study from 1997 to 2014. J. Clean. Prod. 2017, 140, 840–846. [Google Scholar] [CrossRef]

- Irani, Z.; Sharif, A.M.; Lee, H.; Aktas, E.; Topaloğlu, Z.; van’t Wout, T.; Huda, S. Managing food security through food waste and loss: Small data to big data. Comput. Oper. Res. 2018, 98, 367–383. [Google Scholar] [CrossRef]

- Rijpkema, A.W.; Rossi, R.; van der Vorst, J.G. Effective sourcing strategies for perishable product supply chains. Int. J. Phys. Distr. Logist. 2014, 44, 494–510. [Google Scholar] [CrossRef]

- Tromp, S.O.; Haijema, R.; Rijgersberg, H.; der Vorst, J.G. A systematic approach to preventing chilled-food waste at the retail outlet. Int. J. Prod. Econ. 2016, 182, 508–518. [Google Scholar] [CrossRef]

- Sgarbossa, F.; Russo, I. A proactive model in sustainable food supply chain: Insight from a case study. Int. J. Prod. Econ. 2017, 183, 596–606. [Google Scholar] [CrossRef]

- Muriana, C. Effectiveness of the food recovery at the retailing stage under shelf life uncertainty: An application to Italian food chains. Waste Manag. 2015, 41, 159–168. [Google Scholar] [CrossRef]

- Ahumada, O.; Villalobos, J.R. Application of planning models in the agri-food supply chain: A review. Eur. J. Oper. Res. 2009, 196, 1–20. [Google Scholar] [CrossRef]

- Wang, H.H.; Wang, Y.; Delgado, M.S. The transition to modern agriculture: Contract farming in developing economies. Am. J. Agric. Econ. 2014, 96, 1257–1271. [Google Scholar] [CrossRef]

- Lee, D.; Sönmez, E.; Gómez, M.I.; Fan, X. Combining two wrongs to make two rights: Mitigating food insecurity and food waste through gleaning operations. Food Policy 2017, 68, 40–52. [Google Scholar] [CrossRef]

- Brulard, N.; Cung, V.; Catusse, N.; Dutrieux, C. An integrated sizing and planning problem in designing diverse vegetable farming systems. Int. J. Prod. Res. 2018, 57, 1018–1036. [Google Scholar] [CrossRef]

- Mogale, D.G.; Dolgui, A.; Kandhway, R.; Kumar, S.K.; Tiwari, M.K. A multiperiod inventory transportation model for tactical planning of food grain supply chain. Comput. Ind. Eng. 2017, 110, 379–394. [Google Scholar] [CrossRef]

- Soto-Silva, W.E.; Nadal-Roig, E.; González-Araya, M.C.; Pla-Aragones, L.M. Operational research models applied to the fresh fruit supply chain. Eur. J. Oper. Res. 2016, 251, 345–355. [Google Scholar] [CrossRef]

- Thompson, B.; Toma, L.; Barnes, A.P.; Revoredo-Giha, C. The effect of date labels on willingness to consume dairy products: Implications for food waste reduction. Waste Manag. 2018, 78, 124–134. [Google Scholar] [CrossRef]

- Mishra, N.; Singh, A. Use of twitter data for waste minimisation in beef supply chain. Ann. Oper. Res. 2018, 270, 337–359. [Google Scholar] [CrossRef]

- Bustos, C.A.; Moors, E.H. Reducing post-harvest food losses through innovative collaboration: Insights from the Colombian and Mexican avocado supply chains. J. Clean. Prod. 2018, 199, 1020–1034. [Google Scholar] [CrossRef]

- Shukla, M.; Jharkharia, S. Agri-Fresh Produce Supply Chain Management: A State-of-the-Art Literature Review. Int. J. Oper. Prod. Man. 2013, 33, 114–158. [Google Scholar] [CrossRef]

- Beretta, C.; Stoessel, F.; Baier, U.; Hellweg, S. Quantifying food losses and the potential for reduction in Switzerland. Waste Manag. 2013, 33, 764–773. [Google Scholar] [CrossRef]

- Behzadi, G.; O’Sullivan, M.J.; Olsen, T.L.; Zhang, A. Agribusiness supply chain risk management: A review of quantitative decision models. Omega 2018, 79, 21–42. [Google Scholar] [CrossRef]

- United States Department of Agriculture (USDA). The Estimated Amount, Value, and Calories of Postharvest Food Losses at the Retail and Consumer Levels in the United States. Available online: https://www.ers.usda.gov/publications/pub-details/?pubid=43836 (accessed on 18 November 2020).

- FUSIONS. FUSIONS Definitional Framework for Food Waste. Available online: http://www.eu-fusions.org/phocadownload/Publications/FUSIONS%20Definitional%20Framework%20for%20Food%20Waste%202014.pdf (accessed on 18 November 2020).

- Bellemare, M.F.; Çakir, M.; Peterson, H.H.; Novak, L.; Rudi, J. On the measurement of food waste. Am. J. Agric. Econ. 2017, 99, 1148–1158. [Google Scholar] [CrossRef]

- Muriana, C. A focus on the state of the art of food waste/losses issue and suggestions for future researches. Waste Manag. 2017, 68, 557–570. [Google Scholar] [CrossRef] [PubMed]

- Willersinn, C.; Möbius, S.; Mouron, P.; Lansche, J.; Mack, G. Environmental impacts of food losses along the entire Swiss potato supply chain-Current situation and reduction potentials. J. Clean. Prod. 2017, 140, 860–870. [Google Scholar] [CrossRef]

- McCarthy, B.; Liu, H.B. ‘Waste not, want not’ Exploring green consumers’ attitudes towards wasting edible food and actions to tackle food waste. Br. Food J. 2017, 119, 2519–2531. [Google Scholar] [CrossRef]

- Pinto, R.S.; dos Santos, R.M.P.; Melo, F.F.S.; Campos, S.S.; Cordovil, C.M.D.S. A simple awareness campaign to promote food waste reduction in a University canteen. Waste Manag. 2018, 76, 28–38. [Google Scholar] [CrossRef]

- Filimonau, V.; Gherbin, A. An exploratory study of food waste management practices in the UK grocery retail sector. J. Clean. Prod. 2017, 167, 1184–1194. [Google Scholar] [CrossRef]

- Garrone, P.; Melacini, M.; Perego, A.; Sert, S. Reducing food waste in food manufacturing companies. J. Clean. Prod. 2016, 137, 1076–1085. [Google Scholar] [CrossRef]

- Gokarn, S.; Kuthambalayan, T.S. Analysis of challenges inhibiting the reduction of waste in food supply chain. J. Clean. Prod. 2017, 168, 595–604. [Google Scholar] [CrossRef]

- Halloran, A.; Clement, J.; Kornum, N.; Bucatariu, C.; Magid, J. Addressing food waste reduction in Denmark. Food Policy 2017, 49, 294–301. [Google Scholar] [CrossRef]

- Zhang, H.; Duan, H.; Andric, J.M.; Song, M.; Yang, B. Characterization of household food waste and strategies for its reduction: A Shenzhen City case study. Waste Manag. 2018, 78, 426–433. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, I.; Sobral, P.; Peças, P.; Henriques, E. A sustainable business model to fight food waste. J. Clean. Prod. 2018, 177, 262–275. [Google Scholar] [CrossRef]

- Formentini, M.; Taticchi, P. Corporate sustainability approaches and governance mechanisms in sustainable supply chain management. J. Clean. Prod. 2016, 112, 1920–1933. [Google Scholar] [CrossRef]

- Szabó-Bódi, B.; Kasza, G.; Szakos, D. Assessment of household food waste in Hungary. Br. Food J. 2018, 120, 625–638. [Google Scholar] [CrossRef]

- Shearer, L.; Gatersleben, B.; Morse, S.; Smyth, M.; Hunt, S. A problem unstuck? Evaluating the effectiveness of sticker prompts for encouraging household food waste recycling behavior. Waste Manag. 2017, 60, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Tongarlak, M.H. Converting retail food waste into by-product. Eur. J. Oper. Res. 2017, 257, 944–956. [Google Scholar] [CrossRef]

- Govindan, K. Sustainable consumption and production in the food supply chain: A conceptual framework. Int. J. Prod. Econ. 2018, 195, 419–431. [Google Scholar] [CrossRef]

- Koester, U. Food loss and waste as an economic and policy problem. In World Agricultural Resources and Food Security; Schmitz, A., Kennedy, P.L., Schmitz, T.G., Eds.; Emerald Publishing Limited: Bingley, UK, 2017; Volume 17, pp. 275–289. [Google Scholar] [CrossRef]

- Buzby, J.C.; Hyman, J. Total and per capita value of food loss in the United States. Food Policy 2012, 37, 561–570. [Google Scholar] [CrossRef]

- Rutten, M. What economic theory tells us about the impacts of reducing food losses and/or waste: Implications for research, policy and practice. Agric. Food Secur. 2013, 2, 1–13. [Google Scholar] [CrossRef]

- Ridoutt, B.G.; Juliano, P.; Sanguansri, P.; Sellahewa, J. The water footprint of food waste: Case study of fresh mango in Australia. J. Clean. Prod. 2010, 18, 1714–1721. [Google Scholar] [CrossRef]

- Kummu, M.; de Moel, H.; Porkka, M.; Siebert, S.; Varis, O.; Ward, P.J. Lost food, wasted resources: Global food supply chain losses and their impacts on freshwater, cropland, and fertiliser use. Sci. Total Environ. 2012, 438, 477–489. [Google Scholar] [CrossRef] [PubMed]

- Dorward, L.J. Where are the best opportunities for reducing greenhouse gas emissions in the food system (including the food chain)? A comment. Food Policy 2012, 37, 463–466. [Google Scholar] [CrossRef]

- Kim, M.; Song, H.; Song, Y.; Jeong, I.; Kim, J. Evaluation of food waste disposal options in terms of global warming and energy recovery: Korea. Int. J. Energy Environ. Eng. 2013, 4, 1. [Google Scholar] [CrossRef]

- García-Herrero, L.; De Menna, F.; Vittuari, M. Food waste at school. The environmental and cost impact of a canteen meal. Waste Manag. 2019, 100, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Coderoni, S.; Perito, M.A. Sustainable consumption in the circular economy. An analysis of consumers’ purchase intentions for waste-to-value food. J. Clean. Prod. 2020, 252, 119870. [Google Scholar] [CrossRef]

- Lam, C.M.; Iris, K.M.; Medel, F.; Tsang, D.C.; Hsu, S.C.; Poon, C.S. Life-cycle cost-benefit analysis on sustainable food waste management: The case of Hong Kong International Airport. J. Clean. Prod. 2018, 187, 751–762. [Google Scholar] [CrossRef]

- Salemdeeb, R.; Vivanco, D.F.; Al-Tabbaa, A.; zu Ermgassen, E.K. A holistic approach to the environmental evaluation of food waste prevention. Waste Manag. 2017, 59, 442–450. [Google Scholar] [CrossRef] [PubMed]

- Reutter, B.; Lant, P.; Reynolds, C.; Lane, J. Food waste consequences: Environmentally extended input-output as a framework for analysis. J. Clean. Prod. 2017, 153, 506–514. [Google Scholar] [CrossRef]

- Scherhaufer, S.; Moates, G.; Hartikainen, H.; Waldron, K.; Obersteiner, G. Environmental impacts of food waste in Europe. Waste Manag. 2018, 77, 98–113. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Van Der Vorst, J.G.; Tromp, S.O.; Zee, D.J.V.D. Simulation modeling for food supply chain redesign; integrated decision making on product quality, sustainability and logistics. Int. J. Prod. Res. 2009, 47, 6611–6631. [Google Scholar] [CrossRef]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2010, 465, 3065–3081. [Google Scholar] [CrossRef] [PubMed]

- Banasik, A.; Kanellopoulos, A.; Claassen, G.D.H.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.A.J. Assessing alternative production options for eco-efficient food supply chains using multi-objective optimization. Ann. Oper. Res. 2017, 250, 341–362. [Google Scholar] [CrossRef]

- Nikolaou, K.; Tsakiridou, E.; Anastasiadis, F.; Mattas, K. Alternative Distribution Channels of Fruits and Vegetables. In Sustainable Agriculture and Food Security; Mattas, K., Baourakis, G., Zopounidis, C., Eds.; Springer: Cham, Switzerland, 2018; pp. 109–120. [Google Scholar]

- Tostivint, C.; de Veron, S.; Jan, O.; Lanctuit, H.; Hutton, Z.V.; Loubière, M. Measuring food waste in a dairy supply chain in Pakistan. J. Clean. Prod. 2017, 145, 221–231. [Google Scholar] [CrossRef]

- Kaipia, R.; Dukovska-Popovska, I.; Loikkanen, L. Creating sustainable fresh food supply chains through waste reduction. Int. J. Phys. Distr. Logist. 2013, 43, 262–276. [Google Scholar] [CrossRef]

- FAO. Reduction of FLW in Europe and Central Asia Synthesis Report; FAO: Rome, Italy, 2013. [Google Scholar]

- Thamagasorn, M.; Pharino, C. An analysis of food waste from a flight catering business for sustainable food waste management: A case study of halal food production process. J. Clean. Prod. 2019, 228, 845–855. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; Haijema, R.; van der Vorst, J.G. Modeling an Inventory Routing Problem for perishable products with environmental considerations and demand uncertainty. Int. J. Prod. Econ. 2015, 164, 118–133. [Google Scholar] [CrossRef]

- Stangherlin, I.D.C.; Ribeiro, J.L.D.; Barcellos, M. Consumer behavior towards suboptimal food products: A strategy for food waste reduction. Br. Food J. 2019, 121, 2396–2412. [Google Scholar] [CrossRef]

- Talia, D.E.; Simeone, M.; Scarpato, D. Consumer behaviour types in household food waste. J. Clean. Prod. 2018, 214, 166–172. [Google Scholar] [CrossRef]

- Setti, M.; Falasconi, L.; Segrè, A.; Cusano, I.; Vittuari, M. Italian consumers’ income and food waste behavior. Br. Food J. 2016, 118, 1731–1746. [Google Scholar] [CrossRef]

- Setti, M.; Banchelli, F.; Falasconi, L.; Segrè, A.; Vittuari, M. Consumers’ food cycle and household waste. When behaviors matter. J. Clean. Prod. 2018, 185, 694–706. [Google Scholar] [CrossRef]

- Despoudi, S.; Papaioannou, G.; Saridakis, G.; Dani, S. Does collaboration pay in agricultural supply chain? An empirical approach. Int. J. Prod. Res. 2018, 56, 4396–4417. [Google Scholar] [CrossRef]

- Gaiani, S.; Caldeira, S.; Adorno, V.; Segrè, A.; Vittuari, M. Food wasters: Profiling consumers’ attitude to waste food in Italy. Waste Manag. 2018, 72, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Gardas, B.B.; Raut, R.D.; Narkhede, B. Evaluating critical causal factors for post-harvest losses (PHL) in the fruit and vegetables supply chain in India using the DEMATEL approach. J. Clean. Prod. 2018, 199, 47–61. [Google Scholar] [CrossRef]

- Macheka, L.; Spelt, E.; van der Vorst, J.G.; Luning, P.A. Exploration of logistics and quality control activities in view of context characteristics and postharvest losses in fresh produce chains: A case study for tomatoes. Food Control 2017, 77, 221–234. [Google Scholar] [CrossRef]

- Macheka, L.; Spelt, E.J.; Bakker, E.J.; van der Vorst, J.G.; Luning, P.A. Identification of determinants of postharvest losses in Zimbabwean tomato supply chains as basis for dedicated interventions. Food Control 2018, 87, 135–144. [Google Scholar] [CrossRef]

- Pauls-Worm, K.G.; Hendrix, E.M.; Alcoba, A.G.; Haijema, R. Order quantities for perishable inventory control with non-stationary demand and a fill rate constraint. Int. J. Prod. Econ. 2016, 181, 238–246. [Google Scholar] [CrossRef]

- Raak, N.; Symmank, C.; Zahn, S.; Aschemann-Witzel, J.; Rohm, H. Processing-and product-related causes for food waste and implications for the food supply chain. Waste Manag. 2017, 61, 461–472. [Google Scholar] [CrossRef]

- Reardon, T.; Chen, K.; Minten, B.; Adriano, L. The Quiet Revolution in Staple Food Value Chains: Enter the Dragon, the Elephant, and the Tiger; Asian Development Bank and International Food Policy Research Institute: Mandaluyong City, Philippines, 2012; pp. 286–290. [Google Scholar]

- Yang, W.M.; Hu, D.H. Reconstruction of Agricultural Product Value Chain by Connecting Agriculture with Supermarkets under Farm Food Safety Perspective. Agric. Econ. Manag. 2013, 3, 33–40. (In Chinese) [Google Scholar]

- Reardon, T.; Timmer, C.P. Transformation of agricultural output in developing countries since 1950: How has thinking changed. In Handbook of Agricultural Economics, 1st ed.; Evenson, R., Pingali, P., Eds.; Elsevier: North Holland, The Netherlands, 2007; Volume 3, pp. 2807–2855. Available online: https://www.sciencedirect.com/science/article/pii/S1574007206030556 (accessed on 19 November 2020). [CrossRef]

- Jia, J.D.; Zhang, D.K.; Zhang, Y.X.; Kong, L.X.; Zhang, P.Y. Development Report of Chinese Agricultural Products Circulation Industry, 1st ed.; Social Sciences Academic Press: Beijing, China, 2013; pp. 150–176. (In Chinese) [Google Scholar]

- Mourad, M. Recycling, recovering and preventing “food waste”: Competing solutions for food systems sustainability in the United States and France. J. Clean. Prod. 2016, 126, 461–477. [Google Scholar] [CrossRef]

- Liu, K.M.; Lin, S.H.; Hsieh, J.C.; Tzeng, G.H. Improving the food waste composting facilities site selection for sustainable development using a hybrid modified MADM model. Waste Manag. 2018, 75, 44–59. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Herrero, I.; Hoehn, D.; Margallo, M.; Laso, J.; Bala, A.; Batlle-Bayer, L.; Aldaco, R. On the estimation of potential food waste reduction to support sustainable production and consumption policies. Food Policy 2018, 80, 24–38. [Google Scholar] [CrossRef]

- Li, Q.; Yu, P.; Wu, X. Shelf life extending packaging, inventory control and grocery retailing. Prod. Oper. Manag. 2017, 26, 1369–1382. [Google Scholar] [CrossRef]

- Haass, R.; Dittmer, P.; Veigt, M.; Lütjen, M. Reducing food losses and carbon emission by using autonomous control-A simulation study of the intelligent container. Int. J. Prod. Econ. 2015, 164, 400–408. [Google Scholar] [CrossRef]

- Grunow, M.; Piramuthu, S. RFID in highly perishable food supply chains–remaining shelf life to supplant expiry date? Int. J. Prod. Econ. 2013, 146, 717–727. [Google Scholar] [CrossRef]

- Janssen, A.M.; de Vries, M.A.N.; Boer, E.P.; Kremer, S. Fresh, frozen, or ambient food equivalents and their impact on food waste generation in Dutch households. Waste Manag. 2017, 67, 298–307. [Google Scholar] [CrossRef]

- Katare, B.; Serebrennikov, D.; Wang, H.H.; Wetzstein, M. Social-optimal household food waste: Taxes and government incentives. Am. J. Agric. Econ. 2017, 99, 499–509. [Google Scholar] [CrossRef]

- Chalak, A.; Abou-Daher, C.; Chaaban, J.; Abiad, M.G. The global economic and regulatory determinants of household food waste generation: A cross-country analysis. Waste Manag. 2016, 48, 418–422. [Google Scholar] [CrossRef]

- Liljestrand, K. Logistics solutions for reducing food waste. Int. J. Phys. Distr. Logist. 2017, 47, 318–339. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Liu, Y. Barriers to circular food supply chains in China. Supply Chain Manag. 2019, 24, 677–696. [Google Scholar] [CrossRef]

- Song, G.; Semakula, H.M.; Fullana-i-Palmer, P. Chinese household food waste and its’ climatic burden driven by urbanization: A bayesian belief network modelling for reduction possibilities in the context of global efforts. J. Clean. Prod. 2018, 202, 916–924. [Google Scholar] [CrossRef]

- Michalec, A.; Fodor, M.; Hayes, E.; Longhurst, J. Co-designing food waste services in the catering sector. Br. Food J. 2018, 120, 2762–2777. [Google Scholar] [CrossRef]

- Spada, A.; Conte, A.; Del Nobile, M.A. The influence of shelf life on food waste: A model-based approach by empirical market evidence. J. Clean. Prod. 2018, 172, 3410–3414. [Google Scholar] [CrossRef]

- Secondi, L.; Principato, L.; Ruini, L.; Guidi, M. Reusing Food Waste in Food Manufacturing Companies: The Case of the Tomato-Sauce Supply Chain. Sustainability 2019, 11, 2154. [Google Scholar] [CrossRef]

- Principato, L.; Ruini, L.; Guidi, M.; Secondi, L. Adopting the circular economy approach on food loss and waste: The case of Italian pasta production. Resour. Conserv. Recycl. 2019, 144, 82–89. [Google Scholar] [CrossRef]

- Tonini, D.; Albizzati, P.F.; Astrup, T.F. Environmental impacts of food waste: Learnings and challenges from a case study on UK. Waste Manag. 2018, 76, 744–766. [Google Scholar] [CrossRef]

- Wikström, F.; Williams, H.; Venkatesh, G. The influence of packaging attributes on recycling and food waste behavior—An environmental comparison of two packaging alternatives. J. Clean. Prod. 2016, 137, 895–902. [Google Scholar] [CrossRef]

- Ahumada, O.; Villalobos, J.R. A tactical model for planning the production and distribution of fresh produce. Ann. Oper. Res. 2011, 190, 339–358. [Google Scholar] [CrossRef]

- Orgut, I.S.; Ivy, J.; Uzsoy, R.; Wilson, J.R. Modeling for the equitable and effective distribution of donated food under capacity constraints. IIE Trans. 2016, 48, 252–266. [Google Scholar] [CrossRef]

- Entrup, M.L.; Günther, H.O.; Van Beek, P.; Grunow, M.; Seiler, T. Mixed- Integer Linear Programming approaches to shelf-life-integrated planning and scheduling in yoghurt production. Int. J. Prod. Res. 2005, 43, 5071–5100. [Google Scholar] [CrossRef]

- Widodo, K.H.; Nagasawa, H.; Morizawa, K.; Ota, M. A periodical flowering-harvesting model for delivering agricultural fresh products. Eur. J. Oper. Res. 2006, 170, 24–43. [Google Scholar] [CrossRef]

- An, K.; Ouyang, Y. Robust grain supply chain design considering post-harvest loss and harvest timing equilibrium. Transp. Res. Logist. 2016, 88, 110–128. [Google Scholar] [CrossRef]

- Herbon, A.; Khmelnitsky, E. Optimal dynamic pricing and ordering of a perishable product under additive effects of price and time on demand. Eur. J. Oper. Res. 2017, 260, 546–556. [Google Scholar] [CrossRef]

- Wang, C.; Chen, X. Joint order and pricing decisions for fresh produce with put option contracts. J. Oper. Res. Soc. 2018, 69, 474–484. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Y. Robust optimization on sustainable biodiesel supply chain produced from waste cooking oil under price uncertainty. Waste Manag. 2017, 60, 329–339. [Google Scholar] [CrossRef]

- Tromp, S.O.; Rijgersberg, H.; da Silva, F.P.; Bartels, P. Retail benefits of dynamic expiry dates-Simulating opportunity losses due to product loss, discount policy and out of stock. Int. J. Prod. Econ. 2012, 139, 14–21. [Google Scholar] [CrossRef]

- Kiil, K.; Hvolby, H.H.; Fraser, K.; Dreyer, H.; Strandhagen, J.O. Automatic replenishment of perishables in grocery retailing: The value of utilizing remaining shelf life information. Br. Food J. 2018, 120, 2033–2046. [Google Scholar] [CrossRef]

- Reddy, R.H.; Kumar, S.K.; Fernandes, K.J.; Tiwari, M.K. A Multi-Agent System based simulation approach for planning procurement operations and scheduling with multiple cross-docks. Comput. Ind. Eng. 2017, 107, 289–300. [Google Scholar] [CrossRef]

- Teller, C.; Holweg, C.; Reiner, G.; Kotzab, H. Retail store operations and food waste. J. Clean. Prod. 2018, 185, 981–997. [Google Scholar] [CrossRef]

- Janssen, L.; Sauer, J.; Claus, T.; Nehls, U. Development and simulation analysis of a new perishable inventory model with a closing days constraint under non-stationary stochastic demand. Comput. Ind. Eng. 2018, 118, 9–22. [Google Scholar] [CrossRef]

- Fikar, C. A decision support system to investigate food losses in e-grocery deliveries. Comput. Ind. Eng. 2018, 117, 282–290. [Google Scholar] [CrossRef]

- Gautam, S.; Acedo, A.L., Jr.; Schreinemachers, P.; Subedi, B.P. Volume and value of postharvest losses: The case of tomatoes in Nepal. Br. Food J. 2017, 119, 2547–2558. [Google Scholar] [CrossRef]

- Elimelech, E.; Ayalon, O.; Ert, E. What gets measured gets managed: A new method of measuring household food waste. Waste Manag. 2018, 76, 68–81. [Google Scholar] [CrossRef] [PubMed]

- van Herpen, E.; van der Lans, I.A.; Holthuysen, N.; Nijenhuis-de Vries, M. Comparing wasted apples and oranges: An assessment of methods to measure household food waste. Waste Manag. 2019, 88, 71–84. [Google Scholar] [CrossRef]

- Elimelech, E.; Ert, E.; Ayalon, O. Exploring the drivers behind self-reported and measured food wastage. Sustainability 2019, 11, 5677. [Google Scholar] [CrossRef]

- Coughlan, P.; Coghlan, D. Action research for operations management. Int. J. Oper. Prod. Manag. 2002, 22, 220–240. [Google Scholar] [CrossRef]

- Rapoport, R.N. Three dilemmas in action research: With Special Reference to the Tavistock Experience. Hum. Relat. 1970, 23, 499–513. [Google Scholar] [CrossRef]

- Formentini, M.; Ellram, L.M.; Boem, M.; Da Re, G. Finding true north: Design and implementation of a strategic sourcing framework. Ind. Market Manag. 2019, 77, 182–197. [Google Scholar] [CrossRef]

- Fleetwood, J. Social justice, food loss, and the sustainable development goals in the era of COVID-19. Sustainability 2020, 12, 5027. [Google Scholar] [CrossRef]

- Principato, L.; Secondi, L.; Cicatiello, C.; Mattia, G. Caring more about food: The unexpected positive effect of the Covid-19 lockdown on household food management and waste. Socio-Econ. Plan. Sci. 2020, 100953. [Google Scholar] [CrossRef]

- Qian, K.; Javadi, F.; Hiramatsu, M. Influence of the COVID-19 pandemic on household food waste behavior in Japan. Sustainability 2020, 12, 9942. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).